The Variation Law of Fracture Conductivity of Shale Gas Reservoir Fracturing–Flowback Integration

Abstract

1. Introduction

2. Experimental Preparation and Principles

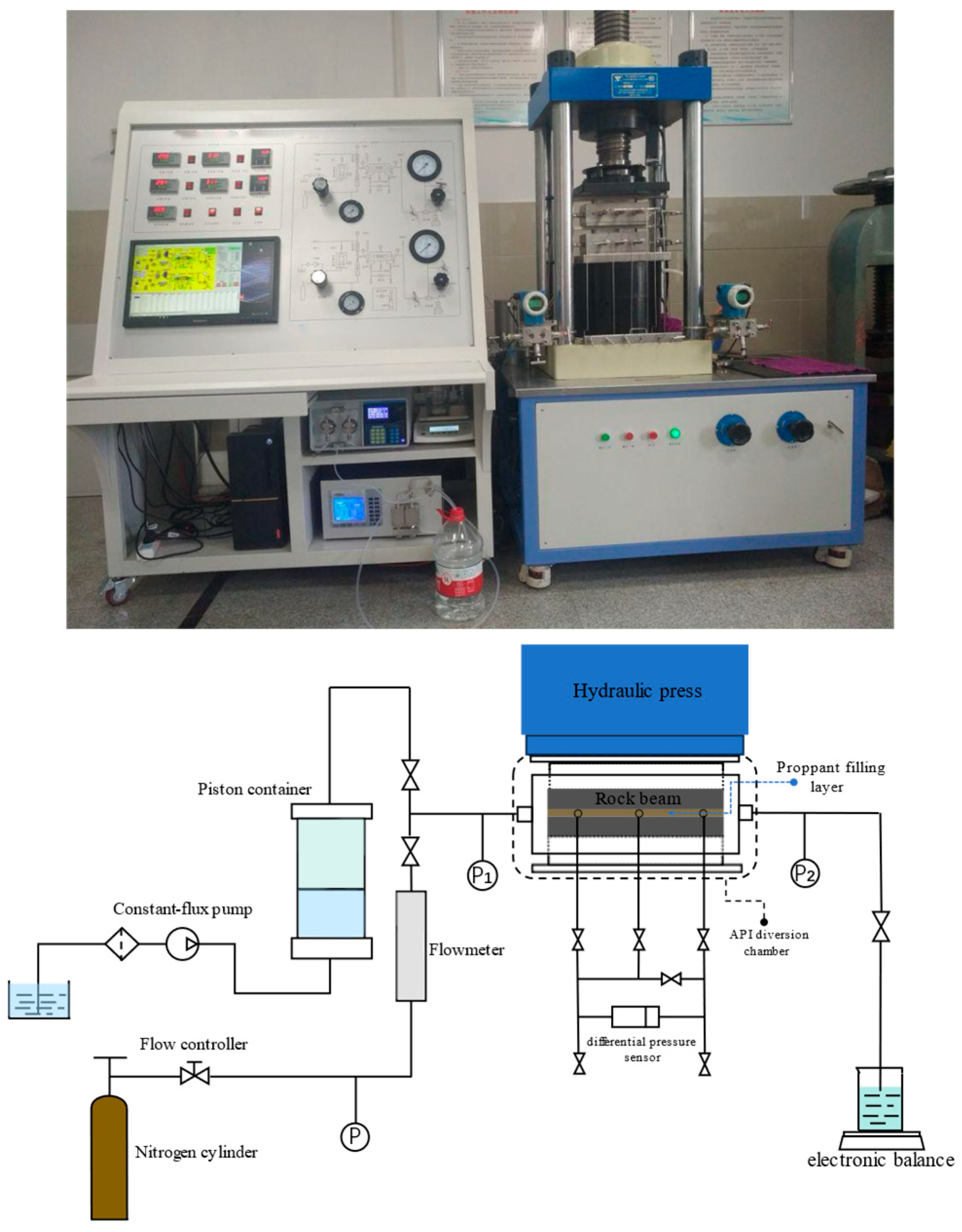

2.1. Experimental Device

2.2. Experimental Materials

2.3. Experimental Principles

3. Experimental Method

3.1. Experiments Simulating the Process of Fracturing and Flowback

3.1.1. Experimental Design

3.1.2. Experimental Flow

3.2. Experiments to Simulate Different Production Rates Under Shale Gas Well Working System

4. Analysis of Experimental Results

4.1. Effect of Different Fracturing Materials on Fracture Inflow Capacity

4.1.1. Fracturing Fluid Type

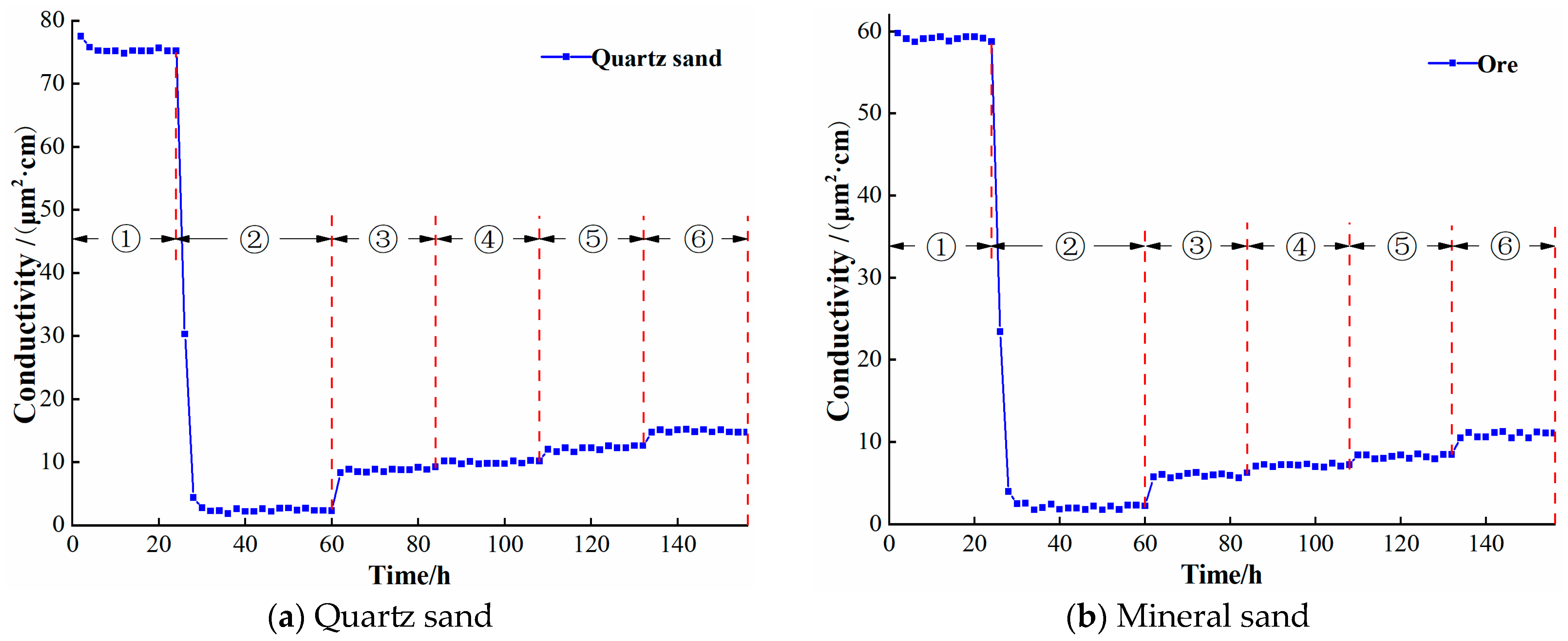

4.1.2. Proppant Type

4.1.3. Proppant Particle Size

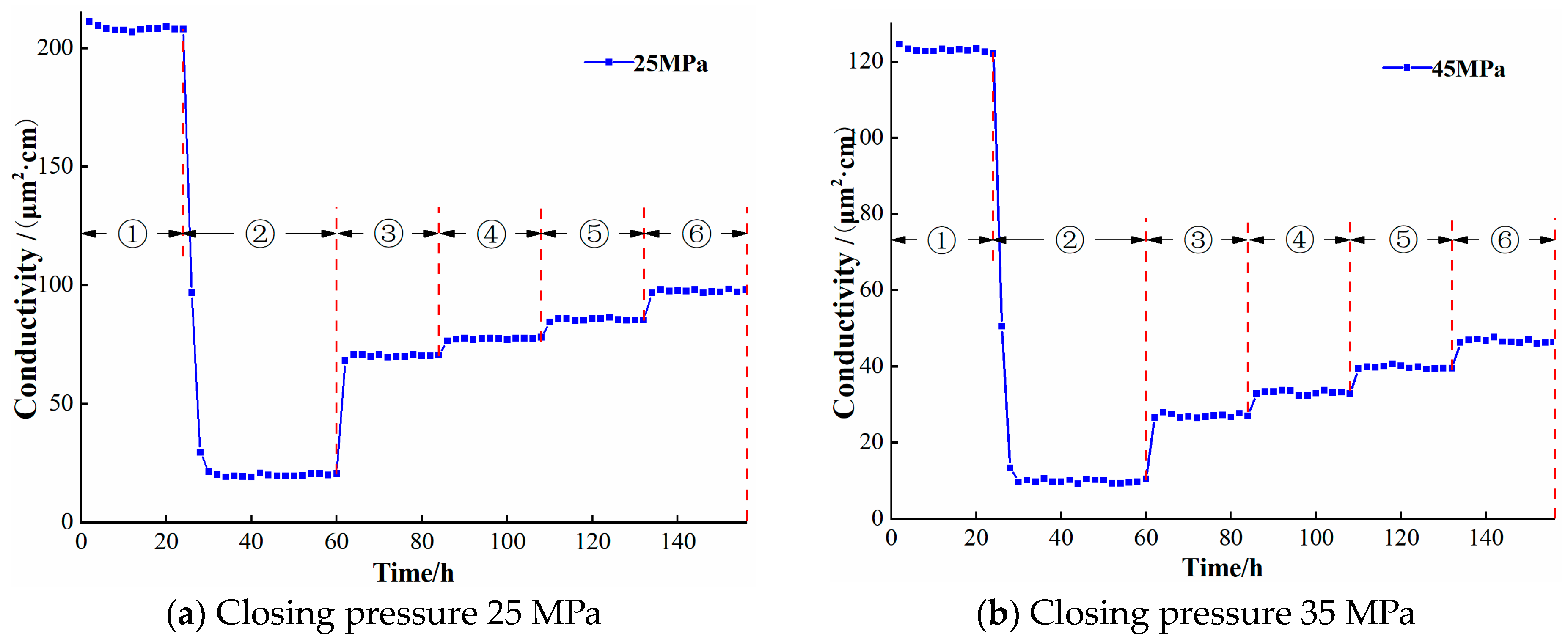

4.1.4. Closure Pressure

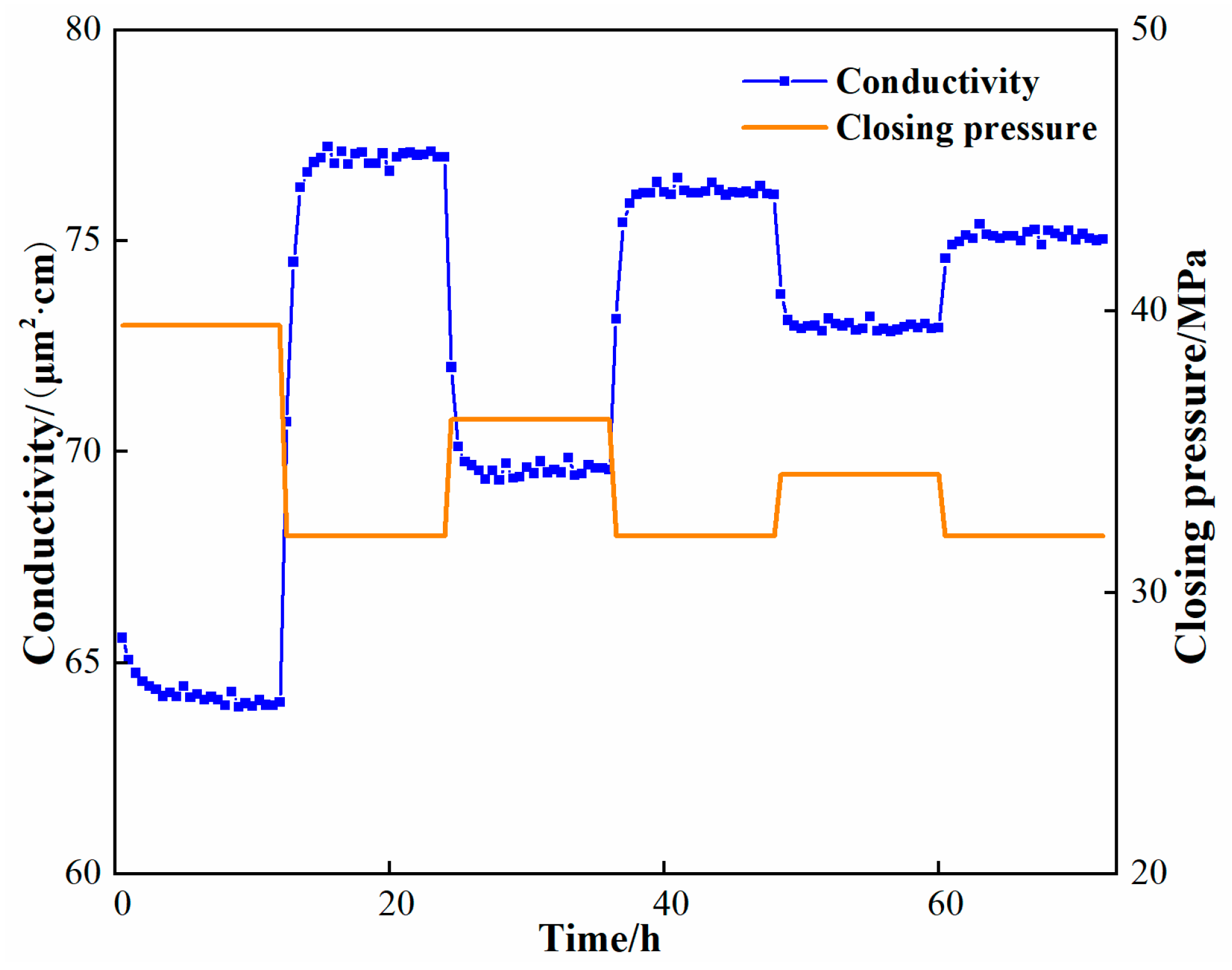

4.2. Impact of Shale Gas Well Working System

5. Conclusions

- This paper investigates the changing law and injury mechanism of proppant fracture conductivity in shale gas reservoirs during the integrated process of fracturing–flowback and production through indoor experiments, which is a guide to the design of fracturing schemes and production optimization in the field.

- Simulating the production process of fracturing–flowback and production, the proppant fracture capacity gradually picks up as the gas discharge increases. When the reservoir closure pressure is higher, the rise in the inflow conductivity is more affected, and the inflow conductivity rises slowly.

- Frequent switching off and on of wells due to different working rules in the middle and late stages of production leads to fluctuations in closure pressure, and fluctuations in closure pressure have a large impact on inflow capacity. The increase in inflow conductivity after well closure under three production regimes of 7 × 104 m3/d, 6 × 104 m3/d, and 5 × 104 m3/d were 20.6%, 9.4%, and 2.8%, respectively.

- The influence of reservoir depth on fracture conductivity cannot be ignored. With the exploration and development of deep shale gas, these issues will gradually gain more attention.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, H.; Liu, S.; He, B.S.; Chen, M.; Cao, Y.F. Research on hydraulic fracturing mechanism of shale gas reservoir. Sci. Technol. Eng. 2014, 14, 23–25. [Google Scholar] [CrossRef]

- Jiang, Y.Q.; Dong, D.Z.; Chi, L.; Shen, Y.F.; Jiang, C.; He, B.W. Basic characteristics of shale gas reservoirs and their evaluation. Nat. Gas Ind. 2010, 30, 7–12+113–114. [Google Scholar] [CrossRef]

- Wang, X.; Winterfeld, P.; Ma, X.; Ye, D.; Miao, J.; Wang, Y.; Wang, C.; Wu, Y.-S. Simulation of Coupled Hydraulic Fracturing Propagation and Gas Well Performance in Shale Gas Reservoirs. In Proceedings of the SPE Unconventional Resources Conference, The Woodlands, TX, USA, 1–3 April 2014. [Google Scholar]

- Ju, Y.W.; Bu, H.L.; Guang, G.C. Main characteristics of shale gas reservoirs and their impact on reservoir modification. Adv. Earth Sci. 2014, 29, 492–506. [Google Scholar]

- Li, Q.; Li, Q.; Wang, F.; Wu, J.; Wang, Y. The Carrying Behavior of Water-Based Fracturing Fluid in Shale Reservoir Fractures and Molecular Dynamics of Sand-Carrying Mechanism. Processes 2024, 12, 2051. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Han, Y. A Numerical Investigation on Kick Control with the Displacement Kill Method during a Well Test in a Deep-Water Gas Reservoir: A Case Study. Processes 2024, 12, 2090. [Google Scholar] [CrossRef]

- Meng, L.; Shi, H.; Zhou, C.J.; Hui, B.; Li, P.; Zhao, J.S. Evaluation and optimization of proppant inflow capacity for fracturing in tight gas reservoirs. J. Xi’an Pet. Univ. (Nat. Sci. Ed.) 2022, 37, 59–64. [Google Scholar] [CrossRef]

- Zhou, Z.H.; Zhu, W.Y.; Song, Z.Y. Effect of clear water on the damage of shale microfracture conductivity. In Proceedings of the Twenty-Third Annual Academic Conference of the Beijing Mechanics Society, Beijing Mechanics Society, Beijing, China, 14 January 2017. [Google Scholar]

- Elputranto, R.; Cirdi, A.P.; Akkutlu, I.Y. Formation Damage Mechanisms Due to Hydraulic Fracturing of Shale Gas Wells. In Proceedings of the SPE Europec, Virtual, 1–3 December 2020. [Google Scholar]

- Chen, Y.X. Research on the Mechanism of Post-Pressure Return and Drainage of Oil and Gas Wells and the Optimization Method of Working Regime. Doctoral Thesis, China University of Petroleum (East China), Dongying, China, 2019. [Google Scholar]

- Wen, Q.Z.; Wang, Q. Analysis and discussion of factors affecting long-term inflow capacity of proppant. Inn. Mong. Petrochem. Ind. 2003, 29, 101–104. [Google Scholar] [CrossRef]

- Wang, S.B. Overview of clear water fracturing technology. Nat. Gas Explor. Dev. 2005, 28, 39–42+72. [Google Scholar] [CrossRef]

- Fu, L.P. Research on Self-Polymerizing Proppant for Channel Fracturing. Doctoral Thesis, China University of Petroleum (East China), Dongying, China, 2017. [Google Scholar]

- Zhu, J.J.; Zhang, G.Q.; Qiao, G.F.; Xiao, B. Research and pilot application of slickwater for shale gas fracturing. Petrochem. Appl. 2013, 32, 24–28. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, S.C.; Zhang, W.Z.; Wen, Q.Z. Experimental study on long-term hydraulic conductivity of proppant combinations with different particle sizes in composite fracturing. Nat. Gas Ind. 2005, 25, 64–66+155–156. [Google Scholar] [CrossRef]

- Eline, V.F.; Akkutlu, I.Y.; Moridis, G.J. Impact of Hydraulic Fracturing Fluid Damage on Shale Gas Well Production Performance. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 26–28 September 2016. [Google Scholar]

- Hui, G.; Chen, Z.; Schultz, R.; Chen, S.; Song, Z.; Zhang, Z.; Song, Y.; Wang, H.; Wang, M.; Gu, F. Intricate unconventional fracture networks provide fluid diffusion pathways to reactivate pre-existing faults in unconventional reservoirs. Energy 2023, 282, 128803. [Google Scholar] [CrossRef]

- Liu, Q.G.; Tang, F.P.; Feng, G.Q.; Yan, Z.H.; Hu, X.P.; Chen, J.; Li, Y. Influence of different degrees of stress sensitivity on bottomhole pressure dynamics in switching wells. Oil Gas Geol. 2007, 523–527. [Google Scholar] [CrossRef]

- Han, H.F.; Peng, J.L.; Wu, J.; Gao, J.; Wang, L. Testing method for long-term inflow capacity of shale-supported fractures and modification of testing device. Drill. Process 2018, 41, 55–58+5. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Q. Experimental study on flow conductivity of hydraulically fractured complex fractures in shale gas reservoirs. J. Xi’an Pet. Univ. (Nat. Sci. Ed.) 2017, 32, 73–77. [Google Scholar] [CrossRef]

| Experiment Number | Type of Proppant | Proppant Mesh | Fracturing Fluid Type | Closing Pressure |

|---|---|---|---|---|

| 1 | ceramic granule | 20/40 mesh | distilled water | 35 MPa |

| 2 | ceramic granule | 20/40 mesh | slickwater fracturing fluid | 35 MPa |

| 3 | ceramic granule | 20/40 mesh | Polymer Fracturing Fluid | 35 MPa |

| 4 | quartz sand | 20/40 mesh | distilled water | 35 MPa |

| 5 | mineral sand | 20/40 mesh | distilled water | 35 MPa |

| 6 | ceramic granule | 40/70 mesh | distilled water | 35 MPa |

| 7 | ceramic granule | 70/140 mesh | distilled water | 35 MPa |

| 8 | ceramic granule | 40/70 mesh | distilled water | 25 MPa |

| 9 | ceramic granule | 40/70 mesh | distilled water | 45 MPa |

| Production Rate/(×104 m3/d) | Wellbore Pressure/MPa | Closing Pressure/MPa |

|---|---|---|

| 7 | 13.0 | 39.5 |

| 6 | 19.7 | 36.15 |

| 5 | 23.6 | 34.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, D.; Li, Z.; Li, C.; Guo, Y. The Variation Law of Fracture Conductivity of Shale Gas Reservoir Fracturing–Flowback Integration. Processes 2024, 12, 2908. https://doi.org/10.3390/pr12122908

Xu D, Li Z, Li C, Guo Y. The Variation Law of Fracture Conductivity of Shale Gas Reservoir Fracturing–Flowback Integration. Processes. 2024; 12(12):2908. https://doi.org/10.3390/pr12122908

Chicago/Turabian StyleXu, Dongjin, Zhiwen Li, Changheng Li, and Yukai Guo. 2024. "The Variation Law of Fracture Conductivity of Shale Gas Reservoir Fracturing–Flowback Integration" Processes 12, no. 12: 2908. https://doi.org/10.3390/pr12122908

APA StyleXu, D., Li, Z., Li, C., & Guo, Y. (2024). The Variation Law of Fracture Conductivity of Shale Gas Reservoir Fracturing–Flowback Integration. Processes, 12(12), 2908. https://doi.org/10.3390/pr12122908