Quantitative Description of Pore and Fracture Distribution Heterogeneity Using Mercury Removal Curve and Applicability of Fractal Models

Abstract

1. Introduction

2. Experimental Testing and Fractal Theory

2.1. Sample Preparation and Experimental Testing

2.2. Fractal Theory

3. Results and Discussion

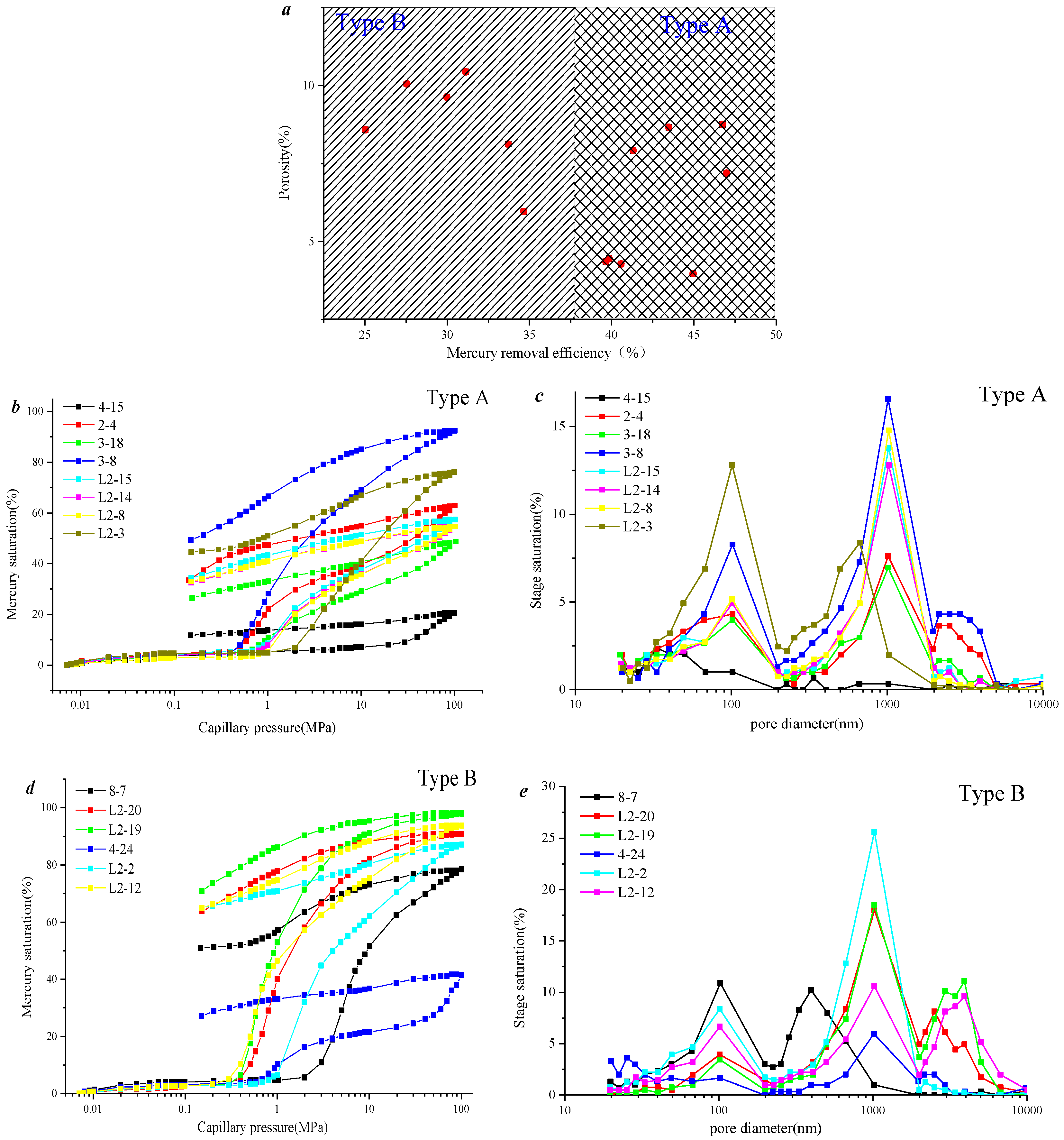

3.1. Pore Distribution Characteristics by Using HPMI Test

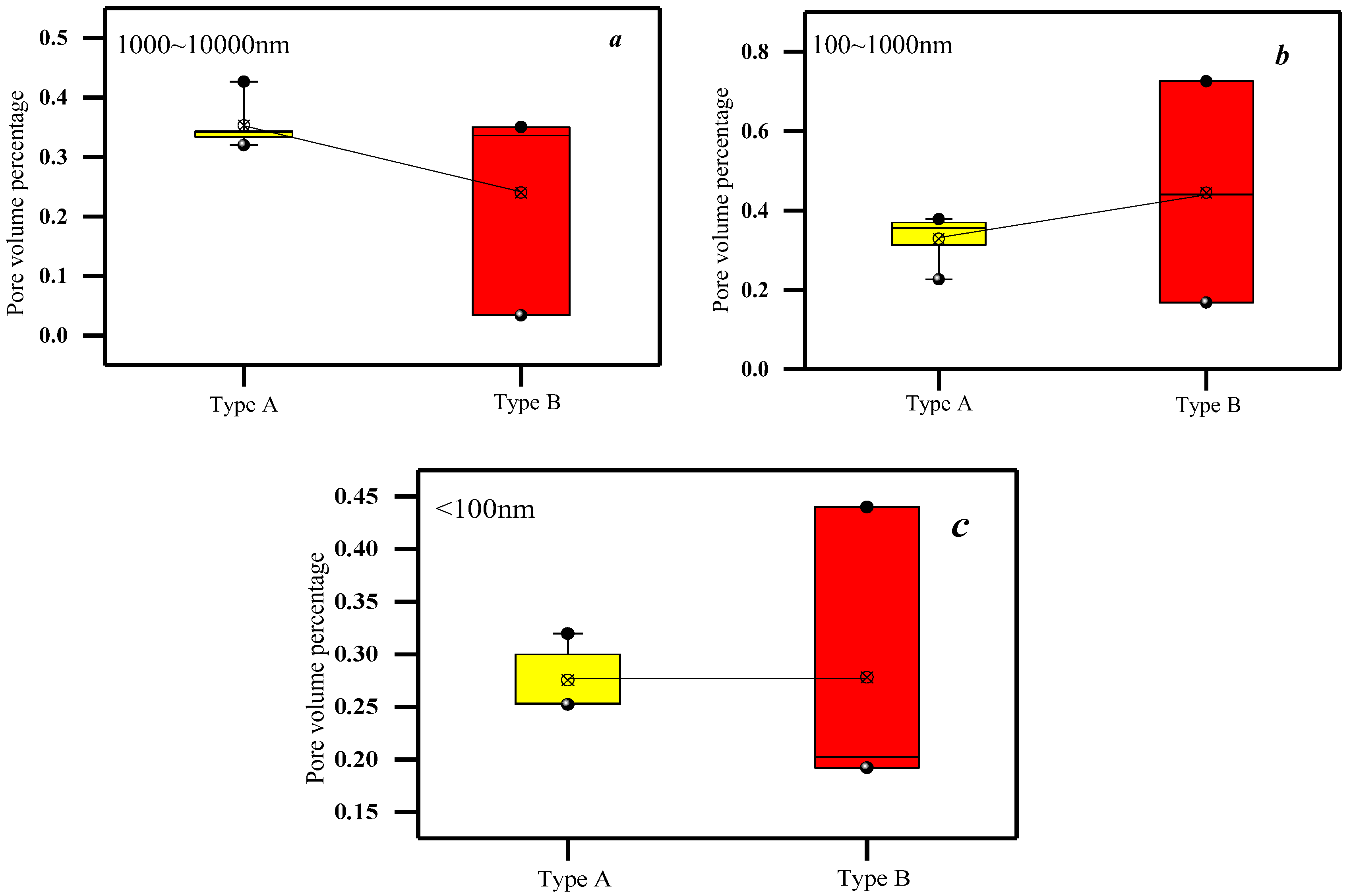

3.2. Pore and Fracture Distribution Heterogeneity by Using Mercury Inlet Curve

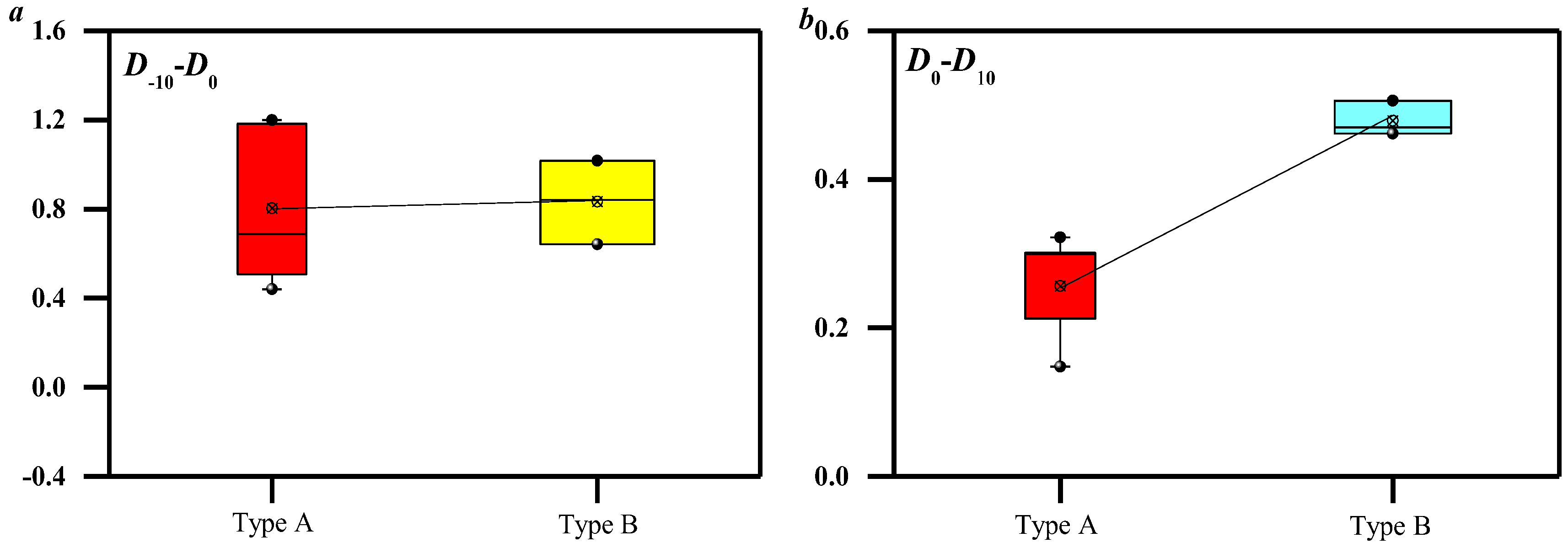

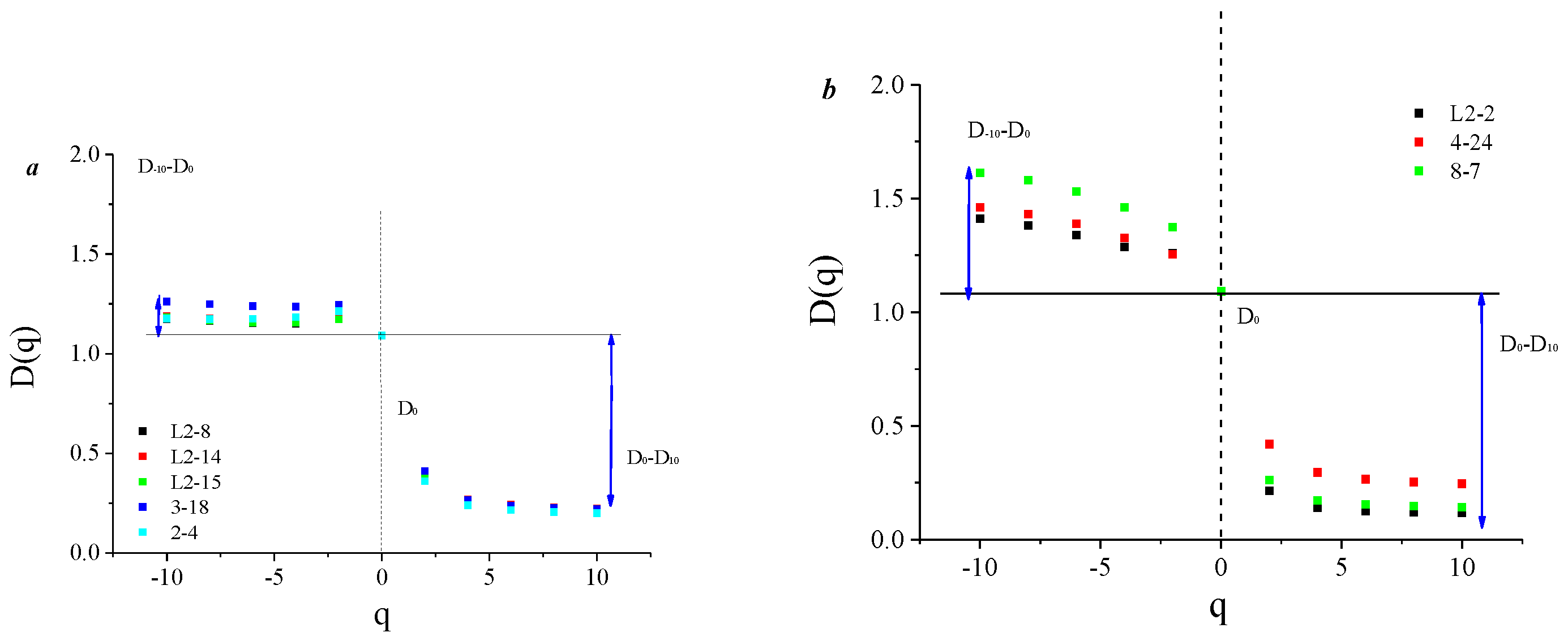

3.3. Quantitative Description of Heterogeneity of Pore and Fracture Distribution Based on Mercury Removal Curves

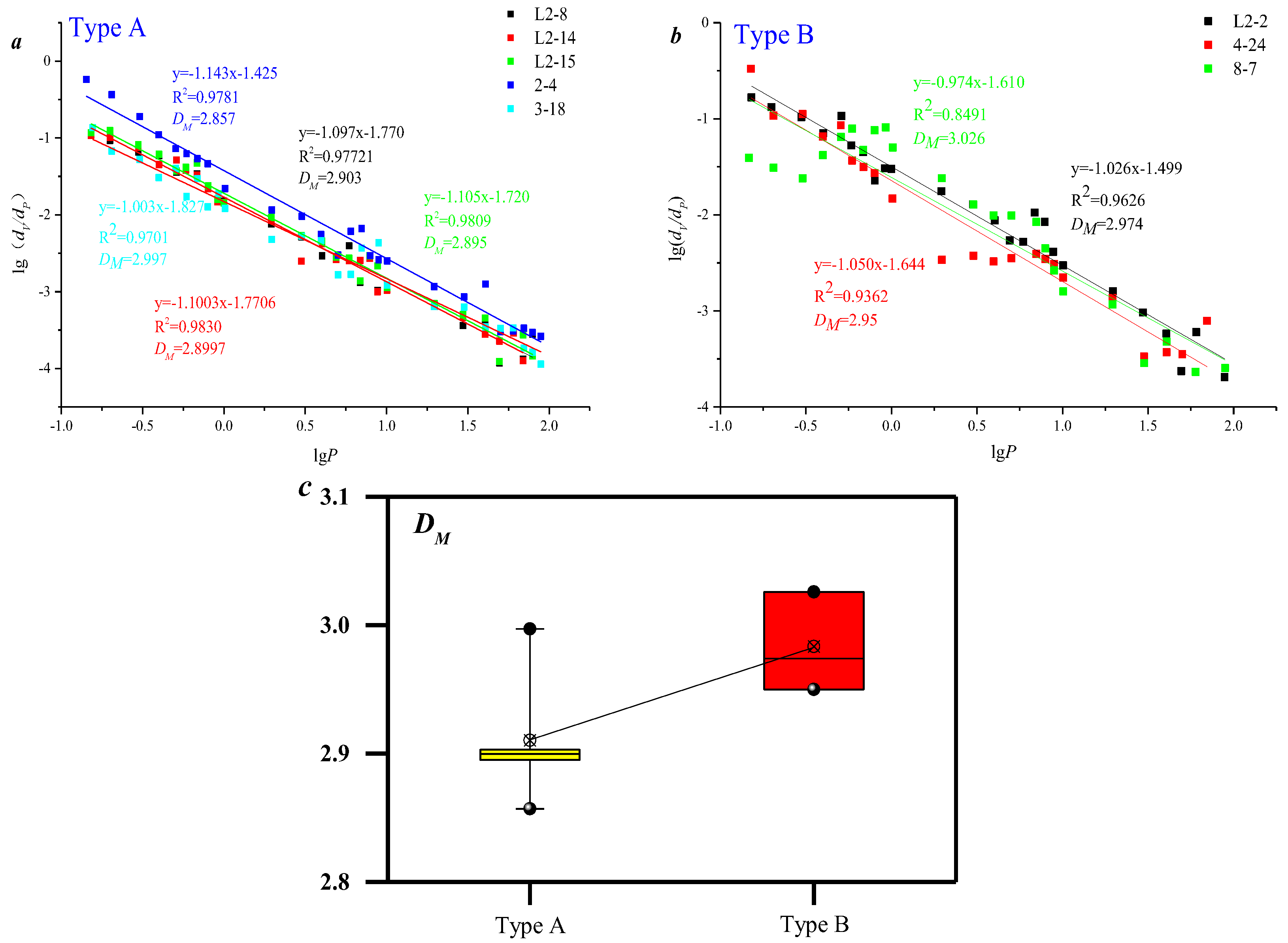

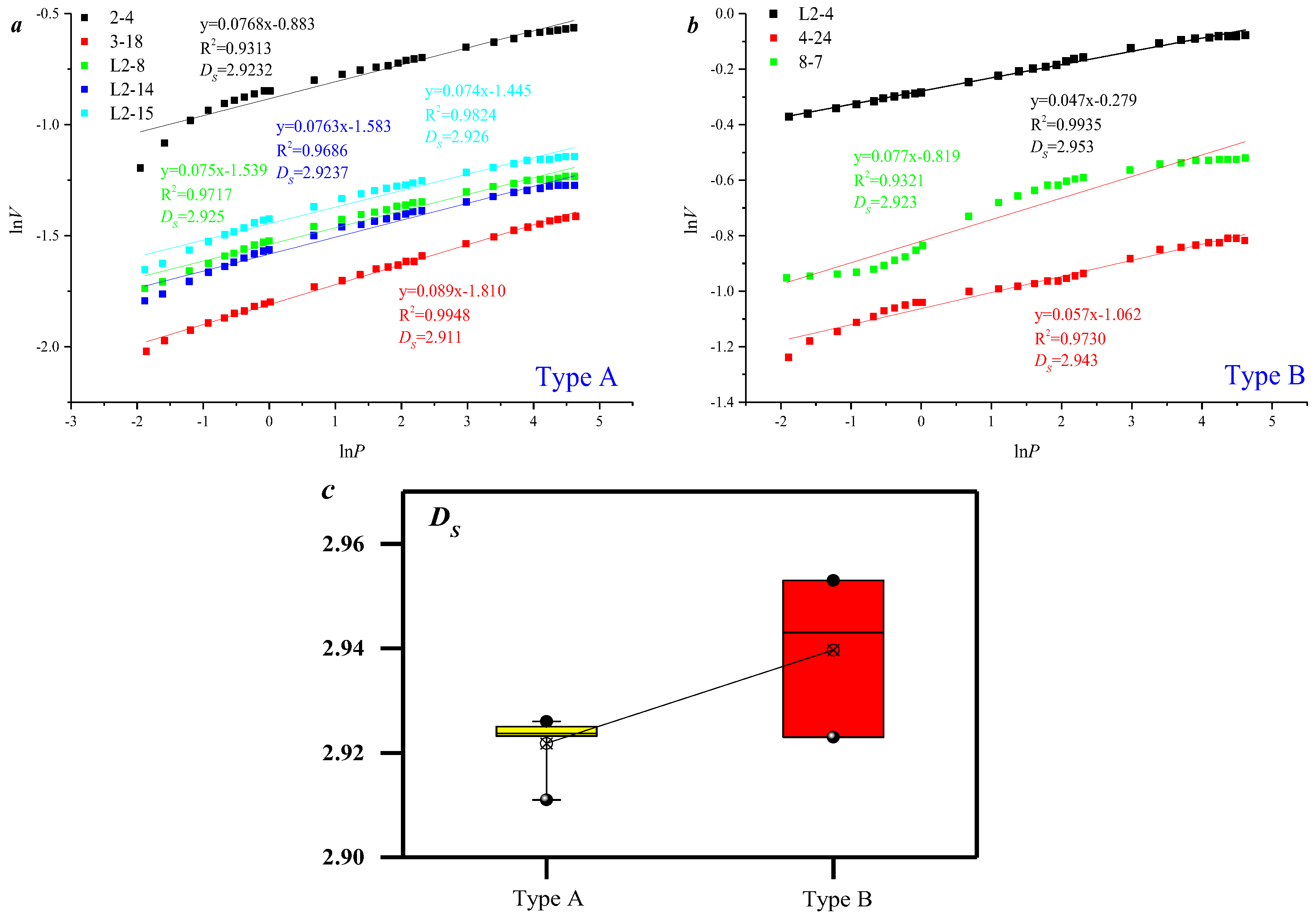

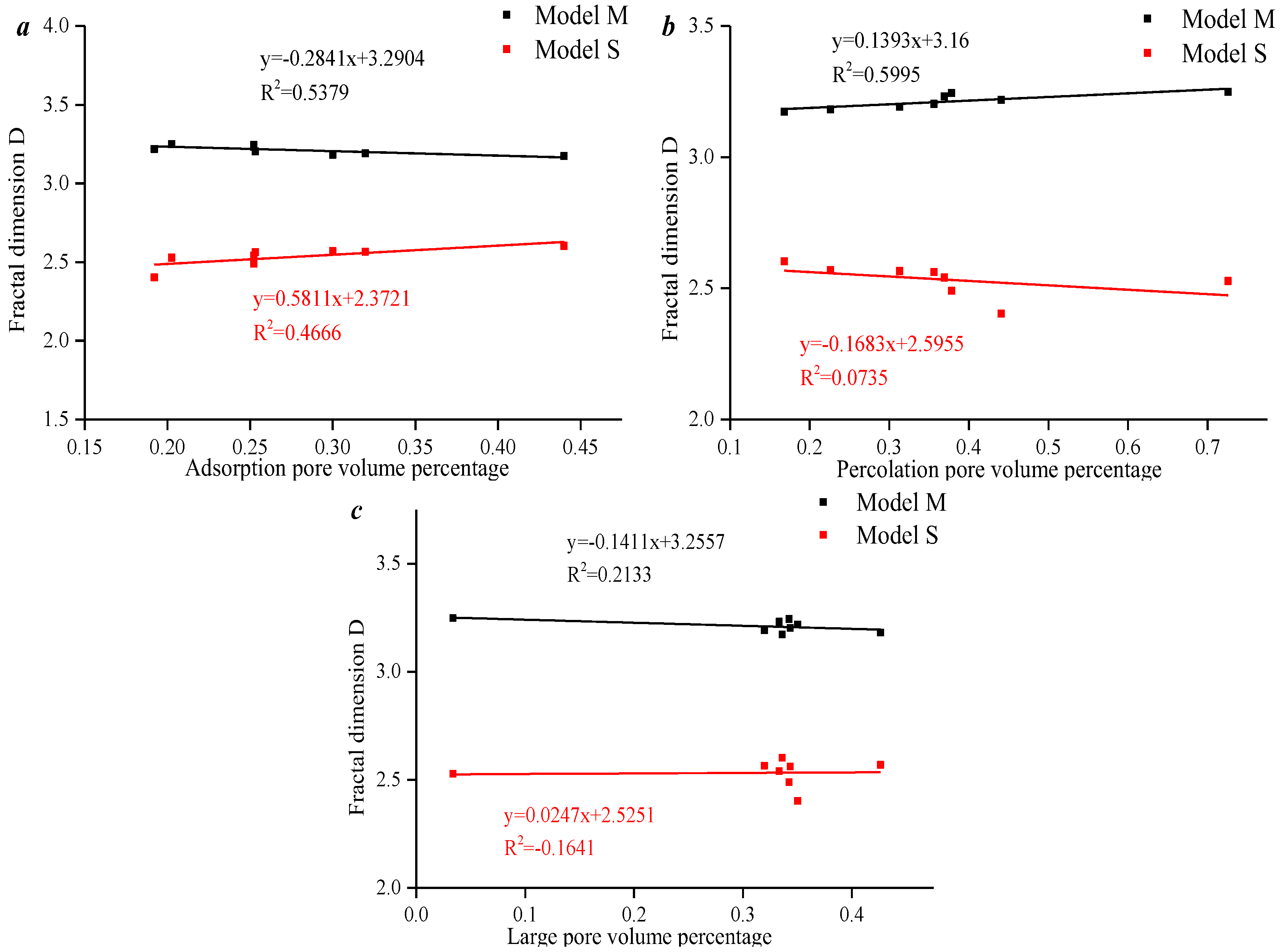

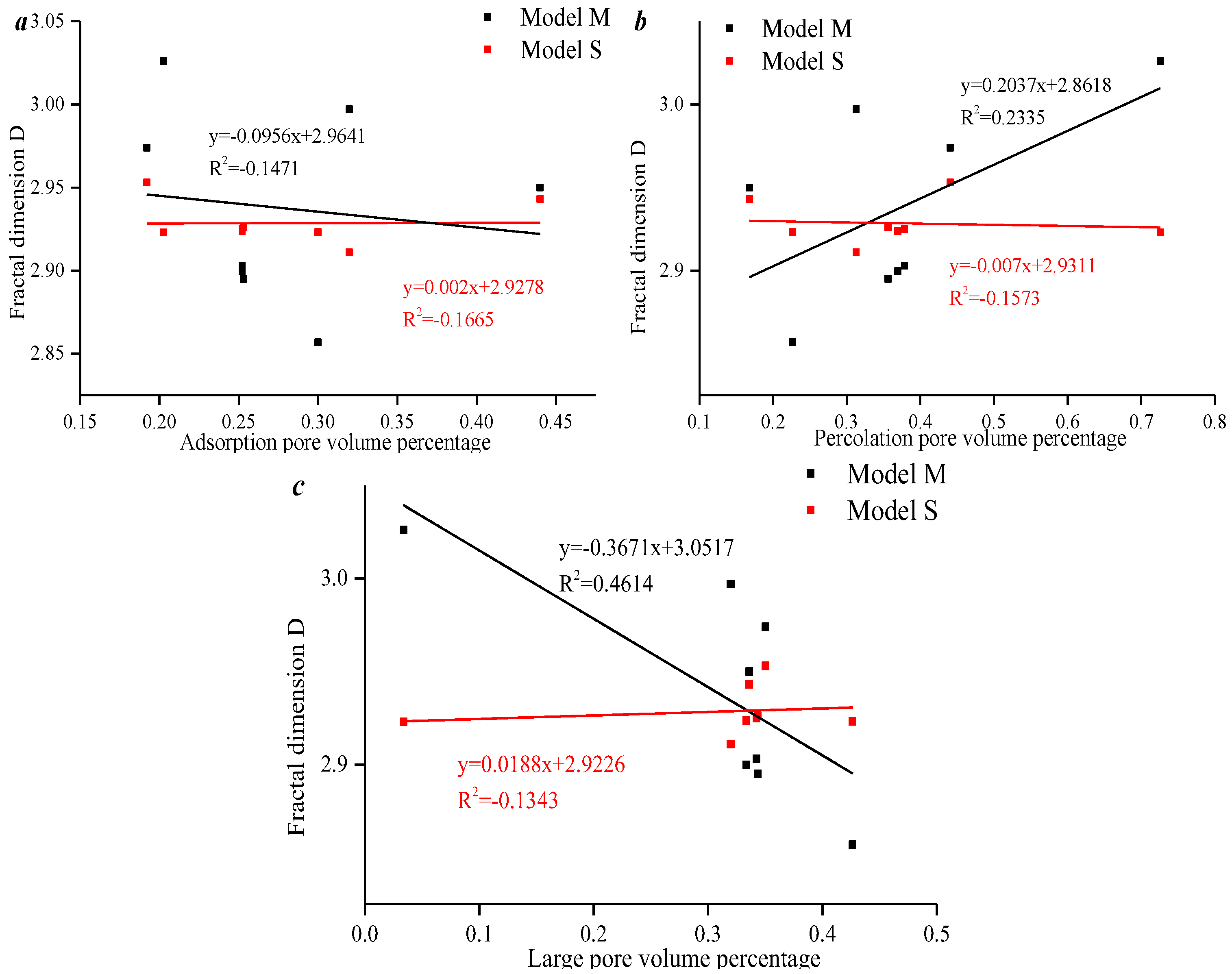

3.4. The Influencing Factors the Pore Fractal Characteristics and Applicability Analysis

4. Conclusions

- (1)

- Based on the mercury removal efficiency and porosity, the samples can be divided into two types: type A (mercury removal efficiency above 35%) and type B (mercury removal efficiency below 35%). Generally, type A belongs to micro-pore-developed types, while type B belongs to macro-pore-developed types.

- (2)

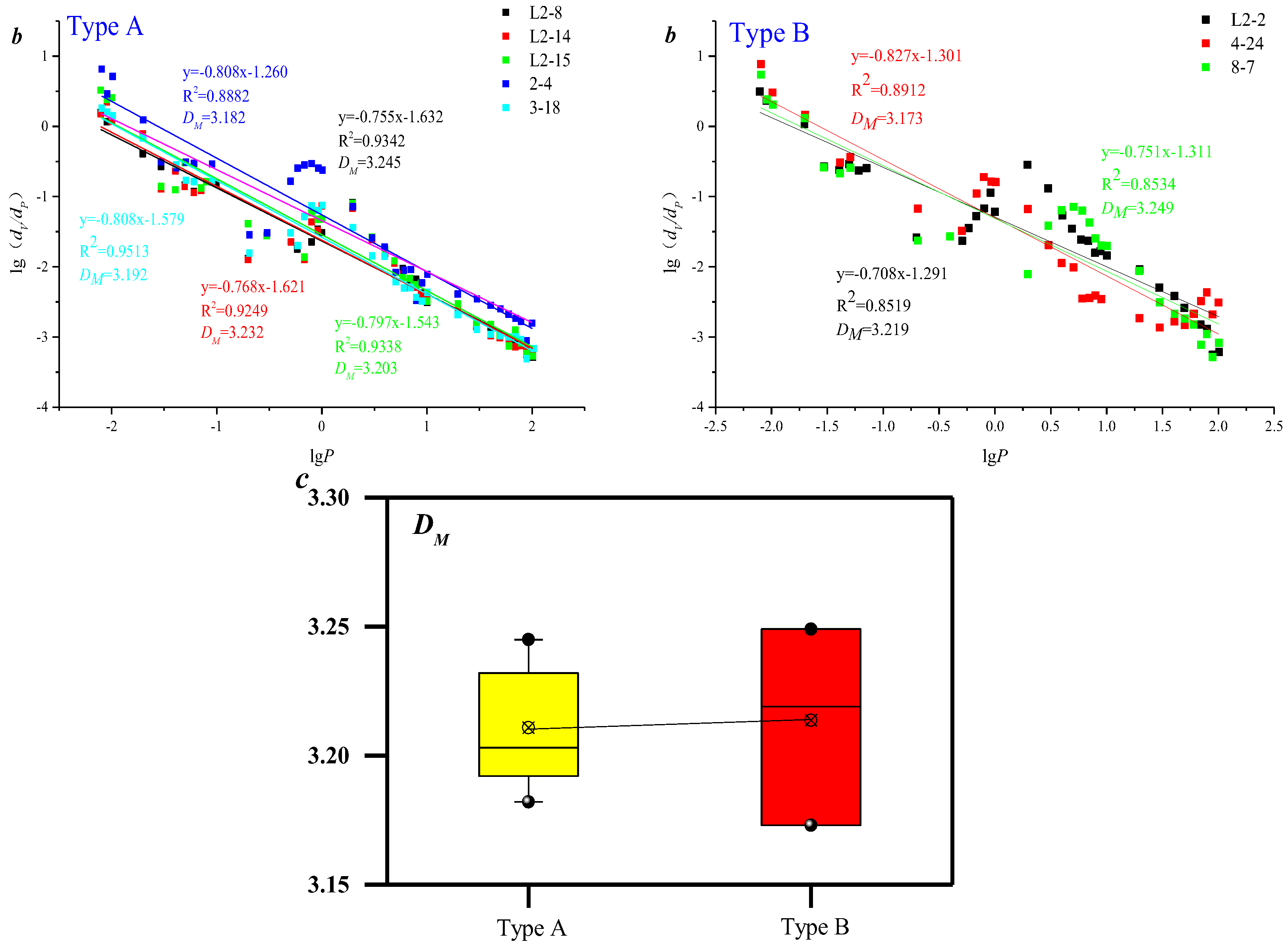

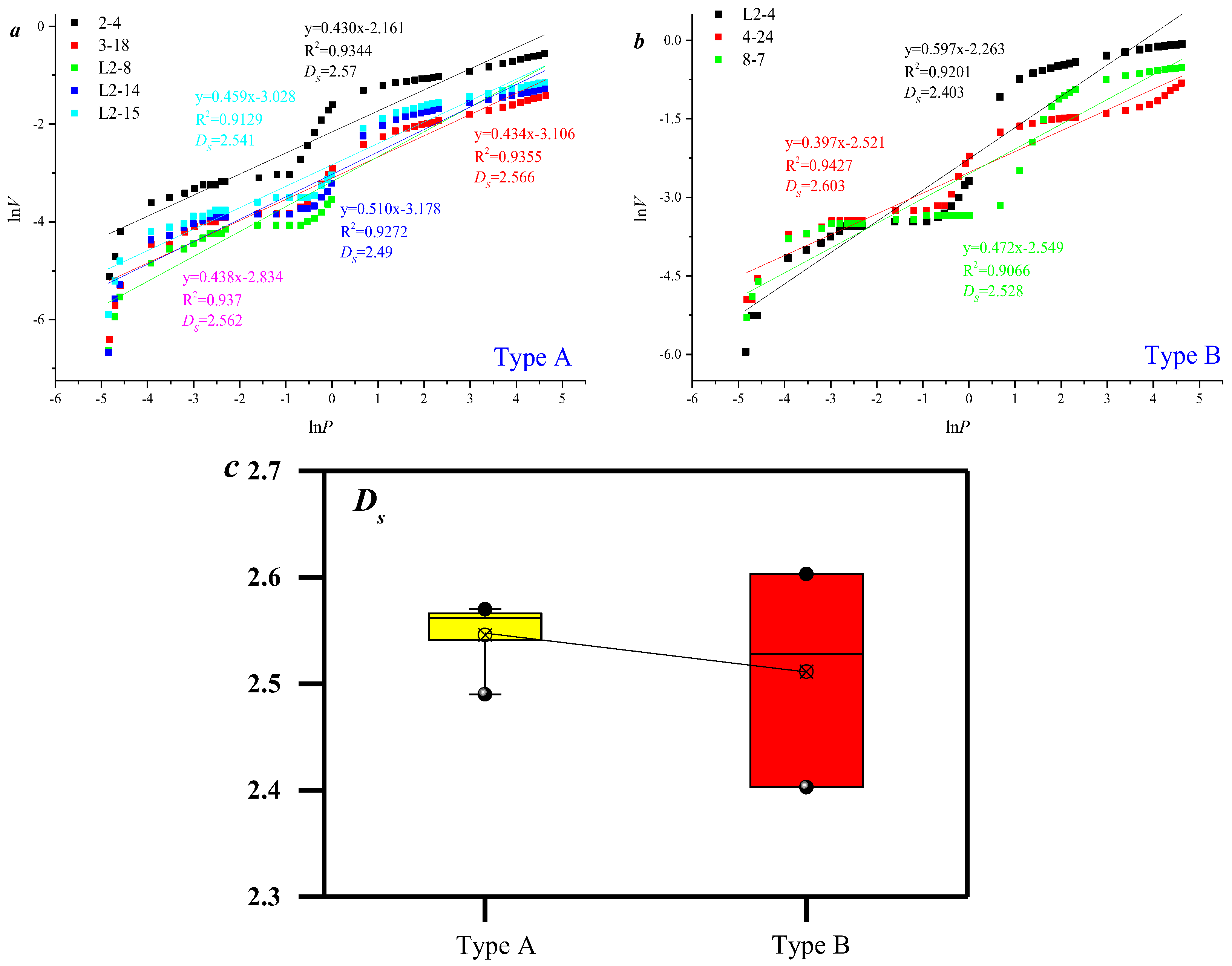

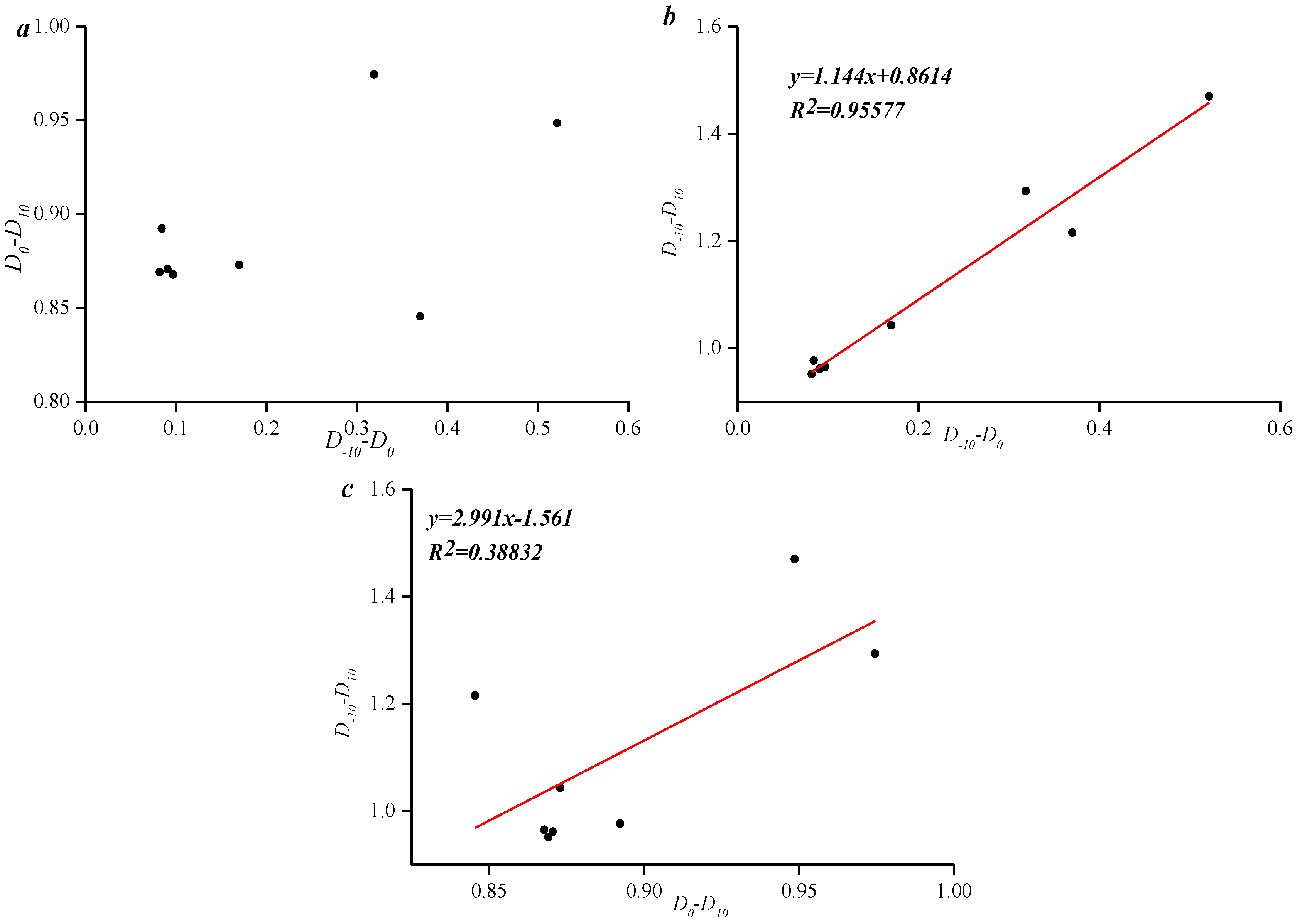

- The M model indicates that the pore-filling desorption hysteresis (PFDH) of type A and type B is consistent, whereas the S model shows that the PFDH of type A is significantly stronger than that of type B. This difference can be attributed to the fact that the M model represents the complexity of the specific surface area, while the S model represents the roughness of the pore volume. A positive correlation was found between D−10–D0 and D−10–D10, indicating that PFDH is influenced by the low-pore-volume region, whereas there was no correlation between D0–D10 and D−10–D10. PFDH affects the storage characteristics of coalbed methane. By studying the PFDH, it is possible to evaluate the reserves and distribution patterns. Coalbed methane undergoes gas migration within the coal body through adsorption and desorption, and the PFDH can affect the path and velocity of gas migration within the coal. Studying the PFDH helps to gain a deeper understanding of the migration patterns of gases, guiding the extraction of coalbed methane and improving mining efficiency.

- (3)

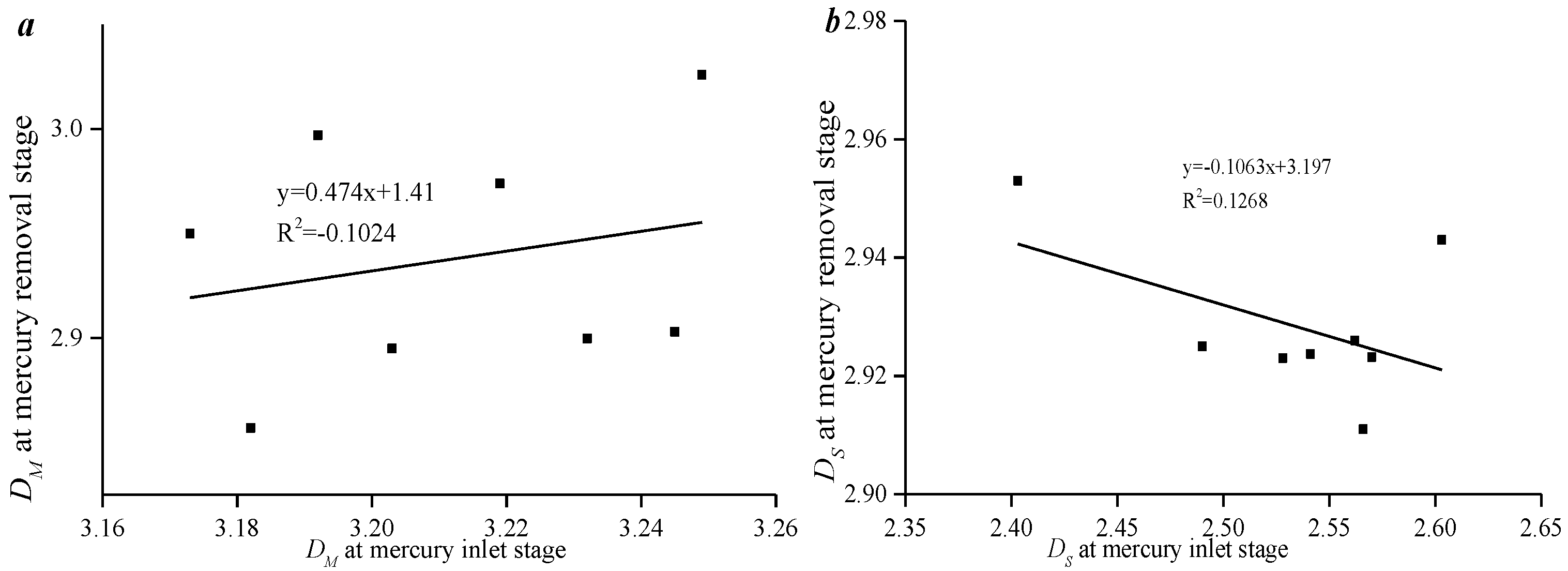

- Different from the mercury intrusion curves (MICs), the calculation results of the mercury retention curves (MRCs) based on two single fractal models indicate that the pore-filling desorption hysteresis (PFDH) of type B is stronger than that of type A. Additionally, the multifractal characteristics of MRC differ from those of MIC, indicating that the fractal characteristics of MRC are distinct from those of MIC. The mercury migration curve reflects the adsorption, desorption, and migration processes of gases in pores. Understanding the migration patterns and characteristics of gas in coal seams is of significance for guiding the extraction process of coalbed methane. By studying the advance and retreat mercury curves, we can understand the migration patterns of gases under different pore structures, guide the layout of mining wells and the adjustment of mining parameters, and improve the efficiency of coalbed methane extraction.

- (4)

- The relationship between DM and the pore volume percentage at different stages suggests that the M model can better characterize the pore-filling desorption hysteresis (PFDH) at the mercury inlet stage. Similarly, the results of the mercury removal fractal calculation indicate that DM also has a relationship with the pore volume percentage at different stages, further supporting the idea that the M model can better characterize PFDH at the mercury removal stage.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lou, Y.; Su, Y.; Gao, W.; Wang, W.; Xiong, W.; Chen, J.; Xia, P. Pore characteristics and fractal characterization variability of typical middle- and high-rank coal reserves: A case study of middle- and high-rank coal samples in western Guizhou. Front. Energy Res. 2022, 10, 981530. [Google Scholar] [CrossRef]

- Deng, J.; Zhao, J.; Huang, A.; Zhang, Y.; Wang, C.; Shu, C. Thermal behavior and microcharacterization analysis of second-oxidized coal. J. Therm. Anal. Calorim. 2017, 127, 439–448. [Google Scholar] [CrossRef]

- Li, J.; Lu, S.; Cai, Y.; Xue, H.; Cai, J. Impact of coal ranks on dynamic gas flow: An experimental investigation. Fuel 2017, 194, 17–26. [Google Scholar] [CrossRef]

- Niu, C.; Xia, W.; Xie, G. Effect of low-temperature pyrolysis on surface properties of sub-bituminous coal sample and its relationship to flotation response. Fuel 2017, 208, 469–475. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, C.; Tang, D.; Gan, Q.; Niu, X.; Wang, K.; Shen, R. Coal pore size distributions controlled by the coalification process: An experimental study of coals from the Junggar, Ordos and Qinshui basins in China. Fuel 2017, 206, 352–363. [Google Scholar] [CrossRef]

- Hodot, B.B. Outburst of Coal and Coalbed Gas (Chinese Translation); China Industry Press: Beijing, China, 1966. [Google Scholar]

- IUPAC (International Union of Pure and Applied Chemistry). Physical chemistry division commission on colloid and surface chemistry, subcommittee on characterization of porous solids: Recommendations for the characterization of porous solids (technical report). Afr. J. Pure Appl. Chem. 1994, 66, 1739–1758. [Google Scholar] [CrossRef]

- Tatsumi, K.; Corish, J. Name and symbol of the element with atomic number 112 (IUPAC Recommendations 2010). Pure Appl. Chem. 2010, 82, 753–755. [Google Scholar] [CrossRef]

- Wang, C.; Cheng, Y. Role of coal deformation energy in coal and gas outburst: A review. Fuel 2023, 332, 126019. [Google Scholar] [CrossRef]

- Zhao, J.; Tian, S.; Zou, Q.; Xie, H.; Ran, Q.; Ma, T.; Zhang, X. Effect of SiO2-H2O nanofluids on wettability of pulverized coal and the modification mechanism. Fuel 2024, 359, 130396. [Google Scholar] [CrossRef]

- Zhao, J.; Tian, S.; Li, P.; Xie, H.; Cai, J. Molecular dynamics simulation and experimental research on the influence of SiO2-H2O nanofluids on wettability of low-rank coal. Colloids Surf. A Physicochem. Eng. Asp. 2023, 679, 132580. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, D.; Cai, Y.; Karpyn, Z.; Yao, Y. Comparative analysis of nanopore structure and its effect on methane adsorption capacity of Southern Junggar coalfield coals by gas adsorption and FIB-SEM tomography. Microporous Mesoporous Mater. 2018, 272, 117–128. [Google Scholar] [CrossRef]

- Ling, L.Q.; Xin, S.P.; Zhao, F.W.; Xiang, J.C.; Ju, H.D. Study on the Pore Structures and Adsorption Characteristics of Coking Coal of Liulin Mining in China Under the Condition of High Temperature and High Pressure. Front. Earth Sci. 2022, 10, 877462. [Google Scholar] [CrossRef]

- Guo, S.; Cao, Y.; Zhang, J.; Zhang, X.; Meng, B.; Liu, S. Pore-Microfracture Structure Alteration of Coal Induced by High-Pressure CO2 Gas Fracturing. Energy Fuels 2023, 37, 4341–4348. [Google Scholar] [CrossRef]

- Wei, P.; Liang, Y.; Zhao, S.; Peng, S.; Li, X.; Meng, R. Characterization of Pores and Fractures in Soft Coal from the No. 5 Soft Coalbed in the Chenghe Mining Area. Processes 2019, 7, 13. [Google Scholar] [CrossRef]

- Liu, M.; Xie, R.; Li, C.; Li, X.; Jin, G.; Guo, J. Determining the segmentation point for calculating the fractal dimension from mercury injection capillary pressure curves in tight sandstone. J. Geophys. Eng. 2018, 15, 1350–1362. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, C.; Nepal, S.; Yang, C.; Dou, W.; Chen, J. A hybrid approach for scalable sub-tree anonymization over big data using MapReduce on cloud. J. Comput. Syst. Sci. 2014, 80, 1008–1020. [Google Scholar] [CrossRef]

- Yue, G.; Liu, H.; Yue, J.; Li, M.; Liang, W. Influence radius of gas extraction borehole in an anisotropic coal seam: Underground in-situ measurement and modeling. Energy Sci. Eng. 2019, 7, 694–709. [Google Scholar] [CrossRef]

- Zhao, B.; Yi, H.; Tang, X.; Li, Q.; Liu, D.; Gao, F. Copper modified activated coke for mercury removal from coal-fired flue gas. Chem. Eng. J. 2016, 286, 585–593. [Google Scholar] [CrossRef]

- Mei, J.; Wang, C.; Kong, L.; Liu, X.; Hu, Q.; Zhao, H.; Yang, S. Outstanding Performance of Recyclable Amorphous MoS3 Supported on TiO2 for Capturing High Concentrations of Gaseous Elemental Mercury: Mechanism, Kinetics, and Application. Environ. Sci. Technol. 2019, 53, 4480–4489. [Google Scholar] [CrossRef]

- Wang, G.; Shen, J.; Liu, S.; Jiang, C.; Qin, X. Three-dimensional modeling and analysis of macro-pore structure of coal using combined X-ray CT imaging and fractal theory. Int. J. Rock Mech. Min. Sci. 2019, 123, 1040–1082. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, C.; Chu, X.; Vandeginste, V.; Ju, W. Multifractal Analysis in Characterizing Adsorption Pore Heterogeneity of Middle- and High-Rank Coal Reservoirs. ACS Omega 2020, 5, 19385–19401. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Xiao, R.; Huang, H.; Xiao, G. Comparison of non-catalytic and catalytic fast pyrolysis of corncob in a fluidized bed reactor. Bioresour. Technol. 2009, 100, 1428–1434. [Google Scholar] [CrossRef] [PubMed]

- Hui, S.; Lv, Y.; Niu, Y.; Kan, H.; Wang, D.; Li, P. Experimental comparative study on ash fusion characteristics of Ningdong coal under oxidizing and reducing atmosphere by means of SiO2-Al2O3-(CaO + MgO + Na2O + K2O) pseudo-ternary diagrams. Fuel 2019, 258, 116–137. [Google Scholar] [CrossRef]

- Kashif, M.; Cao, Y.; Yuan, G.; Asif, M.; Javed, K.; Mendez, J.N.; Khan, D.; Miruo, L. Pore size distribution, their geometry and connectivity in deeply buried Paleogene Es1 sandstone reservoir, Nanpu Sag, East China. Pet. Sci. 2019, 16, 981–1000. [Google Scholar] [CrossRef]

- Otalvaro, I.F.; Neto, M.P.C.; Delage, P.; Caicedo, B. Relationship between soil structure and water retention properties in a residual compacted soil. Eng. Geol. 2016, 205, 73–80. [Google Scholar] [CrossRef]

- Peng, J.; Han, H.; Xia, Q.; Li, B. Evaluation of the pore structure of tight sandstone reservoirs based on multifractal analysis: A case study from the Kepingtage Formation in the Shuntuoguole uplift, Tarim Basin, NW China. J. Geophys. Eng. 2018, 15, 1122–1136. [Google Scholar] [CrossRef]

- Zhao, L.; Guanhua, N.; Lulu, S.; Qian, S.; Shang, L.; Kai, D.; Jingna, X.; Gang, W. Effect of ionic liquid treatment on pore structure and fractal characteristics of low rank coal. Fuel 2020, 262, 116513. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, Y. Comparative Evaluation of Pore Structure Heterogeneity in Low-Permeability Tight Sandstones Using Different Fractal Models Based on NMR Technology: A Case Study of Benxi Formation in the Central Ordos Basin. Energy Fuels 2020, 34, 13924–13942. [Google Scholar] [CrossRef]

- Zhang, M.; Duan, C.; Li, G.; Fu, X.; Zhong, Q.; Liu, H.; Dong, Z. Determinations of the multifractal characteristics of the pore structures of low-, middle-, and high-rank coal using high-pressure mercury injection. J. Pet. Sci. Eng. 2021, 203, 108656. [Google Scholar] [CrossRef]

| Sample Number | Porosity (%) | Permeability (10−3 μm2) | Mercury Removal Efficiency (%) | Percent Pore Volume (%) | ||

|---|---|---|---|---|---|---|

| 1000~10,000 nm | 100~1000 nm | <100 nm | ||||

| 4-15 | 8.660 | 1.510 | 43.470 | 0.082 | 0.115 | 0.607 |

| 2-4 | 7.190 | 1.210 | 46.987 | 0.395 | 0.226 | 0.300 |

| 3-18 | 3.970 | 0.250 | 44.954 | 0.279 | 0.313 | 0.320 |

| 3-8 | 8.750 | 1.610 | 46.737 | 0.437 | 0.355 | 0.161 |

| L2-15 | 4.450 | 0.120 | 39.853 | 0.305 | 0.356 | 0.253 |

| L2-14 | 4.280 | 0.130 | 40.570 | 0.302 | 0.369 | 0.252 |

| L2-8 | 4.360 | 0.130 | 39.641 | 0.311 | 0.378 | 0.252 |

| L2-3 | 7.920 | 0.120 | 41.312 | 0.029 | 0.618 | 0.291 |

| 8-7 | 5.960 | 0.100 | 34.648 | 0.017 | 0.726 | 0.203 |

| L2-20 | 9.630 | 0.700 | 29.982 | 0.607 | 0.309 | 0.051 |

| L2-19 | 10.050 | 1.470 | 27.547 | 0.698 | 0.236 | 0.035 |

| 4-24 | 8.120 | 1.000 | 33.716 | 0.304 | 0.168 | 0.440 |

| L2-2 | 8.580 | 0.560 | 25.024 | 0.333 | 0.441 | 0.192 |

| L2-12 | 10.440 | 1.960 | 31.130 | 0.575 | 0.265 | 0.126 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chong, H.; Liu, X.; Xi, D.; Zhang, J.; Vandeginste, V.; Wang, D.; Yao, P. Quantitative Description of Pore and Fracture Distribution Heterogeneity Using Mercury Removal Curve and Applicability of Fractal Models. Processes 2024, 12, 917. https://doi.org/10.3390/pr12050917

Chong H, Liu X, Xi D, Zhang J, Vandeginste V, Wang D, Yao P. Quantitative Description of Pore and Fracture Distribution Heterogeneity Using Mercury Removal Curve and Applicability of Fractal Models. Processes. 2024; 12(5):917. https://doi.org/10.3390/pr12050917

Chicago/Turabian StyleChong, Huasheng, Xiao Liu, Danyang Xi, Junjian Zhang, Veerle Vandeginste, Dongdong Wang, and Peng Yao. 2024. "Quantitative Description of Pore and Fracture Distribution Heterogeneity Using Mercury Removal Curve and Applicability of Fractal Models" Processes 12, no. 5: 917. https://doi.org/10.3390/pr12050917

APA StyleChong, H., Liu, X., Xi, D., Zhang, J., Vandeginste, V., Wang, D., & Yao, P. (2024). Quantitative Description of Pore and Fracture Distribution Heterogeneity Using Mercury Removal Curve and Applicability of Fractal Models. Processes, 12(5), 917. https://doi.org/10.3390/pr12050917