Predicting Alloying Element Yield in Converter Steelmaking Using t-SNE-WOA-LSTM

Abstract

1. Introduction

2. Data Preprocessing and Methodology

2.1. Data Preprocessing

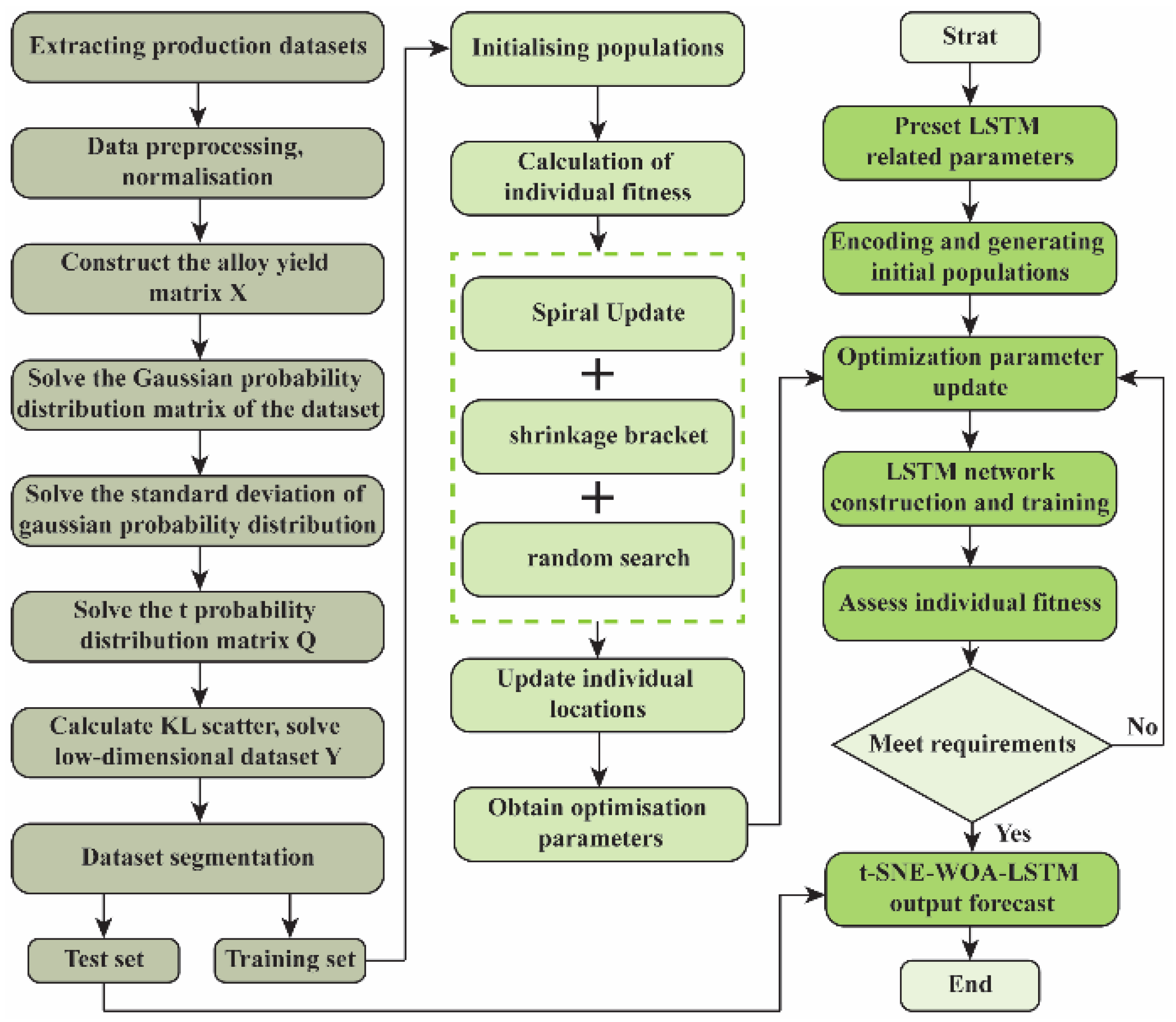

2.2. Methodology of t-SNE-WOA-LSTM

2.3. Evaluation Indicators

3. Results and Discussion

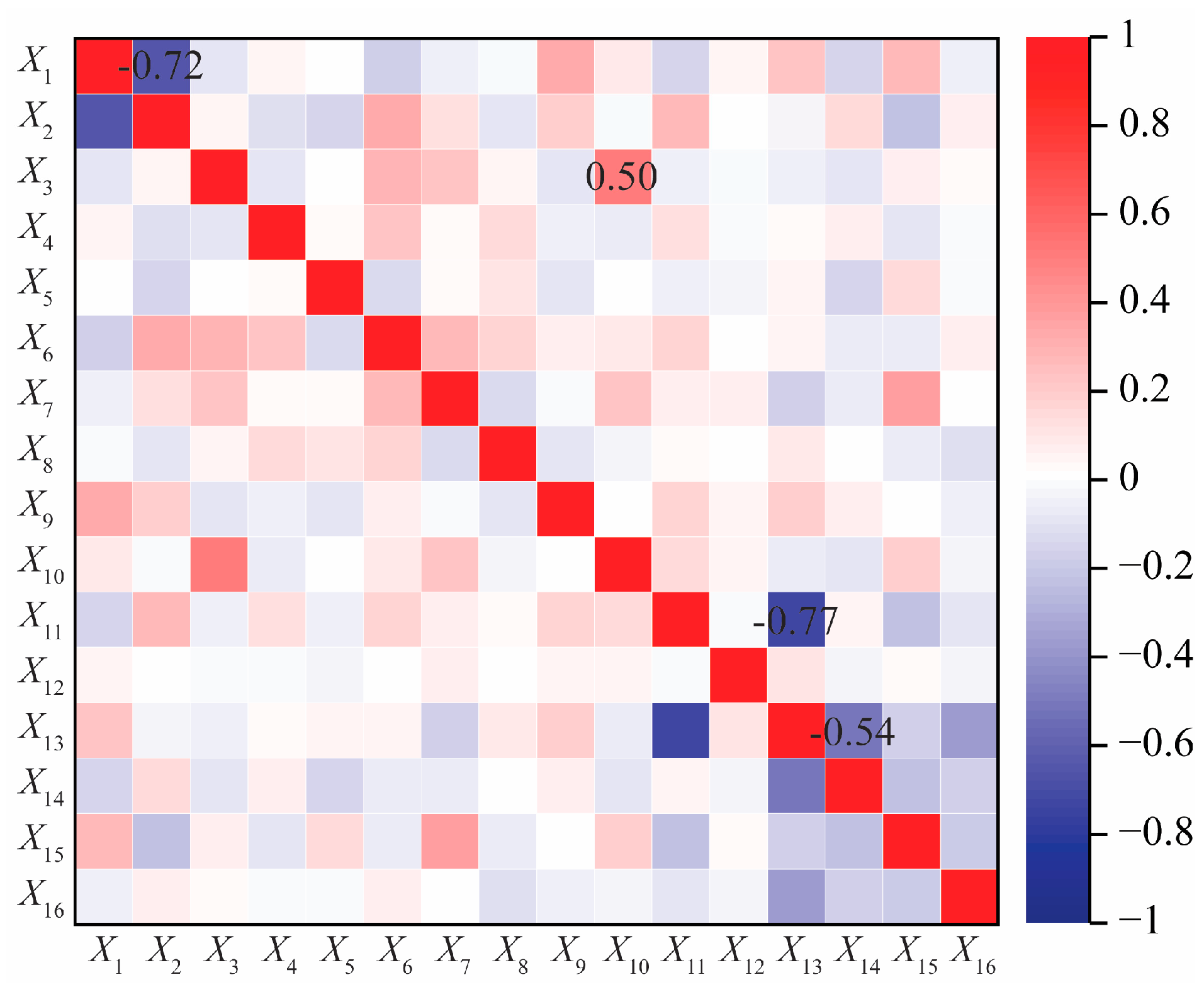

3.1. Correlation Analysis

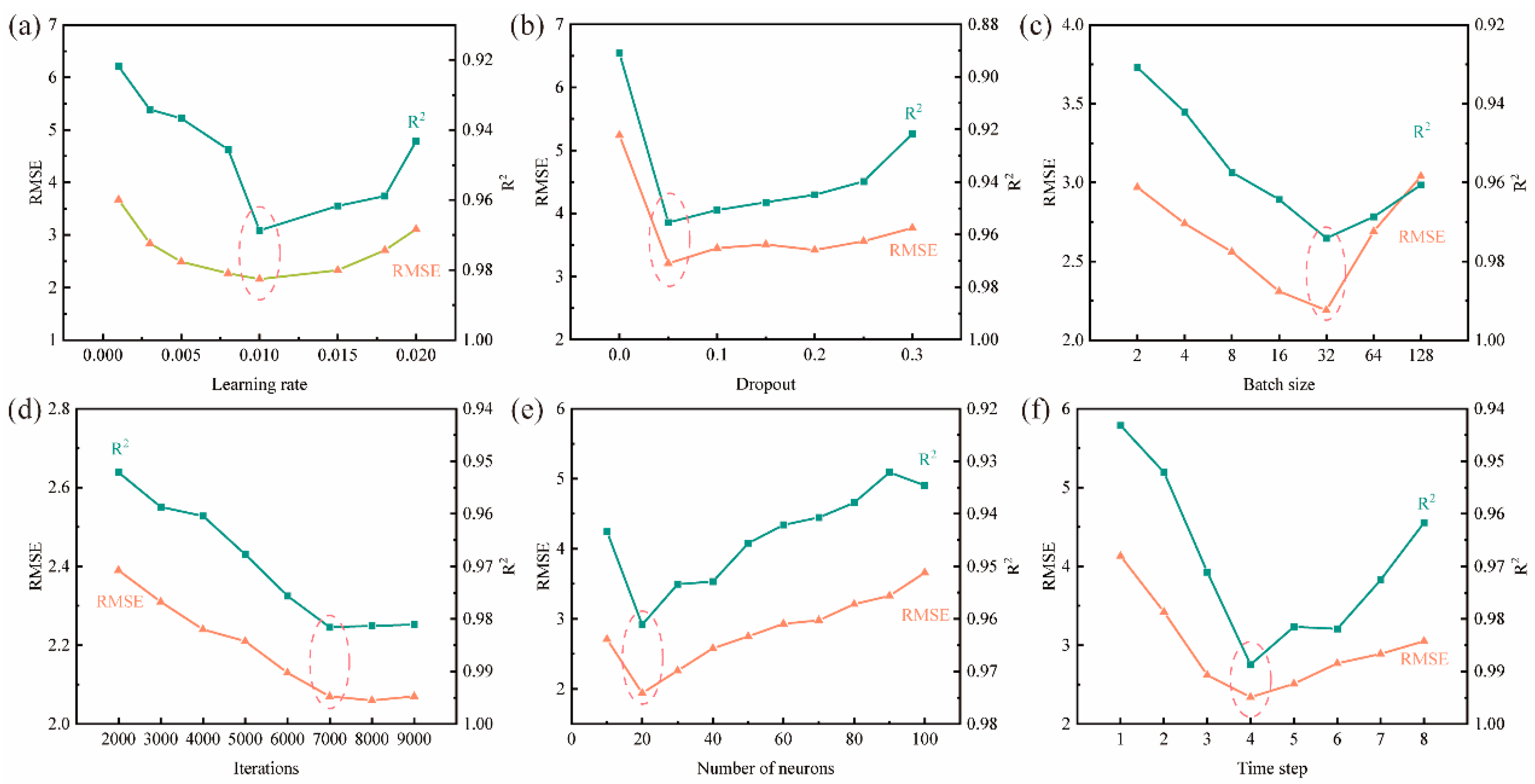

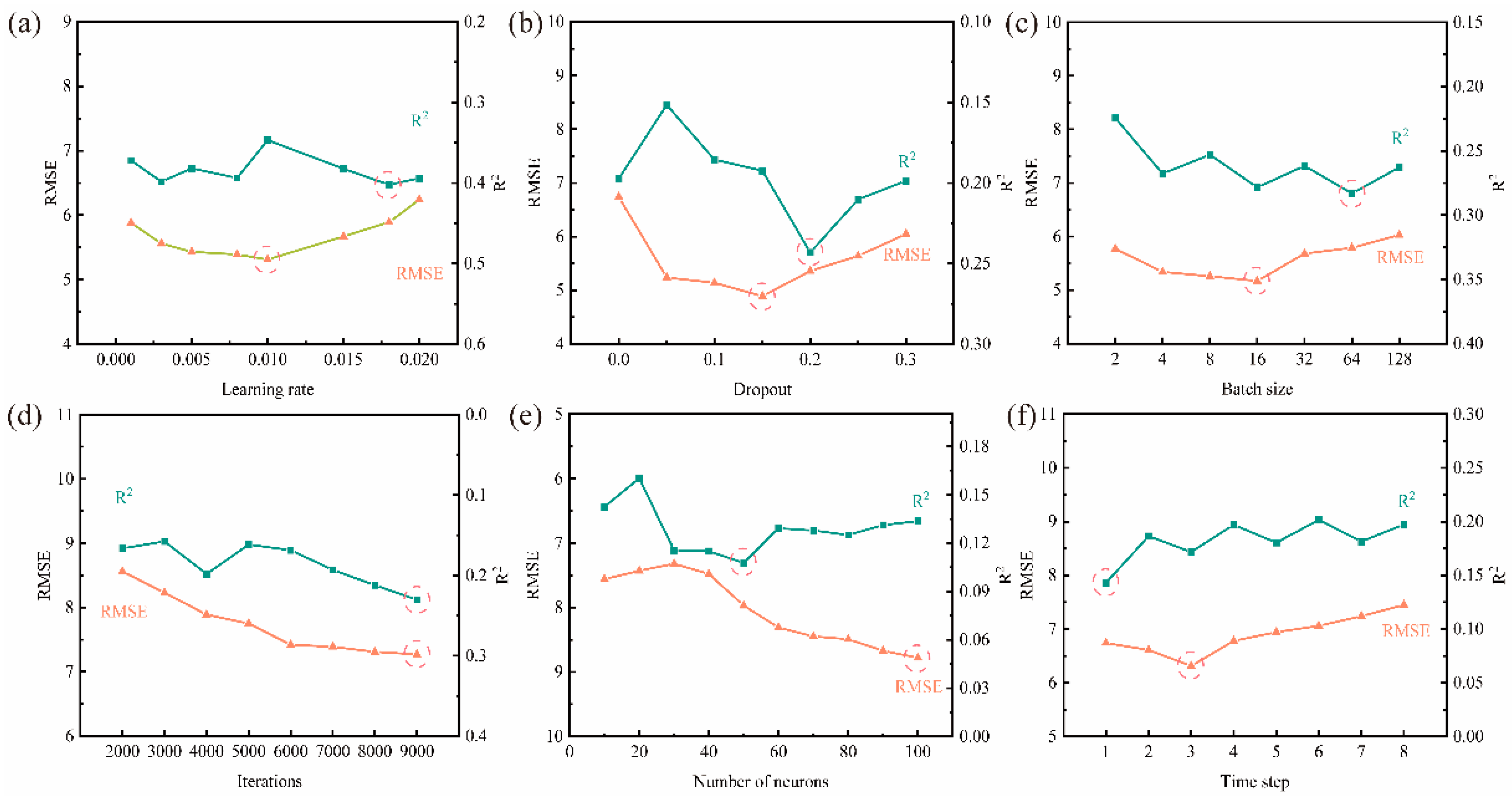

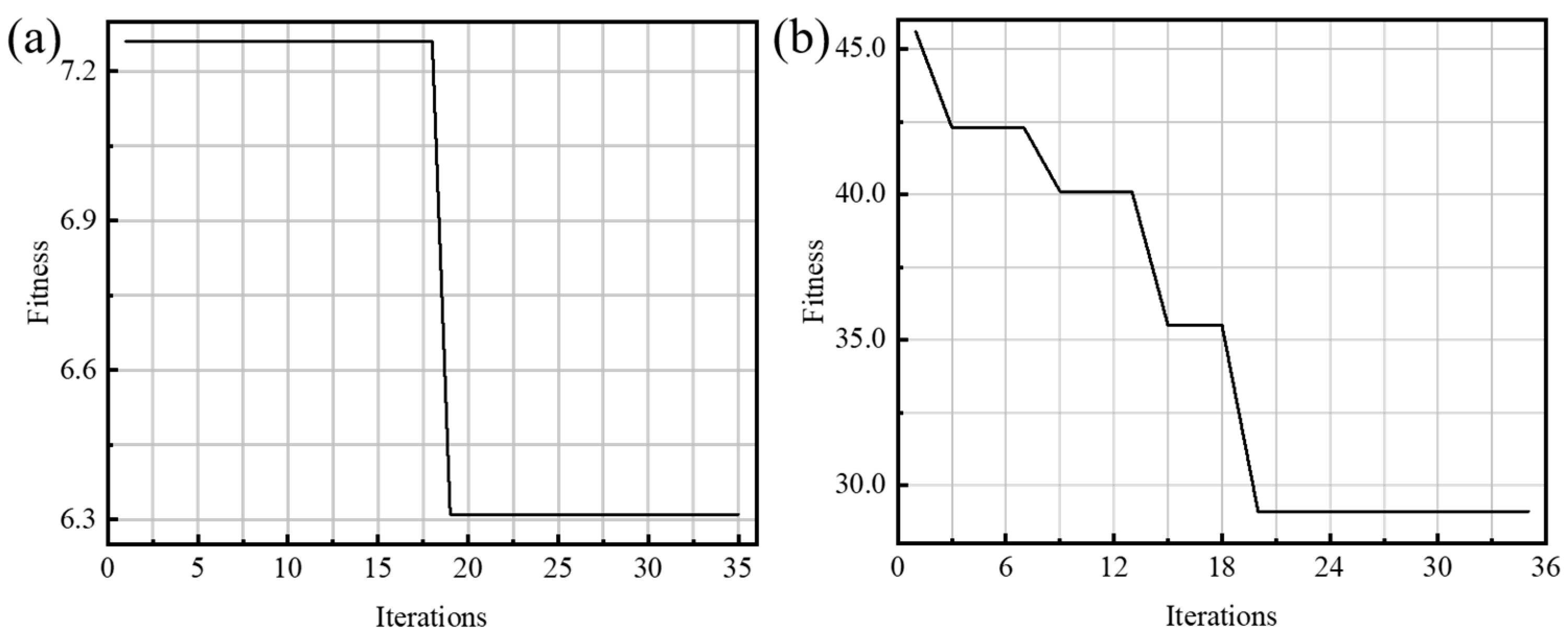

3.2. The Effect of the Structure on the Prediction Results

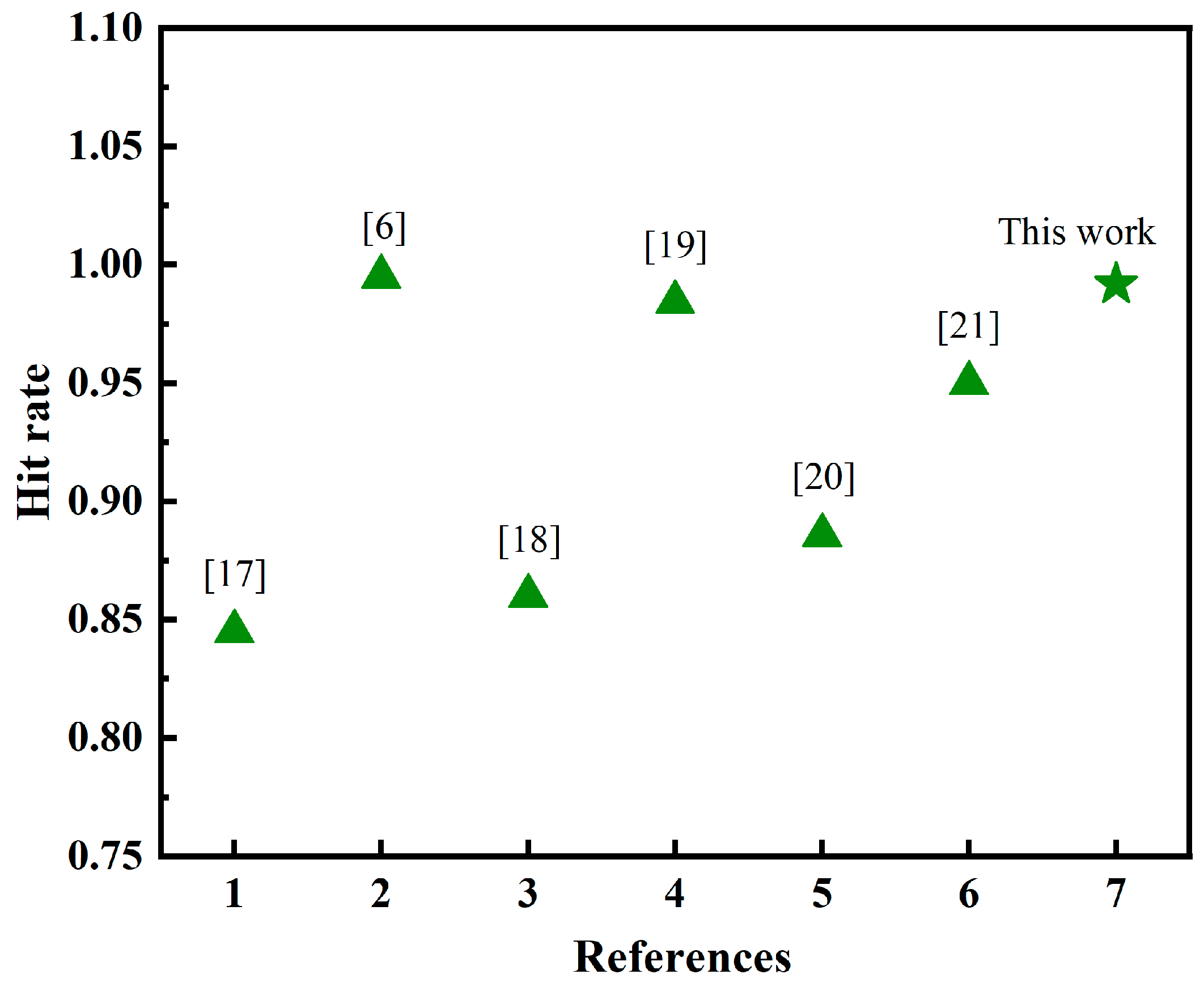

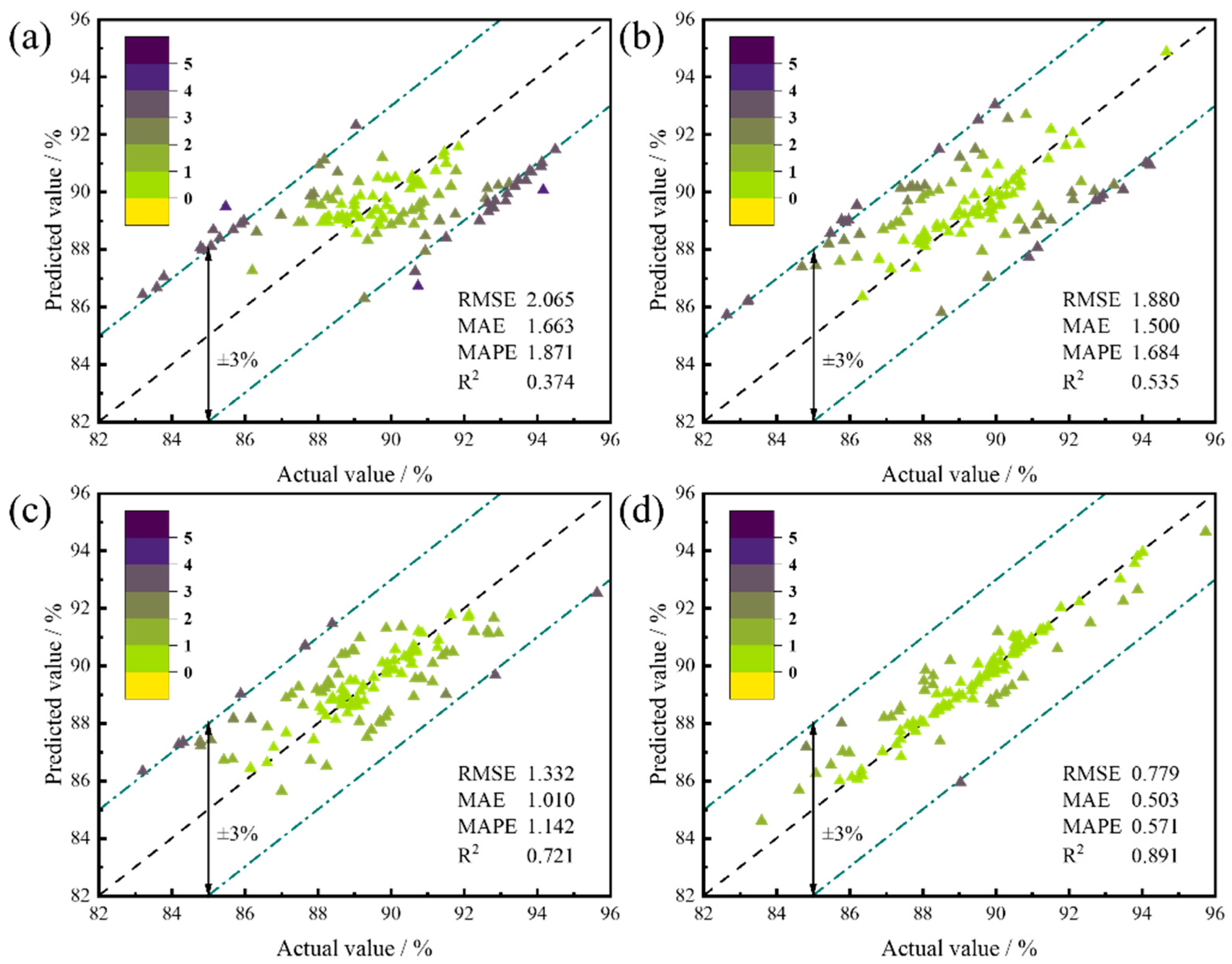

3.3. Comparison of the t-SNE-WOA–LSTM Model with Other Models

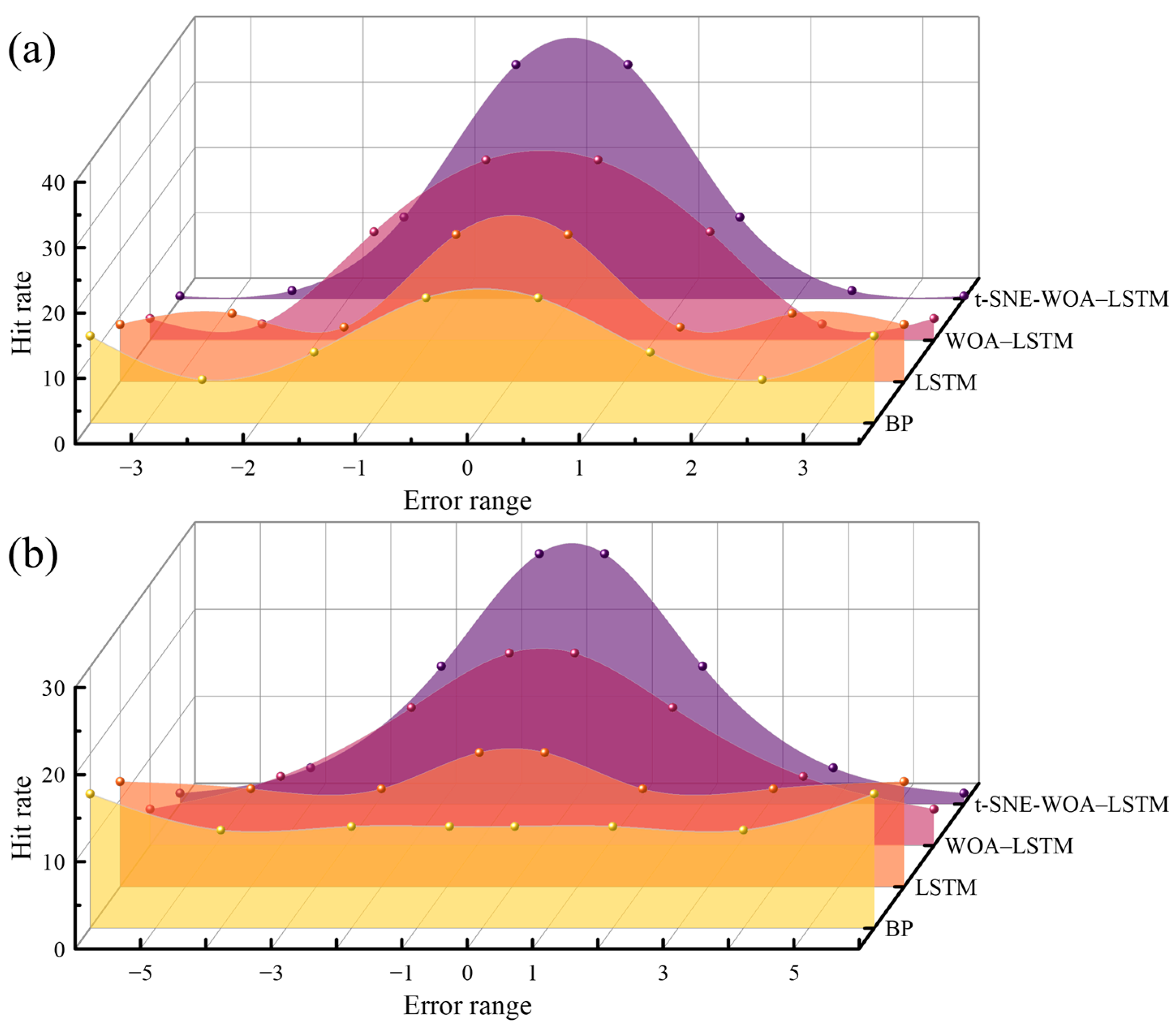

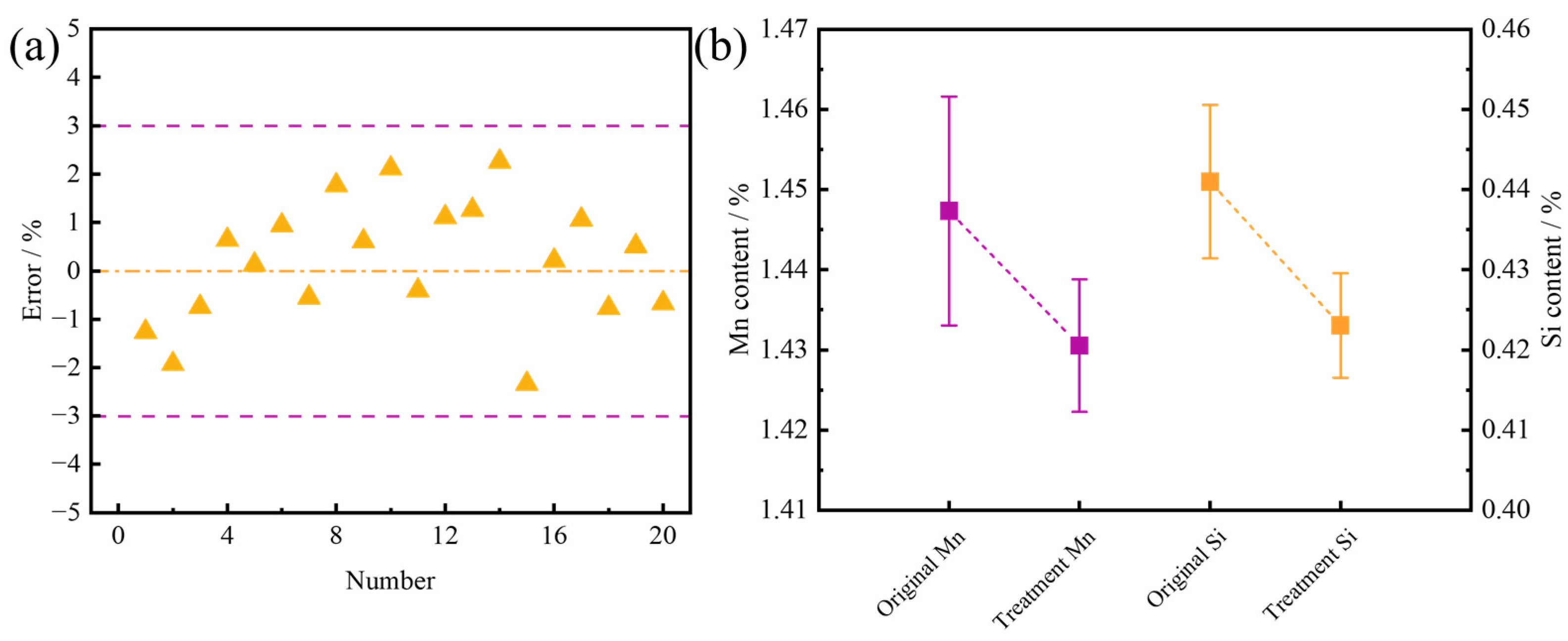

3.4. Application Effect Evaluation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fan, Z.Y.; Friedmann, S.J. Low-carbon production of iron and steel: Technology options, economic assessment, and policy. Joule 2021, 5, 829–862. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Jiao, K.X.; Zhang, J.L.; Guo, Z.Y. A review on low carbon emissions projects of steel industry in the World. J. Clean. Prod. 2021, 306, 127259. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Yu, L.H.; Cui, K.K.; Wang, H.; Fu, T. Carbon capture and storage technology by steel-making slags: Recent progress and future challenges. Chem. Eng. J. 2023, 455, 140552. [Google Scholar] [CrossRef]

- Ren, L.; Zhou, S.; Peng, T.D.; Ou, X.M. A review of CO2 emissions reduction technologies and low-carbon development in the iron and steel industry focusing on China. Renew. Sustain. Energy Rev. 2021, 143, 110846. [Google Scholar] [CrossRef]

- Zheng, R.X.; Bao, Y.P.; Wang, Z.L. Intelligent control model of steelmaking using ferroalloy reduction and its application. Chin. J. Eng. 2021, 43, 1689–1697. [Google Scholar]

- Xin, Z.C.; Zhang, J.S.; Jin, Y.; Zheng, J.; Liu, Q. Predicting the alloying element yield in a ladle furnace using principal component analysis and deep neural network. Int. J. Miner. Metall. Mater. 2023, 30, 335–344. [Google Scholar] [CrossRef]

- Zeng, J.Q. Thoughts on intellectualization improvement of iron and steel production process. Met. Ind. Autom. 2019, 43, 1. [Google Scholar]

- Zhou, C.G.; Hu, J.Z.; Jiang, C.M.; Wang, S.H.; Ai, L.Q.; Chen, H. Prediction model of phosphorus content in dephosphorization converter end point based on BP neural network algorithm. Steelmaking 2021, 37, 10–15. [Google Scholar]

- Wu, S.W.; Yang, J. A convolutional neural network-based model for predicting lime utilization ratio in the KR desulfurization process. Metall. Res. Technol. 2021, 118, 603. [Google Scholar] [CrossRef]

- Xie, Q.; Suvarna, M.; Li, J.L.; Zhu, X.Z.; Cai, J.J.; Wang, X.N. Online prediction of mechanical properties of hot rolled steel plate using machine learning. Mater. Des. 2021, 197, 109201. [Google Scholar] [CrossRef]

- Acosta, S.M.; Amoroso, A.L.; Sant’Anna, Â.M.O.; Junior, O.C. Predictive modeling in a steelmaking process using optimized relevance vector regression and support vector regression. Ann. Oper. Res. 2022, 316, 905–926. [Google Scholar] [CrossRef]

- Xie, T.Y.; Zhang, C.D.; Zhou, Q.L.; Tian, Z.Q.; Liu, S.; Guo, H.J. TSC prediction and dynamic control of BOF steelmaking with state-of-the-art machine learning and deep learning methods. J. Iron Steel Res. Int. 2024, 31, 174–194. [Google Scholar] [CrossRef]

- Zheng, R.X.; Bao, Y.P.; Zhao, L.H.; Xing, L.D. Method to predict alloy yield based on multiple raw material conditions and a PSO-LSTM network. J. Mater. Res. Technol. 2023, 27, 3310–3322. [Google Scholar] [CrossRef]

- Marani, M.; Zeinali, M.; Songmene, V.; Mechefske, C.K. Tool wear prediction in high-speed turning of a steel alloy using long short-term memory modelling. Measurement 2021, 177, 109329. [Google Scholar] [CrossRef]

- Xu, Z.; Mao, Z.Z. Analysis and prediction of influencing factor on element recovery in ladle furnace. Iron Steel 2012, 47, 34–37. [Google Scholar] [CrossRef]

- Song, C.N.; Cao, J.G.; Wang, L.L.; Xiao, J.; Zhao, Q.F. The prediction model for transverse thickness difference of electric steel in 6-high cold rolling mills based on GA-PSO-SVR approach. Steel Res. Int. 2022, 93, 2200302. [Google Scholar] [CrossRef]

- Nath, N.K.; Mandal, K.; Singh, A.K.; Basu, B.; Bhanu, C.; Kumar, S.; Ghosh, A. Ladle furnace on-line reckoner for prediction and control of steel temperature and composition. Ironmak Steelmak 2006, 33, 140–150. [Google Scholar] [CrossRef]

- Yi, Z.; Chai, L.; Liu, H.K.; Yang, L. Prediction model of C and Mn alloy yield in LF based on AO-ENN. China Metall. 2022, 32, 40–48+57. [Google Scholar]

- He, X.Y.; Wang, M.; Ji, J.L.; Bao, Y.P.; Yang, J.F.; Wang, Z.L. Prediction of Mn alloying yield in converter tapping process based on GA-BP neural network. Steelmaking 2022, 38, 14–20. [Google Scholar]

- Han, M.; Xu, Q.; Zhao, Y.; Lin, D.; Yang, X.L. Calculation of alloy addition to yied-predict model BOF steelmaking. Steelmaking 2010, 26, 44–47. [Google Scholar]

- Zhou, K.X.; Lin, W.H.; Sun, J.K.; Feng, X.M.; Fang, W.; Liu, Q. Aprediction model to calculate Mn yield during BOF alloying process using improved extreme learning machine. J. Cent. South Univ. (Sci. Technol.) 2021, 52, 1399–1406. [Google Scholar]

- Liu, X.; Bao, Y.P.; Zhao, L.H.; Gu, C. Establishment and Application of Steel Composition Prediction Model Based on t-Distributed Stochastic Neighbor Embedding (t-SNE) Dimensionality Reduction Algorithm. J. Sust. Metall. 2024. [Google Scholar] [CrossRef]

- Kobak, D.; Linderman, G.C. Initialization is critical for preserving global data structure in both t-SNE and UMAP. Nat. Biotechnol. 2021, 39, 156–157. [Google Scholar] [CrossRef] [PubMed]

- Kang, B.; Garcia, D.; Lijffijt, J.; Santos-Rodríguez, R.; De, T. Conditional t-SNE: More informative t-SNE embeddings. Mach. Learn. 2021, 110, 2905–2940. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.J.; Dong, N.; Wang, Z.Y. A Fault-Tolerant Soft Sensor Algorithm Based on Long Short-Term Memory Network for Uneven Batch Process. Processes 2024, 12, 495. [Google Scholar] [CrossRef]

- Song, X.M.; Yin, F.B.; Zhao, D.F. Fused Data-Driven Approach for Early Warning Method of Abnormal Conditions in Chemical Process. Processes 2023, 11, 2435. [Google Scholar] [CrossRef]

- Ouladbrahim, A.; Belaidi, I.; Khatir, S.; Magagnini, E.; Capozucca, R.; Wahab, M.A. Experimental crack identification of API X70 steel pipeline using improved Artificial Neural Networks based on Whale Optimization Algorithm. Mech. Mater. 2022, 166, 104200. [Google Scholar] [CrossRef]

- Eze, E.; Ajmal, T. Dissolved oxygen forecasting in aquaculture: A hybrid model approach. Appl. Sci. 2020, 10, 7079. [Google Scholar] [CrossRef]

- Tanvir, M.H.; Hussain, A.; Rahman, M.T.; Ishraq, S.; Zishan, K.; Rahul, S.T.T.; Habib, M.A. Multi-objective optimization of turning operation of stainless steel using a hybrid whale optimization algorithm. J. Manuf. Mater. Process. 2020, 4, 64. [Google Scholar] [CrossRef]

- Afzal, S.; Ziapour, B.M.; Shokri, A.; Shakibi, H.; Sobhani, B. Building energy consumption prediction using multilayer perceptron neural network-assisted models; comparison of different optimization algorithms. Energy 2023, 282, 128446. [Google Scholar] [CrossRef]

- Shi, C.Y.; Wang, B.S.; Guo, S.Y.; Sun, P.; Ma, Z.C.; Wang, Y.K.; Zhang, L.; Wu, C.L. Energy Consumption Prediction of Steelmaking Process Based on Improved Whale Optimization Algorithm and Stochastic Configuration Network. JOM 2023, 75, 4320–4331. [Google Scholar] [CrossRef]

| Alloying Element | Model | Hit Rate | Advantages | Disadvantages | Reference |

|---|---|---|---|---|---|

| Mn | MLR | 84.50% | (1) Non-linear learning; (2) scalability; (3) sparsity | (1) Multicollinearity problem; (2) high correlation among total variables | [17] |

| Mn | PCA–DNN | 99.50% | (1) Highly non-linear problems; (2) large-scale data | (1) Difficult to train; (2) poor model interpretability | [6] |

| Mn | AO-ENN | 86.00% | (1) Stronger learning and memory skills; (2) easy to train; (3) highly interpretable | (1) Relatively high computational complexity; (2) easy to fall into local minima | [18] |

| Mn | GA-BP | 98.42% | (1) Strong non-linear mapping capability; (2) high self-learning and self-adaptive capabilities; (3) some fault tolerance | (1) Slow convergence speed; (2) easy to fall into local minima | [19] |

| Mn | SVM | 88.57% | (1) Generalization properties; (2) high-dimensional issues; (3) avoiding neural network structure selection and local minima problems | (1) Sensitive to missing data; (2) no generic solution to non-linear problems | [20] |

| Mn | IPSO-ELM | 95.00% | (1) Fast training; (2) high-dimensional issues; (4) avoiding neural network structure selection and local minima problems | (1) Poor model interpretability; (2) affected by random initialization weights | [21] |

| Si | MLR | 73.50% | (1) Non-linear learning; (2) scalability; (3) sparsity | (1) Multicollinearity problem; (2) high correlation among total variables | [17] |

| Si | PCA–DNN | 98.80% | (1) Highly non-linear problems; (2) large-scale data | (1) Difficult to train; (2) poor model interpretability | [6] |

| C | AO-ENN | 88.00% | (1) Stronger learning and memory skills; (2) easy to train; (3) highly interpretable | (1) Relatively high computational complexity; (2) easy to fall into local minima | [18] |

| C | Si | Mn | P | S |

|---|---|---|---|---|

| 0.15–0.17 | 0.41–0.45 | 1.42–1.46 | ≤0.025 | ≤0.010 |

| No | Indicator Variables | Maximum | Minimum | Mean | Range |

|---|---|---|---|---|---|

| X1 | Molten iron loading quantity [t] | 88.12 | 70.08 | 80.01 | 18.04 |

| X2 | Scrap steel loading quantity [t] | 13.8 | 0 | 6.50 | 13.8 |

| X3 | Number of turndown/times | 3 | 1 | 1.43 | 2 |

| X4 | Tapping temperature [°C] | 1682 | 1535 | 1602.87 | 147 |

| X5 | Nitrogen consumption [m3] | 1734 | 306 | 956.74 | 1428 |

| X6 | Oxygen consumption [m3] | 3962 | 1911 | 2668.16 | 2051 |

| X7 | Lime addition amount [kg] | 3361 | 591 | 1488.40 | 2770 |

| X8 | Light-burned dolomite addition amount [kg] | 2592 | 0 | 823.72 | 2592 |

| X9 | Tapping weight [t] | 91.6 | 72 | 82.30 | 19.6 |

| X10 | C content of molten iron [%] | 0.14 | 0.02 | 0.066 | 0.12 |

| X11 | Mn content of molten iron [%] | 0.158 | 0.005 | 0.046 | 0.153 |

| X12 | Ferrosilicon alloy [kg] | 190 | 0 | 73.1 | 190 |

| X13 | Silicomanganese alloy [kg] | 2045 | 881 | 1589.53 | 1164 |

| X14 | High carbon manganese alloy [kg] | 403 | 0 | 40.90 | 403 |

| X15 | Medium-carbon manganese alloy [kg] | 512 | 0 | 62.99 | 512 |

| X16 | Low-carbon manganese alloy [kg] | 599 | 0 | 24.51 | 599 |

| Y1 | Yield of the Si element [%] | 92.84 | 66.34 | 77.43 | 26.58 |

| Y2 | Yield of the Mn element [%] | 99.28 | 80.25 | 89.31 | 18.33 |

| Element | Learning Rate | Dropout Rate | Batch Size | Iterations | Number of Neurons | Time Step |

|---|---|---|---|---|---|---|

| Mn | 0.0100 | 0.0500 | 32 | 194 | 30 | 4 |

| Si | 0.0043 | 0.4621 | 16 | 89 | 56 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Qu, X.; Xie, X.; Li, S.; Bao, Y.; Zhao, L. Predicting Alloying Element Yield in Converter Steelmaking Using t-SNE-WOA-LSTM. Processes 2024, 12, 974. https://doi.org/10.3390/pr12050974

Liu X, Qu X, Xie X, Li S, Bao Y, Zhao L. Predicting Alloying Element Yield in Converter Steelmaking Using t-SNE-WOA-LSTM. Processes. 2024; 12(5):974. https://doi.org/10.3390/pr12050974

Chicago/Turabian StyleLiu, Xin, Xihui Qu, Xinjun Xie, Sijun Li, Yanping Bao, and Lihua Zhao. 2024. "Predicting Alloying Element Yield in Converter Steelmaking Using t-SNE-WOA-LSTM" Processes 12, no. 5: 974. https://doi.org/10.3390/pr12050974

APA StyleLiu, X., Qu, X., Xie, X., Li, S., Bao, Y., & Zhao, L. (2024). Predicting Alloying Element Yield in Converter Steelmaking Using t-SNE-WOA-LSTM. Processes, 12(5), 974. https://doi.org/10.3390/pr12050974