Research and Applications of New Fracturing Technology in Low-Abundance and Greater-Depth Well LN-1 Reservoirs

Abstract

1. Introduction

2. Geological Characteristics and Fracturing Difficulties of the LN Block

2.1. Geological Characteristics of the LN Block

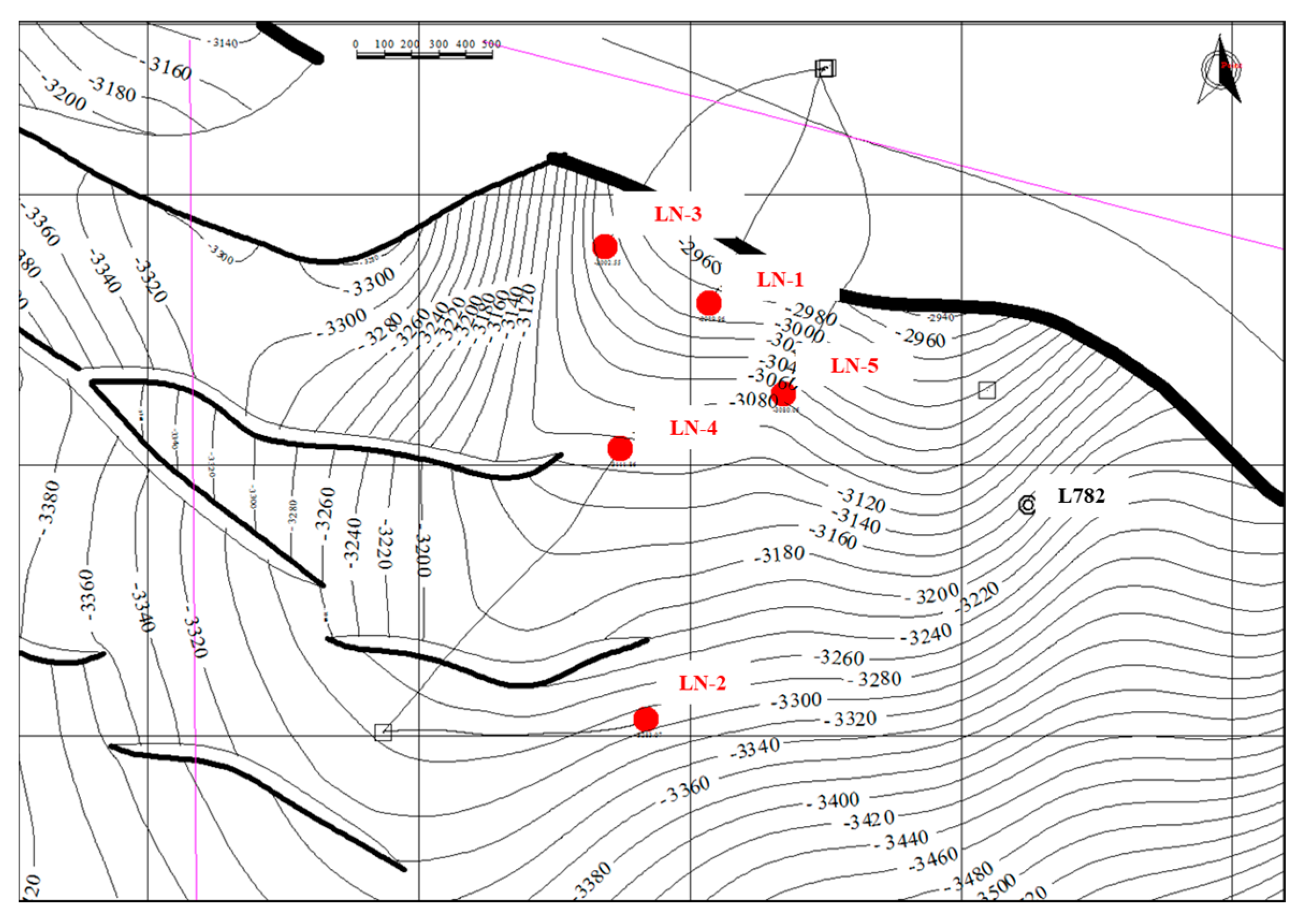

2.1.1. Structural Feature

2.1.2. Mineral Composition

2.1.3. Reservoir Characteristics

- (1)

- Permeability

- (2)

- Sensibility

- (3)

- Oil–water property

- (4)

- Temperature–pressure system

- (5)

- Sand body distribution

- (6)

- Reservoir stress analysis

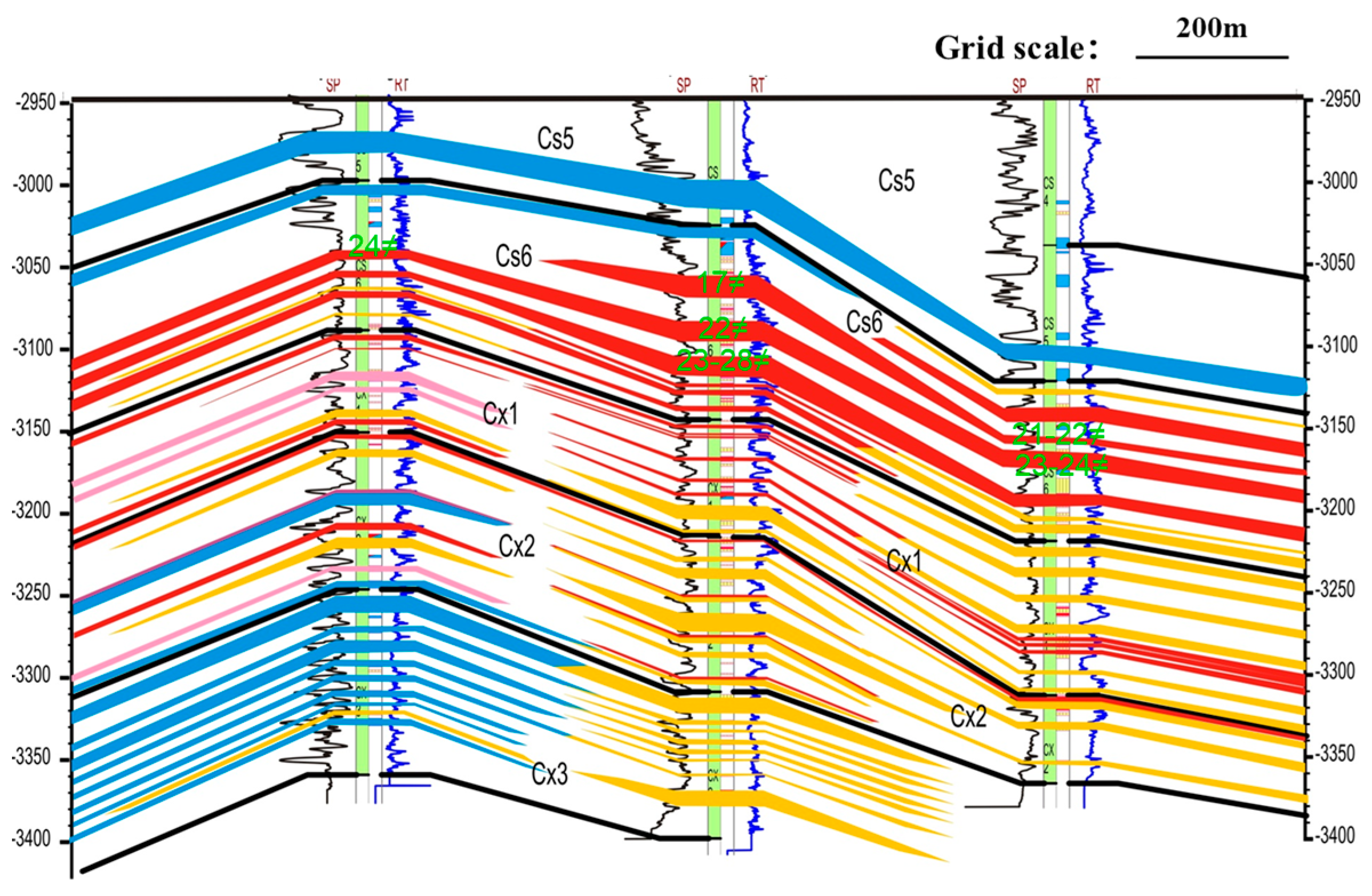

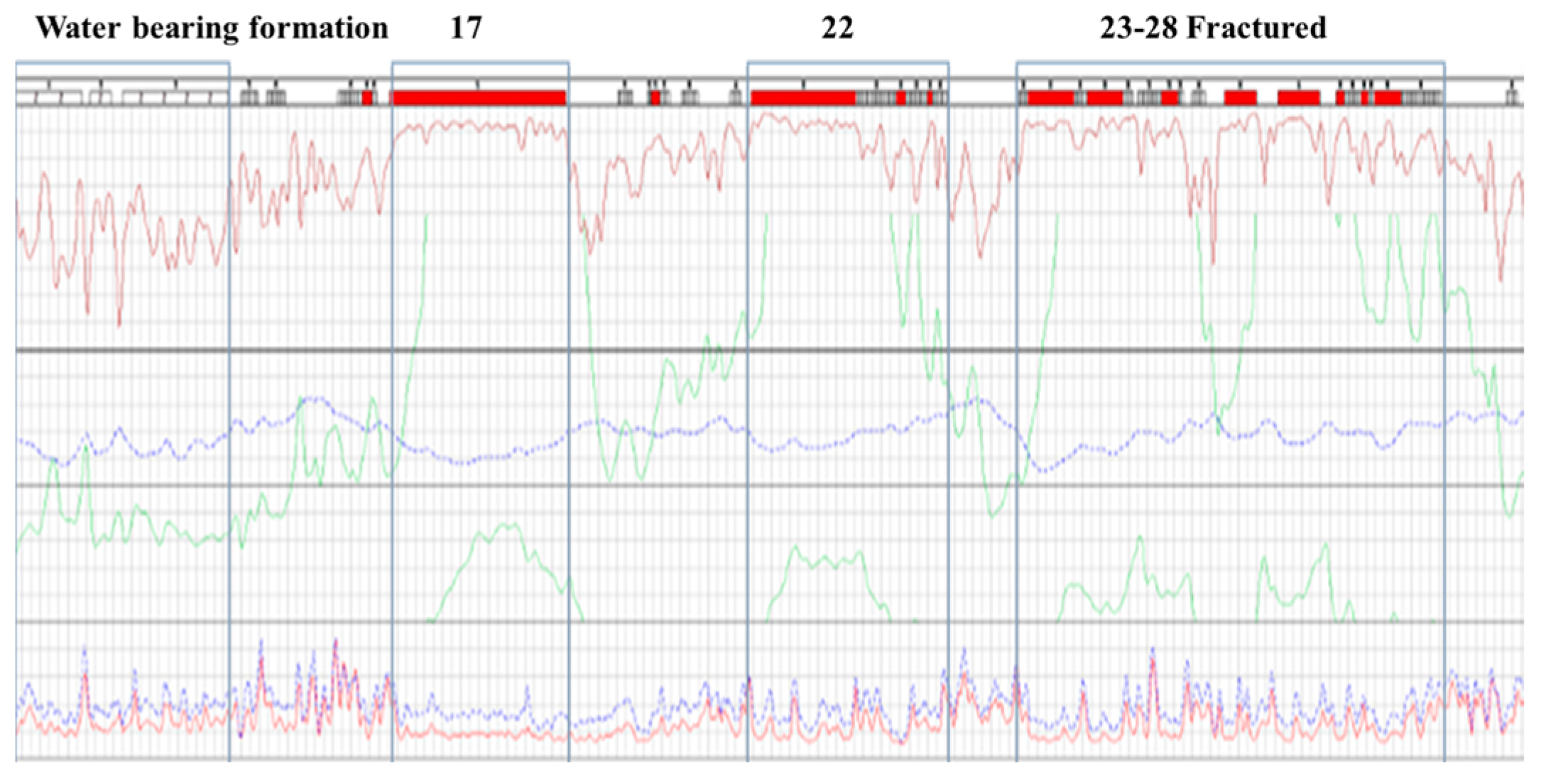

2.1.4. Logging Map of the LN-1 Well

2.2. Fracturing Difficulties of the LN Block

2.2.1. Analysis of the Adjacent Well Fracturing Situation

2.2.2. Fracturing Difficulties of the LN-1 Well

- (1)

- Poor material foundation was identified for the LN-1 well, and we encountered difficulty in stabilizing production after fracturing. This area is a deep low-abundance oil reservoir, and its productivity shows the declining law of typical low-permeability reservoirs. The initial production is high, the decline is fast, the natural energy of the reservoir is insufficient, the pressure drop is fast, and the annual decline rate of elastic development is 36.4~40.2%.

- (2)

- The effect of conventional fracturing process reform is poor. The well 23#–28# adopted the general fracturing process and produced 3756 t of oil in 6 years after fracturing. The longitudinal span of the reservoir is large, the difference between layers is large, the adaptability of large-scale general fracturing is poor, and the effective communication and transformation of each layer cannot be guaranteed.

- (3)

- Stage fracturing has achieved a certain stimulation effect, but when limited by the scale of fracturing reconstruction, the stimulation effect is poor. According to the fracturing effect of multiple intervals in adjacent oil wells, it is concluded that under the condition that the thickness of the reservoir and the amount of sand added are not different, the multi-stage fracturing shows a better oil increase effect. In the LN-5 well with the same sand body as this well, the CS6 effective thickness is 10.2, and sand body thickness is 18.3 m, and the sand addition is 25 m3. The fracturing scale is small, which has a certain impact on the later production capacity.

- (4)

- The reservoir in this block has moderate water sensitivity and a pressure coefficient of 1.03, which is not conducive to the flowback of fracturing fluid after fracturing.

- (5)

- The thickness of the reconstructed sand body is large, and the well-logging data show that the sand body is highly different. It is necessary to consider the influence of perforation sweet spot selection and proppant settlement in the fracture on the flow conductivity.

3. Key Technology of Fracturing Stimulation in the LN-1 Well

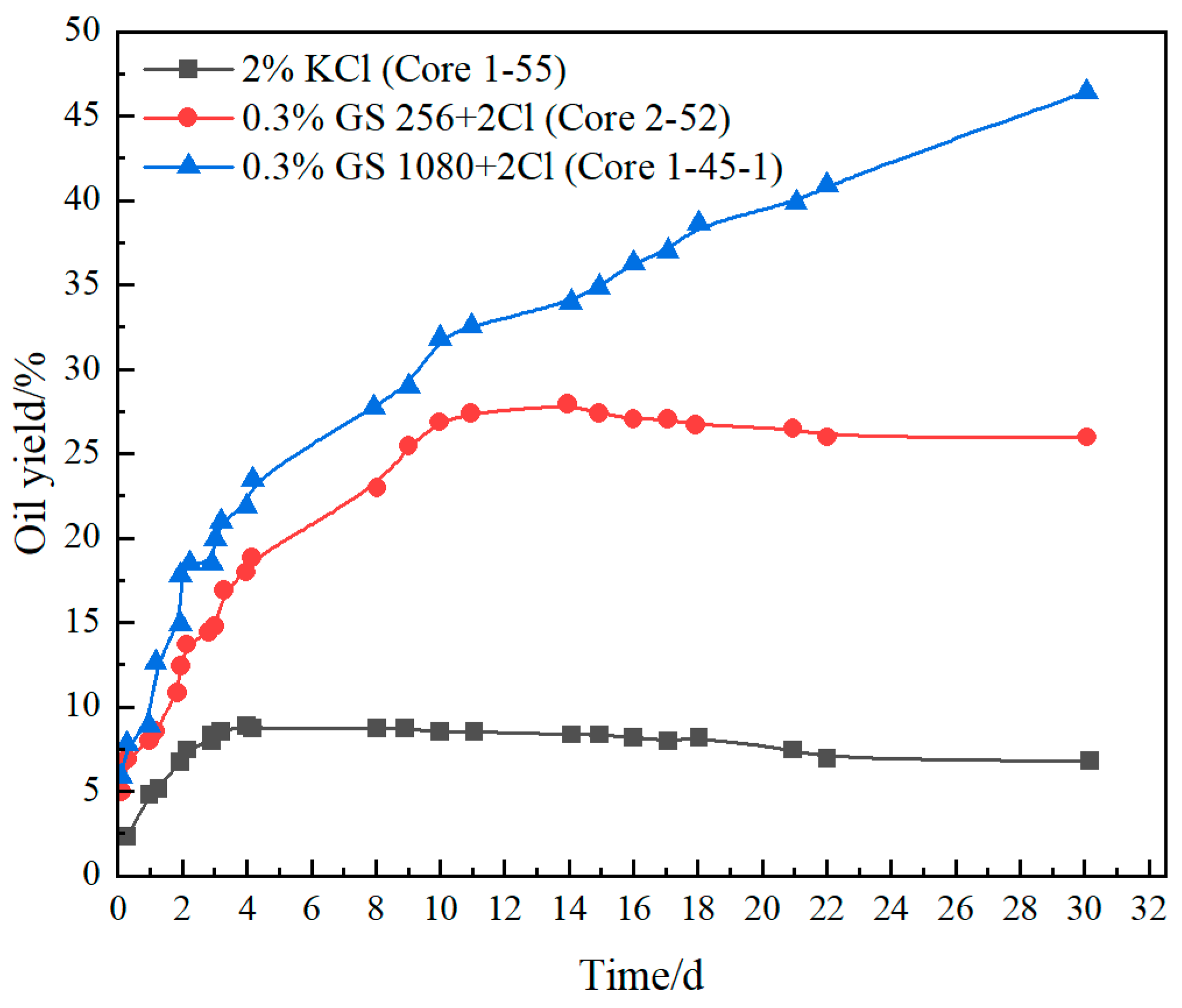

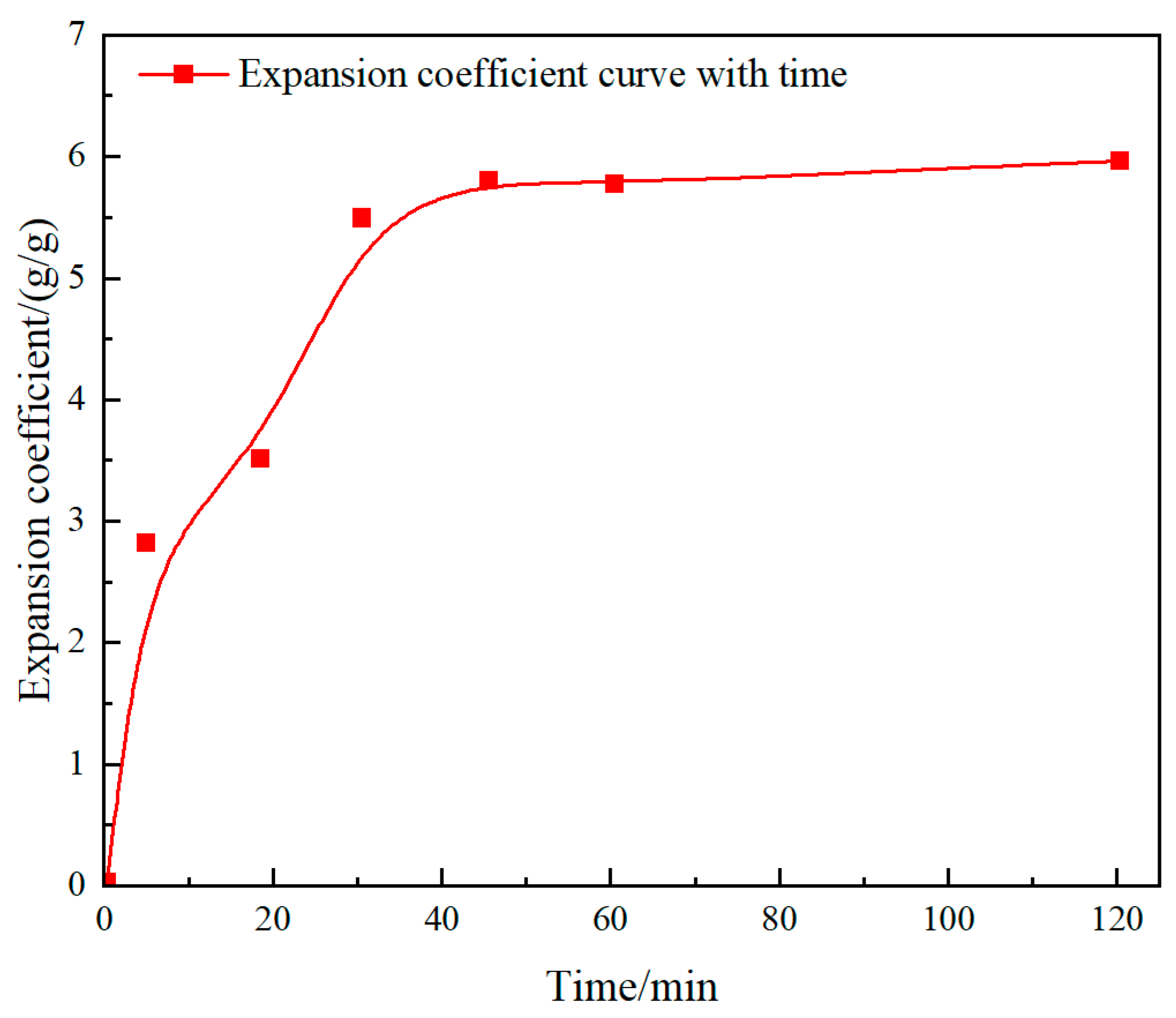

3.1. New High-Efficiency Stimulation Fracturing Fluid System

3.1.1. Reason for Adoption

3.1.2. New High-Efficiency Stimulation Fracturing Fluid System

- (1)

- (2)

- The reservoir rock wettability is changed. By reducing the adsorption of crude oil on the rock surface and changing the surface wettability, the water-phase capillary force is enhanced, the self-imbibition rate is increased, the existing oil/water balance is broken, and crude oil production is increased.

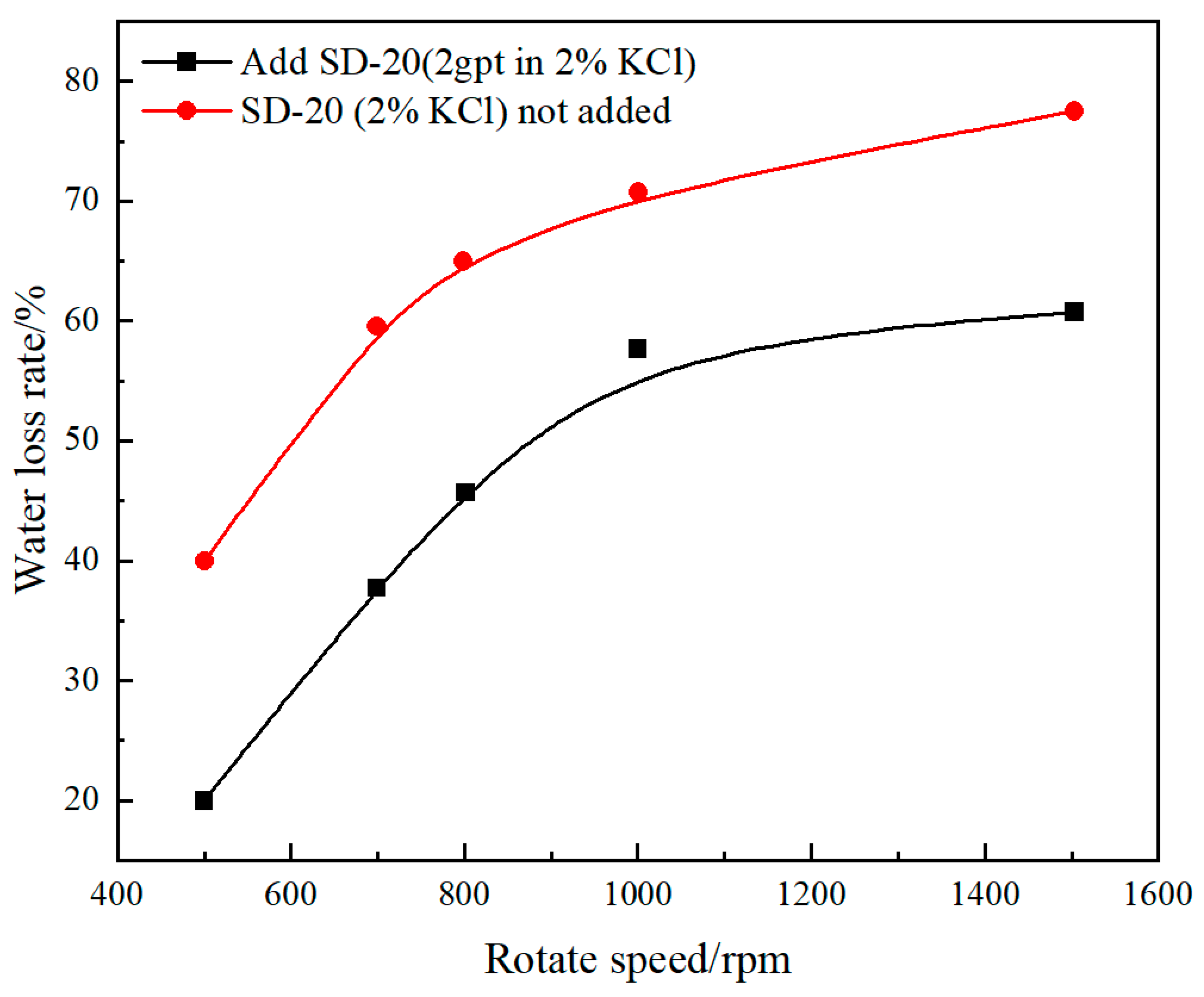

3.1.3. Optimization of Discharge Aid

3.1.4. Surfactant Optimization

- (1)

- It meets the fracturing fluid fracture-making and sand-carrying performance requirements.

- (2)

- It can effectively reduce the resistance brought by the adsorption force of fracturing residual fluid.

- (3)

- It has lower surface tension and effective change in wettability.

- (4)

- It effectively helps to clean the residual oil adsorbed in the rock.

- (5)

- In this research, the added efficient discharge aid and surfactant do not contain fluorocarbon, environmental protection, and are pollutant-free.

3.2. Cluster Perforating Process

3.3. High Diversion Channel Fracturing

3.3.1. Reason for Adoption

- (1)

- To reduce the proppant settling rate, improve the proppant placement effect in the fracture, and increase the propping fracture height.

- (2)

- To change the “surface” support to “point” support, greatly improving the fracture conductivity.

- (3)

- The amount of proppant in high-speed channel fracturing is about 70% of that in conventional processes, saving construction costs.

3.3.2. Fiber Optimization

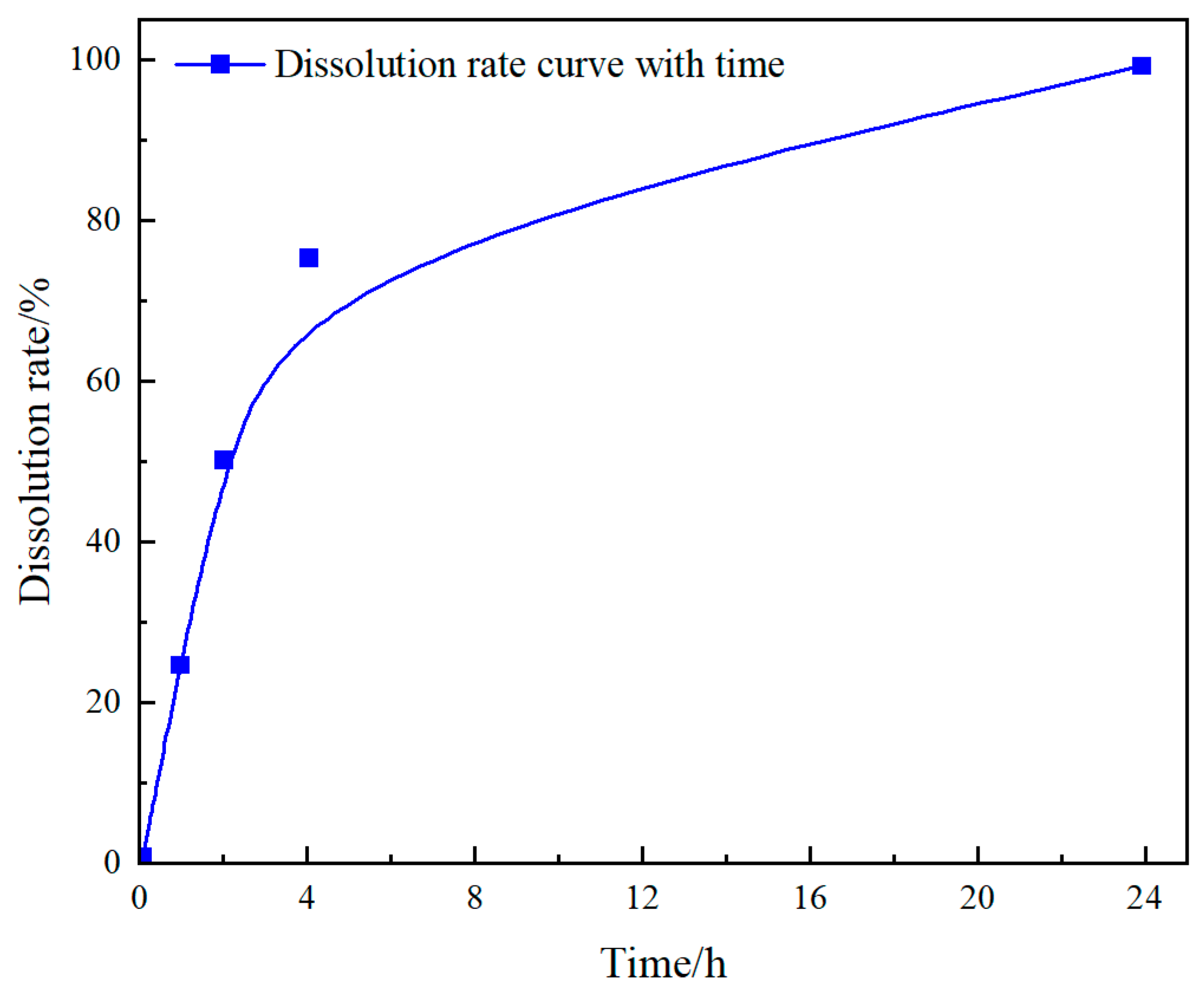

3.4. Temporary Plugging to Fracturing Technology

3.4.1. Reason for Adoption

- (1)

- Temporary plugging in the joint can form complex cracks. The sand body of the target layer is thinned to the east and west and peaked out in the northwest direction of 17# (shown in Figure 2). If a single long fracture is formed in this kind of reservoir, the stimulation effect is limited. By adopting the process of in-seam temporary plugging, the cracks are forced to form complex cracks, and the spread width of the crack system is increased to improve the transformation effect [38,39].

- (2)

- The inter-cluster (layer) temporary plugging technology can improve the uniformity of reservoir longitudinal reconstruction. Layer 17# uses centralized perforation, which does not require temporary inter-cluster plugging. The physical properties of layer 22# are very different, and there is a stress difference of about 4 MPa. In the construction, the low-stress part is pressed open first. If no temporary plugging is carried out, the majority of fracturing fluid may enter the low-stress layer, while the high-stress layer does not allow even a small amount of fracturing fluid to enter, resulting in inadequate and uneven transformation.

3.4.2. Temporary Plugging Agent Type Optimization

3.4.3. Particle Size Optimization of Temporary Plugging Agent

3.4.4. Optimization of Temporary Plugging Agent Dosage

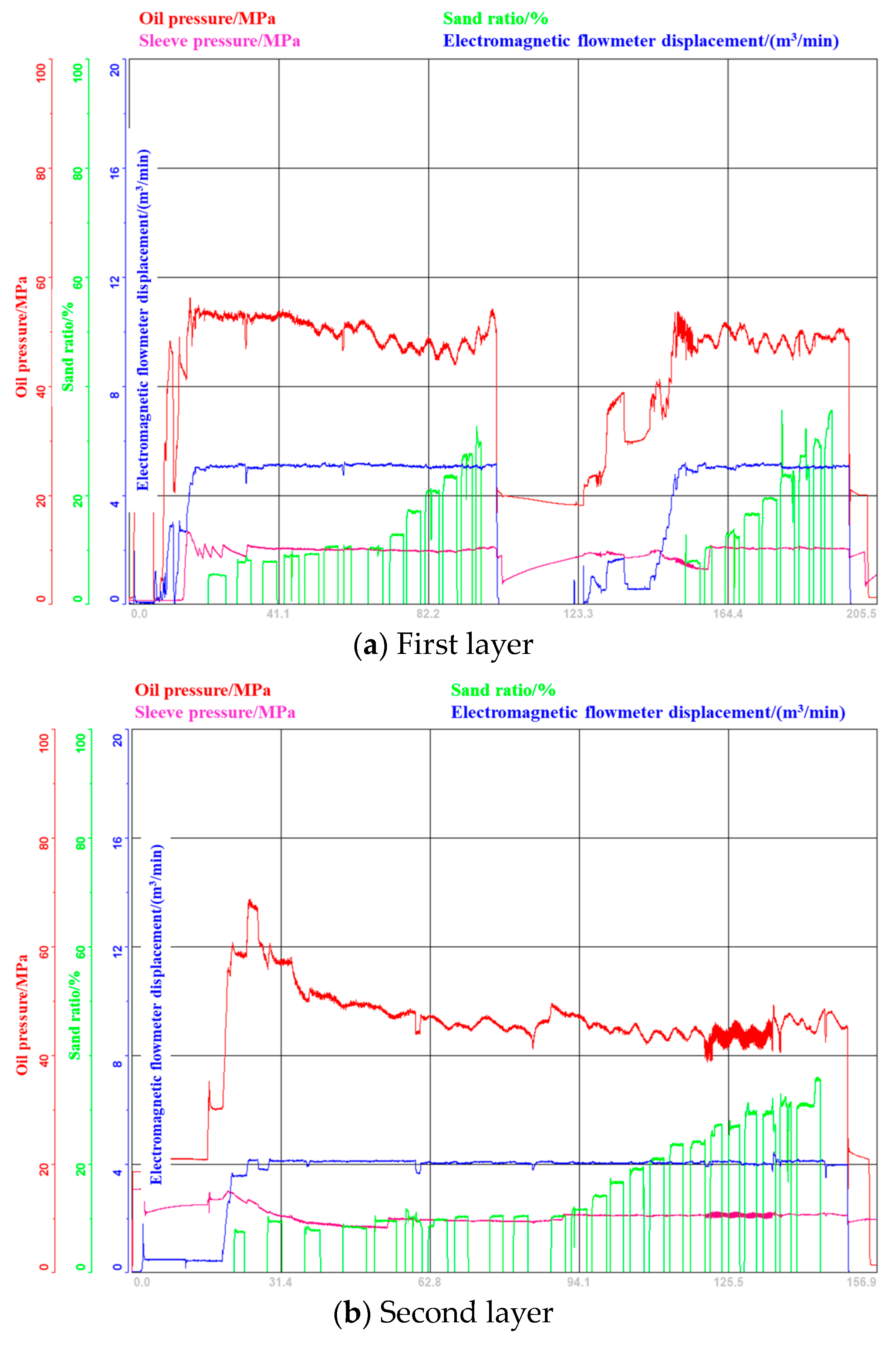

4. Construction Process and Effect

5. Conclusions

- (1)

- Laboratory experiments show that the new high-efficiency stimulation fracturing fluid flowback rate is 15–19% higher than the conventional fracturing fluid system, and the oil washing efficiency is 46.5%. The new high-efficiency stimulation fracturing fluid system has the effect of low damage, changing oil reservoir wettability, and has better adaptability to this kind of oilfield with low natural energy and water sensitivity.

- (2)

- According to the temporary plugging and turning fracturing process optimized at the spread point of the sand body in well LN-1, obvious pressure rise was seen in each addition of the temporary plugging agent in the middle fracture and the interlayer temporary plugging agent, which played a role in sealing the old fracture and increasing the net pressure in the fracture to open the new fracture.

- (3)

- The LN block is a low-abundance and greater-depth reservoir with weak natural energy and elastic development, and the conventional fracturing effect is poor. The new fracturing stimulation series technology has achieved good test results in the well LN-1, which can provide technical guidance for the efficient development of low-abundance, deeper, and difficult-to-develop oil reservoirs.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, L.J.; Sun, T.W.; Han, X.B.; Shi, J.C.; Zhang, J.S.; Tang, H.T.; Yu, H.Y. Feasibility of advanced CO2 injection and well pattern adjustment to improve oil recovery and CO2 storage in tight-oil reservoirs. Processes 2023, 11, 3104. [Google Scholar] [CrossRef]

- Cao, A.Q.; Li, Z.M.; Zheng, L.; Bai, H.; Zhu, D.; Li, B.F. Nuclear magnetic resonance study of CO2 flooding in tight oil reservoirs: Effects of matrix permeability and fracture. Geoenergy Sci. Eng. 2023, 225, 211692. [Google Scholar] [CrossRef]

- Bao, M.T.; Kong, X.P.; Jiang, G.C.; Wang, X.L.; Li, X.M. Laboratory study on activating indigenous microorganisms to enhance oil recovery in Shengli Oilfield. J. Pet. Sci. Eng. 2009, 66, 42–46. [Google Scholar] [CrossRef]

- Li, C.F.; Li, Y.; Li, X.M.; Cao, Y.B.; Song, Y.T. The Application of microbial enhanced oil recovery technology in Shengli Oilfield. Pet. Sci. Technol. 2015, 33, 556–560. [Google Scholar] [CrossRef]

- Cui, Q.F.; Sun, S.S.; Luo, Y.J.; Yu, L.; Zhang, Z.Z. Comparison of in-situ and ex-situ microbial enhanced oil recovery by strain Pseudomonas aeruginosa WJ-1 in laboratory sand-pack columns. Pet. Sci. Technol. 2017, 35, 2044–2050. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, J.; Zhang, L.Q.; Han, Z.H. Numerical investigation of injection-induced fracture propagation in brittle rocks with two injection wells by a modified fluid-mechanical coupling model. Energies 2020, 13, 4718. [Google Scholar] [CrossRef]

- Wang, B.; Fang, Y.; Li, L.Z.; Liu, Z. Automatic optimization of multi-well multi-stage fracturing treatments combining geomechanical simulation, reservoir simulation and intelligent algorithm. Processes 2023, 11, 1759. [Google Scholar] [CrossRef]

- Lu, C.; Ma, L.; Guo, J.C.; Zhao, L.; Xu, S.Q.; Chen, B.G.; Zhou, Y.L.; Yuan, H.R.; Tang, Z.B. Fracture parameters optimization and field application in low-permeability sandstone reservoirs under fracturing flooding conditions. Processes 2023, 11, 285. [Google Scholar] [CrossRef]

- Kong, X.W.; Wan, X.; Li, S.; Liu, Z.C.; Chen, M.Z.; Shen, J.W. Experimental evaluation and optimization of improved conductivity of gelling acid etched fractures in deep, low-permeability reservoirs. Fuel 2023, 348, 128468. [Google Scholar] [CrossRef]

- Wu, B.L.; Wu, G.A.; Wang, L.; Lou, Y.S.; Liu, S.Y.; Yin, B.; Li, S.Z. Study on fracturing parameters optimization of horizontal wells in low-permeability reservoirs in South China Sea. Processes 2023, 11, 2999. [Google Scholar] [CrossRef]

- Cheng, B.Y.; Li, J.J.; Li, J.Q.; Su, H.; Tang, L.H.; Yu, F.W.; Jiang, H.Q. Pore-scale formation damage caused by fracturing fluids in low-permeability sandy conglomerate reservoirs. J. Pet. Sci. Eng. 2022, 208, 109301. [Google Scholar] [CrossRef]

- Li, X.; Chen, X.; Xu, Z.H.; Pu, C.S. A novel foam flooding for enhanced oil recovery in fractured low-permeability reservoirs: Performance evaluation and mechanism study. SPE J. 2022, 27, 2408–2424. [Google Scholar] [CrossRef]

- Li, N.Y.; Chen, F.; Yu, J.J.; Han, P.H.; Kang, J. Pre-acid system for improving the hydraulic fracturing effect in low-permeability tight gas reservoir. J. Pet. Explor. Prod. 2021, 11, 1761–1780. [Google Scholar] [CrossRef]

- Li, N.Y.; Zhu, S.J.; Li, Y.; Zhao, J.R.; Long, B.; Chen, F.; Wang, E.Z.; Feng, W.T.; Hu, Y.N.; Wang, S.B.; et al. Fracturing-flooding technology for low permeability reservoirs: A review. Petroleum 2023, in press. [CrossRef]

- Liu, W.C.; Zhang, Q.T.; Zhu, W.Y. Numerical simulation of multi-stage fractured horizontal well in low-permeable oil reservoir with threshold pressure gradient with moving boundary. J. Pet. Sci. Eng. 2019, 178, 1112–1127. [Google Scholar] [CrossRef]

- Wang, J.; Xie, H.P.; Matthai, S.K.; Hu, J.J.; Li, C.B. The role of natural fracture activation in hydraulic fracturing for deep unconventional geo-energy reservoir stimulation. Pet. Sci. 2023, 20, 2141–2164. [Google Scholar] [CrossRef]

- Guo, T.K.; Gong, F.C.; Shen, L.; Qu, Z.Q.; Qi, N.; Wang, T. Multi-fractured stimulation technique of hydraulic fracturing assisted by radial slim holes. J. Pet. Sci. Eng. 2019, 174, 572–583. [Google Scholar] [CrossRef]

- Liu, X.F.; Jia, X.Q.; Niu, Y.; Nie, B.S.; Zhang, C.P.; Song, D.Z. Alterations in coal mechanical properties and permeability influenced by liquid CO2 phase change fracturing. Fuel 2023, 354, 129254. [Google Scholar] [CrossRef]

- Liang, T.B.; Wei, D.Y.; Zhou, F.J.; Li, X.H.; Yuan, L.S.; Wang, B.; Lu, J. Field experiments on multi-stage chemical diversion in low-permeability HPHT reservoirs. J. Pet. Sci. Eng. 2020, 187, 106738. [Google Scholar] [CrossRef]

- Zhao, L.Q.; Chen, Y.X.; Du, J.; Liu, P.L.; Li, N.Y.; Luo, Z.F.; Zhang, C.C.; Huang, F.S. Experimental study on a new type of self-propping fracturing technology. Energy 2019, 183, 249–261. [Google Scholar] [CrossRef]

- Veliev, M.M. Specifics of cyclic water flooding for development systems made up with horizontal wells. Neft. Khoz. Oil Ind. J. 2021, 7, 86–89. [Google Scholar]

- Bi, G. Structural design and flow field characteristics analysis of a new spin-on multi-hole jet drill bit for radial horizontal wells. Geoenergy Sci. Eng. 2023, 230, 212173. [Google Scholar] [CrossRef]

- Zhang, C.; Song, Z.Y.; Zhao, Y.X. Staged multicluster hydraulic fracture propagation mechanism and its influencing factors in horizontal wells for CBM development. Energy Sci. Eng. 2023, 11, 448–462. [Google Scholar] [CrossRef]

- Qi, N.; Chen, G.B.; Liang, C.; Guo, T.K.; Liu, G.L.; Zhang, K. Numerical simulation and analysis of the influence of fracture geometry on wormhole propagation in carbonate reservoirs. Chem. Eng. Sci. 2019, 198, 124–143. [Google Scholar] [CrossRef]

- Gao, M.W.; Zhang, M.S.; Du, H.Y.; Zhao, M.W.; Dai, C.L.; You, Q.; Liu, S.; Jin, Z.H. A novel triple responsive smart fluid for tight oil fracturing-oil expulsion integration. Petrol. Sci. 2023, 20, 982–992. [Google Scholar] [CrossRef]

- Wu, B.C.; Ma, X.F.; Li, J.M.; Tian, G.; Xiong, D.; Zou, Y.S.; Zhang, S.C. Numerical simulation of fracture propagation of multi-cluster perforation and fracturing in horizontal wells: A case study of Mahu oilfield. Energies 2022, 15, 5579. [Google Scholar] [CrossRef]

- Xing, X.S.; Wu, G.G.; Zhou, J.; Zhang, A.S.; Hou, Y.N.; Xie, X.; Wu, J.S.; Kong, X.W.; Li, S. Finite element study on the initiation of new fractures in temporary plugging fracturing. Front. Phys. 2023, 11, 1227917. [Google Scholar] [CrossRef]

- Qi, M.; Yang, E.; Liu, Y.; Dong, C.; Chen, X. Research and application of a controllable permeability refracturing technology in a high- water- cut potential layer. SPE Prod. Oper. 2023, 38, 478–489. [Google Scholar] [CrossRef]

- Tao, X.J.; Gan, M.Z.; Yao, Z.H.; Bai, J.W.; Yang, M.Z.; Su, G.D.; Zheng, L.H. Enhancing the production of tight sandstone gas well through fuzzy-ball fluid temporary plugging with diverting fractures and water cutting after refracturing in one operation. J. Pet. Sci. Eng. 2022, 217, 110883. [Google Scholar] [CrossRef]

- Li, X.J.; Zhang, Q.J.; Liu, P.; Li, T.; Liu, G.F.; Liu, Z.K.; Zhao, H.F. Investigation on the microscopic damage mechanism of fracturing fluids to low-permeability sandstone oil reservoir by nuclear magnetic resonance. J. Pet. Sci. Eng. 2022, 209, 109821. [Google Scholar] [CrossRef]

- Chen, M.J.; Yan, M.L.; Kang, Y.L.; Fang, S.D.; Liu, H.; Wang, W.H.; Shen, J.K.; Chen, Z.Q. Shale formation damage during fracturing fluid imbibition and flowback process considering adsorbed methane. Energies 2022, 15, 9176. [Google Scholar] [CrossRef]

- Shao, J.X.; You, L.J.; Kang, Y.L.; Chen, M.J.; Tian, J. Salinity of flowback fracturing fluid in shale reservoir and its reservoir damage: Experimental and field study. J. Pet. Sci. Eng. 2022, 211, 110217. [Google Scholar] [CrossRef]

- Wang, J.; Huang, Y.; Zhang, Y.; Zhou, F.; Yao, E.; Wang, R. Study of fracturing fluid on gel breaking performance and damage to fracture conductivity. J. Pet. Sci. Eng. 2020, 193, 107443. [Google Scholar] [CrossRef]

- Lei, Q.; Yang, Z.W.; Weng, D.W.; Liu, H.T.; Guan, B.S.; Cai, B.; Fu, H.F.; Liu, Z.L.; Duan, Y.Y.; Liang, T.C.; et al. Techniques for improving fracture-controlled stimulated reservoir volume in ultra-deep fractured tight reservoirs: A case study of Kuqa piedmont clastic reservoirs, Tarim Basin, NW China. Petrol. Explor. Dev. 2022, 49, 1169–1184. [Google Scholar] [CrossRef]

- Liu, C.; Li, Y.Y.; Wang, P.; Jiao, H.Y.; Yao, X.T.; Zhao, G.; Dai, C.L.; You, Q. Preparation and performance evaluation of nano-composite fracturing fluid with good oil displacement ability in tight reservoir. J. Mol. Liq. 2022, 367, 120494. [Google Scholar] [CrossRef]

- Guo, X.Q.; Liu, J.; Du, Z.G.; Tang, K.; Cao, D.Y.; He, Z.Q. Mechanical characteristics of cluster perforation string under running process in horizontal wells with unconventional oil/gas reservoirs. SPE. Prod. Oper. 2022, 37, 664–680. [Google Scholar] [CrossRef]

- Fan, Q.H.; Ma, Y.G.; Wang, J.P.; Chen, L.; Ye, Z.Q.; Xu, Y.J.; Li, H.; Wang, B. Investigation into the perforation optimization in conglomerate reservoir based on a field test. Processes 2023, 11, 2446. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhang, H.; Feng, Y.H.; Li, J.L.; Yang, Y.; She, J.P. A composite temporary plugging technology for hydraulic fracture diverting treatment in gas shales: Using degradable particle/powder gels (DPGs) and proppants as temporary plugging agents. J. Pet. Sci. Eng. 2022, 216, 110851. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, C.L.; Yi, X.Y.; Li, L.; Chen, W.H.; Han, X. Technology and application of segmented temporary plugging acid fracturing in highly deviated wells in ultradeep carbonate reservoirs in Southwest China. ACS Omega 2020, 5, 25009–25015. [Google Scholar] [CrossRef]

| Well | Modified Horizon | Time | Perforation Thickness (m) | Span (m) | Sand Addition (m3) | Sand Strength (m3/m) | Daily Fluid Production (t) | Daily Oil Production (t) | Number of Stages |

|---|---|---|---|---|---|---|---|---|---|

| LN-4 | CX1 | 2008.11 | 6.5 | 14 | 26.3 | 1.9 | 8.5 | 7 | once |

| LN-1 | CS6 | 2012.05 | 21 | 32.6 | 80 | 2.5 | 8.4 | 5.4 | once |

| LN-5 | CX1+2 | 2012.02 | 14.6 | 14.9 | 60 | 4.0 | 5.0 | 3.1 | once |

| LN-5 | CS6 | 2012.10 | 9 | 29.1 | 65 | 2.2 | 13.3 | 7.8 | Tier 2 |

| LN-3 | CX1+S6 | 2012.12 | 12 | 17.6 | 75.4 | 4.3 | 14 | 13.1 | Tier 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, M.; Chen, D.; Wang, L.; Wang, T.; Song, W.; Wang, J. Research and Applications of New Fracturing Technology in Low-Abundance and Greater-Depth Well LN-1 Reservoirs. Processes 2024, 12, 482. https://doi.org/10.3390/pr12030482

Shi M, Chen D, Wang L, Wang T, Song W, Wang J. Research and Applications of New Fracturing Technology in Low-Abundance and Greater-Depth Well LN-1 Reservoirs. Processes. 2024; 12(3):482. https://doi.org/10.3390/pr12030482

Chicago/Turabian StyleShi, Minghua, Dechun Chen, Liangliang Wang, Tengfei Wang, Wei Song, and Jiexiang Wang. 2024. "Research and Applications of New Fracturing Technology in Low-Abundance and Greater-Depth Well LN-1 Reservoirs" Processes 12, no. 3: 482. https://doi.org/10.3390/pr12030482

APA StyleShi, M., Chen, D., Wang, L., Wang, T., Song, W., & Wang, J. (2024). Research and Applications of New Fracturing Technology in Low-Abundance and Greater-Depth Well LN-1 Reservoirs. Processes, 12(3), 482. https://doi.org/10.3390/pr12030482