Computational and Experimental Studies on the Behavior of Sprays with Different Orifice Characteristics and Fuel Properties of Biodiesel Crude Palm Oil (CPO) on a Premix Injector—A Comprehensive Review

Abstract

1. Introduction

1.1. Biodiesel as an Alternative Fuel

1.2. Spray Combustion and Its Key Contribution

1.3. Advanced Application Techniques in the Burner System for Emission Reduction

2. Biodiesel Crude Palm Oil (CPO) as an Alternative Fuel

2.1. CPO

2.2. Properties of CPO

2.3. Palm Oil Biodiesel (POB)

2.4. Investigations into Crude Palm Oil (CPO)

3. Background of CFD Simulation

3.1. Governing Equations [45]

- (i)

- Continuity equation:

- (ii)

- Momentum equation:

- (iii)

- Energy equation:

3.2. The Turbulence Models Equations [45]

- (i)

- Standard k–ε turbulence model [47]:

- (ii)

- RNG k–ε turbulence model [48]:

- (iii)

- Realizable k–ε turbulence model [49]:

- (iv)

- k–ω two-equation turbulence model [50]:

- (v)

- SST transition turbulence model [51]:

3.3. Mesh Density

4. Premix Injector

4.1. Fuel–Air Premixing

4.2. Effects of Swirling Flow

4.3. Cavitation

5. Orifice Geometries of Injector

5.1. Orifice Diameter

5.2. Nozzle Hole Shape

5.3. Conical Nozzle

5.4. Cylindrical Nozzle

5.5. Influences of Hole-Shaped Nozzles

6. Spray Characteristics

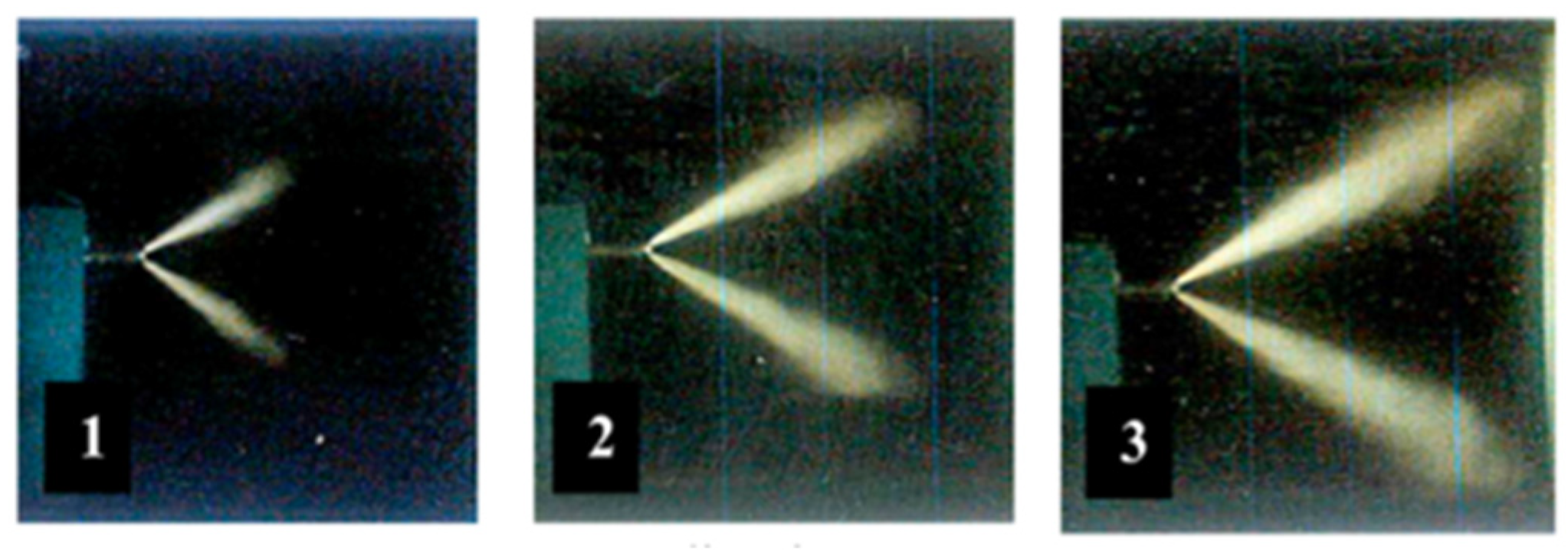

6.1. Spray Penetration

6.2. Spray Angle and Dispersion

6.3. Spray Droplets

6.4. Sauter Mean Diameter (SMD)

6.5. Influence of Fuel on Spray Characteristics

6.6. Spray Analysis

7. Conclusions

- (i)

- Biodiesel from crude palm oil is capable of reducing the cavitation inside the orifice.

- (ii)

- The Reynolds stress turbulence model and the Transition SST model are found to reasonably be the better turbulence models in the simulation of mixing.

- (iii)

- Premix injectors can reduce emissions in the combustion process.

- (iv)

- The application of swirling flow enhances the fuel and air mixing.

- (v)

- Although cavitation could significantly improve the spray atomization, it may damage the orifice.

- (vi)

- The cylindrical orifice is concluded to be a highly cavitating orifice, while the conical orifice is able to reduce the cavitation inside the orifice.

- (vii)

- Spray characteristics can enhance the overall combustion performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Altarazi, Y.S.M.; Yusaf, T.; Yu, J.; Gires, E.; Ghafir, M.F.A.; Lucas, J. A review of engine performance and emissions using single and dual biodiesel fuels: Research paths, challenges, motivations and recommendations. Fuel 2022, 326, 125072. [Google Scholar] [CrossRef]

- Tuan, T.N.; Okada, H.; Tsukamoto, T.; Ohe, K.; Iwasawa, K. Effect of rounding-off nozzle hole inlet on fuel injection and combustion characteristics under high-temperature and high-pressure. Mar. Eng. 2007, 42, 288–294. [Google Scholar] [CrossRef] [PubMed]

- Tezel, Y. Spray Characteristics of Emulsified Biodiesel-Diesel Blends in a Constant Volume Combustion Chamber; Izmir Institute of Technology: Urla, Turkey, 2020. [Google Scholar]

- Som, S.; Longman, D.E.; Ramírez, A.I.; Aggarwal, S.K. A comparison of injector flow and spray characteristics of biodiesel with petrodiesel. Fuel 2010, 89, 4014–4024. [Google Scholar] [CrossRef]

- Battistoni, M.; Grimaldi, C.N. Numerical analysis of injector flow and spray characteristics from diesel injectors using fossil and biodiesel fuels. Appl. Energy 2012, 97, 656–666. [Google Scholar] [CrossRef]

- Zhou, H.; Yang, Y.; Liu, H.; Hang, Q. Numerical simulation of the combustion characteristics of a low NOx swirl burner: Influence of the primary air pipe. Fuel 2014, 130, 168–176. [Google Scholar] [CrossRef]

- Som, S.; Aggarwal, S.K.; El-Hannouny, E.M.; Longman, D.E. Investigation of nozzle flow and cavitation characteristics in a diesel injector. J. Eng. Gas Turbines Power 2010, 132, 42802. [Google Scholar] [CrossRef]

- Yaacob, N.S.M.; Khalid, A.; Jaat, N.; Andsaler, A.R.; Azizul, M.A.; Sapit, A. Simulation and modelling of spray characteristics, spray penetration length and injection pressure of biodiesel. AIP Conf. Proc. 2024, 2998, 030003. [Google Scholar]

- Hariharan, P.; Periasamy, C.; Gollahalli, S.R. Effect of elliptic burner geometry and air equivalence ratio on the nitric oxide emissions from turbulent hydrogen flames. Int. J. Hydrogen Energy 2007, 32, 1095–1102. [Google Scholar] [CrossRef]

- Ravikumar, J.; Saravanan, S. Performance and emission analysis on blends of diesel, restaurant yellow grease and n-pentanol in direct-injection diesel engine. Environ. Sci. Pollut. Res. 2017, 24, 5381–5390. [Google Scholar] [CrossRef]

- Rahman, K.M.; Mashud, M.; Roknuzzaman, M.; Al Galib, A. Biodiesel from Jatropha oil as an alternative fuel for diesel engine. Int. J. Mech. Mechatron. 2010, 10, 1–6. [Google Scholar]

- Raja, S.A. Biodiesel production from jatropha oil and its characterization. Res. J. Chem. Sci. 2011, 1, 81–87. [Google Scholar]

- Antolın, G.; Tinaut, F.V.; Briceno, Y.; Castano, V.; Perez, C.; Ramırez, A.I. Optimisation of biodiesel production by sunflower oil transesterification. Bioresour. Technol. 2002, 83, 111–114. [Google Scholar] [CrossRef]

- Corro, G.; Tellez, N.; Bañuelos, F.; Mendoza, M.E. Biodiesel from Jatropha curcas oil using Zn for esterification step and solar radiation as energy source. Fuel 2012, 97, 72–79. [Google Scholar] [CrossRef]

- Vicente, G.; Martınez, M.; Aracil, J. Integrated biodiesel production: A comparison of different homogeneous catalysts systems. Bioresour. Technol. 2004, 92, 297–305. [Google Scholar] [CrossRef] [PubMed]

- Broukal, J.; Hájek, J. Validation of an effervescent spray model with secondary atomization and its application to modeling of a large-scale furnace. Appl. Therm. Eng. 2011, 31, 2153–2164. [Google Scholar] [CrossRef]

- Bari, S.; Zhang, C.; Kafrawi, F.; Lee, K.H. Study of Spray Behaviors to Correlate with Engine Performance and Emissions of a Diesel Engine Using Canola-Based Biodiesel. Fuels 2022, 3, 87–112. [Google Scholar] [CrossRef]

- Jaafar, M.N.M.; Ishak, M.S.A.; Arizal, M.A.A. Spray Characteristic of Palm Biofuel Blends. Int. J. Mech. Mater. Eng. 2010, 5, 214–221. [Google Scholar]

- Lefebvre, A.H. Atomization and Sprays (Hemisphere, New York, 1989). In Effect of Coal Particle Size on CWS Atomization; American Society of Mechanical Engineers: New York, NY, USA, 1997; pp. 27–78. [Google Scholar]

- Khalid, A.; Tamaldin, N.; Jaat, M.; Ali, M.F.M.; Manshoor, B.; Zaman, I. Impacts of biodiesel storage duration on fuel properties and emissions. Procedia Eng. 2013, 68, 225–230. [Google Scholar] [CrossRef]

- Khalid, A.; Azman, N.; Zakaria, H.; Manshoor, B.; Zaman, I.; Sapit, A.; Leman, A.M. Effects of storage duration on biodiesel properties derived from waste cooking oil. Appl. Mech. Mater. 2014, 554, 494–499. [Google Scholar] [CrossRef]

- Suh, H.K.; Park, S.H.; Lee, C.S. Experimental investigation of nozzle cavitating flow characteristics for diesel and biodiesel fuels. Int. J. Automot. Technol. 2008, 9, 217–224. [Google Scholar] [CrossRef]

- Benajes, J.; Pastor, J.V.; Payri, R.; Plazas, A.H. Analysis of the influence of diesel nozzle geometry in the injection rate characteristic. J. Fluids Eng. 2004, 126, 63–71. [Google Scholar] [CrossRef]

- Payri, R.; Garcia, J.M.; Salvador, F.J.; Gimeno, J. Using spray momentum flux measurements to understand the influence of diesel nozzle geometry on spray characteristics. Fuel 2005, 84, 551–561. [Google Scholar] [CrossRef]

- Han, J.-S.; Lu, P.-H.; Xie, X.-B.; Lai, M.-C.; Henein, N.A. Investigation of Diesel Spray Primary Break-Up and Development for Different Nozzle Geometries; SAE Technical Paper; SAE: Warrendale, PA, USA, 2002. [Google Scholar]

- Som, S.; Ramirez, A.I.; Longman, D.E.; Aggarwal, S.K. Effect of nozzle orifice geometry on spray, combustion, and emission characteristics under diesel engine conditions. Fuel 2011, 90, 1267–1276. [Google Scholar] [CrossRef]

- Reis, L.; Carvalho, J.A., Jr.; Nascimento, M.A.R.; Rodrigues, L.O.; Dias, F.L.G.; Sobrinho, P.M. Numerical modeling of flow through an industrial burner orifice. Appl. Therm. Eng. 2014, 67, 201–213. [Google Scholar] [CrossRef]

- Huang, L.; Li, Z.; Sun, R.; Zhou, J. Numerical study on the effect of the Over-Fire-Air to the air flow and coal combustion in a 670 t/h wall-fired boiler. Fuel Process. Technol. 2006, 87, 363–371. [Google Scholar] [CrossRef]

- Zeng, L.; Li, Z.; Zhao, G.; Shen, S.; Zhang, F. Numerical simulation of combustion characteristics and NOx emissions in a 300 MWe utility boiler with different outer secondary-air vane angles. Energy Fuels 2010, 24, 5349–5358. [Google Scholar] [CrossRef]

- Miller, B. Fuel considerations and burner design for ultra-supercritical power plants. In Ultra-Supercritical Coal Power Plants; Elsevier: Amsterdam, The Netherlands, 2013; pp. 57–80. [Google Scholar]

- Hayyan, A.; Mjalli, F.S.; Hashim, M.A.; Hayyan, M.; AlNashef, I.M.; Al-Zahrani, S.M.; Al-Saadi, M.A. Ethanesulfonic acid-based esterification of industrial acidic crude palm oil for biodiesel production. Bioresour. Technol. 2011, 102, 9564–9570. [Google Scholar] [CrossRef] [PubMed]

- Goh, S.H.; Choo, Y.M.; Ong, A.S.H. Minor components in palm oil. In Proceedings of the 1987 International Oil Palm/Palm Oil Conference. Progress and Prospects. Conference II. Technology, Kuala Lumpur, Malaysia, 29 June–1 July 1987; pp. 95–101. [Google Scholar]

- Neupane, D. Biofuels from renewable sources, a potential option for biodiesel production. Bioengineering 2022, 10, 29. [Google Scholar] [CrossRef]

- Hendro, J.; Zahra, H.S. Biodiesel production from crude palm oil (CPO) through variation steps of esterification-transesterification and its evaluations. AIP Conf. Proc. 2024, 3071, 020011. [Google Scholar]

- Maulidiyah, M.; Watoni, A.H.; Maliana, N.; Irwan, I.; Salim, L.O.A.; Arham, Z.; Nurdin, M. Biodiesel production from crude palm oil using sulfuric acid and K2O Catalysts through a two-stage reaction. Biointerface Res. Appl. Chem. 2021, 12, 3150–3160. [Google Scholar]

- Motasemi, F.; Ani, F.N. The production of biodiesel from waste cooking oil using microwave irradiation. J. Mek. 2011, 32, 61–72. [Google Scholar]

- Benjumea, P.; Agudelo, J.; Agudelo, A. Basic properties of palm oil biodiesel–diesel blends. Fuel 2008, 87, 2069–2075. [Google Scholar] [CrossRef]

- Schumacher, L.G.; Van Gerpen, J.; Adams, B. Biodiesel fuels. Encycl. Energy 2004, 1, 151–162. [Google Scholar]

- Leevijit, T.; Prateepchaikul, G. Comparative performance and emissions of IDI-turbo automobile diesel engine operated using degummed, deacidified mixed crude palm oil–diesel blends. Fuel 2011, 90, 1487–1491. [Google Scholar] [CrossRef]

- Phoungthong, K.; Tekasakul, S.; Tekasakul, P.; Prateepchaikul, G.; Jindapetch, N.; Furuuchi, M.; Hata, M. Emissions of particulate matter and associated polycyclic aromatic hydrocarbons from agricultural diesel engine fueled with degummed, deacidified mixed crude palm oil blends. J. Environ. Sci. 2013, 25, 751–757. [Google Scholar] [CrossRef]

- Khalid, A.; Jaat, C.Y.M.; Zaman, I.; Manshoor, B.; Ali, M.F.M. Effect of preheated fuel on mixture formation of biodiesel spray. Appl. Mech. Mater. 2013, 393, 493–498. [Google Scholar] [CrossRef]

- Khalid, A.; Sies, M.F.; Manshoor, B.; Latip, L.; Amirnordin, S.H. Investigation of Mixture formation and Flame Development in Emulsified Biodiesel Burner Combustion. In Proceedings of the 2014 International Conference on Industrial Engineering and Operations Management. Bali, Indonesia: Industrial Engineering and Operations Management (IOEM), Bali, Indonesia, 7–9 January 2014. [Google Scholar]

- Jaafar, M.N.M.; Eldrainy, Y.A.; Asril, M.H. Experimental investigation of spray characteristics of refined bleached and deodorized palm oil and diesel blends using phase Doppler particle analyzer. Int. J. Phys. Sci. 2011, 6, 6674–6680. [Google Scholar]

- Zuo, W. Introduction of Computational Fluid Dynamics; Cambridge University Press: St. Petersburg, Russia, 2005. [Google Scholar]

- Li, A.G.T.; Pannala, S.; Shahnama, M.; Syamlal, M. CFD simulations of circulating fluidized bed risers, part I: Grid study. Powder Technol. 2014, 254, 170–180. [Google Scholar] [CrossRef]

- Jones, W.P.; Marquis, A.J.; Vogiatzaki, K. Large-eddy simulation of spray combustion in a gas turbine combustor. Combust. Flame 2014, 161, 222–239. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; Pearson Education: London, UK, 2007. [Google Scholar]

- Choundhury, D. Introduction to the Renormalization Group Method and Turbulence Modelling; TM-107; Fluent Inc.: New York, NY, USA, 1993. [Google Scholar]

- Shih, T.-H.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J. A new k-ϵ eddy viscosity model for high reynolds number turbulent flows. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Wilcox, D.C. Formulation of the kw turbulence model revisited. AIAA J. 2008, 46, 2823–2838. [Google Scholar] [CrossRef]

- Menter, F.R.; Langtry, R.B.; Likki, S.R.; Suzen, Y.B.; Huang, P.G.; Völker, S. A correlation-based transition model using local variables—Part I: Model formulation. J. Turbomach. 2006, 128, 413–422. [Google Scholar] [CrossRef]

- Zhang, H.R.; Yu, Y. A guidance to grid size design for CFD numerical simulation of hypersonic flows. Procedia Eng. 2013, 67, 178–187. [Google Scholar] [CrossRef]

- Djamal, H.D.; Woon, Q.Y.; Suzairin, M.S.; Amirnordin, S.H. Effects of Geometrical Parameters to the Performance of Louvered Fin Heat Exchangers. Appl. Mech. Mater. 2015, 773, 398. [Google Scholar] [CrossRef]

- Amirnordin, S.H.; Djamal, H.D.; Mansor, M.N.; Khalid, A.; Suzairin, M.S.; Raghavan, V.R. Pressure drop and heat transfer characteristics of louvered fin heat exchangers. Appl. Mech. Mater. 2014, 465, 500–504. [Google Scholar] [CrossRef]

- Pan, S.; Feng, D.H.; Ding, G.H.; Tian, Z.; Yang, Y.; Li, H. Grid dependency and convergence of hypersonic aerothermal simulation. Acta Aeronaut. Astronaut. Sin. 2010, 31, 493–499. [Google Scholar]

- Yan, C.; Yu, J.; Li, J. Scheme effect and grid dependency in CFD computations of heat transfer. Acta Aerodyn. Sin. 2006, 1, 22. [Google Scholar]

- Dorri, A.; Hoxha, A. Influence of hole geometry in the cavitation phenomena of diesel injectors, a numerical investigation. Goriv. Maz. Čas. Tribol. Teh. Podmaz. Primjen. Tekućih Plinovitih Goriv. Inž. Izgaranja 2009, 48, 361–371. [Google Scholar]

- Lefebvre, A.H.; Ballal, D.R. Gas Turbine Combustion: Alternative Fuels and Emissions; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- No, S.; Gu, J.; Moon, H.; Lee, C.; Jo, Y. An Introduction to Combustion Concepts and Applications; McGraw-Hill: Seoul, Republic of Korea, 2011. [Google Scholar]

- Yatsufusa, T.; Kidoguchi, Y.; Nakagawa, D. Improvement of emissions and burning limits in burner combustion using an injector on the concept of fuel-water internally rapid mixing. J. Energy Power Eng. 2014, 8, 11. [Google Scholar]

- Gollahalli, S.R. An experimental study of the combustion of unsupported drops of residual oils and emulsions. Combust. Sci. Technol. 1979, 19, 245–250. [Google Scholar] [CrossRef]

- Lasheras, J.C.; Fernandez-Pello, A.C.; Dryer, F.L. Initial observations on the free droplet combustion characteristics of water-in-fuel emulsions. Combust. Sci. Technol. 1979, 21, 1–14. [Google Scholar] [CrossRef]

- Mizutani, Y.; Taki, A. Burning and emission characteristics and combustion mechanisms of water-in-oil-emulsion sprays: 1st report, properties of emulsions and their burning and emission characteristics. Trans. Jpn. Soc. Mech. Eng. Ser. B 1981, 47, 2379–2385. [Google Scholar] [CrossRef]

- Hiroyasu, H.; Arai, M.; Nishida, K. The Combustion of Water-in-Heavy Oil Emulsions: 1st Report, Combustion Characteristics of Emulsion Sprays. J. JSME (B) 1985, 48, 1182–1188. [Google Scholar] [CrossRef]

- Yatsufusa, T.; Kumura, T.; Nakagawa, Y.; Kidoguchi, Y. Advantage of using water-emulsified fuel on combustion and emission characteristics. Fuel 2009, 5, 60o. [Google Scholar]

- Tassi, P.; Rohmer, O.; Schimchowitsch, S.; Eschenlauer, A.; Bonnefond, A.; Margiocchi, F.; Poisson, F.; Muzet, A. Living alongside railway tracks: Long-term effects of nocturnal noise on sleep and cardiovascular reactivity as a function of age. Environ. Int. 2010, 36, 683–689. [Google Scholar] [CrossRef]

- Lefebvre, A.H.; McDonell, V.G. Atomization and Sprays; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Genova, T.; Otero, M.; Morales, A.; Stiehl, B.; Martin, S.; Ahmed, K. Preheating and premixing effects on NOx emissions in a high-pressure axially staged combustor. Combust. Flame 2022, 235, 111710. [Google Scholar] [CrossRef]

- Goh, E.; Sirignano, M.; Li, J.; Nair, V.; Emerson, B.; Lieuwen, T.; Seitzman, J. Prediction of minimum achievable NOx levels for fuel-staged combustors. Combust. Flame 2019, 200, 276–285. [Google Scholar] [CrossRef]

- Sirignano, M.D.; Nair, V.; Emerson, B.L.; Seitzman, J.; Lieuwen, T.C. Nitrogen oxide emissions from premixed reacting jets in a vitiated crossflow. Combust. Sci. Technol. 2020, 192, 1389–1419. [Google Scholar] [CrossRef]

- Liu, C.; Liu, F.; Yang, J.; Mu, Y.; Xu, G. Investigations of the effects of spray characteristics on the flame pattern and combustion stability of a swirl-cup combustor. Fuel 2015, 139, 529–536. [Google Scholar] [CrossRef]

- Syred, N.; Beer, J.M. Combustion in swirling flows: A review. Combust. Flame 1974, 23, 143–201. [Google Scholar] [CrossRef]

- Driscoll, J.; Temme, J. Role of swirl in flame stabilization. In Proceedings of the 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011; Volume 108. [Google Scholar]

- Wang, Y.; Sohn, C.H. Effects of swirl premixed flame interaction on NOx emission in a gas turbine combustor with multi-burners. J. Energy Inst. 2023, 109, 101274. [Google Scholar] [CrossRef]

- Abdelkader, H.; Abdelhalim, B. The Effect of Swirl Intensity on the Flow Behavior and Combustion Characteristics of a Lean Propane-Air Flame. Fluid Dyn. Mater. Process. 2022, 18, 1749–1762. [Google Scholar] [CrossRef]

- Mishra, S.; Mishra, K.B. Effect of swirl number on structural and emission characteristics of moderate size burner flames. Process Saf. Environ. Prot. 2024, 189, 1151–1160. [Google Scholar] [CrossRef]

- Rahman, M.M.; Tanaka, N.; Yokobori, S.; Hirai, S. Three Dimensional Numerical Analysis of Two Phase Flow Separation Using Swirling Fluidics. Energy Power Eng. 2013, 5, 301. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, V. Effect of swirl on combustion dynamics in a lean-premixed swirl-stabilized combustor. Proc. Combust. Inst. 2005, 30, 1775–1782. [Google Scholar] [CrossRef]

- Eiamsa-ard, S.; Ridluan, A.; Somravysin, P.; Promvonge, P. Numerical investigation of turbulent flow through a circular orifice. KMITL Sci. J 2008, 8, 44–50. [Google Scholar]

- Coughtrie, A.R.; Borman, D.J.; Sleigh, P.A. Effects of turbulence modelling on prediction of flow characteristics in a bench-scale anaerobic gas-lift digester. Bioresour. Technol. 2013, 138, 297–306. [Google Scholar] [CrossRef]

- German, A.E.; Mahmud, T. Modelling of non-premixed swirl burner flows using a Reynolds-stress turbulence closure. Fuel 2005, 84, 583–594. [Google Scholar] [CrossRef]

- Kevorkijan, L.; Biluš, I.; Torres-Jiménez, E.; Lešnik, L. The Effect of Fuel Quality on Cavitation Phenomena in Common-Rail Diesel Injector—A Numerical Study. Sustainability 2024, 16, 5074. [Google Scholar] [CrossRef]

- Dafsari, R.A.; Lee, H.J.; Han, J.; Lee, J. Evaluation of the atomization characteristics of aviation fuels with different viscosities using a pressure swirl atomizer. Int. J. Heat Mass Transf. 2019, 145, 118704. [Google Scholar] [CrossRef]

- Sun, Y.; Guan, Z.; Hooman, K. Cavitation in diesel fuel injector nozzles and its influence on atomization and spray. Chem. Eng. Technol. 2019, 42, 6–29. [Google Scholar] [CrossRef]

- Cristofaro, M.; Edelbauer, W.; Koukouvinis, P.; Gavaises, M. A numerical study on the effect of cavitation erosion in a diesel injector. Appl. Math. Model. 2020, 78, 200–216. [Google Scholar] [CrossRef]

- Zhang, X.; He, Z.; Wang, Q.; Tao, X.; Zhou, Z.; Xia, X.; Zhang, W. Effect of fuel temperature on cavitation flow inside vertical multi-hole nozzles and spray characteristics with different nozzle geometries. Exp. Therm. Fluid Sci. 2018, 91, 374–387. [Google Scholar] [CrossRef]

- He, Z.; Guan, W.; Wang, C.; Guo, G.; Zhang, L.; Gavaises, M. Assessment of turbulence and cavitation models in prediction of vortex induced cavitating flow in fuel injector nozzles. Int. J. Multiph. Flow 2022, 157, 104251. [Google Scholar] [CrossRef]

- Wang, C.; Li, G.-X.; Sun, Z.-Y.; Wang, L.; Sun, S.-P.; Gu, J.-J.; Wu, X.-J. Effects of structure parameters on flow and cavitation characteristics within control valve of fuel injector for modern diesel engine. Energy Convers. Manag. 2016, 124, 104–115. [Google Scholar] [CrossRef]

- Mohan, B.; Yang, W.; Chou, S. Cavitation in injector nozzle holes–a parametric study. Eng. Appl. Comput. Fluid Mech. 2014, 8, 70–81. [Google Scholar] [CrossRef]

- Jia, M.; Xie, M.; Liu, H.; Lam, W.-H.; Wang, T. Numerical simulation of cavitation in the conical-spray nozzle for diesel premixed charge compression ignition engines. Fuel 2011, 90, 2652–2661. [Google Scholar] [CrossRef]

- Yang, L.; Fu, Q.; Qu, Y.; Zhang, W.; Du, M.; Xu, B. Spray characteristics of gelled propellants in swirl injectors. Fuel 2012, 97, 253–261. [Google Scholar] [CrossRef]

- Daikoku, M.; Furudate, H.; Inamura, T. Effect of Cavitation in the Cylindrical Nozzle on the Liquid Breakup Process. In Proceedings of the 9th ICLASS, Sorrento, Italy, 13–17 July 2003; pp. 12–17. [Google Scholar]

- Hamid, A.H.A.; Atan, R. Spray characteristics of jet–swirl nozzles for thrust chamber injector. Aerosp. Sci. Technol. 2009, 13, 192–196. [Google Scholar] [CrossRef]

- Halder, M.R.; Dash, S.K.; Som, S.K. A numerical and experimental investigation on the coefficients of discharge and the spray cone angle of a solid cone swirl nozzle. Exp. Therm. Fluid Sci. 2004, 28, 297–305. [Google Scholar] [CrossRef]

- Sun, Z.-Y.; Li, G.-X.; Chen, C.; Yu, Y.-S.; Gao, G.-X. Numerical investigation on effects of nozzle’s geometric parameters on the flow and the cavitation characteristics within injector’s nozzle for a high-pressure common-rail DI diesel engine. Energy Convers. Manag. 2015, 89, 843–861. [Google Scholar] [CrossRef]

- Pandey, R.K.; Rehman, A.; Sarviya, R.M. Impact of alternative fuel properties on fuel spray behavior and atomization. Renew. Sustain. Energy Rev. 2012, 16, 1762–1778. [Google Scholar] [CrossRef]

- Du, C.; Andersson, M.; Andersson, S. Effects of nozzle geometry on the characteristics of an evaporating diesel spray. SAE Int. J. Fuels Lubr. 2016, 9, 493–513. [Google Scholar] [CrossRef]

- Payri, R.; Margot, X.; Salvador, F.J. A Numerical Study of the Influence of Diesel Nozzle Geometry on the Inner Cavitating Flow; SAE Technical Paper; SAE: Warrendale, PA, USA, 2002. [Google Scholar]

- Blessing, M.; König, G.; Krüger, C.; Michels, U.; Schwarz, V. Analysis of flow and cavitation phenomena in diesel injection nozzles and its effects on spray and mixture formation. SAE Trans. 2003, 112, 1694–1706. [Google Scholar]

- Elbaz, A.M.; Zayed, M.F.; Samy, M.; Roberts, W.L.; Mansour, M.S. The flow field structure of highly stabilized partially premixed flames in a concentric flow conical nozzle burner with coflow. Exp. Therm. Fluid Sci. 2016, 73, 2–9. [Google Scholar] [CrossRef]

- Pougatch, K.; Salcudean, M.; McMillan, J. Influence of conical nozzle attachments on horizontal spray dispersion in a fluidized bed. Chem. Eng. Res. Des. 2012, 90, 1506–1516. [Google Scholar] [CrossRef]

- Ishimoto, J.; Hoshina, H.; Tsuchiyama, T.; Watanabe, H.; Haga, A.; Sato, F. Integrated simulation of the atomization process of a liquid jet through a cylindrical nozzle. Interdiscip. Inf. Sci. 2007, 13, 7–16. [Google Scholar] [CrossRef]

- Payri, F.; Bermúdez, V.; Payri, R.; Salvador, F.J. The influence of cavitation on the internal flow and the spray characteristics in diesel injection nozzles. Fuel 2004, 83, 419–431. [Google Scholar] [CrossRef]

- Hountalas, D.T.; Zannis, T.C.; Mavropoulos, G.C.; Schwarz, V.; Benajes, J.; Gonzalez, C.A. Use of a Multi-Zone Combustion Model to Interpret the Effect of Injector Nozzle Hole Geometry on HD DI Diesel Engine Performance and Pollutant Emissions; SAE Technical Paper; SAE: Warrendale, PA, USA, 2005. [Google Scholar]

- Das, S.; VanBrocklin, P.G. Effect of design and operating parameters on the spray characteristics of an outward opening injector. In Proceedings of the 13th International Multidimensional Engine Modeling User’s Group Meeting, Detroit, MI, USA, 2 March 2003; pp. 1–6. [Google Scholar]

- Lin, Y.-S.; Lin, H.-P. Study on the spray characteristics of methyl esters from waste cooking oil at elevated temperature. Renew. Energy 2010, 35, 1900–1907. [Google Scholar] [CrossRef]

- Khalid, A.; Amirnordin, S.H.; Lambosi, L.; Manshoor, B.; Sies, M.F.; Salleh, H. Spray characteristic of diesel-water injector for burner system. Adv. Mater. Res. 2014, 845, 66–70. [Google Scholar] [CrossRef]

- Fung, M. Experimental and Numerical Study of Spray Characteristics of Nasal Spray Device. Ph.D. Thesis, RMIT University, Melbourne, Australia, 2013. [Google Scholar]

- Bayvel, L.P. Liquid Atomization; Routledge: London, UK, 2019. [Google Scholar]

- Ashgriz, N. Handbook of Atomization and Sprays: Theory and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Gopinath, S.; Devan, P.K.; Sabarish, V.; Babu, B.V.S.; Sakthivel, S.; Vignesh, P. Effect of spray characteristics influences combustion in DI diesel engine—A review. Mater. Today Proc. 2020, 33, 52–65. [Google Scholar] [CrossRef]

- Baumgarten, C. Mixture Formation in Internal Combustion Engines; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Jedelský, J.; Jícha, M. Spray characteristics and liquid distribution of multi-hole effervescent atomisers for industrial burners. Appl. Therm. Eng. 2016, 96, 286–296. [Google Scholar] [CrossRef]

- Fung, M.C.; Inthanvong, K.; Yang, W.; Tu, J. Experimental and numerical modelling of nasal spray atomisation. In Proceedings of the Ninth International Conference on CFD in the Minerals and Process Industries, Melbourne, Australia, 10–12 December 2012; pp. 1–6. [Google Scholar]

- Yasin, M.F.M.; Cant, R.S.; Chong, C.T.; Hochgreb, S. Discrete multicomponent model for biodiesel spray combustion simulation. Fuel 2014, 126, 44–54. [Google Scholar] [CrossRef]

| Properties | ASTM Standard | CPO | RBD | WCO |

|---|---|---|---|---|

| Acid value (mg KOH/g) | D 974 | - | - | 18.21 |

| Flash point (°C) | D3828 | 214 | 266 | |

| Cloud point (°C) | D97 | 43 | 15 | |

| Pour point (°C) | D97 | 14 | 7 | |

| Density at 27 °C (kg/L) | D1217 | 0.9042–65 | 0.885 | 0.8989 |

| Calorific value (kJ/kg) | D976 | 39,285 | 39,357 | 39,198 |

| Kinematic viscosity at 40 °C (cSt) | D445 | 60 | 42 | 46.5 |

| Color | Visual | Orange | Light yellow | Reddish brown |

| Sulfur content | IP242 | - | 0.0325 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Didane, D.H.; Chin, R.Y.S.; Khalid, A. Computational and Experimental Studies on the Behavior of Sprays with Different Orifice Characteristics and Fuel Properties of Biodiesel Crude Palm Oil (CPO) on a Premix Injector—A Comprehensive Review. Processes 2024, 12, 2907. https://doi.org/10.3390/pr12122907

Didane DH, Chin RYS, Khalid A. Computational and Experimental Studies on the Behavior of Sprays with Different Orifice Characteristics and Fuel Properties of Biodiesel Crude Palm Oil (CPO) on a Premix Injector—A Comprehensive Review. Processes. 2024; 12(12):2907. https://doi.org/10.3390/pr12122907

Chicago/Turabian StyleDidane, Djamal Hissein, Ronny Yii Shi Chin, and Amir Khalid. 2024. "Computational and Experimental Studies on the Behavior of Sprays with Different Orifice Characteristics and Fuel Properties of Biodiesel Crude Palm Oil (CPO) on a Premix Injector—A Comprehensive Review" Processes 12, no. 12: 2907. https://doi.org/10.3390/pr12122907

APA StyleDidane, D. H., Chin, R. Y. S., & Khalid, A. (2024). Computational and Experimental Studies on the Behavior of Sprays with Different Orifice Characteristics and Fuel Properties of Biodiesel Crude Palm Oil (CPO) on a Premix Injector—A Comprehensive Review. Processes, 12(12), 2907. https://doi.org/10.3390/pr12122907