Analysis of Control Factors for Sensitivity of Coalbed Methane Reservoirs

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Experimental Instruments

2.3. Experimental Methods

2.3.1. Test Standards

2.3.2. Experimental Data Processing

- (1)

- Main experimental content

- (2)

- Pressure Sensitivity Test

- (3)

- Sensitivity Experiment

- (4)

- Water Sensitivity Experiment

- (5)

- Acid Sensitivity Experiment

- (6)

- Alkali Sensitivity Experiment

3. Results

3.1. Coal Rock Reservoir Characteristics

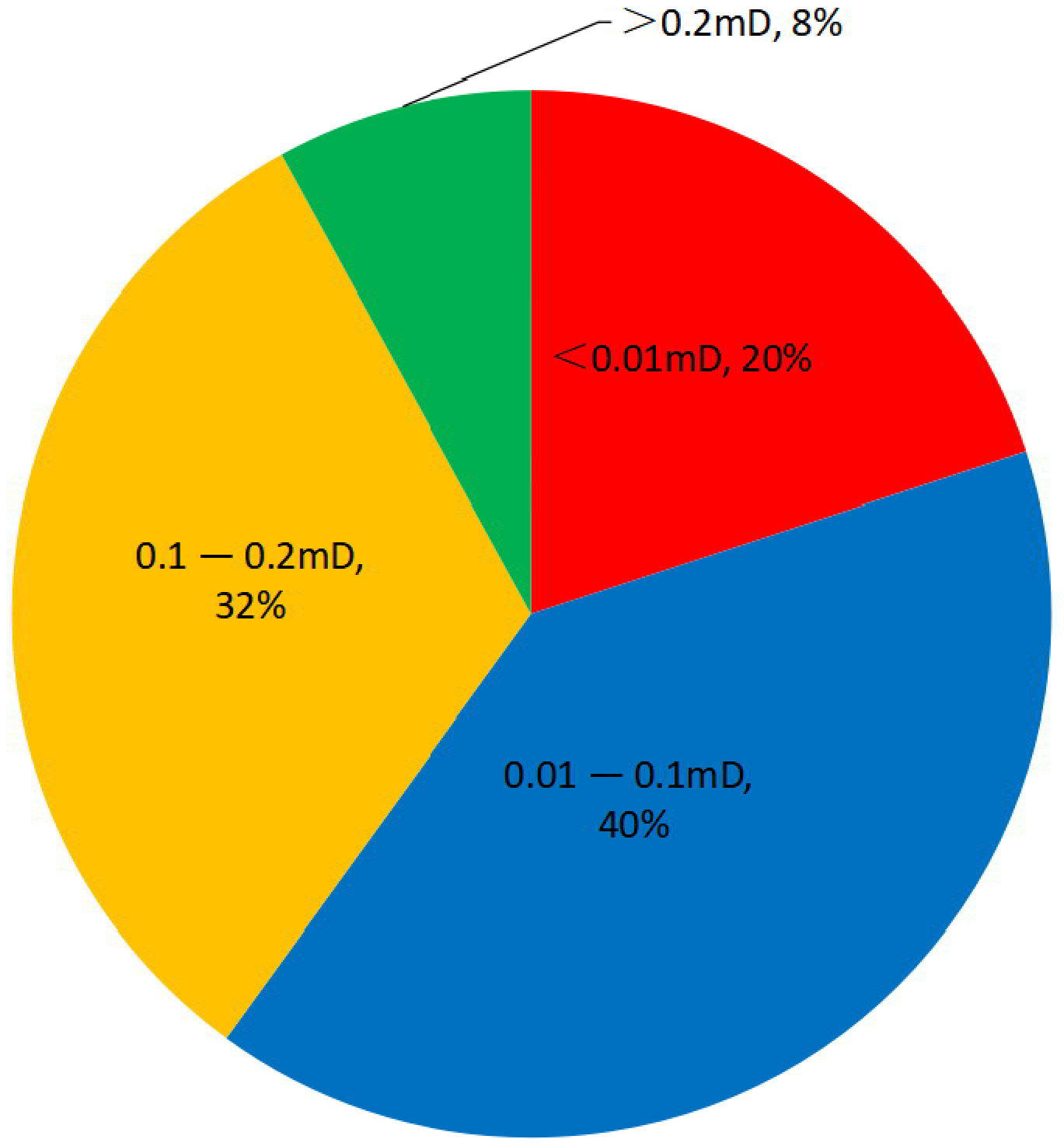

3.1.1. Pore and Permeability Characteristics

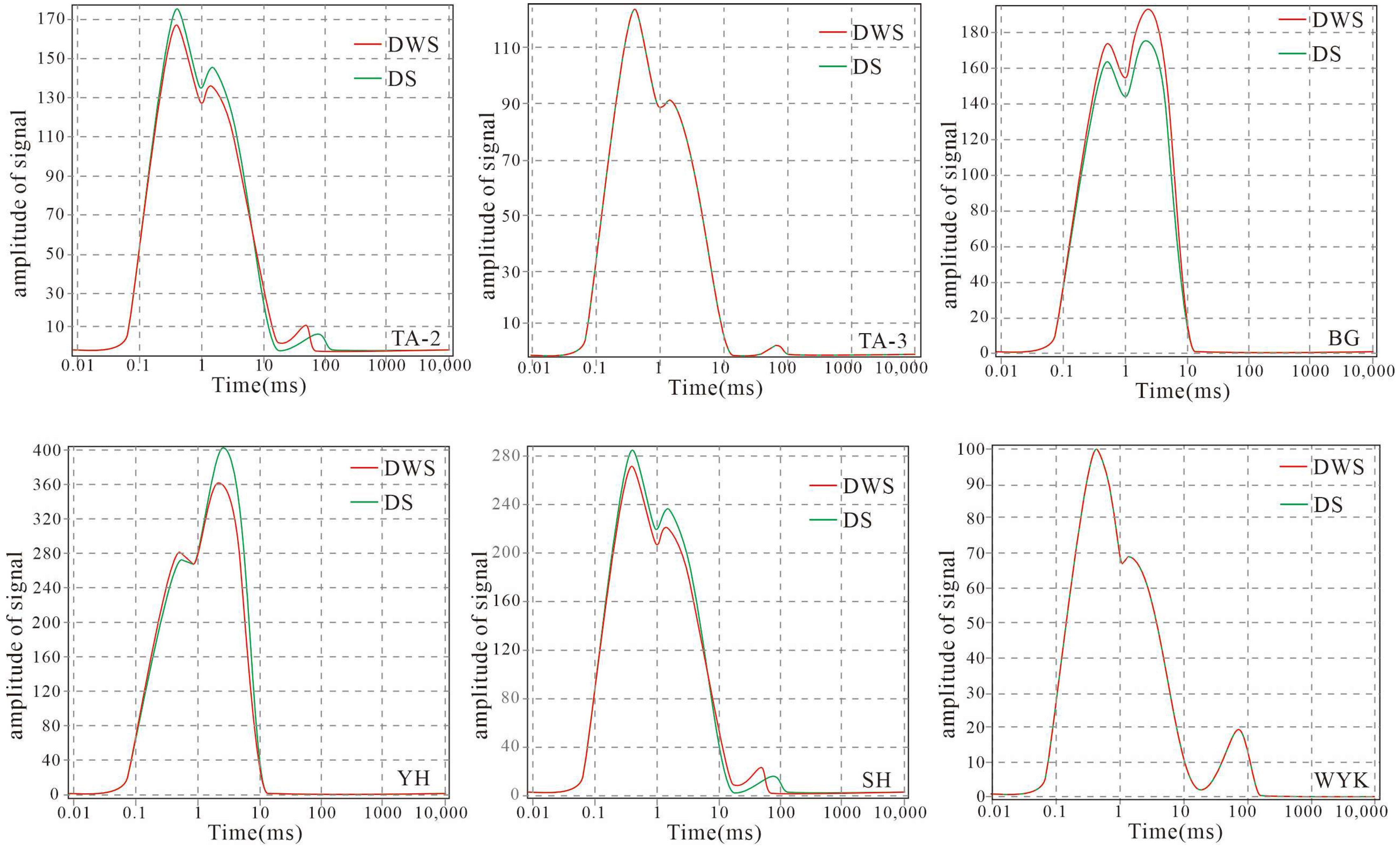

3.1.2. Pore Structure

3.1.3. Coal Rock Density

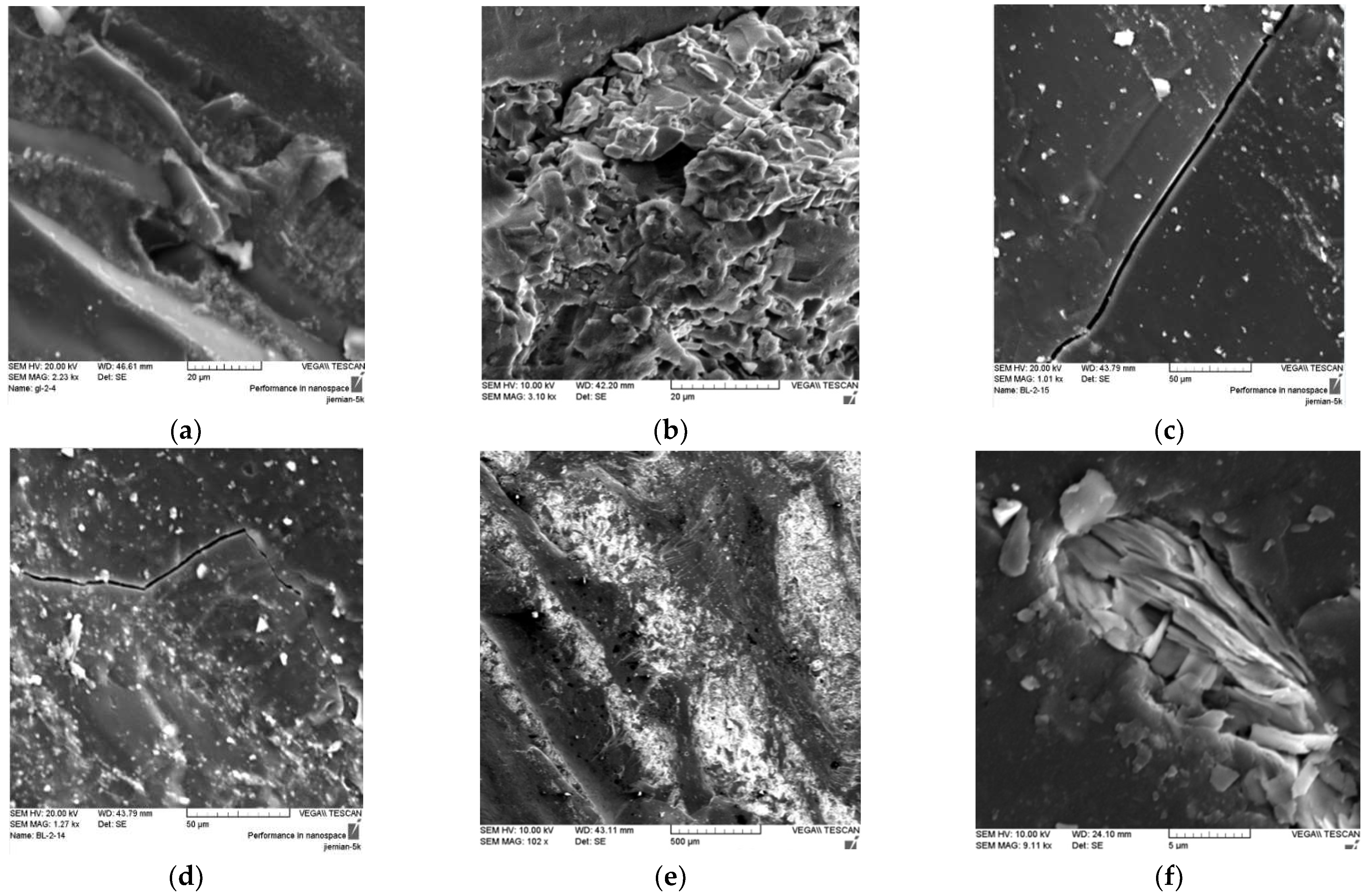

3.1.4. Microstructural Characteristics of Coal Reservoirs

3.2. Comparison Analysis of Sensitivity Between Raw Coal and Briquette Coal

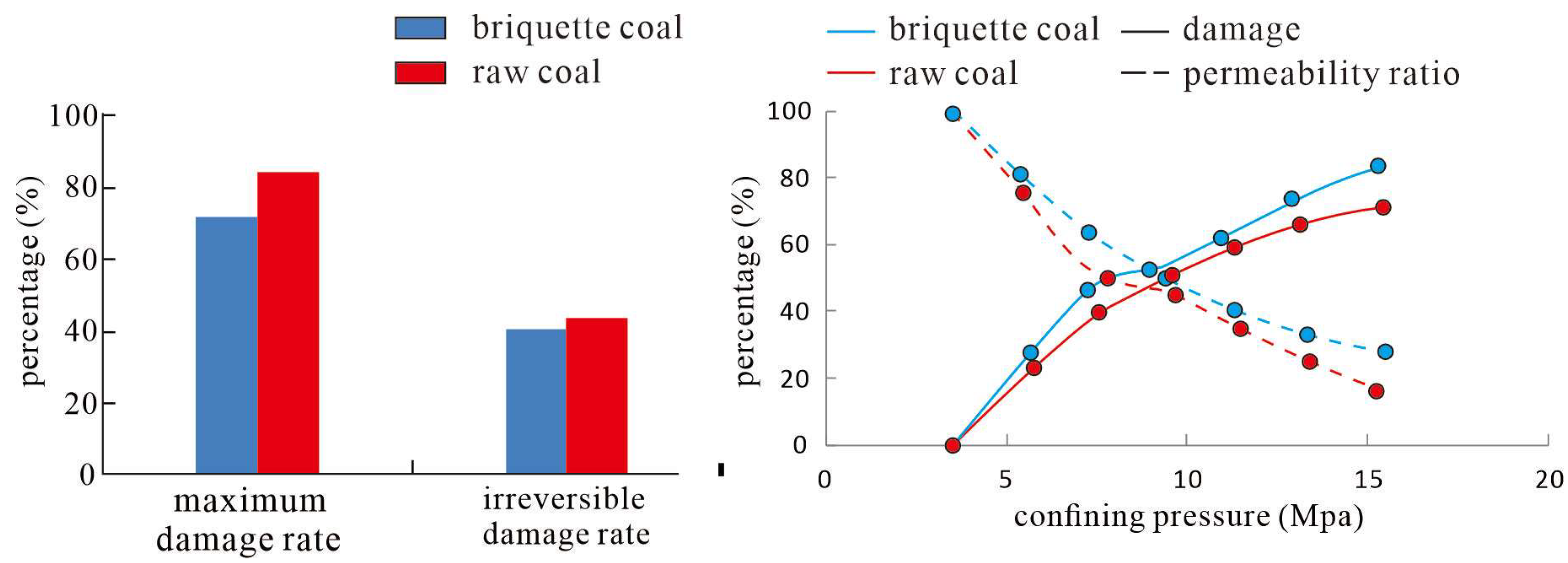

3.2.1. Comparison Analysis of Stress Sensitivity

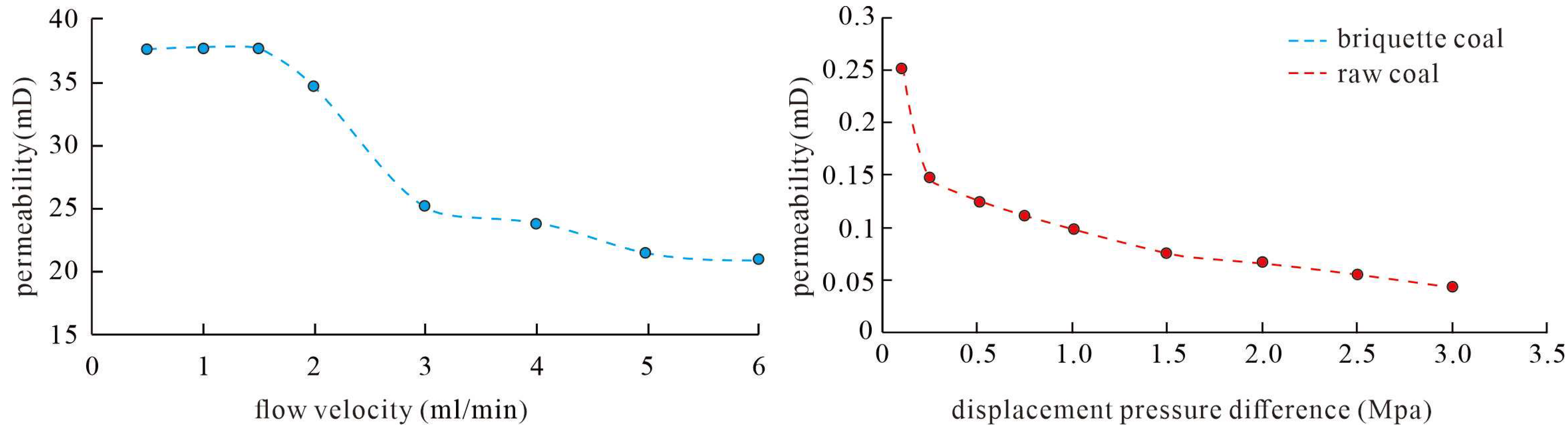

3.2.2. Comparison of Rapid Sensitivity

3.2.3. Water Sensitivity Comparison

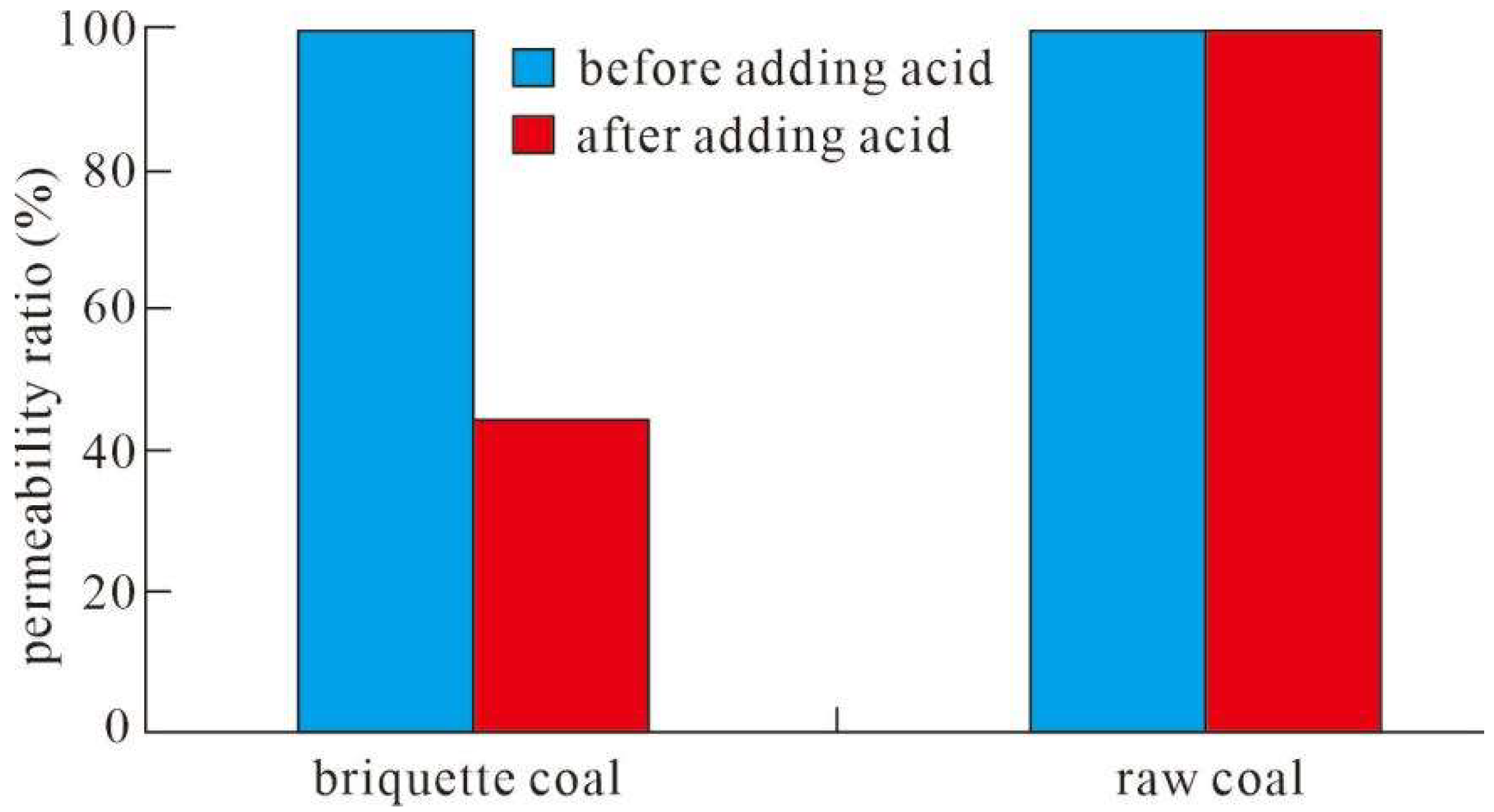

3.2.4. Acid Sensitivity Comparison

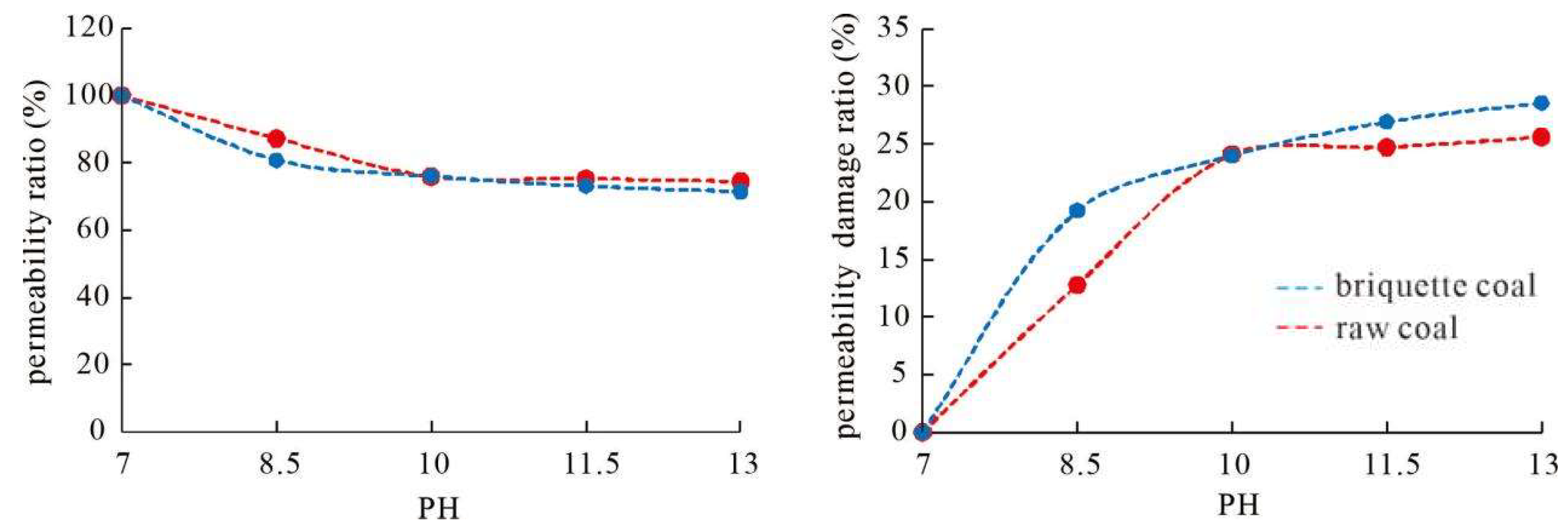

3.2.5. Comparison of Alkali Sensitivity

- The alkali damage degree of molded coal and raw coal samples is similar, both being weakly alkali sensitive;

- The alkali damage rates of molded coal and raw coal samples are positively correlated with the alkalinity of the alkali solution, and the damage rate increases rapidly at lower pH (7–10), while the rate of increase in damage slows down at higher pH (10–13);

- The trends of permeability ratios and permeability damage rates of molded coal and raw coal samples with varying pH values are basically consistent (Figure 10).

4. Conclusions

- (1)

- Coal reservoirs (whether raw coal or processed coal) exhibit strong stress sensitivity and significant irreversible damage, showing strong stress sensitivity, with permeability decreasing exponentially as effective stress increases. Raw coal, due to its more fragile natural fracture structure, has a higher maximum damage rate and irreversible damage rate than processed coal. This indicates that stress disturbances during the development process can permanently damage the permeability of the reservoir, necessitating optimization of engineering pressure control.

- (2)

- Acid sensitivity is controlled by reservoir structure, and briquette coal is more prone to damage. There is a significant difference in acid sensitivity between briquette coal and raw coal; briquette coal, due to its artificially compacted structure, experiences mineral dissolution after acid injection, leading to particle compaction and a 55.5% decrease in permeability. In contrast, raw coal maintains its permeability after acid treatment due to its natural skeletal support. This indicates that the fracturing fluid/acid formulation needs to be designed based on the structural differences in the coal body to avoid misleading field measures from briquette coal experimental conclusions.

- (3)

- The critical conditions for rate sensitivity and water sensitivity are dominated by microstructure. Rate sensitivity: the critical flow rate of raw coal is lower than that of briquette coal, as damage in raw coal originates from mineral detachment, while in briquette coal, it comes from particle displacement. Water sensitivity: raw coal experiences zero permeability due to fracture closure under low pressure, while the damage rate under high pressure is similar to that of briquette coal. This indicates that flow rate should be controlled in the early stages of production to avoid low-pressure-induced water lock damage.

- (4)

- Alkaline sensitivity is weak but highly consistent, with damage positively correlated with pH. Both raw coal and briquette coal exhibit weak alkaline sensitivity, with the permeability damage rate increasing with rising pH, and damage accelerates more rapidly in the low pH range. The damage trends of both are highly consistent, indicating that the harm from alkaline fluids to coal reservoirs is controllable, but pH should be limited to ≤10 to mitigate damage.

- (5)

- The coal–rock sensitivity measured in the laboratory is a static intrinsic property. It describes the inherent tendency of the coal body to change when external forces such as stress and fluids change. This value cannot be directly equated to the on-site risk, but it can be used to classify the risks of different coal layers in the mining area and even different regions, thereby formulating more targeted monitoring strategies.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CBM | Coal bed methane |

| ECBM | Enhanced Coal Bed Methane |

| SEM | scanning electron microscopy |

| NMR | nuclear magnetic resonance |

References

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Palmer, I.; Mansoori, J. How permeability depends on stress and pore pressure in coalbeds: A new model. SPE Reserv. Eval. Eng. 1998, 1, 539–544. [Google Scholar] [CrossRef]

- Wang, S.; Elsworth, D.; Liu, J. Permeability evolution during progressive deformation of intact coal and implications for instability in underground coal seams. Int. J. Rock Mech. Min. Sci. 2011, 48, 455–461. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). World Energy Outlook 2021; IEA Publications: Paris, France, 2021. [Google Scholar]

- Busch, A.; Gensterblum, Y.; Krooss, B.M.; Littke, R. Methane and carbon dioxide adsorption-diffusion experiments on coal: Upscaling and modeling. Int. J. Coal Geol. 2004, 60, 151–168. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Tang, D.; Tang, S.; Huang, W. Fractal characterization of adsorption-pores of coals from North China: An investigation on CH4 adsorption capacity of coals. Int. J. Coal Geol. 2008, 73, 27–42. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Bustin, R.M. The effect of pore structure and gas pressure upon the transport properties of coal: A laboratory and modeling study. 1. Isotherms and pore volume distributions. Fuel 1999, 78, 1333–1344. [Google Scholar] [CrossRef]

- Zang, Y.; Xin, X.; Xu, T.; Li, Y.; Shen, H.; Yuan, Y.; Zhu, H. Comparative Study on Improving the Production of Class 1 and Class 3 Reservoirs by Using Enlarged Permeable Well Wall Technology. Energy Fuels 2024, 38, 5862–5880. [Google Scholar] [CrossRef]

- Leng, K.; Guan, B.; Jiang, C.; Liu, W. Integrated Analysis of Pore and Fracture Networks in Deep Coal Seams: Implications for Enhanced Reservoir Stimulation. Energies 2025, 18, 3235. [Google Scholar] [CrossRef]

- Su, E.; Zhu, X.; Chen, X.; Zou, Q.; Yang, K.; Chen, H.; Wei, J. Analysis of Methane Diffusion on Permeability Rebound and Recovery in Coal Reservoirs: Implications for Deep Coalbed Methane-Enhanced Extraction. Phys. Fluids 2024, 36, 077101. [Google Scholar] [CrossRef]

- Wang, G.; Han, Z.; Xu, H.; Peng, S.; Huang, Q.; Long, Q. Effect of Coal Moisture Content on Gas Desorption and Diffusion: A Theoretical Model and Numerical Solution. Phys. Fluids 2024, 36, 077102. [Google Scholar] [CrossRef]

- Mazumder, S.; Wolf, K.H. Differential swelling and permeability change of coal in response to CO2 injection for ECBM. Int. J. Coal Geol. 2008, 74, 123–138. [Google Scholar] [CrossRef]

- Gu, H.; Lai, X.; Tao, M.; Cao, W.; Yang, Z. The role of porosity in the dynamic disturbance resistance of water-saturated coal. Int. J. Rock Mech. Min. Sci. 2023, 170, 105540. [Google Scholar] [CrossRef]

- Xu, Y.; Lun, Z.; Hu, Z.; Guo, J.; Zhou, X.; Wang, H.; Zhao, C.; Zhang, G.; Zhang, D. Alterations in pore and fracture structure of coal matrix and its surrounding rocks due to long-term CO2-H2O-rock interaction: Implications for CO2-ECBM. Fuel 2023, 352, 129104. [Google Scholar] [CrossRef]

- Wang, G.X.; Massarotto, P.; Rudolph, V. An improved permeability model of coal for coalbed methane recovery and CO2 geosequestration. Int. J. Coal Geol. 2009, 77, 127–136. [Google Scholar] [CrossRef]

- Zhao, W.; Zhao, D.; Wang, K.; Fan, L.; Zhao, Z.; Dong, H.; Shu, L. Will greenhouse gas emissions increase with mining depth in coal mines? An analysis of gas occurrence under varying in-situ stress conditions. Sci. Total Environ. 2024, 945, 173957. [Google Scholar] [CrossRef]

- Li, K.; Ling, B.; Bi, R.; Wei, Y.; Zhang, W.; Li, S. Numerical Simulation of the Physical Critical Conversion Depth of Deep Coal Seam. Mod. Min. 2016, 9–10+14. [Google Scholar] [CrossRef]

- Vishal, V.; Ranjith, P.G.; Singh, T.N. CO2 permeability of Indian bituminous coals: Implications for carbon sequestration. Int. J. Coal Geol. 2013, 105, 36–47. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Elsworth, D. How sorption-induced matrix deformation affects gas flow in coal seams: A new FE model. Int. J. Rock Mech. Min. Sci. 2008, 45, 1226–1236. [Google Scholar] [CrossRef]

- Jiao, Z.; Ma, J.; Ni, Z.; Bao, W.; Lan, J.; Dong, C. Study on Mechanical Response and Failure Characteristics of Coal Specimens Under the Coupling Effect of Joints and Drillings. Processes 2025, 13, 2605. [Google Scholar] [CrossRef]

- Khumalo, A.; Wang, C.; Tan, T.; Khan, M.S. Research on Deep Separation Technology of Multi–Source By–Products in Coking Coal. ChemEngineering 2025, 9, 92. [Google Scholar] [CrossRef]

- Song, H.; An, H.; Liu, S.; Yu, Z.F.; Jin, Y.; Wang, B.Y.; Wang, C.Z. Controlling geological factors and coalbed methane enrichment areas in Southern Wuxiang Block, Qinshui Basin. J. Coal Sci. 2021, 46, 3974–3987. [Google Scholar] [CrossRef]

- Xia, D.; Guo, H.; Luo, Y.; Ma, J.Q.; Chen, S.L.; Wang, Z. Experimental study on reducing outburst proneness of coal seam via alkaline solution. Chin. J. Coal Sci. 2015, 40, 1768–1773. [Google Scholar] [CrossRef]

- Yang, S.; Wen, G.; Yan, F.; Li, H.; Liu, Y.; Wu, W. Swelling characteristics and permeability evolution of anthracite coal containing expansive clay under water-saturated conditions. Fuel 2020, 279, 118481. [Google Scholar] [CrossRef]

- Yang, S.; Wen, G.; Yan, F.; Zhang, M.; Zhao, X. Evaluating the maximum rate of penetration for drilling borehole in soft coal seam. Energy Sci. Eng. 2020, 8, 3273–3284. [Google Scholar] [CrossRef]

- Chen, Z.; Pan, Z.; Liu, J.; Connell, L.D.; Elsworth, D. Effect of the effective stress coefficient and sorption-induced strain on the evolution of coal permeability: Experimental observations. Int. J. Greenh. Gas Control. 2011, 5, 1284–1293. [Google Scholar] [CrossRef]

- Pan, Z.; Connell, L.D.; Camilleri, M. Laboratory characterisation of coal reservoir permeability for primary and enhanced coalbed methane recovery. Int. J. Coal Geol. 2010, 82, 252–261. [Google Scholar] [CrossRef]

- Shi, J.Q.; Durucan, S. A model for changes in coalbed permeability during primary and enhanced methane recovery. SPE Reserv. Eval. Eng. 2005, 8, 291–299. [Google Scholar] [CrossRef]

- Li, S.; Tang, D.; Pan, Z.; Xu, H.; Guo, L.L. Evaluation of coalbed methane potential of different coal reservoirs in China. Int. J. Coal Geol. 2013, 115, 1–11. [Google Scholar]

- Meng, Z.; Zhang, J.; Wang, R. In-situ stress, pore pressure and stress-dependent permeability in the Southern Qinshui Basin. Int. J. Rock Mech. Min. Sci. 2011, 48, 122–131. [Google Scholar] [CrossRef]

- Pan, Z.; Connell, L.D. Modelling permeability for coal reservoirs: A review of analytical models and testing data. Int. J. Coal Geol. 2012, 92, 1–44. [Google Scholar] [CrossRef]

- NB/T 10889-2021; The Damage Evaluation Method for Water Based Fracturing Fluid Using Briquette. National Energy Administration: Beijing, China, 2021.

- Gao, X.; Li, C.Y.; Zhang, B.Y. Experimental study on optimization of molding pressure and pressure holding time in briquette preparation. J. Heilongjiang Univ. Sci. Technol. 2021, 31, 197–202. [Google Scholar]

- Sun, J. Evaluation of Nitrogen Flow Rate Sensitivity of Coalbed Gas Reservoirs; China University of Petroleum: Beijing, China, 2021. [Google Scholar]

- Hu, Q.; Jia, H.; Fan, B.; Mao, C.H.; Zhang, Q.; Zhang, X.M.; Liu, C.C.; Qin, M.F. Concept, testing method and mathematical model of stress uploading sensitivity of coal. J. China Coal Soc. 2022, 47 (Suppl. S1), 204–213. [Google Scholar] [CrossRef]

- Xu, J.; Jia, L.; Gan, Q.; Peng, S.; Yan, F.; Wang, X.; Dai, S.; Jiao, F.; Li, Q.; Chen, Y. Experimental method for optimizing the molding conditions of hot-pressed briquette. J. China Coal Soc. 2024, 49, 739–752. [Google Scholar] [CrossRef]

- Yang, S.; Liu, P.; Lu, W. Study on triaxial compression tests on briquette coal specimens with different binder contents. J. Min. Strat. Control. Eng. 2023, 5, 023027. [Google Scholar] [CrossRef]

- Hu, X.; Liang, W.; Hou, S.; Zhu, X.; Huang, W. Experimental Study of Effect of Temperature and Stress on Permeability Characteristics of Raw Coal and Shaped Coal. Rock Soil Mech. 2012, 31, 1222–1229. [Google Scholar]

| Experiment Name | Variable Parameters | Purpose |

|---|---|---|

| Stress-sensitive | confining pressure | By changing the confining pressure, the net stress exerted on the coal and rock can be altered. |

| Rapid-sensitive | Pressure at the outlet end of the core sample | By altering the pressure at the outlet end, the flow rate of the fluid in the coal rock can be changed. |

| Water-sensitive | fluid | The change in permeability of coal rock when using 8% standard saline and distilled water. |

| Acid-sensitive | Properties of acidic fluids | By altering the properties of the acidic fluids flowing through the coal sample, the changes in the permeability of the coal rock when different acidic fluids pass through it were measured. |

| Alkali-sensitive | Properties of alkaline fluids | By altering the properties of the alkaline fluids flowing through the coal sample, the changes in permeability caused by different alkaline fluid flows passing through the coal sample can be determined. |

| Stress Sensitivity Damage Rate (%) | Damage Degree |

|---|---|

| D ≤ 5 | No |

| 5 < D ≤ 30 | Weak |

| 30 < D ≤ 50 | Moderately Weak |

| 50 < D ≤ 0 | Moderately Strong |

| D > 70 | Strong |

| Stress Sensitivity Damage Rate (%) | Damage Degree |

|---|---|

| D ≤ 5 | No |

| 5 < D ≤ 30 | Weak |

| 30 < D ≤ 50 | Moderately Weak |

| 50 < D ≤ 70 | Moderately Strong |

| D > 70 | Strong |

| Water Sensitivity Damage Rate (%) | Damage Degree |

|---|---|

| Dw ≤ 5 | No |

| 5 < Dw ≤ 30 | Weak |

| 30 < Dw ≤ 50 | Moderately Weak |

| 50 < Dw ≤ 70 | Moderately Strong |

| 70 < Dw ≤ 90 | Strong |

| Acid Sensitivity Damage Rate (%) | Damage Degree |

|---|---|

| Dac ≤ 5 | No |

| 5 < Dac ≤ 30 | Weak |

| 30 < Dac ≤ 50 | Moderately Weak |

| 50 < Dac ≤ 70 | Moderately Strong |

| Dac > 70 | Strong |

| Alkali Sensitivity Damage Rate (%) | Damage Degree |

|---|---|

| Dal ≤ 5 | No |

| 5 < Dal ≤ 30 | Weak |

| 30 < Dal ≤ 50 | Moderately Weak |

| 50 < Dal ≤ 70 | Moderately Strong |

| Dal > 70 | Strong |

| Sample ID | Conventional Analysis Results | Nuclear Magnetic Resonance Analysis Results | |||

|---|---|---|---|---|---|

| Gas-Measured Porosity (%) | Apparent Rock Density (g/cm3) | Nuclear Magnetic Porosity (%) | Pore Volume Percentage (%) | ||

| Less than 10 ms | Greater than 10 ms | ||||

| TA2 | 2.95 | 1.11 | 3.18 | 98.12 | 1.88 |

| TA3 | 1.73 | 1.04 | 1.89 | 99.98 | 0.02 |

| BG | 4.82 | 1.42 | 5.09 | 93.23 | 6.77 |

| YH | 7.14 | 1.52 | 7.72 | 99.79 | 0.21 |

| SH | 3.58 | 1.45 | 3.93 | 98.36 | 1.64 |

| WYK | 1.85 | 1.36 | 1.91 | 97.86 | 2.14 |

| Moisture Content (%) | True Density (g/cm3) | Apparent Density (g/cm3) | Density Difference (g/cm3) | |

|---|---|---|---|---|

| Maximum Value | 1.36 | 1.984 | 1.789 | 0.578 |

| Minimum value | 0.57 | 1.132 | 0.859 | 0.005 |

| Average value | 0.85 | 1.53 | 1.19 | 0.333 |

| Sample Number | Initial Permeability/mD | Fitting Parameter b | Maximum Damage Rate (%) | Irreversible Damage Rate (%) | Sensitivity Evaluation |

|---|---|---|---|---|---|

| TA (Coke) | 262.04 | 0.10 | 71.4 | 40.2 | Strong |

| Tang’an 2 (Raw Coal) | 0.037 | 0.14 | 83.8 | 43.2 | Strong |

| Raw Coal | Damage Rate Corresponding to Different Pressure Conditions (MPa) | Maximum Water Sensitivity Damage Rate (%) | Water Sensitivity Damage Level | ||

| 0.5 | 1 | 1.5 | |||

| 1 | 1 | 0.36 | 100 | Strong | |

| Briquette coal | Damage rate corresponding to different flow rates (mL/min) | Maximum damage rate due to water sensitivity (%) | Degree of damage due to water sensitivity | ||

| 1 | 3 | 5 | |||

| 0.27 | 0.299 | 0.29 | 29.90 | Weak | |

| Briquette Coal | Raw Coal | |

|---|---|---|

| Acid solution | 15% HCL | |

| Permeability before acid addition/mD | 34.77 | 0.02 |

| Permeability after acid addition/mD | 15.47 | 0.02 |

| Acid sensitivity permeability damage rate/% | 55.5 | 0 |

| Acid sensitivity | Damage | None |

| Sample Number | Permeability Damage Rate/% at pH = 8.5 | Evaluation | Ph = 13 Permeability Damage Rate/% | Evaluation |

|---|---|---|---|---|

| TA (Briquette Coal) | 19.23 | Weak | 28.58 | Weak |

| Tang’an 2 (Raw Coal) | 12.77 | Weak | 25.61 | Weak |

| Comparison Dimension | Advantages of This Study | Representative Recent Literature and Key Viewpoints |

|---|---|---|

| Methodological Innovation | Dual-sample (“undisturbed coal-briquette”) comparative system directly quantifies the systematic bias of briquette experiments in overestimating acid sensitivity and underestimating water sensitivity at low pressure. | Developed an optimized method for hot-pressed briquettes aiming to make their mechanical and permeability properties closer to undisturbed coal. However, it did not directly address the systematic bias in sensitivity evaluation, indirectly acknowledging differences exist between briquette and undisturbed coal [36]. |

| Understanding Acid Sensitivity Mechanism | Revealed that structural integrity is a prerequisite for acid sensitivity. Briquettes show strong acid sensitivity due to structural collapse post-mineral dissolution, while undisturbed coal remains stable due to its natural skeleton support. | Studied the effect of binders on the mechanical properties of briquettes. While not directly researching acid sensitivity, their findings on how briquette structural strength is affected by preparation parameters support the view that “poor structural integrity of briquettes easily leads to deformation or failure,” which partially echoes the structural control theory for acid sensitivity presented in this study [37]. |

| Critical Conditions for Velocity & Water Sensitivity | Discovered that undisturbed coal has a lower critical flow velocity (due to fine particle detachment) and exhibits an abrupt change in water sensitivity at low pressure (fracture closure), emphasizing the necessity of guiding drainage systems based on undisturbed coal data. | Proposed the concept and testing method for the stress loading rate sensitivity of coal, emphasizing the damage of stress variation rate to permeability. Although focusing on stress rate rather than fluid flow rate, their research deepens the understanding of coal sensitivity, which is related to this study’s focus on how critical conditions cause reservoir damage [35]. |

| Irreversibility of Stress Sensitivity | Confirmed the strong irreversible damage from stress sensitivity, and notably that the irreversible damage rate is higher in undisturbed coal than in briquettes, strengthening the argument for optimizing engineering pressure management to prevent permanent reservoir damage. | Experimentally confirmed that coal undergoes plastic deformation in pore structure after experiencing high confining pressure, leading to irreversible loss of porosity and permeability, i.e., permanent irreversible damage, directly supporting this study’s conclusion on the irreversibility of stress sensitivity [38]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Zhang, C.; Fan, B.; Zhang, J.; Zhao, Z. Analysis of Control Factors for Sensitivity of Coalbed Methane Reservoirs. Processes 2025, 13, 3133. https://doi.org/10.3390/pr13103133

Li P, Zhang C, Fan B, Zhang J, Zhao Z. Analysis of Control Factors for Sensitivity of Coalbed Methane Reservoirs. Processes. 2025; 13(10):3133. https://doi.org/10.3390/pr13103133

Chicago/Turabian StyleLi, Peng, Cong Zhang, Bin Fan, Jie Zhang, and Zhongxiang Zhao. 2025. "Analysis of Control Factors for Sensitivity of Coalbed Methane Reservoirs" Processes 13, no. 10: 3133. https://doi.org/10.3390/pr13103133

APA StyleLi, P., Zhang, C., Fan, B., Zhang, J., & Zhao, Z. (2025). Analysis of Control Factors for Sensitivity of Coalbed Methane Reservoirs. Processes, 13(10), 3133. https://doi.org/10.3390/pr13103133