1. Introduction

Blending and scheduling (or blend scheduling) are considered crucial operations in petroleum and metallurgical refineries, petrochemical industrial parks, food processing sites, pulp and paper productions, to name a few. The main goal in these processing industries is to transform different component-quality raw materials into useful products such as gasoline, jet fuel, and diesel (from hydrocarbon crude oils) and metal alloys (from mineral crude ores). Blend scheduling operations play a pivotal role in managing and controlling inventory levels or stocks of diverse component-quality raw materials, such as crude oils, crude ores, and biomasses, stored in tanks, piles, recipients, containers, and similar storage units. In petroleum refineries, these blend-stocks provide material streams for (a) processing of raw or intermediate component-quality streams in unit-operations throughout a process plant network and (b) production of finished fuels to be transferred to customers using the assignment of blend-stocks of input-like-output products (ILOP), such as gasoline-like streams that can be mixed to produce final grades of gasoline to be sold in fuel stations.

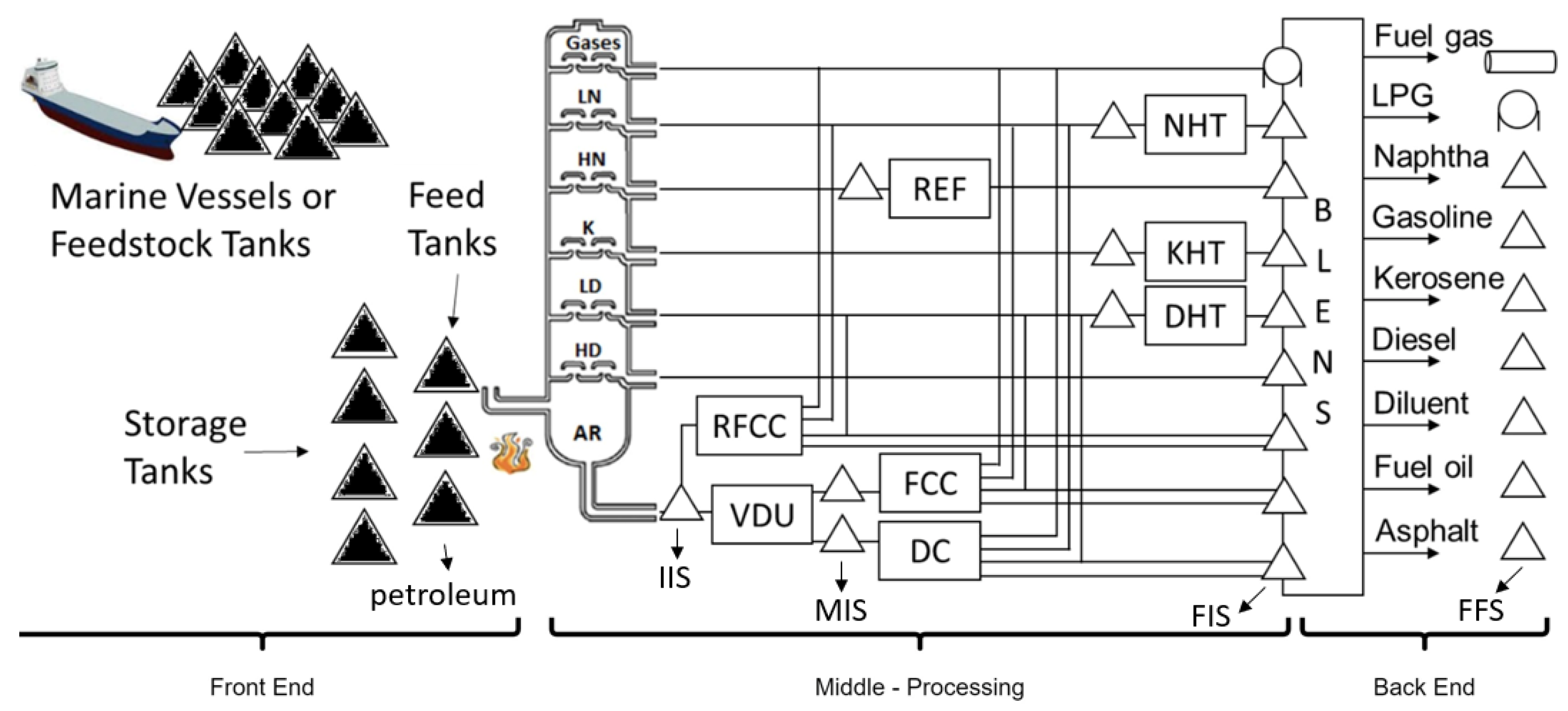

In the petroleum processing industry, a highly complex solution of quantity, logic, and quality decision variables is formed. In this industrial process, crude-oil (or petroleum) streams are transformed into unfinished refined product distillates (such as naphtha, kerosene, and diesel fractions) in distillation columns or towers, as seen in

Figure 1. These physical separation processes yield initial intermediate stocks (IIS) of hydrocarbon fractions in tanks connecting downstream process-units, formed by continuous processes in its majority, with few semi-continuous and batch processes throughout the refinery process network. Moving downstream to the distillation columns, process units, like the residue fluid catalytic cracking (RFCC), produce output process streams that are responsible for the production of (a) middle intermediate stocks (MIS) for use in other processes (such as for molecular change in hydro-catalytic or thermal cracking, carbon-chain rearrangement in reforming units, or hydro-treatment in hydrotreaters) and (b) final intermediate stocks (FIS) for the final blend-shops. The outputs of the processing units fed by the MIS mostly form the FIS for the final blend scheduling that produces finished fuel stocks (FFS) to be then certified before being dispatched to clients via pipelines, trucks, or other transportation modes.

Given the supply of finished fuels (such as jet fuel, premium gasoline, bunker, etc.) to consumers, and considering the design, operations, and controls of the unit operations and tanks in the petroleum refining process network, effective management of crude-oil raw materials or petroleum component-quality is crucial before processing in distillation columns at the front-end of the petroleum refinery. It is necessary to know the petroleum renderings, distillation curves, or yields of distilled products from the purchased crude-oil raw materials in the final petroleum bulk of the refinery site distillation units to manage the yields of the product outputs and operational variables in distillation processes and downstream units. Blend scheduling of petroleum raw material stocks (in marine vessels, feedstock tanks, or storage tanks) at the front-end of the refinery network can be managed (assigned and, if needed, blended) to determine the final bulk component-quality of the petroleum in the feed tanks. The final feed for the distillation unit consists of a bulk of hydrocarbon fractions mixed in the final petroleum feed that needs to be separated, converted, treated, blended, and so on, through refining processes in the middle-processing section to produce useful refined products.

In the back-end section of the refinery network, final stages of blend scheduling problems are essential to specify the qualities of finished fuels, such as regular and premium gasoline, diesel, jet fuel, and more. Occasionally, considering the scale and scope of the petroleum refinery plant, bench-marked by the complexity index of the refinery process network capacities and capabilities, blend scheduling maneuvering can also be included in the middle-processing section of the refinery network process to determine intermediate feedstocks, such as for RFCC and hydrotreaters of naphtha, kerosene and diesel (NHT, KHT, DHT).

Given the scale and scope of BS problems, simulation approaches are commonly used in petroleum refineries to simulate chosen scheduling assignments of blend-stocks for the loading of petroleum (dispatched to the refineries) and unloading of products (dispatched from the refineries). For loading of petroleum into the refinery site and related storage and feed tank topology, in an industrial-like perspective, the average values of the blended component yields for final amounts of distillates are fundamentally determined using simulation or simplified optimization approaches for blend scheduling of a given feed quality in the processing of the final crude-oil stream (the crude distillation process feed). This determination is important for the operations of the petroleum distillation processes since hydraulic limits of the renderings or distillates (fuel gas, liquid petroleum gas, light naphtha, heavy naphtha, kerosene, light diesel, heavy diesel, residuum fractions) must be accounted for in blend scheduling problems of the crude-oil management. It considers volume-based component yields or ranges of fractions of the crude-oil basket, mix, diet, or feed (primary factor for the distillates’ quantities and qualities in the distillation columns) and the operational settings (temperature, pressure, internal reflux ratio, etc.) in distillation units (secondary factor for the distillates’ production).

For the unloading of products dispatched from the refineries, quantities of final intermediate stocks (FIS) in the back-end, assigned to be blended to final quantity and quality streams of the FFS, need to be managed in a way that meets given specifications (to be certified in a laboratory in the refinery) before these fuel-stocks are dispatched for distribution to fuel stations. For example, a simulation step is a practice to meet specification on octane number of gasoline grades (regular, premium, etc.) since this is among the most complex blended properties to be determined. This blended property is governed by antagonistic and synergistic molecular interactions of the components in the intermediate tanks of the gasoline-like streams, whereby aromatic and olefinic component contents are required to be known since this is part of the calculation for the resulting RON/MON grade of gasoline.

An efficient large-scale and complex-scope blend scheduling solution in the petroleum refinery can potentially provide a monthly time-horizon (as in a planning problem), with details of a scheduling solution during the modeling stage formulate the following:

time-steps within a hour;

non-aggregated inventories or topology of the blend scheduling network;

truly logistics constraints to be respected;

precise blended quality addressing slack or excess of quality (under- or over-specified, respectively).

From this state-of-the-art blend scheduling solution scenario, refineries can explore opportunities of spot market (unplanned or unexpected contract) to sell, locally or globally, the surpluses of finished goods when the contracted market (planned or expected), previously scheduled from weeks to a month (potentially every hour), are fulfilled. For long-term stock-like hydrocarbon commodities (such as crude-oils and gasoline), spot market values are frequently (if not always) higher than the contracted agreement market. Therefore, it is important to reach the so-called spotting level of service [

1], when the time-horizon of the detailed blend scheduling problem is within the window of spot businesses (from a couple of weeks to a month). In contrast, for long-term markets, refineries are required to provide the quantity of specified products to customers as per the agreement.

Specifically, the literature review section of this paper on blend scheduling (BS) solutions in petroleum refining categorizes the literature into BS of crude-oil, gasoline, and other distillates (such as diesel and fuel oil). The BS solutions (reviewed and to be proposed as a perspective view) cover (a) optimization and simulation approaches, (b) batch or continuous mixtures, (c) continuous and discrete-time formulations, (d) scale and scope of the BS solutions. If following an optimization approach, how are the mathematical models and optimization techniques defined to handle a non-convex mixed-integer nonlinear programming (MINLP) problem formed by logistics and quality problems to be solved in the determination of the quantity, logic, and quality decisions found in the petroleum refinery operations. As to be seen in this paper, optimization models in petroleum refineries for BS problems focus mainly on the operations research of (a) loading and storage of crude-oils, (b) gasoline production, and (c) overall managing of the refinery inventory.

The remainder of this paper is structured as follows. In

Section 2, an industrial perspective on blend scheduling (BS) in petroleum refineries is provided. In

Section 3, the literature review section of this paper on blend scheduling (BS) solutions in petroleum refining categorizes the literature for discussion into BS of crude-oil, gasoline, and other distillates (such as diesel and fuel oil) by overlapping the keywords “blend*”, “sched*”, and “refin*”.

Section 4 outlines the perspective view on BS in petroleum refineries, emphasizing unaddressed batch versus continuous (or sequential versus simultaneous) blend scheduling cases, along with discussions on challenges related to solving large-scale and complex-scope blend scheduling problems, whereby proposed approaches to solve such issues are defined. The framework or design of the solution to the blend scheduling problem proposed in this paper introduces the way forward for large-scale and complex-scope blend-shops in petroleum refineries. Final remarks and conclusions are presented in

Section 5 and

Section 6.

2. Blend Scheduling in Petroleum Refineries: Current State

2.1. Planned versus Actual Blend Scheduling

Petroleum refineries operate in a constantly changing and complex environment. They must adapt their initial production plans regularly due to issues that arise in individual parts of the refineries’ operations. These plans, or more specifically, these schedules, are meticulously programmed to optimize various aspects, such as process variables and inventory or blend-stock operations, which are crucial for maintaining the quality of the products and better utilization of resources of both equipment and crude-oil raw materials. Within the petroleum refining process, temperature, pressure, and flow rates in different parts of the operation are closely monitored and controlled by the production team. Adhering to these precise conditions is essential to ensure that the final products meet strict quality standards required by industry regulations and consumers. This tight control over the process is fundamental to achieving the desired product quality. Efficient use of capacities and capabilities of equipment is another key aspect of refinery operations. The production team aims to maximize product output to increase profitability by making the best use of each piece of equipment. This prevents deviations from established production norms and operational restrictions. Keeping equipment well-maintained is crucial for guaranteeing a smooth production process and meeting market demand effectively.

Besides the quality control of material streams/stocks throughout the petroleum refinery process network, inventory management of these materials is also crucial for ensuring that the refinery can continue to operate smoothly, especially during emergencies like shutdowns. For example, in the event of an unexpected shutdown of a hydrotreater unit, the feed that typically comes from the distillation unit will be diverted to an intermediate inventory tank. This is maneuvered to reduce the chances of any disruptions or shutdowns in the distillation unit’s operations. Conversely, if the distillation unit experiences a shutdown for any reason, the raw distillate stream/stock feed will be received from the intermediate tank. This ensures that the hydrotreater unit can continue to operate smoothly during the distillation unit shutdown. The aforementioned shutdown events, considered unexpected, can be circumvented for hours, shifts, or days on average, allowing the operations of upstream and downstream units, considering that there is inventory as space-to-be-filled (STBF) or stock-to-be-drawn (STBD). If these events delay longer than initially planned for the unexpected shutdown recovery, then intermediate inventories cannot handle longer, and probably other measures must be put in place such as the shutting down of more process units as well.

Deviations in product quality can have a significant impact on both production quantity and quality within the refinery, necessitating careful evaluation and adjustments. For example, if the research octane number (RON) of a specific gasoline product exceeds regulated specifications, production adjustments may be needed, such as reducing the utilization or production of the high RON component to maintain the desired balance with lower RON components in the final blend-shops for producing the FFS in a multi-period perspective. Also, another low-RON FIS inventory can be utilized to maintain the FFS without excess of quality. When multiple high-RON components are not available, additives like methyl tertiary butyl ether (MTBE) can be strategically used to optimize production processes and respond effectively to market demands, although it is not sustainable since many countries already banned this component because of potential damage to health and the environment. In this case, ethanol (CH

3-CH

2-OH) can play a vital role in meeting the demands of RON (as in USA and Europe with the E10 and E5, gasoline mixed with 10% and 5% of ethanol, respectively) or even go further with the inclusion of flex-fuel fleet operating pure ethanol or pure gasoline or any mixture of both as in Brazil [

2].

Furthermore, demand fluctuations can exert a substantial influence on refinery operations. In response to shifts in demand, the refinery may need to increase or decrease production and potentially redirect surpluses of products. This is particularly important in situations where export commitments require adjustment to accommodate these fluctuations. Adaptability in production scheduling and its necessary blends is essential to handle these demand fluctuations while maintaining operational efficiency and competitiveness. However, this needs an automated engine taking decisions in an online (or at least on-demand) re-scheduling perspective [

3].

The use of simulation methods for operations in refineries presents a significant challenge when it comes to quickly adapting to unexpected changes. As discussed earlier, various factors like process unit disruptions or alterations in the quality of raw or intermediate material streams/stocks can significantly affect the established production program. Even small inaccuracies in feed calculations can lead to substantial shifts in tank inventory levels, requiring revisions to the production already decided and in the course of the action, which may involve increasing or decreasing the output of the processing plant. Therefore, the adoption of simulation methods can be hindered by the time-consuming process of adjusting schedules that have already taken a considerable amount of time to develop.

The complex nature of petroleum refinery operations highlights the need for swift adaptability in the decision-making process. While simulation tools offer many advantages (faster or immediate solution of each simulated scenario, can be more detailed in the model), they face challenges in promptly responding to unforeseen events (when looking for a feasible solution), as previously discussed. These decision-making complexities in the simulation-based approach emphasize the importance of exploring solutions, autonomously, to enhance production flexibility in the refinery settings.

A potential measure to mitigate the issues of the simulation environment is to implement an optimization tool that can automate the decision-making processes for the production scheduling team. This tool would reduce the time required to prepare (a) production schedules and blending recipes, (b) analysis of import and export frontlines, and (c) what-if cases on petroleum raw material supply and fuel product demand considering the network of process-unit-operations (for their throughputs) and tanks (for their inventories). In the case of emergencies like shutdowns, changes in production due to petroleum feed yield variations, unexpected final fuel demands, or any disruption in the process, the optimization-based or automated decision-making tool can find a solution to adapt quickly and efficiently, reducing the risk of human errors on the decisions to be made, avoiding infeasible or unprofitable production.

2.2. Manual Optimization (via Simulation) versus Algorithmic Optimization

Despite the significant advancements in optimization-based methodologies within academic and industrial spheres in recent decades, the prevalent utilization of simulation persists for scenarios that could potentially be addressed through optimization. This holds for the management of blend-stocks of crude-oils, intermediate materials, and fuels in petroleum refineries. Simulation strategies rely on achieving feasibility through trial-and-error procedures for the assignment of stocks and equipment, as well as quantities and qualities of the transferred, processed, or transformed material.

Simulation can provide meaningful and useful resources to quickly obtain a rigorous or detailed level of information on what is formulated in the model for a selected operational scenario. For example, simulation can provide information on the degree of hydrocarbon fractionation in a separation process and molecular reaction in a conversion process concerning the settings or parameters of the process transformation. On the other hand, optimization offers the capability for automatic and systematic searching across the solution space, considering quantity, logic, and quality domains. Although more computationally expensive, optimization has been increasingly used due to recent technological improvements and research developments in the context of Industry 4.0 (I4.0).

Recent I4.0 developments encompass digital transformation, big data, machinery automation, advanced analytics, and automated decision-making frameworks for industrial-like instances covering large-scale and complex-scope cases. These offer opportunities for improvement in multiple applications of diverse fields. I4.0 technologies provide further automation of decisions with faster and more efficient operations, reduced costs, and precise matching of product quality (without excess of quality as much as possible in blend scheduling problems as the ones proposed in this paper). The urgency to replace outdated processes and tools with more efficient and automated systems—both in decisions and executions—is critical for achieving safer, more profitable, and more efficient industrial operations.

For a feasible I4.0 application, advances in modeling and solving algorithms (MSA) in network or flowsheet optimization are capable of delivering in time the demanded fast discrete optimization solution when handling assignment of equipment and material balances in a process network as found in the petroleum refinery. For example, Brunaud et al. [

4] showcased discrete optimization problems for large-scale flowsheet networks solved in less than a minute when formulating the problems in the unit-operation-port-state superstructure (UOPSS) flowsheet formulation from Kelly [

5]. The authors compare the UOPSS to the traditional state-task network (STN) [

6,

7] and resource-task network (RTN) [

8] formulations. It reduces the optimization processing time in the UOPSS by around four- to ten-fold when compared against large-scale instances.

Franzoi et al. [

9] examines the decision-making capabilities of simulation and optimization techniques from an industrial perspective. It aims to provide insights into when and how each approach can be effectively utilized to address complex industrial problems such as the full petroleum case (from petroleum loading to fuel unloading) solved in their work. The authors discuss the strengths and limitations of simulation and optimization techniques. Simulation is praised for its ability to capture system behavior and provide detailed insights into complex processes. It allows for experimentation and exploration of different scenarios, facilitating a better understanding of system dynamics and identifying potential bottlenecks or inefficiencies. On the other hand, optimization techniques are lauded for their ability to generate optimal solutions by considering multiple variables and constraints. Optimization enables decision-makers to find the most efficient course of action to achieve desired objectives. The authors highlight that the choice between simulation and optimization depends on various factors, such as problem complexity, computational requirements, available data, level of uncertainty, etc. Carefully considering these factors is crucial in determining the most suitable approach for a given problem. To illustrate the practical application of simulation and optimization in decision-making processes, the authors present case studies and examples from diverse industries, including chemical manufacturing, supply chain management, and energy systems. These examples demonstrate how simulation and optimization techniques have been effectively employed to improve operational efficiency, optimize resource allocation, and enhance decision-making in real-world industrial settings. The paper concludes by emphasizing the importance of a holistic approach that combines the strengths of simulation and optimization techniques. It highlights the need for interdisciplinary collaboration and integration of both approaches to fully leverage their potential in solving complex industrial problems.

Blend scheduling can be useful for the adjustment of the logistics and qualities problems that can be flexibly managed to adapt to any unexpected changes that might occur in the supply of diverse component-quality raw materials and demand of finished goods such as gasoline and diesel products. In this case, by restrictions on scaling the size and complexity of the problems, the utilization of equipment when integrating quantity, logic, and quality variables and constraints in industrial-like blend-shops is still without the use of an optimization search, with the support of an automated decision-making algorithm. Nevertheless, at least one solution to apply optimization can be the use of decomposition strategies and ad hoc approaches to automate the solution search as we will address in

Section 4.

2.2.1. Simulation in Blend Scheduling

Petroleum refinery operations require decision variables over a complex processing network, in which planning and scheduling decision-making are often performed aided by computer-based software and resources. Particularly, the blend scheduling (BS) decision-making comprising crude-oil management (feedstock edge), processing feeds in unit operations, and production of finished fuels (product edge), leads to feasible or suboptimal solutions since these are typically performed based on manual or trial-and-error decisions in the petroleum refinery site. Blend scheduling problems are a mix of discrete and continuous decisions in quantity, logic, and quality variables forming the so-called qualogistics solution. The main issue in simulation instead of optimization arises in the trial-and-error or try-and-test of the logic variables (assignment of tanks, for example), relying on simulating events to test feasibility or optimize the remaining LP or NLP problems. Since the user is responsible for manually testing different scenarios and keeping track of convoluted decision trees that do not work or prove feasible, this time-consuming procedure is not reliable since it may take hours, and does not even guarantee feasible solutions.

For the management of petroleum or crude oils, considering their unloading from diverse modes of transportation and their loading into the refinery walls for storage and feeding stages, a combinatorial explosive problem to test all possible scenarios becomes challenging when scaling since this varies by the number of crude-oils to be unloaded, the unloading–loading pipeline network, storage tanks’ availability and spaces to be filled, and blend scheduling topology and mixture (if sequential or simultaneous) between the storage/feed tanks and the distillation units. Once the selections or assignments are given by the scheduler using a simulation of events, the remaining quantity or LP problems (without considering properties) and quality or NLP problems (addressing quantities and qualities together) must be solved. Otherwise, it continues solely considering simulation of the amounts or quantities of the selected or assigned discrete (simulated) variables in order to identify the qualities of the blended or output material stream. This is a reality for industrial-like blend-shops as in the gasoline production considering octane number calculations, whereby the selected tanks of input-like-output gasoline streams such as reformate and hydrotreated light cracked naphtha from RFCC/FCC are added and the final ON quality is calculated for every amount of the input streams.

2.2.2. Optimization in Blend Scheduling

Crude-oil or petroleum refinery operations are highly complex and present a very dynamic environment mostly because of the molecular nature of crude oil feedstocks and the operational complexities required in such an industry. Moreover, in recent decades, crude oil refineries have grown increasingly more complex, operate with lower margin profits, and face tighter competition [

10]. In addition, refinery operations are moving towards molecular and compositional management to meet product specifications and environmental regulatory requirements, which brings complexities and difficulties that cannot be often controlled. Therefore, smarter strategies are required for safe, flexible, and adaptive operations. In this context, many challenges arise in terms of controlling the operations and balancing the computational tractability with solution quality [

11]. For industrial-sized blend scheduling production of complex processing facilities typically found in the crude-oil refining sites, phenomenological (separating, converting, blending) and procedural (sequences, setups, startups) optimizations make it very difficult to solve as a full space MINLP model. Several strategies developed in the literature address solution strategies for nonconvex MINLP refinery scheduling problems based on approximation, linearization, excursion, relaxation, fixation, clustering, decomposition, and other heuristic-based and size-reduction approaches, for handling such complicated models that vary in a three-dimensional quantity–logic–quality (QLQ) relationship space. Some of them are presented as follows:

NLP approaches in a complete solution by relaxation of binary variables as continuous variables (the full space approach) with further MILP solution in an outer-approximation as in Duran and Grossmann [

12];

NLP constraint relaxations or approximation as LP formulas in MILPs as in Lee et al. [

13]; Castro and Grossmann [

14]; Kelly et al. [

15];

MILP-NLP hierarchical or phenomenological decomposition by fixing MILP results in NLP programs as in Mouret et al. [

16]; Castro and Grossmann [

14]; Cafaro et al. [

17]; Menezes et al. [

18];

MILP approximations by selecting specific points of the NLP space to be treated as modes of operations as in Jackson and Grossmann [

19]; Menezes et al. [

20]; Castillo-Castillo and Mahalec [

21].

Recent technological advances in computer-aided resources, coupled with more efficient decision-making modeling and solution algorithms enable us to address a discrete-time (DT) formulation for crude-oil blend scheduling (for a week time-horizon with uniform hourly time-steps) that uses a raw material quality minimization or clustering algorithm to reduce the size (by fixation of the feedstock storage assignment) of the nonconvex MINLP or QLQ blend scheduling problem. As to be seen in

Section 3 and

Section 4, in the MINLP solution towards industrial-like blend-shops, the QLQ problem is solved in the so-called hierarchical or phenomenological decomposition heuristic (PDH) that partitions MINLP models into two simpler submodels. The former is referred to as logistics, and includes quantity and logic information, as is formulated as an MILP model. The latter is referred to as quality, includes quantity and quality information, and is formulated as an NLP model. The subproblems are solved in a sequential and iterative strategy until convergence of both solutions Menezes et al. [

18]. Advances in high-performance computing (HPC) and modeling and solving algorithms (MSA) have enabled technology to optimize large-scale and multiple-scope complex logistics and quality problems found in crude-oil blend scheduling operations formulated in discrete-time with small time-steps (1 h to 8 h). If this is applied for a week to a month as a time horizon, the named spotting level of service is reached by solving a scheduling detailed problem for a time-horizon of monthly operational planning. It allows the scheduler and the commercialization segments of the producer and logistics, and supply chain of internal and outsourced frameworks to be interconnected, permitting opportunities to explore higher returns in the spot market of commodities such as for liquid hydrocarbon streams. Advanced data analytics capabilities systemized and integrated into MSA and HPC enhancements have the needs for the blend scheduling re-optimization in an online cycle considering the thorough support of advances in information and communication technology (ICT) and auxiliary mechatronics [

22].

2.3. Under- and Over-Specification of Quality

In terms of logistics and quality (or qualogistics) of raw, intermediate, and final material streams to be solely assigned or blended or, simultaneously assigned and blended (assigned to be blended), blended stream quality giveaway (or excess of targeted or contracted qualities) is one of the critical and perennial causes of financial losses in the refinery business. Giveaway describes giving a product with higher quality than the committed (or contracted) quality for the same price.

In the blend scheduling of finished fuels, zero or reduced giveaways prevent losses in the petroleum refinery processing site since premium quality (excess of quality) in finished fuel products means:

better quality raw materials are processed than needed.

more constrained processes are made unnecessarily.

some component tank of a better quality is being used to meet quantity demands.

These concerns of operating in a non-optimal region on the excess in quality of the management of blend-stocks can be extended to avoidance of (a) out-of-specification (off-specification) products (finished or still to be processed) and (b) partial or total re-processing of the final blended stream such as liquid petroleum gas (LPG) and gasoline to be processed in thermal/catalytic cracking units and fuel-oil or bunker to crude-oil distillation units (CDU).

If finished products after blend scheduling fail to meet specifications, corrective measures are taken. For instance, better quality materials segregated for enhancing final product qualities can rectify the intended production. However, if quality correction affects incoming deliveries or cannot be completed successfully, government waivers may permit the sale of unspecified products to consumers, a critical contingency plan to prevent fuel station shortages. As a last resort, discounts in selling price may be considered, enabling distributors to manage another round of blend scheduling on-site to rectify the product (i.e., just-in-time trimming, tweaking, or touching up the blend).

The petroleum refinery scheduling for the production of finished goods (such as fuels and petrochemicals) is a very complex problem due to the scale and scope of the operational programs to be determined. It is worsened by the characteristics of the hydrocarbon material variation in component-quality streams (petroleum, fractions, fuels) to be blended and assigned to equipment that is mostly connected by networked continuous processes and tanks. The petroleum refining industry challenges the development of solutions to address the scheduling of the blend-stocks to be processed from crude-oil or petroleum raw materials to finished goods (fuels or petrochemicals). Unresolved issues persist within industrial blend-shops, forming the focal point of this article, aimed at revealing prior research and perspectives on blend scheduling in petroleum refineries.

One of these issues derive from the MINLP decomposition as NLP-MILP or MILP-NLP. The former, the so-called full-space, solves a relaxed NLP problem and an MILP after. The latter, named hierarchical, solves an MILP by neglecting or approximating NLP constraints first, to then, for the logic solutions found, solve the NLP problem. Other challenges related to NLP constraints for ad hoc correlations such as octane number in gasoline use surrogate modeling as linear and nonlinear correlations in hierarchically decomposed solutions. Other approaches towards large-scale and complex-scope BS in petroleum refineries are also discussed. These are found in

Section 4, but, before, a literature review on this topic is given in the following section.

4. Perspectives on Blend Scheduling Optimization in Petroleum Refineries

Integration of large-scale and complex-scope blend scheduling problems within petroleum refineries poses challenges due to the intricacies of the refining processes and the nature of raw, intermediate, and finished material streams. In this field, the raw materials are made from a mixture of molecules from C1 to C80+ in the carbon-chain structure. These must be segregated by separation processes and those heavy streams with C30+ (heavier than diesel stream) must be converted to smaller carbon-chain (CC) size molecules by cracking the CC in thermal and catalytic conversion processes, yielding higher added value petroleum fractions (such as naphtha, kerosene and diesel streams). In addition, all the unfinished streams after separation and conversion process units must be treated to clean the streams/stocks from impurities such as hetero-atoms as sulfur (S) and nitrogen (N). Consequently, the quality, reflected in the molecular characteristics of mixed streams within a stock, becomes crucial. Input streams into process units must be tracked from a molecular blend scheduling perspective, aligning with the precision molecular blend scheduling outlined in Joly et al. [

59] within the Industry 4.0 paradigm, for the molecule to be in the right place at the scheduled moment in a proper way.

The logistics and blending of these quality-dependent streams and stocks, integral to processing, transformation, and transfer, constitute what we term the qualogistics problem. Furthermore, given the continuous-process nature and inventory tanks in a networked plant, scheduling in petroleum processing relies on proper settings or hyper-parameters concerning time modeling. This involves either uniform discretization of time in a discrete-time modeling approach or the fixation of few events within predetermined time points in the future within continuous-time modeling. These predetermined time points along with the time horizon and continuous variables like duration, starting-time point, and end-time point (of the non-fixed events), are crucial for effective continuous-time modeling.

4.1. Modeling of Time for Blend Scheduling Operations

Two distinct approaches for time discretization are utilized in scheduling operations. Discrete-time formulation uniformly divides time, requiring all events to begin, continue, or end at the limit (start or end) of a time step. Conversely, continuous-time formulation treats time as a continuous variable, allowing flexibility in specifying the exact start and end dates of events within the time horizon (Méndez et al. [

49]; Saharidis et al. [

60]; Hou et al. [

61]). While the main drawback of discrete-time is the combinatorial complexity that scales with the number of binary decisions (potentially in each time-step of the entire time-horizon), implementation issues arise from continuous-time formulations, in which the execution of tasks by the operators in the plant cannot be easily performed or synchronized, in addition to the need for defining a few time events to represent the operations in the plant. Floudas and Lin [

62] point out that the main advantage of discrete-time is to provide a work window reference that facilitates the coordination of the scheduling executions by the operators. In realistic scenarios, the operational bottleneck arises due to the number of tasks to be executed and the available operators to supervise or perform manual and automated scheduling operations in the field. Therefore, operational peers favor executions within a time window of hours or shifts instead of exact moments indicated by continuous-time representations. Instead of expecting operations at precise moments, discrete-time schedules provide work window references, facilitating coordination among operators.

Besides the difficulties in coordinating the execution of continuous-time schedules by the operators on an industrial scale, another major issue is how to define a priori which and how many time-points for the fixation of some events should be selected within the future schedule. Hence, the operation in continuous-time can be seen as a reactive (instead of proactive) process-of-work. On the other hand, in discrete-time an optimal schedule for each time-step exists, and operational concerns such as possible overflow in tanks due to time discretization can be easily circumvented in the field by the numerous buffers, alarms, and measurements typically found in the distributed control systems (DCS) that are available for operators and schedulers. Another important benefit of discrete-time is that ad hoc features are easier to be reproduced [

63]. For example, instead of counting on solely inventory constraints in tanks or relatively simple logistics relationships in continuous-time, the modeler, in a discrete-time, can reproduce operations practiced in the field such as fill-draw-delay, filling-full, and drawing-empty constraints for tanks as found in Zyngier and Kelly [

64]. These complex constraints are only possible when the problem is determined systematically (in a pre-defined pace or time-step) as in the discrete-time representation. Other strengths and weaknesses of discrete and continuous time formulations are summarized in Pinto et al. [

25] and Lee and Maravelias [

65].

Because of the modeling and solution aspects of large-scale NP-hard crude-oil scheduling formulations, the literature on the topic has mostly employed continuous-time approaches in recent decades (Jia et al. [

50]; Reddy et al. [

66]; Reddy et al. [

31]; Mouret et al. [

16]; Castro and Grossmann [

14]; Cerda et al. [

33]). However, with the recent technological advances in decision-making modeling, solving algorithms, and computer-aided resources as discussed in Harjunkoski et al. [

67], discrete-time approaches can be efficiently employed for large-scale industrial applications, although possibly requiring the assistance of additional modeling (decomposition) and solving (heuristic) strategies.

4.2. Petroleum Refinery Blend Scheduling: Modeling Ingredients for Large-Scale and Complex-Scope Problems

Although discrete-time modeling of blend scheduling of large-scale and complex-scope problems imposes combinatorial challenges to solve, it is possible to reach reduced computer processing times by using proper modeling (for example, the UOPSS formulation from Kelly [

5]) and parallel processing using high-performance computing resources. However, other ingredients are worth to be discussed in the following and these are summarized in

Table 2.

To properly manage blend-stock needs in daily to hourly blend scheduling operations, an enterprise-wide optimization (EWO) framework proposed by Menezes et al. [

68] aims to bridge the gap between procurement and scheduling in crude-oil refineries by addressing a series of solutions on integrating these different levels of decision-making. The proposed EWO framework improves overall performance and cost efficiency by effectively coordinating these two critical aspects of refinery operations. Concerning blend-stocks to be managed, the paper emphasizes the significance of considering factors such as feedstock availability, blending requirements, and product demands when making procurement and scheduling decisions. It leads to better blend-stock management in the blend scheduling needs on petroleum, intermediate streams/stocks to be processed, and intermediate streams/stocks to be assigned and blended for certification into final fuels before their dispatching to the final stages of the supply chain. A series of solutions from tactical to operational decision-making in a feedforward (decision) and feedback (detailed parameters) flow of information facilitates the convergence of the petroleum quality demands in the feed or charging tanks. The feedforward flow of information is the higher level decisions and the feedback flow is the detailed parameters from inner solutions for recalculation of outer solutions.

Towards large-scale problems in BS cases, Menezes and Kelly [

1] present a high-quality blend scheduling solution for decision-making in processing industries. It emphasizes the integration or the realization of a scheduling solution within a time horizon of planning to achieve a state known as spotting. This state allows increased profitability by exploring spot market opportunities. The paper highlights various challenges in reaching the spotting stage, such as determining the necessary time grid for scheduling solutions, integrating planning and scheduling strategies, and incorporating required process details in modeling, among other details. The authors present industrial-size examples of scheduling optimization in a petroleum refinery in Asia. It includes the production of lubes and asphalts with sequence-dependent switchovers between modes of operation, as well as gasoline blend scheduling operations using decomposition strategies and factor-flow cuts based on nominal amounts of qualities presented in Kelly et al. [

15]. The paper discusses the benefits of optimization-based decisions using mixed-integer linear programming (MILP), which include optimized schedules, improved coordination with sales and marketing, enhanced stewardship in feedstock selection and operations planning, therefore, capturing spot market opportunities, and aligning blend schedules with product quality specifications.

Franzoi et al. [

69] present a design for online process and blend scheduling optimization that focuses on the design aspects of blend scheduling and processing in manufacturing operations. The authors specifically address scenarios where raw materials with varying compositions are segregated, stocked, and blended to meet the quality requirements of the plant’s feed. The paper discusses the impact of storage and blend operations’ topology and process design network on the scheduling production of intermediate streams and final products. It emphasizes the need for improved scheduling that takes into account real-time plant updates and varying feed quality demands in response to market variations and process changes.

From the process network down to the product distribution in the intermediate or middle-processing section side of the petroleum refinery, there are definitions on the assignments and amounts of distillates to be dispatched downstream for further process-shops and blend-shops considering diverse tank farms and nodes for the distribution. However, such integration of the refining process and tank storage systems can become intractable for industrial-sized problems with complex scheduling configurations considering time-varying rundown supply rates, product demands, and pricing. For this, Menezes et al. [

70] propose to model the dispositions of distillates using unit-operations as modes of transportation from the distillation unit sources to the tanks of process-shops and blend-shops for downstream processing and blending before the primary distribution of the finished fuel stocks. Additionally, by solving with pooling (groups of tanks) first and then post-solve to depool by disaggregating the pooled solution, the determination of the distillate dispositions to tank assignments is facilitated given that scaling to industrial-sized cases without tank aggregation is complicated or impossible to solve if using optimization methods as highlighted in the examples.

Scheduling decision-making is often calculated and implemented using unreliable or inaccurate data from process networks such as the quality of the streams/stocks. Therefore, infeasibilities and inconsistencies in the production are expected. For improved operations, it is fundamental to minimize plant-model mismatches, in which the current state of the system is continuously updated. A moving horizon rescheduling framework can be proposed as a systematic bi-layer framework that simulates the closed-loop scheduling optimization within a moving horizon approach. It handles disturbances, reduces plant-model mismatches by updating the state of the system, and provides a systematic fashion for improved rescheduling implementation with blend scheduling demands to be operated [

71].

Franzoi and Menezes [

72] explore the optimization of scheduling in industrial processes, focusing on three key factors: time-steps, time-horizon, and rescheduling. The authors aim to provide insights into how these factors influence scheduling performance and efficiency. They emphasize the importance of selecting appropriate time-steps, which determine the granularity of scheduling decisions. Striking a balance between capturing important process dynamics accurately and managing computational complexity is crucial when choosing time-steps. The paper discusses the trade-offs associated with different time-step choices and their implications for scheduling effectiveness, whereby the blending processes to be scheduled can be affected by these key aspects of the BS problems to be solved.

Large-scale discrete-time scheduling optimization in industrial-size applications in Franzoi and Menezes [

73] addresses the challenges associated with optimizing blend scheduling decisions in complex industrial systems. The authors propose a discrete-time scheduling optimization framework and provide large-scale and complex-scope case studies to demonstrate its effectiveness. The paper emphasizes the need for efficient scheduling in industrial operations that involve a large number of tasks and resources. The proposed framework considers various constraints and objectives, aiming to improve overall system performance. The case studies presented in the paper showcase the practical implementation of the scheduling optimization framework. These studies underscore the importance of considering real-world constraints and objectives in the optimization process to reach the precision logistics and quality demands of the BS operations. Given its immense scale (around thousands of binary and continuous variables and constraints), to be able to solve in reasonable processing time, chronological (temporal) and relax-and-fix algorithms are applied, but they perform as well as the non-decomposed cases that find solutions within an hour instead of minutes as in the decomposed instances.

4.3. Qualogistics Solutions in Blend Scheduling: Challenges to Solve

Optimizing crude-oil, gasoline, or any other distillate blending and scheduling yields a non-convex mixed-integer nonlinear programming (MINLP) problem. This is solved in heuristic/ad hoc algorithmic propositions based on decomposition strategies. In the full-space algorithm (without neglecting any decision variables and constraints), the binary variable relaxation that forms nonlinear programming (NLP), in the first stage of the approach, may lead to convergence issues due to the no-robustness of NLP solvers. Furthermore, there is no guarantee to reach a global optimal solution since the full-space algorithm solves an NLP problem to then address the mixed-integer linear programming (MILP) problem in outer-approximation algorithms via an iterative NLP-MILP decomposition as proposed in Duran and Grossmann [

12].

On the other hand, to avoid these NLP-MILP decomposition drawbacks when addressing MINLP problems, an alternative strategy is to solve first the MILP stage by neglecting or dropping nonlinear relationships (as the nonlinear quality balances from the blending of streams/stocks) to then solve the NLP problem of the second stage, when fixating the assignments or discrete/binary solutions of the MILP into the NLP. However, in this so-called hierarchical decomposition, neglecting these quality balances may lead to infeasible solutions in the NLP stage as certain component-quality stocks might fail to fulfill demanded pooled component-quality requirements. An alternative is to use a solution pool engine generation (found in CPLEX, GUROBI and XPRESS solvers) to generate dozens, hundreds, or thousands (or as much as needed) of MILP solutions to be solved again in the NLP optimization for the solution [0,1] of the binary or discrete variables found in the MILP. It increases the chance of assigning petroleum storage tanks with the required component-quality to prepare petroleum feed tanks. The same is valid for the intermediate and final blend scheduling, whereby the properties or qualities (not more components for yields/rendering of distillates) needs to be matched to specify (1) intermediate streams, fractions, or stocks in further processing (such as in hydrotreaters) and (2) finished fuel stocks (FFS) for certification (via laboratory experiments) before dispatching to distribution and consumption.

Integrated into this MILP-NLP logistics-quality decomposition, Kelly et al. [

74] propose an unsupervised clustering machine learning approach using the component-quality information on the unloaded petroleum stocks in refinery storage tanks. Based on multiple petroleum streams to be stocked and blended for the CDU feeding, there will be many cases that for storage of a petroleum stream in tanks with initial amounts or heels of other types of petroleum, there will be a necessary mixture (of the initial stock and added streams) for the sake of the storage operation. In these circumstances, there will be a rule-of-thumb or procedure to preferably blend those streams-for-stocks (SFS) that minimize the overall quality variation among all streams to be stocked before the preparation of the feed tanks to be processed in the CDUs. This preferred blend of petroleum streams to similar component-quality tanks assists in setting up to 0 or 1 (no or yes) the loading-storage assignments in the MILP logistics solutions. This pre-scheduling or fixation of the assignments using the results of the clustering reduces the MILP processing demands in the decomposed NLP-MILP or MILP-NLP strategies.

The solution of the hierarchical decomposition of the MINLP or more specifically the MILP-NLP approach in blend scheduling problems has been proven in Kelly et al. [

75] for the third largest petroleum refinery plant (among roughly 600 sites in operations worldwide). This MILP-NLP blending and scheduling case, formulated considering 5 days as time-horizon and 2 h as time-step, presents tens of thousands of binary variables and constraints and this is solved in an approximated quarter of an hour. A key element to reach such a solution is the approach from [

74] for feedstock storage assignment clustering algorithm that pre-assign loading-storage petroleum streams before the MILP solution (of the MILP-NLP decomposition) while providing component-quality in CDU feed demands within a broader NLP search spaces since the overall quality variation is minimized in the pre-assignment of the clustering in the storage tanks. Other advances that allowed the solution of such large-scale blend scheduling are the UOPSS flowsheet formulation from [

5] and the Industrial Algorithms’ proprietary sequential linear programming quadratic engine (SLPQPE) for the NLP stage.

However, the major drawback in the MILP-NLP solution, explained previously, is that, since the component-quality information is neglected, there is no guarantee in the BS solution to assign component-quality givers or suppliers for the component–quality necessary for (a) the petroleum processing in the front-end of the refineries or (b) for the product demands of the receivers or demanders based on the contracted or spotting sale markets for the precision qualogistics state of the art based on decision-making for tank-blend-stocks (either for petroleum feeds or production of final fuels to be certified and delivered). Rare occasions of intermediate blend-stocks streams can be also considered as a scheduled to be blended (or blend scheduled) operational problem for processing of these feeds in process-units under their modes of operations (if a unit can have multiple states of operational production). Residue fluid catalytic cracking (RFCC) and hydrotreating (HDT) units (as seen in

Figure 1) are examples of where BS optimization problems can also play an important role in a precision manufacturing state-of-the-art solution, reaching the optimal state of operations.

By totally neglecting any quality information on the blend-stock givers in an MILP-NLP or hierarchical decomposition, the best algorithm possible is to conduct a pool of solution to be tried for each logistics solution of the MILP stage (using or not the solution pool setting in the solvers with this feature) in the NLP problem. But, besides the possible infeasibility that is related to component-quality demands not fulfilled in the NLP stage by neglecting nonlinear component-quality balances in the MILP, the NLP solving can yield an infeasible or local optimum result inherent to the NLP solutions. If in each MILP-NLP pair, there are active variations in initial values of the independent terms of the nonlinear approximations of the Taylor series expansions of each nonlinear term, the number of possible solution combinations explodes. In this scenario, the MILP-NLP pairs are multiplied by the number of initial point datasets to be given for the nonlinear terms of the constraints found in each of the NLP problems (programs or instances) for the nonlinear variables’ initial value variations (IVV).

To overcome the burden of exploding sets of solutions in the MILP-NLP-IVV combinations (MILP-NLP pairs multiplied by the number of IVV datasets), with or without the support of the solution pool settings found in the CPLEX, GUROBI and XPRESS solvers, Kelly et al. [

15] propose that instead of totally neglecting quality information in the MILP-NLP hierarchical decomposition, it can be approximated or considered the following fundamental blending of streams-for-stocks (SFS) in blend-shops to be made. For the parameters or fixed/given qualities of the component-quality inputs and specifications (component yields, blended properties, etc.) of the quantity–quality product outputs, if three conditions apply, then, the following fundamentals are necessary to meet a quantity–quality (QQ) conservation in a blend-shop:

BS design or topology as continuous blending into a convergent point of the mixture.

input and output intensive values of the qualities are multiplied by their quantities (in total amount flows, when in volume, or weighted amounts per component or total, when in mass).

mathematically manipulating the creation of a fictitious variable named factor-flow (FF) to close the QQ balance in the output product side.

This overall truth on blending-of-stream is possible only if the qualities or properties of the inputs (or feedstocks) and outputs (in this case using the upper or lower bounds of the desired/targeted/regulated specifications of the output products) are known or given. When replacing nonlinear balances for qualities by a QQ conservation law in the MILP, amounts of qualities in both sides of the continuous-blending process in the blenders are preserved [

15]. Considering

x as a flow,

i as inputs,

j as outputs,

p as properties,

t as time-intervals, for an upper bound of property specification, to the product fixed quality, specification, or factor

multiplied by its total amount, a slack or negative factor-flow variable

must close the QQ balance in Equation (

1), so

. A positive factor-flow or surplus

is necessary for a lower bounded property of the product specification or factor

. If the factor-flow

is zero, it means the blended property is binding (at the bound) and there is no slack or surplus of quality. In both cases, in lower or upper bounds, if there is an excess of quality, by not reaching what is lacking to the maximum allowed value (upper bound) or exceeding the minimal permitted (lower bound), it probably represents one unprofitable or unexplored situation in the blend-shop.

The QQ balance in Equation (

1) impedes the MILP solution to observe all inputs without component-quality values, but considers them with an amount of quality by the overall input–output QQ preservation. This QQ-FF approach in the MILP avoids the assignment of blend-stocks that would not provide component-quality enough for the quality demands on the specifications in the NLP optimization (or simulation step) in the second stage of the hierarchical decomposition. For the case considering a simulation in the second stage, the successive substitution MILP from Kelly et al. [

15] proves to reach a near-optimal solution for volume- and mass-based blended governing rules. In the algorithm, considering the input flows found in the MILP, the error on the difference of the proxied quality in Equation (

1) and the true volume- and mass-based formulas (calculated in the post-optimization stage) are used successively to correct the factor or specification of the blended stream for the next SS-MILP iteration.

Equally to the factor-flow balance in Equation (

1), one can propose an ad hoc or black-box modeling to find basis-functions (causation) and their respective parameter-values (correlation) for an ordinary least squares regression supervised machine learning (OLSR-SVML). It can be developed for research and motor octane number (RON and MON) considering that RON/MON are fundamentally unique for each recipe of the blending of streams from the final intermediate stocks (FISs). Both synergistic and antagonistic molecular interactions on the level of ramification of the molecules matter on the final blended property for RON and MON. This sphericity is the reason for process units as the reformate (REF), where linear conformation molecules in the heavy naphtha streams are converted into cyclic molecules in naphthenic and aromatic conformations. Therefore, potentially, linear and nonlinear correlations can be determined and added in MILP-NLP or SS-MILP approaches where linear, bilinear, trilinear, etc., terms of the linear and nonlinear correlations in surrogate modeling frameworks can be found.

Surrogate models using supervised machine learning for the blending of gasoline streams are determined in Ali et al. [

76]. In their case, the Ethyl Equation [

77] for RON and MON is used as the source of synthetic data whereby Latin Hypercube Sampling (LHS) is used for the input streams (independent variables) as the recipe of the gasoline-like tanks producing finished fuel stocks (FFSs) of gasoline to be certified and sold. It determines the output streams or dependent variables on blended quality properties. In the surrogate modeling framework, bilinear terms on the amounts of the nine component tanks present good performance in the predictions.

This modeling-based twin of the OLSR-SVML formulas should be proxy enough to be comparable to the true volume- and mass-based fundamental-based siblings used in the SS-MILP algorithm in [

15]. Therefore, although volume- and mass-based formulas are known and yield near to the global optimum in the SS-MILP algorithm or they can be used in the second stage of the MILP-NLP considering MILP with factor-flow cuts shown in Equation (

1), these known formulas can be also modeled as an OLSR-SVML for testing-proving the ML methodology. Adaptive sampling SVML algorithms and their applications in the petroleum refining operations are found for cutpoint optimization in distillation columns in Franzoi et al. [

78] and for reaction systems in Franzoi et al. [

79].

4.4. Towards Industrial-like Blend-Shops: Way Forward

Kelly et al. [

15] propose a successive substitution (SS) using MILP (SS-MILP) with a simulation stage to compute the blended qualities for the input flows found every MILP solution. This is satisfactory for volume- and mass-based properties. In their research, the blended quality error, the difference between the proposed QQ factor-flow balance and the true values (for the quantities found in the MILP) by knowing the blending formulas, are used iteratively until the quality of the simulated stage converges to the given specification.

Future research can prove if the SS-MILP can be applied for ad hoc formulas as RON/MON, therefore it can be used to generalize the SS-MILP algorithm for any blending governing rules in the petroleum refinery since any formula can be surrogated or proxy’d as an OLSR-SVML of modeling basis-functions and parameter-values in the function based on data modeling methodology. For this, multiple inputs for single/multiple outputs (MISO and MIMO) regressed supervised machine learning blending formulas for RON and MON and other properties can be developed and integrated into the SS-MILP approach or even in a MILP-NLP decomposition. The needed resources to generate datasets use rigorous simulation software (as Aspen-Plus, Hysys, or PETRO-SIM) for the generation of synthetic data for the blending of gasoline-like streams when determining RON/MON output values. Also, by using experimental values from the blend scheduling recipes performed in the blend-shops, surrogate models can be developed.

4.4.1. Ordinary Least Squares Regression via Supervised Machine Learning

To avoid NLP formulas in the first stage of the SS-MILP algorithm, linear regressed formulas need to be determined and added to the MILP problems. Although this is an incomplete modeling prediction with, solely, linear terms for the blending formulas since this is treated as a linear programming (LP) approach inside the SS-MILP, any research can attempt to prove that this would be enough to assign the blend-stocks necessary to give quality for the final blends instead of neglecting any quality information. The second stage solution (via optimization as an NLP or simply as a simulation) can use the complete formula prediction since the nonlinear correlations of the OLSR-SVML can be solved in this stage (optimized to find new input quantities for the blended quality or simulated to find the blended quality for the found assignments and quantities in the MILP solution and successively converge by using the calculated errors from a previous iteration to the next as in [

15]).

The second stage solution (either an NLP optimization or a simulation) could utilize complete formula predictions since the nonlinear correlations of the OLSR-SVML can be addressed in this stage. For this, the use of surrogate models seems a promising shortcoming to skip NLP-solving issues, by reducing the complexities of the formulas or to model unknown ones. Surrogates are built following a bilinear functional form estimation as in Equation (

2) that correlates the normalized

x (independent variables or IV) and

y (dependent variables or DV) sets, with coefficients of

and

to be predicted using this correlation. The intercept or independent term of the prediction is eliminated to avoid multi-collinearity issues. The estimation uses MIQP optimization, utilizing the objective function in Equation (

3) that minimizes the least-squares error (LSE) for linearly regressing the y into Y

i, subject to constraints (

4) to (

6), using training points only, with

z as a binary decision variable for the causations of the correlated terms and big

M as a sufficiently large number.

4.4.2. Batch (or Sequential) versus Continuous (or Simultaneous) Blend Scheduling

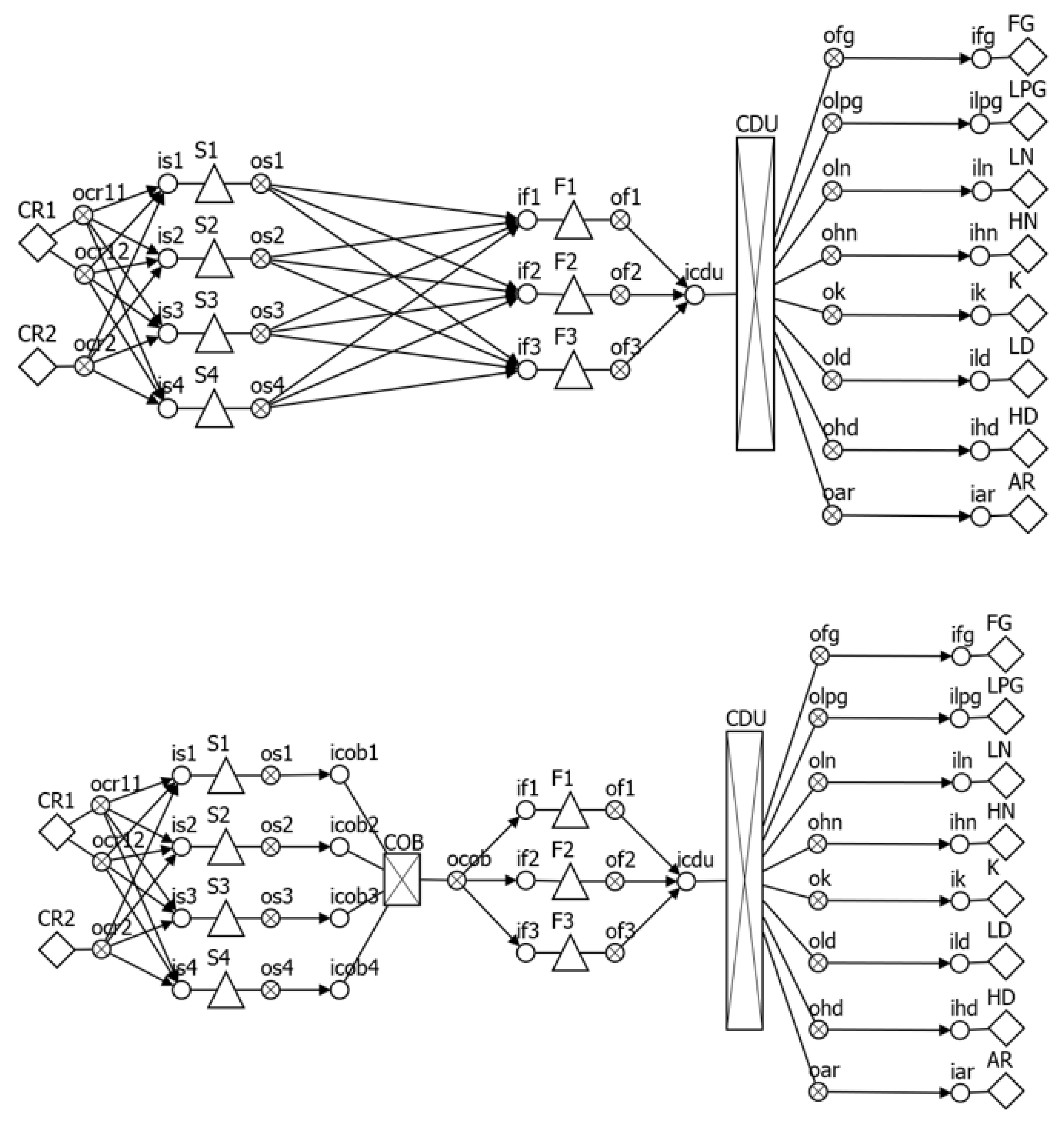

Notably, the SS-MILP’s limitation lies in its application only to continuous blending processes converging to a single mixture point. It does not suit batch (sequential) mixture topology commonly found in petroleum and intermediate stream assignments within refineries’ front-end and middle sections (as seen in

Figure 1). Research to be developed can investigate innovative solutions to solve a real topology and logistics constraints for the real batch (or sequential) mixture design as seen in

Figure 2, which, as demonstrated by Franzoi et al. [

69] represents more complex issues to solve than the continuous blending and impedes reaching optimal results (in the scheduling operations), if the distillation column network of towers in the crude and vacuum distillation units (CDUs and VDUs) is considered in the true design. Ahmednooh et al. [

80] demonstrated a tutorial case that if it is pretended to be a continuous mixture to apply the SS-MILP first and, then, with the quantities found in it, a second solution for the real topology and logistics constraints must be able to solve the problem for the real batch mixture topology by having the previously found quantity as hard bounds with tolerance or as soft bounds (or targets) with performance weights. The procedure is supported by the following statement: “for the final blended quality to be matched to property specifications, it does not matter how the blend scheduling is made, but matters how much are added of the amounts or quantities of the inputs in the final blended amount”.

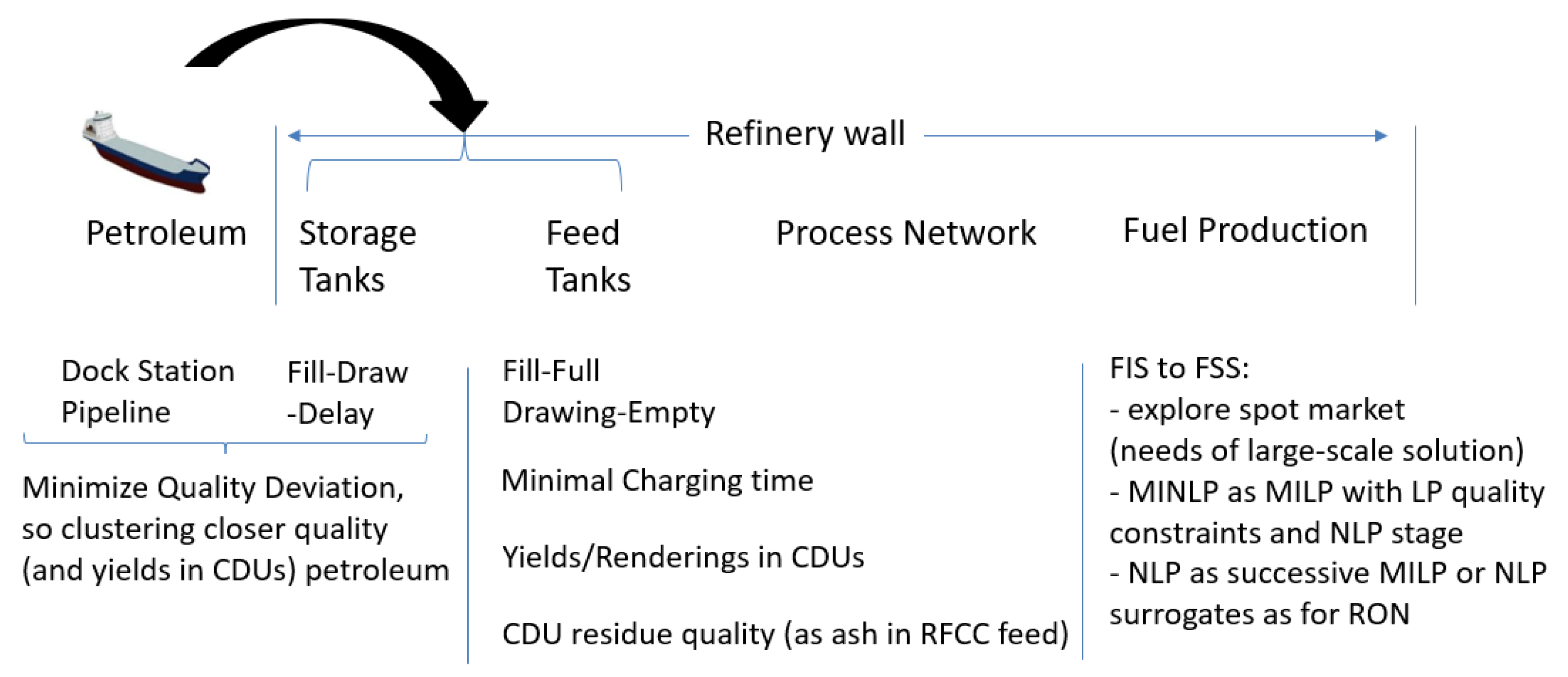

Figure 3 concentrates on the main constraints, goals, and approaches in refinery blend scheduling to be covered and proposed as future research on the topic. For petroleum blend-shops, when loading it into the refinery, clustering similar component-quality petroleum is necessary to enlarge the quality search space in a simulation approach or NLP optimization for the determination of feed quality needs. This can be, for example, acidity in naphtha streams, Conradson carbon residue (CCR) in atmospheric residue (ATR) streams, and hydraulic limits of any output streams or distillates.

5. Final Remarks

5.1. Blend Scheduling Dynamics and Challenges in Petroleum Refining

The intricate blend scheduling landscape within petroleum refineries encompasses a delicate balance between planned and actual scheduling, necessitating meticulous planning amidst constant operational changes. Optimization strategies are crucial to manage process variables, inventory, and equipment utilization while ensuring adherence to quality standards. This involves close monitoring of conditions such as temperature, pressure, and flow rates to maintain product quality and maximize equipment capacity, preventing deviations from established production norms.

Inventory management assumes a pivotal role, particularly during emergencies like shutdowns. Responding to unexpected events requires redirecting material flows to intermediate tanks to sustain operations, albeit temporarily. Managing production quantities involves navigating factors like feed availability and demand fluctuations, frequently necessitating adjustments to meet petroleum feed requirements or market demands. Maintaining product quality, such as controlling gasoline ON, demands strategic adjustments and, if necessary, the utilization of additives like ethanol or MTBE, despite environmental constraints on the latter.

The industry seeks more efficient solutions to enhance blend scheduling practices. While simulation tools aid in comprehending complex processes, their adaptability to unforeseen events remains a challenge. Emerging optimization tools offer the potential to automate decision-making, reduce blend scheduling time, conduct inventory analysis, and address emergencies, thereby minimizing errors and enhancing feasibility. However, prevailing simulation approaches heavily rely on trial-and-error methods for blend-stock assignments, showcasing the ongoing need for refinement and improvement.

5.2. Emerging Technologies and Future Directions in Blend Scheduling for Petroleum Refining

Blend scheduling complexities also relate to under- or over-specification of product quality, which can lead to financial losses. Mitigating these concerns involves avoiding excessive quality in products (over-specification) and preventing re-processing or out-of-specification scenarios (under-specification). An efficient blend scheduling solution in refineries can provide a detailed monthly time-horizon, accounting for time-steps, precise blended quality, and logistics constraints, offering insights into spot market opportunities to sell surplus finished goods when contracted markets are fulfilled.

The blend scheduling process in petroleum refining encounters several challenges and areas for improvement across different hydrocarbon materials, including crude-oil, gasoline, and other distillates. Challenges persist in optimizing gasoline blend scheduling due to managing multiple orders, meeting delivery time windows, and accommodating varying product recipes. Challenges also arise in optimizing other distillates blend scheduling, particularly in diesel production, where improvements in interface identification constraints and interruptions handling are warranted. Challenges encompass refining operations across different hydrocarbon materials, proving the need for continued research and innovation to enhance scheduling practices in petroleum refining.

Blend scheduling in petroleum refining is evolving significantly, driven by the need for precise molecular tracking and optimization. Emerging technologies explore advancements in molecular blend scheduling within petroleum refineries. One significant direction involves integrating Industry 4.0-level precision into scheduling operations. This advancement focuses on refining raw materials, which consist of molecules varying from C1 to C80+ in carbon-chain structure. Separation processes segregate these molecules, particularly heavier streams with C30+ converted into smaller carbon-chain molecules through thermal and catalytic conversion processes, yielding valuable petroleum fractions like naphtha, kerosene, and diesel streams.

Blend scheduling challenges emerge from this complex process, termed as qualogistics, where molecular characteristics of input streams into process units matter. Modeling time for these operations is critical and involves two approaches: discrete-time, with uniform time discretization, and continuous-time, considering time as a continuous variable. While discrete-time simplifies coordination, continuous-time offers flexibility but poses challenges in execution coordination.

Future directions entail refining blend scheduling solutions using machine learning for predicting and optimizing properties like RON and MON (octane numbers), alongside refining algorithms to suit both continuous and batch blending topologies. This involves developing predictive models for properties using advanced regression techniques and integrating these predictions into blend scheduling solutions to cater to various process complexities.

The stages in the proposed research avenue in blend scheduling are as follows:

For a blender or blending unit, the MISO/MIMO OLSR-SVML predictions for RON and MON in both LP and NLP versions to be used in the MILP-NLP decomposition. In this case, there is no need to know the formulas as volume- and mass-based qualities for specific gravity and sulfur concentration.

Blend scheduling optimization for both continuous (simultaneous) and batch (sequential) mixtures. If this is continuous, then the approach presented by Kelly et al. [

15] is enough to be applied using factor-flow balances for known blending formulas or OLSR-SVML for unknown formulas. However, if the BS holds a batch mixture topology, one solution can be to solve a fictitious case of continuous blending to determine the quantities or amounts of each blending component or input to then solve the real batch mixture topology by using the quantities/amounts determined previously, as hard or soft bounds.

6. Conclusions

In conclusion, the surveyed literature on petroleum and distilled fuel blend scheduling in petroleum refinery operations provides valuable insights into various aspects of scheduling optimization. The papers address challenges such as integrating procurement and scheduling decisions, achieving spotting for increased profitability, selecting appropriate time-steps and time-horizons, and considering the trade-offs between simulation and optimization techniques. The authors also discuss the application of optimization methods to solve the blend scheduling MINLP to improve operational efficiency and resource utilization.

This paper highlights the importance of holistic decision-making by integrating planning and scheduling, considering real-world constraints and objectives, and leveraging advanced solving algorithms for blend scheduling in petroleum refineries. This research article emphasizes the potential benefits of optimization-based decisions, including improved operational efficiency, cost reduction, better coordination with sales and marketing, and capturing spot market opportunities. Additionally, the literature emphasizes the significance of high-quality process system engineering (PSE) solutions and the integration of blend design and process design to achieve high-performance operations.

Overall, the surveyed literature contributes to our understanding of blend scheduling optimization in industrial processes, providing insights and practical examples that can enhance operational efficiency and performance in the processing and petroleum refining industries. These studies highlight the value of considering real-world complexities, utilizing optimization techniques, and adopting a comprehensive approach to decision-making to achieve the desired blend scheduling outcomes.

Unaddressed development of blending formulas using surrogate or proxy modeling via basis-function sub-set selection to determine the causation–correlation pairs of the independent variables (input quantities) for prediction of RON and MON (dependent variables) or any other property allows the blend scheduling problems to become independent of knowing blending formulas. These formulas obtained via ordinary least square regression using supervised machine learning can be predicted as a linear version to be used in the MILP stage of the BS problem and as a nonlinear one to be used in the NLP stage or even in the simulation stage if the MINLP algorithm to be addressed uses successive-MILP algorithms as in [

15]. Moreover, the blend scheduling solution using predicted RON/MON formulas or any other property can be integrated into any BS topology in both continuous (simultaneous) and batch (sequential) mixtures. In the case of a batch mixture, one can first solve a fictitious case of continuous blending to use the amounts or quantities of the blending components/inputs as given values in the batch mixture problem in the following.