Solar Water Heating System with Absorption Heat Transformer for Annual Continuous Water Heating

Abstract

1. Introduction

2. Methods and Materials

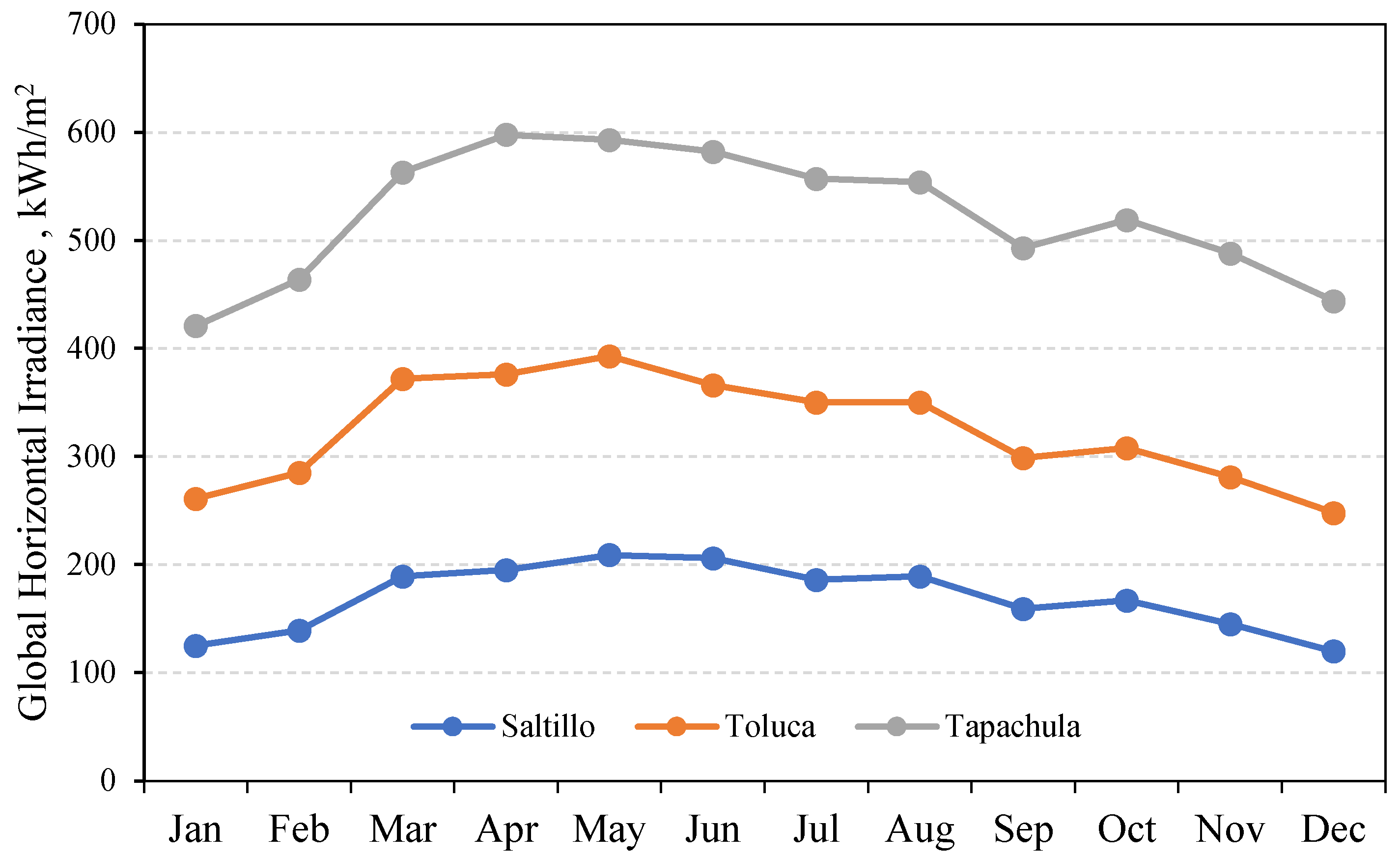

2.1. Testing Places

- Saltillo (north): Semiarid, hot summers and cold winters (17 °C annual average). Average annual precipitation: 479.2 mm (summer). Average annual GHI: 2150 kWh/m2-year.

- Toluca (center): Temperate, warm summers and cool winters (12.6 °C annual average). Average annual precipitation: 980 mm (summer). Average annual GHI: 1900 kWh/m2-year.

- Tapachula (southeast): Tropical humid, hot and humid summers, dry and mild winters (27 °C annual average). Average annual precipitation: 2182 mm (summer). Average annual GHI: 2300 kWh/m2-year.

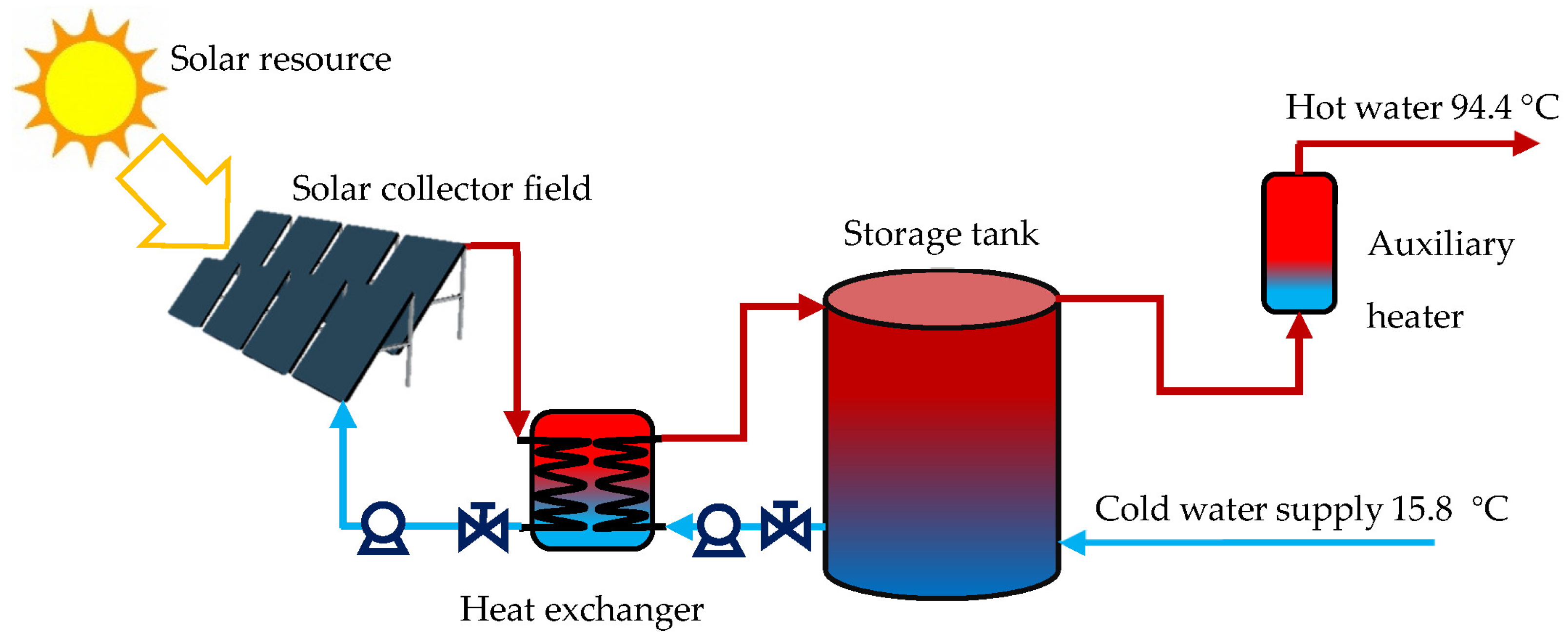

2.2. Solar Water Heating System

2.2.1. Description

2.2.2. Calculation

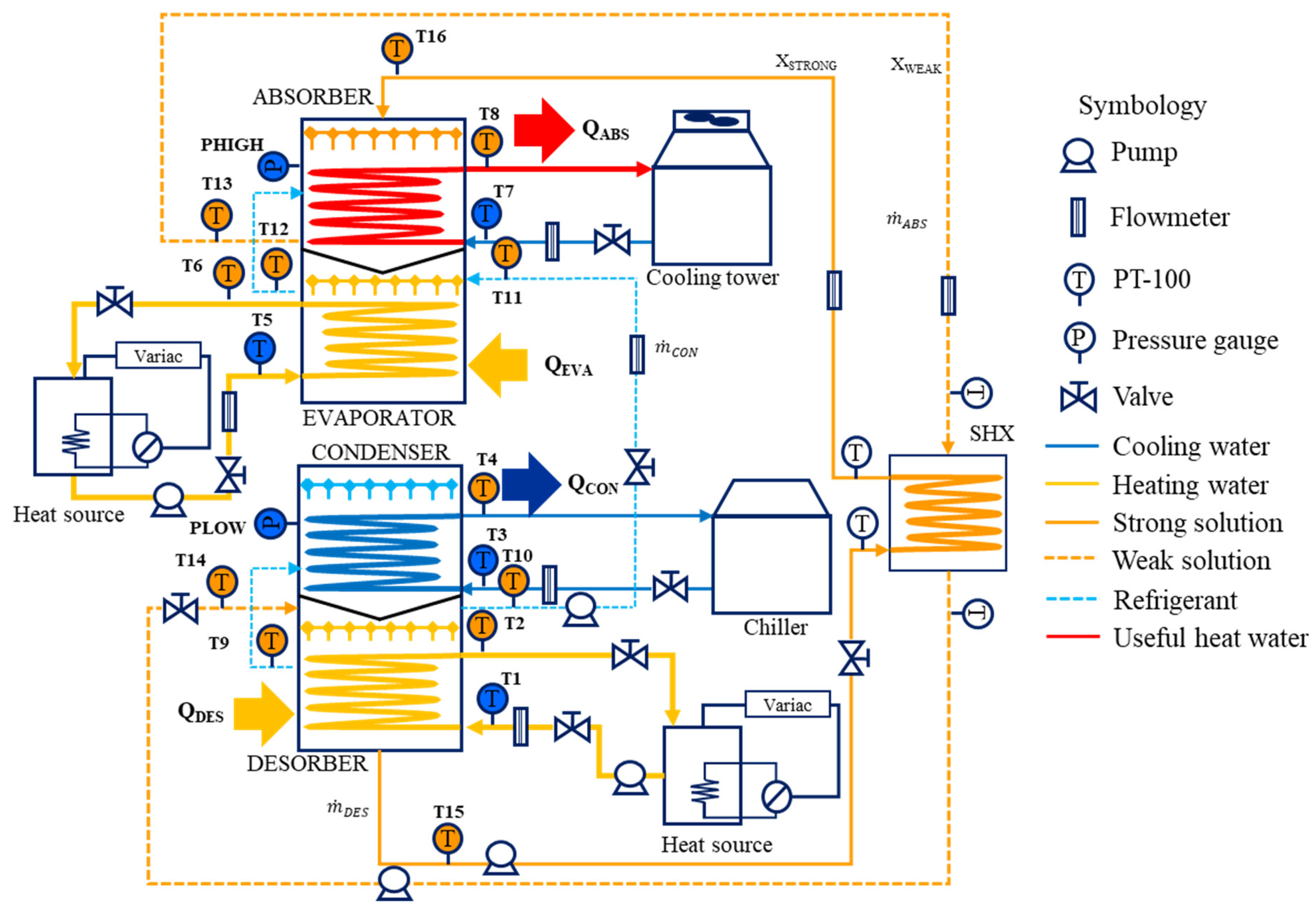

2.3. Absorption Heat Transformer

2.3.1. Description

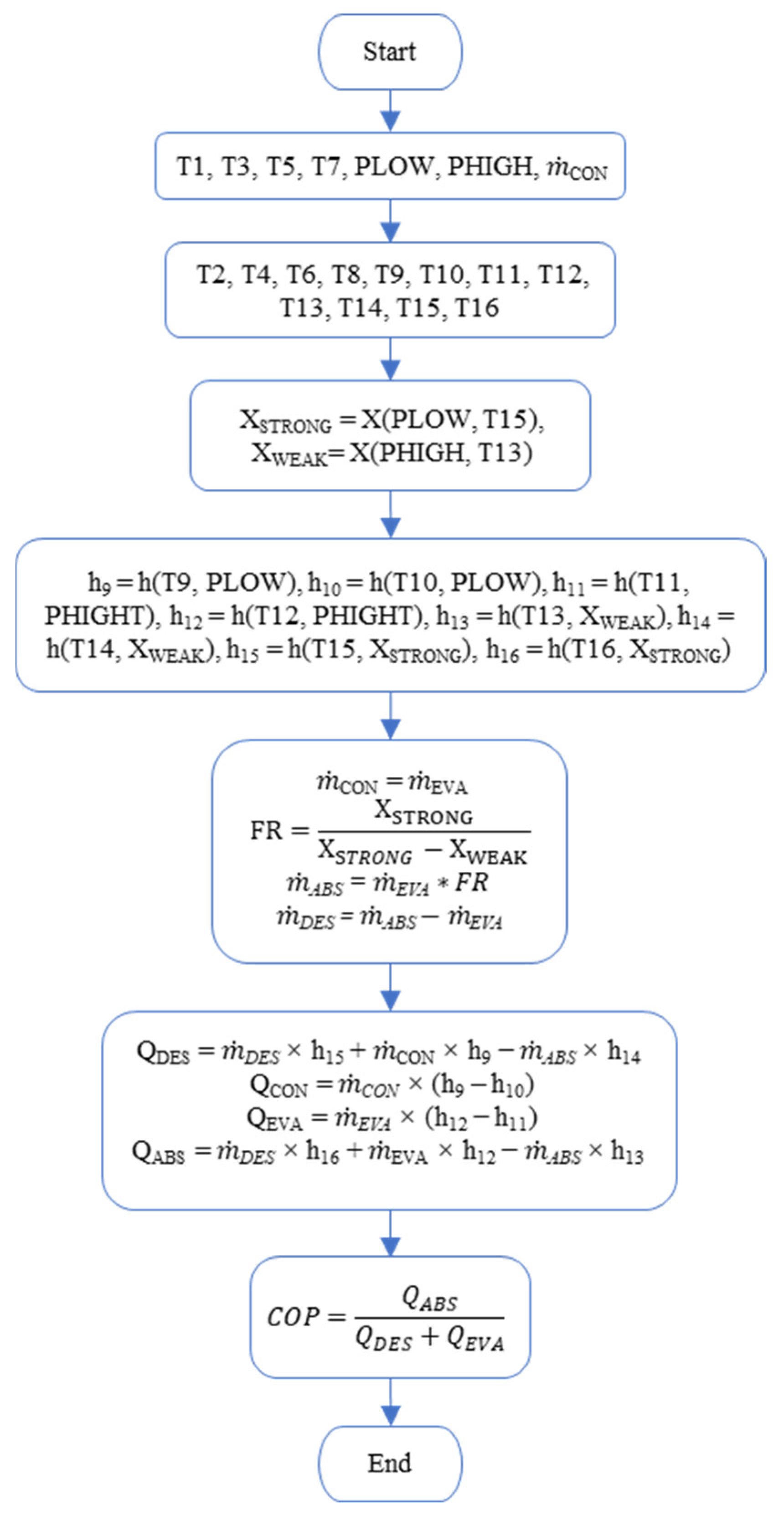

2.3.2. Calculation by ANN

2.3.3. Thermodynamic Algorithm

2.4. SWHS and AHT Coupling

2.5. Comparative Parameters

3. Results and Discussion

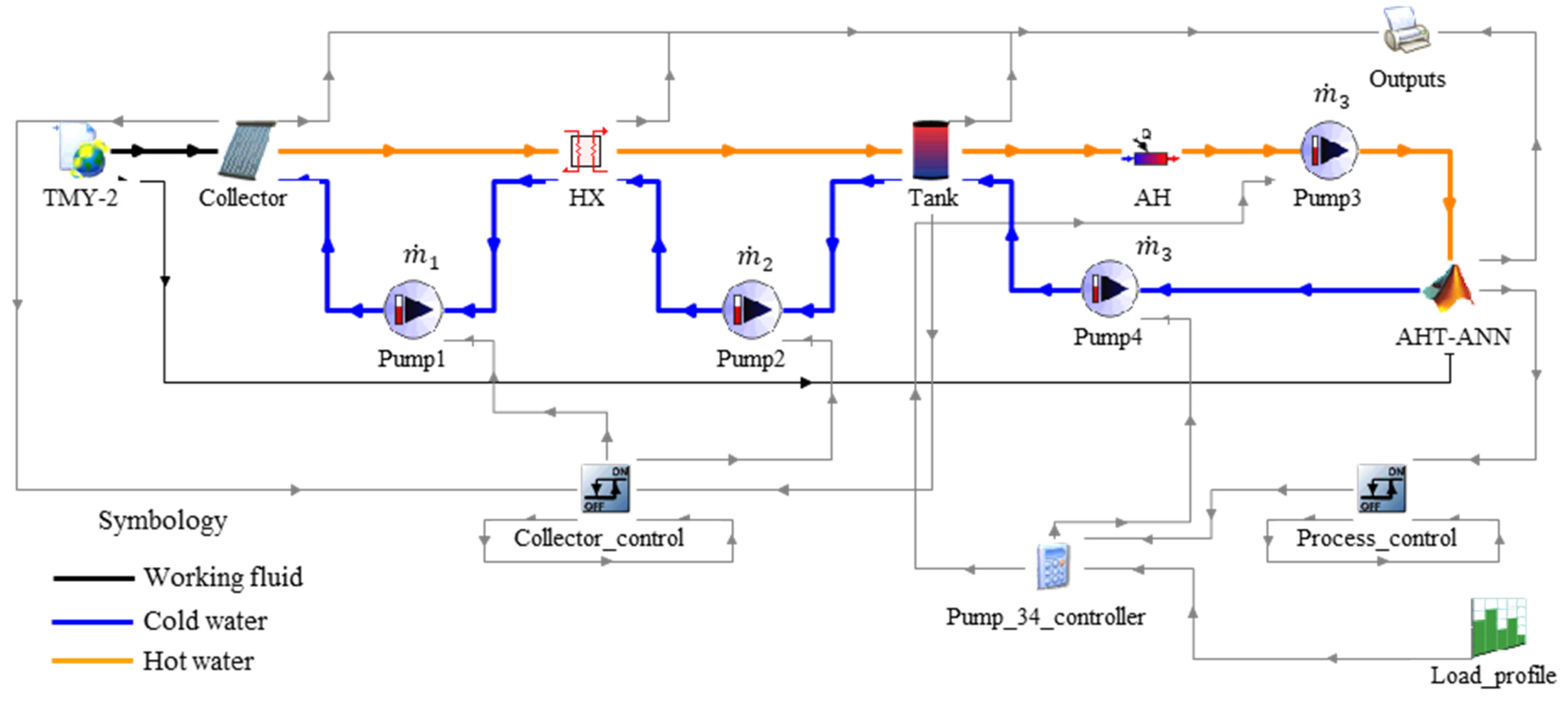

3.1. SWHS Simulation Platform

3.2. Absorption Heat Transformer Simulation

3.3. Performance Comparison of SWHS-AHT and Conventional SWHS

3.3.1. Optimal Configurations

3.3.2. Utilization Ratio vs. Solar Fraction and Solar Heat Gain

3.3.3. Net Solar Collector Area vs. Auxiliary Heat and Solar Fraction

3.3.4. Net Solar Collector Area vs. Storage Tank Volume and Auxiliary Heat

3.4. Annual Performance of the SWHS-AHT System

4. Conclusions

- The SWHS-AHT achieved a minimal variation in SF compared to the conventional SWHS in all cities. The SWHS-AHT reached an SF of 99.6% compared to 99.0% for the conventional SWHS.

- The SWHS-AHT delivered superior SHG compared to the conventional SWHS in all cities. The SWHS-AHT achieved a maximum SHG of 1352.0 kWh/m2-year with a collector area of 50 m2, whereas the conventional SWHS reached a maximum SHG of 811.9 kWh/m2-year with the same Ac.

- The SWHS-AHT required a significantly smaller Ac to achieve a comparable Qaux compared to the conventional SWHS. This reduction ranged from 42.9 to 60%. For instance, in Saltillo, the SWHS-AHT achieved a Qaux of 1301.7 kW-year with an Ac of 130 m2, while the conventional SWHS required an Ac of 300 m2 for a slightly higher Qaux of 1317.9 kW-year. This translates to potential cost savings due to a reduced number of solar collectors needed for the SWHS-AHT system. Optimal SWHS-AHT configurations achieved target Qaux values with UR ranging from 49.4 to 345.6 L/m2-day and VR of 120 L/m2 while utilizing mass flow rates of 1.38 kg/s. In contrast, conventional SWHS configurations required UR from 3 to 33.8 L/m2-day, VR of 40 L/m2, and lower mass flow rates of 0.972 kg/s for comparable performance.

- The Vt exhibited a linear relationship with the Ac for both systems. However, the SWHS-AHT achieved a comparable Vt to the conventional SWHS despite requiring a smaller Ac.

- The SWHS-AHT demonstrated activation performance comparable to the findings of Varela-Martinez et al. by maintaining a GTL of 12.9 °C and a COP of 0.44 throughout the year. This improvement stemmed from the ANN’s effective monitoring of the AHT prototype temperatures.

- It is crucial to acknowledge that the SWHS-AHT configurations exhibiting the highest performance in this study demanded high SF values, ranging from 99.0% to 99.6%.

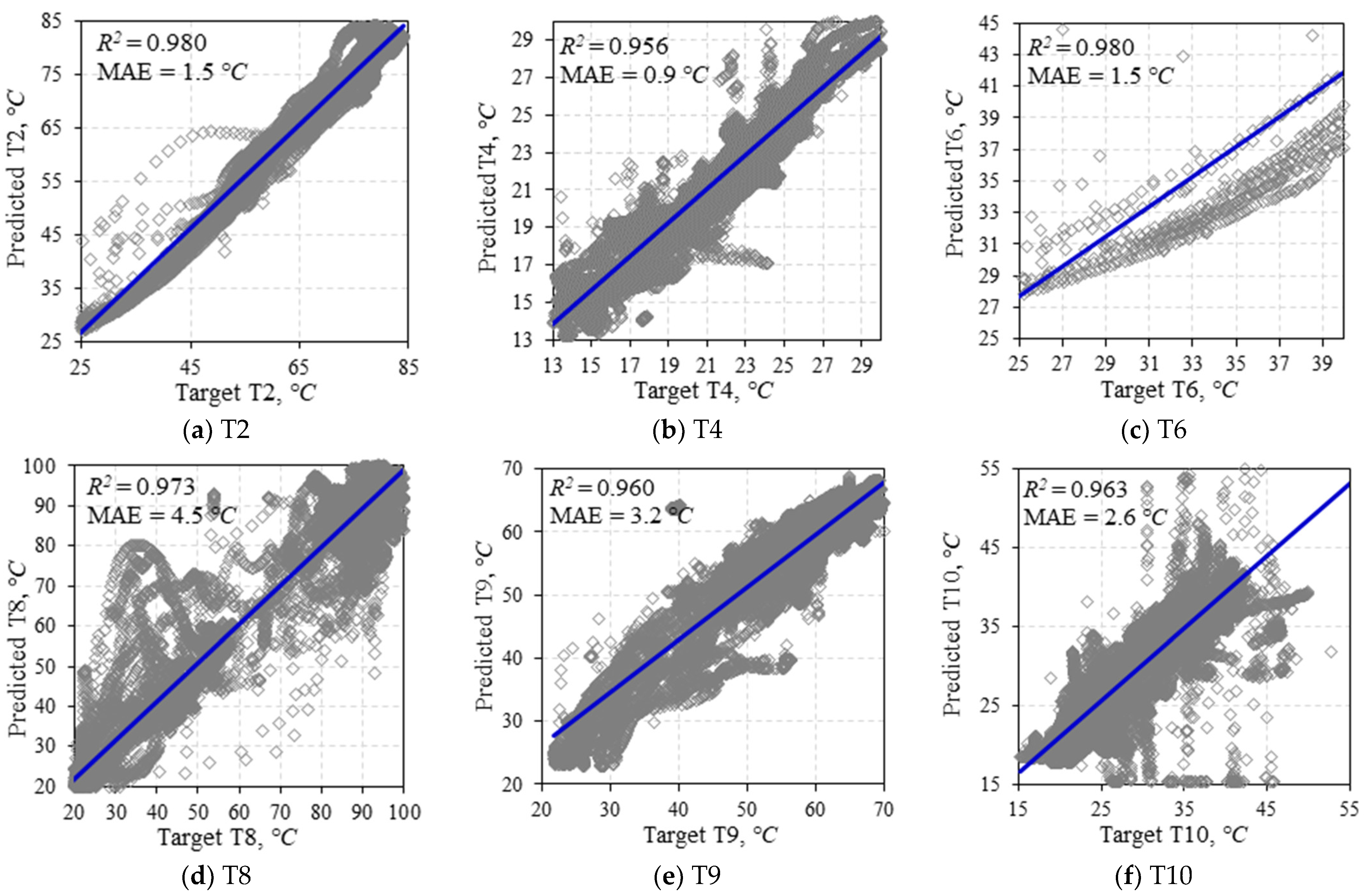

- Tracking the predicted variables reveals consistent quality of fit across all cases, with an average R2 of 0.964 and an average MAE of 2.7 °C for the 12 predicted temperatures. These results validate the effectiveness of the proposed system in various thermal conditions. The ability of the SWHS-AHT to maintain performance despite variations in heat sources is an important aspect of ensuring the continuous availability of hot water in any process that requires it.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Ac | Net Solar Collector Area, m2 |

| AH | Auxiliary Heater |

| AHT | Absorption Heat Transformer |

| ANN | Artificial Neural Network |

| b1 | Vector bias in the hidden layer |

| b2 | Vector bias in the output layer |

| COP | Coefficient of Performance, dimensionless |

| Demand | Water demand, L/day |

| Des/Con | Desorber/Condenser |

| ETC | Evacuated Tube Collector |

| Eva/Abs | Evaporator/Absorber |

| FR | Flux Relation, dimensionless |

| GHI | Global Horizontal Irradiance, kWh/m2 |

| GTL | Gross of Temperature Lift, °C |

| h | Specific enthalpy, kJ/kg |

| H2O/LiBr | Water–Lithium–Bromide |

| HE | Heat Exchanger |

| k | k-value for k-fold cross-validation |

| LOGSIG | Logarithm of the Sigmoid Transfer Function |

| Mass flow rate, kg/s | |

| , | Mass flow in Pum_1, kg/s |

| , | Mass flow in Pum_2, kg/s |

| , | Mass flow in Pum_3 and 4, kg/s |

| MAE | Mean Absolute Error, K |

| n | Data number |

| PHIGH | High line pressure, kPa |

| PLOW | Low line pressure, kPa |

| PURELIN | Purely Linear Transfer Function |

| Q | Heat flux rate, kW |

| Qaux | Heat flow provided by auxiliary heater, kWh/year |

| QDemand | Heat flow demanded by the system, kWh/year |

| QSolar | Heat flow provided by solar collectors, kWh/year |

| R2 | Coefficient of determination, dimensionless |

| SHX | Solution Heat Exchanger |

| SF | Solar Fraction, % |

| SHG | Solar Heat Gain, kWh/m2-year |

| SWHS | Solar Water Heating Systems |

| SHX | Solution Heat eXchanger |

| SMN | National Meteorological Service |

| T | Temperature, °C |

| T1 | Desorber heating water input temperature, °C |

| T2 | Desorber heating water output temperature, °C |

| T3 | Condenser cooling water input temperature, °C |

| T4 | Condenser cooling water output temperature, °C |

| T5 | Evaporator heating water input temperature, °C |

| T6 | Evaporator heating water output temperature, °C |

| T7 | Absorber useful water input temperature, °C |

| T8 | Absorber useful water output temperature, °C |

| T9 | Desorber refrigerant output temperature, °C |

| T10 | Condenser refrigerant output temperature, °C |

| T11 | Evaporator refrigerant input temperature, °C |

| T12 | Evaporator refrigerant output temperature, °C |

| T13 | Absorber weak solution output temperature, °C |

| T14 | Desorber weak solution input temperature, °C |

| T15 | Desorber strong solution output temperature, °C |

| T16 | Absorber strong solution input temperature, °C |

| TANSIG | Tangent Sigmoid Transfer Function |

| TMY-2 | Climatological data of a typical year in TMY-2 format |

| TRNSYS | Transient System Simulation Program |

| UR | Utilization Ratio, liters/m2-day |

| Volshell | Shell volume, m3 |

| VR | Volume Ratio, L/m2 |

| Vt | Storage Tank Volume, m3 |

| Work flux rate, kW | |

| W1 | Weight matrix in the hidden layer |

| W2 | Weight matrix in the output layer |

| X | Input vector |

| xi | Target value |

| XStrong | Strong concentration solution, % |

| XWeak | Weak concentration, % |

| Y | Predicted variable |

| yi | Predicted value |

| β | Surface density, m2/m3 |

| Mean value of xi | |

| Subscripts | |

| ABS | Absorber |

| CON | Condenser |

| COOL | Cooling water |

| DES | Desorber |

| Determined | Determined value |

| EVA | Evaporator |

| HEA | Heating |

| Int | Input |

| Out | Output |

| Target | Target value |

| USE | Water of use |

References

- Kumar, L.; Hasanuzzaman, M.; Rahim, N.A. Global Advancement of Solar Thermal Energy Technologies for Industrial Process Heat and Its Future Prospects: A Review. Energy Convers. Manag. 2019, 195, 885–908. [Google Scholar] [CrossRef]

- Salgado-Conrado, L.; Lopez-Montelongo, A. Barriers and Solutions of Solar Water Heaters in Mexican Household. Sol. Energy 2019, 188, 831–838. [Google Scholar] [CrossRef]

- McMillan, C.; Xi, W.; Zhang, J.; Masanet, E.; Kurup, P.; Schoeneberger, C.; Meyers, S.; Margolis, R. Evaluating the Economic Parity of Solar for Industrial Process Heat. Sol. Energy Adv. 2021, 1, 100011. [Google Scholar] [CrossRef]

- Ritchie, H.; Rosado, P.; Roser, M. Energy. Available online: https://ourworldindata.org/energy (accessed on 23 November 2023).

- Tuncer, A.D.; Aytaç, İ.; Variyenli, H.İ.; Khanlari, A.; Mantıcı, S.; Karartı, A. Improving the Performance of a Heat Pipe Evacuated Solar Water Collector Using a Magnetic NiFe2O4/Water Nanofluid. Therm. Sci. Eng. Prog. 2023, 45, 102107. [Google Scholar] [CrossRef]

- Delgado-Gonzaga, J.; Juárez-Romero, D.; Saravanan, R.; Márquez-Nolasco, A.; Huicochea, A.; Morales, L.I. Performance Analysis of a Dual Component Generator-Condenser of an Absorption Heat Transformer for Water Desalination. Therm. Sci. Eng. Prog. 2020, 20, 100651. [Google Scholar] [CrossRef]

- Rivera, W.; Best, R.; Cardoso, M.J.; Romero, R.J. A Review of Absorption Heat Transformers. Appl. Therm. Eng. 2015, 91, 654–670. [Google Scholar] [CrossRef]

- Benli, H. Potential Application of Solar Water Heaters for Hot Water Production in Turkey. Renew. Sustain. Energy Rev. 2016, 54, 99–109. [Google Scholar] [CrossRef]

- Jaisankar, S.; Ananth, J.; Thulasi, S.; Jayasuthakar, S.T.; Sheeba, K.N. A Comprehensive Review on Solar Water Heaters. Renew. Sustain. Energy Rev. 2011, 15, 3045–3050. [Google Scholar] [CrossRef]

- Faisal Ahmed, S.; Khalid, M.; Vaka, M.; Walvekar, R.; Numan, A.; Khaliq Rasheed, A.; Mujawar Mubarak, N. Recent Progress in Solar Water Heaters and Solar Collectors: A Comprehensive Review. Therm. Sci. Eng. Prog. 2021, 25, 100981. [Google Scholar] [CrossRef]

- Sabiha, M.A.; Saidur, R.; Hassani, S.; Said, Z.; Mekhilef, S. Energy Performance of an Evacuated Tube Solar Collector Using Single Walled Carbon Nanotubes Nanofluids. Energy Convers. Manag. 2015, 105, 1377–1388. [Google Scholar] [CrossRef]

- Sharifi, S.; Nozad Heravi, F.; Shirmohammadi, R.; Ghasempour, R.; Petrakopoulou, F.; Romeo, L.M. Comprehensive Thermodynamic and Operational Optimization of a Solar-Assisted LiBr/Water Absorption Refrigeration System. Energy Rep. 2020, 6, 2309–2323. [Google Scholar] [CrossRef]

- Al-Mamun, M.R.; Roy, H.; Islam, M.S.; Ali, M.R.; Hossain, M.I.; Saad Aly, M.A.; Hossain Khan, M.Z.; Marwani, H.M.; Islam, A.; Haque, E.; et al. State-of-the-Art in Solar Water Heating (SWH) Systems for Sustainable Solar Energy Utilization: A Comprehensive Review. Sol. Energy 2023, 264, 111998. [Google Scholar] [CrossRef]

- Gautam, A.; Chamoli, S.; Kumar, A.; Singh, S. A Review on Technical Improvements, Economic Feasibility and World Scenario of Solar Water Heating System. Renew. Sustain. Energy Rev. 2017, 68, 541–562. [Google Scholar] [CrossRef]

- SHIP Solar Heat for Industrial Processes. Available online: http://ship-plants.info/ (accessed on 28 May 2024).

- Chopra, K.; Tyagi, V.V.; Pathak, S.K.; Sharma, R.K.; Mansor, M.; Goel, V.; Sari, A. 5E Analysis of a Novel Designed Hot Water Storage Header Integrated Vacuum Tube Solar Water Heater. Therm. Sci. Eng. Prog. 2023, 42, 101929. [Google Scholar] [CrossRef]

- Lee, M.; Shin, Y.; Cho, H. Performance Evaluation of Flat Plate and Vacuum Tube Solar Collectors by Applying a MWCNT/Fe3O4 Binary Nanofluid. Energies 2020, 13, 1715. [Google Scholar] [CrossRef]

- Ismail, K.A.R.; Teles, M.P.R.; Lino, F.A.M. Comparative Analysis of Eccentric Evacuated Tube Solar Collector with Circular and Rectangular Absorber Working with Nanofluid. Clean. Eng. Technol. 2021, 3, 100105. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A.; Worek, W.M. Solar Engineering of Thermal Processes, 4th ed.; Wiley: New York, NY, USA, 2003; Volume 116, 944p, ISBN 1118418123. [Google Scholar]

- Ononogbo, C.; Nwosu, E.C.; Nwakuba, N.R.; Nwaji, G.N.; Nwufo, O.C.; Chukwuezie, O.C.; Chukwu, M.M.; Anyanwu, E.E. Opportunities of Waste Heat Recovery from Various Sources: Review of Technologies and Implementation. Heliyon 2023, 9, e13590. [Google Scholar] [CrossRef] [PubMed]

- Mehrjouiee, H.; Fallah, M.; Mohammad, S.; Mahmoudi, S. Advanced Exergy Analysis of a Double Absorption Heat Transformer Recovering Industrial Waste Heat for Pure Water Production. Therm. Sci. Eng. Prog. 2024, 47, 102242. [Google Scholar] [CrossRef]

- Liu, Z.; Lu, D.; Tao, S.; Chen, R.; Gong, M. Experimental Study on Using 85 °C Low-Grade Heat to Generate <120 °C Steam by a Temperature-Distributed Absorption Heat Transformer. Energy 2024, 299, 131491. [Google Scholar] [CrossRef]

- Cudok, F.; Giannetti, N.; Ciganda, J.L.C.; Aoyama, J.; Babu, P.; Coronas, A.; Fujii, T.; Inoue, N.; Saito, K.; Yamaguchi, S.; et al. Absorption Heat Transformer-State-of-the-Art of Industrial Applications. Renew. Sustain. Energy Rev. 2021, 141, 110757. [Google Scholar] [CrossRef]

- Perez, S.G.; Huicochea, A.; Urquiza, G.; Hernández, A.H.; Siqueiros, J. The Commissioning of Absorption Heat Transformer for Water Distillation Using Solar Panels. Desalin. Water Treat. 2020, 204, 1–11. [Google Scholar] [CrossRef]

- Salata, F.; Coppi, M. A First Approach Study on the Desalination of Sea Water Using Heat Transformers Powered by Solar Ponds. Appl. Energy 2014, 136, 611–618. [Google Scholar] [CrossRef]

- Gomri, R. Energy and Exergy Analyses of Seawater Desalination System Integrated in a Solar Heat Transformer. Desalination 2009, 249, 188–196. [Google Scholar] [CrossRef]

- Wang, J.; Chen, H.; Deng, H.; Dong, F. A Combined Power and Steam System Integrated with Solar Photovoltaic/Thermal Collector: Thermodynamic Characteristics and Cost-Benefit Analyses. Case Stud. Therm. Eng. 2022, 39, 102477. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Wang, L.; Bu, X.; Zeng, J.; Xie, N.; Xu, Q. A Solar-Assisted Double Absorption Heat Transformer: Off-Design Performance and Optimum Control Strategy. Energy Convers. Manag. 2019, 196, 614–622. [Google Scholar] [CrossRef]

- Liu, F.; Sui, J.; Liu, T.; Jin, H. Energy and Exergy Analysis in Typical Days of a Steam Generation System with Gas Boiler Hybrid Solar-Assisted Absorption Heat Transformer. Appl. Therm. Eng. 2017, 115, 715–725. [Google Scholar] [CrossRef]

- Chaiyat, N.; Kiatsiriroat, T. Simulation and Experimental Study of Solar-Absorption Heat Transformer Integrating with Two-Stage High Temperature Vapor Compression Heat Pump. Case Stud. Therm. Eng. 2014, 4, 166–174. [Google Scholar] [CrossRef]

- INEGI Instituto Nacional de Estadística y Geografía. Available online: https://www.inegi.org.mx/app/areasgeograficas/#collapse-Resumen (accessed on 21 May 2024).

- SENER Secretaria de Energía. Available online: https://www.gob.mx/sener (accessed on 21 May 2024).

- SMN Servicio Meteorologico Nacional. Available online: https://smn.conagua.gob.mx/es/ (accessed on 23 November 2023).

- Heß, S.; Oliva, A. Guide to Solar Thermal System Design for Selected Industrial Processes; O. Ö. Energiesparverband: Linz, Austria, 2010. [Google Scholar]

- Duffie, J.; Beckman, W.; Worek, W.M. Solar Engineering of Thermal Processes, 2nd ed.; Wiley: New York, NY, USA, 1991; 919p. [Google Scholar]

- winsconsin University TRNSYS 16.1. Available online: https://sel.me.wisc.edu/trnsys/features/ (accessed on 2 June 2019).

- Kalogirou, S.A. Designing and Modeling Solar Energy Systems. In Solar Energy Engineering; Elsevier: Amsterdam, The Netherlands, 2014; pp. 583–699. [Google Scholar] [CrossRef]

- Tamhane, A.C. Single Factor Experiments: Completely Randomized Designs. In Statistical Analysis of Designed Experiments; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; pp. 70–125. ISBN 9781118491621. [Google Scholar]

- López-Pérez, L.A.; Flores-Prieto, J.; Ríos-Rojas, C. Comfort Temperature Prediction According to Adaptive Approach for Educational Buildings in Tropical Climate Using Artificial Neural Networks. Energy Build. 2021, 251, 111328. [Google Scholar] [CrossRef]

- Tian, Z.; Perers, B.; Furbo, S.; Fan, J. Annual Measured and Simulated Thermal Performance Analysis of a Hybrid Solar District Heating Plant with Flat Plate Collectors and Parabolic Trough Collectors in Series. Appl. Energy 2017, 205, 417–427. [Google Scholar] [CrossRef]

- Hernández, J.A.; Bassam, A.; Siqueiros, J.; Juárez-Romero, D. Optimum Operating Conditions for a Water Purification Process Integrated to a Heat Transformer with Energy Recycling Using Neural Network Inverse. Renew. Energy 2009, 34, 1084–1091. [Google Scholar] [CrossRef]

- Solís-Pérez, J.E.; Gómez-Aguilar, J.F.; Hernández, J.A.; Escobar-Jiménez, R.F.; Viera-Martin, E.; Conde-Gutiérrez, R.A.; Cruz-Jacobo, U. Global Optimization Algorithms Applied to Solve a Multi-Variable Inverse Artificial Neural Network to Improve the Performance of an Absorption Heat Transformer with Energy Recycling. Appl. Soft Comput. J. 2019, 85, 105801. [Google Scholar] [CrossRef]

- Morales, L.I.; Conde-Gutiérrez, R.A.; Hernández, J.A.; Huicochea, A.; Juárez-Romero, D.; Siqueiros, J. Optimization of an Absorption Heat Transformer with Two-Duplex Components Using Inverse Neural Network and Solved by Genetic Algorithm. Appl. Therm. Eng. 2015, 85, 322–333. [Google Scholar] [CrossRef]

- Varela-Martínez, K.; Hernández, J.A.; Juárez, D.; Huicochea, A. Heat Transfer Study of Four Nested Helical Coils inside an Absorption Heat Transformer. Exp. Heat Transf. 2022, 35, 993–1015. [Google Scholar] [CrossRef]

- MathWorks Inc. Statistics and Machine Learning ToolboxTM User’s Guide. 1993. Available online: http://cda.psych.uiuc.edu/matlab_pdf/stats.pdf (accessed on 28 May 2024).

- Delgado-Gonzaga, J.; Rivera, W.; Juárez-Romero, D. Integration of Cycles by Absorption for the Production of Desalinated Water and Cooling. Appl. Therm. Eng. 2023, 220, 119718. [Google Scholar] [CrossRef]

- Demesa, N.; Hernández, J.A.; Juárez, D.; Huicochea, A. Experimental Assessment of Heat Exchangers with Nested Helical Coils for an Absorption Heat Transformer. Exp. Heat Transf. 2021, 34, 140–161. [Google Scholar] [CrossRef]

- Bern, C.; Huguenin-landl, B.; Studer, C. Handbook Part I: Software Global Meteorological Database Version 7 Software and Data for Engineers, Planers and Education. 2017. Available online: https://meteonorm.com/assets/downloads/mn73_software.pdf (accessed on 13 April 2024).

- Deng, Z.; Chen, Q. Artificial Neural Network Models Using Thermal Sensations and Occupants’ Behavior for Predicting Thermal Comfort. Energy Build. 2018, 174, 587–602. [Google Scholar] [CrossRef]

| Project | Location | Year of Operations Start | Installed Net Collector Area, m2 | Storage Volume, m3 | Installed Thermal Power, kWth | Kind of Fuel Used | Solar Thermal Energy Used for | Temperature Range, °C | Life Time, Year | Solar Fraction, % | Investment Costs, €/m2 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Poultry Processing | Simpang Renggam, Malaysia | 2017 | 181.35 | 8 | 163.2 | − | − | 70–75 | − | 80 | 498.4 |

| SKZ | Würzburg, Germany | 2018 | 46 | 6 | 32.2 | − | Hot water bath | − | 37 | 1050.0 | |

| Petri | Germany | 2018 | 256 | 15 | 179.2 | − | − | 60 | − | 34 | 291.8 |

| Die Badische Staatsbrauerei Rothaus AG | Grafenhausen, Germany | 2018 | 998 | 50 | 698.6 | Fuel oil | Cleaning bottles and heating water | 15–85 | − | − | 771.5 |

| FIMA Bulking | Klang, Malaysia | 2019 | 481 | 3 | − | Fuel oil | − | − | − | − | 427.3 |

| IOI Pan-Century Oleochemicals Sdn Bhd | Jalan Pekeliling, Malaysia | 2020 | 255.75 | 20 | 338.25 | Natural gas | Pre-heating water to boiler | 70–75 | − | 10 | 273.7 |

| Clean Energy Heating Project in Shandong Dingtai Animal Husbandry Company | Jinan, China | 2020 | 3825 | 270 | 1175 | Natural gas | Heating and hot water supply for pig breeding | 45–55 | 25 | 70 | 94.1 |

| Rongxing meat and poultry processing | Rongcheng City, China | 2021 | 1018.4 | 40 | 712.88 | − | Used for hot water requirement of processing workshop | 55–60 | 20 | 75 | 173.1 |

| Weishan County Fisheries | Jining city, China | 2021 | 3800 | 200 | 2660 | − | Used for water heating of nursery pond in fishing ground | 25–28 | 20 | 60 | 141.5 |

| Haiyang Zhongtai Garment Factory Project | Jining city, China | 2021 | 5836 | 360 | 4085.2 | − | Used for rinsing water heating in printing and dyeing rinsing workshop | 60–70 | − | 80 | 184.3 |

| Dongwang Dairy Farm | Lianyungang City, China | 2022 | 211.5 | 39 | 110 | − | Producing high-temperature hot water for pasteurization of milk | 60–85 | 15 | 30 | 323.8 |

| Component | Description | Type | Identifier |

|---|---|---|---|

| Solar resource | Climatological data of a typical year, in TMY-2 format | 15-2 | TMY-2 |

| Solar collector field | Evacuated tube collector | 71 | Collector |

| Heat exchanger | To counterflow | 5b | HX |

| Hydraulic pump | Variable speed pump | 110 | Pump1, 2, 3 and 4 |

| Storage tank | Stratified, vertical and uniform loss hot water tank | 158 | Tank |

| Auxiliary heater | Auxiliary heater with electric resistors | 138 | AH |

| Auxiliary element | Calculator tool | − | Pump_34_controller |

| Load profile | Hot water demand required in the process | 14 h | Load_profile |

| Differential controller, On-Off | On/Off signal | 2b | Collector_control |

| Process_control | |||

| Printer | Represents the output analysis variables in a data sheet | 25a | Output |

| Thermodynamic algorithm | Calls the thermodynamic algorithm implemented in MATLAB | 55 | AHT-ANN |

| Parameter | Sensor | Description | Mean | SD | Min. | Max. |

|---|---|---|---|---|---|---|

| Temperature, °C | T1 | Desorber heating water input temperature | 75.8 | 10.9 | 23.0 | 86.8 |

| T2 | Desorber heating water output temperature | 71.6 | 10.4 | 22.8 | 81.8 | |

| T3 | Condenser cooling water input temperature | 20.0 | 3.1 | 12.7 | 29.8 | |

| T4 | Condenser cooling water output temperature | 22.0 | 3.7 | 12.5 | 32.1 | |

| T5 | Evaporator heating water input temperature | 76.5 | 10.7 | 22.0 | 95.1 | |

| T6 | Evaporator heating water output temperature | 72.9 | 10.1 | 22.6 | 94.4 | |

| T7 | Absorber useful water input temperature | 24.7 | 7.0 | 15.7 | 70.6 | |

| T8 | Absorber useful water output temperature | 73.9 | 29.9 | 16.1 | 111.4 | |

| T9 | Desorber refrigerant output temperature | 56.2 | 11.1 | 21.8 | 71.8 | |

| T10 | Condenser refrigerant output temperature | 31.1 | 5.5 | 15.2 | 47.7 | |

| T11 | Evaporator refrigerant input temperature | 31.6 | 5.6 | 20.3 | 62.7 | |

| T12 | Evaporator refrigerant output temperature | 48.0 | 11.0 | 21.0 | 75.0 | |

| T13 | Absorber weak solution output temperature | 80.5 | 22.9 | 15.3 | 123.0 | |

| T14 | Desorber weak solution input temperature | 60.7 | 15.5 | 18.4 | 82.0 | |

| T15 | Desorber strong solution output temperature | 66.3 | 13.6 | 23.3 | 85.6 | |

| T16 | Absorber strong solution input temperature | 69.8 | 19.3 | 22.6 | 107.0 | |

| Pressure, kPa | PLOW | Low-pressure line | 3.7 | 2.6 | 2.6 | 12.7 |

| PHIGH | High-pressure line | 20.6 | 10.1 | 1.3 | 43.3 | |

| Mass Flow, kg/s | Condenser mass flow rate | 4.5 × 10−4 | 3.14 × 10−4 | 5.3 × 10−5 | 2.2 × 10−3 | |

| Desorber mass flow rate | 4.2 × 10−2 | 0.1 | 1.8 × 10−5 | 0.93 | ||

| Absorber mass flow rate | 2.3 × 10−2 | 4.5 × 10−2 | 2.4 × 10−5 | 0.89 | ||

| Concentration, % | XSTRONG | Strong solution concentration LiBr/H2O | 59.8 | 4.2 | 48.8 | 69.4 |

| XWEAK | Weak solution concentration LiBr/H2O | 57.1 | 4.9 | 45.0 | 67.4 |

| Component | Parameter | Value |

|---|---|---|

| TMY-2 | Environmental conditions for a typical year | TMY-2 format |

| Collector | Type | Evacuated tubes |

| Net collector area | Variable | |

| Fluid heat carrier (70% water, 30% ethylene glycol) | Density, 1035 kg/m3 | |

| Specific heat, 3.72 kJ/kg K | ||

| Efficiency parameters | First-term solar collector thermal efficiency equation (dimensionless), 0.811 | |

| Second-term solar collector thermal efficiency equation, 2.71 W/m2 K | ||

| Third-term solar collector thermal efficiency equation, 0.01 W/m2 K | ||

| Azimuthal angle, ° | In front of the Equator | |

| Tilt angle | 18 ° | |

| HX | Flow direction | Counterflow |

| Fluid heat carrier (70% water, 30% ethylene glycol), cold side | Density, 1035 kg/m3 | |

| Specific heat, 3.72 kJ/kg K | ||

| Fluid heat carrier (water), hot side | Density, 1000 kg/m3 | |

| Specific heat, 4.19 kJ/kg K | ||

| Heat transfer coefficient | 24 kW/K | |

| Pump1 | Working fluid | 70% water, 30% ethylene glycol |

| Capacity | 6000 kg/h | |

| Rated power | 6 kW | |

| Use efficiency | 0.6 | |

| Engine efficiency | 0.9 | |

| Pump1, 2, 3 and 4 | Working fluid | Water |

| Capacity | 6000 kg/h | |

| Rated power | 5 kW | |

| Use efficiency | 0.6 | |

| Engine efficiency | 0.9 | |

| Tank | Type | Vertically stratified thermostatic storage tank |

| Volume | Variable | |

| Working fluid, water | Density, 1000 kg/m3 | |

| Specific heat, 4.19 kJ/kg K | ||

| Heat transfer coefficient, | 0.83 kJ/h m2 K | |

| Stratification sections | 5 | |

| AH | Working fluid, water | Density, 1000 kg/m3 |

| Specific heat, 4.19 kJ/kg K | ||

| Efficiency | 0.8 |

| System | Storage Tank Requirements | Useful Water Production | ||||||

|---|---|---|---|---|---|---|---|---|

| Demand, L/day | , kg/s | Tint, °C | Tout, °C | Demand, L/day | , kg/s | Tint, °C | Tout, °C | |

| SWHS-AHT | 17,280 | 0.2 | 15.8 | 81.2 | 1693.4 | 0.019 | 15.8 | 94.4 |

| SWHS [44] | 1693.4 | 0.019 | 15.8 | 94.4 | ||||

| Hyperparameter Selection | |||||||||||

| Coefficient | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1 | |

| Learning rate | R2, − | 0.900 | 0.912 | 0.912 | 0.935 | 0.926 | 0.925 | 0.927 | 0.923 | 0.922 | 0.921 |

| MAE, °C | 4 | 3.8 | 3.9 | 3.6 | 3.8 | 3.8 | 3.8 | 4 | 3.9 | 4 | |

| Momentum | R2, − | 0.91 | 0.927 | 0.923 | 0.922 | 0.9208 | 0.940 | 0.924 | 0.925 | 0.925 | 0.925 |

| MAE, °C | 3.8 | 3.8 | 4 | 3.9 | 4 | 3.6 | 3.8 | 3.8 | 3.8 | 3.7 | |

| k-Value Selection | |||||||||||

| k | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | |

| R2, − | 0.905 | 0.923 | 0.920 | 0.930 | 0.928 | 0.928 | 0.915 | 0.924 | 0.921 | 0.922 | |

| MAE, °C | 4 | 3.8 | 3.5 | 3.2 | 3.4 | 3.6 | 3.6 | 3.8 | 3.8 | 3.9 | |

| AHT-ANN Optimization | |||||||||||

| Neuron | 2 | 4 | 6 | 8 | 10 | 12 | 15 | 16 | 18 | 20 | |

| LOGSIG | R2, − | 0.866 | 0.886 | 0.901 | 0.914 | 0.926 | 0.918 | 0.951 | 0.951 | 0.950 | 0.950 |

| MAE, °C | 7.2 | 5.6 | 4.9 | 4.3 | 4 | 3.6 | 2.8 | 2.8 | 2.8 | 2.9 | |

| TANSIG | R2, − | 0.866 | 0.885 | 0.904 | 0.916 | 0.93 | 0.933 | 0.964 | 0.964 | 0.954 | 0.952 |

| MAE, °C | 7.2 | 5.6 | 4.8 | 4.2 | 3.6 | 3.4 | 2.7 | 2.7 | 2.8 | 2.8 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Pérez, L.A.; Torres-Díaz, T.; Pérez Grajales, S.G.; Flores Prieto, J.J.; Juárez Romero, D.; Hernández Pérez, J.A.; Huicochea, A. Solar Water Heating System with Absorption Heat Transformer for Annual Continuous Water Heating. Processes 2024, 12, 1650. https://doi.org/10.3390/pr12081650

López-Pérez LA, Torres-Díaz T, Pérez Grajales SG, Flores Prieto JJ, Juárez Romero D, Hernández Pérez JA, Huicochea A. Solar Water Heating System with Absorption Heat Transformer for Annual Continuous Water Heating. Processes. 2024; 12(8):1650. https://doi.org/10.3390/pr12081650

Chicago/Turabian StyleLópez-Pérez, Luis Adrián, Tabai Torres-Díaz, Sandro Guadalupe Pérez Grajales, José Jassón Flores Prieto, David Juárez Romero, José Alfredo Hernández Pérez, and Armando Huicochea. 2024. "Solar Water Heating System with Absorption Heat Transformer for Annual Continuous Water Heating" Processes 12, no. 8: 1650. https://doi.org/10.3390/pr12081650

APA StyleLópez-Pérez, L. A., Torres-Díaz, T., Pérez Grajales, S. G., Flores Prieto, J. J., Juárez Romero, D., Hernández Pérez, J. A., & Huicochea, A. (2024). Solar Water Heating System with Absorption Heat Transformer for Annual Continuous Water Heating. Processes, 12(8), 1650. https://doi.org/10.3390/pr12081650