Quantitative Mechanisms of Long-Term Drilling-Fluid–Coal Interaction and Strength Deterioration in Deep CBM Formations

Abstract

1. Introduction

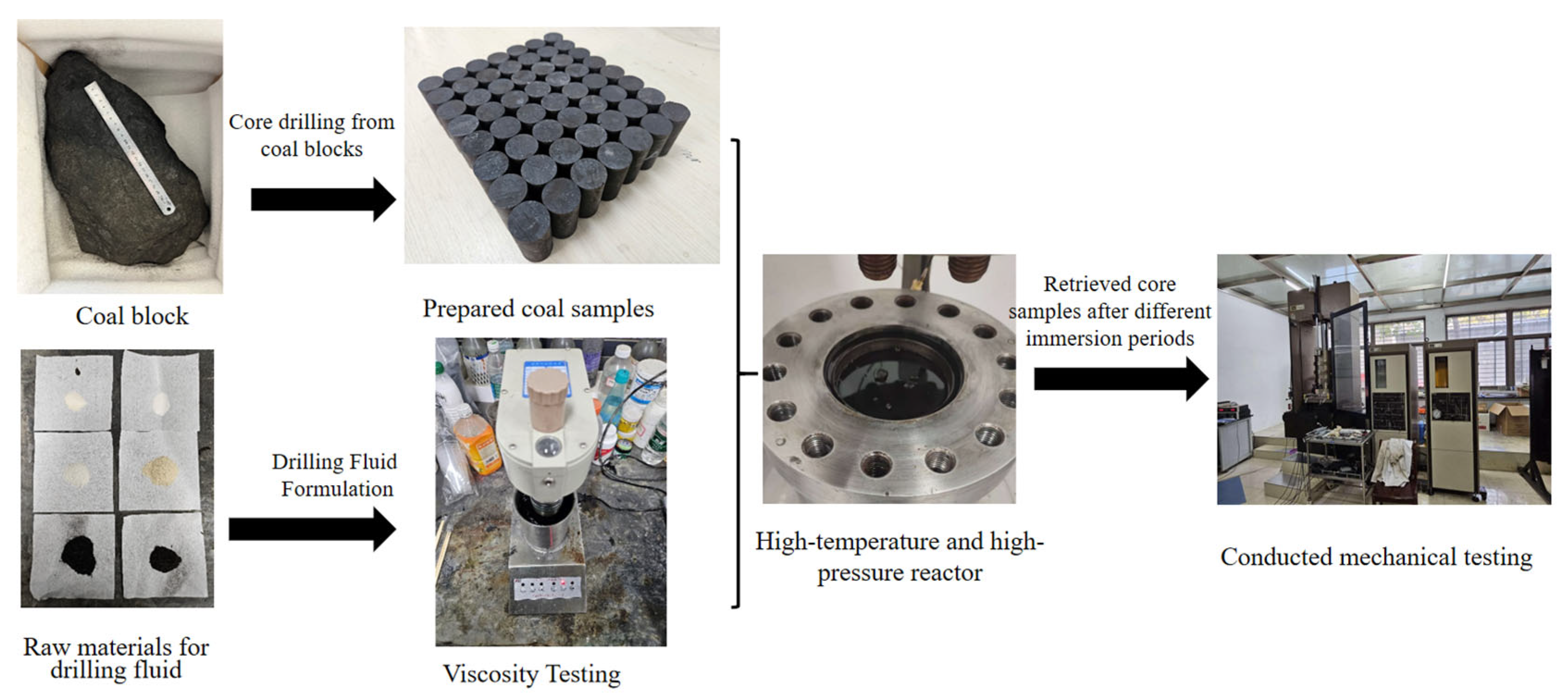

2. Coal Specimen Preparation and Drilling-Fluid Formulation

2.1. Coal Specimen Preparation

2.2. Drilling Fluid Preparation

3. Experimental Scheme

4. Test Equipment and Test Method

4.1. High-Temperature and High-Pressure Reactor

4.2. Uniaxial/Triaxial Compression Testing Equipment

4.3. Millimeter Indentation Test Equipment

5. Test Results

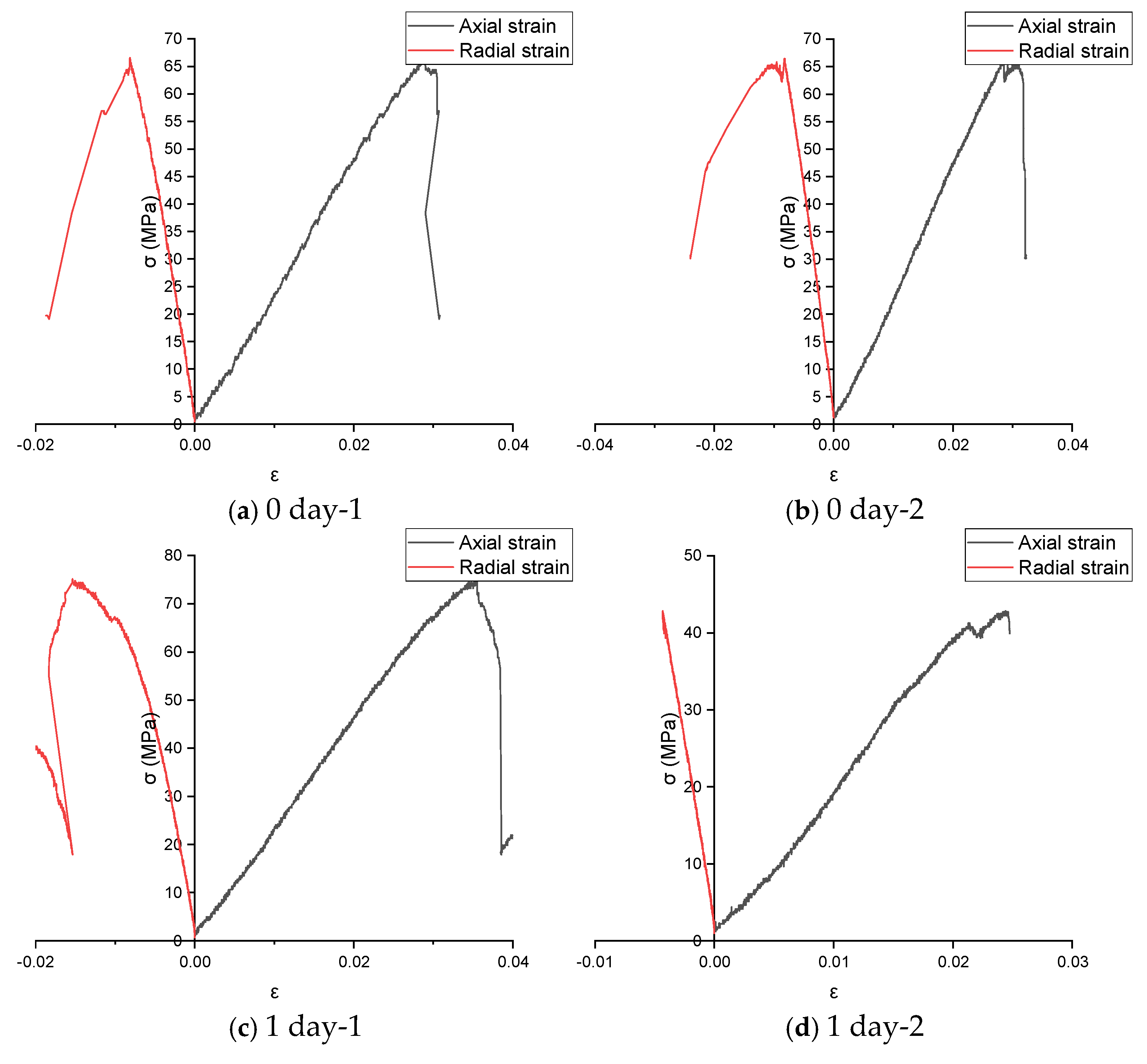

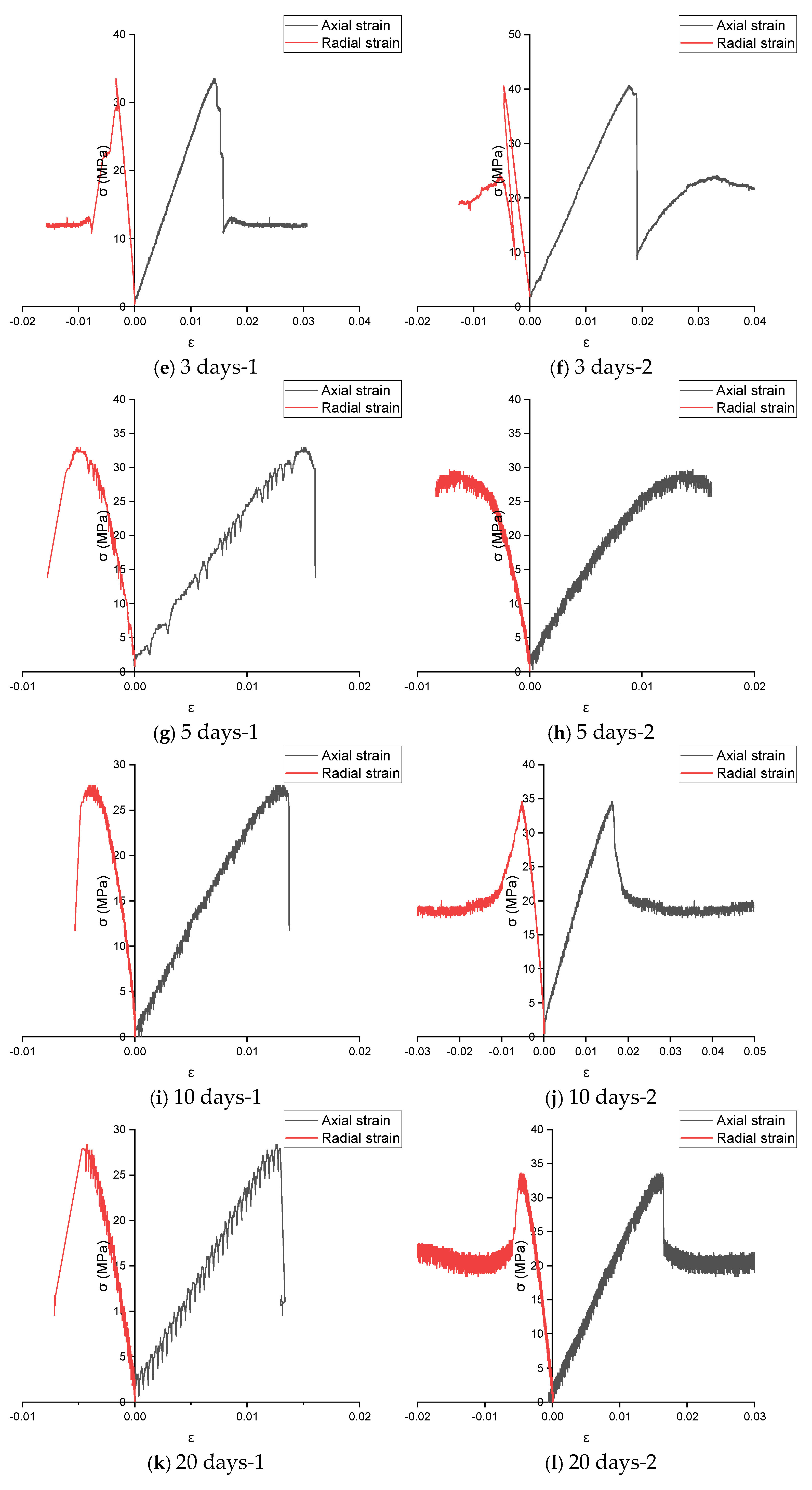

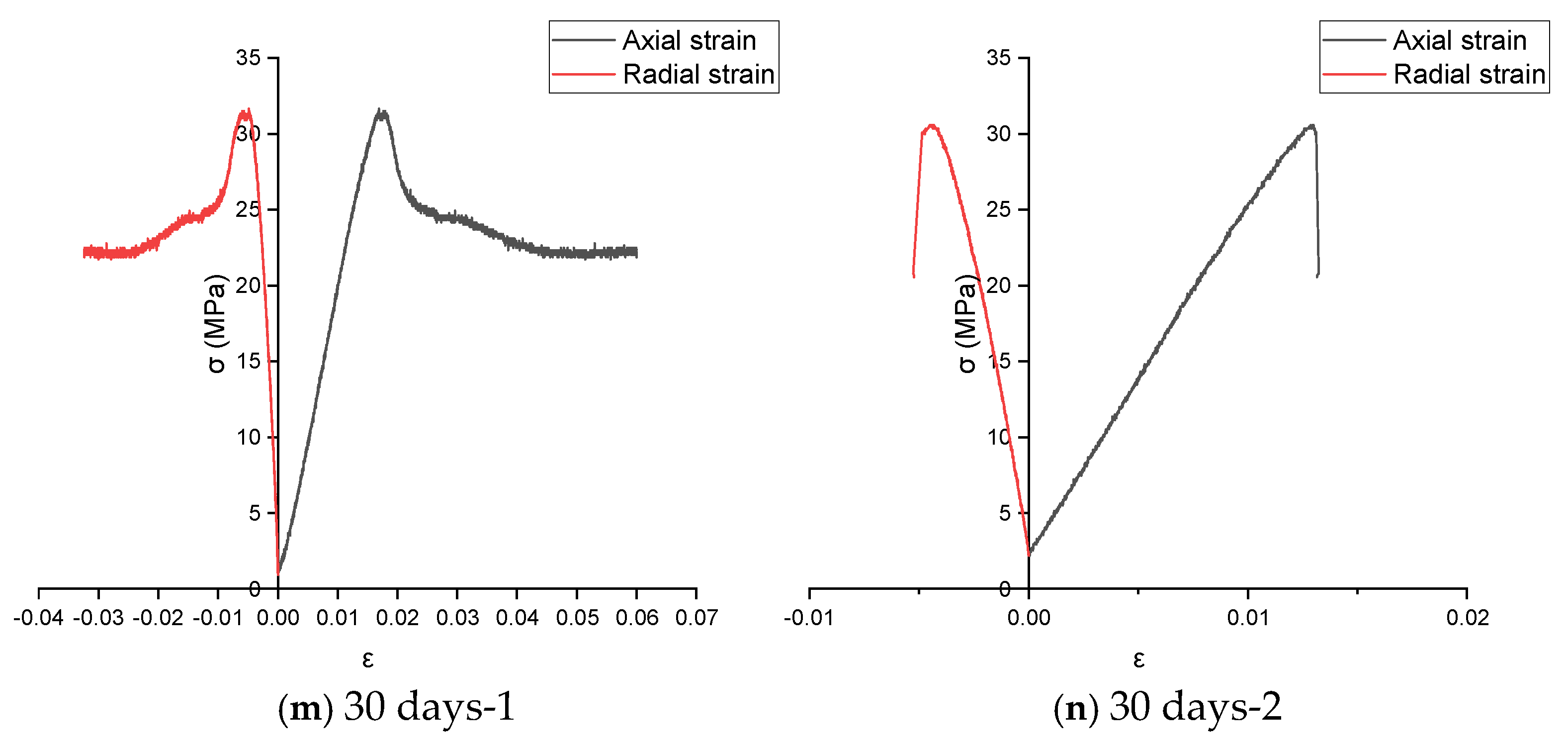

5.1. Compressive Strength of Coal Under Different Immersion Times

5.2. Cohesion and Internal Friction Angle of Coal Under Different Immersion Times

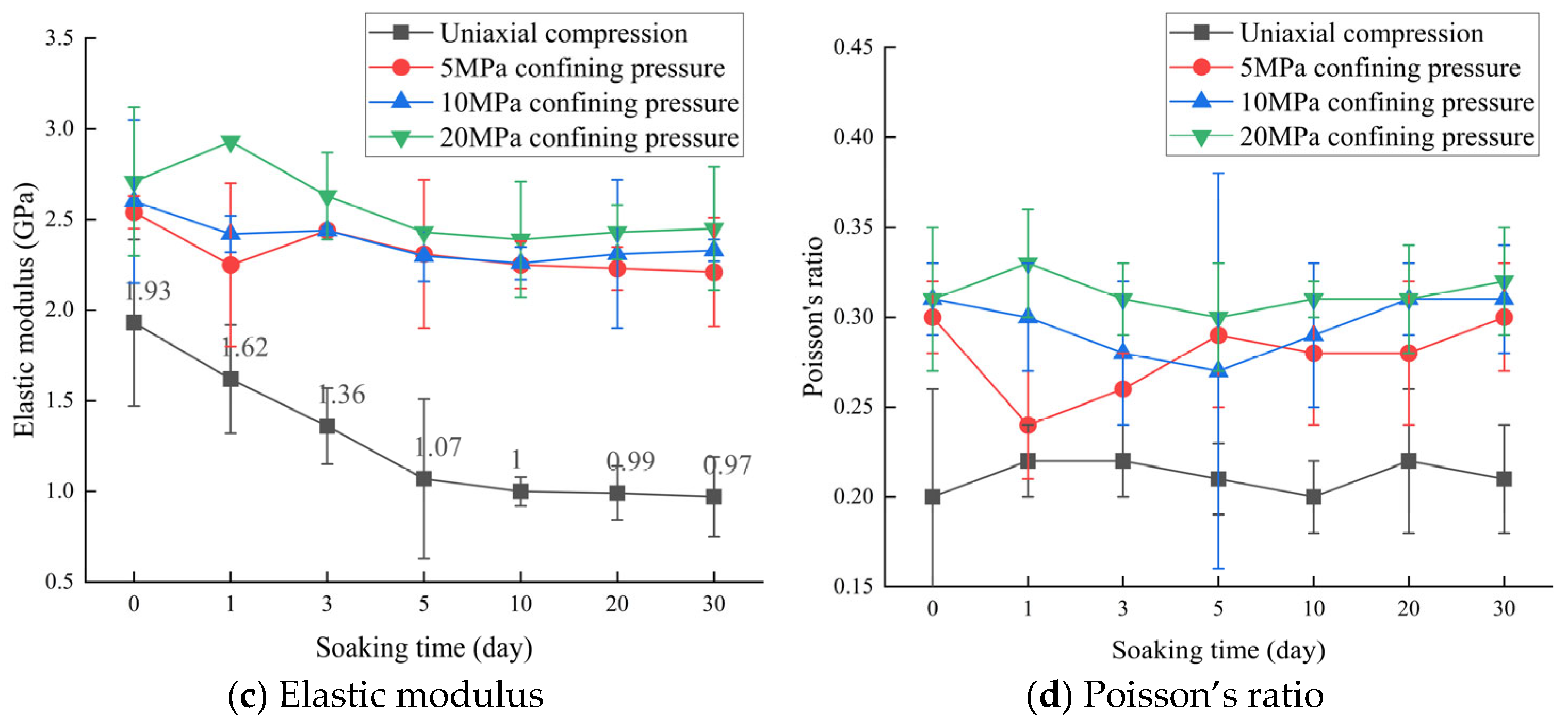

5.3. Elastic Modulus and Poisson’s Ratio of Coal Under Different Immersion Times

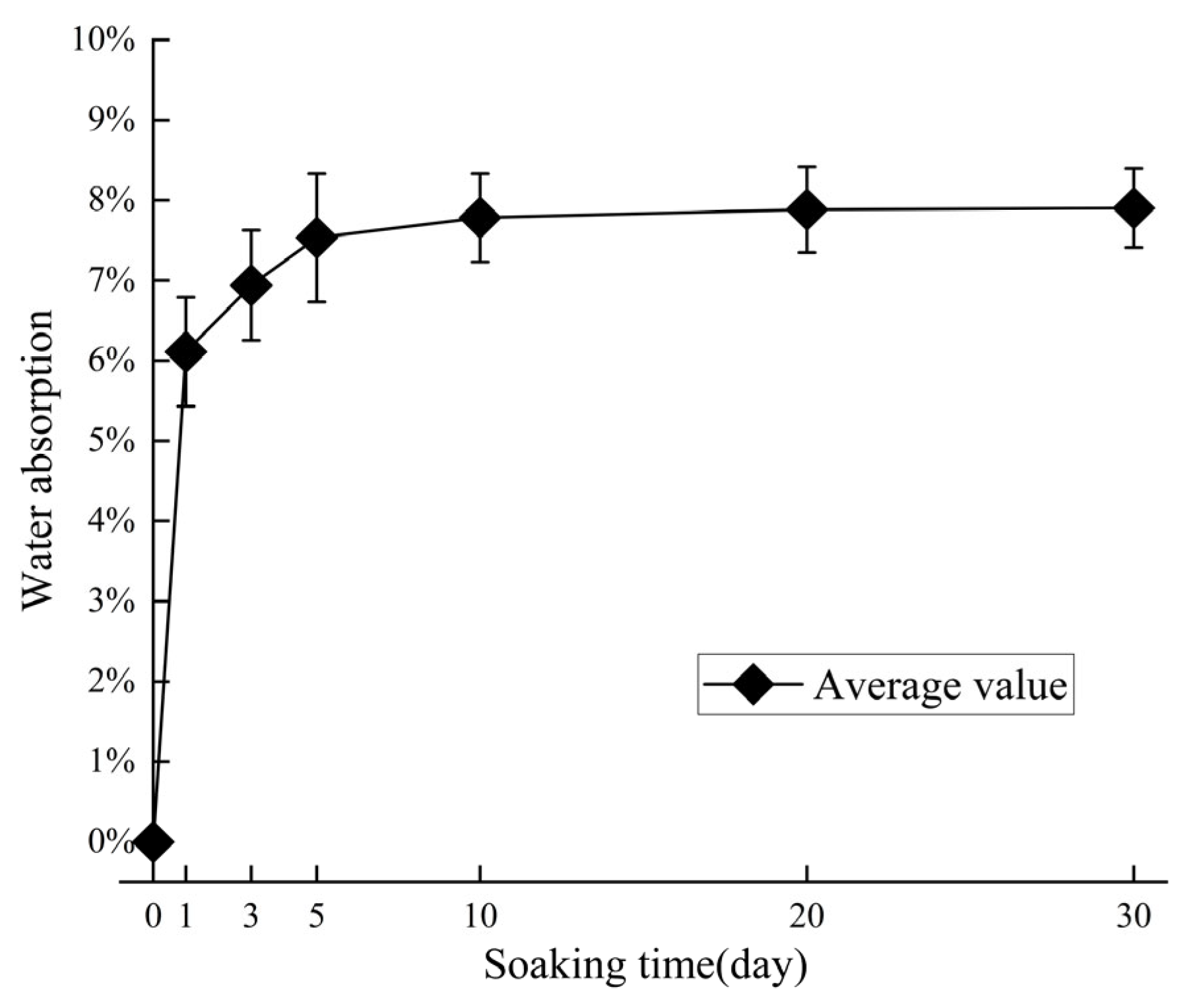

5.4. Water Absorption Rate of Coal Under Different Immersion Times

6. Discussion and Analysis

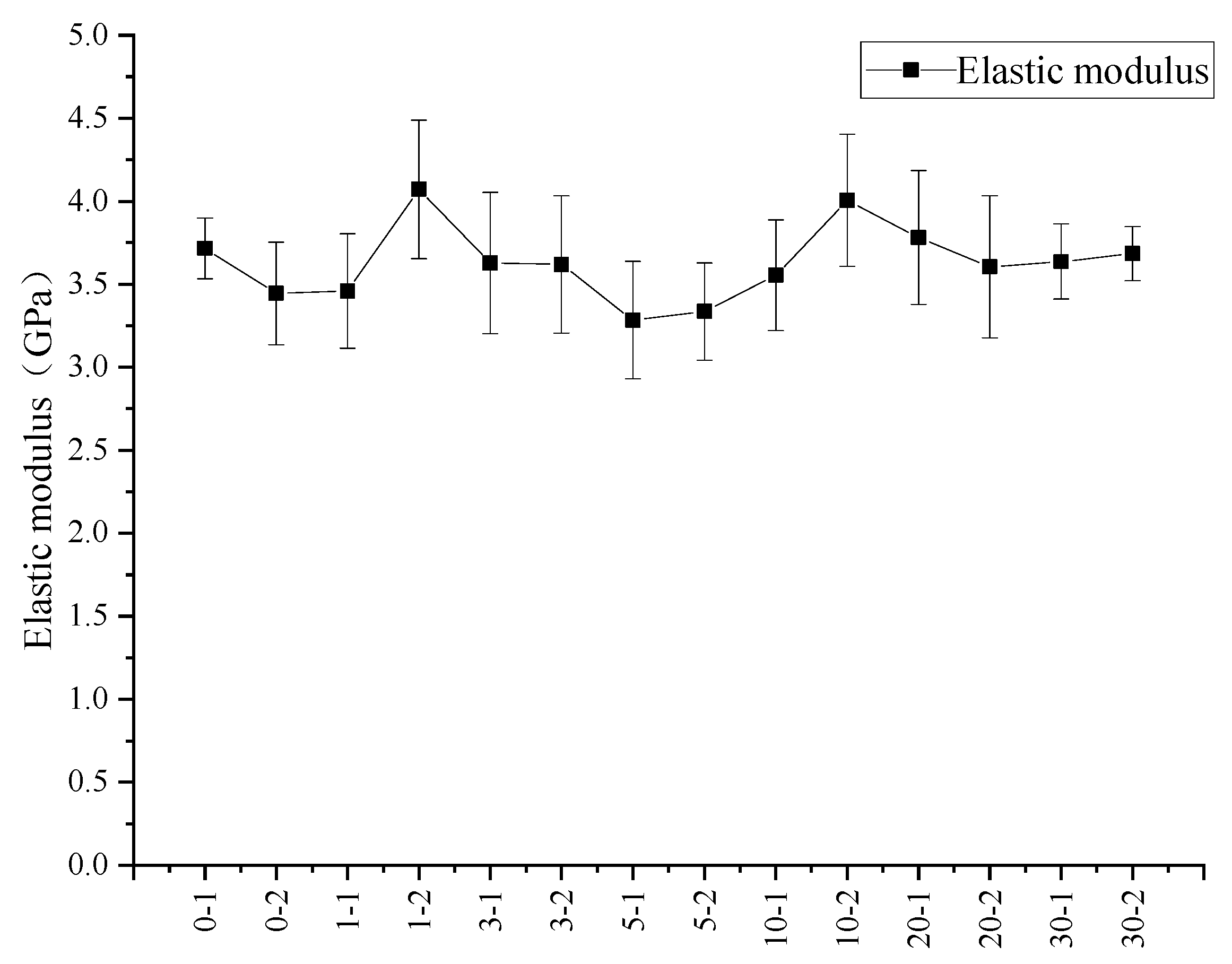

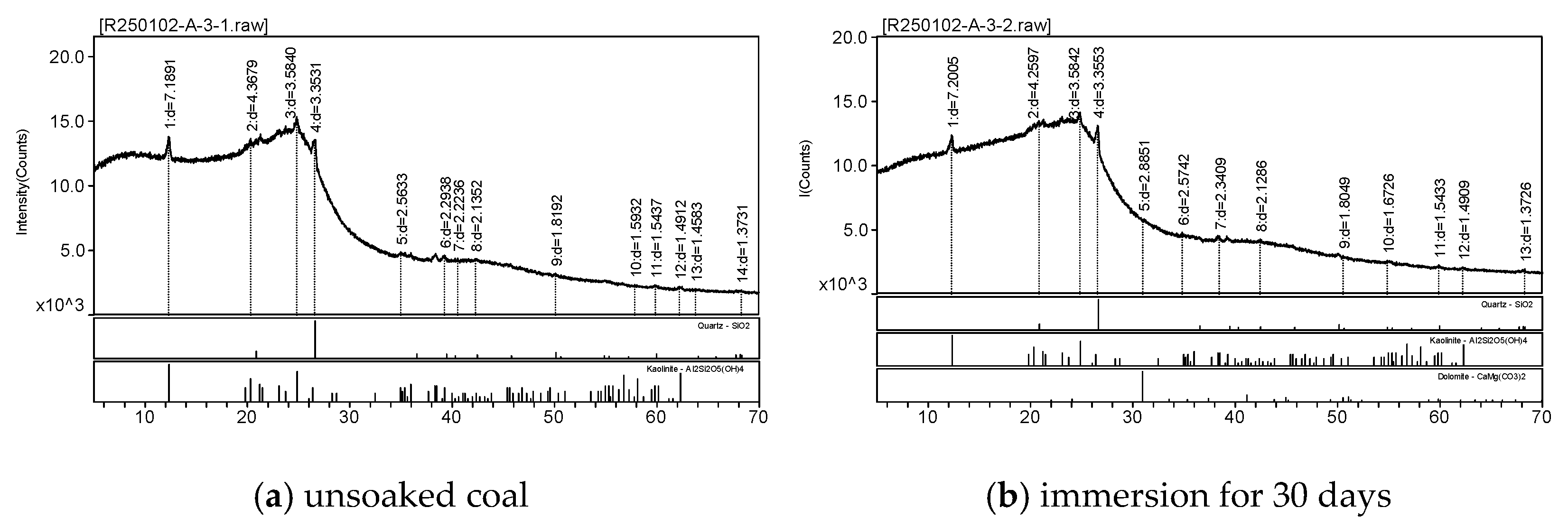

6.1. Elastic Modulus and Mineral Composition Changes in Coal Matrix

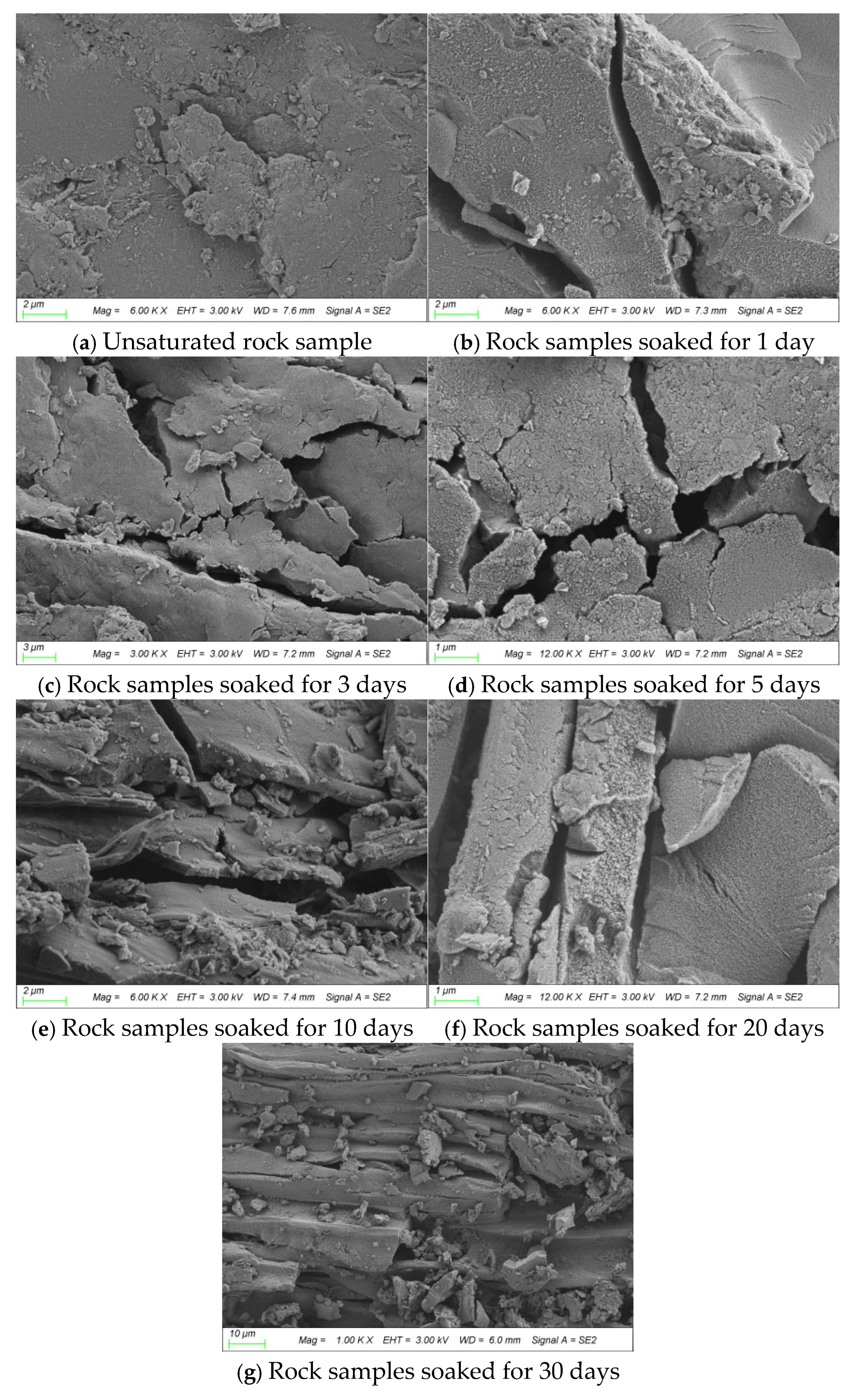

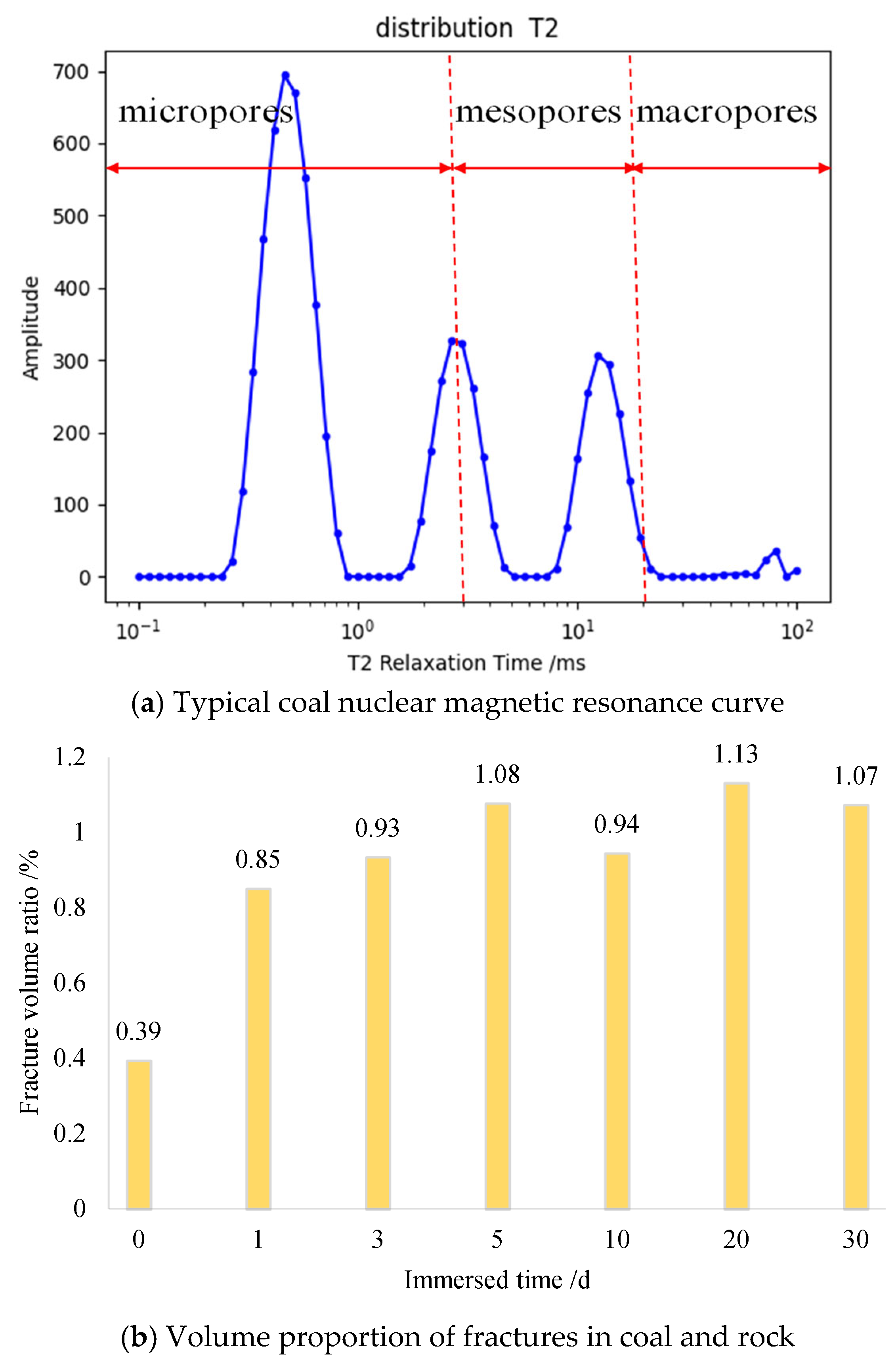

6.2. Development of Coal Fractures

6.3. Development Mechanism of Coal’s Fractures

6.4. Correlation Between Water Absorption Rate and Strength Parameters of Coal

7. Conclusions

- With increasing immersion time, the peak strength, elastic modulus, cohesion, and internal friction angle of coal rock all show a declining trend: Within the first 5 days, the uniaxial compressive strength decreased from 36.85 MPa to 22.0 MPa (−40%), the elastic modulus from 1.93 GPa to 1.07 GPa (−45%), cohesion from 14.5 MPa to 5.9 MPa (−59%), and internal friction angle from 24.9° to 19.8° (−21%). After this period, the parameters stabilized. Confining pressure has a protective effect on the mechanical properties of coal rock. Even after 30 days under 20 MPa confining pressure, the strength loss reached 43%, but the absolute value remained at 51.3 MPa. The relative decline in strength decreased with increasing confining pressure.

- The overall degradation of coal rock mechanical properties caused by high-temperature and high-pressure drilling fluid immersion is primarily due to two fracture-fluid interaction mechanisms: Hydraulic wedging-induced fracture propagation: High-pressure drilling fluid creates a pressure field within fractures, promoting their propagation. Under axial pressure, the fluid acts as a “hydraulic wedge,” further accelerating fracture expansion. NMR measurements showed an increase in fracture volume fraction from 0.39% to 1.08%. Fracture surface lubrication-induced reduction in internal friction angle: High-pressure drilling fluid infiltrates fractures, forming a “liquid film” that reduces the friction coefficient of fracture surfaces. This is reflected in the gradual decrease in internal friction angle with prolonged immersion time.

- Water absorption exhibits a negative linear correlation with strength (R2 ≥ 0.84), and confining pressure significantly amplifies the water-induced weakening effect: For every 1% increase in water absorption, strength decreases by 170.84 MPa under no confining pressure and by 808.25 MPa under 20 MPa confining pressure, representing a 4.7-fold increase in the slope. This quantitative relationship provides direct evidence for predicting wellbore stability in deep coalbed methane drilling.

- It should be noted that the current study employed static immersion to reveal the “limiting” weakening trend of long-term drilling-fluid–coal interaction. However, under actual field conditions, coal formations are subjected to dynamic loads such as drilling vibrations, cyclic tripping operations, and bottomhole pressure fluctuations. Future research should focus on cyclic loading–unloading experiments or simulated rotary drilling tests to compare the degradation rates under dynamic versus static conditions. This will help validate the applicability thresholds (e.g., the 5-day criterion) and quantitative relationships established in this study under realistic drilling disturbances, thereby providing a more comprehensive time-load coupled basis for predicting wellbore stability in deep coalbed methane (CBM) reservoirs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, Z.; Li, G.; Yang, R.; Li, G. Review and development trends of coalbed methane exploitation technology in China. J. China Coal Soc. 2022, 47, 3212–3238. [Google Scholar] [CrossRef]

- Gao, D.; Bi, Y.; Xian, B. Progress in high-efficiency well types and drilling/completion technologies for coalbed methane development in China. J. Nat. Gas Ind. 2022, 42, 1–18. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, L.; Li, X.; Dou, H.; Luo, P. Research progress of drilling fluid technology for CBM reservoir protection. J. Nat. Gas Ind. 2024, 44, 182–194. [Google Scholar] [CrossRef]

- Fan, X.; Meng, C.; Zhang, Q.; Ma, T.; Li, Z.; Wang, X.; Zhang, J.; Zhao, P.; Deng, J.; Zhou, G. Research progress in the evaluation theory and control technology of wellbore instability in ultra-deep strata. J. Nat. Gas Ind. 2024, 44, 159–176. [Google Scholar] [CrossRef]

- Zhu, B.; Wu, Q.; Yang, J.; Cui, T. Study of pore pressure change during mining and its application on water inrush prevention: A numerical simulation case in Zhaogezhuang coalmine, China. J. Environ. Earth Sci. 2014, 71, 2115–2132. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, X.; Yan, X.; Zhang, L.; Liu, Y. An analytic model of wellbore stability for coal drilling base on limit equilibrium method. J. China Coal Soc. 2016, 41, 909–916. [Google Scholar] [CrossRef]

- Shen, R.; Qu, P.; Yang, H. Research progress and development trends of coal-bed wellbore-stability technologies. J. Pet. Drill. Tech. 2010, 38, 1–7. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, D.; Zhang, H.; Liu, M.; Liu, F.; Wei, K. Study on the influence of drilling fluid filtration on stability of coalbed wellbore. J. Coal Mine Saf. 2021, 52, 78–84. [Google Scholar]

- Li, X.; Kang, Y. Effect of fracturing-fluid immersion on methane adsorption/desorption of coal. J. Nat. Gas Sci. Eng. 2016, 34, 449–457. [Google Scholar] [CrossRef]

- Srungavarapu, M.; Patidar, K.K.; Pathak, A.K.; Mandal, A. Performance studies of water-based drilling fluid for drilling through hydrate-bearing sediments. J. Appl. Clay Sci. 2018, 152, 211–220. [Google Scholar] [CrossRef]

- Zhou, A.; He, Y.; Wang, K.; Li, B.; Wang, Y.; Yang, Y. Hydraulic fracture propagation in soft coal composite reservoirs: Mechanical responses and energy dissipation mechanisms. Int. J. Min. Sci. Technol. 2025, 35, 573–588. [Google Scholar] [CrossRef]

- Liu, Z.; Sheng, K.; Yang, H.; Su, W.; Hu, P.; Dong, B. Numerical simulation study and application of coal-seepage evolution law around water-injection boreholes in the “dynamic–static” pressure zone of a stope. J. Meas. 2022, 195, 111107. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, H.; Tang, X.; Sun, H.; Zhang, B.; Chen, Z. Four-dimensional in-situ stress model of CBM reservoirs based on geology–engineering integration. J. Nat. Gas Ind. 2022, 42, 82–92. [Google Scholar] [CrossRef]

- Zheng, L.; Su, G.; Li, Z.; Peng, R.; Wang, L.; Wei, P.; Han, S. Wellbore-instability control mechanism of fuzzy-ball drilling fluids for coal-bed methane wells via bonding formation. J. Nat. Gas Sci. Eng. 2018, 56, 107–120. [Google Scholar] [CrossRef]

- Fang, Z.; Wang, R.; Yang, C. Opportunities and challenges in deep coalbed methane development. J. China Univ. Min. Technol. 2025, 54, 34–51. [Google Scholar] [CrossRef]

- Ouyang, Y.; Xie, W.; Ding, J.; Feng, F.; Wang, H.; Yang, D.; Ma, C.; Lyu, H. Study on the destabilization mechanism of coal rock with cleats due to drilling fluid. J. Reserv. Eval. Dev. 2025, 15, 284–291. [Google Scholar] [CrossRef]

- Hou, Z.; Wundram, L.; Meyer, R.; Schmidt, M.; Schmitz, S.; Were, P. Development of a long-term wellbore-sealing concept based on numerical simulations and in-situ testing in the Altmark natural-gas field. J. Environ. Earth Sci. 2012, 67, 395–409. [Google Scholar] [CrossRef]

- Qiao, B.; Liu, H.; Wang, S.; Yu, X.; Chen, L. Geological guidance difficulties and countermeasures for deep coal rock gas horizontal wells in Jingbian Gas Field. J. Coal Sci. Technol. 2025. Available online: https://link.cnki.net/urlid/11.2402.TD.20250605.1339.006 (accessed on 25 September 2025).

- Lyu, S.; Wang, S.; Chen, X.; Shah, S.; Li, R.; Xiao, Y.; Dong, Q.; Gu, Y. Experimental study of a degradable polymer drilling-fluid system for coal-bed methane wells. J. Pet. Sci. Eng. 2019, 178, 678–690. [Google Scholar] [CrossRef]

- Gentzis, T.; Deisman, N.; Chalaturnyk, R. A method to predict geomechanical properties and model well stability in horizontal boreholes. Int. J. Coal Geol. 2009, 78, 149–160. [Google Scholar] [CrossRef]

- Zhang, G.; He, S.; Tang, M.; Liu, S.; Deng, F. Effect of fluid invasion on the failure and deformation of deep coal and wellbore stability. In Proceedings of the American Rock Mechanics Association (ARMA-22-11), Santa Fe, NM, USA, 26–29 June 2022. [Google Scholar] [CrossRef]

- Yang, H.; Wang, W.; Tian, Z. Reservoir damage mechanism and protection measures for coal bed methane. J. China Coal Soc. 2014, 39, 158–163. [Google Scholar] [CrossRef]

- Xian, B.; Zhang, L.; Tursun, H.; Yu, P.; Wang, K.; Zhang, Y.; Zhang, Y.; Wang, S.; Li, Z. Damage mechanism of CBM reservoirs and double-layered screen pipes in the horizontal well completion. J. Coal Geol. Explor. 2022, 50, 122–129. [Google Scholar] [CrossRef]

- Shi, Y.; Chen, S.; Yang, X.; Yu, L.; Cai, J. Enhancing wellbore stability of coal-measure strata by electrical inhibition and wettability control. J. Pet. Sci. Eng. 2019, 174, 544–552. [Google Scholar] [CrossRef]

- Zhang, D.; Feng, Y.; Li, Y.; Ren, X.; Kang, H.; Wu, L. Numerical Simulation of Wellbore Stability for CBM Horizontal Well by Finite Element Software. J.Coal Mine Saf. 2018, 49, 144–147. [Google Scholar] [CrossRef]

- Yan, X.; Xiong, X.; Xu, F.; Yu, Y.; Li, S.; Wang, F.; Liu, J.; Feng, Y.; Tang, Z.; Wei, Z. Deep coal geomechanical influence mechanism and its control factors of Daji Block in Ordos Basin. J. China Coal Soc. 2025, 50, 2550–2566. [Google Scholar] [CrossRef]

- Sun, Z.; Liu, X.; Liang, L.; Xiong, J. Analysis on impact factors of borehole wall stability of coalbed methane well. J.Coal Sci. Technol. 2018, 46, 117–122. [Google Scholar] [CrossRef]

- GB/T 40961-2021; Verification Method for Rock Triaxial Testing Apparatus. Standard Press of China: Beijing, China, 2021.

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

| Anti-Collapse Polymeric Plugging Agent | Low-Viscosity Anionic Carboxymethyl Cellulose | Anti-Collapse Fluid-Loss Reducer | Encapsulating Polymer | Anti-Collapse Gilsonite |

|---|---|---|---|---|

| 0.1% | 1.0% | 1.0% | 1.0% | 3.0% |

| Confining Stress/MPa | Immersion Time/day |

|---|---|

| 0 | 0, 1, 3, 5, 10, 20, 30 |

| 5 | |

| 10 | |

| 20 |

| Sample Number | Mineral Mass Fraction (%) | ||||||

|---|---|---|---|---|---|---|---|

| Amorphous | Quartz | Kaolinite | Montmorillonite | Plagioclase | Siderite | Dolomitic | |

| Not soaked-1 | 88.5 | 3.8 | 7.8 | / | / | / | / |

| Not soaked-2 | 91.5 | 2.9 | 5.3 | / | / | / | 0.3 |

| Soak for 1 day-1 | 86.2 | 6.7 | 7.1 | / | / | / | / |

| Soak for 1 day-2 | 88.5 | 4.4 | 6.4 | / | 0.7 | / | / |

| Soak for 3 days-1 | 88.5 | 2.3 | 8.5 | / | / | 0.7 | / |

| Soak for 3 days-2 | 87.6 | 5.0 | 6.8 | 0.7 | / | / | / |

| Soak for 5 days-1 | 93.2 | 1.9 | 5.0 | / | / | / | / |

| Soak for 5 days-2 | 93.1 | 1.9 | 4.9 | / | / | / | / |

| Soak for 10 days-1 | 87.2 | 4.7 | 8.2 | / | / | / | / |

| Soak for 10 days-2 | 91.2 | 1.4 | 7.4 | / | / | / | / |

| Soak for 20 days-1 | 89.7 | 2.7 | 7.6 | / | / | / | / |

| Soak for 20 days-2 | 90.0 | 4.3 | 5.8 | / | / | / | / |

| Soak for 30 days-1 | 88.7 | 3.4 | 6.9 | / | / | 1.0 | / |

| Soak for 30 days-2 | 90.4 | 2.7 | 6.3 | / | / | 0.6 | / |

| Confining Pressure | Linear Fitting Relationship (x = Water Absorption, y = Strength) | R2 |

|---|---|---|

| 0 | y = −170.84x + 25.19 | 0.3783 |

| 5 | y = −324.74x + 57.8 | 0.4315 |

| 10 | y = −433.66x + 73.42 | 0.3596 |

| 20 | y = −808.25x + 117.52 | 0.836 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miao, Q.; Liu, H.; Wang, Y.; Wang, W.; Li, S.; Zhai, W.; Wei, K. Quantitative Mechanisms of Long-Term Drilling-Fluid–Coal Interaction and Strength Deterioration in Deep CBM Formations. Processes 2025, 13, 3183. https://doi.org/10.3390/pr13103183

Miao Q, Liu H, Wang Y, Wang W, Li S, Zhai W, Wei K. Quantitative Mechanisms of Long-Term Drilling-Fluid–Coal Interaction and Strength Deterioration in Deep CBM Formations. Processes. 2025; 13(10):3183. https://doi.org/10.3390/pr13103183

Chicago/Turabian StyleMiao, Qiang, Hongtao Liu, Yubin Wang, Wei Wang, Shichao Li, Wenbao Zhai, and Kai Wei. 2025. "Quantitative Mechanisms of Long-Term Drilling-Fluid–Coal Interaction and Strength Deterioration in Deep CBM Formations" Processes 13, no. 10: 3183. https://doi.org/10.3390/pr13103183

APA StyleMiao, Q., Liu, H., Wang, Y., Wang, W., Li, S., Zhai, W., & Wei, K. (2025). Quantitative Mechanisms of Long-Term Drilling-Fluid–Coal Interaction and Strength Deterioration in Deep CBM Formations. Processes, 13(10), 3183. https://doi.org/10.3390/pr13103183