Abstract

Deep coalbed methane reservoirs must utilize hydraulic fracturing technology to create high-conductivity sand-filled fractures for economical development. However, the mechanism by which proppant embedment affects fracture width in coal rock is not yet clear. In this article, using the discrete element particle flow method, we have developed a numerical simulation model that can replicate the dynamic process of proppant embedment into the fracture surface. By tracking particle positions, we have accurately characterized the dynamic changes in fracture width and proppant embedment depth. The consistency between experimental measurements of average fracture width and numerical results demonstrates the reliability of our numerical model. Using this model, we analyzed the mechanisms by which different proppant particle sizes, number of layers, and closure stresses affect fracture width. The force among particles under different proppant embedment conditions and the induced stress field around the fracture were also studied. Numerical simulation results show that stress concentration formed by proppant embedment in the fracture surface leads to the generation of numerous induced micro-fractures. As the proppant grain size and closure stress increase, the stress concentration formed by proppant embedment in the fracture surface intensifies, and the variability in fracture width along the fracture length direction also increases. With more layers of proppant placement, the particles counteract some of the closure stress, thereby reducing the degree of proppant embedment around the fracture surface.

1. Introduction

In the global energy transition, coalbed methane, a low-carbon and clean energy source, has significant potential to reduce greenhouse gas emissions and is therefore regarded as one of the key transitional energy sources for achieving the Sustainable Development Goals [1,2]. Coalbed methane is typically found within the fractures of coal seams, with deposits buried at depths exceeding one thousand to several thousand meters referred to as “deep coalbed methane” [3]. The development of deep coalbed methane is significant for increasing natural gas supplies and optimizing the energy structure [4], yet it also faces technical challenges and economic risks [5,6]. As technology advances and experience accumulates, the exploitation of deep coalbed methane will gradually achieve scalability and economic viability [7,8].

Hydraulic fracturing technology plays a key role in the development of deep coalbed methane [9,10,11]. It significantly enhances the production capacity of coalbed gas wells and extends the stable production period, thus becoming one of the main technologies currently used in coalbed methane development [12]. The width of the fractures created by fracturing is crucial for long-term stable production. A 20% reduction in fracture width could lead to a 50% to 60% decrease in production capacity [13]. Therefore, appropriately increasing the fracture width can effectively enhance the conductivity of coalbed methane, thereby ensuring that the production capacity of gas wells continues to meet development demands [14]. However, as the burial depth increases, the closure stress of the coal rock reservoir gradually intensifies [15].

Due to the relatively soft nature of coal rock reservoirs, the embedding of proppants under high closure stress significantly impacts the effective support fracture width [16,17]. Li studied how proppant arrangements affect fracture conductivity in coal reservoirs. They highlighted that coalbed rock has a low elastic modulus and a high Poisson’s ratio. During fracturing and flowback, proppant embedding causes contact deformation between proppants and fracture surfaces, impacting conductivity [18]. In coal seams, Li analyzed proppant embedding mechanisms in fractures and their effect on conductivity. They identified various coal fracture surface damages and energy release mechanisms, suggesting proppant embedding reduces fracture opening and affects conductivity [19]. However, these regularities are mainly summarized from experimental studies, and it is difficult to analyze the causes of this phenomenon from a mechanistic perspective.

Numerous experimental studies have demonstrated that factors such as closure stress, reservoir rock hardness, proppant hardness, and type significantly affect proppant embedment [20]. Sheng noted that higher closure pressure correlates with increased embedment depth of proppants within shale plates, which concurrently induces local stress concentration and narrows unsupported fracture channels, thereby diminishing fracture conductivity [21]. Lacy contends that the hardness of the formation is a more significant factor influencing proppant embedment. In soft, wet sandstone, when the proppant concentration is two pounds per foot, it can lead to a reduction in fracture width by 60% or more [13]. Ahamed argues that coal reservoirs exhibit a greater susceptibility to proppant embedment issues due to their comparatively softer rock surfaces relative to surrounding reservoir rocks. They identify key factors impacting the performance of proppants in coal reservoirs as including proppant concentration, size, fracturing fluid type, and selection of the appropriate proppant type [22]. Mittal simulated long-term permeability characteristics of proppant-filled layers under oil reservoir conditions in the laboratory, finding that normalized compaction in shale plates was 5% greater than in metal plates due to effects from embedded proppants [23]. Bandara conducted an experimental investigation under multi-cycle loading conditions to elucidate the crushing and embedding mechanisms associated with various types of proppants during fracturing processes, analyzing how different sizes and concentrations influence these phenomena under similar loading conditions [24]. Although previous experimental investigations have provided intuitive or indirect insights into the adverse impacts of proppant embedding on permeability within filled layers, conducting experiments specifically focused on measuring fracture permeability related to this phenomenon may require several hours or longer, making multiple tests time-consuming and costly.

Theoretical simulation calculations can quantitatively assess the influence of proppant embedding depth on fracture width to a certain extent. Volk investigated the factors affecting proppant embedment depth and proposed an empirical equation for non-crushed proppants embedded in sandstone and shale based on their analysis [25]. Mueller proposed a modeling method for proppant embedment based on the size distribution and density of various proppants, utilizing surface-formed indentation hardness to calculate the degree of embedding [26]. Li developed a rhombohedral model to calculate the flow capacity of sand-containing fractures by integrating the principles of elastoplastic ball contact, capillary bundle model, and Karman Kozeny equation. Their model factors in parameters such as rock and proppant deformation, particle size, proppant layers, and closure pressure, allowing for the calculation of width and permeability changes in sand-containing fractures during compression [27]. Chen proposed a model of proppant embedding as a function of effective stress by combining the Hertz contact model with a power-law model, similar to the Oliver–Pharr model. This approach enables flexible simulation of different curvature shapes or trends of the embedding curve by adjusting the power exponent λ [28]. Shi used the Hertz contact model to calculate the width of supporting fractures and studied the size effect of proppants, focusing on proppant deformation and embedding. They identified the particle size of proppants as the most sensitive influencing factor, followed by proppant concentration, proppant pumping rate, proppant elastic modulus, and proppant pumping method. They noted that compared to other factors, the influence of formation elastic modulus and Poisson’s ratio can be disregarded [29]. After reviewing a series of previous studies, it was found that both individual experiments and theoretical simulations are insufficient for directly observing the dynamic embedment process of proppants within hydraulic fractures. This limits our ability to unveil the underlying micro-mechanisms of proppant embedment. Therefore, it is necessary to combine numerical simulation methods with experimental approaches for a comprehensive investigation.

Currently, while numerical simulation studies on proppant embedment are ongoing, there are certain limitations in these studies regarding the mechanisms by which proppant embedment affects fracture width. Fan combined three-dimensional continuum–discrete mechanics with the lattice Boltzmann (LB) method to systematically simulate the effects of fracture axial and confining stresses, number of proppant layers, proppant size, spatial distribution of proppants, and proppant breakage [30]. Zheng established a three-dimensional discrete element model for proppant breakage and its impact on fracture conductivity. Although they discussed various factors affecting conductivity, they did not thoroughly analyze the influence of proppant embedment on fracture width [14]. Liu utilized computational fluid dynamics (CFD) in conjunction with COMSOL Multiphysics to calculate the variations in permeability, concluding that both permeability and porosity decrease with increased proppant embedment, with the most significant reduction (nearly half) occurring within the first 20% of embedment [31]. Deng used the three-dimensional discrete element method (3D DEM) to simulate the interaction between shale and proppants in hydraulic fracturing and to assess the average fracture width under different proppant sizes, Young’s modulus, and pressure levels. However, their analysis did not include a statistical examination of changes before and after fracture surface closure and the key control mechanisms that contributed to these changes [32]. Meanwhile, Bolintineanu utilized the discrete element method (DEM) for simplified simulations, focusing solely on the generation of static proppant filling structures to analyze proppant filling height and evaluate the proppant diversion effect based on the final fracture width, without considering the interaction process between the proppant and the fracture surface [33]. Zhang employed a combination of elastic–plastic theory and the material point method to develop a numerical model for the embedding of proppants in a coalbed reservoir. This approach addressed the issue in experiments where neglecting coal particle detachment led to underestimation of proppant embedding depth [34]. Lu established a numerical model to simulate the elastic–plastic deformation of proppants embedded into rough fracture surfaces. They analyzed the embedding process of proppants in coarse fractures under closing stresses and identified factors affecting the width of the propped fracture [35]. Ahamed proposed a simplified material model based on the Drucker–Prager failure criterion to describe proppant embedding behavior in hydraulic fracturing. They suggested that modifying the elastic modulus to account for surface changes due to pore fluid saturation may provide an underestimation for proppant embedment measurements in coal [36]. However, their work did not quantitatively evaluate the impact of proppant embedding on the propped fracture width. Presently, there is limited numerical simulation research focused on the quantitative evaluation of proppant embedment behavior. Most studies primarily discuss the factors affecting embedment in relation to fracture conductivity. While some researchers have examined how the average fracture width varies with different parameters after closure, they have not systematically analyzed the dynamic changes in fracture width before and after closure to explore the underlying mechanisms of embedment influence.

In response to the aforementioned challenges, this study implements the discrete element flow method to construct a numerical simulation model for proppant embedding in coal seam reservoirs. The model simulates the dynamic process of proppant embedding in fracture surfaces during closure, calibrated with laboratory experiments. Subsequently, the study develops key methodologies for characterizing fracture width and proppant embedding depth. Lastly, the influence of factors such as proppant size, number of placement layers, and closure stress on fracture width is investigated. The research aims to identify optimal proppant parameters, offering theoretical support to optimize hydraulic fracturing operations in coal seam reservoirs.

2. Establishment and Validation of the Model

2.1. Principles of Discrete Element Particle Flow Code

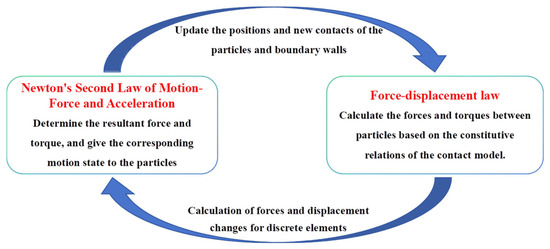

The Discrete Element Particle Flow Code (PFC) operates by discretizing rock–soil into disk particles or spherical particles. Particle movement is governed by their interactions through contact with one another and is not entirely unconstrained. The principles governing particle motion are depicted in Figure 1, wherein the constitutive relationship based on the contact model uses the force–displacement law to calculate contact forces and displacement changes between particles. Subsequently, Newton’s second law of motion is used to update particle positions and identify contact points and stacking distances. These processes are iteratively refined until system equilibrium is achieved or failure occurs in the rock–soil, as illustrated in Figure 1.

Figure 1.

Principles of particle motion.

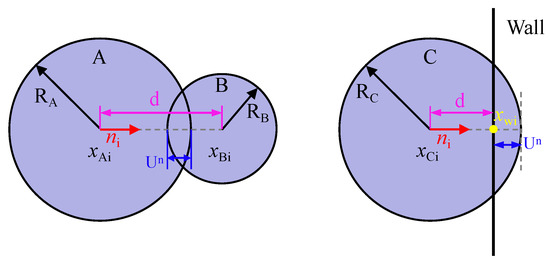

First, the discrete element particle flow simulation adheres to the force–displacement law. Based on the constitutive relations of the contact model, the forces and torques between particles are calculated according to the force–displacement law. As shown in Figure 2, in a two-dimensional model, the contact point of the particle element is located in the ‘overlap’ region of the two solid elements. When particles come into contact, the normal direction of the contact plane aligns with the line connecting their centers. When a particle contacts a wall, this normal direction is defined as the direction of the shortest distance from the particle’s center to the wall.

Figure 2.

Schematic representation of various contact types in the discrete element particle flow method (Caption: A, B, and C respectively represent three arbitrary distinct particles).

The unit normal vector ni of the contact plane between two particles, as well as the ni of the contact plane between a particle and a wall, can be calculated using the following formula:

In Equation (1), xAi, xBi, and xCi represent the positions of the centers of particles A, B, and C, respectively. xWi represents the intersection point of the unit normal vector ni with the wall. d represents the distance between the centers of particles or the distance from a particle center to the wall. The formula for calculating this distance d is as follows:

The equation for determining the position xδi of the contact point across various contact modes is presented as follows:

In Equation (3), RA represents the radius of particle A, RB represents the radius of particle B, and RC represents the radius of particle C. Additionally, Un represents the extent of overlap between particles or between particles and the wall.

The contact force vector Fi acting between two interacting bodies can be resolved into a normal component and a tangential component:

The formula for calculating the normal component, Fin, is as follows:

In Equation (5), Kn represents the normal stiffness at the contact point.

Second, the discrete element particle flow simulation follows the laws of motion. Based on the resultant force and torque acting on the particles, combined with Newton’s Second Law of Motion, the motion state of the particles can be determined. This manifests in two forms: translation and rotation. The basic equations of motion are as follows:

Equation (6) delineates the translational equation, represents acceleration. m represents the mass of the particle unit. gi represents the vector of volumetric force acceleration, such as gravitational load. Equation (7) articulates the rotational equation. represents angular acceleration. Mi represents the resultant moment acting on the particles. I indicates the principal moment of inertia.

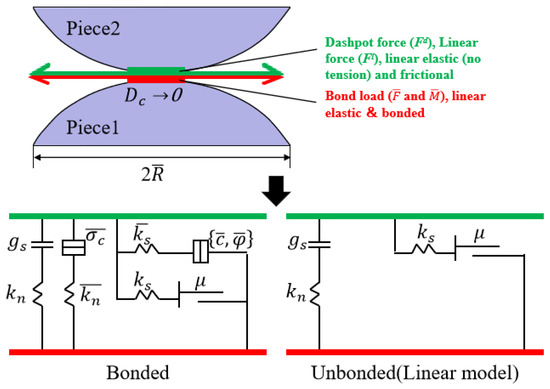

Finally, there are various contact models in the discrete element method for particles, and this study primarily focuses on the linear parallel bond model (Figure 3). The linear parallel bond model includes both parallel bonding and linear contact. The linear contact only acts under compression, with a mechanism similar to the linear model. The mechanical model of the parallel bond model can be described as follows:

Figure 3.

Linear parallel bonding model.

The mathematical expressions for the contact force and moment within the linear parallel bonding model are as follows:

In Equation (8), represents the linear force; represents the damping force; and represents the parallel bonding force. In Equation (9), represents the parallel bonding moment. The formulae for calculating both the parallel bonding force and moment are presented as follows:

In Equation (10), represents the normal parallel bonding force; represents the tangential parallel bonding force; and represents the normal component of the unit direction vector. In Equation (11), represents the rotational torque, which is consistently equal to zero in the two-dimensional model presented in this article, and represents the bending moment.

A parallel bond is capable of simultaneously transmitting both forces and torques. If the maximum normal or shear force on the parallel bond exceeds its normal or shear strength, the failure of the bond will occur.

2.2. Establishment of Proppant Embedding Model

This study employs PFC2D software (version 6.0), which utilizes a two-dimensional simulation. Two-dimensional modeling offers key advantages over three-dimensional modeling, including faster computation due to fewer degrees of freedom and easier result analysis and visualization. Therefore, two-dimensional simulations are often preferred. However, it acknowledges inherent limitations in representing three-dimensional phenomena. Despite this, the manual encourages using simplified two-dimensional models throughout the modeling process to validate hypotheses and algorithms whenever possible [37].

Research by David et al. [38] also shows that in the stress–strain relationship, both two-dimensional (2D) and three-dimensional (3D) systems exhibit linear elastic behavior during the initial small deformation stage, with scaled deviatoric stress values being highly consistent. As deformation increases, the stress reaches a peak and then gradually decreases to a critical flow state. In this process, stress decreases more rapidly in 2D and more gently in 3D. Additionally, the peak isotropic stress is higher in 2D than in 3D, while the peak deviatoric stress is lower in 2D than in 3D. At the critical state, the isotropic stress levels are similar in both 2D and 3D, but the critical deviatoric stress value is slightly higher in 3D.

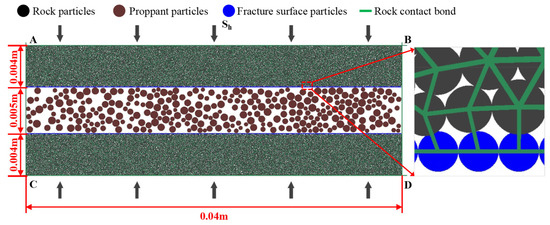

A script was written based on the particle flow code (PFC 2D) to meet the requirements of the numerical simulation. Within the numerical rock sample model, after the calibration of micro-parameters, a hydraulic fracture with specific dimensions (0.04 m in length and 0.005 m in width) was preset. Numerical proppants were then arranged inside the hydraulic fracture at a specific packing density, as depicted in Figure 4. In the Figure 4, black disks represent rock particles, brown disks represent proppant particles, blue disks signify fracture surface particles, and green lines illustrate the connections between rock particles. The surface particles of the fractures and the rock particles are classified into different groups so as to track and monitor the relative position changes in the surface particles of the fractures during the fracture closure process. A servo mechanism is used to apply the minimum horizontal principal stress to the numerical rock sample model. Subsequently, the embedding process of numerical proppants within hydraulic fractures is simulated and studied under different conditions. In conjunction with laboratory physical experiments, the accuracy of the numerical model was calibrated, systematically and comprehensively revealing the influence of proppant parameters and geostress parameters on the proppant embedment mechanism [39].

Figure 4.

Proppant embedding numerical simulation model (Caption: A, B, C, D respectively represent the four vertices of the model. The arrow represents the minimum horizontal principal stress).

2.3. Calibration of Parameters for Numerical Rock Samples

A core sample was taken from Well A at a depth of 2260 m in the Yichuan–Huanglong coal reservoir. The core was processed into standard samples with a height of 50 mm and a diameter of 25 mm. Using a triaxial rock mechanics servo testing system, a uniaxial compression test was conducted under a confining pressure of 0 MPa. The mechanical parameters, including elastic modulus, Poisson’s ratio, and compressive strength, were measured, as shown in Table 1.

Table 1.

The main microscopic parameters of the model.

To ensure consistency between the numerical simulation and actual physical phenomena, we conducted a uniaxial compression numerical simulation to select appropriate micro-parameters for the numerical rock sample model. Using the uniaxial compression test as an example, a script was developed in the particle flow software (PFC) to generate a rectangular wall with a height of 50 mm (the height of the core) and a width of 25 mm (the core diameter). Inside the wall, circular particles of specific sizes and quantities were arranged in a certain pattern. The linear parallel bond model was used to bond the particles together, and internal unbalanced forces were eliminated. Stress was then applied to the upper and lower walls (green lines) to replicate the uniaxial compression rock mechanics experiment. During the application of stress, the internal contact bonds in the numerical rock sample break, generating a fracture (represented by red short lines). A script was used to monitor the stress–strain curve and calculate macroscopic mechanical parameters such as Young’s modulus, Poisson’s ratio, and compressive strength.

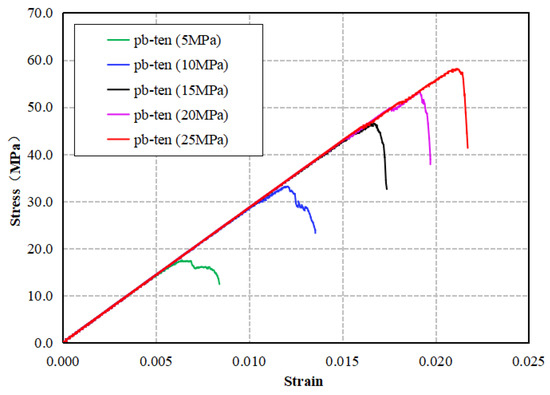

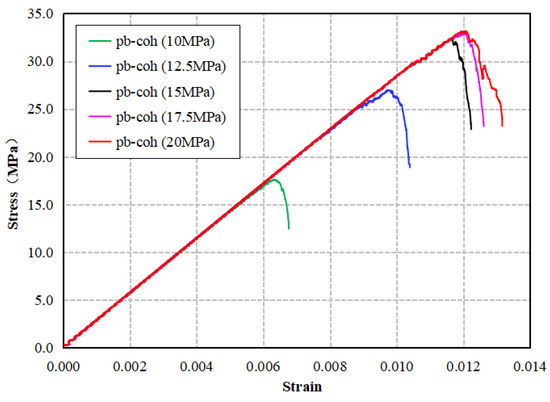

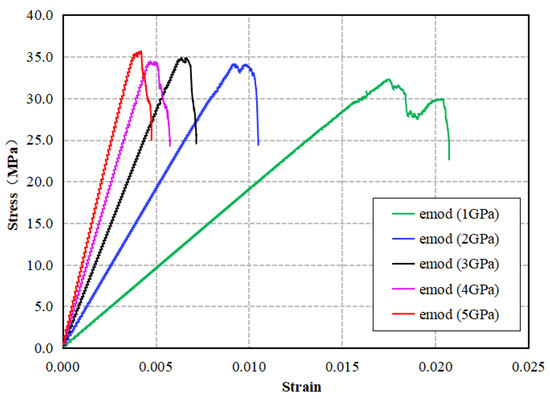

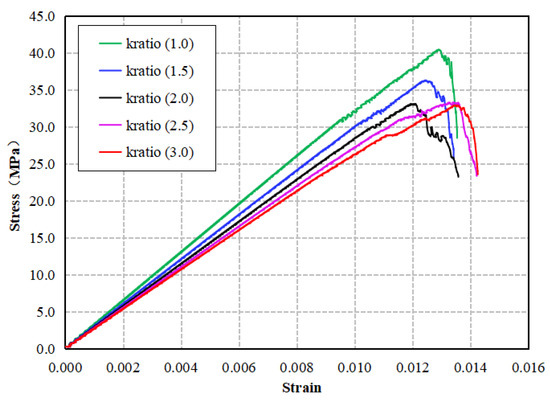

Before conducting parameter calibration, it is first necessary to discuss the influence of the main mesoscopic parameters in the model on mechanical parameters such as the compressive strength, Young’s modulus, and Poisson’s ratio of the numerical core. Based on the established numerical core model, with other parameters fixed, adjust the values of main mesoscopic parameters (including tensile strength of contact bonding pb-ten, cohesive force of contact bonding pb-coh, stiffness ratio kratio, and Effective Modulus emod), respectively, to explore the sensitivity of the mesoscopic parameters. The main microscopic parameters of the model are shown in Table 1, and the results are presented in Figure 5, Figure 6, Figure 7 and Figure 8, respectively.

Figure 5.

Pb-ten sensitivity analysis.

Figure 6.

Pb-coh sensitivity analysis.

Figure 7.

Emod sensitivity analysis.

Figure 8.

Kratio sensitivity analysis.

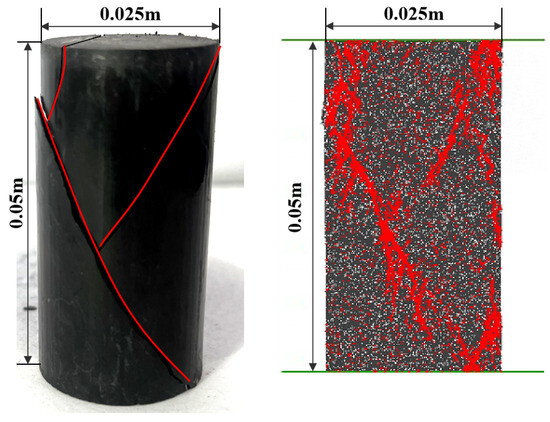

When using experimentally measured mechanical parameters such as compressive strength, Young’s modulus, and Poisson’s ratio as fitting parameters to calibrate the mesoscopic parameters of numerical cores, the results that fully match the experimentally measured rock mechanical parameters are not necessarily unique. Therefore, it is necessary to compare the internal crack morphology generated during uniaxial compression of numerical cores with that of actual cores to determine the uniqueness of the fitting parameters. The fracture patterns from the uniaxial compression experiments in the laboratory and the numerical simulation were then compared and analyzed, as shown in Figure 9. The rock sample predominantly exhibited diagonal fractures, with the red line segments in the figure delineating the regions where fracture and failure occur within the rock model. The fracture patterns observed in the numerical rock sample align closely with those induced by uniaxial compression during laboratory experiments. Table 2 presents the final calibration results of the numerical rock sample, encompassing both macroscopic and microscopic parameters. Notably, among the simulated elastic modulus, Poisson’s ratio, and compressive strength, the macroscopic parameters derived from simulations are within 5% of experimental findings, suggesting that this numerical rock sample model can accurately represent a real reservoir rock sample. Future investigations will utilize these microscopic parameters as a benchmark to establish a particle-embedding numerical simulation model aimed at exploring how particle embedding influences fracture width within targeted blocks.

Figure 9.

Numerical rock sample mechanics experiment and simulation.

Table 2.

Calibration results of macroscopic and microscopic parameters of numerical rock sample model.

2.4. Model Scale Effect

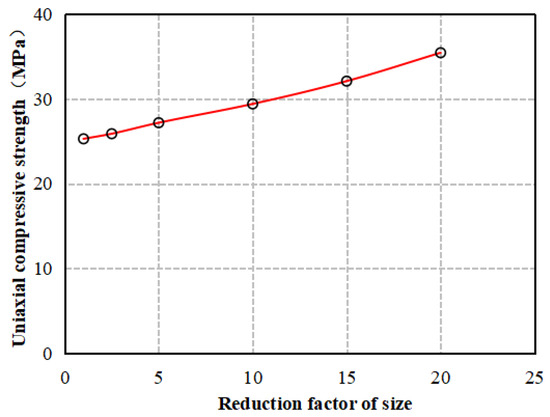

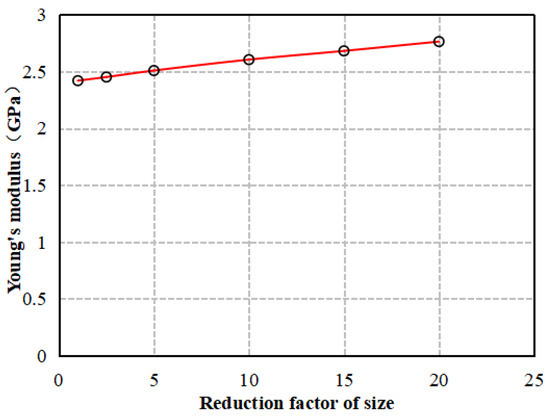

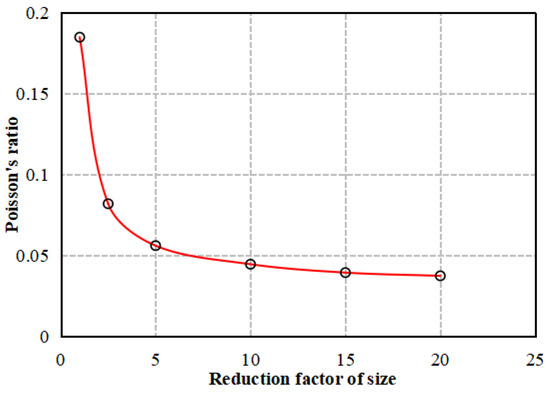

In the particle discrete element numerical simulation method, the size of the sample model has a certain impact on the test results. The base model size is 0.05 × 0.1 m, and the particle size ranges from 0.0000332 to 0.00002. Based on the model with completed parameter calibration, the sample was scaled down by 2.5 times, 5 times, 10 times, 15 times, and 20 times, respectively, and the particles were also scaled down by the same respective factors to investigate the influence of size effect on the mechanical parameters of the model. The results are shown in Figure 10, Figure 11 and Figure 12.

Figure 10.

Variation law of uniaxial compressive strength.

Figure 11.

Variation law of Young’s modulus.

Figure 12.

Variation law of Poisson’s ratio.

The results show that when the size was scaled down by 2.5 times, the compressive strength of the model was 25.90 MPa, Young’s modulus was 2.45 GPa, and Poisson’s ratio was 0.082. When scaled down by 5 times, the compressive strength was 27.20 MPa, Young’s modulus was 2.51 GPa, and Poisson’s ratio was 0.056. When scaled down by 10 times, the compressive strength was 29.42 MPa, Young’s modulus was 2.61 GPa, and Poisson’s ratio was 0.045. When scaled down by 15 times, the compressive strength was 32.11 MPa, Young’s modulus was 2.68 GPa, and Poisson’s ratio was 0.039. When scaled down by 20 times, the compressive strength was 35.46 MPa, Young’s modulus was 2.76 GPa, and Poisson’s ratio was 0.037. As the scaling-down factor increased, the compressive strength and Young’s modulus increased to a certain extent, while Poisson’s ratio decreased to a certain extent. Based on the scale effect analysis, the particle size used in calibration should also be used in subsequent model establishment.

2.5. Verification of Proppant Embedded Particle Flow Model

A total of 220 proppant particles (20–40 mesh) were placed in a 0.04 mm long fracture, achieving a proppant concentration of approximately 3 kg/m2. Using a script to create a FISH function, the placement of the proppants and the changes in fracture width during the closure process were monitored under closure stresses of 15 MPa, 20 MPa, 25 MPa, 30 MPa, and 35 MPa, respectively. The conditions were simulated for both steel and rock plates, and the average fracture width under different conditions was calculated.

To validate the accuracy of the model, this study used a displacement sensor in a conductivity experimental device to measure the width of fractures at different closure pressures in experiments involving 20–40 mesh ceramsite. Full-diameter coal core samples were taken from Well X at a depth of 2260 m, and 10 rock slabs were machined with dimensions of 177 mm in length, 37 mm in width, and rounded ends with a diameter of 37 mm. Proppant embedment was verified by placing 20–40 mesh coated ceramite with a sand laying strength of 3 kg/m2 and a steel plate or rock slab into the API conductivity experimental device and applying a closing stress of 15–35 MPa.

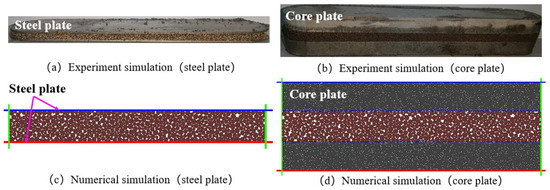

As shown in Figure 13, panels (a) and (b) illustrate the tests for proppant embedment in rock and steel plates, while panels (c) and (d) depict the simulation of proppant embedment in steel and rock plates.

Figure 13.

Proppant embedding experiment and simulation.

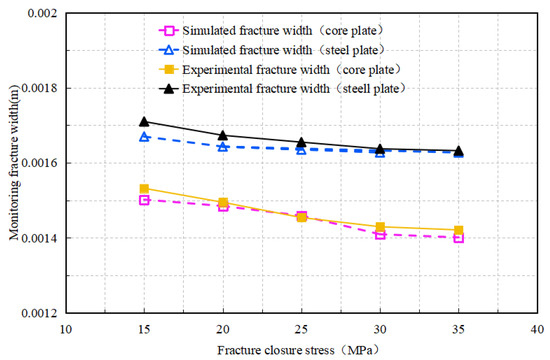

Figure 14 depicts the curves of average fracture width obtained from laboratory experiments, alongside the simulated average fracture width as a function of closure pressure. The data in the figure indicate a close alignment between the experimental results and those from the numerical simulations, with an error margin of less than 5%. The average difference between the steel plate experiments and the simulated fracture width is approximately 0.00006 m, while the average difference between the rock plate experiments and the simulated fracture width is approximately 0.00005 m. This consistency serves to validate the correctness of the model. Building on this validation, subsequent research will use this model for numerical simulations concerning proppant embedding.

Figure 14.

Model verification results.

In practical scenarios, proppant injected into fractures exhibits uneven placement, with higher concentrations in some areas and lower concentrations in others, and this can be approximately classified into single-layer and multi-layer placement patterns. Additionally, fractures in real-world applications are relatively large, allowing observation of the proppant placement effect, which is characterized by a gradual reduction in the number of layers, from the near-wellbore region to the far-wellbore zone. This enables a comprehensive assessment of how proppant distribution at all positions within actual fractures influences proppant embedment.

However, experimental and simulation studies simplify the problem by focusing on an arbitrary segment along the fracture length, thereby neglecting variations in proppant distribution across the entire fracture length. Consequently, the results from these studies only reflect the impact of local conditions and cannot fully capture the influence of proppant distribution within actual fractures on proppant embedment.

2.6. Calculation of Fracture Width and Embedding Depth

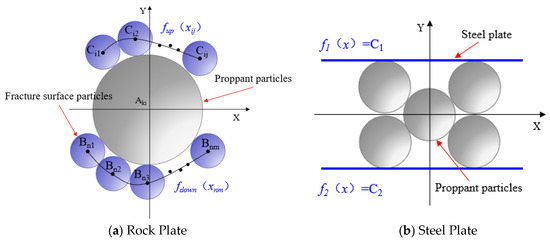

During the investigation of proppant embedment, while calculating the average fracture width provides a qualitative assessment of whether proppants are embedded in the fracture surface, it does not clarify the underlying embedment mechanisms. Therefore, this article establishes key technical methods for characterizing fracture width and embedding depth to observe changes across the entire fracture surface during the closure process under different proppant filling schemes. Figure 15a illustrates the theoretical model of rock plate embedment, while Figure 15b represents the theoretical model for steel plate simulation. In these illustrations, the blue disk symbolizes the fracture surface particles, the gray disk represents the proppant particles, and the blue straight line denotes the steel plate.

Figure 15.

Characterization model of propped fracture width based on particle flow method.

The formula for calculating fracture width in simulations of rock plates and steel plates is presented as follows.

In Equation (12), represents the width of the fracture at any position on the rock plate simulation, in meters; represents the vertical coordinate of any rock particle on the upper fracture surface along the fracture length, in meters; represents the vertical coordinate of any rock particle on the lower fracture surface along the fracture length, in meters; represents the radius of any rock particle on the upper fracture surface along the fracture length, in meters; and represents the radius of any rock particle on the lower fracture surface along the fracture length, in meters.

In Equation (13), represents the average fracture width of the rock plate simulation, in meters, while L represents the length selected for the model along the fracture length, also in meters.

In Equation (14), represents the average fracture width of the steel plate simulation, in meters; represents the fracture width at any position along the surface of the steel plate simulation, in meters; represents the vertical coordinate at any point along the length of the fracture on the upper surface of the steel plate, with a constant denoted as C1, in meters; and represents the vertical coordinate at any position along the length of the fracture on the lower surface of the steel plate, with a constant represented as C2, in meters.

The formulae for calculating the embedding depth and the average embedding depth of the proppant at any position along the fracture length direction is presented as follows.

The formula for calculating the embedding degree is as follows.

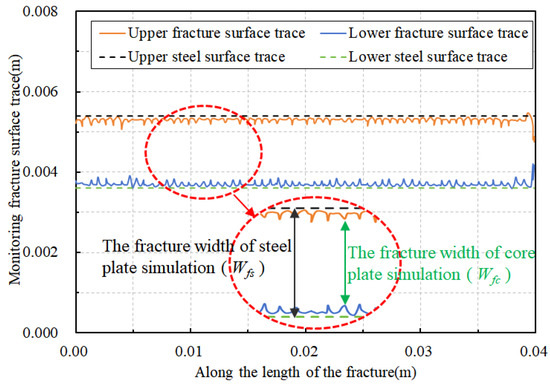

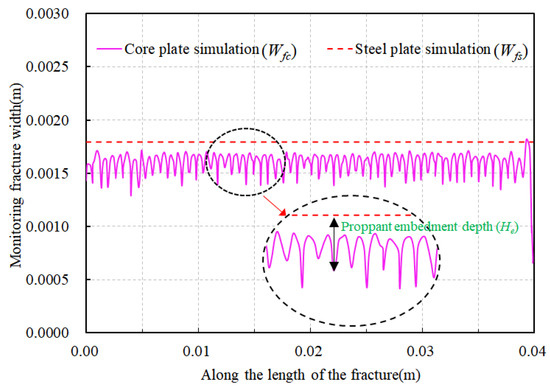

Based on this, a length of 0.04 m along the fracture direction is selected as the research object. Using a single-layer particle embedding model as an example, a PFC script file is developed to track and monitor the changes in particle positions on the fracture surface. This enables the dynamic monitoring of the fracture surface during the closure process. The functional relationships between the fracture length, propped fracture width, and embedding depth are illustrated in Figure 16 and Figure 17 below. In Figure 16, the orange curve represents the trajectory of the upper fracture surface, while the black dashed line indicates the trajectory of the upper steel plate. The blue curve depicts the lower fracture surface, and the green dashed line represents the trajectory of the lower steel plate. The difference between the orange curve and the blue curve in Figure 16 is the simulated fracture width of the core, corresponding to the purple curve in Figure 17. The difference between the black dashed line and the green dashed line in Figure 16 represents the simulated fracture width of the steel plates, corresponding to the red dashed line in Figure 17. Additionally, the difference between the red dashed line and the purple curve in Figure 17 represents the embedding depth of the proppant into the fracture surface. Subsequently, this method will be used to study the dynamic changes in fracture width and proppant embedding depth during the fracture closure process, providing a foundation for understanding the embedding mechanism of proppants.

Figure 16.

Calculation and characterization of the simulated fracture width in steel plates and in rock plates.

Figure 17.

Monitoring curve of fracture width in steel plates and in rock plates.

3. Study on the Effect of Proppant Embedment on Fracture Width

3.1. Proppant Particle Size

To investigate the effect of proppant particle size on embedding, a numerical simulation model of rock plates and steel plates will be established using a three-layer proppant system as an example. The study will examine the embedding patterns of proppants at a closure stress of 30 MPa under various particle sizes, including 20 mesh, 40 mesh, 60 mesh, 80 mesh, and 100 mesh (where mesh size = 15,000/micrometer). The aim is to analyze the changes in fracture width and embedding depth of proppants under different scenarios.

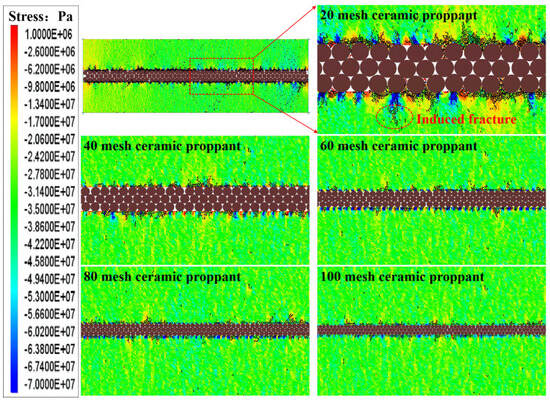

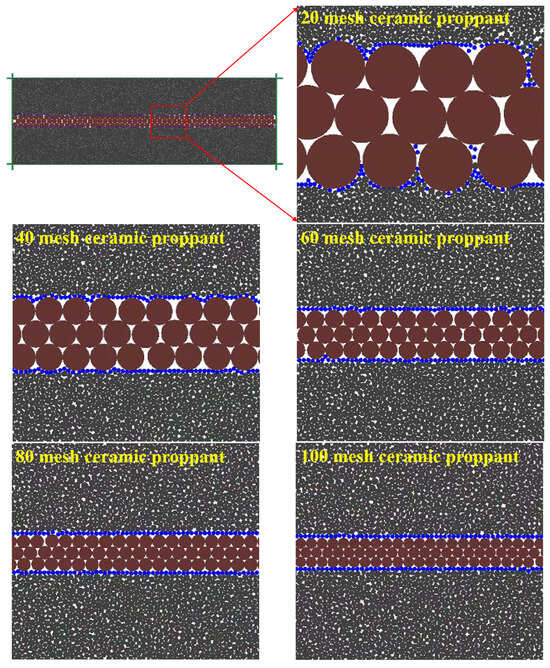

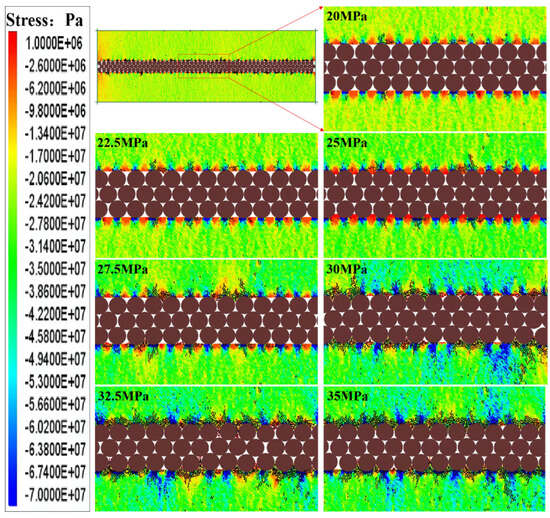

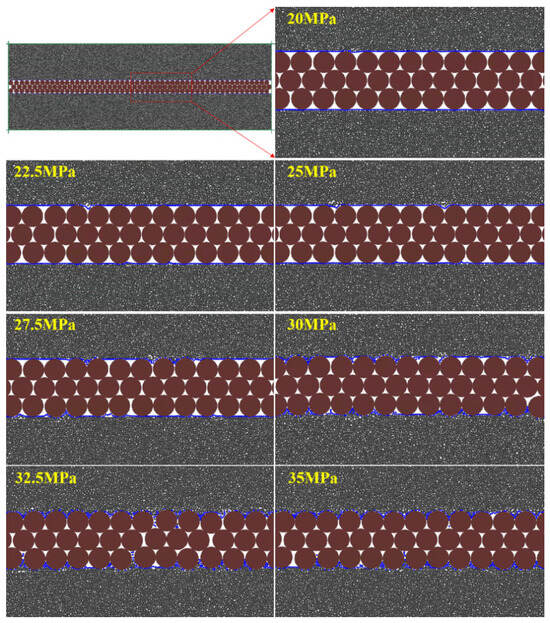

From the stress distribution diagram after fracture closure shown in Figure 18, it can be observed that the reservoir at the contact points between the proppant and the fracture surface is mainly subjected to compressive stress (blue areas), while the reservoir at the contact gap is primarily under tensile stress (red areas). In the comparison of stress distribution diagrams for different proppant sizes, the stress concentration factor (SCF) in the region of maximum compressive stress concentration is approximately 18.6 for 20-mesh ceramic proppant, 4.22 for 40-mesh, 2.78 for 60-mesh, 2.43 for 80-mesh, and 2.23 for 100-mesh. A smaller proppant mesh size corresponds to a larger particle size, and the stress concentration factor in the maximum compressive stress concentration area is larger. Combining this with the proppant embedding model in Figure 19, it is evident that under the same closure stress and number of layers, as the mesh size of the proppant decreases and the particle size increases, there are fewer contact points between proppants and the fracture surface per unit fracture length. Therefore, the compressive stress concentration at the contact points and the tensile stress at the contact gaps will be more significant, and the undulation degree of the fracture surface area will be relatively greater. In contrast, as the proppant particle size decreases, the number of contact points between the proppant and the fracture surface will increase, and the undulation degree of the fracture surface will be less significant.

Figure 18.

Stress distribution after fracture closure (different mesh sizes of proppants).

Figure 19.

Proppant embedding model after fracture closure (different mesh sizes of proppants).

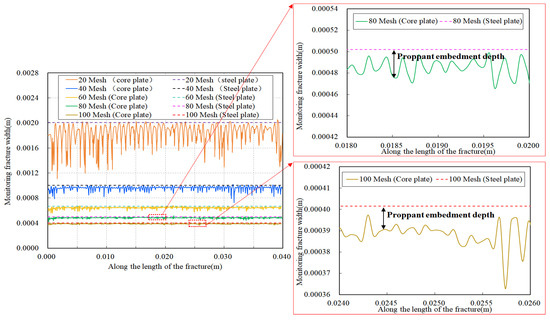

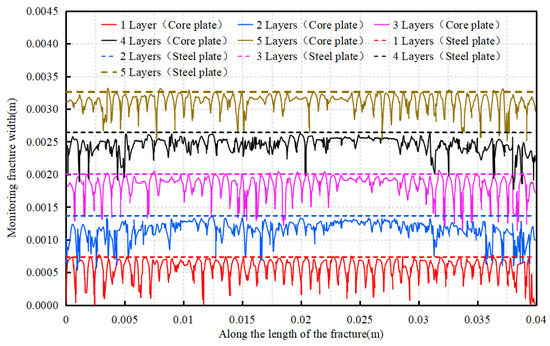

Figure 20 shows the curve of propped fracture width variation along the propped fracture length direction. Under the same conditions, as the mesh size of the proppant increases and the particle size decreases, the propped fracture width gradually decreases. Additionally, the overall propped fracture width measured by the steel plate fracture monitoring is higher than that obtained from the rock plate simulations, indicating that during the fracture closure process, the proppant still embeds into the fracture surfaces, affecting the propped fracture width. Furthermore, it can be observed that as the proppant particle size decreases, the degree of fluctuation in propped fracture width also diminishes. This is primarily because smaller particle sizes result in a greater number of proppants arranged per unit length of the propped fracture. During the fracture closure process, this leads to an increased number of contact points between the proppants and the fracture surface. Under the same closure pressure, the interaction force between a single proppant and the fracture surface is reduced, thereby resulting in a decreased degree of fluctuation in propped fracture width along the length of the propped fracture.

Figure 20.

Simulation monitoring fracture width curves of different mesh sizes of proppants for rock and steel plates.

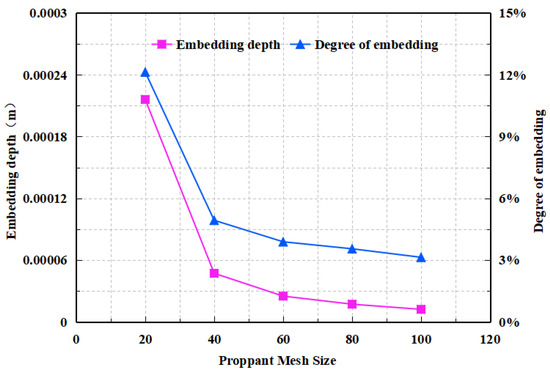

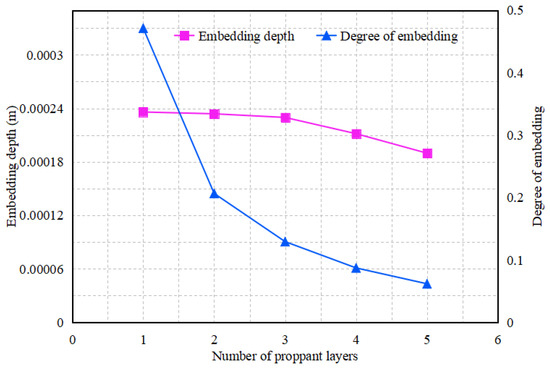

Figure 21 illustrates the average embedment depth and the degree of embedment. Under the same conditions, as the mesh size of the proppant increases and the particle size decreases, both the average embedment depth and the degree of embedment exhibit an overall downward trend. This indicates that larger particle sizes are more likely to embed into the fracture surfaces, resulting in a more pronounced effect on propped fracture width. Conversely, as the proppant particle size decreases, the trend of reduction in embedment depth and degree of embedment becomes less significant.

Figure 21.

Embedding results of different proppant mesh sizes.

3.2. The Number of Layers in Proppant Placement

The number of proppant layers has a significant effect on the propped fracture width, and it also greatly influences the embedment depth. To investigate how the number of proppant layers affects their embedment into the fracture surfaces, numerical simulation models for 20-mesh proppants were established for single-layer, double-layer, triple-layer, quadruple-layer, and quintuple-layer arrangements based on preliminary modeling. The study analyzes the variations in propped fracture width and embedment depth under different plans. The simulation results are illustrated in the figures below.

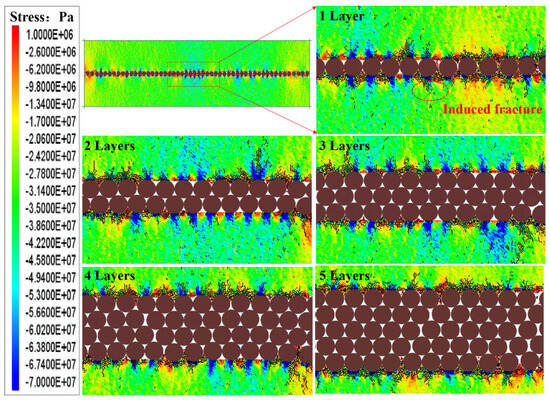

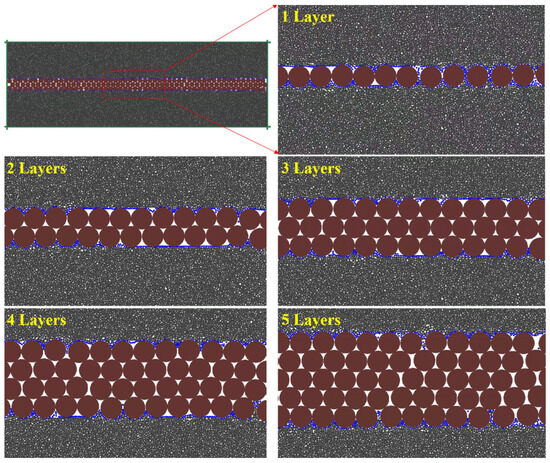

From the stress distribution map shown in Figure 22 after fracture closure, it can be observed that the areas where the proppant contacts the fracture surfaces primarily experience compressive stress (blue regions), while the contact gap areas are mainly subjected to tensile stress (red regions). In the comparison of stress distribution diagrams for 20-mesh ceramic proppant with different layer counts, the SCF in the region of maximum compressive stress concentration is approximately 23.9 for single-layer proppant, 19.63 for two layers, 18.63 for three layers, 16.5 for four layers, and 15.5 for five layers. The greater the number of proppant layers, the smaller the stress concentration factor in the maximum compressive stress concentration area. Combining with the proppant embedment model in Figure 23, it can be clearly seen that under all schemes, the fracture surfaces have a certain degree of undulation. Next, further analysis will be carried out by integrating the force chain diagrams and fracture width monitoring curves.

Figure 22.

Stress distribution after fracture closure (different layers of proppant placement).

Figure 23.

Proppant embedding model after fracture closure (different layers of proppant placement).

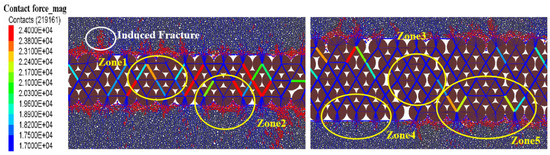

Figure 24 illustrates the force chain diagrams of three-layer and five-layer proppants after fracture closure. In the force chain analysis diagram, the color of the force chain represents the specific value of the force chain. The closer the force chain is to red, the larger the force chain value; the closer it is to blue, the smaller the force chain value. In Figure 24, the force chain values between proppants in Region 1 range from approximately 1559.28 N to 23,843.4 N, in Region 2 from approximately 4768.95 N to 26,241.6 N, in Region 3 from approximately 1543.12 N to 18,071.9 N, in Region 4 from approximately 1441.54 N to 15,300.1 N, and in Region 5 from approximately 1566.42 N to 22,823.7 N. A comparison between the force chain diagrams in Region 1 and Region 3 reveals that the particles in the three-layer proppant arrangement experience greater contact forces due to being compressed by surrounding particles compared to those in the five-layer arrangement. With the same particle size, both arrangements contact the fracture surface with the same number of proppants; however, the greater number of proppant layers in the five-layer arrangement leads to some degree of force cancelation from the closing stress within that structure. By comparing the stress distributions and force chain diagrams in Region 2 and Region 4, it can be clearly seen that the proppant particles close to the fracture surface bear greater compressive force from the internal proppant particles. Furthermore, by comparing the embedment models in Region 4 and Region 5, it can be found that in regions with larger contact forces, the undulation degree of the fracture surface is greater.

Figure 24.

Embedded force chain diagram of three and five layers of proppant after fracture closure.

As illustrated in Figure 25, the curve of fracture width variation along the fracture length indicates that, under consistent conditions, increasing the number of proppant layers results in a gradual increase in propped fracture width. Furthermore, the fracture width measured using steel plate monitoring is consistently higher than that found in rock plate simulations, suggesting that the proppants still embed into the fracture surfaces during the closure process, affecting the fracture width. It is noted that the rock plate simulation shows considerable fluctuations in fracture width, making it difficult to intuitively assess the impact of proppant embedment on propped fracture width. Future research will need to consider the differences in monitoring fracture width between steel and rock plates to further investigate the effects of proppant embedment on fracture width.

Figure 25.

Simulation monitoring fracture width curves of rock and steel plates with different laying layers.

The average embedment depth and embedment degree are illustrated in Figure 26. Under constant conditions, as the number of proppant layers increases, the propped fracture width also increases; however, the overall embedment depth and degree of embedment show a decreasing trend. This indicates that a greater number of proppant layers makes it more difficult for the proppants to embed into the fracture surfaces, while fewer layers allow for easier embedment. Additionally, the rate of decrease in embedment depth slows down as the number of layers increases, while the rate of decrease in embedment degree accelerates.

Figure 26.

Embedding results of different layers of proppants.

3.3. Fracture Closure Stress

Under the influence of closure stress, local stress concentration occurs near the proppant and the fracture surface, causing the embedment of proppants into the fracture. To investigate the impact of closure stress on proppant embedment, a numerical simulation model was established using three layers of 20-mesh proppant for both rock and steel plates. The study explored the embedment patterns of proppants during fracture closure under various closure stresses of 20 MPa, 22.5 MPa, 25 MPa, 27.5 MPa, 30 MPa, 32.5 MPa, and 35 MPa, comparing the variations in propped fracture width and embedment depth across different plans.

Figure 27 and Figure 28 depict the stress distribution and embedment models under varying closure stresses. In the comparison of stress distribution diagrams under different closure stresses, the SCF in the region of maximum compressive stress concentration is approximately 14.81 at a closure stress of 20 MPa, 15.15 at 22.5 MPa, 15.94 at 25 MPa, 16.68 at 27.5 MPa, 18.63 at 30 MPa, 19.75 at 32.5 MPa, and 21.00 at 35 MPa. It can be observed that under the same conditions of proppant particle size and layer number, higher closure stress will lead to more concentrated compressive stress and tensile stress at the contact points and contact gaps between the proppant and the fracture surface, and the undulation degree of the fracture surface will be more significant. In contrast, lower closure stress will result in a less significant undulation degree of the fracture surface.

Figure 27.

Stress distribution of proppant after fracture closure (different closure stresses).

Figure 28.

Proppant embedding model after fracture closure (different closure stresses).

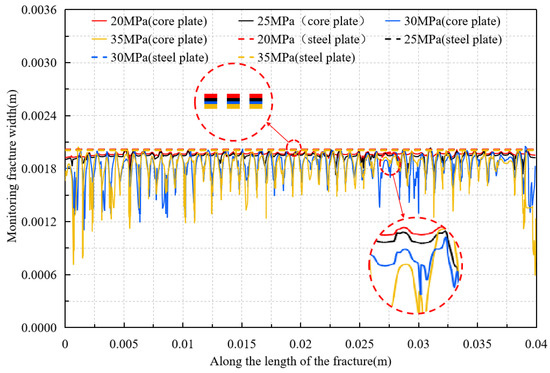

The curve of fracture width variation along the length of the fracture is shown in Figure 29. The fracture width obtained from steel plate fracturing monitoring is consistently higher than that measured through rock plate simulations, indicating that proppants still embed into the fracture surfaces during the fracture closure process, thereby affecting the fracture width. Under constant conditions, as closure stress increases, the propped fracture width gradually decreases. However, the differences in fracture width across various plans are not particularly pronounced. Therefore, it is essential to analyze the difference in monitored fracture widths between steel and rock plates to study the impact of proppant embedment on fracture width.

Figure 29.

Simulation monitoring fracture width curves of rock and steel plates with different closure stresses.

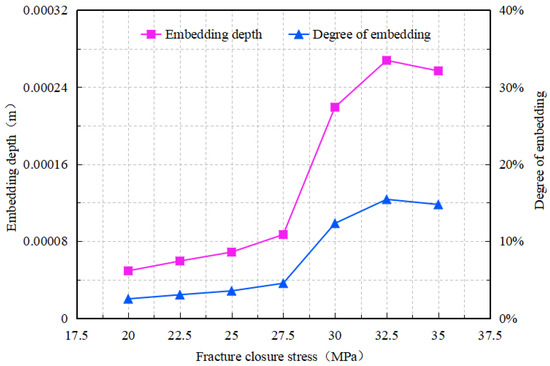

The average embedment depth and degree of embedment are illustrated in Figure 30. Under consistent conditions, as closure stress increases, both embedment depth and degree exhibit an overall upward trend. This suggests that higher closure stress will lead to proppants embedding into the fracture surfaces more easily. Furthermore, within a certain range of closure stress, the rates of increase in embedment depth and degree become more significant as closure stress rises. However, once the closure stress reaches a certain threshold, further increases in closure stress result in diminishing increments in embedment depth and degree.

Figure 30.

Embedding results of different closure stresses.

4. Conclusions

This paper establishes a numerical simulation model based on the discrete element method for the dynamic process of proppant embedding into fracture surfaces. Using this model, we analyzed the mechanisms by which different proppant particle sizes, the number of sand layers, and closure stress affect proppant embedding into rock and the resulting fracture width. The results are as follows:

- The results of the average fracture width monitored in laboratory experiments with changes in closure pressure are generally consistent with those obtained from simulation monitoring, with an error margin within 5%, thus verifying the correctness of this model.

- The contact areas and contact gap areas between the proppant and the fracture surface lead to a certain degree of undulation on the fracture surface due to the concentration of compressive stress and tensile stress. Additionally, the fracture width monitored during steel plate fracturing is overall higher than that obtained from rock plate simulations, indicating that during the fracture closure process, proppants still embed into the fracture walls.

- As the proppant particle size and closure stress increase, the stress concentration formed by proppant embedding into the fracture surface becomes stronger, leading to greater fluctuations in fracture width along the fracture length direction. With an increase in the number of sand layers, proppant particles can offset some of the closure stress, thereby reducing the degree of proppant embedding around the fracture surface.

- When designing a fracturing program, it is imperative to first ensure that the proppant size and the number of layers in proppant placement meet the design requirements for fracture conductivity and fracture width. Subsequently, an appropriate reduction in proppant size combined with an increase in the number of proppant placement layers should be implemented to mitigate the adverse effects of proppant embedment.

Author Contributions

Y.Z.: Conceptualization and Writing—Original Draft Preparation; D.Z.: Conceptualization and Writing—Review and Editing; C.L.: Validation; Y.W.: Formal Analysis; H.W.: Methodology and Writing—Review and Editing; P.Z.: Investigation; Q.W.: Data Curation. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (Grant Nos. 52504036, 52404039, U23B2089); the Shaanxi Provincial Natural Science Basic Research Program Project (grant number 2024JC-YBQN-0554, 2024JC-YBQN-0378); and the Scientific Research Program Funded by Shaanxi Provincial Education Department (Program No. 24JK0597).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jenkins, C.D.; Boyer, C.M. Coalbed-and shale-gas reservoirs. J. Pet. Technol. 2008, 60, 92–99. [Google Scholar] [CrossRef]

- Lu, J.; Zhao, S.; Sun, Y.; Tang, H. Gas production peaks in China: Research and strategic proposals. Nat. Gas Ind. B 2018, 5, 371–379. [Google Scholar] [CrossRef]

- Langenberg, C.; Beaton, A.; Berhane, H. Regional evaluation of the coalbed-methane potential of the Foothills/Mountains of Alberta, Canada. Int. J. Coal Geol. 2006, 65, 114–128. [Google Scholar] [CrossRef]

- Zou, C.; Chen, Y.; Kong, L.; Sun, F.; Chen, S.; Dong, Z. Underground coal gasification and its strategic significance to the development of natural gas industry in China. Pet. Explor. Dev. 2019, 46, 205–215. [Google Scholar] [CrossRef]

- Clarkson, C.; Bustin, M. Coalbed Methane: Current Evaluation Methods, Future Technical Challenges. In Proceedings of the SPE Unconventional Gas Conference, Pittsburgh, PA, USA, 23–25 February 2010; Society of Petroleum Engineers: Houston, TX, USA, 2010. [Google Scholar]

- Lau, H.C.; Li, H.; Huang, S. Challenges and opportunities of coalbed methane development in China. Energy Fuels 2017, 31, 4588–4602. [Google Scholar] [CrossRef]

- Li, S.; Qin, Y.; Tang, D.; Shen, J.; Wang, J.; Chen, S. A comprehensive review of deep coalbed methane and recent developments in China. Int. J. Coal Geol. 2023, 279, 104369. [Google Scholar] [CrossRef]

- Ouyang, Z.; Wang, H.; Sun, B.; Liu, Y.; Fu, X.; Dou, W.; Du, L.; Zhang, B.; Luo, B.; Yang, M. Quantitative prediction of deep coalbed methane content in Daning-Jixian Block, Ordos Basin, China. Processes 2023, 11, 3093. [Google Scholar] [CrossRef]

- Johnson, R.L., Jr.; Flottman, T.; Campagna, D.J. Improving results of coalbed methane development strategies by integrating geomechanics and hydraulic fracturing technologies. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Melbourne, Australia, 8–10 October 2002; SPE: Houston, TX, USA, 2002. [Google Scholar]

- Lu, Y.; Yang, Z.; Li, X.; Han, J.; Ji, G. Problems and methods for optimization of hydraulic fracturing of deep coal beds in China. Chem. Technol. Fuels Oils 2015, 51, 41–48. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, D.; Zou, Y. Effect mechanism of seepage force on the hydraulic fracture propagation. Int. J. Coal Sci. Technol. 2024, 11, 43. [Google Scholar] [CrossRef]

- Xu, J.; Zhai, C.; Qin, L.; Liu, S. Pulse hydraulic fracturing technology and its application in coalbed methane extraction. Int. J. Oil Gas Coal Technol. 2018, 19, 115–133. [Google Scholar] [CrossRef]

- Lacy, L.; Rickards, A.; Bilden, D. Fracture width and embedment testing in soft reservoir sandstone. SPE Drill. Complet. 1998, 13, 25–29. [Google Scholar] [CrossRef]

- Zheng, W.; Tannant, D.D. Influence of proppant fragmentation on fracture conductivity-insights from three-dimensional discrete element modeling. J. Pet. Sci. Eng. 2019, 177, 1010–1023. [Google Scholar] [CrossRef]

- Coulter, G.; Wells, R. The advantages of high proppant concentration in fracture stimulation. J. Pet. Technol. 1972, 24, 643–650. [Google Scholar] [CrossRef]

- Raymond, L.; Binder, G., Jr. Productivity of wells in vertically fractured, damaged formations. J. Pet. Technol. 1967, 19, 120–130. [Google Scholar] [CrossRef]

- Suarez-Rivera, R.; Behrmann, L.; Green, S.; Burghardt, J.; Stanchits, S.; Edelman, E.; Surdi, A. Defining three regions of hydraulic fracture connectivity, in unconventional reservoirs, help designing completions with improved long-term productivity. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013; SPE: Houston, TX, USA, 2013. [Google Scholar]

- Li, Y.; Meng, W.; Rui, R. The calculation of coal rock fracture conductivity with Different Arrangements of proppants. Geofluids 2018, 2018, 4938294. [Google Scholar] [CrossRef]

- Li, H.; Huang, B.; Cheng, Q. Mechanism of single proppant pressure embedded in coal seam fracture. Energy Fuels 2021, 35, 7756–7767. [Google Scholar] [CrossRef]

- Penny, G. An evaluation of the effects of environmental conditions and fracturing fluids upon the long-term conductivity of proppants. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 27–30 September 1987; SPE: Houston, TX, USA, 1987. [Google Scholar]

- Zhi, S.; Elsworth, D. Proppant embedment in coal and shale: Impacts of stress hardening and sorption. Int. J. Coal Geol. 2020, 227, 103545. [Google Scholar] [CrossRef]

- Ahamed, M.; Perera, M.; Dong-yin, L.; Ranjith, P.; Matthai, S. Proppant damage mechanisms in coal seam reservoirs during the hydraulic fracturing process: A review. Fuel 2019, 253, 615–629. [Google Scholar] [CrossRef]

- Mittal, A.; Rai, C.S.; Sondergeld, C.H. A study of propped-fracture conductivity: Impairment mechanisms under laboratory conditions. In Proceedings of the SPWLA Annual Logging Symposium, Oklahoma City, OK, USA, 17–21 June 2017; SPWLA: Houston, TX, USA, 2017. [Google Scholar]

- Bandara, K.; Ranjith, P.; Rathnaweera, T.; Wanniarachchi, W.; Yang, S. Crushing and embedment of proppant packs under cyclic loading: An insight to enhanced unconventional oil/gas recovery. Geosci. Front. 2021, 12, 100970. [Google Scholar] [CrossRef]

- Volk, L.J.; Raible, C.J.; Carroll, H.B.; Spears, J.S. Embedment of high strength proppant into low-permeability reservoir rock. In Proceedings of the SPE Rocky Mountain Petroleum Technology Conference/Low-Permeability Reservoirs Symposium, Denver, CO, USA, 27–29 May 1981; SPE: Houston, TX, USA, 1981. [Google Scholar]

- Mueller, M.; Amro, M. Indentaion hardness for improved proppant embedment prediction in shale formations. In Proceedings of the SPE European Formation Damage Conference and Exhibition, Budapest, Hungary, 3–5 June 2015; SPE: Houston, TX, USA, 2015. [Google Scholar]

- Li, H.; Wang, K.; Xie, J.; Li, Y.; Zhu, S. A new mathematical model to calculate sand-packed fracture conductivity. J. Nat. Gas Sci. Eng. 2016, 35, 567–582. [Google Scholar] [CrossRef]

- Chen, D.; Ye, Z.; Pan, Z.; Zhou, Y.; Zhang, J. A permeability model for the hydraulic fracture filled with proppant packs under combined effect of compaction and embedment. J. Pet. Sci. Eng. 2017, 149, 428–435. [Google Scholar] [CrossRef]

- Shi, F.; Wang, X.; Liu, C.; Liu, H.; Wu, H. An XFEM-based numerical model to calculate conductivity of propped fracture considering proppant transport, embedment and crushing. J. Pet. Sci. 2018, 167, 615–626. [Google Scholar] [CrossRef]

- Fan, M.; Han, Y.; Chen, C. Thermal–Mechanical Modeling of a Rock/Proppant System to Investigate the Role of Shale Creep on Proppant Embedment and Fracture Conductivity. Rock Mech. Rock Eng. 2021, 54, 6495–6510. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Guo, J.; Zhu, H.; Zeng, J. Numerical modeling of the conductivity of the particle monolayer with reduced size. Geofluids 2018, 2018, 7073091. [Google Scholar] [CrossRef]

- Deng, S.; Li, H.; Ma, G.; Huang, H.; Li, X. Simulation of shale–proppant interaction in hydraulic fracturing by the discrete element method. Int. J. Rock Mech. Min. Sci. 2014, 70, 219–228. [Google Scholar] [CrossRef]

- Bolintineanu, D.S.; Rao, R.R.; Lechman, J.B.; Romero, J.A.; Jove-Colon, C.F.; Quintana, E.C.; Bauer, S.J.; Ingraham, M.D. Simulations of the effects of proppant placement on the conductivity and mechanical stability of hydraulic fractures. Int. J. Rock Mech. Min. Sci. 2017, 100, 188–198. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, L.; Fang, L. Numerical study of proppant embedment under proppant-coal seam interaction. Powder Technol. 2024, 451, 120456. [Google Scholar] [CrossRef]

- Lu, C.; Liu, J.; Huang, F. Numerical simulation of proppant embedment in rough surfaces based on full reverse reconstruction. J. Pet. Explor. Prod. Technol. 2022, 12, 2599–2608. [Google Scholar] [CrossRef]

- Ahamed, M.; Perera, M.; Ranjith, P. Implementation of an elastoplastic constitutive model to study the proppant embedment in coal under different pore fluid saturation conditions: A numerical and experimental study. Fuel 2022, 317, 123488. [Google Scholar] [CrossRef]

- Itasca, C.G. PFC2D-Particle Flow Code in 2 Dimensions, Version 6.0 User’s Manual; Itasca Consulting Group: Minneapolis, MN, USA, 2019. [Google Scholar]

- David, C.T.; García-Rojo, R.; Herrmann, H.J.; Luding, S. Powder flow testing with 2D and 3D biaxial and triaxial simulations. Part. Part. Syst. Charact. 2007, 24, 29–33. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, D. Mechanistic study on the effect of seepage force on hydraulic fracture initiation. Fatigue Fract. Eng. Mater. Struct. 2024, 47, 1602–1619. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).