Evolution of Rheological and Microscopic Properties of Asphalt Binders under Fuel Corrosion

Abstract

1. Introduction

1.1. Background

1.2. Literature Review

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Test Sample

- (1)

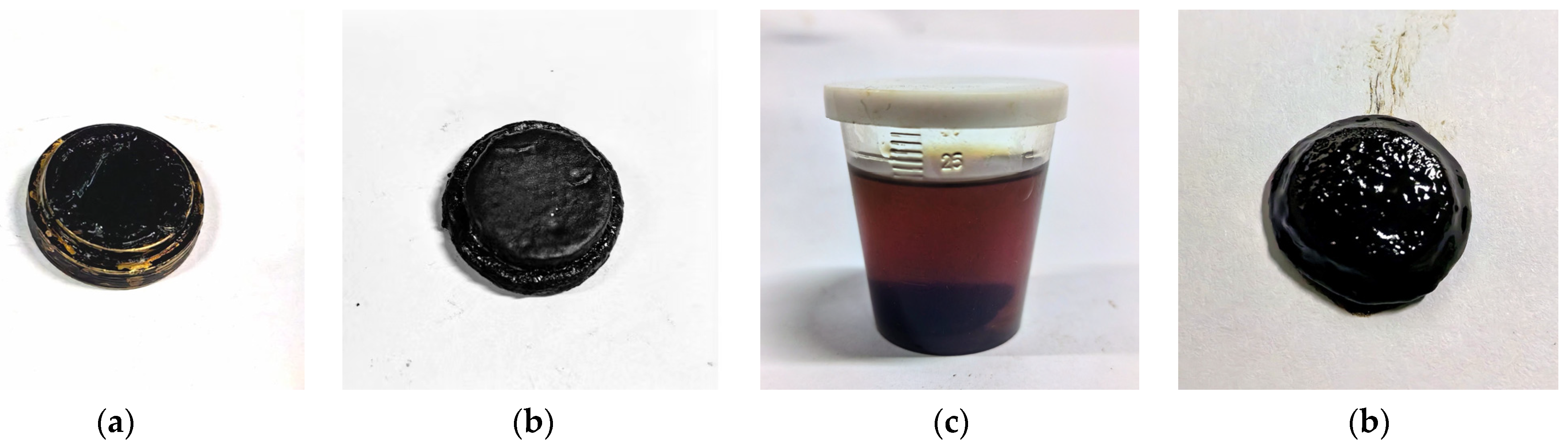

- The asphalt samples were prepared and demolded at 25 °C and used as original samples, as shown in Figure 1a,b.

- (2)

- The samples were immersed in a 100 mL beaker containing 20 mL of 0# diesel fuel, as shown in Figure 1c.

- (3)

- After durations of 1 h, 2 h, 4 h, 8 h, and 24 h, the samples were removed from the beaker, wiped with filter paper, and dried for 2 h at 25 °C to sample different degrees of fuel corrosion damage, as shown in Figure 1d.

2.3. Test Methods

2.3.1. The Mass Loss Test

2.3.2. The Dynamic Shear Rheometer (DSR) Test

2.3.3. The Multiple Stress Creep Recovery (MSCR) Test

2.3.4. The Bending Beam Rheometer (BBR) Test

2.3.5. Morphological Observation

2.3.6. Fourier Transform Infrared Spectroscopy (FTIR) Test

2.3.7. Asphalt Four-Component Test

3. Results and Discussion

3.1. The Mass Loss Test

3.2. Rheological Properties

3.2.1. DSR Tests

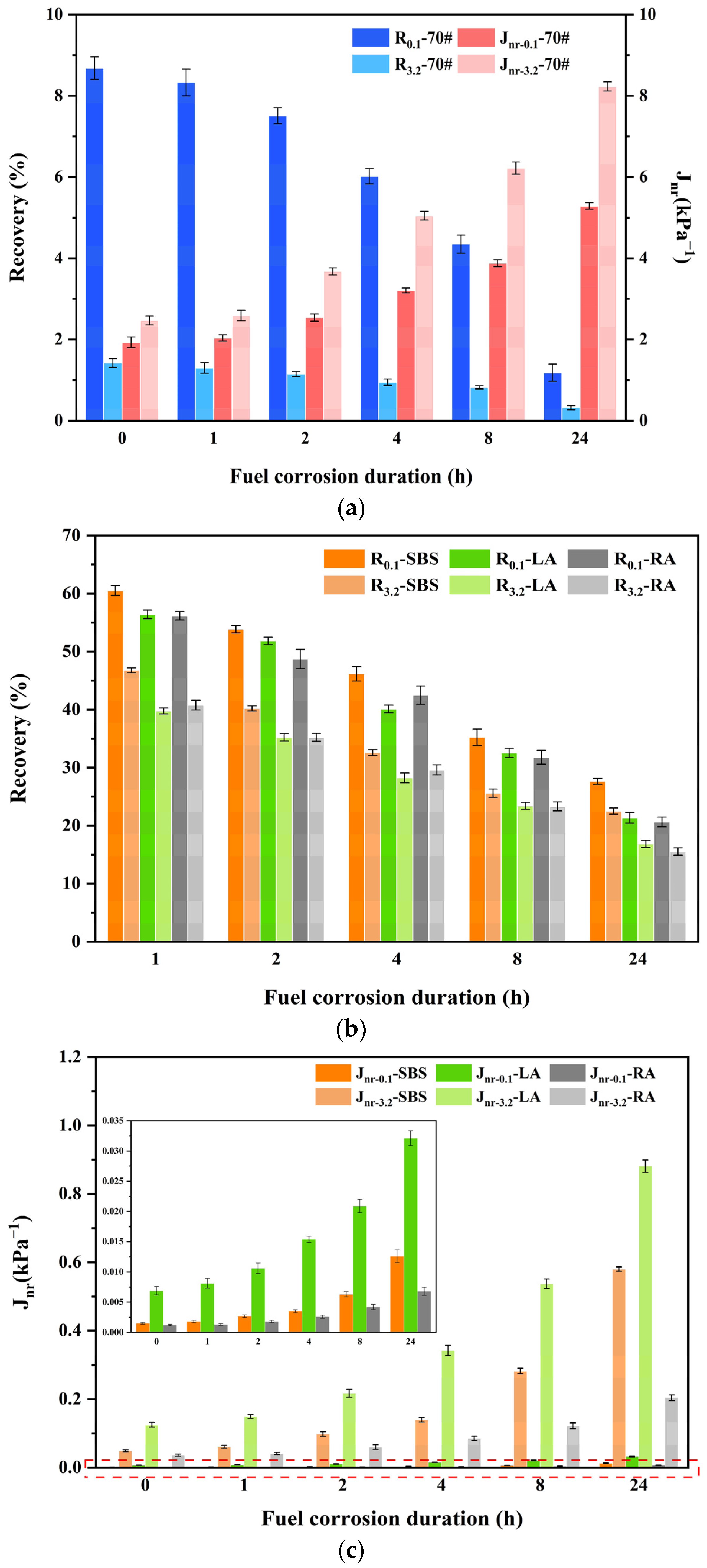

3.2.2. MSCR Tests

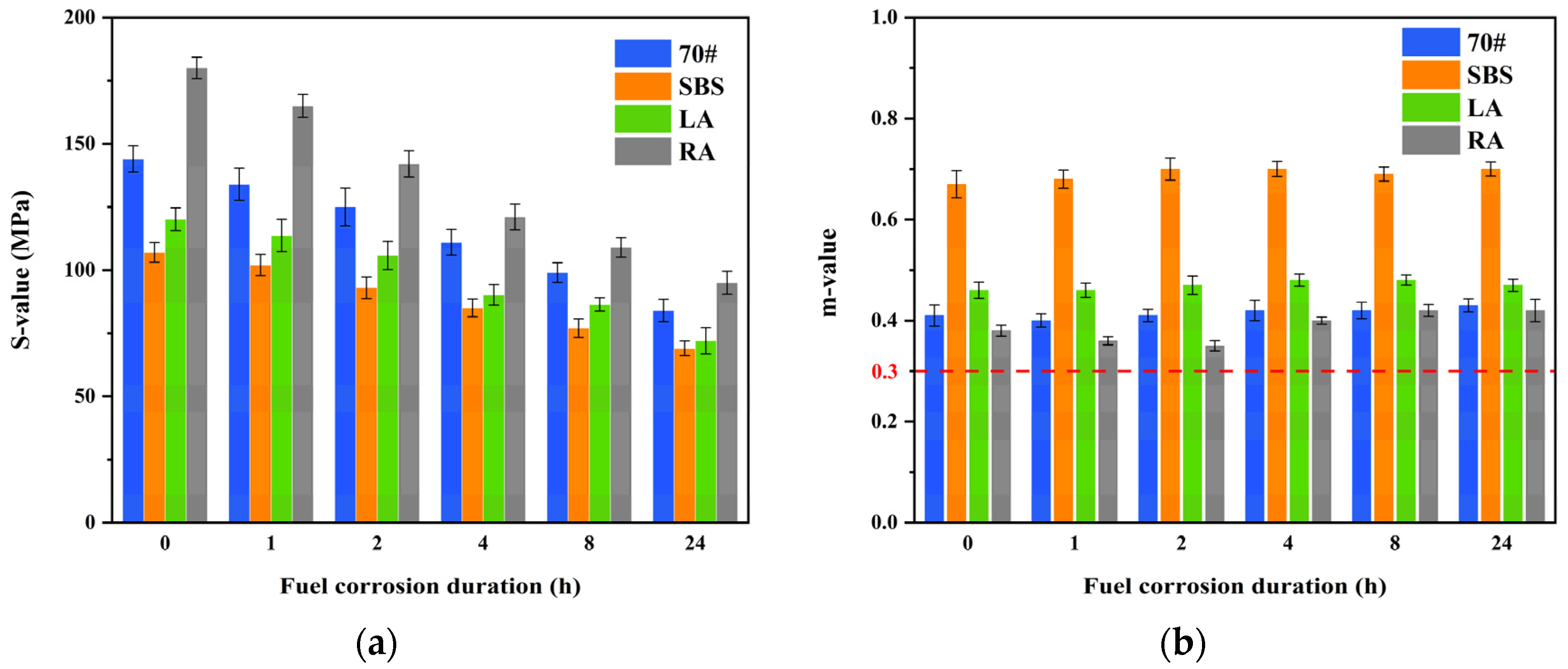

3.2.3. BBR Tests

3.3. Microscopic Mechanisms

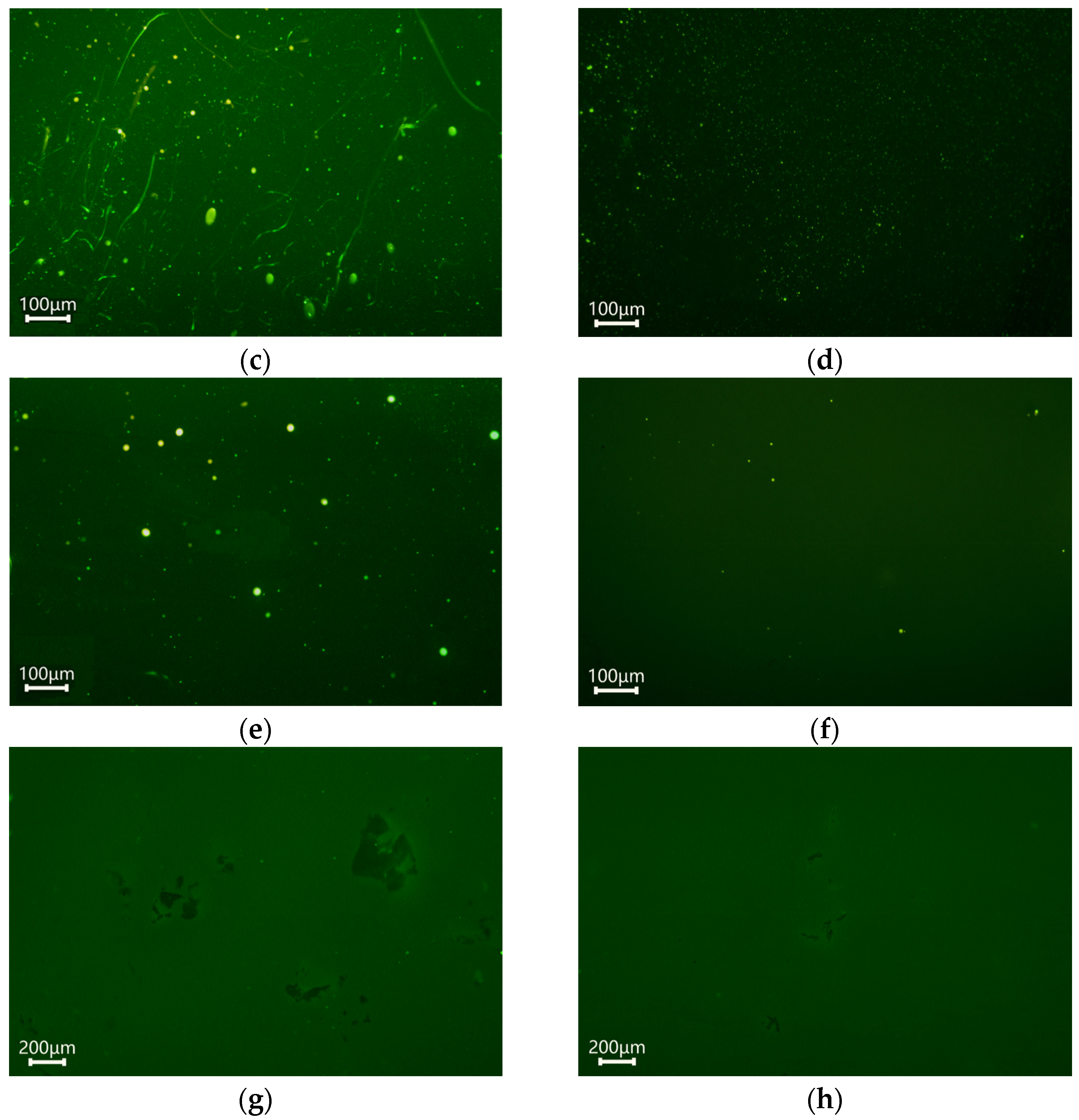

3.3.1. Morphological Observations

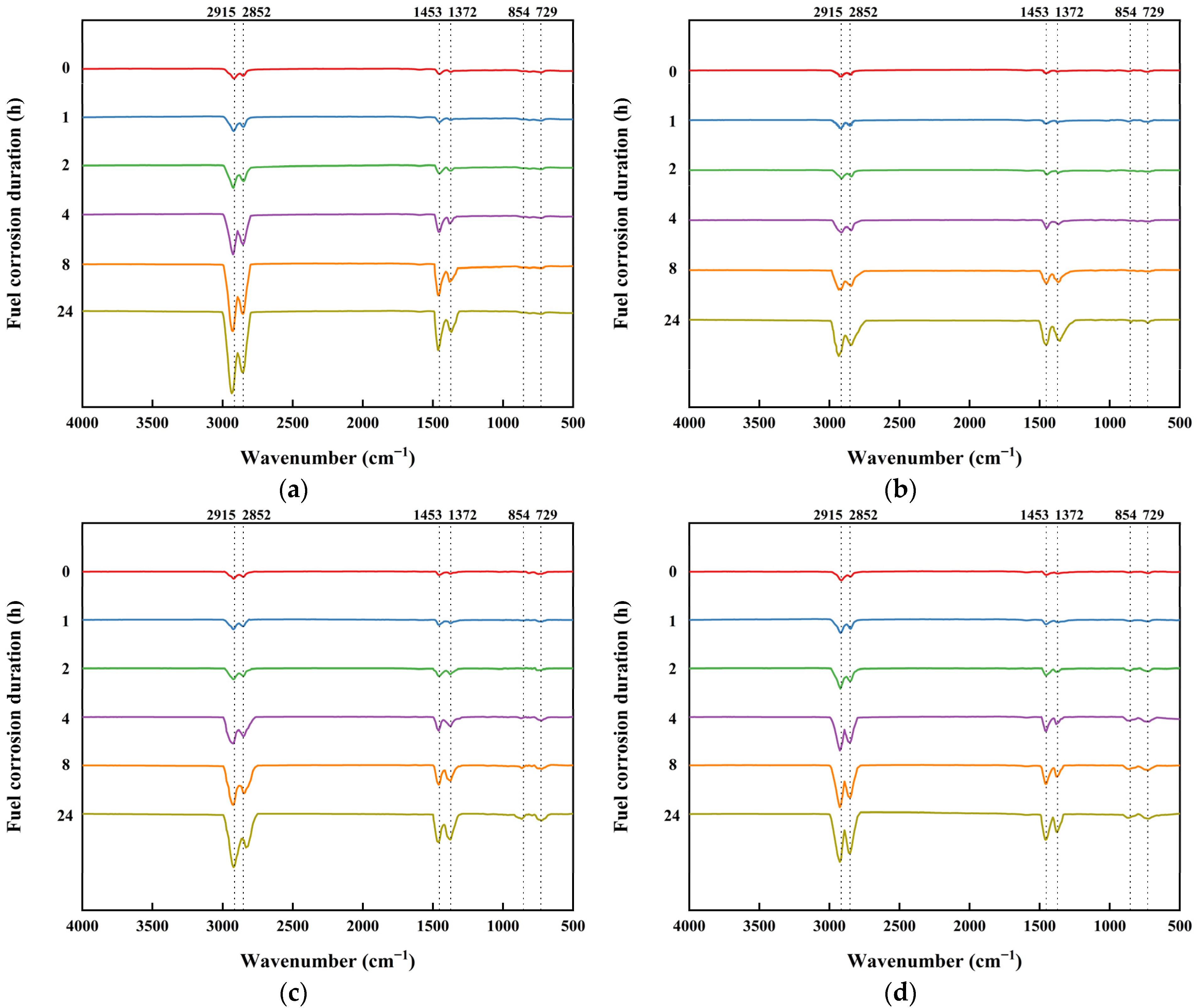

3.3.2. FTIR Tests

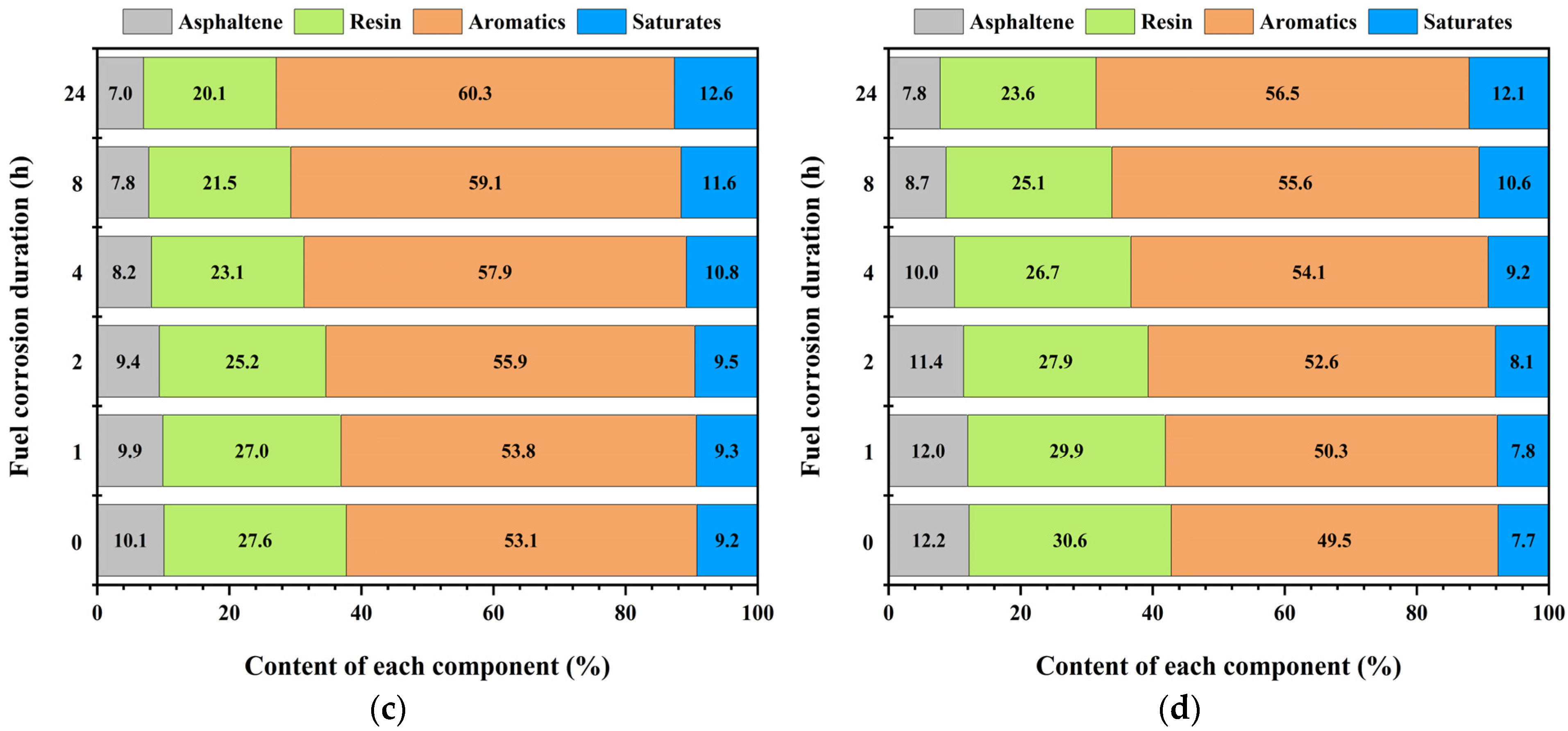

3.3.3. Asphalt Four-Component Tests

4. Conclusions

- (1)

- In terms of mass loss, modified asphalts such as SBS, LA, and RA are more fuel-corrosion-resistant than base asphalt. The asphalt binder is continuously dissolved, with greater mass loss as the degree of fuel corrosion deepens.

- (2)

- The rutting factor G*/sinδ of the asphalt decreases as fuel corrosion increases. However, modified asphalts have a significantly improved high-temperature deformation resistance compared to base asphalt and a reduced temperature sensitivity. Among them, RA has the best high-temperature rheological performance, and LA is superior to SBS once it reaches high levels of fuel corrosion damage.

- (3)

- R and Jnr determined in the MSCR tests similarly demonstrate improvement in the high-temperature rheological properties of modified asphalt binders. Under the effect of fuel corrosion, the stress sensitivity of the asphalt binders is elevated, and their load-bearing capacity deteriorates. RA has a better resistance to deformation, and SBS demonstrates excellent recovery.

- (4)

- The results of the BBR tests show that fuel corrosion improves the low-temperature cracking resistance of the asphalt binders to some extent, with SBS having the best resistance to low-temperature cracking and RA having the worst.

- (5)

- By observing the microscopic morphology of the asphalt binders, it is shown that diesel fuel erodes the modifiers, which can disrupt the structure of the bands and lines formed by linear SBS, the point structure of LDPE, and the morphology of the rubber particles, resulting in a change in the binders’ rheological properties.

- (6)

- Fuel and asphalt binder have similar chemical compositions. Therefore, the corrosion process mainly involves physical dissolution, and no chemical reaction occurs. At the same time, heavy components are converted into light components. The evolution of the rheological and microscopic properties of asphalt under fuel corrosion is consistent and can be mutually corroborated.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, J.Z. Test and Research on Resistance to Corrosion of Asphalt Mixture in Diesel Oil. Highway 2012, 07, 229–232. [Google Scholar]

- Tan, Z.Y.; Li, H. Diesel oil spill’s impact on road performance of asphalt pavement. Sci. Technol. Eng. 2018, 18, 326–330. [Google Scholar]

- Li, Q.; Ma, X.; Li, K.; Zhao, K. Experiment on Anti-fuel Oil Corrosion Performance of Stone Mastic Asphalt Mixtures. J. Build. Mater. 2020, 23, 664–670. [Google Scholar] [CrossRef]

- Cao, X.F.; Li, H.; Li, S.Q.; Zhang, G.M. Research on the Long-term Impact of Diesel Leak on Asphalt Concrete Pavement. Highway 2016, 61, 194–198. [Google Scholar]

- Chen, K.; Yuan, J.A.; Zhang, Y.C. Effect of oil erosion on high temperature performance of asphalt mixture. Shanghai Highw. 2013, 1, 59–60. [Google Scholar]

- Zhang, R.; Huang, X.M. Analysis on the oil corrosion performance of asphalt binders and mixtures. Highway 2006, 51, 173–175. [Google Scholar]

- Mora, B.A.; Hilpert, M. Differences in Infiltration and Evaporation of Diesel and Gasoline Droplets Spilled onto Concrete Pavement. Sustainability 2017, 9, 1271. [Google Scholar] [CrossRef]

- Li, H.; Li, S.Q. The Research on Asphalt Oil Corrosion Mechanism. Highw. Eng. 2016, 41, 229–231. [Google Scholar]

- Pratico, F.G.; Ammendola, R.; Moro, A. Fuel resistance of HMAs: Theory and experiments. Int. J. Pavement Res. Technol. 2008, 1, 100–106. [Google Scholar]

- Giuliani, F.; Merusi, F.; Rastelli, S. Experimental evaluation of fuel damage in bituminous materials. In Proceedings of the 88th TRB Annual Meeting—Transportation Research Board, National Research Council, Washington, DC, USA, 11–15 January 2009. [Google Scholar]

- Merusi, F.; Giuliani, F.; Filippi, S.; Moggi, P.; Polacco, G. Kerosene-Resistant Asphalt Binders Based on Nonconventional Modification. J. Transp. Eng. 2011, 137, 874–881. [Google Scholar] [CrossRef]

- Giuliani, F.; Merusi, F.; Filippi, S.; Biondi, D.; Finocchiaro, M.L.; Polacco, G. Effects of polymer modification on the fuel resistance of asphalt binders. Fuel 2009, 88, 1539–1546. [Google Scholar] [CrossRef]

- Mao, S.P.; Huang, H.H.; Bo, P.; Sun, M.T. High Temperature Performance of Oil-resistant Modified Asphalt Based on Rheological Properties. Sci. Technol. Eng. 2021, 21, 5518–5523. [Google Scholar]

- Liu, W.; Li, H.; Lin, H.; Du, X.; Sun, M.; Liu, S. Effects of a Fuel-Resistant Modifier on the High-Temperature Characteristics of Asphalt Binders. Sustainability 2021, 13, 7924. [Google Scholar] [CrossRef]

- Chaturabong, P.; Lim, T.T.; Wong, Y.D. Effective surface treatment techniques for refinishing oil-stained road surface. Constr. Build. Mater. 2018, 159, 64–72. [Google Scholar] [CrossRef]

- Du, X.; Liu, S.; Zhang, H.; Liu, W.; Lin, H. A test method to evaluate the fuel oil corrosion resistance of asphalt binders. Constr. Build. Mater. 2021, 292, 123416. [Google Scholar] [CrossRef]

- Abbas, A.; Eyad, M.; Papagiannakis, T.; Shenoy, A. Modelling asphalt mastic stiffness using discrete element analysis and micromechanics-based models. Int. J. Pavement Eng. 2005, 6, 137–146. [Google Scholar] [CrossRef]

- Zhao, W.; Xing, C.; Yan, C. Review on aging of SBS Modified Asphalt for Road. J. Munic. Technol. 2023, 41, 18–25. [Google Scholar] [CrossRef]

- Nisar, J.; Shafi Mir, M.; Vivek. Study on optimal preparation and rheological characteristics of waste low density polyethylene (LDPE)/styrene butadiene styrene (SBS) composite modified asphalt binder. Constr. Build. Mater. 2023, 407, 133459. [Google Scholar] [CrossRef]

- Duan, H.; Zhu, C.; Zhang, H.; Zhang, S.; Xiao, F.; Amirkhanian, S. Investigation on rheological characteristics of low-emissions crumb rubber modified asphalt. Int. J. Pavement Eng. 2023, 24, 2164891. [Google Scholar] [CrossRef]

- Joumblat, R.; Al Basiouni Al Masri, Z.; Al Khateeb, G.; Elkordi, A.; El Tallis, A.R.; Absi, J. State-of-the-Art Review on Permanent Deformation Characterization of Asphalt Concrete Pavements. Sustainability 2023, 15, 1166. [Google Scholar] [CrossRef]

- Joumblat, R.; Kassem, H.A.; Al Basiouni Al Masri, Z.; Elkordi, A.; Al-Khateeb, G.; Absi, J. Performance evaluation of hot-mix asphalt with municipal solid waste incineration fly ash using the stress sweep rutting test. Innov. Infrastruct. Solut. 2023, 8, 261. [Google Scholar] [CrossRef]

- Lin, H.; Sun, M.; Du, X.; Zhang, H. Sustainable Use of COVID-19 Face Masks in Asphalt Binder and Asphalt Mixture. J. Mater. Civ. Eng. 2023, 35, 9. [Google Scholar] [CrossRef]

- Li, J.; Liu, F.; Hu, M.; Zhou, C.; Su, L.; Cao, P. Investigation on the Performance of Fire and Smoke Suppressing Asphalt Materials for Tunnels. Processes 2023, 11, 3038. [Google Scholar] [CrossRef]

- Yang, X.; Peng, C.; Chen, J.; Liu, G.; He, X. Effect of short-term aging on rheological properties of bio-asphalt/SBS/PPA composite modified asphalt. Case Stud. Constr. Mater. 2023, 19, e2439. [Google Scholar] [CrossRef]

- Liu, S.; Wang, H.; Yang, J.; Luo, S.; Liu, Y.; Huang, W.; Hu, J.; Xu, G.; Min, Z. Biomass waste to produce bio oil as rejuvenator for asphalt based on pyrolysis technology. Int. J. Pavement Eng. 2024, 25, 2287695. [Google Scholar] [CrossRef]

- Du, B.; Li, R.; Guo, F.; Cai, R.; Pei, J. Evaluation of Rheological and Microscopic Properties of SBS-Modified Asphalt Binder with Multiple Regeneration. J. Mater. Civ. Eng. 2023, 35, 12. [Google Scholar] [CrossRef]

- Giuliani, F.; Merusi, F. Anti-kerosene asphalt binders designed for airfield pavements. A rheological approach to fuel resistance evaluation. In Proceedings of the International ISAP Symposium on Asphalt Pavements and Environment, Zurich, Switzerland, 18–20 August 2008. [Google Scholar]

- AASHTO T 315; Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012.

- Dongre, R.; D’Angelo, J.; Baumgardner, G.; Reinke, G. New developments in refinement of the superpave high temperature specification parameter. In Proceedings of the 40th Annual Meeting of the Petersen Asphalt Research Conference, Laramie, WY, USA, 22–25 June 2003. [Google Scholar]

- AASHTO T 350; Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014.

- AASHTO T 313; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- ASTM D4124-09; Standard Test Method for Separation of Asphalt into Four Fractions. American Society of Testing Materials: West Conshohocken, PA, USA, 2018.

| Property | Density (g/cm³) | Melting Point (℃) | Melt Flow Index (g/10 min) |

|---|---|---|---|

| LDPE | 0.925 | 121 | 50 |

| Property | Volatiles (%) | 300% Stress at Definite Elongation (MPa) | Tensile Strength (MPa) | Elongation at Break (%) | Hardness (A) |

|---|---|---|---|---|---|

| Linear SBS | ≤0.7 | ≥2.2 | ≥16 | ≥700 | ≥68 |

| Property | Penetration at 25 °C (0.1 mm) | Softening Point (°C) | Ductility (cm) |

|---|---|---|---|

| 70# | 75.4 | 55.4 | 53.1 (10 °C) |

| LA | 38.2 | 61.6 | 29.6 (5 °C) |

| SBS | 30.0 | 63.2 | 32.3 (5 °C) |

| RA | 45.0 | 58.4 | 21.5 (5 °C) |

| Fuel Corrosion Duration (h) | 70# | SBS | LA | RA |

|---|---|---|---|---|

| 0 | 0.2798 | 31.6667 | 17.1159 | 29.0000 |

| 1 | 0.2696 | 32.8889 | 17.3951 | 30.5385 |

| 2 | 0.4488 | 35.2963 | 19.4717 | 32.3333 |

| 4 | 0.5732 | 38.7143 | 21.2078 | 31.6923 |

| 8 | 0.6031 | 43.7619 | 24.6938 | 28.0476 |

| 24 | 0.5558 | 45.0317 | 26.4455 | 29.0000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, M.; Li, H.; Zhang, S.; Liu, W.; Zhang, H.; Lin, H.; Sun, M. Evolution of Rheological and Microscopic Properties of Asphalt Binders under Fuel Corrosion. Processes 2024, 12, 403. https://doi.org/10.3390/pr12020403

Lv M, Li H, Zhang S, Liu W, Zhang H, Lin H, Sun M. Evolution of Rheological and Microscopic Properties of Asphalt Binders under Fuel Corrosion. Processes. 2024; 12(2):403. https://doi.org/10.3390/pr12020403

Chicago/Turabian StyleLv, Ming, Hongjun Li, Shiping Zhang, Wenchang Liu, Hongchao Zhang, Hongwei Lin, and Mutian Sun. 2024. "Evolution of Rheological and Microscopic Properties of Asphalt Binders under Fuel Corrosion" Processes 12, no. 2: 403. https://doi.org/10.3390/pr12020403

APA StyleLv, M., Li, H., Zhang, S., Liu, W., Zhang, H., Lin, H., & Sun, M. (2024). Evolution of Rheological and Microscopic Properties of Asphalt Binders under Fuel Corrosion. Processes, 12(2), 403. https://doi.org/10.3390/pr12020403