The Application of Sheep Wool in the Building Industry and in the Removal of Pollutants from the Environment

Abstract

1. Introduction

2. Wool in the Construction Industry

2.1. Thermal and Acoustic Insulation

2.2. Composites

3. Sheep Wool as an Adsorbent

3.1. The Removal of Chromium (Hexavalent/Trivalent)

3.2. The Removal of Other Species Using Wool

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Regulation (EC) No 1069/2009 Laying Down Health Rules as Regards Animal By-Products and Derived Products Not Intended for Human Consumption and Repealing Regulation (EC) No 1774/2002 (Animal By-Products Regulation). Available online: https://eur-lex.europa.eu/EN/legal-content/summary/animal-by-products-not-intended-for-human-consumption.html (accessed on 8 April 2024).

- Statistical Atlas, Eurostat Regional Yearbook. 2023. Available online: https://ec.europa.eu/statistical-atlas/viewer/?mids=BKGCNT,BKNUTS2,C13M02,CNTOVL&o=1,1,1,0.7&ch=C01,ENV,C13¢er=49.97812,19.97593,3&lcis=C13M02& (accessed on 8 April 2024).

- Czaplicki, Z.; Matyjas-Zgondek, E.; Strzelecki, S. Scouring of Sheep Wool Using an Acoustic Ultrasound Wave. Fibres Text. East. Eur. 2021, 29, 44–48. [Google Scholar] [CrossRef]

- Giteru, S.G.; Ramsey, D.H.; Hou, Y.; Cong, L.; Mohan, A.; Bekhit, A.E.D.A. Wool keratin as a novel alternative protein: A comprehensive review of extraction, purification, nutrition, safety, and food applications. Compr. Rev. Food Sci. Food Saf. 2023, 22, 643–687. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.R.; Zheng, R.; Tang, J.; Sun, H.J.; Wang, J. A mini-review on building insulation materials from perspective of plastic pollution: Current issues and natural fibres as a possible solution. J. Hazard. Mater. 2022, 438, 129449. [Google Scholar] [CrossRef] [PubMed]

- Starkova, O.; Sabalina, A.; Voikiva, V.; Osite, A. Environmental Effects on Strength and Failure Strain Distributions of Sheep Wool Fibers. Polymers 2022, 14, 2651. [Google Scholar] [CrossRef] [PubMed]

- Naik, D.L.; Fronk, T.H. Weibull Distribution Analysis of the Tensile Strength of the Kenaf Bast Fiber. Fibers Polym. 2016, 17, 1696–1701. [Google Scholar] [CrossRef]

- Ijjada, N.; Nayaka, R.R. Review on properties of some thermal insulating materials providing more comfort in the building. Mater. Today Proc. 2022, 58, 1354–1359. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative analysis of building insulation material properties and performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Volf, M.; Diviš, J.; Havlík, F. Thermal; moisture and biological behaviour of natural insulating materials. Energy Procedia 2015, 78, 1599–1604. [Google Scholar] [CrossRef]

- Swiss Centre for Life Cycle Inventories. The Ecoinvent Database. 2015. Available online: http://www.ecoinvent.org/database/ (accessed on 8 April 2024).

- Ahmed, A.; Qayoum, A.; Mir, F.Q. Investigation of the Thermal Behavior of the Natural Insulation Materials for Low Temperature Regions. J. Build. Eng. 2019, 26, 100849. [Google Scholar] [CrossRef]

- Florea, I.; Manea, D.L. Analysis of Thermal Insulation Building Materials Based on Natural Fibers. Procedia Manuf. 2019, 32, 230–235. [Google Scholar] [CrossRef]

- Bosia, D.; Savio, L.; Thiebat, F.; Patrucco, A.; Fantucci, S.; Piccablotto, G.; Marino, D. Sheep Wool for Sustainable Architecture. Energy Procedia 2015, 78, 315–320. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Acoustic characterization of natural fibers for sound absorption applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Del Rey, R.; Uris, A.; Alba, J.; Candelas, P. Characterization of Sheep Wool as a Sustainable Material for Acoustic Applications. Materials 2017, 10, 1277. [Google Scholar] [CrossRef] [PubMed]

- El Wazna, M.; El Fatihi, M.; El Bouari, A.; Cherkaoui, O. Thermo physical characterization of sustainable insulation materials made from textile waste. J. Build. Eng. 2017, 12, 196–201. [Google Scholar] [CrossRef]

- Silva-Santos, M.C.; Oliveira, M.S.; Giacomin, A.M.; Laktim, M.C.; Baruque-Ramos, J. Flammability on textile of flight crew professional clothing. IOP Conf. Ser. Mater. Sci. Eng. 2017, 254, 052006. [Google Scholar] [CrossRef]

- Galán-Marín, C.; Rivera-Gómez, C.; Petric, J. Clay-based composite stabilized with natural polymer and fibre. Constr. Build. Mater. 2010, 24, 1462–1468. [Google Scholar] [CrossRef]

- Parlato, M.C.M.; Cuomo, M.; Porto, S.M.C. Natural Fibers Reinforcement for Earthen Building Components: Mechanical Performances of a Low Quality Sheep Wool (“Valle Del Belice” Sheep). Constr. Build. Mater. 2022, 326, 126855. [Google Scholar] [CrossRef]

- Mounir, S.; Khabbazi, A.; Khaldoun, A.; Maaloufa, Y.; El Hamdouni, Y. Thermal Inertia and Thermal Properties of the CompoSite Material Clay-Wool. Sustain. Cities Soc. 2015, 19, 191–199. [Google Scholar] [CrossRef]

- Statuto, D.; Bochicchio, M.; Sica, C.; Picuno, P. Experimental development of clay bricks reinforced with agricultural by-products. In Proceedings of the 46th International Symposium “Actual Tasks on Agricultural Engineering”, Opatija, Croatia, 1 March 2018; p. 595. [Google Scholar]

- Atbir, A.; Cherkaoui, M.; El Wardi, F.Z.; Khabbazi, A. Improvement of thermomechanical characteristics of multilayer biomaterial of and clay. Mater. Today Proc. 2022, 58, 1331–1336. [Google Scholar] [CrossRef]

- Fantilli, A.P.; Sicardi, S.; Dotti, F. The use of wool as fiber-reinforcement in cement-based mortar. Constr. Build. Mater. 2017, 139, 562–569. [Google Scholar] [CrossRef]

- Tiza, T.M.; Singh, S.K.; Kumar, L.; Shettar, M.P.; Singh, S.P. Assessing the potentials of Bamboo and sheep wool fiber as sustainable construction materials: A review. Mater. Today Proc. 2021, 47, 4484–4489. [Google Scholar] [CrossRef]

- Alyousef, R.; Alabduljabbar, H.; Mohammadhosseini, H.; Mohamed, A.M.; Siddika, A.; Alrshoudi, F.; Alaskar, A. Utilization of Sheep Wool as Potential Fibrous Materials in the Production of Concrete Composites. J. Build. Eng. 2020, 30, 101216. [Google Scholar] [CrossRef]

- Jóźwiak-Niedźwiedzka, D.; Fantilli, A.P. Wool-Reinforced Cement Based Composites. Materials 2020, 13, 3590. [Google Scholar] [CrossRef] [PubMed]

- Dénes, O.; Florea, I.; Manea, D.L. Utilization of Sheep Wool as a Building Material. Procedia Manuf. 2019, 32, 236–241. [Google Scholar] [CrossRef]

- Dénes, T.-O.; Iştoan, R.; Tǎmaş-Gavrea, D.R.; Manea, D.L.; Hegyi, A.; Popa, F.; Vasile, O. Analysis of Sheep Wool-Based Composites for Building Insulation. Polymers 2022, 14, 2109. [Google Scholar] [CrossRef] [PubMed]

- Bousshine, S.; Ouakarrouch, M.; Bybi, A.; Laaroussi, N.; Garoum, M.; Tilioua, A. Acoustical and thermal characterization of sustainable materials derived from vegetable, agricultural, and animal fibers. Appl. Acoust. 2021, 187, 108520. [Google Scholar] [CrossRef]

- Urdanpilleta, M.; Leceta, I.; Guerrero, P.; de la Caba, P.K. Sustainable Sheep Wool/Soy Protein Biocomposites for Sound Absorption. Polymers 2022, 14, 5231. [Google Scholar] [CrossRef]

- Tanjung, F.A.; Zulkepli, N.N. Chapter 9—Thermoplastic polymer/wool composites. In Wool Fiber Reinforced Polymer Composites, 1st ed.; Sabu, T., Seiko, J., Eds.; Woodhead Publishing: Sawston, UK, 2022; pp. 155–179. [Google Scholar] [CrossRef]

- Ilangovan, M.; Navada, A.P.; Guna, V.; Touchaleaume, F.; Saulnier, B.; Grohens, Y.; Reddy, N. Hybrid biocomposites with high thermal and noise insulation from discarded wool, poultry feathers, and their blends. Constr. Build. Mater. 2022, 345, 128324. [Google Scholar] [CrossRef]

- Sharma, Y.K.; Meena, A.; Sahu, M.; Dalai, A. Experimental investigation on mechanical and thermal characteristics of waste sheep wool fiber-filled epoxy composites. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Pennacchio, R.; Savio, L.; Bosia, D.; Thiebat, F.; Piccablotto, G.; Patrucco, A.; Fantucci, S. Fitness: Sheep-wool and hemp sustainable insulation panels. In Proceedings of the Energy Procedia 111 8th International Conference on Sustainability in Energy and Buildings, Turin, Italy, 11–13 September 2016. [Google Scholar]

- Quintana-Gallardo, A.; Alba, J.; del Rey, R.; Crespo-Amorós, J.E.; Guillén-Guillamón, I. Life-Cycle Assessment and Acoustic Simulation of Drywall Building Partitions with Bio-Based Materials. Polymers 2020, 12, 1965. [Google Scholar] [CrossRef]

- Nußholz, J.L.K.; Rasmussen, F.N.; Milios, L. Circular building materials: Carbon saving potential and the role of business model innovation and public policy. Resour. Conserv. Recycl. 2019, 141, 308–316. [Google Scholar] [CrossRef]

- Alyousef, R.R. Enhanced acoustic properties of concrete composites comprising modified waste sheep wool fibers. J. Build. Eng. 2022, 56, 104815. [Google Scholar] [CrossRef]

- Altin, M.; Yildirim, G.Ş. Investigation of usability of boron doped sheep wool as insulation material and comparison with existing insulation materials. Constr. Build. Mater. 2022, 331, 127303. [Google Scholar] [CrossRef]

- Vasina, M.; Straznicky, P.; Hrbacek, P.; Rusnakova, S.; Bosak, O.; Kubliha, M. Investigation of Physical Properties of Polymer Composites Filled with Sheep Wool. Polymers 2024, 16, 690. [Google Scholar] [CrossRef] [PubMed]

- Bahij, S.; Omary, S.; Belhaj, E.; Steiner, V.; Feugeas, F. Peeling Force Required for the Detachment of Non-Woven Plastic Tissue from the Surface of Mortar Prisms. Polymers 2023, 15, 4286. [Google Scholar] [CrossRef]

- Caven, B.; Bechtold, T. Reverse engineering of wool fibre into its constituent components as functional additives to form wool based structures. Procedia Eng. 2017, 200, 128–134. [Google Scholar] [CrossRef]

- Jumean, F.H.; Khamis, M.I.; Sara, Z.A.; AbouRich, M.S. Concurrent Removal and Reduction of Cr(VI) by Wool: Short and Long Term Equilibration Studies. Am. J. Anal. Chem. 2015, 6, 47–57. [Google Scholar] [CrossRef][Green Version]

- Ray, P.; Sabri, A.M.; Ibrahim, T.H.; Khamis, M.I.; Jumean, F.H. Design and optimization of a batch sequential contactor for the removal of chromium(VI) from industrial wastewater using sheep wool as a low-cost adsorbent. Desalin. Water Treat. 2018, 13, 109–113. [Google Scholar] [CrossRef]

- Badrelzaman, M.; Khamis, M.I.; Ibrahim, T.H.; Jumean, F.H. Scale-Up of Self-Regenerating Semi-Batch Adsorption Cycles through Concurrent Adsorption and Reduction of Cr(VI) on Sheep Wool. Processes 2020, 8, 1092. [Google Scholar] [CrossRef]

- Khamis, M.I.; Ibrahim, T.H.; Jumean, F.H.; Sara, Z.A.; Atallah, B.A. Cyclic Sequential Removal of Alizarin Red S Dye and Cr(VI) Ions Using Wool as a Low-Cost Adsorbent. Processes 2020, 8, 556. [Google Scholar] [CrossRef]

- Meenarathi, B.; Agathian, K.; Anbarasan, R. Modification of wool fibre’s structural properties as a cheap adsorbent for the elimination of Cr6+ and Rhodamine6g dye from aqueous solution. Int. J. Biol. Macromol. 2023, 253, 127160. [Google Scholar] [CrossRef] [PubMed]

- Jin, X.; Wang, H.; Jin, X.; Wang, H.; Chen, L.; Wang, W.; Lin, T.; Zhu, Z. Preparation of keratin/PET nanofiber membrane and its high adsorption performance of Cr(VI). Sci. Total Environ. 2020, 710, 135546. [Google Scholar] [CrossRef]

- Porubská, M.; Hanzlíková, Z.; Braniša, J.; Kleinová, A.; Hybler, P.; Fülöp, M.; Ondruška, J.; Jomová, K. The effect of electron beam on sheep wool. Polym. Degrad. Stab. 2015, 111, 151–158. [Google Scholar] [CrossRef]

- Braniša, J.; Kleinová, A.; Jomová, K.; Malá, R.; Morgunov, V.; Porubská, M. Some Properties of Electron Beam-Irradiated Sheep Wool Linked to Cr(III) Sorption. Molecules 2019, 24, 4401. [Google Scholar] [CrossRef] [PubMed]

- Braniša, J.; Jomová, K.; Lapčík, Ľ.; Porubská, M. Testing of electron beam irradiated sheep wool for adsorption of Cr(III) and Co(II) of higher concentrations. Polym. Test. 2021, 99, 107191. [Google Scholar] [CrossRef]

- Porubská, M.; Kleinová, A.; Hybler, P.; Braniša, J. Why Natural or Electron Irradiated Sheep Wool Show Anomalous Sorption of Higher Concentrations of Copper(II). Molecules 2018, 23, 3180. [Google Scholar] [CrossRef]

- Porubská, M.; Jomová, K.; Lapčík, Ľ.; Braniša, J. Radiation-modified wool for adsorption of redox metals and potentially for nanoparticles. Nanotechnol. Rev. 2020, 9, 1017–1026. [Google Scholar] [CrossRef]

- Braniša, J.; Kleinová, A.; Jomová, K.; Weissabel, R.; Cvik, M.; Branišová, Z.; Porubská, M. Sheep Wool Humidity under Electron Irradiation Affects Wool Sorptivity towards Co(II) Ions. Molecules 2021, 26, 5206. [Google Scholar] [CrossRef] [PubMed]

- Braniša, J.; Jomová, K.; Kovalčíková, R.; Hybler, P.; Porubská, M. Role of Post-Exposure Time in Co(II) Sorption of Higher Concentrations on Electron Irradiated Sheep Wool. Molecules 2019, 24, 2639. [Google Scholar] [CrossRef]

- Braniša, J.; Koóšová, K.; Lendelová, K.; Porubská, M. Competitive Adsorption of Cr(III) and Cu(II) on Electron Beam Irradiated Sheep Wool from Binary Solutions Can be Controlled by the Absorbed Dose. ACS Omega 2022, 7, 38015–38024. [Google Scholar] [CrossRef]

- Porubská, M.; Koóšová, K.; Braniša, J. Competitive Cation Adsorption on Electron-Irradiated Sheep Wool Changes the Fitting of Adsorption Isotherms for Single-Component Solutions. Processes 2023, 11, 502. [Google Scholar] [CrossRef]

- Enkhzaya, S.; Shiomori, K.; Oyuntsetseg, B. Effective adsorption of Au(III) and Cu(II) by chemically treated sheep wool and the binding mechanism. J. Environ. Chem. Eng. 2022, 8, 104021. [Google Scholar] [CrossRef]

- Olawale, S.A.; Bonilla-Petriciolet, A.; Mendoza-Castillo, D.I.; Okafor, C.C.; Sellaoui, L.; Badawi, M. Thermodynamics and Mechanism of the Adsorption of Heavy Metal Ions on Keratin Biomasses for Wastewater Detoxification. Adsorpt. Sci. Technol. 2022, 2022, 7384924. [Google Scholar] [CrossRef]

- Zimmerman, B.; Chow, J.; Abbott, A.G.; Ellison, M.S.; Kennedy, M.S.; Dean, D. Variation of Surface Charge along the Surface of Wool Fibers Assessed by High-Resolution Force Spectroscopy. J. Eng. Fiber. Fabr. 2011, 6, 61–66. [Google Scholar] [CrossRef] [PubMed]

- Porubská, M.; Cvik, M.; Jomová, K.; Branišová, Z.; Braniša, J. Nitrate removal from aqueous solution by way of adsorption on modified sheep wool. Surf. Innov. 2022, 10, 68–75. [Google Scholar] [CrossRef]

- Pang, L.; Lin, S.; Krakowiak, J.; Yu, S.; Hewitt, J. Performance analysis of sheep wool fibres as a water filter medium for human enteric virus removal. J. Water Proc. Eng. 2022, 47, 102800. [Google Scholar] [CrossRef]

- Mansour, E.; Curling, S.; Stéphan, A.; Ormondroyd, G. Absorption of volatile organic compounds by different wool types. Green Mater 2016, 4, 1–7. [Google Scholar] [CrossRef]

- Hegyi, A.; Bulacu, C.; Szilagyi, H.; Lăzărescu, A.-V.; Meiţă, V.; Vizureanu, P.; Sandu, M. Improving Indoor Air Quality by Using Sheep Wool Thermal Insulation. Materials 2021, 14, 2443. [Google Scholar] [CrossRef]

| Insulation Type | Density | Thermal Conductivity | Specific Heat Capacity | Sound Absorption Coefficient |

|---|---|---|---|---|

| Notion (unit) | ρ (kg/m3) | k (mW/mK) | cp (J/g°C) | α (−) |

| Sheep wool | 10–20 | 38–54 | 1.3–1.7 | 0.056–1.12 |

| Rubber | 500–930 | 100–140 | – | 0.2–0.8 |

| Polystyrene fibres | 15–60 | 34–39 | 1.2 | 0.61–0.75 |

| Granulated Rubber | 550 | 135 | – | 00.96 |

| Expanded Polystyrene | 18–50 | 29–41 | 1.25 | 0.22–03.65 |

| Extruded Polystyrene | 32–40 | 32–37 | 1.45–1.7 | 0.2–0.65 |

| Polyurethane | 30–160 | 22–35 | 1.3–1.45 | 0.67 or 0.8 |

| Fiber | LOI | Classification |

|---|---|---|

| Flax | 17.4 | LOI < 20.95–Flammable |

| Cotton | 18.4 | |

| Polyester | 20.6 | |

| Wool | 25.2 | 21 < LOI < 28–Slow burning |

| Insulating Material | Primary Energy (MJ) Calculated for Functional Unit = Mass per 1 m2 of Insulation Materials to Get an R-Value (Insulation) = 2.5 m2 K/W | ||||

|---|---|---|---|---|---|

| Raw Material Supply | Raw Material Transport | Insulation Material Production | Packaging | Total | |

| 100% wool * | 0 | 8.02 | 54.63 | 2.55 | 65.20 |

| 80% wool + 20% PET | 38.05 | 8.54 | 43.89 | 4.93 | 95.41 |

| 50% wool + 50% hemp | 13.95 | 24.57 | 147.35 | 16.77 | 202.64 |

| Rock wool | 46.16 | 5.83 | 143.93 | 8.70 | 204.62 |

| Expanded PS | 232.42 | 5.79 | 47.25 | 4.12 | 289.58 |

| Glass wool | 56.43 | 9.25 | 254.38 | 0.00 | 320.06 |

| Section | Topic | Authors |

|---|---|---|

| Section 2.1 | Thermal and acoustic insulation | |

| Plastics’ consumption in the construction industry. | Zhao et al. [5] | |

| The effect of the environmental degradation of wool. | Starkova et al. [6] | |

| Weibull distribution. | Naik and Fronk [7] | |

| The distribution of publications related to the price of insulating materials. | Ijjada and Nayaka [8] | |

| A comparative analysis of building insulation. | Kumar et al. [9] | |

| The necessary input energy for natural insulators and conventional mineral wool. | Volf et al. [10] | |

| The mechanism of wool thermal insulation. | Database [11] | |

| The thermal- and moisture-buffering of wool. | Ahmed et al. [12] | |

| The humidity adsorption mechanism, the hysteresis of the adsorption–desorption process. | Florea and Manea [13] | |

| The thermal and sound insulation of soft mats made of wool and polyester fibers. | Bosia et al. [14] | |

| The testing of several natural materials for sound absorption; a comparison of experimental and theoretical results. | Berardi and Iannace [15] | |

| The sound-absorbing properties of wool. | del Rey et al. [16] | |

| The thermal conductivity of wool compared to that of conventional insulating materials. | El Wazna et al. [17] | |

| The Limiting Oxygen Index of wool. | Silva-Santos et al. [18] | |

| The fire characteristics of wool. | Ahmed et al. [12] | |

| Section 2.2 | Composites | |

| Wool as a reinforcement in clay. | Galán-Marín et al. [19] | |

| Waste wool for soil compaction for building components. | Also Parlato et al. [20] | |

| The thermal insulation properties of adobe blocks made of clay and wool. | Mounira et al. [21] | |

| Adobe bricks from clay mixed with plant or animal fibers. | Statuto et al. [22] | |

| Adobe bricks from clay and wool fibers oriented transversely; their thermal and bending characteristics. | Atbir et al. [23] | |

| Wool fibers in cement mortars. | Fantilli et al. [24] | |

| Wool fibers in cement mortars; an ecological point of view. | Tiza et al. [25] | |

| Immersing wool in salt water; composites of concrete and wool; their compressive strengths, tensile and flexural strengths. | Alyousef et al. [26] | |

| Composites based on cement and wool. | Jóźwiak-Niedźwiedzka and Fantilli [27] | |

| The thermal insulation properties of sheep wool; a comparison with synthetic fibers. | Dénes et al. [28] | |

| The thermal and acoustic conductivity of composites made of wool and acrylic-polyurethane resin and natural rubber latex. | Dénes et al. [29] | |

| The acoustic and thermal characteristics of some renewable materials including wool. | Bousshine et al. [30] | |

| A biocomposite prepared by mixing sheep wool with a soy protein isolate. | Urdanpillet et al. [31] | |

| The incorporation of wool fibers into thermoplastic matrices generating composites. | Tanjung and Zulkepli [32] | |

| A hybrid composite with a polypropylene matrix, wool and poultry feathers. | Ilangovan et al. [33] | |

| An epoxy-based polymer composite-filled waste sheep wool fiber. | Sharma et al. [34] | |

| The thermal and acoustic insulation parameters of wool, rock and glass wool and composites with hemp; their energy consumption. | Pennacchio et al. [35] | |

| The responsibility of the building industry for one-third of the total carbon emissions in the world. | Quintana-Gallardo et al. [36] | |

| Biocomposite panels have significantly lower environmental impacts. | Nußholz et al. [37] | |

| Immersing wool in a saline solution, increasing the surface friction of the fibers and the adhesion to the cement matrix. | Alyousef [38] | |

| A comparison of boards made of boron-doped sheep wool with those made of rock wool and EPS. | Altin and Yildirim [39] | |

| The incorporation of sheep wool in epoxy, polyurethane, and polyester matrices; the damping of mechanical vibrations, sound absorption, light transmission and electrical conductivity. | Vasina et al. [40] | |

| An examination of the adhesion properties between non-woven plastic sheets and cement mortar. | Bahij et al. [41] | |

| How wool fibers can be separated into individual components. | Caven and Bechtold [42] | |

| Section 3.1 | The Removal of chromium (hexavalent/trivalent) | |

| The effect of contact time on the adsorption process of Cr(VI) on sheep wool; the possible change in the oxidation state of chromium. | Jumean et al. [43] | |

| Changes in the oxidation state of adsorbed Cr with wool contact time and pH. | Ray et al. [44] | |

| The optimization of wool regeneration; designing a pilot plant. | Badrelzaman et al. [45] | |

| The removal of Alizarin red S (ARS) dye adsorbing on wool from wastewater; the simultaneous regeneration of ARS and removal of Cr(VI). | Khamis et al. [46] | |

| The adsorption of both modified and unmodified forms of the dyes rhodamine6G (R6G) and Cr(VI). | Meenarathi et al. [47] | |

| A keratin/PET nanofiber membrane tested in Cr(VI) adsorption. | Jin et al. [48] | |

| The effect of an accelerated electron beam on wool. | Porubská et al. [49] | |

| The adsorption of Cr(III) on (non)irradiated wool. | Braniša et al. [50] | |

| The fitting of ten models for Cr(III) adsorption isotherms. | Braniša et al. [51] | |

| Section 3.2 | The Removal of other species using wool | |

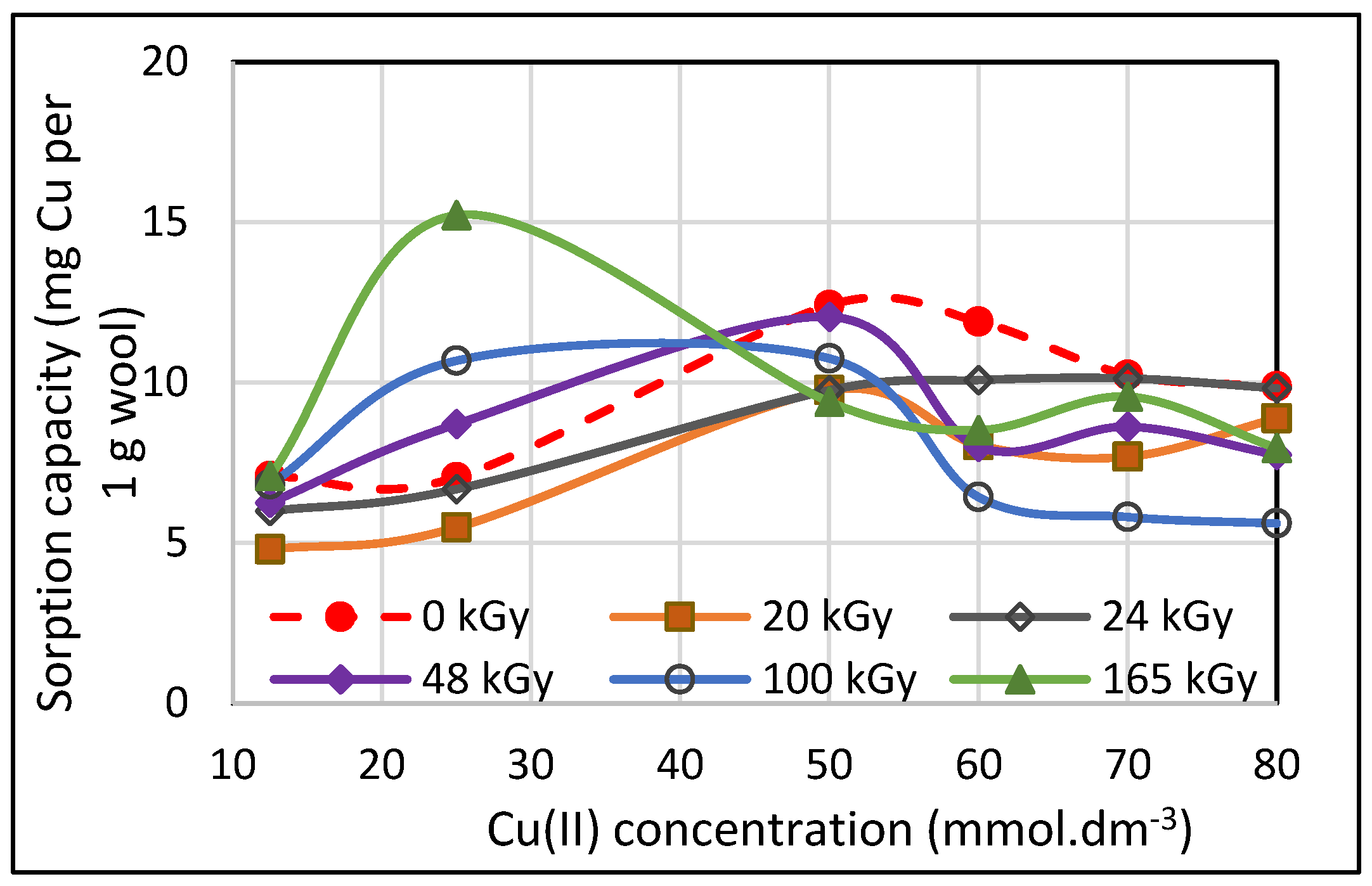

| An anomalous sorption of Cu(II) on natural or electron-irradiated sheep wool. | Porubská et al. [52] | |

| The fitting of ten models for Cu(II) adsorption isotherms. | Porubská et al. [53] | |

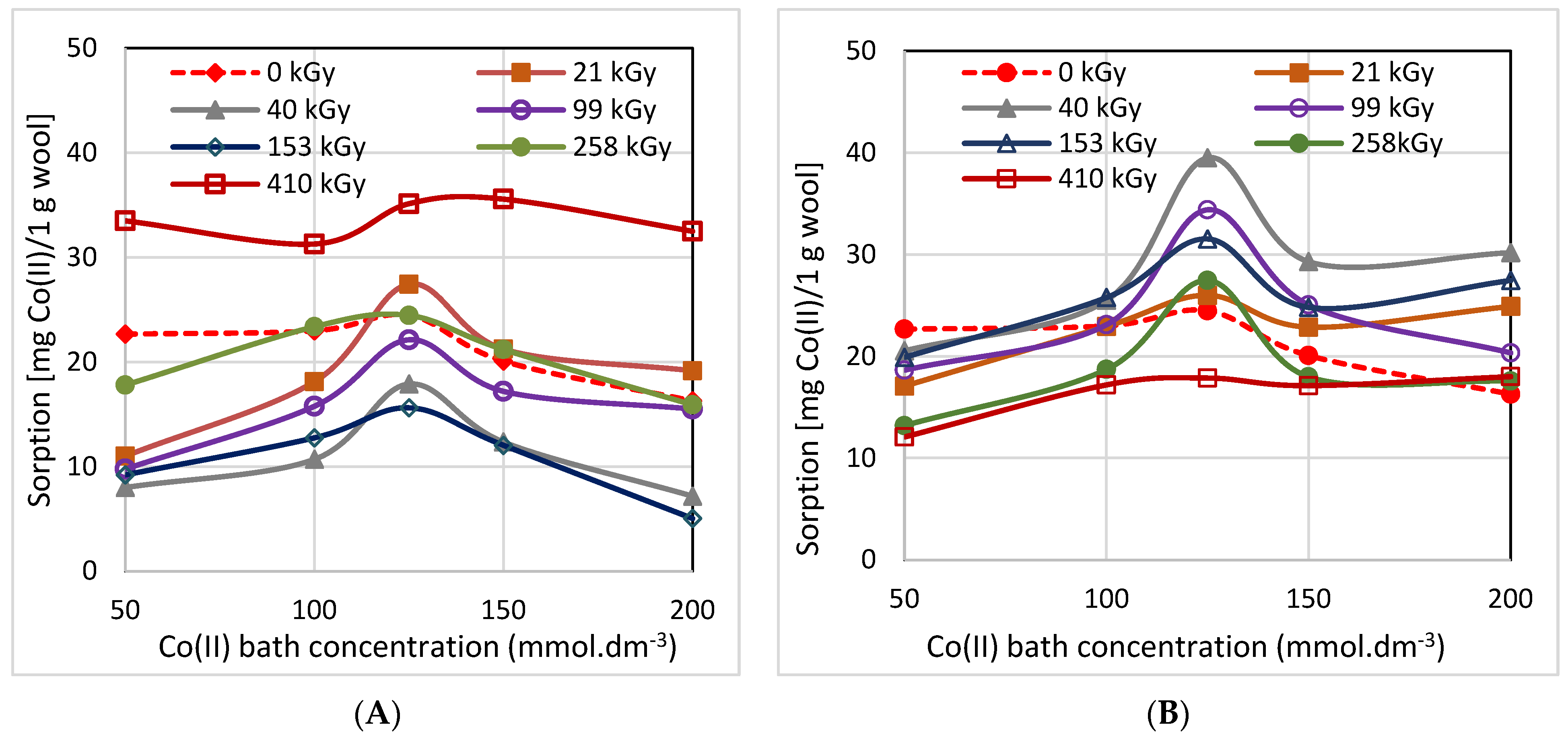

| The effect of wool moisture during electron beam irradiation on Co(II) sorption. | Braniša et al. [54] | |

| The effect of irradiation lapse on Co(II) sorption. | Braniša et al. [55] | |

| The competitive adsorption of Cr(III) and Cu(II) from a binary solution. | Braniša et al. [56] | |

| Competitive cation adsorption on electron-irradiated wool changes the fitting of adsorption isotherms for single-component solutions | Porubská et al. [57] | |

| The adsorptive separation of Cu(II) and Au(III) on wool modified with NaOH, Na2S, NaHSO3, and NaBH4. | Enkhzaya et al. [58] | |

| The application of statistical physics to examine the thermodynamics and mechanisms of adsorption of some heavy metals on wool. | Olawale et al. [59] | |

| Testing the total surface charge of natural sheep wool. | Zimmerman et al. [60] | |

| The adsorption of nitrate anions on modified wool. | Porubská et al. [61] | |

| The capture of three types of viruses of different sizes on the wool-packed column. | Pang et al. [62] | |

| The adsorption of VOCs on wool | Mansour et al. [63] | |

| The ad/absorption of formaldehyde on wool. | Hegyi et al. [64] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Porubská, M.; Koóšová, K.; Braniša, J. The Application of Sheep Wool in the Building Industry and in the Removal of Pollutants from the Environment. Processes 2024, 12, 963. https://doi.org/10.3390/pr12050963

Porubská M, Koóšová K, Braniša J. The Application of Sheep Wool in the Building Industry and in the Removal of Pollutants from the Environment. Processes. 2024; 12(5):963. https://doi.org/10.3390/pr12050963

Chicago/Turabian StylePorubská, Mária, Karin Koóšová, and Jana Braniša. 2024. "The Application of Sheep Wool in the Building Industry and in the Removal of Pollutants from the Environment" Processes 12, no. 5: 963. https://doi.org/10.3390/pr12050963

APA StylePorubská, M., Koóšová, K., & Braniša, J. (2024). The Application of Sheep Wool in the Building Industry and in the Removal of Pollutants from the Environment. Processes, 12(5), 963. https://doi.org/10.3390/pr12050963