Biochar-Aided Heat Transfer in Ground Source Heat Pumps: Effects on Water Capillary Rise and Carbon Storage Capability

Abstract

1. Introduction

- Vertical probes—borehole heat exchangers (VGPs). They require deep vertical boreholes, installation of casing pipes, use of filler materials and insertion of probes, which can be single U-pipe, double U-pipe and coaxial probes [15]. Therefore, installation is expensive, but heat exchange occurs very efficiently. VGPs require a small surface area field.

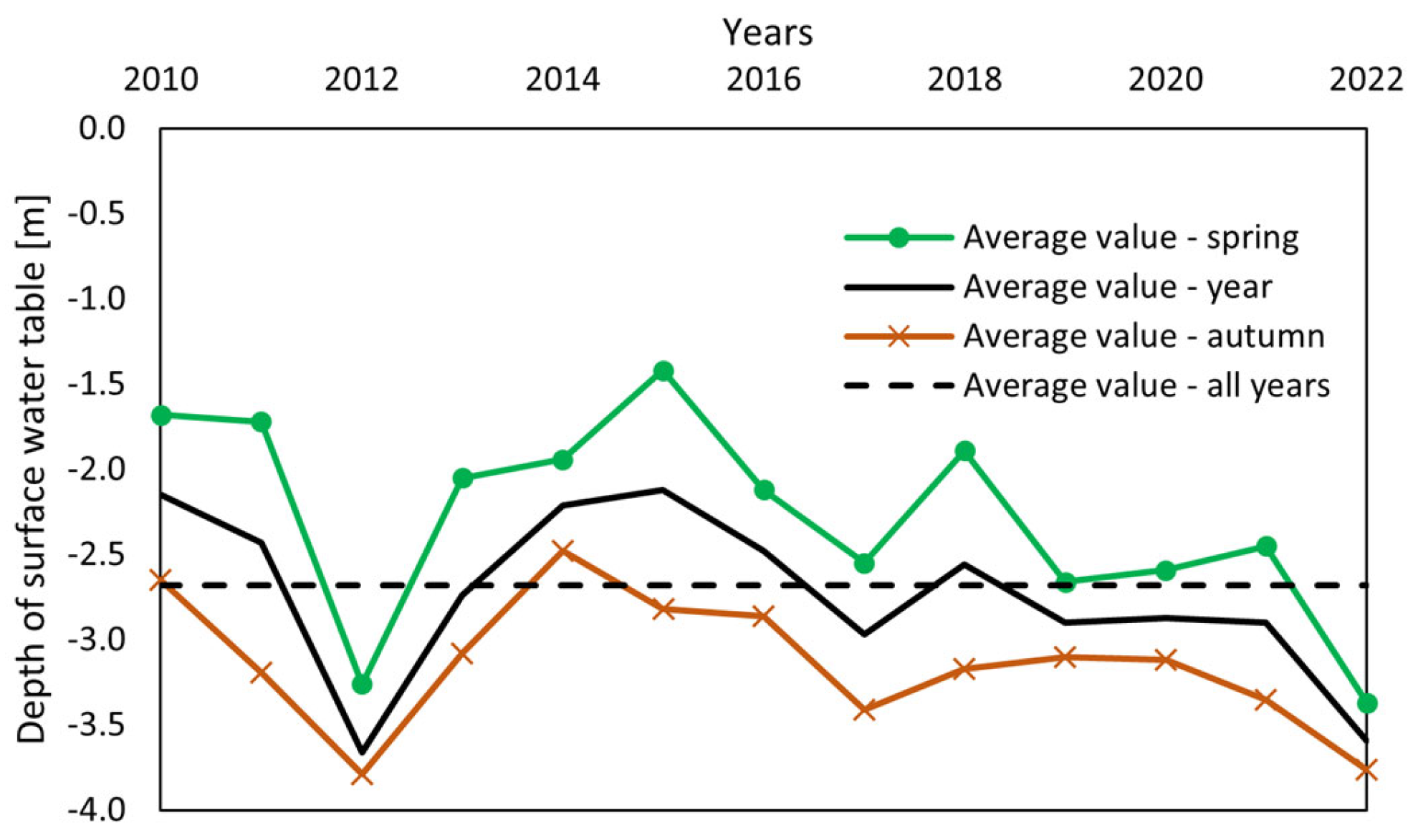

- Horizontal probes—shallow ground heat exchangers (HGPs). They require trenches, usually of high volume. High depths are not reached (1.5 to 2.5 m) but are compensated by high surface areas [16,17]. There are three types of probe distribution: linear distribution, slinky distribution and helical distribution [18]. The cost is lower than VGPs, and the heat transfer efficiency is also lower [19].

2. Materials and Methods

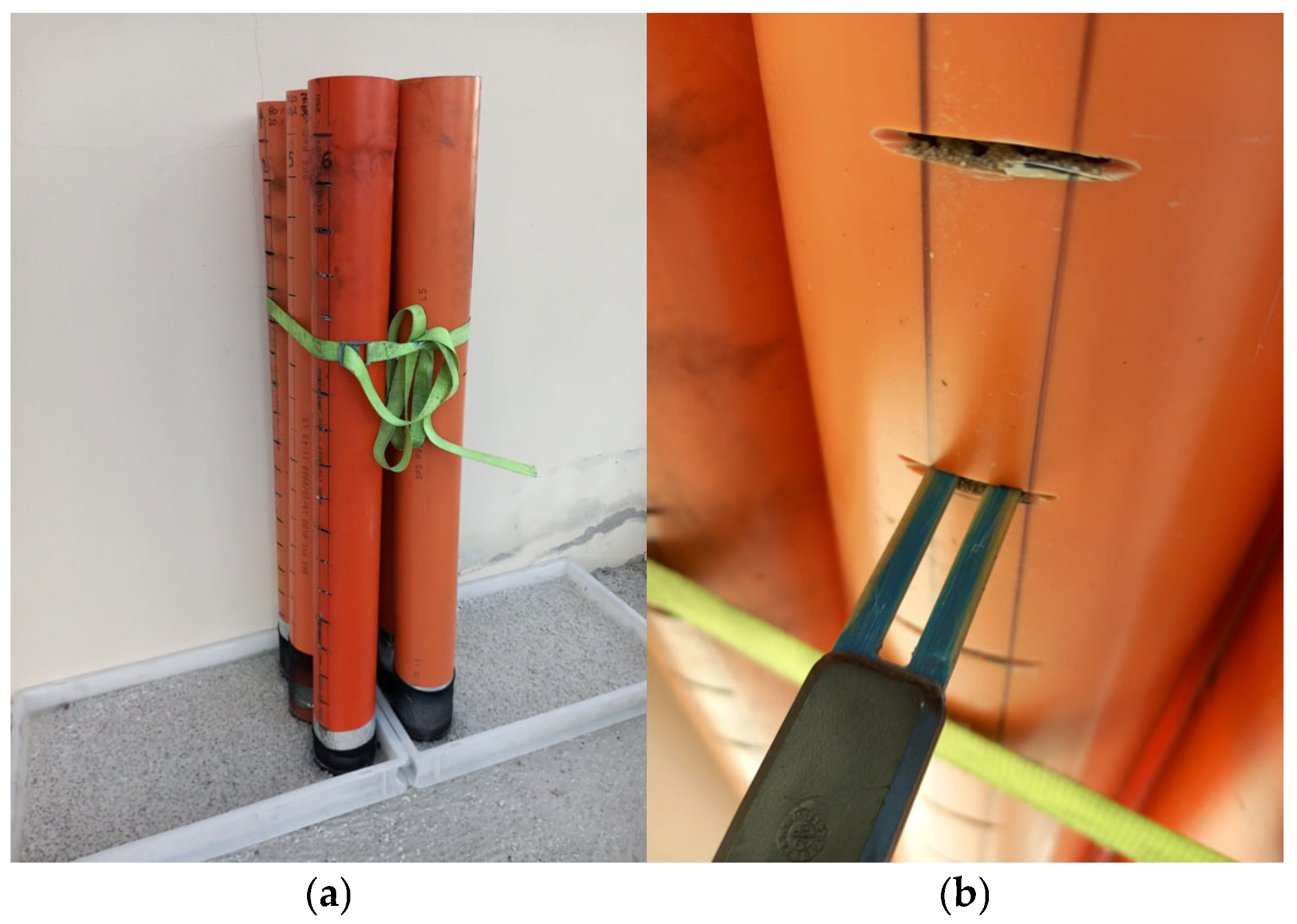

2.1. Method of Measuring Capillary Rise

2.2. Soil Mixture Preparation

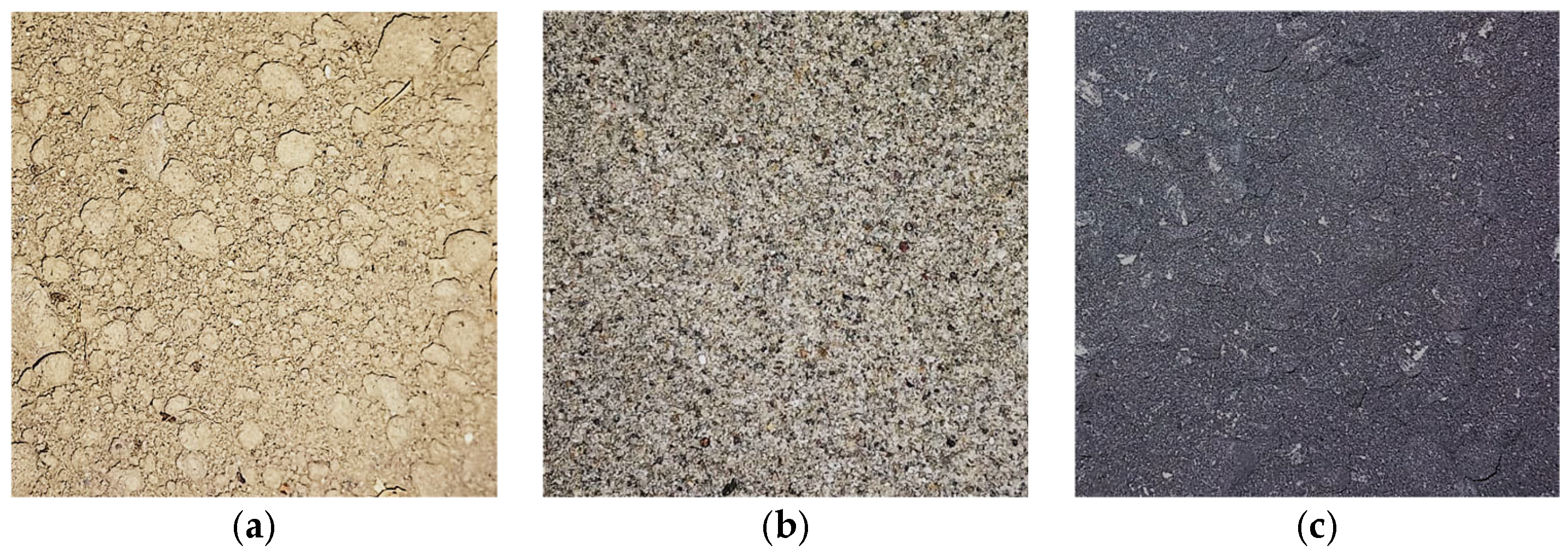

- Plain soil: the soil used for creating the samples of this work was analyzed by core drilling up to 108 cm deep. It is characterized by the prevalence of silt and clay from 4 to 105 cm and the appearance of medium sand from 105 to 108 cm (Figure 3a). Given the limited depth of the excavations for the installation of horizontal geothermal probes, it was decided to use the predominantly silt and clay sample. Plain soil is used as control sample and as basis for the other mixtures.

- Sand: since sand is present to a depth higher than 105 cm and its content is an important factor that influences thermal conductivity apart from water content, porosity and saturation level [26], it was decided to include it among the components of the tested mixtures. Fine standard sand was selected for this work (Figure 3b).

- Biochar: the biochar used in this experiment (Figure 3c) was produced by a Imbert-type reactor of a Urbas biomass gasification power plant with a nominal power of 150 kW. This is a co-current reactor, operating between 800 and 1000 °C, where the biochar is extracted from the reduction zone. This architecture guarantees a carbonized material that is, on average, higher in micro- and nanoporosity when compared to pyrolysis chars. This biochar is certified as a soil improver, according to Italian legislation [33], and can therefore be applied as an amendment to the soil. Unlike construction materials such as sand, which have a defined particle size distribution, biochar lacks a standard granulometry. Therefore, it is essential to report its particle size distribution to contextualize the tests carried out, since it affects the capillary water absorption, increasing moisture retention and, consequently, influencing soil conductivity. The particle size distribution of the Urbas gasifier biochar is detailed in Table 1, showing a notable proportion of fine particles (<0.5 mm) alongside a well-balanced range of coarser fractions [34].

2.3. Carbon Storage Calculation

- is the mass of biochar applied to the geothermal field

- is the organic carbon content in biochar per ton, determined via laboratory analysis and reported in Table 1.

- is the permanence factor accounting for biochar decay over time. In this case, , since biochar from a high-temperature process (gasification > 600 °C) was considered. For example, biochar produced through lower-temperature processes can exhibit a reduced permanence factor, with values dropping as low as 0.65.

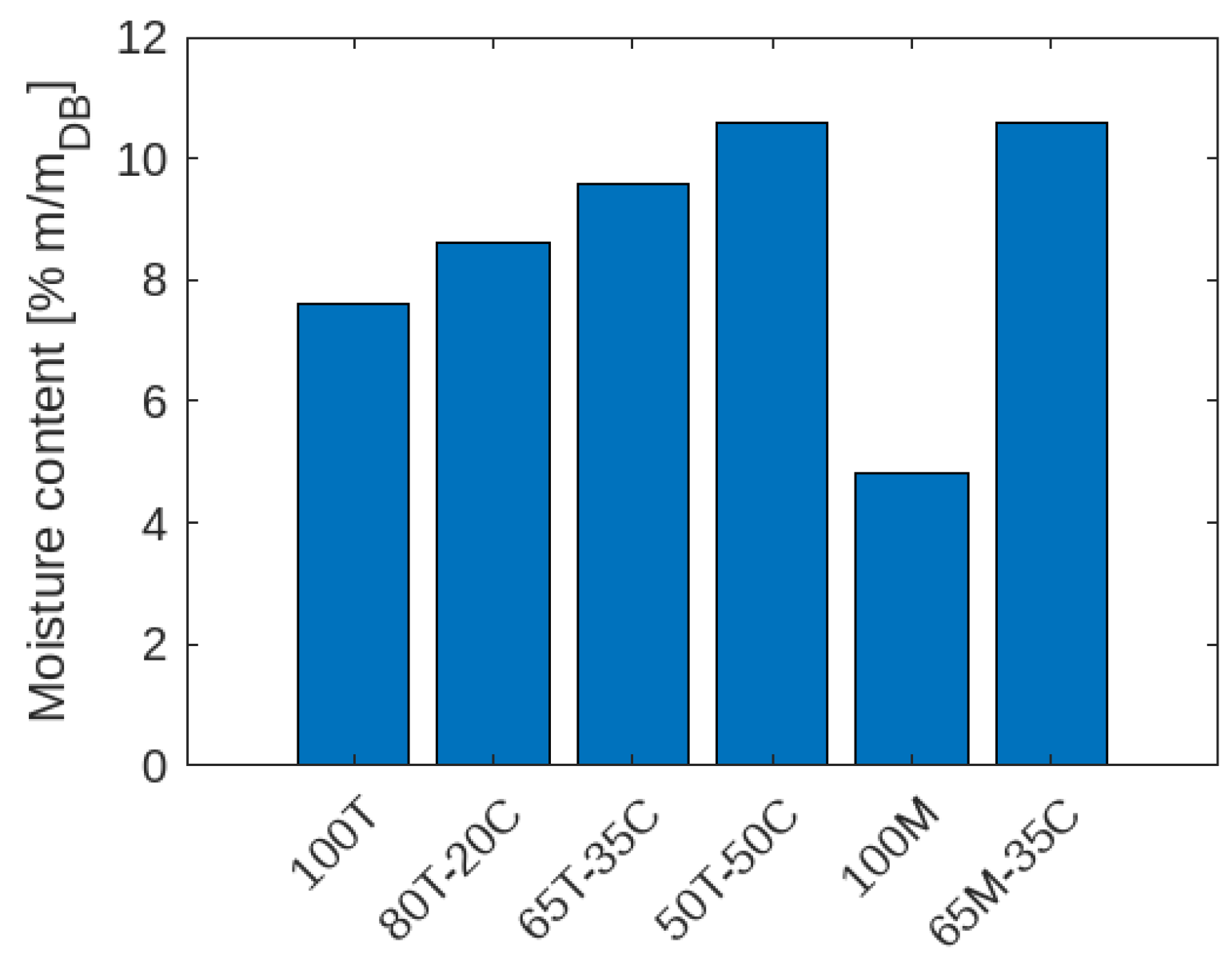

3. Results

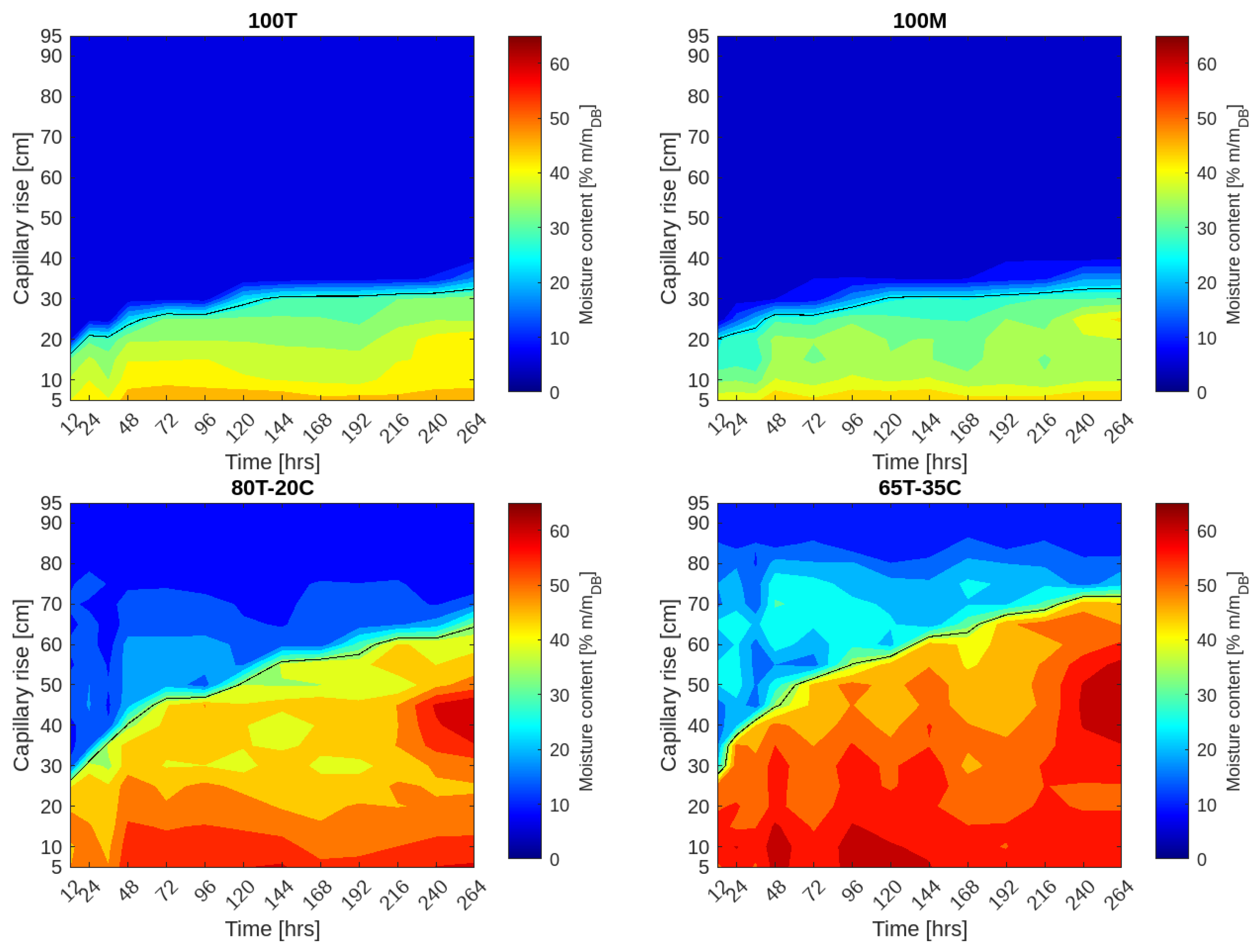

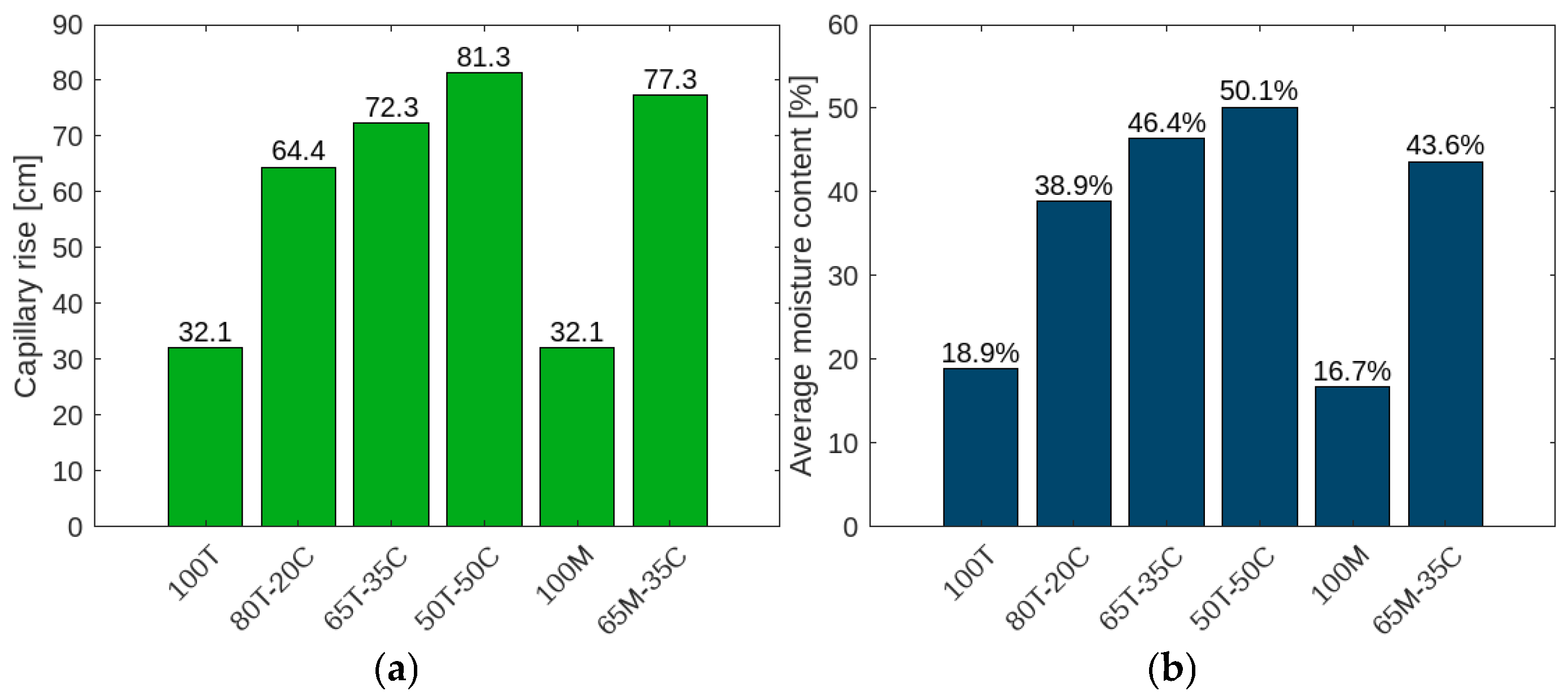

3.1. Capillary Rise

3.2. Carbon Storage Capability

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- A/RES/70/1 Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://sdgs.un.org/2030agenda (accessed on 18 January 2025).

- Sustainable Development Goals (SDG 7). Available online: https://unric.org/en/sdg-7/ (accessed on 25 October 2023).

- Net Zero by 2050—A Roadmap for the Global Energy Sector. Available online: https://www.iea.org/reports/net-zero-by-2050 (accessed on 18 January 2025).

- Shukla, P.R.; Skea, J.; Slade, R. Working Group III Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change. Available online: https://www.ipcc.ch/report/sixth-assessment-report-working-group-3/ (accessed on 18 January 2025).

- Mulabagal, V.; Baah, D.A.; Egiebor, N.O.; Sajjadi, B.; Chen, W.-Y.; Viticoski, R.L.; Hayworth, J.S. Biochar from Biomass: A Strategy for Carbon Dioxide Sequestration, Soil Amendment, Power Generation, CO2 Utilization, and Removal of Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS) in the Environment. In Handbook of Climate Change Mitigation and Adaptation; Lackner, M., Sajjadi, B., Chen, W.-Y., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 1023–1085. ISBN 978-3-030-72578-5. [Google Scholar]

- Smith, P. Soil Carbon Sequestration and Biochar as Negative Emission Technologies. Glob. Change Biol. 2016, 22, 1315–1324. [Google Scholar] [CrossRef] [PubMed]

- Woolf, D.; Amonette, J.E.; Street-Perrott, F.A.; Lehmann, J.; Joseph, S. Sustainable Biochar to Mitigate Global Climate Change. Nat. Commun. 2010, 1, 56. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, S.; Mahmud, M.A.P.; Nguyen, M.D.; Timms, W. Evaluating Fundamental Biochar Properties in Relation to Water Holding Capacity. Chemosphere 2023, 328, 138620. [Google Scholar] [CrossRef] [PubMed]

- Abd Alla, S.; Bianco, V.; Scarpa, F.; Tagliafico, L.A. Electrification of the Residential Heat Demand: An Analysis of the Power Market Potential to Accommodate Heat Pumps. Therm. Sci. Eng. Prog. 2022, 27, 101173. [Google Scholar] [CrossRef]

- Naumann, G.; Schropp, E.; Gaderer, M. Life Cycle Assessment of an Air-Source Heat Pump and a Condensing Gas Boiler Using an Attributional and a Consequential Approach. Procedia CIRP 2022, 105, 351–356. [Google Scholar] [CrossRef]

- Song, M.; Deng, S.; Dang, C.; Mao, N.; Wang, Z. Review on Improvement for Air Source Heat Pump Units during Frosting and Defrosting. Appl. Energy 2018, 211, 1150–1170. [Google Scholar] [CrossRef]

- Kim, B.-J.; Jo, S.-Y.; Jeong, J.-W. Energy Performance Enhancement in Air-Source Heat Pump with a Direct Evaporative Cooler-Applied Condenser. Case Stud. Therm. Eng. 2022, 35, 102137. [Google Scholar] [CrossRef]

- Le, A.T.; Wang, L.; Wang, Y.; Li, D. Measurement Investigation on the Feasibility of Shallow Geothermal Energy for Heating and Cooling Applied in Agricultural Greenhouses of Shouguang City: Ground Temperature Profiles and Geothermal Potential. Inf. Process. Agric. 2021, 8, 251–269. [Google Scholar] [CrossRef]

- Cheng, X. Integrated Energy System in a Green Energy Lab. In Handbook of Energy Systems in Green Buildings; Wang, R., Zhai, X., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–40. ISBN 978-3-662-49088-4. [Google Scholar]

- Raymond, J.; Mercier, S.; Nguyen, L. Designing Coaxial Ground Heat Exchangers with a Thermally Enhanced Outer Pipe. Geotherm. Energy 2015, 3, 7. [Google Scholar] [CrossRef]

- Cui, Y.; Zhu, J.; Twaha, S.; Chu, J.; Bai, H.; Huang, K.; Chen, X.; Zoras, S.; Soleimani, Z. Techno-Economic Assessment of the Horizontal Geothermal Heat Pump Systems: A Comprehensive Review. Energy Convers. Manag. 2019, 191, 208–236. [Google Scholar] [CrossRef]

- Go, G.-H.; Lee, S.-R.; Yoon, S.; Kim, M.-J. Optimum Design of Horizontal Ground-Coupled Heat Pump Systems Using Spiral-Coil-Loop Heat Exchangers. Appl. Energy 2016, 162, 330–345. [Google Scholar] [CrossRef]

- Hou, G.; Taherian, H.; Song, Y.; Jiang, W.; Chen, D. A Systematic Review on Optimal Analysis of Horizontal Heat Exchangers in Ground Source Heat Pump Systems. Renew. Sustain. Energy Rev. 2022, 154, 111830. [Google Scholar] [CrossRef]

- Florides, G.; Theofanous, E.; Iosif-Stylianou, I.; Tassou, S.; Christodoulides, P.; Zomeni, Z.; Tsiolakis, E.; Kalogirou, S.; Messaritis, V.; Pouloupatis, P.; et al. Modeling and Assessment of the Efficiency of Horizontal and Vertical Ground Heat Exchangers. Energy 2013, 58, 655–663. [Google Scholar] [CrossRef]

- Rashid, F.L.; Dhaidan, N.S.; Hussein, A.K.; Al-Mousawi, F.N.; Younis, O. Ground Heat Exchanger in Different Configuration: Review of Recent Advances and Development. Geoenergy Sci. Eng. 2023, 227, 211872. [Google Scholar] [CrossRef]

- Bortoloni, M.; Bottarelli, M.; Su, Y. A Study on the Effect of Ground Surface Boundary Conditions in Modelling Shallow Ground Heat Exchangers. Appl. Therm. Eng. 2017, 111, 1371–1377. [Google Scholar] [CrossRef]

- Maghrabie, H.M.; Abdeltwab, M.M.; Tawfik, M.H.M. Ground-Source Heat Pumps (GSHPs): Materials, Models, Applications, and Sustainability. Energy Build. 2023, 299, 113560. [Google Scholar] [CrossRef]

- Wan, R.; Kong, D.; Kang, J.; Yin, T.; Ning, J.; Ma, J. The Experimental Study on Thermal Conductivity of Backfill Material of Ground Source Heat Pump Based on Iron Tailings. Energy Build. 2018, 174, 1–12. [Google Scholar] [CrossRef]

- Bernier, M.A.; Chahla, A.; Pinel, P. Long-Term Ground-Temperature Changes in Geo-Exchange Systems. ASHRAE Trans. 2008, 114, 342–351. [Google Scholar]

- Zimmerman, R.W. Thermal Conductivity of Fluid-Saturated Rocks. J. Pet. Sci. Eng. 1989, 3, 219–227. [Google Scholar] [CrossRef]

- Liu, W.; Li, R.; Wu, T.; Shi, X.; Zhao, L.; Wu, X.; Hu, G.; Yao, J.; Xiao, Y.; Ma, J.; et al. Simulation of Soil Thermal Conductivity Based on Different Schemes: An Empirical Comparison of 13 Models. Int. J. Therm. Sci. 2023, 190, 108301. [Google Scholar] [CrossRef]

- Morselli, N.; Puglia, M.; Ottani, F.; Pedrazzi, S.; Allesina, G.; Muscio, A.; Tartarini, P. Experimental Investigation of Moisture Influence on Biochar and Biochar-Soil Blends Thermophysical Properties. J. Phys. Conf. Ser. 2024, 2685, 012031. [Google Scholar] [CrossRef]

- ARPAE Livello Delle Acque Sotterranee. Available online: https://webbook.arpae.it/indicatore/Livello-delle-acque-sotterranee-00001/?id=19a0fc0d-7558-11e4-8845-11c9866a0f33 (accessed on 17 November 2023).

- Lane, K.S.; Washburn, D.E.; Krynine, D.P. Capillarity tests by capillarimeter and by soil filled tubes. In Proceedings of the Highway Research Board Proceedings, Washington, DC, USA, 5–8 December 1946; National Academy of Science: Washington, DC, USA, 1947; Volume 26. [Google Scholar]

- Lu, N.; Likos, W.J. Rate of Capillary Rise in Soil. J. Geotech. Geoenvironmental Eng. 2004, 130, 646–650. [Google Scholar] [CrossRef]

- Liu, Q.; Yasufuku, N.; Miao, J.; Ren, J. An Approach for Quick Estimation of Maximum Height of Capillary Rise. Soils Found. 2014, 54, 1241–1245. [Google Scholar] [CrossRef]

- ECH20 EC-5. Available online: https://www.metergroup.com/en/meter-environment/products/ech20-ec-5-soil-moisture-sensor (accessed on 17 November 2023).

- MIIPAF. Decreto Legislativo 29 Aprile 2010, n.75—Riordino e Revisione Della Disciplina in Materia Di Fertilizzanti, a Norma Dell’articolo 13 Della Legge 7 Luglio 2009, n. 88; Gazzetta Ufficiale Della Repubblica Italiana: Rome, Italy, 2010; p. 126. [Google Scholar]

- Homepage—URBAS Energietechnik und Stahlbau. Available online: https://www.urbas.at/ (accessed on 18 January 2025).

- Ottani, F.; Parenti, M.; Pedrazzi, S.; Moscatelli, G.; Allesina, G. Impacts of Gasification Biochar and Its Particle Size on the Thermal Behavior of Organic Waste Co-Composting Process. Sci. Total Environ. 2022, 817, 153022. [Google Scholar] [CrossRef] [PubMed]

- Verra. VM0044 Methodology for Biochar Utilization in Soil and Non-Soil Applications, v1.1; Verra: Washington, DC, USA, 2021. [Google Scholar]

- EU Carbon Permits—Price—Chart—Historical Data—News. Available online: https://tradingeconomics.com/commodity/carbon (accessed on 20 November 2023).

- Household Energy Consumption for Space Heating per M2—European Environment Agency. Available online: https://www.eea.europa.eu/data-and-maps/daviz/unit-consumption-of-space-heating#tab-chart_1 (accessed on 21 November 2023).

- Musurmonov, M. Experimental Analysis of Geothermal Heat Pump. Ph.D. Thesis, Politecnico di Torino, Turin, Italy, 2021. [Google Scholar]

- Gervasio, H.; Dimova, S. Environmental Benchmarks for Buildings. EFIResources: Resource Efficient Construction towards Sustainable Design; Publications Office: Luxembourg, 2018. [Google Scholar]

| Parameter | Value |

|---|---|

| Total organic carbon—dry basis | 72.4% |

| Ash content | 20.5%m/m,DB |

| Fraction of grain size < 0.5 mm | 39.2% |

| Fraction of grain size 0.5 < φ < 2.0 mm | 18.9% |

| Fraction of grain size 2.0 < φ < 5.0 mm | 25.5% |

| Fraction of grain size > 5.0 mm | 16.4% |

| Density | 218 kg m−3 |

| Name | Soil [% v/v] | Biochar [% v/v] | Sand [% v/v] |

|---|---|---|---|

| 100T | 100% | - | - |

| 80T-20C | 80% | 20% | - |

| 65T-35C | 65% | 35% | - |

| 50T-50C | 50% | 50% | - |

| 100M | 70% | - | 30% |

| 65M-35C | 45.5% | 35% | 19.5% |

| Name | Biochar Content [% v/v] | Biochar per Cubic Meter [kg] | Carbon Stored [kg of CO2eq] |

|---|---|---|---|

| 100T | - | - | - |

| 80T-20C | 20% | 43.6 | 103 |

| 65T-35C | 35% | 76.3 | 180.3 |

| 50T-50C | 50% | 109 | 257.5 |

| 100M | - | - | - |

| 65M-35C | 35% | 76.3 | 180.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morselli, N.; Ottani, F.; Puglia, M.; Pedrazzi, S.; Tartarini, P.; Allesina, G. Biochar-Aided Heat Transfer in Ground Source Heat Pumps: Effects on Water Capillary Rise and Carbon Storage Capability. Processes 2025, 13, 279. https://doi.org/10.3390/pr13010279

Morselli N, Ottani F, Puglia M, Pedrazzi S, Tartarini P, Allesina G. Biochar-Aided Heat Transfer in Ground Source Heat Pumps: Effects on Water Capillary Rise and Carbon Storage Capability. Processes. 2025; 13(1):279. https://doi.org/10.3390/pr13010279

Chicago/Turabian StyleMorselli, Nicolò, Filippo Ottani, Marco Puglia, Simone Pedrazzi, Paolo Tartarini, and Giulio Allesina. 2025. "Biochar-Aided Heat Transfer in Ground Source Heat Pumps: Effects on Water Capillary Rise and Carbon Storage Capability" Processes 13, no. 1: 279. https://doi.org/10.3390/pr13010279

APA StyleMorselli, N., Ottani, F., Puglia, M., Pedrazzi, S., Tartarini, P., & Allesina, G. (2025). Biochar-Aided Heat Transfer in Ground Source Heat Pumps: Effects on Water Capillary Rise and Carbon Storage Capability. Processes, 13(1), 279. https://doi.org/10.3390/pr13010279