Abstract

Due to the impact of global warming and climate change, more and more people are starting to have a clearer understanding and vigilance about greenhouse gases. To prevent further deterioration of the global environment, this study examines the coefficients of performance of 21 currently available refrigerants with very low global-warming potential and zero ozone-depleting potential under evaporation temperatures of 10, −20, −40, and −60 °C and condensation temperatures of 30, 40, and 50 °C, respectively. It is found that the use of pure refrigerant in a two-stage refrigeration system to replace the single-stage refrigeration system, in addition to mixing it into an appropriate mixture, can effectively improve the performance coefficient of the refrigeration system. For single-stage vapor compression refrigeration systems, R1234ze(Z), R601, and R1233zd(E) have the best refrigeration performances among the environmentally friendly refrigerants studied, while R441A performs the worst for Teva = 10 °C and −20 °C. Moreover, RE170 has the highest COP of the refrigeration system for Teva = −40 °C and −60 °C. However, R1234yf performs worse in COP when the evaporation temperature is lower, and it ranks last for Teva = −60 °C. When a double-stage vapor compression refrigeration system is employed instead, the percentage increase in the COP of the system using R1234yf becomes the largest for Teva = −40 °C and −60 °C. However, the growth rate of R717 ranks last for Teva = −60 °C. For an R717/R1234yf mixture at an optimum mass fraction of 0.25, the COP of the refrigeration system can be increased up to 25.8% despite an increase of 15.2% in operating pressure compared to R1234yf. The discharge temperature may rise; however, there will be no overheating problem for the compressor.

1. Introduction

Although hydrochlorofluorocarbons (HCFCs) have a low ability to destroy the ozone layer, they can only be used as a transitional alternative refrigerant to chlorofluorocarbons (CFCs), which have a higher risk of damaging the ozone layer. The Montreal Protocol has promoted the use of hydrofluorocarbons (HFCs) to replace HCFCs since 1996. However, despite HFCs having low ozone depletion potential (ODP), they have high global warming potential (GWP). When discharged into the atmosphere, they produce greenhouse gases, causing increasingly serious global warming and climate change. In order to reduce the greenhouse effect in the near future, it is urgent to reduce the use of HFCs and utilize or conduct research towards low-GWP refrigerants such as hydrocarbons (HCs) or hydrofluoroolefins (HFOs).

Up to now, more and more scholars have invested in research on the pressure drop, heat transfer, and safety class of environmentally friendly refrigerants. The COP of a refrigeration system utilizing R134a, R22, R410A, R1234yf, and R1234ze was investigated by Yang and Yeh [1]. The optimal degree of subcooling and lowest operating cost were numerically analyzed to achieve performance enhancement of the system. Employing the first law and the second law of thermodynamics, Yang and Yeh [2] evaluated the COPs, irreversibility, and heat transfer areas of refrigerating systems. The condensing and evaporating temperatures were used to attain the optimum degrees of subcooling, and the maximum savings in initial costs was determined. Considering the replacement of R134a without changing any equipment, Sánchez et al. [3] presented R1234ze(E), R1234yf, R600a, R290, and R152a in an experimental analysis. The test was conducted on the same refrigerating equipment with a hermetic compressor under identical operating conditions. The results showed that R152a could be an appropriate refrigerant to act as a direct substitute for R134a considering the safety requirement. Longo et al. [4] explored the boiling heat transfer of R404A, R290, and R1270 in a plain tube during vaporization. The experiment was carried out at saturated temperatures of 5, 10, and 20 °C up to incipient dryout on the increase in vapor quality to calculate the heat flux and refrigerant mass flux. To determine a suitable refrigerant couple in a cascade refrigeration system, Sun et al. [5] conducted exergy and energy analyses to study the effect of evaporation and condensation temperatures on the systems’ performances. It was revealed that R41 and R170 were suitable for a cycle of low temperature, whereas R161 was suitable for a cycle of high temperature in a system. Employing five different R404A low-GWP replacements, Cabello et al. [6] studied the effects of a suction-line heat exchanger on the performance of refrigeration systems. The experimental results revealed that utilizing a heat exchanger decreased the power consumption in all cases without greatly raising the compressor’s discharge temperature. To replace R134a in a refrigeration system, Sánchez et al. [7] performed an experimental study on power consumptions for six low-GWP substitutes. It was revealed that, compared with R134a, the system using R600a, R744, R152a, R1270, and R290 was able to save power consumptions by 1.2%, 3.9%, 13.7%, 26.3%, and 27.5%, respectively, whereas the system using R1234yf increased the consumed power by about 4.1%. Belman-Flores et al. [8] experimentally evaluated the thermodynamic characteristics of a domestic freezer utilizing a refrigerant of R513A as a replacement for R134a. During a 24 h test period, it was found that the refrigerator using R513A achieved a decrease of 9% in power consumption compared with that using R134a. Using the modified thermal balance method, Kumma et al. [9] evaluated the minimum concentrations of some selected mixtures. Exergy and energy analyses of refrigerant blends as substitutes for R134a were conducted. The results showed that mixtures of R227ea mixtures with HFO-based refrigerants had greater inert effects compared with dilutants of R245fa, R134a, and R125.

In the applications of air conditioning, refrigeration, and freezing, there is an increasing trend of research on the use of environmentally friendly refrigerants to replace high-GWP refrigerants using experimental or theoretical methods. Different metrics of GWP, total equivalent warming impact, and life cycle climate performance were utilized by Makhnatch and Rahmatollah [10] to facilitate the decision-making process of selecting environmentally friendly refrigerants. The results indicated that, from an environmental point of view, R152a, R290, and R1270 were good refrigerants for air conditioners. In order to reduce the phenomenon of global warming, Mota-Babiloni et al. [11] investigated the feasibility of replacing R404A with R448A through an experiment. It was reported that the COP for R448A was larger than that for R404A. In addition, a 70% reduction in GWP was obtained. Domanski et al. [12] analyzed the performances of the selected substitute refrigerants for refrigerating, heating, and air conditioning applications. The results demonstrated that the options for low-GWP refrigerants were rather limited, especially for fluids with similar volumetric capacities to R410A or R404A. Refrigerants which had been identified as having good COPs and low toxicity were slightly flammable. In order to replace the R134a refrigerant in automobile air conditioners, Meng et al. [13] analyzed the characteristics of a R1234yf/R134a mixture through an experiment. It was shown that the COPs of the blend were lower than those of its component, R134a, for both heating and cooling cases. Refrigerants of R459B, R457A, R455A, and R454C were analyzed by Llopis et al. [14] as substitutes for R404A in refrigeration systems. Compared with the R404A refrigerant, the decreases in power consumed by the system without receivers for R459B, R457A, R455A, and R454C were 10.76%, 10.48%, 2.95%, and 2.07%, respectively, under optimum refrigerant charges. Overall, improved system performances and reduced refrigerant charges were obtained for all the low-GWP substitutes. Makhnatch et al. [15] experimentally investigated and compared the performances of a refrigerating system utilizing R134a, R450A, and R513A at condensation temperatures of 40, 50, and 60 °C and evaporation temperatures ranging from −10 to 15 °C. The averaged COPs of the systems with R513A and R450A were 1.8% higher and 5.3% smaller than those of R134a. Employing refrigerants of R1234yf, R717, and R600a in domestic refrigerators, Li et al. [16] compared the energy efficiencies of a refrigeration cycle using R134a. The results showed that, with a COP close to that of R134a, R1234yf could be a suitable substitute for R134a in a current refrigerator. To find the most suitable R23 replacement at a temperature of −60 °C, Qin et al. [17] utilized R1234yf and mixed it with four pure working fluids of R23, R41, R170, and R1132a, respectively, to investigate the COP of a refrigerating system. The results indicated that systems using R1234yf/R41 achieved the highest cooling capacity, whereas systems using R1234yf/R1132a had the greatest COPs and exergy efficiency among the four mixtures. To compare the characteristics of high-GWP R404A, Oruç and Devecioglu [18] carried out an experiment on refrigeration systems using low-GWP R454A and R454C. It was revealed that the coefficients of performance of the systems with R454C and R454A were higher by approximately 10% and 14%, respectively; however, the discharge temperatures of R454C and R454A were also larger compared with those of R404A. Deymi-Dashtebayaz et al. [19] explored the optimum characteristics of cascade refrigeration systems for temperature variations in condensers and evaporators. A model was proposed for the system with six-pair low-GWP refrigerants in low- and high-temperature systems. A maximal COP of 2.09 and an exergy efficiency of 35.32% were achieved at condensing and evaporating temperatures of 40 °C and −30 °C, respectively. Based on the density, freezing point, molecular weight, ODP, and GWP of the HC refrigerants, Faruque et al. [20] theoretically explored the thermodynamic performance of a cascade refrigeration system. The results revealed that the largest exergy efficiency and COP were obtained when Toluenei and Trans-2-butane were utilized in high- and low-temperature cycles. To replace the high-GWP refrigerant of R134a, Işkan and Direk [21] studied the influences of the entrainment ratio and condensation temperature on the cooling capacity of a refrigeration system with an ejector and a dual-evaporator. The results demonstrated that the coefficients of performance of the systems using R1234ze(E) and R515a were 9% and 1% larger, respectively, compared with R134a. Additionally, the cooling performances achieved by R516a were quite close to that of R134a. Utilizing R1234yf and R1234ze(E) as replacements for R410A, Saleem et al. [22] explored the thermal characteristics of fin-and-tube heat exchangers in air conditioning systems. The results revealed that R1234ze(E) and R1234yf achieved maximal increments of 20% in cooling capacity and maximal reductions of 88.6% in pressure drop compared with R410A. Al-Sayyab et al. [23] presented and compared R1234yf, R516A, and R513A, which served as replacements of R134a used in air conditioning systems. It was shown that R513A had the largest COP amongst the selected alternatives. Employing R1234ze(E), R516A, R515B, R513A, R450A, and R152a, Conte et al. [24] studied the thermal characteristics of refrigerating systems. The results revealed that systems using R516A and R513A exhibited larger cooling performances by 3.0% and 4.4%, and systems using R152a and R450A achieved higher energy efficiency ratios by 8.5% and 3.8%, respectively.

Currently, the global awareness of environmental protection and energy conservation is rising. The refrigerants utilized in air conditioning, refrigeration, and freezing systems are facing major environmental challenges. The refrigerants must not only have the characteristics of low GWP as well as ODP, but also allow the system to be operated with high efficiency. Presently, before a permanent, environmentally friendly alternative refrigerant has been discovered and developed, it is advisable to select the existing refrigerants with the best COPs and to exclude banned or soon-to-be-banned refrigerants to reduce harmfulness to the global environment. In this study, a refrigerating system with evaporating temperatures of 10, −20, −40, and −60 °C is investigated. For low-temperature applications, at evaporation temperatures of −40 and −60 °C, a two-stage compressor configuration in the refrigeration system is also investigated for comparison. Furthermore, condensation temperatures of 30, 40, and 50 °C are assumed in the analyses. Finally, to improve the COP of the refrigeration system, an optimum mass fraction analysis of a refrigerant mixture, R717/R1234yf, is performed.

2. Analysis

In order to simplify the complex analysis, this study uses basic thermodynamic equations and makes relevant, simplified assumptions. In this case, the following assumptions are made:

- Steady flow in each component of the system;

- Negligible changes in potential and kinetic energy from entry to exit of each component in the system;

- Isentropic compression in the compressor of the system;

- Insignificant pressure drops in the system’s pipeline;

- Isenthalpic process in the expansion valve of the system.

2.1. Single-Stage Vapor Compression Refrigeration System

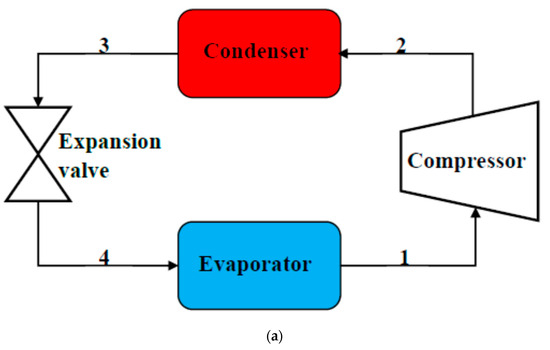

The compressor, condenser, expansion valve or capillary tube, and evaporator are the main devices of a vapor compression refrigeration cycle. A diagram of the vapor compression refrigeration system is shown in Figure 1a. The liquid refrigerant absorbs heat in the evaporator, which needs to be cooled, and turns into a vapor refrigerant. The compressor is then used to compress and transport the vapor refrigerant to the condenser, where the vapor refrigerant releases heat and changes into a liquid state. Then, the high-pressure liquid refrigerant is decompressed through an expansion device or capillary tube and returns to the evaporator, thus completing a cycle. The pressure–enthalpy diagram of a single-stage vapor compression refrigeration cycle is displayed in Figure 1b.

Figure 1.

(a) A single-stage vapor compression refrigeration system and (b) its P-h diagram.

The coefficient of performance of a refrigeration system is the ratio of the refrigeration capacity of the evaporator to the input power of the compressor, and can be written as

for a single-stage vapor compression refrigeration system.

2.2. Two-Stage Vapor Compression Refrigeration System

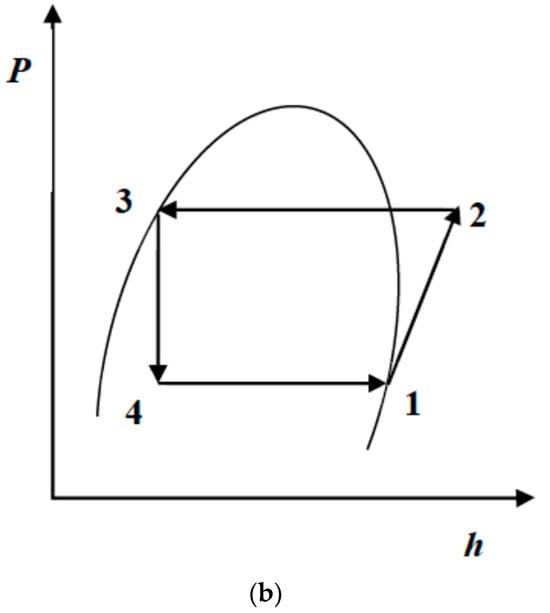

Generally speaking, to achieve a very low-temperature refrigeration system, the compressor output power increases due to the extremely large pressure difference between the exit and inlet of the compressor. In order to reduce the input power of the compressor, an intercooler can be installed between the high- and low-pressure compressors to decrease the consumption power of the compressors and thereby improve the COP of a refrigerating system. Figure 2a,b show a two-stage vapor compression refrigeration system and its P-h diagram. There is an optimum pressure at which the intercooling should take place. The optimum intermediate pressure, Pi, with the minimum power input is obtained as

where P1 represents the suction pressure of a low-stage compressor and P4 stands for the discharge pressure of a high-stage compressor.

Figure 2.

(a) A two-stage vapor compression refrigeration system and (b) its P-h diagram.

The COP of a two-stage vapor compression refrigeration system yields

2.3. Refrigerants

Since the Montreal Protocol and its amendments have banned and controlled CFCs, HCFCs, and HFCs, these refrigerants were not all included in this study. Table 1 shows the refrigerants investigated in this study. In total, there were 21 refrigerants, 12 pure refrigerants, and 9 mixture refrigerants selected for analysis.

Table 1.

Refrigerants selected for investigation in this study [25].

It is apparent that, besides having zero ozone depletion potential (ODP), the refrigerants selected have global warming potential (GWP) values well below 10. Hydrocarbon (HC) refrigerants can effectively solve problems such as the greenhouse effect and ozone layer destruction because of their zero ODP and low GWP. This type of refrigerant has a large amount of latent heat during phase change and can improve the COP of the refrigeration system. However, these refrigerants mostly have issues with high flammability. With a lower GWP and zero ODP, hydro-olefins (HOs) are of little impact to the global environment. It should be noted that hydro-olefins are flammable refrigerants despite the fact that they can achieve high performance in operation. The ODP and GWP of hydrofluoroolefin (HFO) refrigerants are relatively low, and their life cycles in the atmosphere are also short. They are often used as alternative refrigerants. In addition to hydrocarbons, natural refrigerants, including carbon dioxide, ammonia, water, and air, are also favorable. Natural refrigerants do not destroy the ozone layer and have a very low greenhouse effect. In addition, they do not cause adverse effects on the global environment. Carbon dioxide is a colorless fluid, heavier than air at normal conditions and odorless at low concentrations. It is a high-pressure refrigerant; thus, high operating pressures are required for efficient operation. Water freezes at a low temperature while cooling. Air is seldom used as a refrigerant in vapor compression refrigeration systems. Ammonia is an environmentally friendly natural refrigerant with ODP and GWP values of zero. Because of its superior performance, ammonia is widely used in food preservation and refrigeration processes. Ammonia is poisonous and flammable; however, it is easy to detect any leaks with the installation of sensors, thus ensuring enhanced safety. In this regard, R-717 is merely considered for analysis in this study.

3. Solution Procedure and Verification

To evaluate the thermodynamic properties, T, P, h, and s, of the pure refrigerants, a Fortran program was written and linked to REFPROP, a packaged software developed by the National Institute of Standards and Technology (NIST). Additionally, based on the blending rules of the Helmholtz energies, the computing subroutines are compiled into the program for the purpose of calculating the properties of refrigerant mixtures [26].

3.1. Single-Stage Vapor Compression Refrigeration System

It is established that h1 = hg, because state 1 is saturated vapor. Referring to Figure 1b, the pressure–enthalpy (P-h) diagram of the vapor compression refrigeration cycle, the properties of h1, s1, and P1 of each refrigerant can be found for the evaporation temperatures of 10, −20, −40, and −60 °C, respectively, using REFPROP software. Since processes 1 to 2 are isentropic compression processes, it can be understood that s1 = s2. Again, the REFPROP program can be utilized to compute h3 and P3 (=P2) with condensation temperatures of 30 °C, 40 °C, or 50 °C, because state 3 is saturated liquid. Then, once the known s2 and P2 are entered into the REFPROP tool, h2 can be readily determined. As the liquid refrigerant flows through the expansion valve, h4 is thus equal to h3 due to an isenthalpic process. Substituting h1, h2, and h4 into Equation (1), the coefficient of performance of the single-stage vapor compression refrigeration system is then obtained.

3.2. Two-Stage Vapor Compression Refrigeration System

First, the evaporating pressure, P1, and condensing pressure, P4, of each refrigerant are found when the evaporating temperatures are −40 and −60 °C and the condensing temperatures are 30 °C, 40 °C, or 50 °C. Substituting P1 and P4 into Equation (2), the intermediate pressure, P2 or P3, for the minimum power input can be calculated. Through the REFPROP software, the properties of h1 and s1 can be found using input P1 for the state of the saturated liquid. Then, one can obtain h2 using s2 = s1 and the known P2. Next, h3 and h7 can be easily obtained with the calculated P3 for the saturated vapor and liquid states at states 3 and 7, respectively. Similarly, h4 can be evaluated with the aid of s4 = s3 and the known P4. Also, h5 can be attained with the calculated P4 because of the saturated liquid state. Finally, h6 = h5 and h8 = h7 are attributed to the isenthalpic processes as liquid refrigerants pass through the expansion valves. Substituting h1, h2, h3, h4, and h8 into Equation (3), the COP of the two-stage vapor compression refrigeration system is readily obtained.

3.3. Verification

In order to confirm the accuracy of the calculation results of this study, the theoretically predicted COPs of the refrigeration systems are compared with the numerical calculation of Saleh et al. [27]. In the theoretical analysis, the condensing and evaporating temperatures are kept at 35 °C and −10 °C, respectively. A mass flow rate of 1 kg/s and an isentropic efficiency of 0.8 are assumed for the refrigerant and the compressor. Utilizing the BACKONE equation of state, Saleh et al. [27] computed the thermodynamic properties of some selected refrigerants. Table 2 shows the comparisons of the predicted COPs for the present study and the calculated results [27]. It can be observed that the largest discrepancies in COP were 0.51% and 0.54% for the refrigeration systems with R1233zd(E) and R1234ze(E), respectively. As a whole, the present theoretical predictions conform well with those obtained from the earlier work [27].

Table 2.

Comparisons between the predicted COPs in the present study and those of the previously calculated results [27].

4. Results and Discussion

Generally speaking, the evaporation temperature changes with the application. For example, the evaporation temperature of a water chiller is about 0~5 °C, the evaporation temperature of a household air conditioner is about 5~10 °C, and the evaporation temperature of a household refrigerator is about 0~−30 °C. Moreover, an ultra-low-temperature freezer is about −30~−60 °C. Under the circumstances, the COPs of single- and double-stage vapor compression refrigeration systems with evaporating temperatures of 10, −20, −40, and −60 °C and condensation temperatures of 30, 40, and 50 °C, respectively, are investigated in this study. There are, in total, 21 refrigerants, 12 pure refrigerants, and 9 mixture refrigerants investigated in this section. For low-temperature applications, i.e., Teva = −40 and −60 °C, a two-stage vapor compression refrigeration cycle is employed to improve the COP. Additionally, an optimal analysis of the R717/R1243yf mixture is performed for comparison.

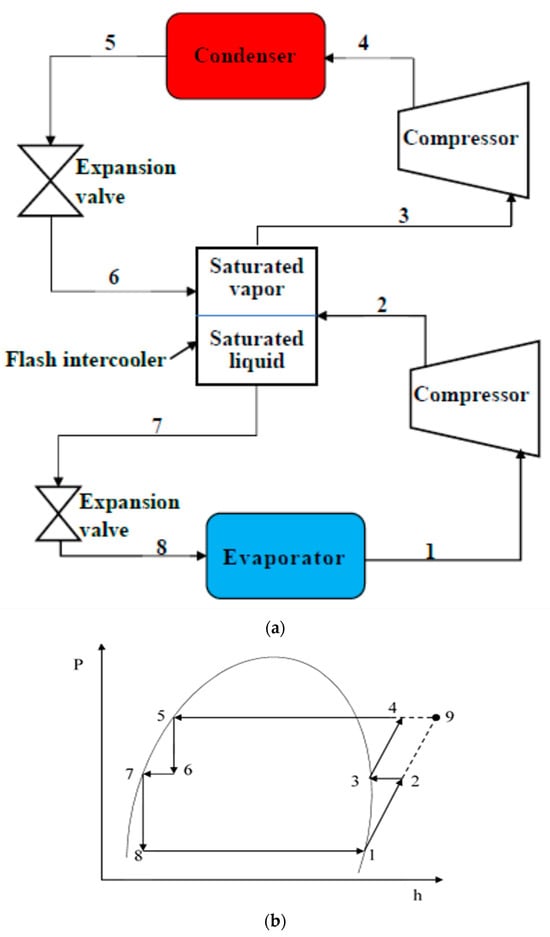

4.1. Single-Stage Vapor Compression Refrigeration System

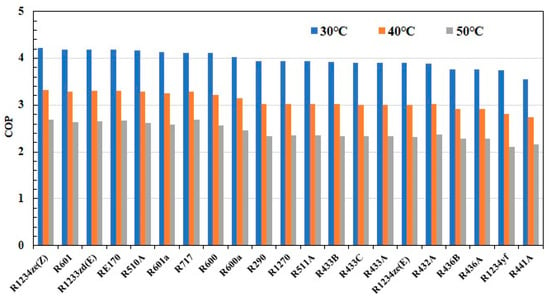

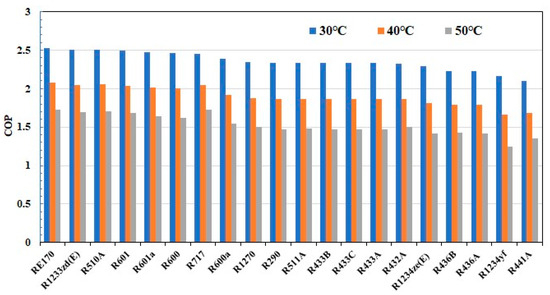

The COPs of single-stage refrigeration systems with various refrigerants for Teva = 10 °C and Tcon = 30 °C, 40 °C, and 50 °C are plotted in Figure 3. For convenience of reading and comparison, the refrigerants are arranged from left to right according to their performances. It can be seen that, when the evaporation temperature is fixed at 10 °C, the COP of the refrigeration system decreases significantly as the condensation temperature increases. The differences in COP of the top five refrigerants are within 1%, and these are R601, R1234ze(Z), R1233zd(E), R601a, and R717. In addition, R436B, R436A, and R441A are mainly used in air conditioners, dehumidifiers, household refrigerators, and freezers. They are all mixtures of natural refrigerants which will not destroy the ozone layer and have no greenhouse effect, but rank third, second, and first from the bottom, respectively. Figure 4 depicts the COPs of single-stage refrigeration systems utilizing different refrigerants for Teva = −20 °C and Tcon = 30 °C, 40 °C, and 50 °C. When the evaporating temperature is reduced, the COP of the refrigeration system also decreases for a fixed Tcon. This is because the area under the process curve, denoting the heat absorbed by the refrigerant, decreases, and the area enclosed by the cycle, representing the net work input, increases on a T-s diagram for a lower Teva. Consequently, the COP of the system is reduced. Meanwhile, as the evaporation temperature of the system drops to −20 °C, the original top five refrigerants with close COPs change to R1234ze(Z), R601, R1233zd(E), RE170, and R510A, respectively. It is noted that R601a, which originally ranked fourth for Teva = 10 °C, drops to sixth place, while R717, which ranked fifth, drops to seventh place. Also, R441A is still in last place. In addition, R1234yf is commonly used in residential air conditioning, domestic refrigerators, and freezers. It ranks last apart from two among all the environmentally friendly refrigerants analyzed for Teva = −20 °C.

Figure 3.

The COPs of single-stage refrigeration systems with refrigerants investigated for Teva = 10 °C and Tcon = 30 °C, 40 °C, and 50 °C.

Figure 4.

The COPs of single-stage refrigeration systems with refrigerants investigated for Teva = −20 °C and Tcon = 30 °C, 40 °C, and 50 °C.

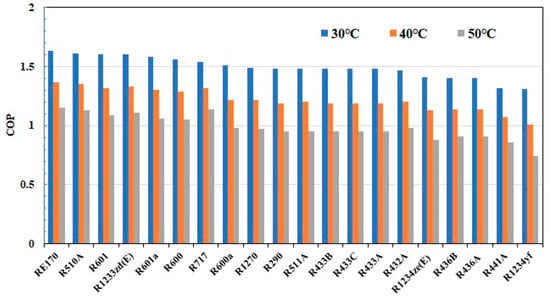

When the evaporation temperature drops to −40 °C, the performance of each refrigerant in the refrigeration system can be observed in Figure 5. Compared with the case of Teva = 10 °C, the COPs dropped from near 13 to around 2.5 for the same batch of refrigerants at Teva = −40 °C. We note that the high-quality refrigerant R1234ze(Z), which ranked first or second in refrigeration performance for Teva = −20 °C and 10 °C, is not included in the ranking for Teva = −40 °C. This is due to the fact that the operating temperature range of R1234ze(Z) is merely from −30 °C to 150 °C. Because of its high critical temperature, 150.12 °C, it is currently suitable for high-temperature heat pumps. Compared with the case of Teva = −20 °C, the top five refrigerants, RE170, R1233zd(E), R510A, R601, and R601a, still maintain their superior performances in the system’s COP for Teva = −40 °C. Moreover, it is worthwhile to point out that RE170 rose from 4th place to 1st place in this case. Due to its zero ODP and very low GWP, RE170 is used as a suitable replacement for HFC refrigerants. Figure 6 illustrates the COPs of the refrigeration systems with various refrigerants for Teva = −60 °C and Tcon = 30 °C, 40 °C, and 50 °C. It was found that the top six refrigerants that led in terms of COP seemed to have changed insignificantly as Teva varied from −40 °C to −60 °C. Apparently, these six refrigerants are suitable for low-temperature refrigerating applications. It is worthwhile to note that R717 only ranked seventh in refrigeration performance for Tcon = 30 °C; however, R717 rose to first place in terms of COP for Tcon = 50 °C. Note that ammonia is widely employed in industrial refrigeration systems with evaporation temperatures ranging from −50 °C to 15 °C. In addition, R1234yf was overtaken by R441A and fell into last place instead.

Figure 5.

The COPs of single-stage refrigeration systems with refrigerants investigated for Teva = −40 °C and Tcon = 30 °C, 40 °C, and 50 °C.

Figure 6.

The COPs of single-stage refrigeration systems with refrigerants investigated for Teva = −60 °C and Tcon = 30 °C, 40 °C, and 50 °C.

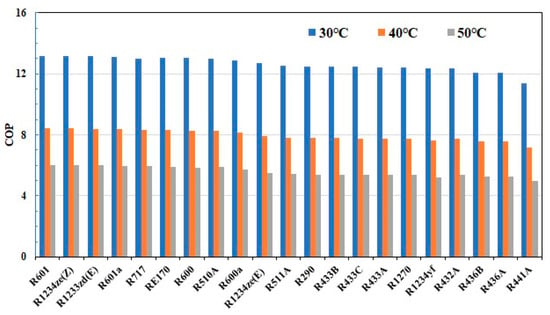

4.2. Double-Stage Vapor Compression Refrigeration System

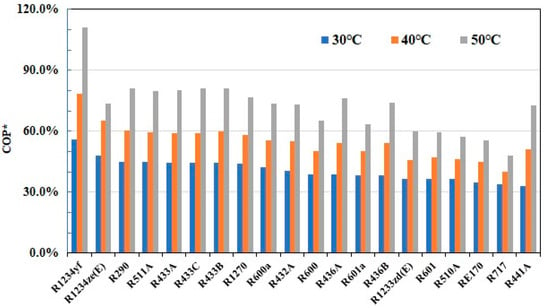

Generally, when the Teva of the refrigeration system is in the range of −30 °C to −60 °C, a lower evaporation pressure will result in a substantial increment in the consumed power of the compressor, which will cause a sharp reduction in the system’s COP. A two-stage vapor compression refrigeration system can then be used to improve the operating efficiency and effectively reduce the exhaust temperature of the compressor. In this study, the intermediate pressure, Pi, of the two-stage refrigeration system was obtained by taking the square root of the product of the compressor’s inlet pressure, P1, and outlet pressure, P4. Figure 7 displays the COPs of double-stage refrigeration systems with the same refrigerants for Teva = −40 °C and Tcon = 30 °C, 40 °C, and 50 °C. As a whole, almost all refrigerants were able to increase the system’s COP by at least 40% when the single-stage refrigeration system was changed to a two-stage refrigeration system. We noted that R1234yf was the largest in terms of the enhancement ratio of the system’s COP. On the contrary, the improvement in the system’s performance with R717 was insignificant. To further understand this phenomenon, the percentage increase in COP achieved using a two-stage compression refrigeration system with intercooling for Teva = −40 °C is given in Figure 8. The enhancement ratio of COP, COP*, is defined as

where the subscripts “dou” and “sin” represent double-stage, or two-stage, and single-stage, respectively. Figure 8 gives the percentage increase in COP achieved using a two-stage compression refrigeration system with intercooling for Teva = −40 °C and Tcon = 30 °C, 40 °C, and 50 °C.

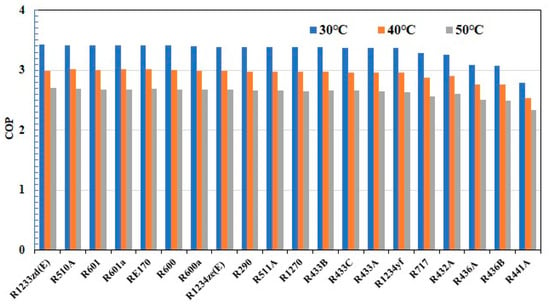

Figure 7.

The COPs of double-stage refrigeration systems with refrigerants investigated for Teva = −40 °C and Tcon = 30 °C, 40 °C, and 50 °C.

Figure 8.

The percentage increase in COP achieved using a two-stage compression refrigeration system with intercooling for Teva = −40 °C and Tcon = 30 °C, 40 °C, and 50 °C.

It was revealed that the COP* rose as the condensation temperature increased. In other words, the COP of the single-stage compression refrigeration system was relatively low at higher condensation temperatures. When a two-stage compression refrigeration system with an intermediate cooling system was utilized, the COP of the system was greatly improved, and COP* naturally increased, particularly at a higher Tcon. Surprisingly, R1234yf had the largest COP* values, with increases of 56%, 78.3%, and 111.2%, respectively, at Tcon = 30 °C, 40 °C, and 50 °C. On the other hand, the average percentage increases in R717 were the smallest among the refrigerants investigated, at 33.9%, 40%, and 48%, respectively, for Tcon = 30 °C, 40 °C, and 50 °C.

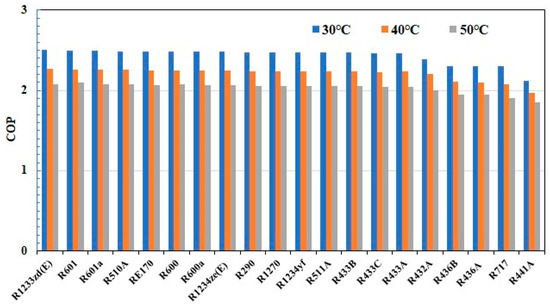

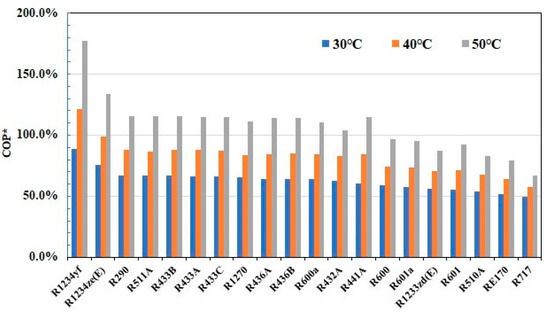

Figure 9 plots the COPs of double-stage refrigeration systems with the same refrigerants for Teva = −60 °C and Tcon = 30 °C, 40 °C, and 50 °C. Similar to the case of Teva = −40 °C, the top 15 refrigerants in the COP of the refrigeration system had very close COPs, and the differences between them were within about 1%. Moreover, the refrigerant with the best refrigeration performance coefficient in the system was R1233zd(E) for both Teva = −40 °C and −60 °C. R1233zd(E) is a non-flammable refrigerant and can be used in chillers, organic Rankine cycles for waste heat recovery, and high-temperature heat pumps. The only major difference is that the maximum COPs of the system are about 3.4 and 2.5 for Teva = −40 °C and −60 °C, respectively, when the condensation temperature is 30 °C. Regarding the ranking of the refrigeration systems’ COP* values, R1234yf and R717 ranked first and last, respectively, for Teva = −60 °C. This is similar to the case of Teva = −40 °C. A detailed description of the percentage increase in COP using a two-stage compression refrigeration system with intercooling for Teva = −60 °C is illustrated in Figure 10. The results indicate that the COP* values of R1234yf were 88.5%, 121.8%, and 177% respectively, while those of R717 were 49.4%, 57.6%, and 66.7%, respectively, for Tcon = 30 °C, 40 °C, and 50 °C. As a whole, the COP* values for Teva = −60 °C were obviously higher than those for Teva = −40 °C. This fully demonstrates that the thermal performance of a two-stage vapor compression refrigeration system is higher when operating at lower temperatures.

Figure 9.

The COPs of double-stage refrigeration systems with refrigerants investigated for Teva = −60 °C and Tcon = 30 °C, 40 °C, and 50 °C.

Figure 10.

The percentage increase in COP by using a two-stage compression refrigeration system with intercooling for Teva = −60 °C and Tcon = 30 °C, 40 °C, and 50 °C.

4.3. Mixture with Optimum Mass Fractions

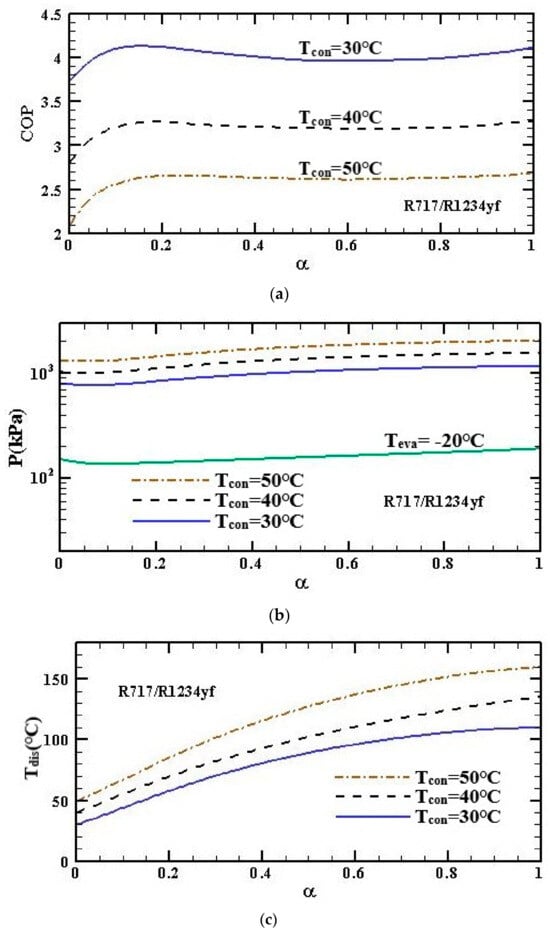

To improve the COP of the refrigeration system, the use of a refrigerant mixture may also be considered in addition to utilizing a two-stage vapor compression refrigeration cycle. Figure 11a–c present the COPs, maximum pressures, and discharge temperatures of a single-stage refrigeration system with various mass fractions for Teva = −20 °C. The mass fraction, α, for the R717/R1234yf mixture is defined as

where and denote the mass fractions of R717 and R1234yf, respectively, in the mixture. When α is equal to zero, it signifies a pure-component R1234yf refrigerant, and when α is unity, it becomes another pure-component R717 refrigerant. It is interesting to learn that as α increases, the COP of the refrigeration system first gradually increases, then reaches a maximum value, and then slowly begins to decrease. When α is around 0.6, it slowly starts to rise again. This can be clearly observed in Figure 11a. When the condensation temperatures of the system are 30, 40, and 50 °C, respectively, similar changing trends in the COP of the system can be found. The only difference is that the COP of the system decreases as the condensing temperature increases. The maximum and minimum pressures in the refrigeration system are displayed in Figure 11b, and the discharge temperatures of the compressor for various α values are given in Figure 11c. It is shown that the higher the condensation temperature is, the larger the working pressure and discharge temperature of the system will be. Since the R717/R1234yf mixture has a local maximum COP in the refrigeration system for a certain α, the optimal mass fraction of the mixture refrigerant can be further obtained to improve the system’s performance. To find the maximum COP, it can be calculated by differentiating the COP with respect to α and equating it to zero. The numerical method of Newton–Raphson was adopted to find the COPmax and the corresponding α, Pdis, Peva, and Tdis of the refrigeration system for the R717/R1234yf mixture. The calculated results are shown in Table 3. At an optimal α of 0.18 for the R717/R1234yf mixture, the COP, Pdis, and Tdis of R717/R1234yf (82/18 wt%) were about 10.2%, 4.6%, and 84.3% higher than those of R1234yf, respectively, for Tcon = 30 °C. Also, with respect to the COP, Pdis, and Tdis of the refrigeration system, the system using R717/R1234yf (75/25 wt%) increased by 25.8%, 15.2%, and 87.8%, respectively, compared to R1234yf for Tcon = 50 °C. Despite the fact that the percentage increase in the compressor discharge temperature seems to be large, the maximum temperature does not exceed 94 °C, which still indicates no possibility of overheating problems. As the discharge line temperature of the compressor rises above 107 °C, the lubricating oil will become thinner, and carbonization may even occur. On the other hand, even though the system’s working pressure will also increase by a maximum of 15.2%, the COP of R717/R1234yf with optimum α can be increased up to 25.8% compared to R1234yf.

Figure 11.

(a) The COPs, (b) maximum pressures and (c) discharge temperatures of a single-stage refrigeration system with various α for R717/R1234yf mixture at Teva = −20 °C.

Table 3.

The maximum COP and the corresponding α, Pdis, Peva, and Tdis of the single-stage vapor compression refrigeration system for R717/R1234yf mixture.

Although combining two suitable pure-component refrigerants into a mixture with proper mass fractions may lead to an increase in both the system’s working pressure and the compressor’s discharge temperature, these factors can be effectively compensated for by the COP enhancement of the system.

5. Conclusions

In this study, the coefficients of performance of refrigeration systems using 21 zero-ODP and low-GWP refrigerants, 12 pure refrigerants, and 9 mixture refrigerants are investigated. A refrigerating system with evaporating temperatures of 10, −20, −40, and −60 °C and condensation temperatures of 30, 40, and 50 °C is utilized in the analyses. An appropriate refrigerant mixture, composed of two low-GWP pure refrigerants, is investigated, and a two-stage vapor compression refrigeration cycle is employed to improve the COP of the system. From the analyses, it can be concluded that:

- When the evaporation temperature was fixed, the higher the condensation temperature, the lower the COP of the refrigeration system; when the condensation temperature was fixed, the evaporation temperature became higher, and a higher COP of the system was obtained.

- R1234ze(Z), R601, and R1233zd(E) had the best refrigeration performances among the environmentally friendly refrigerants studied, while R441A performed the worst for Teva = 10 °C and −20 °C.

- RE170 had the highest COP of the refrigeration system for Teva = −40 °C and −60 °C. However, R1234yf showed a worse performance in terms of COP when the evaporation temperature was much lower, and it ranked last for Teva = −60 °C.

- While changing from a single-stage to two-stage vapor compression refrigeration system, the percentage increase in the COP of the system with R1234yf was the largest for Teva = −40 °C and −60 °C. However, the growth rate of R717 ranked last for Teva = −60 °C.

- The maximum coefficients of performance of the refrigeration systems using an R717/R1234yf mixture were 4.120, 3.278, and 2.654 at optimum mass fractions of 0.18, 0.21, and 0.25, respectively, for Tcon = 30, 40, and 50 °C and Tvea = −20 °C.

- At an optimal α of 0.18, the COP, Pdis, and Tdis of the refrigeration system using R717/R1234yf (82/18 wt%) were about 10.2%, 4.6%, and 84.3% higher than those of R1234yf, respectively, for Tcon = 30 °C and Tvea = −20 °C.

- For the R717/R1234yf mixture, at an optimum α of 0.25, the COP of the refrigeration system can be increased up to 25.8% despite an increase of 15.2% in the operating pressure compared to R1234yf. The discharge temperature of the compressor may also rise; however, there will be no overheating problem.

Author Contributions

Methodology, C.-Y.H. and R.-H.Y.; Software, C.-Y.H.; Formal analysis, R.-H.Y.; Writing—original draft, C.-Y.H.; Writing—review & editing, R.-H.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by NSTC, R.O.C., through contract No. NSTC 112-2221-E-992-051.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| Nomenclature | |

| h | enthalpy of refrigerant, kJ/kg |

| P | pressure, kPa |

| T | temperature, °C |

| Greek symbols | |

| α | mass fraction, defined in Equation (5) |

| Acronym | |

| CFC | chlorofluorocarbon |

| COP | coefficient of performance |

| GWP | global warming potential |

| HC | hydrocarbon |

| HCFC | hydrochlorofluorocarbon |

| HCFO | hydrochlorofluoroolefin |

| HFC | hydrofluorocarbon |

| HFO | hydrofluoroolefin |

| NIST | National Institute of Standards and Technology |

| ODP | ozone depletion potential |

| REFPROP | REFerence fluid PROPerties |

| Subscripts | |

| 1–9 | state |

| con | condensation |

| dis | discharge |

| dou | double |

| eva | evaporation |

| g | vapor |

| i | intermediate |

| max | maximum |

| s | entropy |

| sin | single |

| Superscripts | |

| * | dimensionless parameter, used in Equation (4) |

References

- Yang, M.H.; Yeh, R.H. Theoretical analysis of optimal subcooling for single vapor-compression refrigeration systems. Heat. Transf. Eng. 2015, 36, 912–925. [Google Scholar] [CrossRef]

- Yang, M.H.; Yeh, R.H. Performance and exergy destruction analyses of optimal subcooling for vapor-compression refrigeration systems. Int. J. Heat. Mass. Transf. 2015, 87, 1–10. [Google Scholar] [CrossRef]

- Sánchez, D.; Cabello, R.; Llopis, R.; Arauzo, I.; Catalán-Gil, J.; Torrella, E. Energy performance evaluation of R1234yf, R1234ze(E), R600a, R290 and R152a as low-GWP R134a alternatives. Int. J. Refrig. 2017, 74, 269–282. [Google Scholar] [CrossRef]

- Longo, G.A.; Mancin, S.; Righetti, G.; Zilio, C. Hydrocarbon refrigerants HC290 (Propane) and HC1270 (Propylene) low GWP long-term substitutes for HFC404A: A comparative analysis in vaporisation inside a small-diameter horizontal smooth tube. Appl. Therm. Eng. 2017, 124, 707–715. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, Q.; Xie, Z.; Liu, S.; Su, D.; Cui, Q. Energy and exergy analysis of low GWP refrigerants in cascade refrigeration system. Energy 2019, 170, 1170–1180. [Google Scholar] [CrossRef]

- Cabello, R.; Sánchez, D.; Llopis, R.; Andreu-Nacher, A.; Calleja-Anta, D. Energy impact of the Internal Heat Exchanger in a horizontal freezing cabinet. Experimental evaluation with the R404A low-GWP alternatives R454C, R455A, R468A, R290 and R1270. Int. J. Refrig. 2022, 137, 22–33. [Google Scholar] [CrossRef]

- Sánchez, D.; Andreu-Nácher, A.; Calleja-Anta, D.; Llopis, R.; Cabello, R. Energy impact evaluation of different low-GWP alternatives to replace R134a in a beverage cooler. Experimental analysis and optimization for the pure refrigerants R152a, R1234yf, R290, R1270, R600a and R744. Energy Convers. Manag. 2022, 256, 115388. [Google Scholar] [CrossRef]

- Belman-Flores, J.M.; Heredia-Aricapa, Y.; Pardo-Cely, D.; Rodríguez-Valderrama, D.A.; Alba-Rosano MDe Silva-Romero, J.C. Experimental evaluation of R513A as a low GWP refrigerant to replace R134a in a domestic refrigerator. Int. J. Refrig. 2022, 142, 148–155. [Google Scholar] [CrossRef]

- Kumma, N.; Sarath, S.; Kruthiventi, S.S.H. Exergy and performance analysis of low GWP and Non-flammable HFO based refrigerant mixtures as alternatives to R134a. Therm. Sci. Eng. Prog. 2023, 39, 101691. [Google Scholar] [CrossRef]

- Makhnatch, P.; Khodabandeh, R. The role of environmental metrics (GWP, TEWI, LCCP) in the selection of low GWP refrigerant. Energy Procedia 2014, 61, 2460–2463. [Google Scholar] [CrossRef]

- Mota-Babiloni, A.; Navarro-Esbrí, J.; Peris, B.; Molés, F.; Verdú, G. Experimental evaluation of R448A as R404A lower-GWP alternative in refrigeration systems. Energy Convers. Manag. 2015, 105, 756–762. [Google Scholar] [CrossRef]

- Domanski, P.A.; Brignoli, R.; Brown, J.S.; Kazakov, A.F.; McLinden, M.O. Low-GWP refrigerants for medium and high pressure applications. Int. J. Refrig. 2017, 84, 198–209. [Google Scholar] [CrossRef] [PubMed]

- Meng, Z.; Zhang, H.; Lei, M.; Qin, Y.; Qiu, J. Performance of low GWP R1234yf/R134a mixture as a replacement for R134a in automotive air conditioning systems. Int. J. Heat. Mass. Transf. 2018, 116, 362–370. [Google Scholar] [CrossRef]

- Llopis, R.; Calleja-Anta, D.; Sánchez, D.; Nebot-Andrés, L.; Catalán-Gil, J.; Cabello, R. R-454C, R-459B, R-457A and R-455A as low-GWP replacements of R-404A: Experimental evaluation and optimization. Int. J. Refrig. 2019, 106, 133–143. [Google Scholar] [CrossRef]

- Makhnatch, P.; Mota-Babiloni, A.; Lopez-Belchí, A.; Khodabandeh, R. R450A and R513A as lower GWP mixtures for high ambient temperature countries: Experimental comparison with R134a. Energy 2019, 166, 223–235. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, H.; Chen, X.; Liang, K. Comparative study on energy efficiency of low GWP refrigerants in domestic refrigerators with capacity modulation. Energy Build. 2019, 192, 93–100. [Google Scholar] [CrossRef]

- Qin, Y.; Li, N.; Zhang, H.; Liu, B. Energy and exergy analysis of a Linde-Hampson refrigeration system using R170, R41 and R1132a as low-GWP refrigerant blend components to replace R23. Energy 2021, 229, 120645. [Google Scholar] [CrossRef]

- Oruç, V.; Devecioglu, A. Experimental investigation on the low-GWP HFC/HFO blends R454A and R454C in a R404A refrigeration system. Int. J. Refrig. 2021, 128, 242–251. [Google Scholar] [CrossRef]

- Deymi-Dashtebayaz, M.; Sulin, A.; Ryabova, T.; Sankina, I.; Farahnak, M.; Nazeri, R. Energy, exergoeconomic and environmental optimization of a cascade refrigeration system using different low GWP refrigerants. J. Environ. Chem. Eng. 2021, 9, 106473. [Google Scholar] [CrossRef]

- Faruque, M.W.; Uddin, M.R.; Salehin, S.; Ehsan, M.M. A comprehensive thermodynamic assessment of cascade refrigeration system utilizing low GWP hydrocarbon refrigerants. Int. J. Thermofluids 2022, 15, 100177. [Google Scholar] [CrossRef]

- Işkan, Ü.; Direk, M. Experimental performance evaluation of the dual-evaporator ejector refrigeration system using environmentally friendly refrigerants of R1234ze (E), ND, R515a, R456a, and R516a as a replacement for R134a. J. Clean. Prod. 2022, 352, 131612. [Google Scholar] [CrossRef]

- Saleem, S.; Bradshaw, C.R.; Bach, C.K. Development of design guidelines for fin-and-tube heat exchangers with low-GWP refrigerants. Int. J. Refrig. 2022, 143, 166–181. [Google Scholar] [CrossRef]

- Al-Sayyab, A.K.S.; Navarro-Esbrí, J.; Barrag’an-Cervera, A.; Sarah Kim, S.; Mota-Babiloni, A. Comprehensive experimental evaluation of R1234yf-based low GWP working fluids for refrigeration and heat pumps. Energy Convers. Manag. 2022, 258, 115378. [Google Scholar] [CrossRef]

- Conte, R.; Azzolin, M.; Bernardinello, S.; Del Col, D. Experimental investigation of large scroll compressors working with six low-GWP refrigerants. Therm. Sci. Eng. Prog. 2023, 44, 102043. [Google Scholar] [CrossRef]

- List of Refrigerants. Available online: https://en.wikipedia.org/wiki/List_of_refrigerants (accessed on 4 April 2024).

- NIST Thermodynamic and Transport Properties of Refrigerants and Refrigerant Mixtures REFPROP; Version 9.1; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2016.

- Saleh, B.; Aly, A.A.; Alsehli, M.; Elfasakhany, A.; Bassuoni, M.M. Performance analysis and working fluid selection for single and two stages vapor compression refrigeration cycles. Processes 2020, 8, 1017. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).