Physical Modeling of High-Pressure Flooding and Development of Oil Displacement Agent for Carbonate Fracture-Vuggy Reservoir

Abstract

1. Introduction

2. Experiment

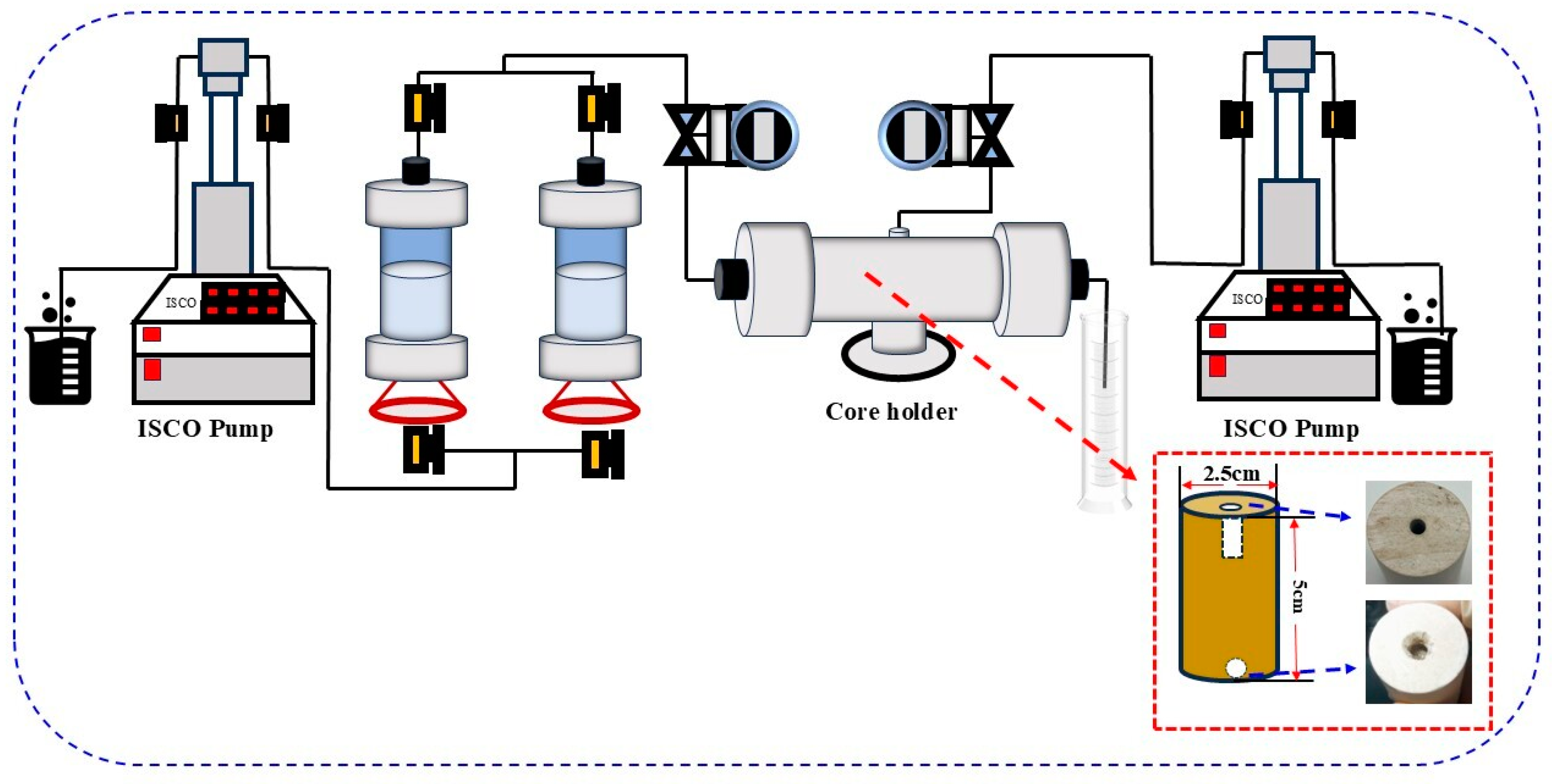

2.1. Pressure Flooding Experiment

- Polishing the two ends of the cut, drilled, and opened core to ensure that its cross-section can fully fit the inlet and outlet ends in the core holder. Connect experimental instruments and pipelines, place the core into the core holder, and apply confining pressure around the core.

- To operate and start the core displacement equipment on the computer, set the water injection flow (or displacement rate), and record the changes in injection pressure during the pressure flooding experiment until the pressure changes stabilize and the outlet of the core gripper releases liquid. Save pressure data during the pressure drive experiment. Record oil recovery data.

- To change the conditions of different rocky cores, injection flows, and displacement rates. Repeat b and record data. The results of the experiment must be subjected to rigorous analysis.

2.2. Three-Dimensional Fluid Structure Coupling Pressure Flooding Experiment

- To drill holes in a natural carbonate rock salt plate that is 50 cm long, 50 cm wide, and 5 cm high, and place it on a workbench to check the connection of each pipeline.

- To operate and start the core displacement equipment on the computer to apply confining pressure to the large rock slab. After the pressurization is completed and stabilized, turn on the displacement device and data acquisition system, monitoring and saving experimental data throughout the process.

- To set the pump inlet flow rate and turn on the collection device to start collecting and replacing. Collect water from the device and wait for the pressure to stabilize before ending the experiment. Inspect, relieve pressure, and unload the device.

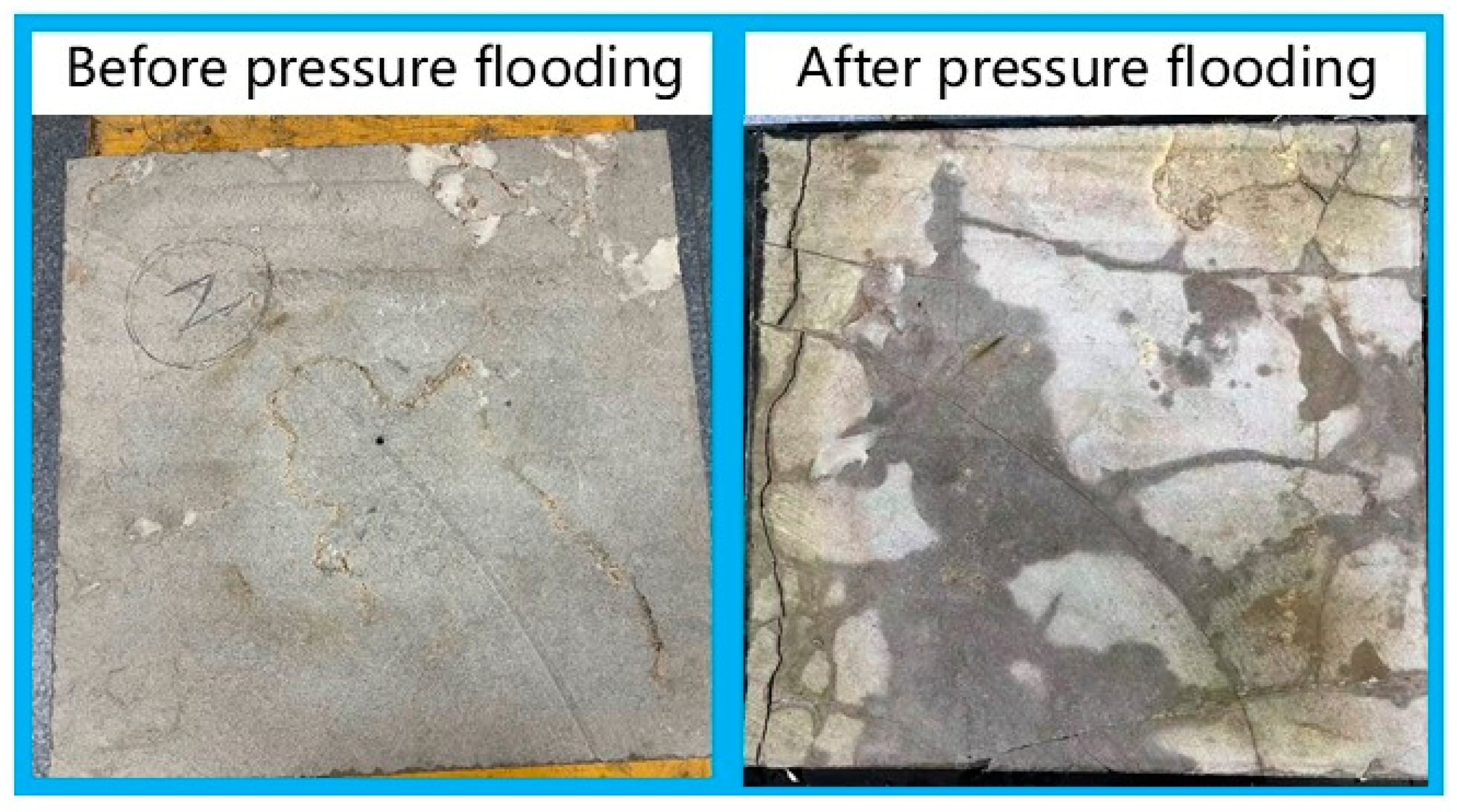

- To take out the large rock slab and observe its crack morphology; take photos and save them.

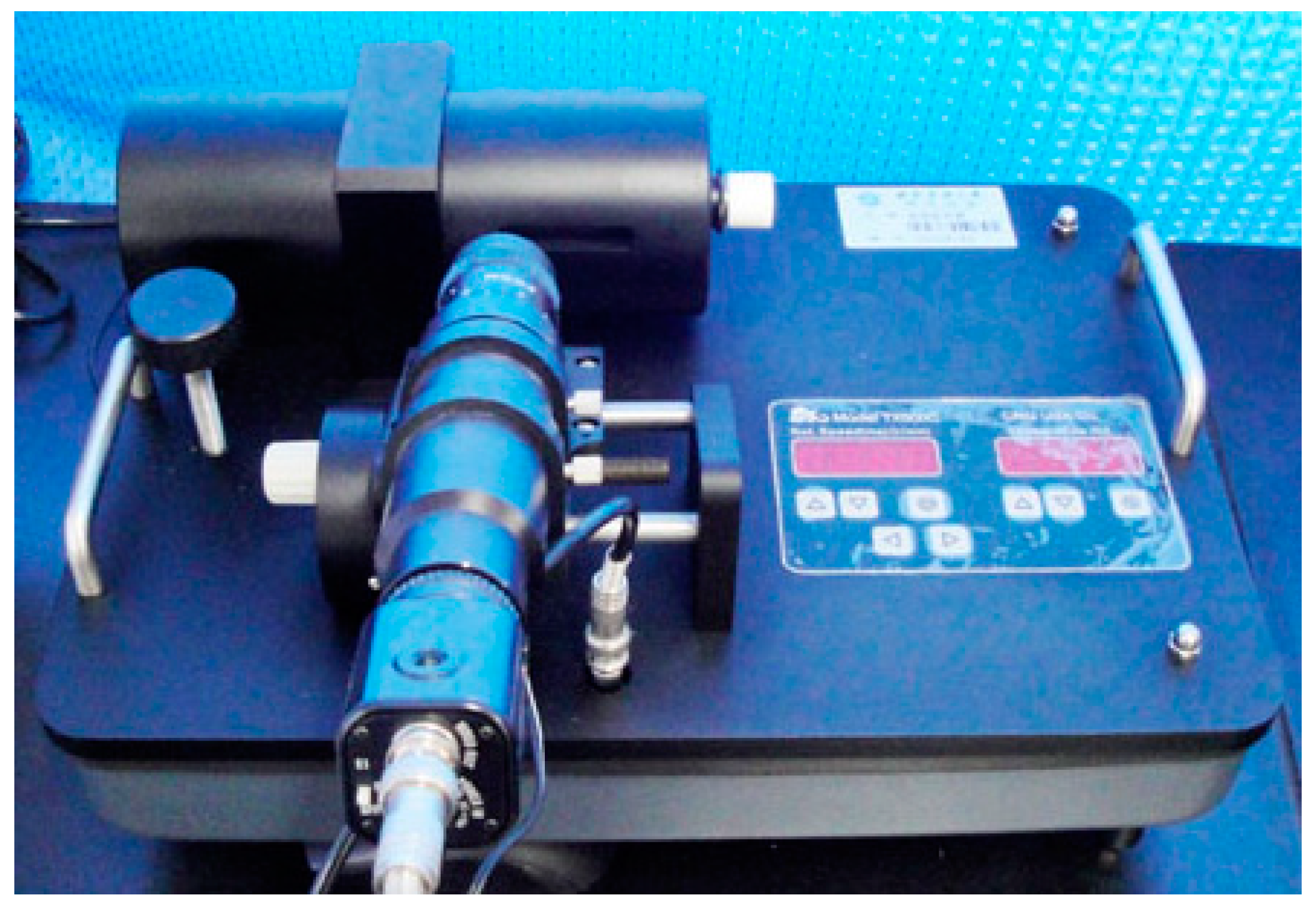

2.3. Interface Tension Experiment

3. Experimental Results and Analysis

3.1. The Influence of Different Factors on Fractures

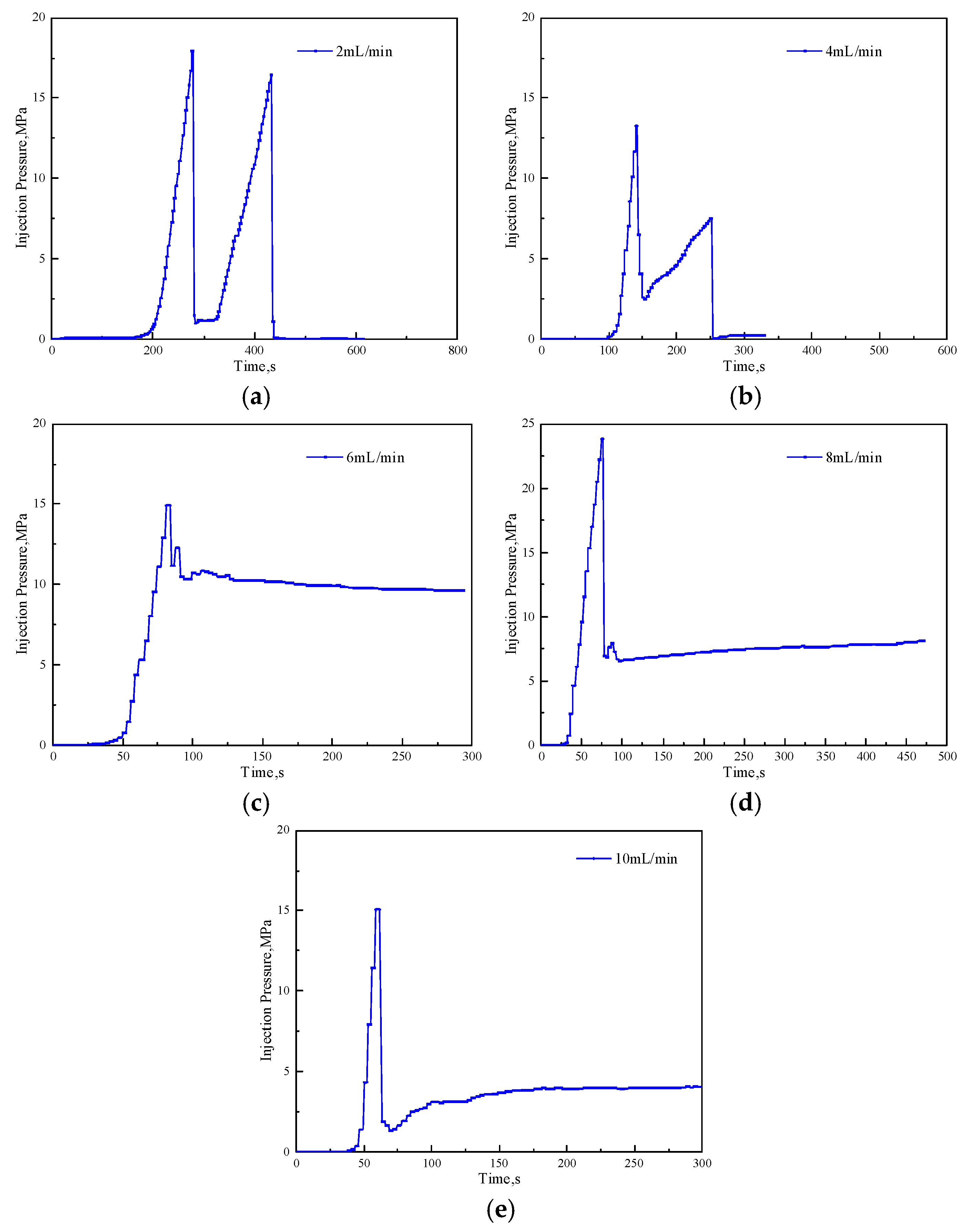

3.1.1. Effects of Different Injection Flows on Fracture Propagation

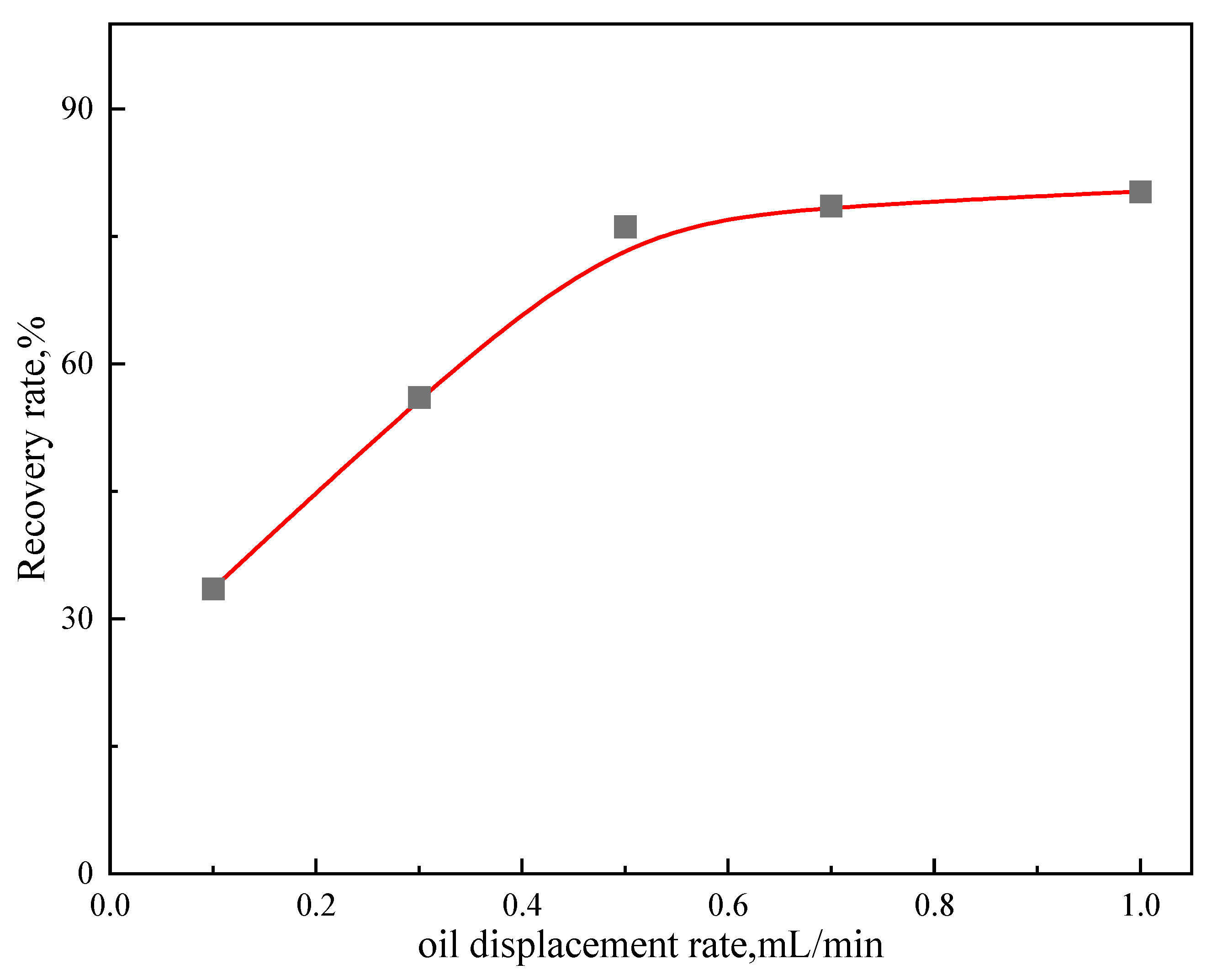

3.1.2. Effects of Different Displacement Rates on Fracture Propagation

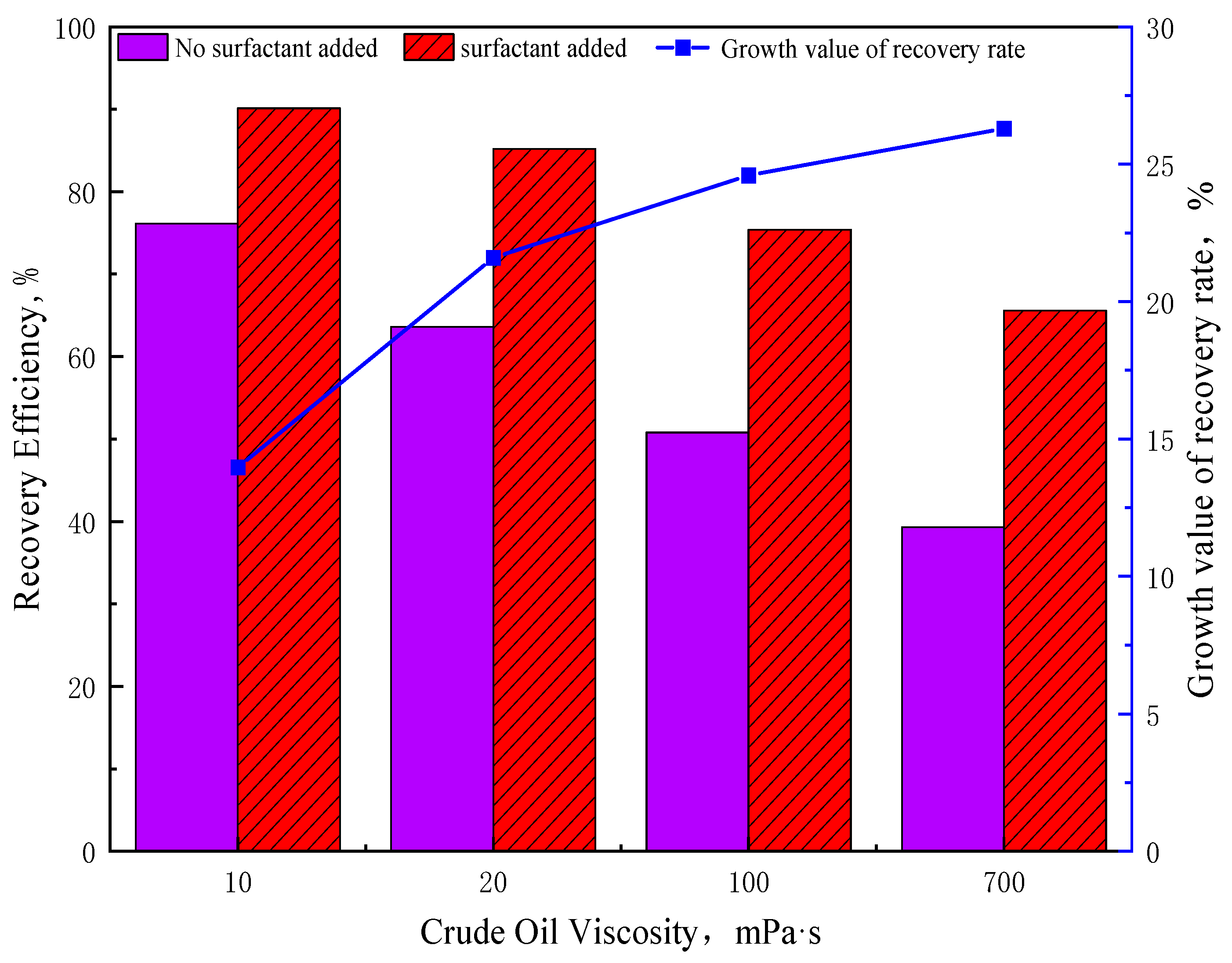

3.1.3. Effects of Crude Oil Viscosity on Fracture Propagation

3.2. Propagation Patterns of Fractures in Rock After Pressure Flooding

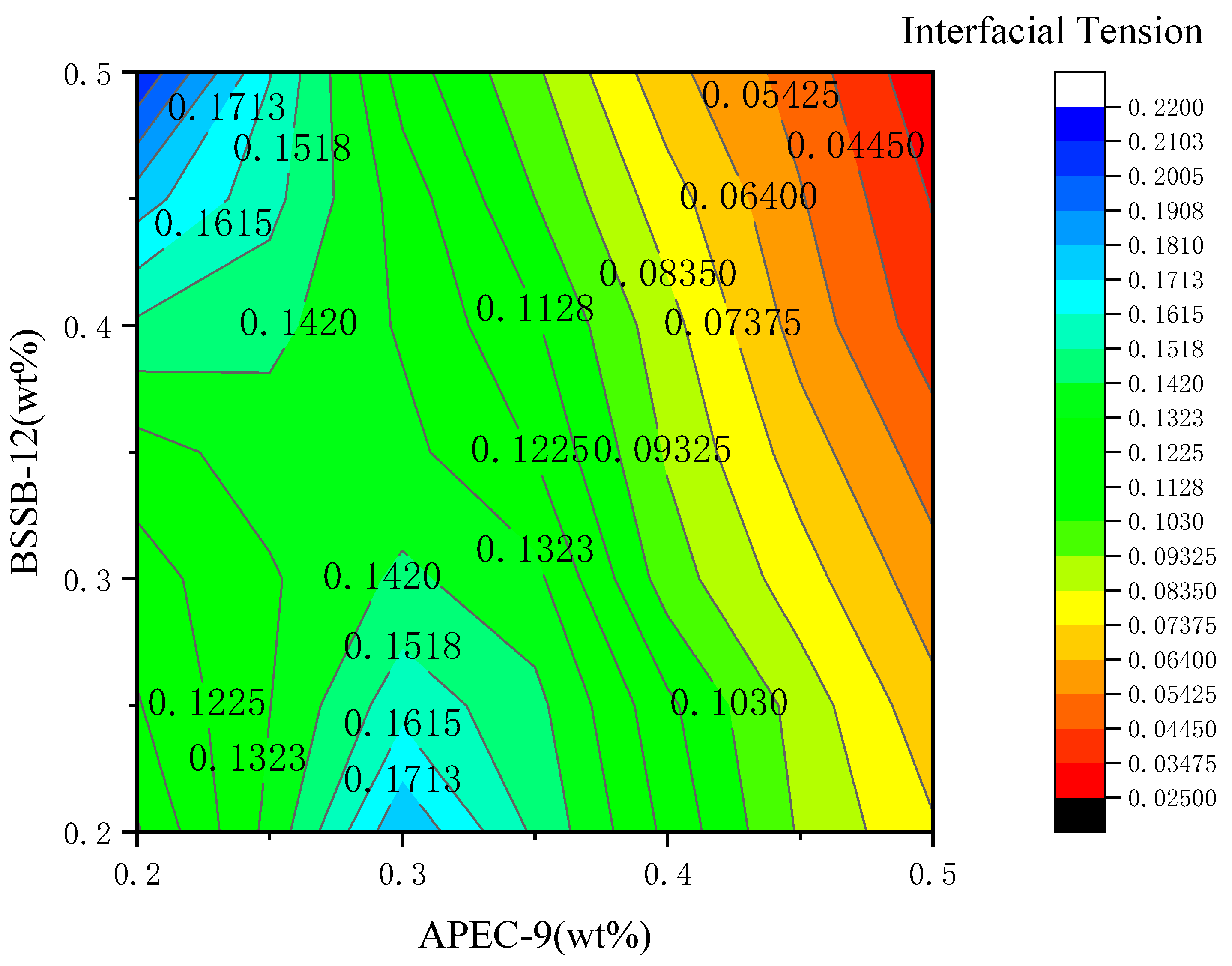

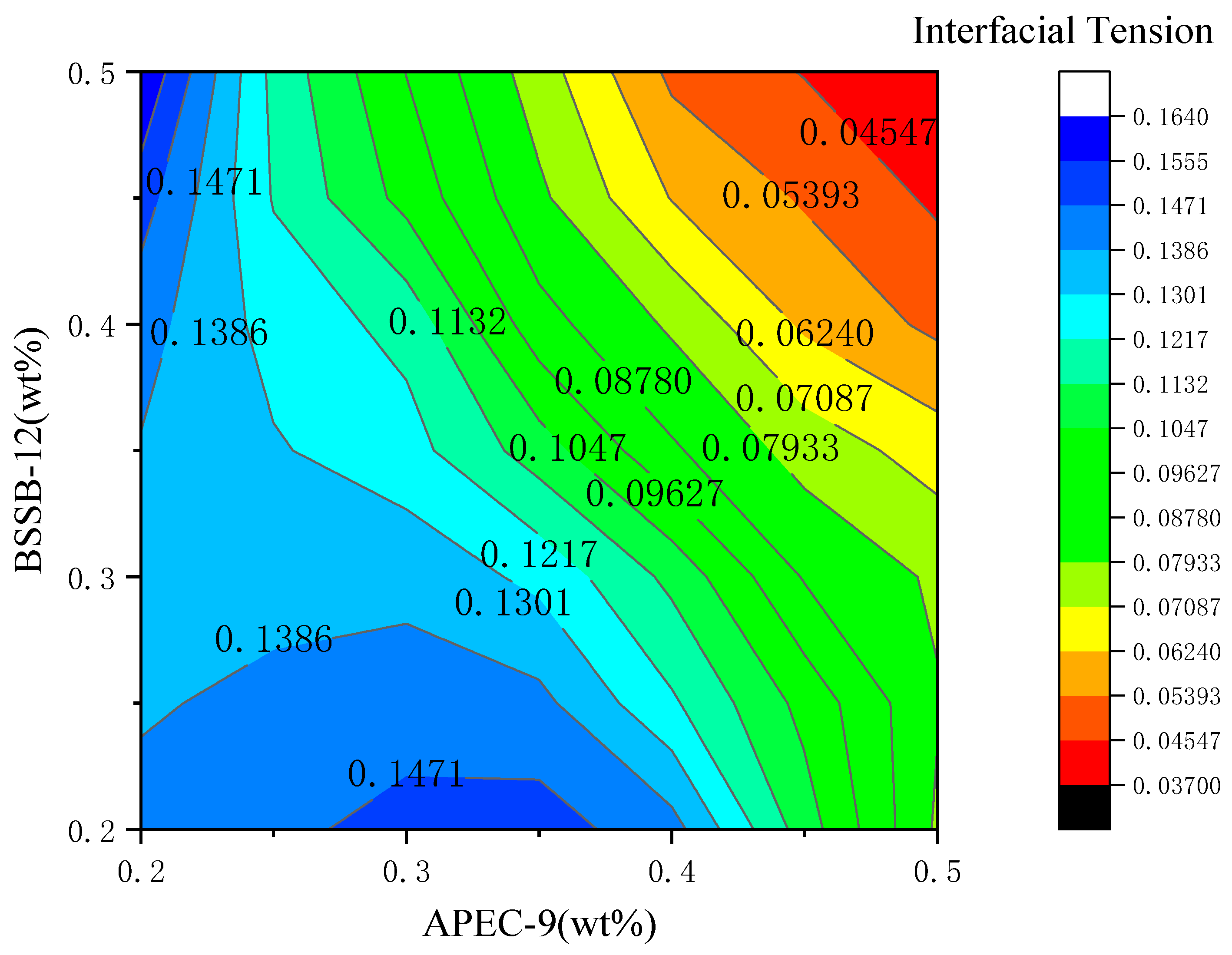

3.3. Screening and Evaluation of Temperature- and Salt-Resistant Surfactant System

3.3.1. Surfactant System Screening

3.3.2. Stability Evaluation of Surfactant System

3.3.3. Performance of Surfactant System in Pressure Flooding

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, H.; Cai, Z.X.; Hao, F.; Hu, W.G.; Lu, X.B.; Wang, Y. Hypogenic origin of paleocaves in the Ordovician carbonates of the southern Tahe oilfield, Tarim basin, northwest China. Geoenergy Sci. Eng. 2023, 225, 211669. [Google Scholar] [CrossRef]

- Zhu, Z.J.; Kang, Z.H.; Chen, H.X.; Wu, F.; Wang, L.; Wang, B.S.; Wei, P.F.; Hou, H.Y. Analysis of the filling patterns and reservoir development models of the Ordovician paleokarst reservoirs in the tahe oilfield. Mar. Pet. Geol. 2024, 161, 106690. [Google Scholar] [CrossRef]

- Zhang, W.B.; Duan, T.Z.; Li, M.; Zhao, H.W.; Shang, X.F.; Wang, Y. Architecture characterization of Ordovician fault-controlled paleokarst carbonate reservoirs in Tuoputai, Tahe oilfield, Tarim Basin, NW China. Pet. Explor. Dev. 2021, 48, 367–380. [Google Scholar] [CrossRef]

- Liu, Y.K.; Wang, F.J.; Wang, Y.H.; Wang, Y.M.; Li, B.H.; Zhang, D.; Yang, G.; Zhi, J.Q.; Sun, S.; Wang, X.; et al. The mechanism of hydraulic fracturing assisted oil displacement to enhance oil recovery in low and medium permeability reservoirs. Pet. Explor. Dev. 2022, 49, 864–873. [Google Scholar] [CrossRef]

- Lin, F.Z.; Tan, C.; Cai, H. Application of Fracturing and Oil Displacement New Technology in Three Types of Oil Reservoirs. Chem. Eng. Equip. 2019, 1, 139–140. [Google Scholar] [CrossRef]

- Shen, H.W.; Ma, Y.C.; Wang, Y.L.; Niu, J.L.; Liu, K.; He, Y.M. Application of integrated technology for water injection and flooding in tight sandstone reservoirs. Petrochem. Appl. 2023, 42, 76–78. [Google Scholar]

- Zhang, Y.F.; Yang, Y.; Sun, Z.G.; Yu, C.L.; S, Q.; Bei, J.P. Physical simulation of pressure flooding and quantitative characterization of fractures in low-permeability reservoirs. Oil Gas Geol. Recovery 2022, 29, 143–149. [Google Scholar]

- Guo, J.C.; Ma, L.; Lu, C. Progress and Development Direction of Fracturing and Oil Displacement Technology in China's Tight Oil Reservoirs. Acta Pet. Sin. 2022, 43, 1788–1797. [Google Scholar]

- Zhang, Y.; Cheng, Y. Feasibility of tapping the remaining potential of pressure plugging after polymer flooding in Lamadian Oilfield, Daqing. Daqing Pet. Geol. Dev. 2022, 41, 109–116. [Google Scholar]

- Cui, C.Z.; Wang, J.K.; Wu, Z.W.; Sui, Y.F.; Li, J.; Lu, S.Q.S. Establishment and Application of Dynamic Fracture Model for Pressure Drive in Tight Oil Reservoirs. Spec. Oil Gas Reserv. 2023, 30, 87–95. [Google Scholar]

- Soomro, N.A. Enhanced oil recovery in high-temperature shale reservoirs using ionic surfactant blends. J. Mol. Liq. 2024, 414, 126221. [Google Scholar] [CrossRef]

- Panthi, K.; Mohanty, K.K. Surfactant-polymer flood with seawater for a high temperature carbonate reservoir. Colloids Surf. A Physicochem. Eng. Asp. 2024, 688, 133615. [Google Scholar] [CrossRef]

- Wu, X.L.; Hou, Z.W.; Wang, H.F.; Yang, Y.; Liu, X.M.; Chen, Z.; Cui, Z.G. Synergistic effects between anionic surfactant SDS and hydrophilic silica nanoparticles in improving foam performance for foam flooding. J. Mol. Liq. 2023, 390, 123156. [Google Scholar] [CrossRef]

- Wang, W.; Liang, M.Y.; Lang, J.Q.; Liang, M.Y.; Lang, J.Q.; Mtui, H.I.; Yang, S.Z.; Mu, B.Z. A new bio-based zwitterionic surfactant with strong interfacial activity at high temperature for enhanced oil recovery. Green Mater. 2023, 2200070. [Google Scholar]

- Saw, R.K.; Rane, P.M.; Joshi, D.; Prakash, S.; Jangid, L.; Mandal, A. Enhanced oil recovery using a novel non-ionic surfactant synthesized from olive oil: Performance and synergistic effects. J. Mol. Liq. 2023, 392, 123452. [Google Scholar] [CrossRef]

- Massarweh, O.; Abushaikha, A.S. Application of surfactants in enhancing oil recovery from tight carbonates: Physicochemical properties and core flooding experiments. Geoenergy Sci. Eng. 2023, 221, 211400. [Google Scholar] [CrossRef]

- Liu, J.B.; Zhong, L.G.; Hao, T.C.; Liu, Y.G.; Zhang, S.J. Pore-scale dynamic behavior and displacement mechanisms of surfactant flooding for heavy oil recovery. J. Mol. Liq. 2022, 349, 118207. [Google Scholar] [CrossRef]

- Tan, F.Q.; Ma, C.M.; Qin, J.H.; Li, X.K.; Liu, W.T. Factors influencing oil recovery by surfactant–polymer flooding in conglomerate reservoirs and its quantitative calculation method. Pet. Sci. 2022, 19, 1198–1210. [Google Scholar] [CrossRef]

- Nezhad, M.S.; Wood, D.A.; Sadatshojaei, E.; Esmaeilzadeh, F. New insight to experimental study of ionic solutions with a non-ionic surfactant on wettability, interfacial tension and micro-model flooding. Fuel 2021, 285, 119126. [Google Scholar] [CrossRef]

- Li, L.J.; Ge, J.J.; Chen, P.F.; Chu, P.J.; Zhang, Z.Y.; Xu, S.Y.; Zhou, X.Y. Hydroxysulfobetaine foamer for potential mobility control application in high-temperature and ultra-high salt reservoirs. Geoenergy Sci. Eng. 2024, 241, 213167. [Google Scholar] [CrossRef]

- Pei, H.H.; Liu, Y.; Shan, J.L.; Zhao, J.W.; Zhang, J.; Wu, Y.H.; Zhang, G.C. Enhancement of in-situ emulsification performance through the synergistic effects of zwitterionic and nonionic-anionic surfactants to improve heavy oil recovery. J. Mol. Liq. 2024, 410, 125562. [Google Scholar] [CrossRef]

- Al-Azani, K.; Abu-Khamsin, S.; Alotaibi, M.; Hussain, S.M.S.; Fahmi, M.; Patil, S. Synergistic performance of an in-house synthesized cationic Gemini surfactant for enhanced oil recovery under harsh conditions. Fuel 2024, 374, 132359. [Google Scholar] [CrossRef]

- Pu, E.Z.; Wang, X.C.; Zhong, C.R.; He, X.G.; Zhu, X. Modification of a hybrid fluoro-surfactant containing double fluorocarbon chains on the carbonate and shale rocks for the wettability reduction of water and oil. Geoenergy Sci. Eng. 2024, 240, 213009. [Google Scholar] [CrossRef]

- Lei, X.T.; Liu, B.J.; Hou, Q.F.; Wang, Y.Y.; Ahmadi, M.; Liu, Z.L.; Chen, Z.X. Switchability and synergistic effect of a CO2-responsive surfactant with co-surfactants at an O/W interface: A molecular insight. J. Mol. Liq. 2024, 405, 125051. [Google Scholar] [CrossRef]

- Bian, S.W.; Liu, P.; Mao, Z.Q.; Huang, W.H.; Zhu, Y.W.; Zhang, L.; Hou, Y.; Zhang, L. Studying the factors determining the ultralow interfacial tensions of betaine solutions against crude oil. Colloids Surf. A Physicochem. Eng. Asp. 2024, 686, 133453. [Google Scholar] [CrossRef]

- Liu, Z.L.; Liu, P.; Hei, Y.X.; Shi, D.; Guo, F.Z.; Li, X.; Leng, W.X.; Lv, Q.C.; Sun, W.C. Synergistic mechanism in anionic/zwitterionic and anionic/nonionic surfactant mixtures on improving the thermal stability of emulsions: An experimental and simulation study. Chem. Eng. Sci. 2024, 289, 119824. [Google Scholar] [CrossRef]

- Yang, J.W.; Wu, T.J.; Liu, Q.N.; Huang, H.; Chen, S.J.; Chen, G. Research of a fracturing-oil displacement integrated working fluid based on betaine surfactant. Colloids Surf. A Physicochem. Eng. Asp. 2024, 686, 133371. [Google Scholar] [CrossRef]

- Wu, H.R.; Tan, R.; Hong, S.P.; Zhou, Q.; Liu, B.Y.; Chang, J.W.; Luan, T.F.; Kang, N.; Hou, J.R. Synergistic anionic/zwitterionic mixed surfactant system with high emulsification efficiency for enhanced oil recovery in low permeability reservoirs. Pet. Sci. 2024, 21, 936–950. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Dai, C.L.; Liu, J.W.; Dong, Y.B.; Liu, J.M.; Sun, N.; Li, L. Anionic-nonionic and nonionic mixed surfactant systems for oil displacement: Impact of ethoxylate chain lengths on the synergistic effect. Colloids Surf. A Physicochem. Eng. Asp. 2023, 678, 132436. [Google Scholar] [CrossRef]

- Li, L.; Sun, Y.; Liu, J.W.; Wang, Z.Z.; Wu, Y.N.; Zhao, M.W.; Dai, C.L. Zwitterionic-nonionic compound surfactant system with low chromatographic separation effect for enhanced oil recovery. J. Mol. Liq. 2023, 390, 123004. [Google Scholar] [CrossRef]

- Noruzi, Y.; Sharifi, M.; Fahimpour, J.; Fahimpour, J.; Sabet, M.; Akbari, M.; Hosseini, S. The State-of-the-Art of wettability alteration in sandstones and Carbonates: A mechanistic review. Fuel 2024, 356, 129570. [Google Scholar] [CrossRef]

- Wei, Z.Y.; Fan, H.M.; Zhang, J.Z.; Liu, S.D.; Yang, Y.H.; Yang, L.Y.; Liu, S.; Li, J.H.; Liu, J.Y. Synergistic effects of surfactant and polymer on the viscosity and oil displacement efficiency. Colloids Surf. A Physicochem. Eng. Asp. 2023, 676, 132245. [Google Scholar] [CrossRef]

- Torabi, F.; Gandomkar, A. Experimental Evaluation of CO2-Soluble Nonionic Surfactants for Wettability Alteration to Intermediate CO2-Oil Wet during Immiscible Gas Injection. SPE J. 2024, 29, 5071–5086. [Google Scholar] [CrossRef]

- Ge, X.J.; Imqam, A. How Anions and Cations Impact the Viscosity and Viscoelasticity of High-Viscosity Friction Reducers. SPE J. 2024, 29, 1076–1090. [Google Scholar] [CrossRef]

- Ataceri, I.Z.; Saputra, I.W.R.; Bagareddy, A.R.; Elkady, M.H.; Schechter, D.S.; Haddix, G.W.; Brock, V.A.; Raney, K.H.; Strickland, C.W.; Morris, G.R. Surfactant Enhanced Oil Recovery Improves Oil Recovery in a Depleted Eagle Ford Unconventional Well: A Case Study. SPE J. 2023, 28, 3180–3191. [Google Scholar] [CrossRef]

- Somoza, A.; Rodríguez-Cabo, B.; Barrio, I.; García-Mayoral, M.F.; Soto, A. Experimental Evaluation of Blends Containing Lineal Alkylbenzene Sulfonates for Surfactant Flooding in Carbonate Reservoirs. SPE Reserv. Eval. Eng. 2023, 26, 1309–1322. [Google Scholar] [CrossRef]

- Sofi, A.; Wang, J.; Salaün, M.; Rousseau, R.; Morvan, M.; Ayirala, S.C. Smartwater Synergy with Chemical EOR: Studying the Potential Synergy with Surfactants. SPE Reserv. Eval. Eng. 2023, 26, 737–747. [Google Scholar] [CrossRef]

- Wang, X.Z.; Zhou, J.M.; Pang, J.Q.; Mohanty, K.K. Nanoparticle-Surfactant Stabilized Strong Foam for Enhanced Oil Recovery in High-Salinity Fractured Carbonate Reservoirs. SPE J. 2023, 28, 1097–1107. [Google Scholar] [CrossRef]

- Xu, L.M.; Han, M.; Cao, D.Q.; Fuseni, A. Catanionic Surfactants for Improving Oil Production in Carbonate Reservoirs. SPE Reserv. Eval. Eng. 2023, 26, 88–98. [Google Scholar] [CrossRef]

- Shi, Y.; Mohanty, K.; Panda, M. Coreflood Tests to Evaluate Enhanced Oil Recovery Potential of Wettability-Altering Surfactants for Oil-Wet Heterogeneous Carbonate Reservoirs. SPE J. 2022, 27, 2882–2894. [Google Scholar] [CrossRef]

- Ding, B.X.; Sang, Q.; Nie, Z.Q.; Li, Z.W.; Dong, M.Z.; Chen, Z.X.; Kantzas, A. An Improved Study of Emulsion Flooding for Conformance Control in a Heterogeneous 2D Model with Lean Zones. SPE J. 2021, 26, 3094–3108. [Google Scholar] [CrossRef]

- Shi, Y.; Miller, C.; Mohanty, K. Surfactant-Aided Low-Salinity Waterflooding for Low-Temperature Carbonate Reservoirs. SPE J. 2021, 26, 2214–2230. [Google Scholar] [CrossRef]

- Thakur, G. Enhanced Recovery Technologies for Unconventional Oil Reservoirs. J. Pet. Technol. 2019, 71, 66–69. [Google Scholar] [CrossRef]

- Carpenter, C. Soaking Flowback with Surfactant Improves Oil Recovery in Unconventional Reservoirs. J. Pet. Technol. 2018, 70, 56–60. [Google Scholar] [CrossRef]

- Olayiwola, S.O.; Dejam, M. Synergistic interaction of nanoparticles with low salinity water and surfactant during alternating injection into sandstone reservoirs to improve oil recovery and reduce formation damage. J. Mol. Liq. 2020, 317, 114228. [Google Scholar] [CrossRef]

- Kang, C.Y.; Wu, J.; Zheng, Y.C.; Lei, L. Studies on the surface properties and microaggregates of cationic/anionic surfactant mixtures based on sulfonate gemini surfactant. J. Mol. Liq. 2020, 320, 114431. [Google Scholar] [CrossRef]

- Khayati, H.; Moslemizadeh, A.; Shahbazi, K.; Shahbazi, K.; Moraveji, M.K.; Riazi, S.H. An experimental investigation on the use of saponin as a non-ionic surfactant for chemical enhanced oil recovery (EOR) in sandstone and carbonate oil reservoirs: IFT, wettability alteration, and oil recovery. Chem. Eng. Res. Des. 2020, 160, 417–425. [Google Scholar] [CrossRef]

- Ahmadi, Y.; Mansouri, M. An experimental investigation of using Ni-doped ZnO–ZrO2 nanoparticles as a new asphaltene deposition inhibitor in ultra low carbonate porous media. Energy Sources 2022, 44, 9429–9447. [Google Scholar] [CrossRef]

- Li, Q.; Liu, L.F.; Sun, D.J.; Xu, Z.H. Recent advances in switchable surfactants for heavy oil production: A review. Energy Geosci. 2024, 5, 100342. [Google Scholar] [CrossRef]

- GB/T 22235-2008; Determination of Liquid Viscosity. Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

| Crude Oil Viscosity, mPa·s | Sewing Injection Speed, mL/min | Oil Displacement Injection Speed, mL/min | Recovery Efficiency, % |

|---|---|---|---|

| 10 | 8 | 0.5 | 76.15 |

| 20 | 8 | 0.5 | 63.6 |

| 100 | 8 | 0.5 | 50.8 |

| 700 | 8 | 0.5 | 39.3 |

| Pressure Flooding Speed/mL/min | Pre-Pressure Permeability/mD | Permeability After Pressure Flooding/mD | Recovery Efficiency/% |

|---|---|---|---|

| 8 | 0.0084 | 1.679 | 76.15 |

| 8 | 0.0072 | 1.592 | 90.12 |

| Crude Oil Viscosity/mPa·s | Sewing Injection Speed/mL/min | Oil Displacement Injection Speed/mL/min | Recovery Efficiency/% | Growth Value of Recovery Rate/% |

|---|---|---|---|---|

| 10 | 8 | 0.5 | 90.12 | 13.97 |

| 20 | 8 | 0.5 | 85.2 | 21.6 |

| 100 | 8 | 0.5 | 75.4 | 24.6 |

| 700 | 8 | 0.5 | 65.6 | 26.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Zhang, W.; Qu, B.; Zhen, E.; Qian, Z.; Ma, S.; Qin, F.; You, Q. Physical Modeling of High-Pressure Flooding and Development of Oil Displacement Agent for Carbonate Fracture-Vuggy Reservoir. Processes 2025, 13, 71. https://doi.org/10.3390/pr13010071

Li J, Zhang W, Qu B, Zhen E, Qian Z, Ma S, Qin F, You Q. Physical Modeling of High-Pressure Flooding and Development of Oil Displacement Agent for Carbonate Fracture-Vuggy Reservoir. Processes. 2025; 13(1):71. https://doi.org/10.3390/pr13010071

Chicago/Turabian StyleLi, Jinghui, Wen Zhang, Bochao Qu, Enlong Zhen, Zhen Qian, Shufen Ma, Fei Qin, and Qing You. 2025. "Physical Modeling of High-Pressure Flooding and Development of Oil Displacement Agent for Carbonate Fracture-Vuggy Reservoir" Processes 13, no. 1: 71. https://doi.org/10.3390/pr13010071

APA StyleLi, J., Zhang, W., Qu, B., Zhen, E., Qian, Z., Ma, S., Qin, F., & You, Q. (2025). Physical Modeling of High-Pressure Flooding and Development of Oil Displacement Agent for Carbonate Fracture-Vuggy Reservoir. Processes, 13(1), 71. https://doi.org/10.3390/pr13010071