1. Introduction

Additive Manufacturing (AM) technology is developing rapidly in various directions as the industry chain continues to improve; by enabling unprecedented geometric and material complexities, it has opened up a new era of product design, thereby opening new avenues for innovation and customization [

1]. The changes in design space and dimensions have given rise to Design for Additive Manufacturing (DFAM) as a critical research field, aimed at fully exploiting the design freedom offered by AM processes.

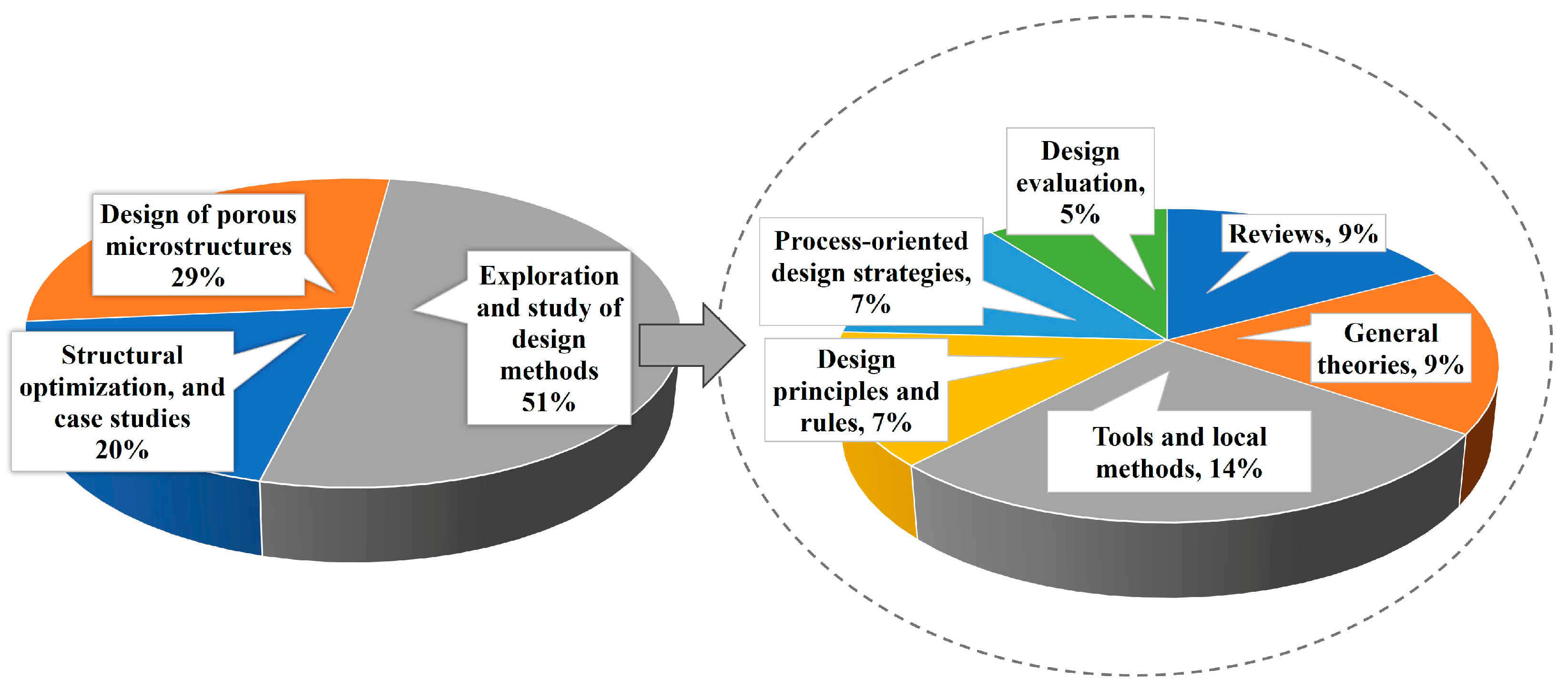

DFAM is defined as [

2,

3] the process of achieving expected performance and other life cycle objectives within the capability of additive manufacturing through the synthesis of shape, size, hierarchy and material composition. After reviewing and categorizing the relevant literature on DFAM, a statistical figure is obtained as shown in

Figure 1, which reveals two primary research streams.

The first stream focuses on the development and application of innovative structures under AM capabilities, including the design of porous microstructures [

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17], macrostructural optimization, and case studies [

18,

19,

20,

21,

22,

23,

24,

25,

26,

27], with application targets often being medical implants, aerospace components, and automotive parts. The second stream concentrates on the exploration and study of design methods, respectively, emphasizing reviews [

28,

29,

30,

31], general theories [

32,

33,

34,

35,

36], tools and local methods [

37,

38,

39,

40,

41,

42,

43,

44], design principles and rules [

45,

46,

47,

48], process-oriented design strategies [

4,

49,

50,

51], and design evaluation [

52,

53,

54].

Despite these advancements, there are few DFAM research achievements and certain limitations due to the novelty of the research topic. Structural innovations typically target component-level improvements, while methodological discussions frequently address single objectives or isolated levels of the design process. These fragmented approaches fail to provide an integrated framework, thereby preventing designers from fully realizing the transformative potential of AM. A critical gap exists for a systematic design methodology that can guide the comprehensive exploitation of AM capabilities from the perspective of function-structure mapping.

In this context, axiomatic design theory emerges as a powerful candidate to address this gap, as it is a systematic design methodology with its core lying in the “zigzag” mapping process between the customer, functional, physical, and process domains. This approach, guided by the Independence Axiom and Information Axiom, breaks cognitive fixedness to achieve globally optimal solutions [

36,

55].

The basic requirements of DFAM naturally align with axiomatic design principles. Therefore, this research integrates axiomatic design with DFAM to develop a comprehensive conceptual design process. By synthesizing the systematic mapping approach of axiomatic design with the unique capabilities of AM, we aim to provide designers with a structured methodology to navigate the expanded design space and fully realize the functional potential of additive manufacturing.

2. Prominent Issues in Method Integration

2.1. The Design Principles of AM

The design principles of AM are reflected in two aspects: fully utilizing the design freedom of AM and fully considering the design constraints of AM, both of which are essential to integrating DFAM with axiomatic design.

Compared with the traditional product design, DFAM reduces the interdependence of manufacturing process variables on the one hand, and the structural forms originally designed for the manufacturing process and assembly process can be omitted or changed. On the other hand, it also expands large and complex design spaces, such as multi-scale structure design, functional gradient material design, lattice metamaterials, and so on [

56,

57]. The design freedom of AM is shown in

Figure 2.

Therefore, the structural features of AM products should diverge from traditional fixed designs, fully leveraging the advantages of AM capabilities while meeting functional requirements.

The design constraints of AM can be divided into two categories: the first is caused by the inherent limitations of the equipment, such as the maximum size under forming space constraints and the minimum feature size considering the influence of nozzles, heat source spots, etc. [

46,

47]. The second type is the design constraints brought by the process characteristics themselves, such as the surface accuracy of the molded parts, the method of support addition and its post-processing, and the mechanical properties of the molded parts. However, the scope of design constraints will become increasingly smaller with the improvement of the technological level.

2.2. The Limitations of the Traditional Axiomatic Design Method on the AM Process

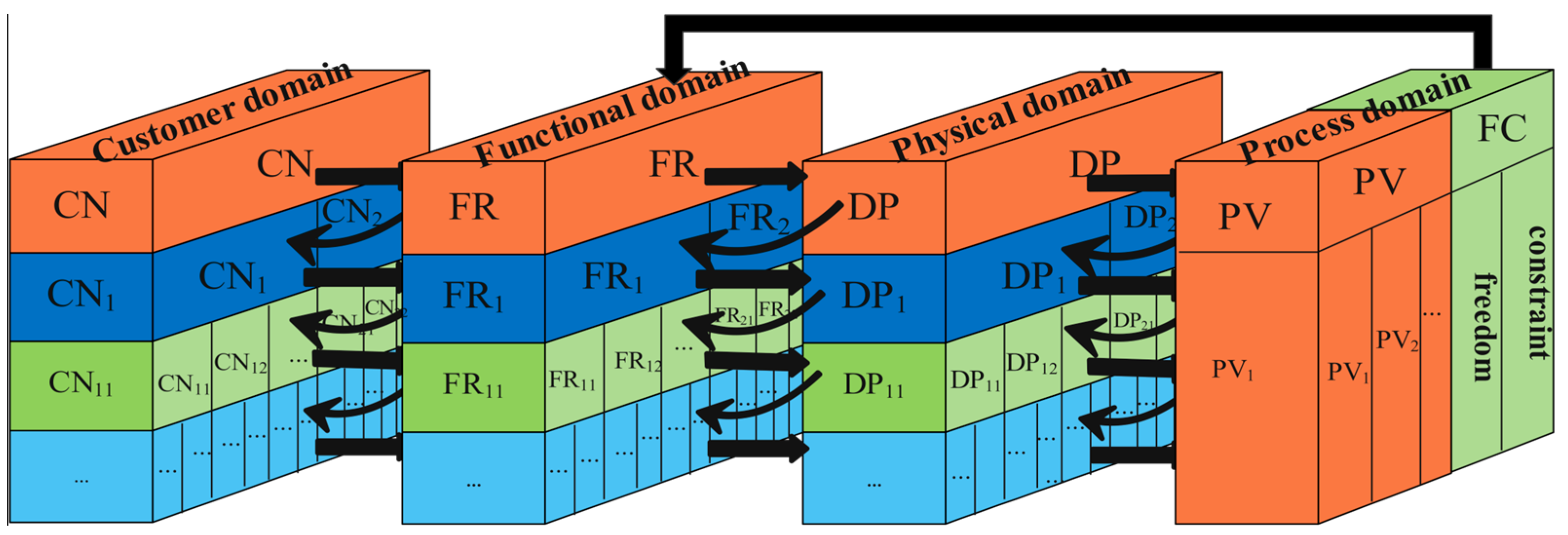

The traditional axiomatic design process is illustrated in

Figure 3, which seeks to map between adjacent domains and assesses part manufacturability by region, enabling different processing technologies in various part areas.

However, Additive Manufacturing (AM), whose process flow is illustrated in

Figure 4, produces a single part in one operation, so process parameters such as slice thickness, scanning speed, and printing direction can only be controlled globally [

58]. This makes it impossible to map process parameters to front-domain structural elements one-to-one. Thus, integrating axiomatic design with AM is needed to derive the conceptual design process for AM-manufactured products.

3. Integration Measures of DFAM and Axiomatic Design

3.1. Division of Affected Areas of Process Domain (“Influence Region Division”)

The AM process domain has a significant impact on both functional decomposition and structural decomposition, which are described as follows.

The influence of the AM process on function analysis is reflected in the upgrading or degradation of product functions: firstly, there are some functions upgraded due to the AM process without paying more time and cost, such as the seamless forming of variable curvature surface that makes the appearance esthetic function upgrade, the bending arrangement of cooling pipes that makes the heat dissipation function upgrade, and the pore surface, which is one-time forming, that makes the sound absorption function upgrade, etc.; Secondly, some functions are degraded, or some auxiliary functions are added due to the process constraints, such as the degradation of surface gloss under the influence of the step effect and the increase in the connectivity function to prepare for support and powder removal.

The influence of the AM process on structural analysis is also reflected in two aspects: on the one hand, the structural design should meet the required functions and be carried out in multiple dimensions; On the other hand, some design constraints should be checked according to the process influence, and some characteristics, such as closed hollow, narrow gap, too small and too large sizes, should be avoided through the adjustment of structural design parameters [

47].

To sum up, the characteristics of the AM process have a certain impact on the decomposition of the functional domain; at the same time, the settings of process variables are also the result of the mapping from the physical domain. In order to describe the overall impact of the process domain accurately, it is divided into two regions. One is used to pre-affect the functional decomposition, which is called “Functional Constraint (FC) integration”; the other is the “Process Variable (PV)” area obtained under the interaction with the design parameters in the physical domain, and the process variables are in a parallel relationship rather than an inclusive relationship.

It should be emphasized that the future AM process should accelerate the realization of adding control strategies for different process requirements in the same part, such as variable-speed printing, variable-precision printing, multi-head printing, color printing, etc., so as to enhance the mapping of process variables and structural design parameters.

3.2. The Ante Displacement of the Influence of the Process Domain (“Process Domain Forward”)

From the above, designers need to upgrade or downgrade the functional requirements during the process of function decomposition to meet the “freedom” and “constraints” introduced by the AM process. Compared with the procedure setting, where process planning is considered last in the traditional theory, the adjustment method is defined as “process domain forward” in this paper. That is, move the “FC” region of the process domain forward to the position parallel to the physics domain, and take the characteristics and variables of the process into account in the decomposition mapping of function and structure. Therefore, the function description and structure design not only meet the needs of customers but also enhance the functional benefits brought by AM. At the same time, it also avoids the design rework caused by process constraints.

Figure 5 shows an illustration of this adjustment mode.

From the comparison between

Figure 3 and

Figure 5, it can be seen that the axiomatic design theory integrated with AM breaks the tree structure of the process domain in traditional axiomatic theory, and the mapping of the process domain is not only between adjacent domains.

3.3. Axiomatic Design Process of AM Products

The flow chart of axiomatic design of AM products is obtained based on the above measures, as shown in

Figure 6. Firstly, the product requirements are obtained, and four design domains are established. On the premise of moving forward the process domain, the final leaf parameters of each design domain, verified by the independence axiom, are obtained through the process of decomposition in the domain and mapping between domains. Among all design schemes that meet the above process, the scheme with the highest probability of meeting the requirements is selected as the final design result based on the minimum information axiom.

The core principle of the DFAM method, integrated with axiomatic design, is to start from the source of design and integrate the degrees of freedom and constraints of AM into the zigzag mapping of various domains. Therefore, compared with existing DFAM methods, this method has a certain degree of globality and provides decision-makers, practitioners, and especially product structure designers with clear design ideas and practical methods, improving the problem of fixed thinking under the limitations of traditional manufacturing.

4. Case Study: Structural Design of Mechanical Fingers Imitating Dexterous Hand

To help designers better understand the proposed conceptual design method and verify its operability in specific part design, mechanical fingers, which are widely used, are employed as a case study.

The target task in this case is to design a mechanical finger structure system that performs the target grasping action, specifically, fine grasping a steel ruler and a pencil, respectively, to execute the scribing operation. In the motion spectrum of the human hand, the thumb and index finger have the highest completion for the fine grasping task, and the cooperative motion relationship between the two and other fingers is small [

59,

60]. Therefore, the operating system composed of two fingers is studied as an independent research object and applied to the target design task.

4.1. Demand Analysis—Manual Grasping Experiment

The experimental method identifies key product design requirements by analyzing optimal hand movements. Ten participants (50% male, with an average age of 25) performed target tasks using only their index fingers and thumbs, while their other fingers remained fixed. Researchers recorded task completion time, success rate, and knuckle curvature data to determine the optimal action combination.

After the experiment, it is concluded that the optimal action strategy of the target task is to pinch and pry the steel ruler on the side—pinch and grasp—place it horizontally on the paper—multi-point fixation—pinch and grasp the pen on the side—adjust the grasping posture—scribe—return and adjust the pen—pinch and grasp on the side—return and adjust the steel ruler.

According to the grasping strategy of the human hand, a mechanical finger system is designed to perform fine grasping tasks.

4.2. Decomposition Mapping of Functional-Structure

The zigzag decomposition mapping method between domains is used to deepen and refine the design. Taking the decomposition mapping of the functional domain and physical domain as an example, the upper function is decomposed according to the function division of the physical result of the upper mapping, and the decomposition result of the physical domain of this layer is mapped at the same time; Repeat the previous step until the target function becomes clear, and gradually refine the conceptual design results of the target structure.

Figure 7 shows the decomposition mapping process of function and structure. The influence of the AM process domain is interspersed in each hierarchy of functional decomposition and structural mapping in the analysis process. For example, based on the AM process, lightweight and esthetic properties are proposed as basic properties rather than additional properties in the functional domain. In addition, in the physical domain, difficult structures such as integrated joints and skin skeletons are used as effective decomposition results, etc.

4.3. Verification of Independence Axiom

The decomposition mapping process should be verified by the independence axiom, which is a protective measure that the design satisfies to minimize the interference between variables of the same hierarchy. The simpler the correspondence between the same hierarchy, the more conducive it is for designers to track the design process and make corresponding adjustments. On the contrary, there will be an adverse phenomenon of “pulling one hair and moving the whole body”.

Taking the design of the functional domain and physical domain as an example, in the function structure hierarchical model, the corresponding relationship between

FR and

DP can be expressed by design Equation (1), that is

where [

A] is a design relation matrix, which should be a diagonal matrix (uncoupled design) or a triangular matrix (quasi-coupled design) in an ideal design whose elements are expressed as Equation (2):

here, the 0, 1 judgment method is used to describe the relationship between function and design parameters.

For the above decomposition mapping process, the design relationship matrix

Ai (i = 1 to 6) of each hierarchy in this case study is established in

Table 1, which satisfies the independence axiom.

4.4. Detailed Design of Typical AM Innovation Features

Using axiomatic design with AM principles, two sets of “double finger” mechanical finger systems were developed. The “process domain forward” strategy enabled integrated manufacturing, lightweighting, and customizable rotation while complying with AM constraints (eliminating narrow gaps/reducing overhangs). Among the structural elements (

DP11111~DP22222) in

Figure 7, the most representative AM characteristic is the flexible integrated spiral joint and the variable density lattice filling finger, as detailed below.

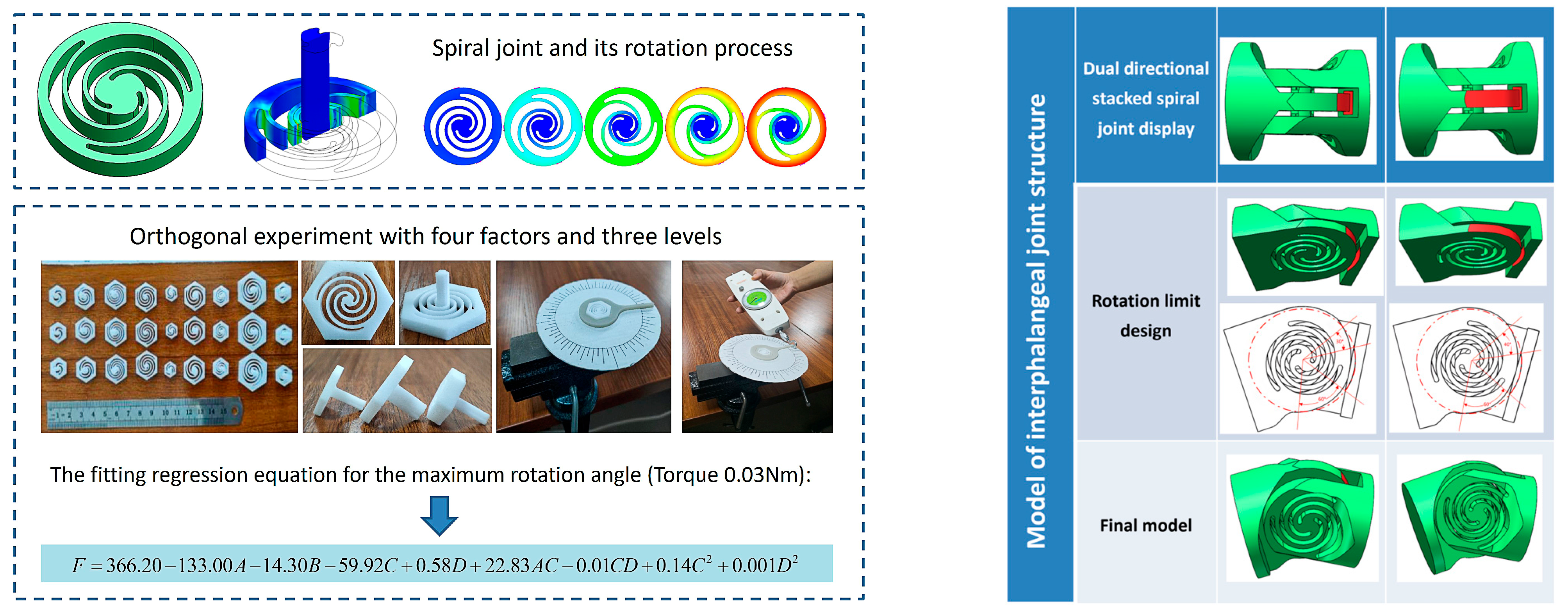

4.4.1. Design of Flexible Integrated Spiral Joint (Interphalangeal Joint)

The mechanical fingers to be manufactured in this case require two types of joints, namely metacarpophalangeal joints and interphalangeal joints.

The first type (metacarpophalangeal joint) is a biaxial joint that drives the proximal phalanx for positioning motion, requiring bidirectional rotation, so a spherical joint with three degrees of freedom is used to simulate it (limiting one of the degrees of freedom). In the design, special spherical and ellipsoidal joint structures with customized mating surfaces are used for the integrated design of the index and thumb metacarpophalangeal joints, endowing specific degrees of freedom and rotation amplitude.

The second type (interphalangeal joint) is a uniaxial joint that drives the distal phalanx to rotate in a single plane for grasping. Due to the lack of self-connectivity in traditional joints, a flexible integrated helical joint is introduced to meet functional and integrated molding requirements. The flexible joint enables rotation and elastic recovery, while the large spacing of helical blades avoids the process constraint of narrow gaps in additive manufacturing.

Preliminary research through orthogonal test simulation and experimental verification shows that the four structural parameters (helical angle, pitch, core diameter, and blade thickness) affect the maximum rotation angle of the joint in decreasing order of influence. A fitting regression equation for the maximum rotation angle of helical joints made of desktop 3D printing material (nylon) was obtained to verify the rotation capability of the target structure.

In this case, parameters of the helical joint are designed based on the rotation capability, the overall size of the mechanical finger, and the grasping force. Firstly, a bidirectional superimposed helical joint is adopted (with the middle and outer layers in opposite directions), doubling the rotation angle of a unidirectional joint to meet angle and size requirements; secondly, the curvature of the outer surface of the middle-layer joint is adjusted to change the mating gap, achieving local interference fit at the maximum rotation angle for limiting positioning to ensure that the joint rotation does not exceed the elastic range of the structure. Finally, the fitting equation predicts a unidirectional rotation angle of 33°, and the bidirectional superposition of angles meets the design requirements.

Figure 8 shows the related research and design results of the bidirectional superimposed helical joint.

4.4.2. Design of Variable Density Lattice Filling Dactylus

The conceptual design adopts a “skin + skeleton” structure. The skeleton must have a specific outer contour and strength to support the skin and transmit forces, while a lightweight design is crucial—its own weight directly affects the lateral force on the joint and thus the rotation performance. Finally, a variable-density lattice filling structure that matches the optimal force transmission path is adopted, which is the result of the structural design under the “process domain forward” approach.

The detailed design method of variable density lattice filling dactylus is a topology optimization method for additive manufacturing, which combines the idea of basic structure topology optimization with unit cell parametric layout optimization to gradually generate the final skeleton structure.

Firstly, the dactylus is subjected to force analysis, and the design area is defined to obtain information such as force positions and magnitudes. Based on the boundary conditions, the minimum weight is determined, and a topology optimization model is established with minimum compliance as the optimization goal. After solving, the topological structure of the optimal force transmission path is obtained. Due to the irregular shape of the topologically optimized structure, which has poor connectivity and supportability for the outer skin, variable-density diamond lattice filling is adopted on this basis.

In basic research on lattice units, a mathematical model has been developed that relates the relative density of the lattice unit to its geometric parameters. For example, for the diamond lattice structure used in this case, the mathematical model is expressed as Equation (3).

where “

r” and “

” represent the cross-sectional radius of the rod and the diameter of the inscribed circle in the cell section, respectively. The lattice filling process is obtained using the relative density mapping method. The specific process is to map the relative density results obtained during the topology optimization of the structure within the design area to the filled lattice cells and then perform detailed modeling based on the corresponding relationship between the obtained results (i.e., lattice cell relative density) and lattice modeling parameters. This cycle is repeated to ultimately achieve lattice filling.

Figure 9 shows the detailed design process of the diamond lattice filling process and variable density lattice filling dactylus.

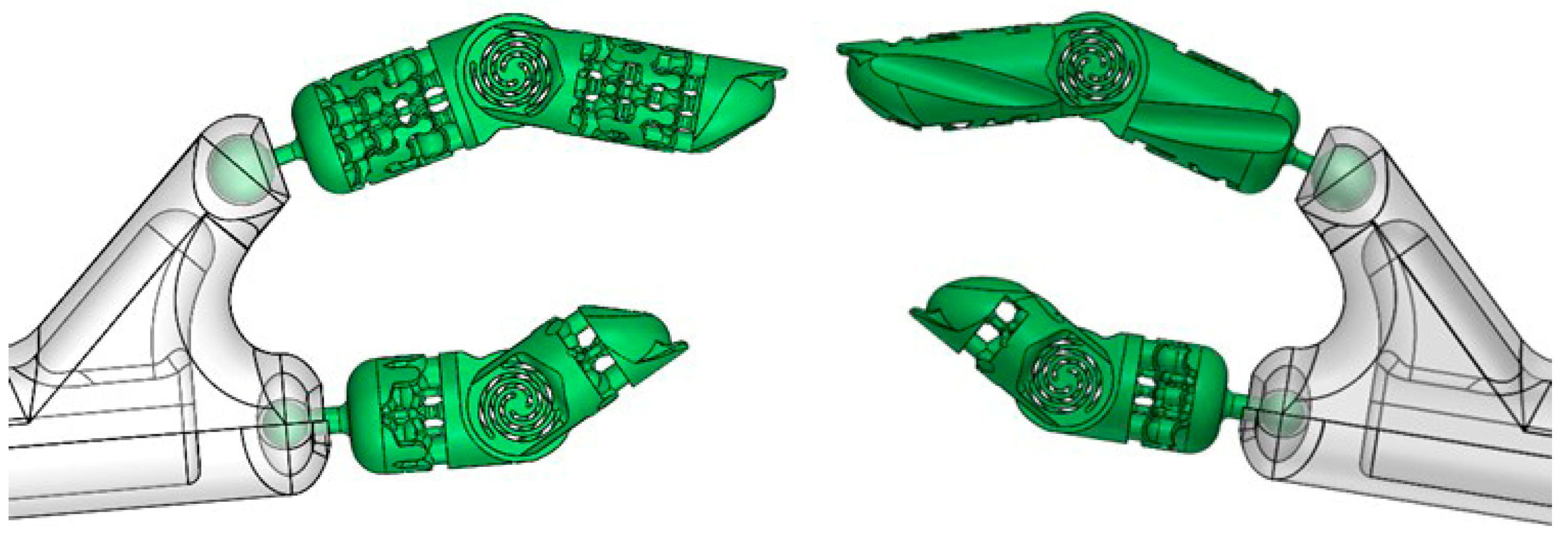

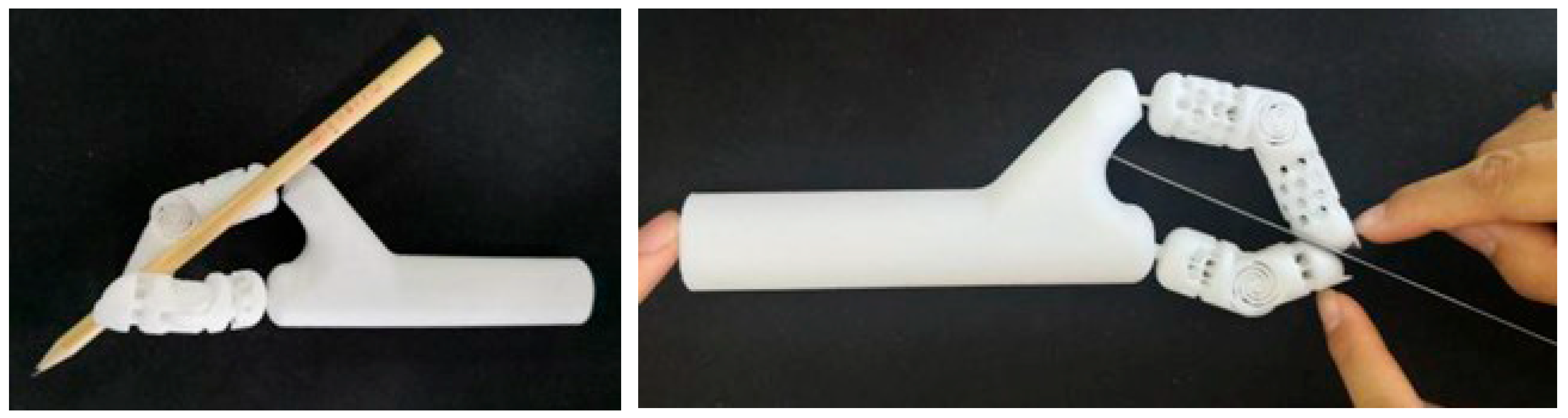

4.5. Designed Product

The designed mechanical fingers are shown in

Figure 10, where the interphalangeal joints were designed in detail as customized flexible joints with integrated function. In addition, the variable density lattice filling is applied to the design practice of mechanical finger filling frames to obtain a lighter finger structure with better force transmission paths.

The SLS process and nylon are selected for the integrated manufacturing of the designed mechanical fingers, and the formed products with perfectly designed features are shown in

Figure 11. Various positions of the knuckles show that the metacarpophalangeal joints have reached the expected degrees of freedom and limit positions. The contact verification in

Figure 12 shows that the contact between the fingers and the target objects is perfectly matched, and the degrees of freedom of each knuckle can fully meet the position conditions required for each target task. Therefore, the design of the mechanical fingers creates reliable conditions for accurate grasping in the subsequent stage.

The range of the moving area of each finger of the designed mechanical finger system is shown in

Figure 13. The grasping action of small objects can be performed in the common range of the moving areas of the two fingers.

Overall, the design results of this case have the following changes compared to traditional design schemes:

Higher integration of parts. The designed mechanical finger has undergone functional integration, using spiral joints instead of traditional motion pairs. It not only connects two independent finger joints into one for assembly-free manufacturing but also achieves customization of their relative rotation angles.

Lightweight implementation under the optimal transmission path. Unlike traditional structural lightweighting achieved through rule-based material reduction, the lightweighting in this case relies on complex pore structures to achieve changes in relative density while balancing optimal mechanical performance and other auxiliary functions (excellent connection with the outer skin).

The irreplaceability of AM advantages. The designed mechanical finger structure has a large number of complex surfaces that cannot be obtained through traditional manufacturing methods, fully utilizing the benefits of additive manufacturing.

5. Conclusions

In conclusion, this study enhances the axiomatic design process to align with the unique characteristics of AM, introducing measures such as “influence region division” and “process domain forward.” The resulting conceptual design framework successfully integrates DFAM principles, offering a systematic approach that promotes the maximization of functional value in AM products.

The case study of a dexterous mechanical finger design demonstrates the practical effectiveness of the proposed method, whose power lies in its ability to systematically decouple functional requirements (e.g., flexible rotation, lightweight) into physical parameters (e.g., integrated flexible joint, lattice infill) without the coupling conflicts typical of traditional design, by ensuring that designs are both functionally robust and manufacturable from the outset, the method increases the probability of ‘first-time-right’ manufacturing, ultimately leading to higher-performing, lighter-weight, and more integrated final products.

The integration of axiomatic design with AM presents a distinct value proposition for both researchers and practitioners. Theoretically, it provides a structured framework that formalizes the exploitation of AM capabilities, moving beyond ad hoc, experience-based design towards a principle-driven methodology. It reveals a new design rule: that the “zigzag” mapping process must be explicitly guided by both the expansion of design freedom and the specific constraints of AM processes. For practitioners, this translates into tangible benefits: the systematic decomposition of functional requirements, guided by the Independence Axiom, significantly reduces design iterations and costly trial-and-error cycles, thereby shortening development time and lowering costs.

While the proposed conceptual design theory is comprehensive, its application across different domains will involve varying functions and evaluation metrics. Future work will address these domain-specific adaptations and delve into the more complex theoretical branches required for the detailed design stage, further extending the applicability and robustness of this framework.

Author Contributions

Conceptualization, X.Y. and W.M.; methodology, X.Y.; software, Y.S.; validation, X.Z. (Xiaoxia Zhao), X.Z. (Xingkai Zhang) and H.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (52075356), PhD Research Startup Foundation of Taiyuan University of Science and Technology (20222033), Scientific Research Foundation for the Introduction of Talent in Shanxi Province (20222135), Science and Technology Projects in Shanxi Province: Basic Research Program—Youth Project (202203021222212, 202203021212322 and 202403021212325), Scientific and Technological Innovation Programs of Higher Education Institutions in Shanxi (2022L295).

Data Availability Statement

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AM | Additive Manufacturing |

| DFAM | Design for Additive Manufacturing |

| FC | Functional Constraint |

| PV | Process Variable |

References

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Chu, C.; Graf, G.; Rosen, D.W. Design for Additive Manufacturing of Cellular Structures. Comput. Aided Des. Appl. 2008, 5, 686–696. [Google Scholar] [CrossRef]

- Rosen, D.W. Computer-Aided Design for Additive Manufacturing of Cellular Structures. Comput. Aided Des. Appl. 2007, 4, 585–594. [Google Scholar] [CrossRef]

- Tammas-Williams, S.; Todd, I. Design for additive manufacturing with site-specific properties in metals and alloys. Scr. Mater. 2017, 135, 105–110. [Google Scholar] [CrossRef]

- Khoda, A.; Ozbolat, I.T.; Koc, B. Designing heterogeneous porous tissue scaffolds for additive manufacturing processes. Comput.-Aided Des. 2013, 45, 1507–1523. [Google Scholar] [CrossRef]

- Ziegler, T.; Jaeger, R.; Koplin, C. A design, mechanical rating, and load adaptation method for cellular components for additive manufacturing. Int. J. Adv. Manuf. Technol. 2017, 90, 2875–2884. [Google Scholar] [CrossRef]

- Cheng, L.; Zhang, P.; Biyikli, E.; Bai, J.; Robbins, J.; Albert. Efficient design optimization of variable-density cellular structures for additive manufacturing: Theory and experimental validation. Rapid Prototyp. J. 2017, 23, 660–677. [Google Scholar] [CrossRef]

- Cheng, L.; Liu, J.; Albert, C. Concurrent lattice infill with feature evolution optimization for additive manufactured heat conduction design. Struct. Multidiscipl. Optim. 2018, 58, 511–535. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S. A design for the additive manufacture of functionally graded porous structures with tailored mechanical properties for biomedical applications. J. Manuf. Process. 2011, 13, 160–170. [Google Scholar] [CrossRef]

- Max, M.; Opgenoord, J.; Willcox, K.E. Design for additive manufacturing: Cellular structures in early-stage aerospace design. Struct. Multidiscipl. Optim. 2019, 60, 411–428. [Google Scholar] [CrossRef]

- Goel, A.; Anand, S. Design of Functionally Graded Lattice Structures using B-splines for Additive Manufacturing. Procedia Manuf. 2019, 34, 655–665. [Google Scholar] [CrossRef]

- Wadbro, E.; Niu, B. Multiscale design for additive manufactured structures with solid coating and periodic infill pattern. Comput. Methods Appl. Mech. Eng. 2019, 357, 112605. [Google Scholar] [CrossRef]

- Savio, G.; Curtarello, A.; Rosso, S.; Meneghello, R.; Concheri, G. Homogenization driven design of lightweight structures for additive manufacturing. Int. J. Interact. Des. Manuf. 2019, 13, 263–276. [Google Scholar] [CrossRef]

- Savio, G.; Meneghello, R.; Concheri, G. Design of variable thickness triply periodic surfaces for additive manufacturing. Prog. Addit. Manuf. 2019, 4, 281–290. [Google Scholar] [CrossRef]

- Hegab Hussien, A. Design for additive manufacturing of composite materials and potential alloys: A review. Manuf. Rev. 2016, 3, 11. [Google Scholar] [CrossRef]

- Shabat, B.Y.; Fischer, A. Design of Adaptive Porous Micro-structures for Additive Manufacturing. Procedia CIRP 2014, 21, 133–137. [Google Scholar] [CrossRef]

- Yang, L. Experimental-assisted design development for an octahedral cellular structure using additive manufacturing. Rapid Prototyp. J. 2015, 21, 168–176. [Google Scholar] [CrossRef]

- Klahn, C.; Leutenecker, B.; Meboldt, M. Design for Additive Manufacturing—Supporting the Substitution of Components in Series Products. Procedia CIRP 2014, 21, 138–143. [Google Scholar] [CrossRef]

- Junk, S.; Klerch, B.; Hochberg, U. Structural Optimization in Lightweight Design for Additive Manufacturing. Procedia CIRP 2019, 84, 277–282. [Google Scholar] [CrossRef]

- Merulla, A.; Gatto, A.; Bassoli, E.; Munteanu, S.I.; Gheorghiu, B.; Pop, M.A.; Bedo, T.; Munteanu, D. Weight reduction by topology optimization of an engine subframe mount, designed for additive manufacturing production. Mater. Today Proc. 2019, 19 Pt 3, 1014–1018. [Google Scholar] [CrossRef]

- Rezayat, H.; Bell, R.J.; Plotkowski, J.A.; Babu, S.S. Multi-solution nature of topology optimization and its application in design for additive manufacturing. Rapid Prototyp. J. 2019, 25, 1475–1481. [Google Scholar] [CrossRef]

- Aremu, A.; Ashcroft, I.; Wildman, R.; Hague, R.; Tuck, C.; Brackett, D. The effects of bidirectional evolutionary structural optimization parameters on an industrial designed component for additive manufacture. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2013, 227, 794–807. [Google Scholar] [CrossRef]

- Pietropaoli, M.; Ahlfeld, R.; Montomoli, F.; Ciani, A.; D’ERcole, M. Design for Additive Manufacturing: Internal Channel Optimization. J. Eng. Gas. Turbines Power-Trans. ASME 2017, 139, 1–9. [Google Scholar] [CrossRef]

- Spallek, J.; Krause, D. Process Types of Customisation and Personalisation in Design for Additive Manufacturing Applied to Vascular Models. Procedia CIRP 2016, 50, 281–286. [Google Scholar] [CrossRef]

- Klahn, C.; Singer, D.; Meboldt, M. Design Guidelines for Additive Manufactured Snap-Fit Joints. Procedia CIRP 2016, 50, 264–269. [Google Scholar] [CrossRef]

- Peto, M.; Ramírez-Cedillo, E.; Hernández, A.; Siller, H.R. Structural design optimization of knee replacement implants for Additive Manufacturing. Procedia Manuf. 2019, 34, 574–583. [Google Scholar] [CrossRef]

- Novak, I.J.; O’Neill, J. A design for additive manufacturing case study: Fingerprint stool on a BigRep ONE. Rapid Prototyping J. 2019, 25, 1069–1079. [Google Scholar] [CrossRef]

- Pradel, P.; Zhu, Z.; Bibb, R.; Moultrie, J. Investigation of design for additive manufacturing in professional design practice. J. Eng. Des. 2018, 29, 165–200. [Google Scholar] [CrossRef]

- Doubrovski, Z.; Verlinden, J.C.; Geraedts, J.M.P. Optimal Design for Additive Manufacturing: Opportunities and Challenges. In Proceedings of the ASME 2011 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Washington, DC, USA, 28–31 August 2011; pp. 635–646. [Google Scholar] [CrossRef]

- Wiberg, A.; Persson, J.; Ölvander, J. Design for additive manufacturing—A review of available design methods and software. Rapid Prototyp. J. 2019, 25, 1080–1094. [Google Scholar] [CrossRef]

- Tang, Y.; Zhao, F.Y. A survey of the design methods for additive manufacturing to improve functional performance. Rapid Prototyp. J. 2016, 22, 569–590. [Google Scholar] [CrossRef]

- Booth, J.W.; Alperovich, J.; Chawla, P.; Ma, J.; Reid, T.N.; Ramani, K. The Design for Additive Manufacturing Worksheet. J. Mech. Des. 2017, 139, 100904. [Google Scholar] [CrossRef]

- Orquéra, M.; Campocasso, S.; Millet, D. Design for Additive Manufacturing Method for a Mechanical System Downsizing. Procedia CIRP 2017, 60, 223–228. [Google Scholar] [CrossRef]

- Ponche, R.; Kerbrat, O.; Mognol, P.; Hascoet, J.-Y. A novel methodology of design for Additive Manufacturing applied to Additive Laser Manufacturing process. Robot. Comput. Integr. Manuf. 2014, 30, 389–398. [Google Scholar] [CrossRef]

- Bin Maidin, S.; Campbell, I.; Pei, E. Development of a design feature database to support design for additive manufacturing. Assem. Autom. 2012, 32, 235–244. [Google Scholar] [CrossRef]

- Salonitis, K. Design for additive manufacturing based on the axiomatic design method. Int. J. Adv. Manuf. Technol. 2016, 87, 989–996. [Google Scholar] [CrossRef]

- Vaughan, M.R.; Crawford, R.H. Effectiveness of virtual models in design for additive manufacturing: A laser sintering case study. Rapid Prototyp. J. 2013, 19, 11–19. [Google Scholar] [CrossRef]

- Zhang, B.; Goel, A.; Ghalsasi, O.; Anand, S. CAD-based design and pre-processing tools for additive manufacturing. J. Manuf. Syst. 2019, 52 Pt B, 227–241. [Google Scholar] [CrossRef]

- Asadollahi-Yazdi, E.; Gardan, J.; Lafon, P. Multi-objective optimization approach in design for additive manufacturing for fused deposition modeling. Rapid Prototyp. J. 2019, 25, 875–887. [Google Scholar] [CrossRef]

- Morretton, E.; Vignat, F.; Pourroy, F.; Marin, P. Impacts of the settings in a design for additive manufacturing process based on topological optimization. Int. J. Interact. Des. Manuf. 2019, 13, 295–308. [Google Scholar] [CrossRef]

- Zhu, Z.; Anwer, N.; Mathieu, L. Geometric deviation modeling with Statistical Shape Analysis in Design for Additive Manufacturing. Procedia CIRP 2019, 84, 496–501. [Google Scholar] [CrossRef]

- Kaspar, J.; Reichwein, J.; Kirchner, E.; Vielhaber, M. Integrated Design Pattern Matrix for Additive Manufacturing—A Holistic Potential Analysis for Systemic Product and Production Engineering. Procedia CIRP 2019, 84, 480–485. [Google Scholar] [CrossRef]

- Ko, H.; Moon, K.S.; Hwang, J. Design for additive manufacturing in customized products. Int. J. Precis. Eng. Manuf. 2015, 16, 2369–2375. [Google Scholar] [CrossRef]

- Yao, X.; Moon, K.S.; Bi, G. A hybrid machine learning approach for additive manufacturing design feature recommendation. Rapid Prototyp. J. 2017, 23, 983–997. [Google Scholar] [CrossRef]

- Rosen, D.W. Research supporting principles for design for additive manufacturing. Virtual Phys. Prototyp. 2014, 9, 225–232. [Google Scholar] [CrossRef]

- Adam, A.G.; Zimmer, D. Design for Additive Manufacturing—Element transitions and aggregated structures. CIRP J. Manuf. Sci. Technol. 2014, 7, 20–28. [Google Scholar] [CrossRef]

- Adam, G.A.O.; Zimmer, D. On design for additive manufacturing: Evaluating geometrical limitations. Rapid Prototyp. J. 2015, 21, 662–670. [Google Scholar] [CrossRef]

- Jee, H.; Witherell, P. A method for modularity in design rules for additive manufacturing. Rapid Prototyp. J. 2017, 23, 1107–1118. [Google Scholar] [CrossRef]

- Zwier, P.M.; Wits, W.W. Design for Additive Manufacturing: Automated Build Orientation Selection and Optimization. Procedia CIRP 2016, 55, 128–133. [Google Scholar] [CrossRef]

- Leutenecker-Twelsiek, B.; Klahn, C.; Meboldt, M. Considering Part Orientation in Design for Additive Manufacturing. Procedia CIRP 2016, 50, 408–413. [Google Scholar] [CrossRef]

- Kadkhoda-Ahmadi, S.; Hassan, A.; Asadollahi-Yazdi, E. Process and resource selection methodology in design for additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 104, 2013–2029. [Google Scholar] [CrossRef]

- Zhang, Y.; Bernard, A.; Gupta, R.K.; Harik, R. Evaluating the Design for Additive Manufacturing: A Process Planning Perspective. Procedia CIRP 2014, 21, 144–150. [Google Scholar] [CrossRef]

- Hällgren, S.; Pejryd, L.; Ekengren, J. (Re)Design for Additive Manufacturing. Procedia CIRP 2016, 50, 246–251. [Google Scholar] [CrossRef]

- Tang, Y.; Mak, K.; Zhao, F.Y. A framework to reduce product environmental impact through design optimization for additive manufacturing. J. Clean. Prod. 2016, 137, 1560–1572. [Google Scholar] [CrossRef]

- Suh, N. Axiomatic Design: Advances and Applications; Mit Pappalardo: Cambridge, MA, USA, 2001; Volume 5, pp. 239–298. [Google Scholar]

- Thompson, M.K.; Moroni, G.; Vaneker, T. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann.-Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Askari, A.; Jamalzadeh, M. A review of structural diversity design and optimization for lattice metamaterials. AIP Adv. 2024, 14, 100–702. [Google Scholar] [CrossRef]

- Kumar, K.; Acherjee, B. Revolutionizing manufacturing: A comprehensive overview of additive manufacturing processes, materials, developments, and challenges. J. Manuf. Process. 2023, 107, 574–619. [Google Scholar] [CrossRef]

- Santello, M.; Flanders, M.; Soechting, J.F. Postural Hand Synergies for Tool Use. J. Neurosci. 1998, 18, 10105–10115. [Google Scholar] [CrossRef]

- Ingram, J.N.; Körding, K.P.; Howard, I.S.; Wolpert, D.M. The statistics of natural hand movements. Exp. Brain Res. 2008, 188, 223–236. [Google Scholar] [CrossRef] [PubMed]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).