Novel Scaling Prediction Model for Gathering and Transportation Station in Changqing Oilfield

Abstract

1. Introduction

2. Oilfield Description

3. Data Preparation

4. Methodologies

4.1. Materials

4.2. Composition Analysis of Water and Scale

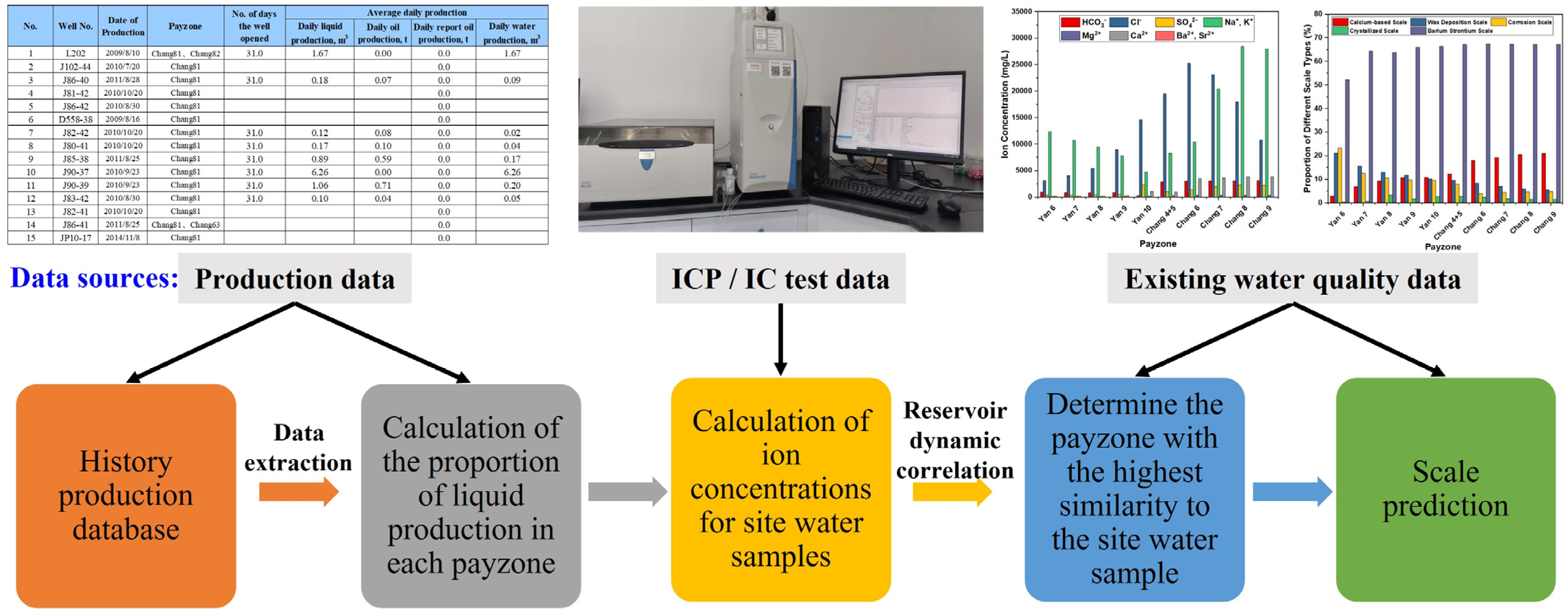

4.3. Scale Prediction Modeling

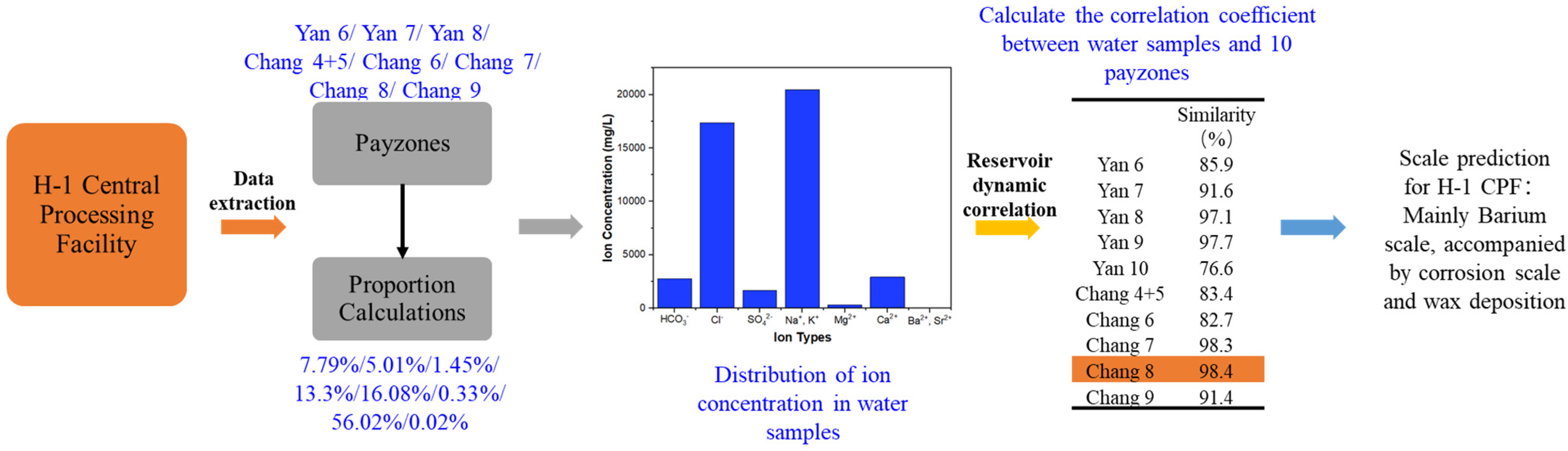

Reservoir Dynamic Correlation Method

5. Results and Discussion

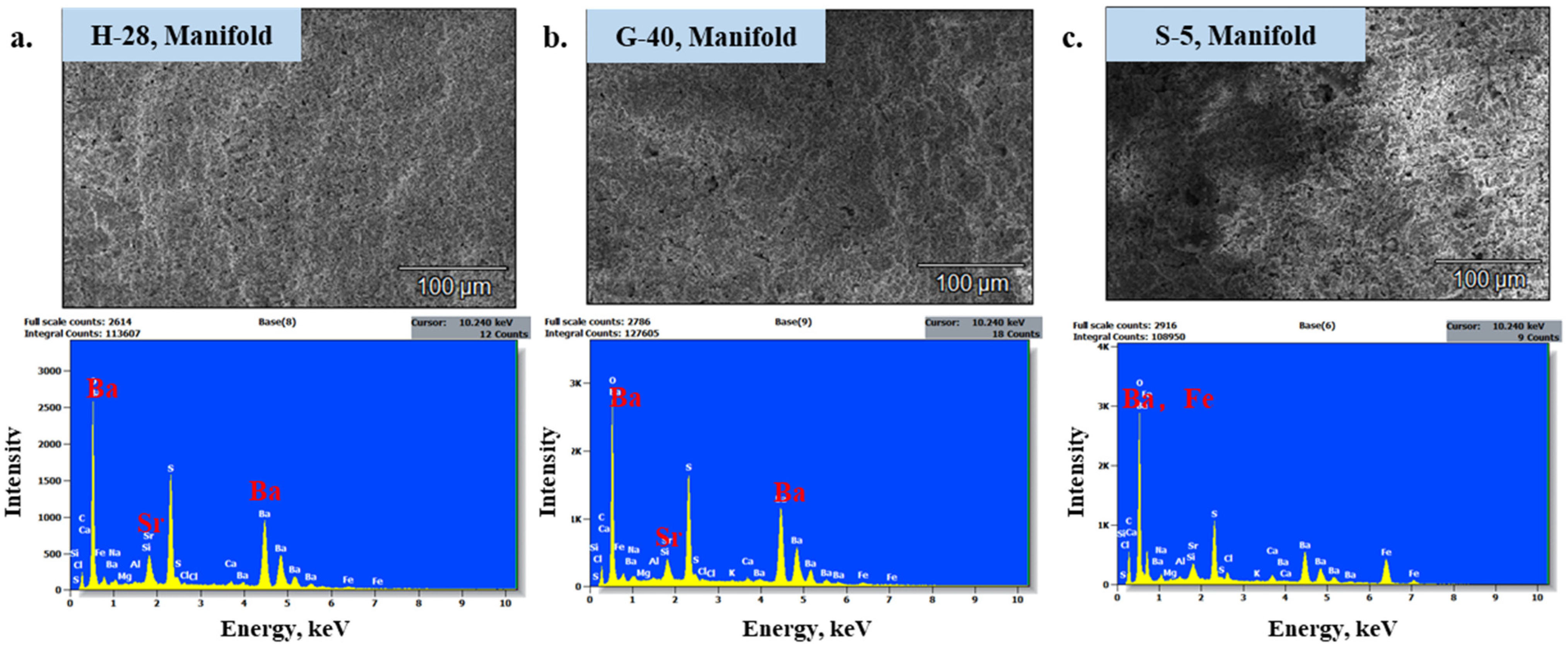

5.1. Composition of Water and Scale Samples

5.2. Scale Characteristics and Scale Mechanisms

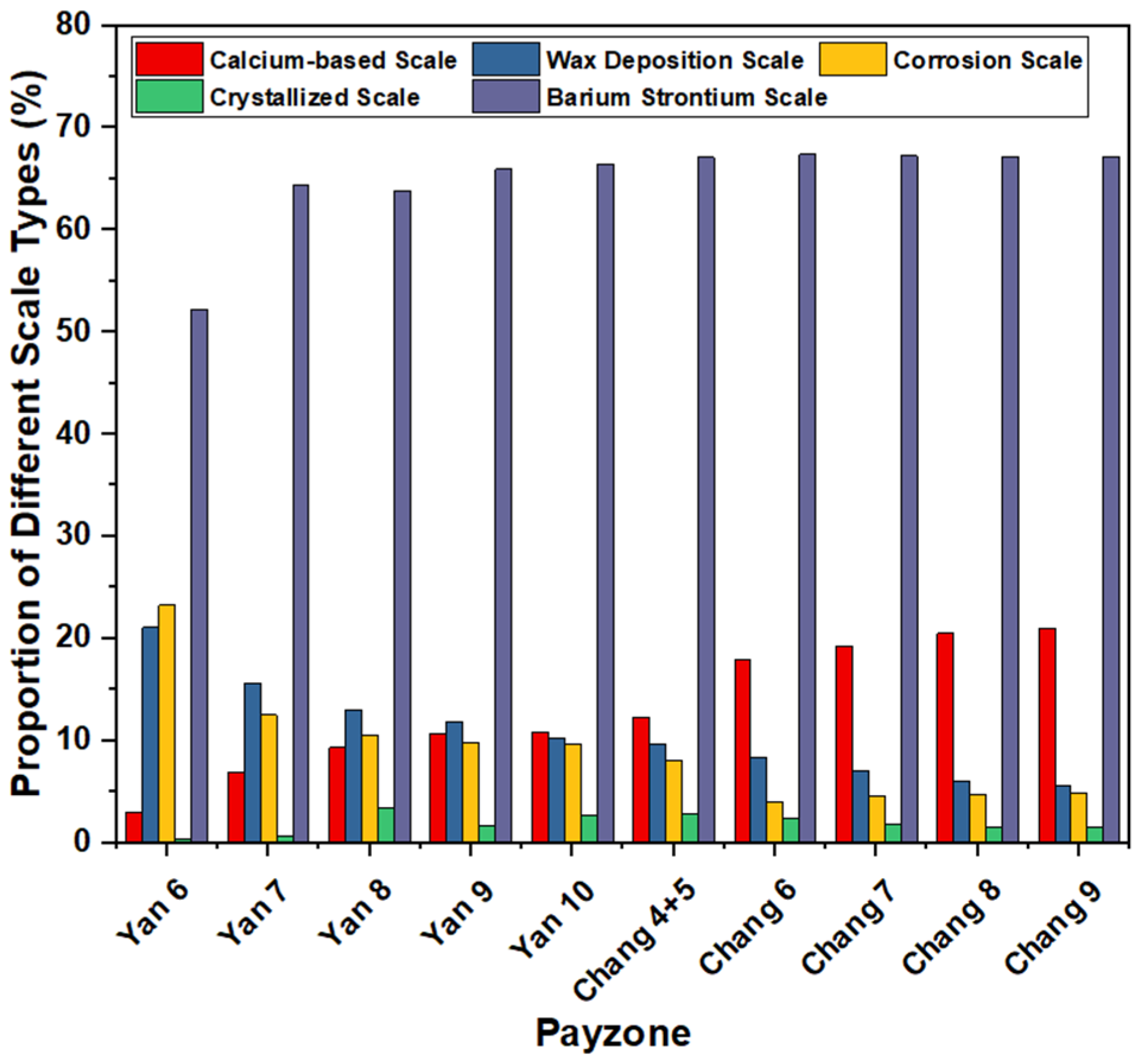

5.3. Scale Prediction

6. Conclusions

- (1)

- Through testing and analysis of water and scale samples from gathering and transportation stations, it was found that for different gathering and transportation stations, the main type of scale sample is barium strontium scale, accompanied by corrosion scale. There are many barium strontium scales and corrosion scales in the main control station, and the heating furnace and export pump are mainly composed of corrosion scales, accompanied by barium strontium scales.

- (2)

- Based on the analysis results of 100 water samples, this study divided the water quality types of produced water in Changqing Oilfield into 10 categories, and analyzed a total of 120 corresponding scale samples. A ‘payzone-scale’ correspondence chart was constructed.

- (3)

- A scale type prediction model for Changqing Oilfield was constructed based on oilfield production data, reservoir dynamic correlation analysis, and water type scale type. The effectiveness of the prediction model was verified through the analytical results of water samples and scale samples from the gathering and transportation station.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Olajire, A.A. A review of oilfield scale management technology for oil and gas production. J. Pet. Sci. Eng. 2015, 135, 723–737. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, X.; Zhang, J.; He, X.; Kang, S.; Pu, J.; Fan, S.; Li, X. Experimental and statistical study on wellbore scaling mechanisms and characteristics for Huanjiang Oilfield. Geofluids 2022, 2022, 9068440. [Google Scholar] [CrossRef]

- Su, X.; Zhou, D.; Wang, H.; Xu, J. Research on the scaling mechanism and countermeasures of tight sandstone gas reservoirs based on nachinelearning. Processes 2024, 12, 527. [Google Scholar] [CrossRef]

- Abdulhussein, Z.A.; Al-Sharify, Z.T.; Alzuraiji, M.; Onyeaka, H. Environmental impact of fouling for crude oil flow in preheat pipes according to oil blends. Heliyon 2023, 9, e21999. [Google Scholar] [CrossRef] [PubMed]

- Spinthaki, A.; Demadis, K.D. Chemical methods for scaling control. In Corrosion and Fouling Control in Desalination Industry; Saji, V.S., Meroufel, A.A., Sorour, A.A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 307–342. [Google Scholar]

- Li, A.; Zhang, H.; Liu, Q.; Zeng, H. Effects of chemical inhibitors on the scaling behaviors of calcite and the associated surface interaction mechanisms. J. Colloid Interface Sci. 2022, 618, 507–517. [Google Scholar] [CrossRef]

- Leal, J.; Nunez, W.; Al-Ismail, S.; Solares, J.R.; Ramanathan, V. Novel mechanical scale clean-out approach to remove iron sulphide scale from tubulars in vertical high pressure and temperature deep gas producers: A case history. In Proceedings of the EUROPEC/EAGE Conference and Exhibition, Amsterdam, The Netherlands, 8–11 June 2009. [Google Scholar]

- Green, T.A.; Leal Jauregui, J.A.; Ginest, N.H.; Al-Bu Ali, M.S.; Vielma, J.R.; Chacon, A. Challenging HPCT scale removal op-erations in high H2S environment successfully completed with interdisciplinary job design and execution. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 10–13 November 2014. [Google Scholar]

- Tian, Y.; Uzun, O.; Shen, Y.; Lei, Z.; Yuan, J.; Chen, J.; Kazemi, H.; Wu, Y.S. Feasibility study of gas injection in low permeability reservoirs of Changqing oilfield. Fuel 2020, 274, 117831. [Google Scholar] [CrossRef]

- He, J.; Yu, H.; He, G.; Zhang, J.; Li, Y. Natural gas development prospect in Changqing gas province of the Ordos Basin. Nat. Gas Ind. B 2022, 9, 197–208. [Google Scholar] [CrossRef]

- SY/T 5523-2016; Method for Analysis of Oilfield Water. National Energy Administration: Beijing, China, 2016.

- SY/T 5329-2012; Water Quality Standard and Practice for Analysis of Oilfield Injecting Waters in Clastic Reservoirs. National Energy Administration: Beijing, China, 2012.

- Fang, X.; Feng, H.; Zhang, Z.; Li, F. Brittleness index prediction method of tight reservoir based on grey correlation and analytic hierarchical process. Pet. Sci. Technol. 2024, 42, 2495–2519. [Google Scholar] [CrossRef]

- Jakubowicz, P.; Steliga, T.; Wojtowicz, K. Analysis of temperature influence on precipitation of secondary sediments during water injection into an absorptive well. Energies 2022, 15, 9130. [Google Scholar] [CrossRef]

| Stations | No. of Samples | Ba | Ca | Fe | Mg | Na | S | Si | Cl | Water Type |

|---|---|---|---|---|---|---|---|---|---|---|

| HZ-54 | 1 | 6.8 | 611.8 | 3.7 | 70.6 | 7209.9 | 24.4 | 29.4 | 11,025.0 | CaCl2 |

| HZ-49 | 1 | 7.9 | 790.2 | 26.4 | 57.4 | 2373.1 | 222.7 | 18.8 | 5268.7 | CaCl2 |

| HZ-12 | 4 | 14.4 | 947.9 | 108.6 | 214.7 | 12,669.9 | 298.5 | 44.8 | 33,701.3 | CaCl2 |

| HZ-29 | 1 | 0.8 | 169.4 | 11.6 | 59.0 | 10,536.3 | 1672.8 | 15.1 | 9568.1 | Na2SO4 |

| HZ-28 | 1 | 1.2 | 7.3 | 1.2 | 1.5 | 68.4 | 41.5 | 5.0 | 27.2 | Na2SO4 |

| HZ-44 | 1 | 3.3 | 6.7 | 6.9 | 1.4 | 36.6 | 55.6 | 4.7 | 30.5 | NaHCO3 |

| H-1 | 3 | 20.4 | 1399.1 | 219.6 | 241.1 | 13,927.9 | 230.2 | 46.8 | 26,217.6 | CaCl2, NaHCO3 |

| HZ-35 | 5 | 18.0 | 5.7 | 24.1 | 0.5 | 21.1 | 150.2 | 4.2 | 33.7 | CaCl2 |

| HZ-55 | 5 | 0.2 | 8.3 | 0.4 | 0.4 | 18.7 | 34.0 | 9.5 | 28.0 | CaCl2 |

| HZ-5 | 2 | 6.0 | 603.5 | 27.4 | 77.6 | 100.7 | 100.8 | 54.2 | 38.4 | Na2SO4 |

| HZ-8 | 7 | 0.5 | 1128.9 | 0.6 | 138.9 | 7002.7 | 349.6 | 18.3 | 16,124.4 | CaCl2 |

| Stations | Site | C | O | Na | Mg | Al | Si | S | Cl | Ca | Fe | Ba | Sr | K | P | Scale Type |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % | % | % | % | % | % | % | % | % | % | % | % | % | % | |||

| HZ-40 | Main control station | 2.87 | 23.5 | 1.13 | 0 | 0.26 | 0.4 | 10.73 | 0.26 | 0.59 | 1.63 | 53.97 | 4.47 | 0.2 | Barium strontium scale | |

| HZ-28 | Main control station | 2.68 | 25.19 | 0.79 | 0 | 0.24 | 0.28 | 11.65 | 0.25 | 0.64 | 1.07 | 50.8 | 6.42 | Barium strontium scale | ||

| HZ-28 | Main control station | 7 | 25.9 | 1.04 | 0 | 0.37 | 0.4 | 10.29 | 0.63 | 1.06 | 11.26 | 35.97 | 6.08 | Barium strontium scale | ||

| BQ-43 | Heater furnace | 3.36 | 29.58 | 0.07 | 0.01 | 0.32 | 1.73 | 2.08 | 0.3 | 1.19 | 60.74 | 0.61 | Corrosion scale | |||

| HZ-1 | Heater outlet | 5.57 | 44.06 | 0.21 | 0.52 | 0.49 | 1.06 | 2.9 | 0.18 | 33.68 | 9.73 | 1.59 | Calcium based scale | |||

| HZ-17 | Buffer tank inlet | 11.58 | 22.04 | 0.92 | 0.01 | 0.3 | 0.39 | 9.77 | 0.5 | 0.94 | 1.6 | 50.13 | 1.8 | Barium strontium scale | ||

| HZ-55 | Main control station to pig receiver | 5.59 | 26.43 | 1.13 | 0.04 | 0.35 | 10.02 | 0.39 | 1.75 | 5.87 | 44.51 | 3.92 | Barium strontium scale | |||

| H-1 | Main control station | 8.46 | 29.23 | 0.95 | 0.15 | 0.79 | 0.81 | 10.39 | 0.41 | 2.3 | 10.6 | 25.52 | 10.11 | 0.28 | Corrosion scale associated with barium strontium scale | |

| H-1 | L38-7 | 8.33 | 25.81 | 3.13 | 0 | 0.25 | 0.24 | 9.17 | 3.09 | 0.68 | 9.33 | 33.46 | 6.51 | Barium strontium scale | ||

| HZ-2 | Main control station to pig receiver | 20.57 | 26.1 | 0.62 | 0.07 | 0.27 | 0.32 | 6.8 | 0.19 | 0.98 | 18.99 | 22.81 | 2.28 | Corrosion scale associated with barium strontium scale | ||

| HZ-2 | Pig receiver to heater furnace | 11.16 | 27.76 | 1.09 | 0.1 | 0.29 | 0.29 | 9.45 | 0.26 | 3 | 3.49 | 38.31 | 4.23 | 0.22 | 0.35 | Barium strontium scale |

| H-1 | L38-31 | 14.18 | 29.3 | 2.02 | 0.07 | 0.05 | 4.97 | 1.56 | 3.68 | 17.82 | 11.03 | 15.32 | Corrosion scale | |||

| H-1 | Pig receiver to heater furnace | 6.96 | 25.76 | 3.24 | 0.04 | 0.24 | 0.64 | 11.59 | 1.12 | 1.2 | 33.82 | 11.2 | 4.19 | Corrosion scale | ||

| H-1 | Main control station | 5.81 | 21.68 | 2.06 | 0.01 | 0.25 | 0.11 | 18.49 | 0.61 | 0.55 | 43.68 | 4.59 | 2.16 | Corrosion scale | ||

| H-1 | Export pump outlet | 11.31 | 26.81 | 2.04 | 0.06 | 1.34 | 11.25 | 0.86 | 0.84 | 22.51 | 17.29 | 5.69 | Corrosion scale associated with barium strontium scale | |||

| H-1 | Export pump inlet | 18.4 | 23.27 | 1.68 | 0.15 | 0.4 | 0.59 | 10.01 | 0.94 | 1.85 | 37.31 | 5.15 | 0.25 | Corrosion scale associated with barium strontium scale | ||

| H-1 | L38-7 | 11.06 | 24.97 | 1.8 | 0.08 | 0.03 | 10.46 | 0.93 | 1.07 | 12.1 | 30.49 | 6.83 | 0.19 | Barium strontium scale | ||

| HZ-43 | Main control station to buffer tank | 5.33 | 28.44 | 0.82 | 0 | 0.38 | 0.41 | 10.39 | 0.78 | 0.94 | 16.09 | 33.72 | 2.69 | Corrosion scale associated with barium strontium scale | ||

| HZ-5 | Main control station | 6.83 | 29.34 | 1.29 | 0.01 | 0.41 | 0.89 | 7.65 | 1.11 | 1.27 | 20.12 | 29.96 | 3.88 | 0.23 | Corrosion scale associated with barium strontium scale | |

| BQ-12-1 | Pig receiver to heater furnace | 20.34 | 23.36 | 0.88 | 0.26 | 0.55 | 8.8 | 0.3 | 0.79 | 1.25 | 43.47 | Barium strontium scale | ||||

| HZ-5 | Heater furnace | 7.05 | 27.53 | 0.95 | 0.18 | 0.29 | 0.47 | 10.67 | 0.18 | 2.29 | 23.84 | 18.9 | 7.64 | Corrosion scale associated with barium strontium scale | ||

| HZ-8 | Pig receiver to heater furnace | 34.48 | 31.1 | 0.62 | 0.54 | 2.05 | 5.12 | 3.58 | 0.33 | 1.22 | 20.13 | 0.3 | 0.52 | Corrosion scale | ||

| HZ-8 | Main control station | 12.16 | 41.09 | 2.06 | 0.85 | 3.65 | 16.36 | 0.68 | 1.96 | 7.96 | 11.69 | 0.11 | 1.42 | Corrosion scale | ||

| HZ-8 | L226-3 | 54.59 | 16.5 | 3.38 | 0.23 | 0.39 | 0.35 | 5.85 | 2.57 | 0.64 | 15.4 | 0.1 | Barium strontium scale | |||

| HZ-8 | L226-4 | 34.44 | 22.9 | 5.6 | 0.19 | 0.45 | 1.32 | 5.31 | 4.75 | 1.81 | 23.12 | 0.12 | Corrosion scale |

| Water Category | Payzone | Water Type | Average Formation Water Salinity (mg/L) | Variance |

|---|---|---|---|---|

| C1 | Yan 6 | NaHCO3 | 17,208 | 126 |

| C2 | Yan 7 | NaHCO3 | 16,569 | 144 |

| C3 | Yan 8 | NaHCO3 | 16,746 | 101 |

| C4 | Yan 9 | CaCl2 | 18,809 | 144 |

| C5 | Yan 10 | CaCl2 | 23,299 | 488 |

| C6 | Chang 4 + 5 | CaCl2 | 33,023 | 365 |

| C7 | Chang 6 | CaCl2 | 44,041 | 342 |

| C8 | Chang 7 | CaCl2 | 52,681 | 117 |

| C9 | Chang 8 | NaHCO3 | 56,121 | 172 |

| C10 | Chang 9 | NaHCO3 | 48,354 | 111 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; You, J.; Zhang, Z.; Dongye, S.; Zhao, J.; Zhang, F.; Zhang, N. Novel Scaling Prediction Model for Gathering and Transportation Station in Changqing Oilfield. Processes 2024, 12, 2915. https://doi.org/10.3390/pr12122915

Liu T, You J, Zhang Z, Dongye S, Zhao J, Zhang F, Zhang N. Novel Scaling Prediction Model for Gathering and Transportation Station in Changqing Oilfield. Processes. 2024; 12(12):2915. https://doi.org/10.3390/pr12122915

Chicago/Turabian StyleLiu, Ting, Jiaqing You, Zheng Zhang, Shengfu Dongye, Jinlin Zhao, Fashi Zhang, and Na Zhang. 2024. "Novel Scaling Prediction Model for Gathering and Transportation Station in Changqing Oilfield" Processes 12, no. 12: 2915. https://doi.org/10.3390/pr12122915

APA StyleLiu, T., You, J., Zhang, Z., Dongye, S., Zhao, J., Zhang, F., & Zhang, N. (2024). Novel Scaling Prediction Model for Gathering and Transportation Station in Changqing Oilfield. Processes, 12(12), 2915. https://doi.org/10.3390/pr12122915