Abstract

The biflavonoid extraction from ginkgo (Ginkgo biloba L.) leaves using solvent-based extraction with 70% ethanol, alone and in combination with enzyme-assisted, ultrasound-assisted, mechanical-assisted, and chemically assisted methods was investigated and the influence of extraction duration was explored. The total content of polyphenols, flavonoids, and phenolic acids in the extracts was determined spectrophotometrically, while individual biflavonoids were identified and quantified using HPLC-DAD. Amentoflavone, bilobetin, ginkgetin, isoginkgetin, and sciadopitysin were identified in all our extracts. Among these, sciadopitysin emerged as the most prevalent biflavonoid with an amount above 1 mg g−1 dw, followed by isoginkgetin. Comparative analysis of the extraction methods revealed that, except for chemically assisted extraction, similar levels of compounds were obtained after 45 min of extraction. However, enzymatic (EAE) and mechanical-assisted extraction (MAE) exhibited significantly higher individual (EAE: 19–41% higher; MAE: 22–67% higher) and total biflavonoid (EAE: 29% higher; MAE 50% higher) levels after just 5 min, suggesting their potential to abbreviate extraction duration and facilitate the efficient retrieval of target compounds. However, as extraction efficiency varies between individual biflavonoids, our findings also underscore the importance of considering specific compounds and extraction kinetics in the optimization of ginkgo leaf extraction processes.

Keywords:

amentoflavone; assisted extraction; biflavonoids; bilobetin; ginkgo; ginkgetin; isoginkgetin; sciadopitysin 1. Introduction

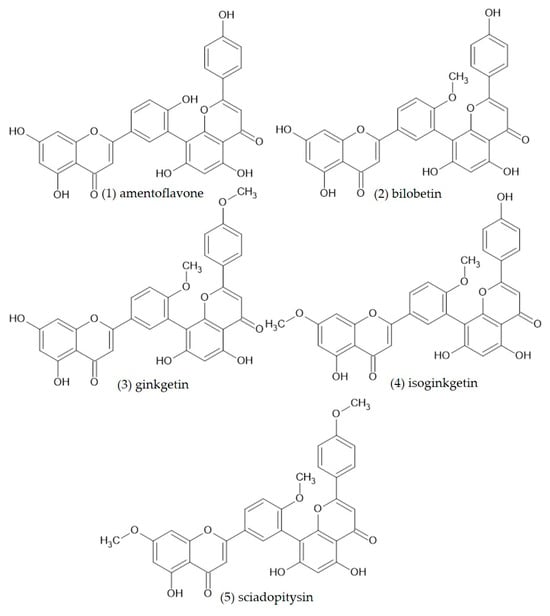

The ginkgo (Ginkgo biloba L.), often referred to as the “maidenhair tree”, is a living fossil that has withstood the test of time for over 270 million years [1]. Revered for its unique fan-shaped leaves and remarkable adaptability, this ancient tree has not only survived but has also become a fascinating topic in modern research and wellness practice. Ginkgo extract, derived from the leaves of the ancient ginkgo tree, has a rich history steeped in traditional medicine and cultural significance [2]. This herbal remedy has endured through the centuries, evolving from its roots in traditional Eastern medicine to a globally recognized dietary supplement with a variety of potential health benefits [1,3]. The standardized extract preparation of ginkgo leaves contains 24% flavonoids, 6% terpene trilactones (TTLs), and less than 5 ppm ginkgolic acid [4]. To date, 110 different flavonoid structures have been identified in a ginkgo, including flavonol and its glycosides, flavone and its glycosides, flavanone and its glycosides, isoflavone and its glycosides, flavan-3-ols, biflavonoids and biginkgosides [4]. Biflavonoids are dimeric structures of flavonoids that have recently gained attention as antimicrobial, especially antiviral agents, and as molecules with the potential for the prevention and treatment of cancer and neurological diseases [3,5]. The first characterized biflavonoid, ginkgetin, was isolated from ginkgo leaves and so far 13 different biflavonoids have been identified in a ginkgo, with amentoflavone, bilobetin, ginkgetin, isoginkgetin, and sciadopitysin being the most abundant [3,6] (Figure 1).

Figure 1.

Chemical structure of five biflavonoids from ginkgo leaves (1) amentoflavone, (2) bilobetin, (3) ginkgetin, (4) isoginkgetin, and (5) sciadopitysin.

Flavonoids, a diverse group of polyphenolic compounds consisting of 6000 different structures, are known for their strong antioxidant properties and numerous health benefits [7]. However, the biological activity of flavonoids can vary considerably due to their structure [7,8]. For example, biflavonoids have significantly lower antioxidant activity than monomeric subunits, but higher neuroprotective potential [9]. The extraction of flavonoids from plant sources requires careful optimization to increase both extraction efficiency and yield without overtaxing resources [10]. Optimizing extraction processes for flavonoids from plant sources is paramount for ensuring maximum yield, minimizing production costs, and facilitating reliable results in research while maintaining product quality [11,12]. By carefully controlling extraction parameters, such as temperature and solvent choice, the degradation of bioactive compounds is minimized, thus preserving their health benefits [12]. Furthermore, optimized processes contribute to reducing environmental impact by minimizing solvent usage and waste generation [13]. Selective extraction techniques enable the isolation of specific compounds tailored to desired applications, thereby unlocking the full potential of plant-derived compounds across various fields [12]. The extraction technique used for flavonoids extraction may be divided into two groups: Conventional techniques (maceration, reflux, and Soxhlet extraction) and modern techniques (extraction by ultrasound, microwaves, pressurized liquid, supercritical fluid, enzyme assistance, matrix solid-phase dispersion, etc.) [12]. Ultrasound-assisted extraction (UAE) uses high-frequency sound waves to break down the cell walls and accelerate the release of bioactive compounds from the plant material. In this method, the plant material is immersed in a solvent and simultaneously sonicated with ultrasonic waves, creating cavitation that breaks down the cell walls and facilitates the extraction of the compounds. UAE is known for its ability to speed up processes, shorten extraction time, and increase yields. It is often used to extract polyphenols, flavonoids, and essential oils [14,15,16]. In enzyme-assisted extraction (EAE), specific enzymes are used to break down the cell walls and release the target compounds. It is selective, environmentally friendly, improves efficiency, and is often used to extract polyphenols, polysaccharides, and proteins [17,18]. Mechanically assisted extraction (MAE) uses mechanical force such as crushing or pressing to break up the plant tissue and improve the release of the substances. It is simple, cost-effective, and suitable for large-scale processes and is generally used for the extraction of oils and lipophilic compounds [19,20]. In chemically assisted extraction (CAE), solvents or reagents are used to dissolve and extract bioactive compounds. This versatile method can be tailored to specific compounds and is efficient for the extraction of polyphenols, alkaloids, and terpenoids from plant material on an industrial scale. Each of the mentioned technique offer various advantages, which are selected based on the target compounds, the properties of the plant material, and the desired extraction efficiency.

Over the years, numerous research endeavors have been dedicated to refining the extraction methods for flavonoids from ginkgo leaves, with a predominant focus on total flavonoids or monomeric flavonoids [21,22,23,24,25,26,27]. Information regarding the targeted extraction of biflavonoids from ginkgo leaves remains scarce. As per our current knowledge, only one study [28] has addressed this issue. Lei et al. [28] optimized the extraction process for four biflavonoids—bilobetin, ginkgetin, isoginkgetin, and sciadopitysin—from ginkgo using ultrasonic-assisted ionic liquid extraction (UAILE). However, it is noteworthy that the authors did not specify the specific part of the ginkgo plant from which the biflavonoids were extracted in their paper. Considering the significant pharmacological potential associated with biflavonoids and the accessibility of ginkgo leaves as a cost-effective source of these compounds, our study aims to assess various extraction techniques, including solvent-based extraction, enzyme-assisted extraction, ultrasound-assisted extraction, mechanical-assisted extraction, and chemically assisted extraction, for isolating biflavonoids from ginkgo leaves. We meticulously examined parameters such as solvent composition and extraction duration to evaluate their impact on the content of total phenolics, total flavonoids, total phenolic acids determined spectrophotometrically, as well as the five most abundant flavonoids from ginkgo leaves—amentoflavone, bilobetin, ginkgetin, isoginkgetin, and sciadopitysin—along with the total biflavonoid content using HPLC-DAD analysis.

2. Materials and Methods

2.1. Plant Material and Extraction

Ginkgo leaves were collected from a ginkgo tree in an urban area in Croatia, air-dried, and stored in a drying cabinet until analysis.

Solid–liquid extraction (SLE): Extracts were prepared by mixing 60 mg of dried and ground ginkgo leaves with 2 mL of 70% ethanol. The samples were briefly mixed and placed in an ultrasonic bath for 10 min, followed by 45 min in the rotator. This is a commonly used method in our laboratory for the preparation of various plant extracts. At the end, the samples were centrifuged and the supernatant was used for further analysis.

Enzyme-assisted extraction (EAE): 60 mg amount of dried and ground leaves were mixed with 0.6 mL of 0.1 M acetate buffer pH 4 with 6% (v/v) enzyme (Viscozyme L (Novozymes, Bagsvaerd, Denmark) a blend of beta-glucanases, pectinases, hemicellulases and xylanases with declared activity ≥ FBGU/g. Each FBG is the amount of enzyme required to hydrolyze β-glucans under the standard condition (30 °C, pH 5.0). The content was briefly homogenized with a vortex and the enzymatic degradation of the lignocellulose was carried out for 4 and 24 h at 50 °C and 200 rpm. After enzymatic treatment, 1.4 mL of 100% ethanol was added to the sample to obtain 70% ethanol in the sample. The procedure that followed was the same as for solid–liquid extraction.

Ultrasound-assisted extraction (UAE): 60 mg amounts of dried and ground leaves were mixed with 0.6 mL of distilled water. The content was briefly homogenized and treated with ultrasound (Sonoplus HD 3100, Berlin, Germany, horn type SH 70 G, 20 kHz, Bandelin GmbH, 62% amplitude) for 10 min with constant cooling. After the ultrasound treatment, 1.4 mL of 100% ethanol was added to the sample to obtain 70% ethanol in the sample. The procedure that followed was the same as for solid–liquid extraction.

Mechanically assisted extraction (MAE): 60 mg of dried and ground leaves were mixed with 0.6 mL of distilled water followed by adding 120 mg of 4 mm glass beads to the sample. The content was shaken at maximum speed of 600 rpm for 20 min. After the mechanical treatment, 1.4 mL of 100% ethanol was added to the sample to obtain 70% ethanol in the sample. The procedure that followed was the same as for solid–liquid extraction.

Chemically assisted extraction (CAE): 60 mg of dried and ground leaves were mixed with 0.5 mL of 0.1% TritonX solution and 10% NaClO solution. The samples were stirred for 48 h at 25 °C at 200 rpm. After chemical treatment, 1.4 mL of 100% ethanol was added to the sample to obtain 70% ethanol in the sample. The procedure that followed was the same as for solid–liquid extraction.

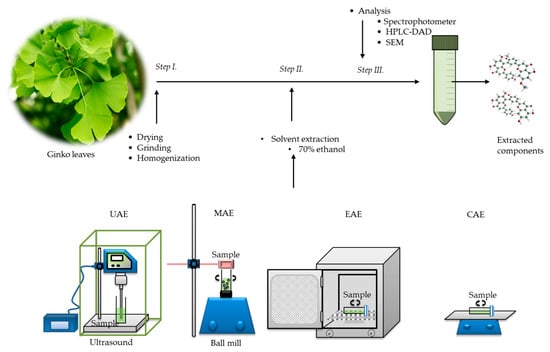

Schematically, extraction process is shown in Figure 2.

Figure 2.

Schematic representation of extraction process.

2.2. Determination of Total Polyphenols, Flavonoids and Phenolic Acids Content

Determination of total phenolic compounds was carried out through a colorimetric reaction involving Folin–Ciocalteu reagent [29]. Absorbance readings at 765 nm were taken after a 2 h incubation period. Gallic acid was employed for the calibration curve, and the outcomes are presented as gallic acid equivalents per dry weight (µg GAE mg−1 dw).

For the determination of total flavonoids, the methodology outlined by Zhinshen et al. [30], adapted to a reduced scale, was employed. The absorbance of the resulting mixture was measured at 510 nm. Catechin was utilized for the calibration curve, and the findings are expressed as catechin equivalents per dry weight (µg CE mg−1 dw).

Total phenolic acids were determined using Arnow’s reagent [31]. Absorbance readings were taken at 505 nm. Caffeic acid served as the standard for constructing the calibration curve, and the results were expressed as caffeic acid equivalents per dry weight (µg CAE mg−1 dw).

2.3. Determination of Individual Biflavonoids Using HPLC-DAD

The analysis of individual biflavonoids, amentoflavone, bilobetin, ginkgetin, isoginkgetin, and sciadopitysin, was performed utilizing an Agilent 1260 Infinity II High-Performance Liquid Chromatography (HPLC) system (Agilent, Santa Clara, CA, USA) equipped with a quaternary pump, autosampler, column compartment, and a diode array detector (DAD). The acquisition and subsequent data processing were carried out employing the Agilent OpenLAB CDS software (version 2.6, Agilent, Santa Clara, CA, USA). Chromatographic separation was achieved using a Zorbax 300Extend-C18 column (Agilent, Santa Clara, CA, USA). Analysis parameters were similar to those published elsewhere [6]. Identification and quantification were accomplished employing commercially available biflavonoid standards, as previously detailed in our report where we also reported curve equation, R2, LOD, and LOQ [6]. Results were expressed per dry weight (dw).

2.4. Scanning Electron Microscopy (SEM)

Scanning electron microscopy (SEM) was used to examine the morphology of the samples using a Tescan Vega 3 SEM (Tescan Brno S.R.O., Brno, Czech Republic) apparatus. The samples were coated for 60 s in an argon plasma with a gold/platinum conductive coating prior to scanning. A 10 kV voltage and a secondary electron (SE) detector were utilized in the study.

2.5. Statistical Analysis

All extractions and measurements were conducted in at least in triplicate, and the results are expressed as mean ± standard deviation (SD). All statistical analyses were performed using XLSTAT Excel data add-on, version 2024.1. One-way ANOVA and subsequent multiple mean comparisons with Tukey’s HSD test were executed, and distinctions between measurements were considered significant at p < 0.05.

3. Results

3.1. Influence of Pretreatment on Total Polyphenols, Flavonoids, Phenolic Acids and Individual and Total Biflavonoids

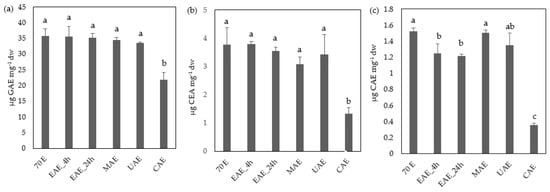

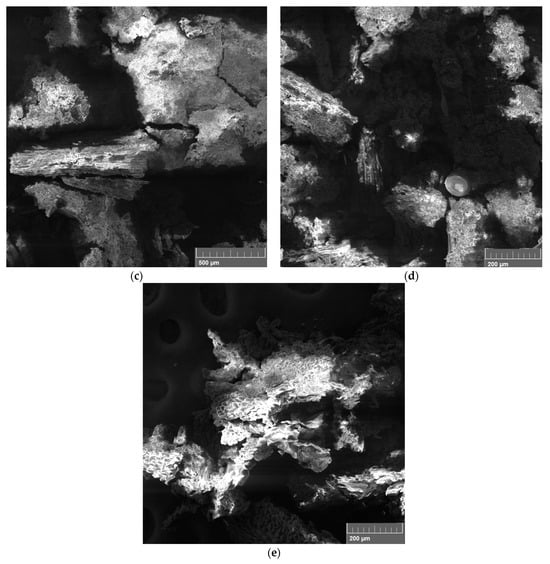

In the initial phase of this research, the impact of various pretreatment processes (EAE, MAE, CAE, and UAE) on the levels of total polyphenols, phenolic acids, and flavonoids was analyzed. The findings from this investigation are shown in Figure 3.

Figure 3.

Influence of different pretreatment methods, enzyme-assisted for 4 h (EAE_4h), enzyme-assisted for 24 h (EAE_24h), mechanical-assisted (MAE), chemically assisted (CAE), and ultrasound-assisted (UAE), and time of extraction on the content of total polyphenols (a), total flavonoids (b) and total phenolic acids (c) in comparison with commonly used solid–liquid extraction using 70% ethanol (70 E). Values marked with different letters are significantly different at p < 0.05.

Overall, the pretreatment methods UAE, MAE, and EAE combined with 70% extraction exhibited comparable outcomes in terms of total polyphenols and total flavonoids when compared to extraction with 70% ethanol alone. However, regarding total phenolic acids, extraction with 70% ethanol alone and MAE yielded the highest content, while CAE and EAE proved to be less effective. Moreover, a comparison of the total polyphenols, total flavonoids, and total phenolic acids obtained after 4 h and 24 h enzymatic treatments of the sample showcased similar extraction efficiencies. Conversely, CAE extraction resulted in significantly lower yields for total polyphenols, flavonoids, and total phenolic acids compared to other methods.

A similar trend across both individual (Table 1) and total biflavonoids (Figure 3) was observed, where UAE, MAE, and EAE yielded comparable results, while CAE resulted in lower amounts. The only exception was amentoflavone, which exhibited the highest concentration, significantly surpassing extraction solely in 70% ethanol, MAE, and CAE in an extract after EAE extraction over 24 h. Notably, in the analyzed sample, amentoflavone appeared in the lowest concentration among the biflavonoids, whereas sciadopitysin followed by isoginkgetin was the most abundant (Table 1).

Table 1.

Influence of different pretreatment methods, enzyme-assisted for 4 h (EAE_4h), enzyme-assisted for 24 h (EAE_24h), mechanical-assisted (MAE), chemically assisted (CAE), and ultrasound-assisted (UAE), and time of extraction on the content of individual biflavonoids in comparison with commonly used solid–liquid extraction using 70% ethanol (70 E). Values marked with different letters are significantly different at p < 0.05.

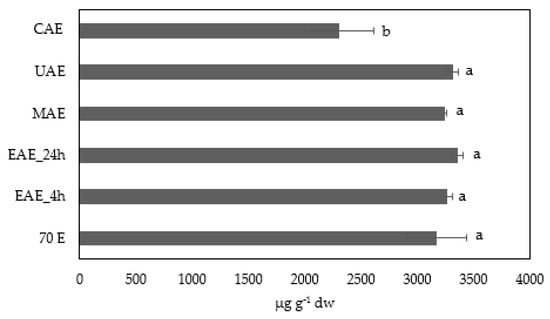

The individual biflavonoid contents mirror those of total biflavonoids (Figure 4), which ranged between 3169 and 3322 µg mg−1 dw in extracts prepared by all tested methods except CEA, which yielded significantly lower amounts of total biflavonoids (2305.33 ± 308.44 µg g−1 dw). Consequently, based on the obtained results, the CAE + 70% ethanol and EAE + 70% ethanol (24 h) methods were excluded from further experiments.

Figure 4.

Influence of different pretreatment methods, enzyme-assisted for 4 h (EAE_4h), enzyme-assisted for 24 h (EAE_24h), mechanical-assisted (MAE), chemically assisted (CAE), and ultrasound-assisted (UAE), and time of extraction on the content of total biflavonoids in comparison with commonly used solid–liquid extraction using 70% ethanol (70 E). Values marked with different letters are significantly different at p < 0.05.

3.2. Influence of Extraction Time on Total Polyphenols, Flavonoids, Phenolic Acids and Individual and Total Biflavonoids

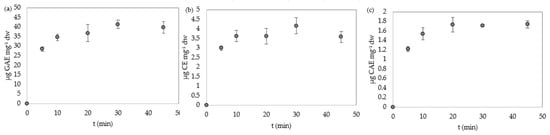

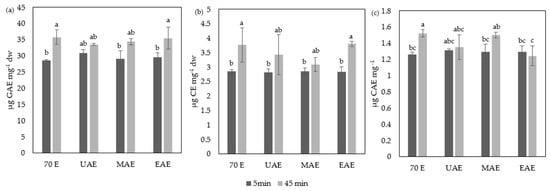

In the second phase of the research, the impact of varying durations of the extraction process with 70% ethanol on the levels of total polyphenols, phenolic acids, flavonoids, individual biflavonoids (amentoflavone, bilobetin, ginkgetin, isoginkgetin, and sciadopitysin), and total bioflavonoids was explored. The results for total polyphenols, total flavonoids, and total phenolic acids can be observed in Figure 5.

Figure 5.

Dynamic change in total polyphenols (a), total flavonoids (b), and total phenolic acids (c) in extract of ginkgo leaves prepared with 70% ethanol.

As illustrated in Figure 5, within the first 10 min, the majority of total polyphenols, flavonoids, and phenolic acids are extracted in 70% ethanol, reaching their peak content within 20 min under the tested material–solvent ratio. Additionally, the extraction dynamics of biflavonoids, with results for individual (a–e) and total biflavonoids (f) were examined and presented in Figure 6.

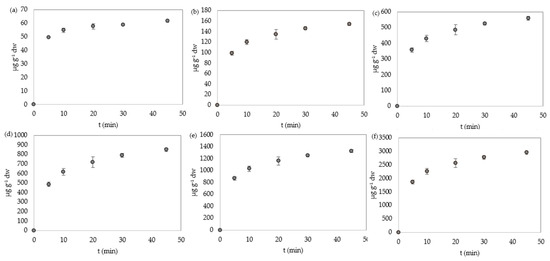

Figure 6.

Dynamic change in amentoflavone (a), bilobetin (b), ginkgetin (c), isoginkgetin (d), sciadopitisyn (e), and total biflavonoids (f) in an extract of ginkgo leaves prepared with 70% ethanol.

The obtained results revealed a positive correlation between the duration of the extraction process and the efficiency of extracting both individual and total biflavonoids content. This was evidenced by the consistent increase in the content of all tested biflavonoids within the extract. While intensive extraction occurred predominantly within the first 10–20 min, performed experiments demonstrated a time-dependent increase in biflavonoids throughout the 45 min duration, suggesting that prolonged extraction may enhance biflavonoids content.

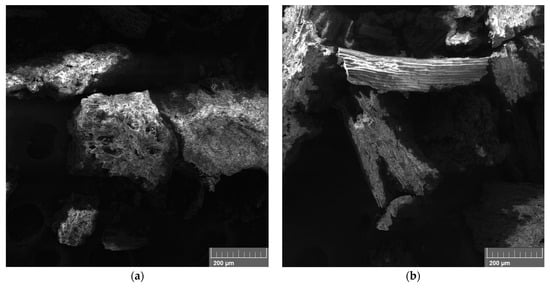

Furthermore, the extraction efficiency of total polyphenols, total flavonoids, and total phenolic acids, along with individual and total biflavonoids, using assisted extraction methods such as UAE, MAE, and EAE was explored. Morphological SEM analyses of ginkgo leaf powder before and after extraction were also conducted (Figure 7). The results unveiled distinct morphological alterations on the surface of the ginkgo leaf powder induced by various treatments. Across all treated samples, microcracks and cellular-level changes were observed, resulting in a visibly different surface structure of the sample.

Figure 7.

Morphological analysis of ginkgo sample (a) before extraction and after extraction with (b) 70% ethanol, (c) ultrasound-assisted (UAE) + 70% ethanol, (d) mechanical-assisted (MEA) + 70% ethanol and (e) enzyme-assisted (EAE) + 70% ethanol.

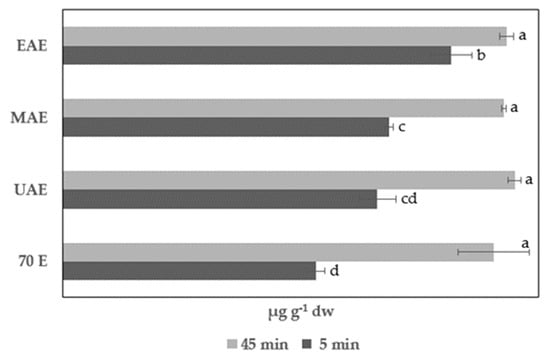

A comparative analysis of assisted extraction efficiency, employing UAE, MAE, and EAE, against extraction with 70% ethanol alone at both 5 min and 45 min durations was conducted (Figure 8, Table 2). Consistent with earlier observations, after 45 min of extraction using all three tested assisted methods, results comparable to those obtained using 70% ethanol alone were observed. Additionally, at the 5 min mark, comparable results for total polyphenols, flavonoids, and phenolic acids were observed.

Figure 8.

Comparison of the content of total polyphenols (a), flavonoids (b), and phenolic acids (c) in solid–liquid extraction using 70% ethanol (70 E), ultrasound-assisted (UAE), mechanical-assisted (MAE), and enzyme-assisted (EAE) extracts for different durations (5 min and 45 min) of the extraction process. Values marked with different letters are significantly different at p < 0.05.

Table 2.

Comparison of the content of individual biflavonoids in extracts for different durations (5 min and 45 min) of the solid–liquid extraction using 70% ethanol (70 E), ultrasound-assisted (UAE), mechanical-assisted (MAE), and enzyme-assisted (EAE) extraction processes. Values marked with different letters are significantly different at p < 0.05.

However, assisted extraction (UAE, MAE, and EAE) exhibited higher amounts of amentoflavone, bilobetin, ginkgetin, isoginkgetin, sciadopitysin, and total biflavonoids compared to extraction with 70% ethanol alone at the 5 min mark (Table 2, Figure 9).

Figure 9.

Comparison of the content of total biflavonoids in solid–liquid extraction using 70% ethanol (70 E), ultrasound-assisted (UAE), mechanical-assisted (MAE), and enzyme-assisted (EAE) extracts for different durations (5 min and 45 min) of the extraction process. Values marked with different letters are significantly different at p < 0.05.

At 5 min, both EAE and MAE resulted in significantly higher amounts of total biflavonoids compared to extraction with 70% ethanol alone (Figure 9). This suggests that the tested assisted extraction methods may effectively reduce the extraction time for biflavonoids.

4. Discussion

In recent years, traditional extraction methods have undergone a significant transformation, giving way to modern techniques meticulously designed to reduce reliance on organic solvents and streamline extraction processes [32]. These innovations are underpinned by a dual commitment to enhancing efficiency and promoting environmental sustainability. In this study, SLE, EAE, UAE, MEA, and CAE were compared. Different treatments induced varied morphological changes on the surface of ginkgo leaf powder (Figure 7), aligning with the existing literature findings [33]. The analysis of SEM photos (Figure 7) of ginkgo leaf powder before and after the application of various extraction methods revealed significant changes in morphological structure. While the structure of the powder before treatment was smooth with adjacent holes of the cell wall arranged densely, the surface of ginkgo leaf powder was damaged severely after the treatments. After the mechanical and ultrasound treatment many cracks appeared on the samples due to cavitation and mechanical friction. When it comes to samples treated with enzymes, lots of new holes appeared and adjacent holes were loosely arranged like in the results reported by Zhang et al. [34]. In the sample treated with 70% ethanol, no significant morphological change was noticed.

Among all evaluated assisted methods, except CAE, comparable amounts of total polyphenols and total flavonoids were obtained, significantly higher than those from CAE (Figure 3). Furthermore, extracts prepared with CAE exhibited significantly lower total phenolic acids content compared to those from SLE with 70% ethanol and UAE and MAE, indicating the superior efficiency of the latter methods. Thus far, it has been reported that mechanochemical-assisted extraction (MCAE), employing 21% solid reagent (NaHCO3) followed by milling, enhances the content of both total flavonoids and monomeric ones in ginkgo extracts [26]. Conversely, in contrast to our findings, CAE yielded significantly lower amounts and was not investigated further regarding extraction time. For EAE in our study, a blend of beta-glucanases, pectinases, hemicellulases, and xylanases was employed, which did not yield higher amounts of total polyphenols, flavonoids, and phenolic acids than in an extraction using just 70% ethanol for 45 min. This contrasts with the findings by Chen et al. [24], who reported increased total flavonoid content in ginkgo leaves pretreated with cellulose and pectinase compared to the control without enzymes. Han et al. [23] also highlighted the significant role of enzymes like polygalacturonase and β-glucosidase in flavonoid extraction. UAE is often recommended in the literature for extracting total flavonoids from ginkgo leaves [35,36], and presented results show comparable efficacy after 45 min as with extraction using 70% ethanol alone. However, as evident from Figure 8, UAE yielded statistically similar results after 5 min as after 45 min, suggesting accelerated extraction of total polyphenols, flavonoids, and total phenolic acids. The literature data showed the beneficial effects of UAE also for extracting other compounds from ginkgo leaves such as polysaccharides [37,38] and ginkgolides [39]. Also, UAE has shown promising results for extraction compounds such as terpene lactones from ginkgo seeds [40]. Similar to UAE, in our experiments MAE demonstrated comparable results for total polyphenols, flavonoids, and phenolic acids after 5 min and 45 min, indicating accelerated extraction with this method as well. In the case of extraction with 70% ethanol alone, the majority of total polyphenols, flavonoids, and phenolic acids were extracted within the first 20 min, after which the amount plateaued (Figure 5). The literature varies regarding extraction times for these compounds from ginkgo without assisted extraction, with Cui et al. [41] performing extractions for 4 h by shaking ginkgo leaves material on a laboratory rotary shaker with different solvents, reporting the highest amounts of total polyphenols and flavonoids in ethanol and methanol extracts. Kobus et al. [42] used maceration for 16 h hours for total flavonoid extraction, but results obtained in our study suggest that such prolonged extraction may not be necessary.

While measurements of total polyphenols, flavonoids, and phenolic acid content are commonly used for optimizing flavonoid extraction from ginkgo leaves [22,26,35,36,41,42], these methods are known to lack specificity [43]. Considering the diverse chemical structures of flavonoids, it is imperative to evaluate the extraction efficiency of each individual compound. In this study, we focused on a less studied group of flavonoids—biflavonoids, specifically the five most abundant biflavonoids in ginkgo leaves [6]. In all the extracts analyzed, amentoflavone, bilobetin, ginkgetin, isoginkgetin, and sciadopitysin were identified. Sciadopitysin was the most abundant, followed by isoginkgetin, which is consistent with the literature data [6,21,28,44]. Similar to total polyphenols and flavonoids, UAE, MAE, and EAE yielded comparable results, while CEA resulted in lower amounts of individual (Table 1) and total biflavonoids (Figure 4) after 45 min of extraction. The exception was amentoflavone, which showed significantly higher amounts in extracts after EAE for 24 h compared to extraction in 70% ethanol alone, MAE, and CEA. This suggests that the localization of amentoflavone within plant tissue/cells benefits from applied enzyme treatments, enhancing its extraction. According to the literature data and MALDI imaging, amentoflavone is localized in the outer part of leaves/tissues [44,45]. Time significantly influences the extraction of all biflavonoids when using only 70% ethanol without pretreatments; a constant increase in individual as well as total biflavonoid content over a 45 min period, with the highest increase occurring in the first 10 min was observed in this study (Figure 6). With assisted extractions (UAE, MAE, and EAE), longer extraction durations also resulted in higher amounts of all individual and total biflavonoids (Table 2, Figure 9). However, similar to the results for total polyphenols, flavonoids, and phenolic acids, higher amounts of all biflavonoids in extracts prepared with pretreatments compared to those without at the 5 min mark were observed. Significantly higher amounts were observed, especially for MAE and EAE. According to the results of this study, these techniques reduce extraction time, enabling the extraction of the highest amounts of biflavonoids in a shorter period using these methods. This aligns with the existing literature, where these techniques are acknowledged as green extraction methods due to their ability to shorten extraction duration and thereby decrease processing costs [20,46]. According to our results, UAE demonstrated higher total and individual biflavonoids content after 5 min of extraction compared to extraction with 70% ethanol alone. However, this increase was statistically significant only for amentoflavone. Lei et al. [28] reported that ultrasonic-assisted ionic liquid extraction may be utilized for extracting four biflavonoids from ginkgo: bilobetin, isoginkgetin, ginkgetin, and sciadopitysin. Similar to our findings, they noted sciadopitysin as the most abundant biflavonoids, followed by isoginkgetin and ginkgetin, with bilobetin being the least abundant. Our findings concerning individual biflavonoids underscore slight variability in extraction dynamics and kinetics due to their diverse chemical structures (Table 2) which is consistent with the finding of Lei et al. [28]. Consequently, for extraction optimization, it is preferable to employ methods capable of identifying individual compounds rather than relying on nonspecific techniques that measure the total content of compounds within a group, as is commonly seen in the literature.

5. Conclusions

In recent years, advancements in extraction techniques have aimed to enhance efficiency and environmental sustainability by minimizing reliance on organic solvents. In this study, various assisted extraction methods, including SLE, EAE, UAE, MAE, and CAE were compared focusing on ginkgo leaf powder. Distinct morphological changes induced by different treatments, consistent with previous research, were observed. Except for CAE extraction, comparable levels of total polyphenols and flavonoids were obtained, surpassing those from CAE. UAE showed comparable efficiency to SLE after 45 min, while EAE and MAE demonstrated higher efficiency after 5 min of extraction. Time significantly influenced extraction efficiency, particularly for biflavonoids, with the highest increase observed within the first 10 min. As per our results, assisted extraction methods such as EAE and MAE may reduce extraction time, facilitating efficient extraction of target compounds. This marks the initial report on biflavonoids, and we advocate for further studies delving into the kinetics of each assisted extraction method and its impact on specific biflavonoids. This study also underscores the importance of considering specific compounds and extraction dynamics when optimizing extraction processes for ginkgo leaves.

Author Contributions

Conceptualization, A.Š. and D.Š.; methodology, A.Š.; formal analysis, L.Š. and I.T.; investigation, L.Š. and I.T.; writing—original draft preparation, D.Š.; writing—review and editing, D.Š., A.Š. and B.Z.; visualization, D.Š. and A.Š.; supervision, A.Š. and B.Z.; project administration, D.Š.; funding acquisition, D.Š. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Croatian Science Foundation project “Biflavonoids role in plants: Ginkgo biloba L. as a model system” under Project No. UIP-2019-04-1018.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Akaberi, M.; Baharara, H.; Amiri, M.S.; Moghadam, A.T.; Sahebkar, A.; Emami, S.A. Ginkgo Biloba: An Updated Review on Pharmacological, Ethnobotanical, and Phytochemical Studies. Pharmacol. Res.-Mod. Chin. Med. 2023, 9, 100331. [Google Scholar] [CrossRef]

- Lin, H.; Li, W.; Lin, C.; Wu, H.; Zhao, Y. International Biological Flora: Ginkgo Biloba. J. Ecol. 2022, 110, 951–982. [Google Scholar] [CrossRef]

- Šamec, D.; Karalija, E.; Dahija, S.; Hassan, S.T.S. Biflavonoids: Important Contributions to the Health Benefits of Ginkgo (Ginkgo biloba L.). Plants 2022, 11, 1381. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Wang, Y.; Zhang, J.; Wang, S. Advances in the Chemical Constituents and Chemical Analysis of Ginkgo Biloba Leaf, Extract, and Phytopharmaceuticals. J. Pharm. Biomed. Anal. 2021, 193, 113704. [Google Scholar] [CrossRef] [PubMed]

- Tatlı Çankaya, İ.İ.; Devkota, H.P.; Zengin, G.; Šamec, D. Neuroprotective Potential of Biflavone Ginkgetin: A Review. Life 2023, 13, 562. [Google Scholar] [CrossRef] [PubMed]

- Kovač Tomas, M.; Jurčević, I.; Šamec, D. Tissue-Specific Profiling of Biflavonoids in Ginkgo (Ginkgo biloba L.). Plants 2022, 12, 147. [Google Scholar] [CrossRef]

- Shen, N.; Wang, T.; Gan, Q.; Liu, S.; Wang, L.; Jin, B. Plant Flavonoids: Classification, Distribution, Biosynthesis, and Antioxidant Activity. Food Chem. 2022, 383, 132531. [Google Scholar] [CrossRef]

- Kumar, S.; Pandey, A.K. Chemistry and Biological Activities of Flavonoids: An Overview. Sci. World J. 2013, 2013, 162750. [Google Scholar] [CrossRef] [PubMed]

- Jurčević Šangut, I.; Šarkanj, B.; Karalija, E.; Šamec, D. A Comparative Analysis of Radical Scavenging, Antifungal and Enzyme Inhibition Activity of 3′-8″-Biflavones and Their Monomeric Subunits. Antioxidants 2023, 12, 1854. [Google Scholar] [CrossRef]

- Jurinjak Tušek, A.; Šamec, D.; Šalić, A. Modern Techniques for Flavonoid Extraction—To Optimize or Not to Optimize? Appl. Sci. 2022, 12, 11865. [Google Scholar] [CrossRef]

- Chávez-González, M.L.; Sepúlveda, L.; Verma, D.K.; Luna-García, H.A.; Rodríguez-Durán, L.V.; Ilina, A.; Aguilar, C.N. Conventional and Emerging Extraction Processes of Flavonoids. Processes 2020, 8, 434. [Google Scholar] [CrossRef]

- Tzanova, M.; Atanasov, V.; Yaneva, Z.; Ivanova, D.; Dinev, T. Selectivity of Current Extraction Techniques for Flavonoids from Plant Materials. Processes 2020, 8, 1222. [Google Scholar] [CrossRef]

- Kumar, M.; Dahuja, A.; Tiwari, S.; Punia, S.; Tak, Y.; Amarowicz, R.; Bhoite, A.G.; Singh, S.; Joshi, S.; Panesar, P.S.; et al. Recent Trends in Extraction of Plant Bioactives Using Green Technologies: A Review. Food Chem. 2021, 353, 129431. [Google Scholar] [CrossRef] [PubMed]

- Yi Ling, Y.; Sook Fun, P.; Yeop, A.; Yusoff, M.M.; Gimbun, J. Assessment of Maceration, Ultrasonic and Microwave Assisted Extraction for Total Phenolic Content, Total Flavonoid Content and Kaempferol Yield from Cassia Alata via Microstructures Analysis. Mater. Today Proc. 2019, 19, 1273–1279. [Google Scholar] [CrossRef]

- Liao, J.; Guo, Z.; Yu, G. Process Intensification and Kinetic Studies of Ultrasound-Assisted Extraction of Flavonoids from Peanut Shells. Ultrason. Sonochem. 2021, 76, 105661. [Google Scholar] [CrossRef] [PubMed]

- Zimare, S.B.; Mankar, G.D.; Barmukh, R.B. Optimization of Ultrasound-Assisted Extraction of Total Phenolics and Flavonoids from the Leaves of Lobelia Nicotianifolia and Their Radical Scavenging Potential. Curr. Res. Green Sustain. Chem. 2021, 4, 100109. [Google Scholar] [CrossRef]

- Saeed, R.; Ahmed, D.; Mushtaq, M. Ultrasound-Aided Enzyme-Assisted Efficient Extraction of Bioactive Compounds from Gymnema Sylvestre and Optimization as per Response Surface Methodology. Sustain. Chem. Pharm. 2022, 29, 100818. [Google Scholar] [CrossRef]

- Krakowska, A.; Rafińska, K.; Walczak, J.; Buszewski, B. Enzyme-Assisted Optimized Supercritical Fluid Extraction to Improve Medicago Sativa Polyphenolics Isolation. Ind. Crops Prod. 2018, 124, 931–940. [Google Scholar] [CrossRef]

- Wu, K.; Ju, T.; Deng, Y.; Xi, J. Mechanochemical Assisted Extraction: A Novel, Efficient, Eco-Friendly Technology. Trends Food Sci. Technol. 2017, 66, 166–175. [Google Scholar] [CrossRef]

- Fan, L.; Fan, W.; Mei, Y.; Liu, L.; Li, L.; Wang, Z.; Yang, L. Mechanochemical Assisted Extraction as a Green Approach in Preparation of Bioactive Components Extraction from Natural Products—A Review. Trends Food Sci. Technol. 2022, 129, 98–110. [Google Scholar] [CrossRef]

- Sati, P.; Dhyani, P.; Bhatt, I.D.; Pandey, A. Ginkgo Biloba Flavonoid Glycosides in Antimicrobial Perspective with Reference to Extraction Method. J. Tradit. Complement. Med. 2019, 9, 15–23. [Google Scholar] [CrossRef] [PubMed]

- Yang, M. Efficient Extraction of Bioactive Flavonoids from Ginkgo Biloba Leaves Using Deep Eutectic Solvent/Water Mixture as Green Media. Chem. Biochem. Eng. Q. 2018, 32, 315–324. [Google Scholar] [CrossRef]

- Han, S.; Chio, C.; Ma, T.; Mokale Kognou, A.L.; Shrestha, S.; Chen, F.; Qin, W. Extracting Flavonoid from Ginkgo Biloba Using Lignocellulolytic Bacteria Paenarthrobacter sp. and Optimized via Response Surface Methodology. Biofuels Bioprod. Biorefining 2021, 15, 867–878. [Google Scholar] [CrossRef]

- Chen, S.; Xing, X.-H.; Huang, J.-J.; Xu, M.-S. Enzyme-Assisted Extraction of Flavonoids from Ginkgo Biloba Leaves: Improvement Effect of Flavonol Transglycosylation Catalyzed by Penicillium Decumbens Cellulase. Enzyme Microb. Technol. 2011, 48, 100–105. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Cao, F.; Su, E.; Wu, C.; Zhao, L.; Ying, R. Improving Flavonoid Extraction from Ginkgo Biloba Leaves by Prefermentation Processing. J. Agric. Food Chem. 2013, 61, 5783–5791. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.-Y.; Mang, Y.-L.; Xie, J.; Wang, P.; Su, W.-K. Response Surface Optimization of Mechanochemical-Assisted Extraction of Flavonoids and Terpene Trilactones from Ginkgo Leaves. Ind. Crops Prod. 2011, 34, 1041–1052. [Google Scholar] [CrossRef]

- Amoussa, A.M.O.; Zhang, L.; Lagnika, C.; Riaz, A.; Zhang, L.; Liu, X.; Beta, T. Effects of Preheating and Drying Methods on Pyridoxine, Phenolic Compounds, Ginkgolic Acids, and Antioxidant Capacity of Ginkgo Biloba Nuts. J. Food Sci. 2021, 86, 4197–4208. [Google Scholar] [CrossRef] [PubMed]

- Lei, J.; Jiang, Y.; Luo, X.; Zheng, Y.; Zhu, L.; Sun, C.; Linghu, L.; Qin, C.; Gang, W. Ultrasonic-Assisted Ionic Liquid Extraction of Four Biflavonoids from Ginkgo biloba L. ChemistrySelect 2021, 6, 3297–3307. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, J.A. Colorimetry of Total Phenolics with Phosphomolybdic-Phosphotungstic Acid Reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar] [CrossRef]

- Zhishen, J.; Mengcheng, T.; Jianming, W. The Determination of Flavonoid Contents in Mulberry and Their Scavenging Effects on Superoxide Radicals. Food Chem. 1999, 64, 555–559. [Google Scholar] [CrossRef]

- European Pharmacopoeia; Council of Europe: Strasbourg, France, 2004; pp. 2377–2378.

- López-Cruz, R.; Sandoval-Contreras, T.; Iñiguez-Moreno, M. Plant Pigments: Classification, Extraction, and Challenge of Their Application in the Food Industry. Food Bioprocess Technol. 2023, 16, 2725–2741. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Sicaire, A.-G.; Meullemiestre, A.; Fabiano-Tixier, A.-S.; Abert-Vian, M. Ultrasound Assisted Extraction of Food and Natural Products. Mechanisms, Techniques, Combinations, Protocols and Applications. A Review. Ultrason. Sonochem. 2017, 34, 540–560. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.-W.; Wang, C.-Z.; Tao, R. Analysis on the Physicochemical Properties of Ginkgo Biloba Leaves after Enzymolysis Based Ultrasound Extraction and Soxhlet Extraction. Molecules 2016, 21, 97. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Liu, B.; Nan, H.; Chen, C.; Li, L. Optimization of Ultrasonic-Assisted Extraction of Flavonoids with Ethanol from Ginkgo Leaves by Response Surface Methodology. In Proceedings of the 2009 IEEE International Symposium on IT in Medicine & Education, Albuquerque, NM, USA, 3–4 August 2009; pp. 1154–1157. [Google Scholar]

- Zhou, G.; Ma, J.; Tang, Y.; Wang, X.; Zhang, J.; Yao, X.; Jiang, W.; Duan, J.-A. Optimization of Ultrasound-Assisted Extraction Followed by Macroporous Resin Purification for Maximal Recovery of Functional Components and Removal of Toxic Components from Ginkgo Biloba Leaves. Biomed. Res. Int. 2018, 2018, 4598067. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Chen, Z.; Shi, H.; Yu, J.; Huang, G.; Huang, H. Ultrasound-Assisted Extraction and Properties of Polysaccharide from Ginkgo Biloba Leaves. Ultrason. Sonochem. 2023, 93, 106295. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Guo, S.; Wang, M.; He, L. PEG-Based Ultrasound-Assisted Enzymatic Extraction of Polysaccharides from Ginkgo Biloba Leaves. Int. J. Biol. Macromol. 2015, 80, 644–650. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Ma, J.; Tang, Y.; Wang, X.; Zhang, J.; Duan, J.-A. Multi-Response Optimization of Ultrasonic Assisted Enzymatic Extraction Followed by Macroporous Resin Purification for Maximal Recovery of Flavonoids and Ginkgolides from Waste Ginkgo Biloba Fallen Leaves. Molecules 2018, 23, 1029. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Yao, X.; Tang, Y.; Qian, D.; Su, S.; Zhang, L.; Jin, C.; Qin, Y.; Duan, J. An Optimized Ultrasound-Assisted Extraction and Simultaneous Quantification of 26 Characteristic Components with Four Structure Types in Functional Foods from Ginkgo Seeds. Food Chem. 2014, 158, 177–185. [Google Scholar] [CrossRef] [PubMed]

- Cui, N.; Zhang, L.; Quan, M.; Xu, J. Profile of the Main Bioactive Compounds and in Vitro Biological Activity of Different Solvent Extracts from Ginkgo Biloba Exocarp. RSC Adv. 2020, 10, 45105–45111. [Google Scholar] [CrossRef]

- Kobus, J.; Flaczyk, E.; Siger, A.; Nogala-Kałucka, M.; Korczak, J.; Pegg, R.B. Phenolic Compounds and Antioxidant Activity of Extracts of Ginkgo Leaves. Eur. J. Lipid Sci. Technol. 2009, 111, 1150–1160. [Google Scholar] [CrossRef]

- Ignat, I.; Volf, I.; Popa, V.I. A Critical Review of Methods for Characterisation of Polyphenolic Compounds in Fruits and Vegetables. Food Chem. 2011, 126, 1821–1835. [Google Scholar] [CrossRef] [PubMed]

- Beck, S.; Stengel, J. Mass Spectrometric Imaging of Flavonoid Glycosides and Biflavonoids in Ginkgo Biloba L. Phytochemistry 2016, 130, 201–206. [Google Scholar] [CrossRef] [PubMed]

- Šamec, D.; Pierz, V.; Srividya, N.; Wüst, M.; Lange, B.M. Assessing Chemical Diversity in Psilotum Nudum (l.) Beauv., a Pantropical Whisk Fern That Has Lost Many of Its Fern-like Characters. Front. Plant Sci. 2019, 10, 459690. [Google Scholar] [CrossRef] [PubMed]

- Nadar, S.S.; Rao, P.; Rathod, V.K. Enzyme Assisted Extraction of Biomolecules as an Approach to Novel Extraction Technology: A Review. Food Res. Int. 2018, 108, 309–330. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).