Rate Transient Analysis for Fractured Wells in Inter-Salt Shale Oil Reservoirs Considering Threshold Pressure Gradient

Abstract

1. Introduction

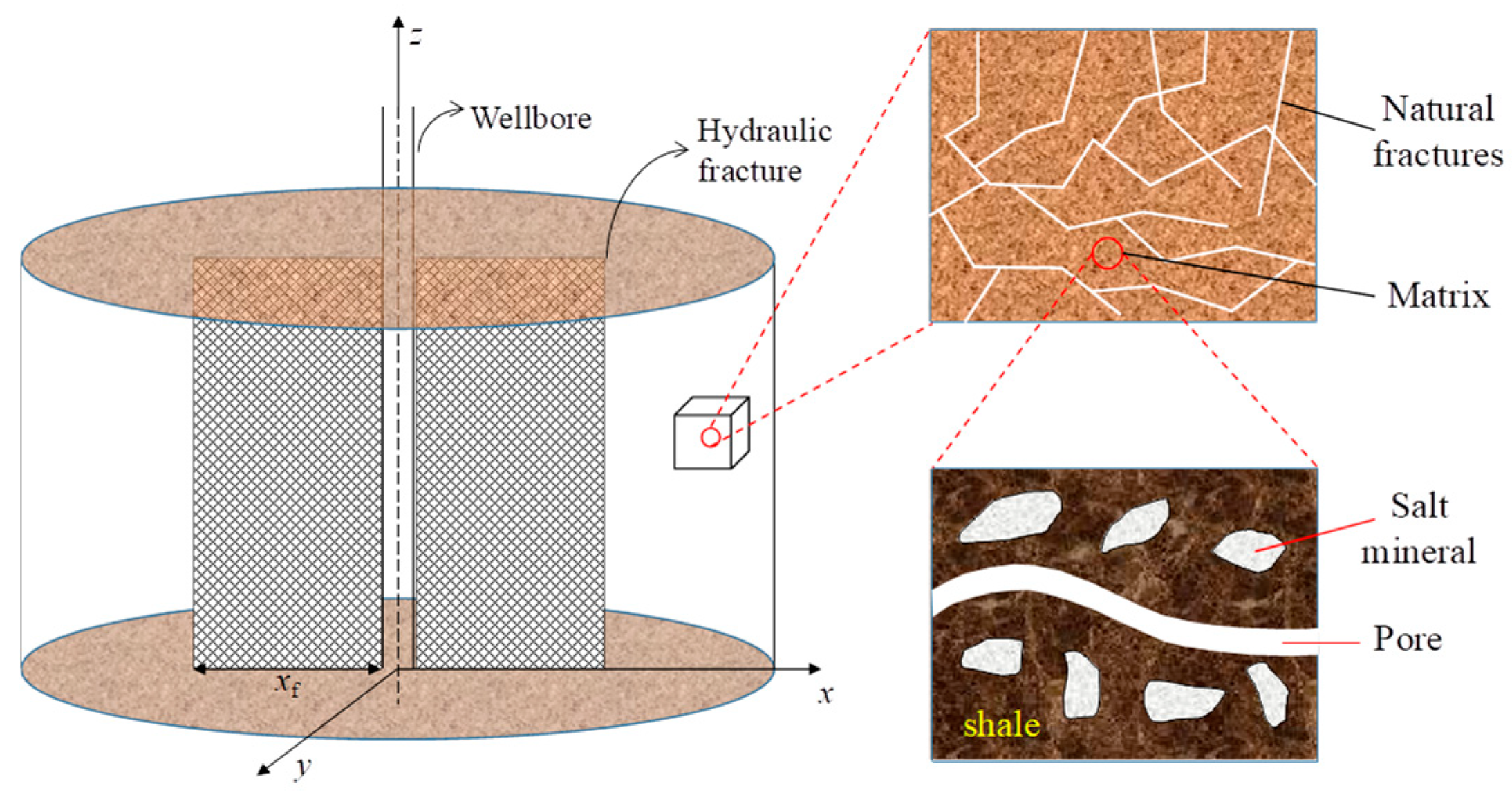

2. Mathematical Model

- (1)

- The inter-salt shale oil reservoir is treated as the dual-porosity system, while the matrix is considered to be a uniformly distributed gas source that supplies gas to the fracture system, and gas does not flow from the matrix system to the wellbore directly;

- (2)

- The reservoir is assumed to be isotropic. The lateral boundary extends infinitely, and the top and bottom boundaries are not permeable.

- (3)

- The fractured well is produced at a constant wellbore pressure or a constant rate, and hydraulic fractures are fully penetrated and have infinite conductivity;

- (4)

- The skin effect and wellbore storage effect are considered;

- (5)

- Oil flow in the inter-salt shale oil reservoir is under isothermal conditions.

2.1. Dimensionless Mathematical Model

2.2. Solution to Mathematical Model

- (1)

- When λBD is equal to 0, both sides of Equation (19) are multiplied by :

- (2)

- When λBD is not equal to 0, Equation (15) is inhomogeneous because its free term does not equal zero. We can use Green’s functions to represent the particular solution, so the general solution can be written as follows:where is Green’s function, and its expression can be written as follows:

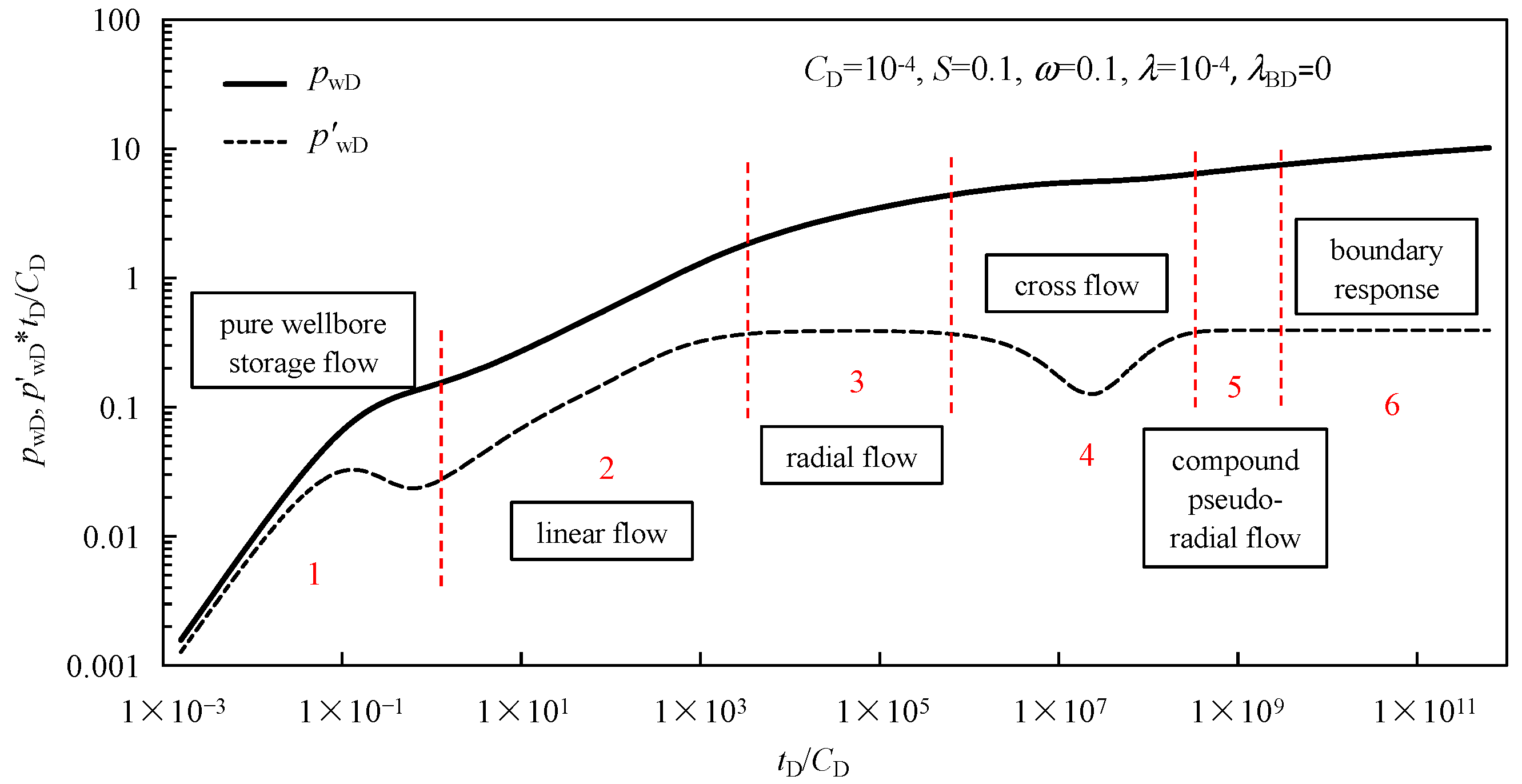

3. Flow Behavior Characteristics

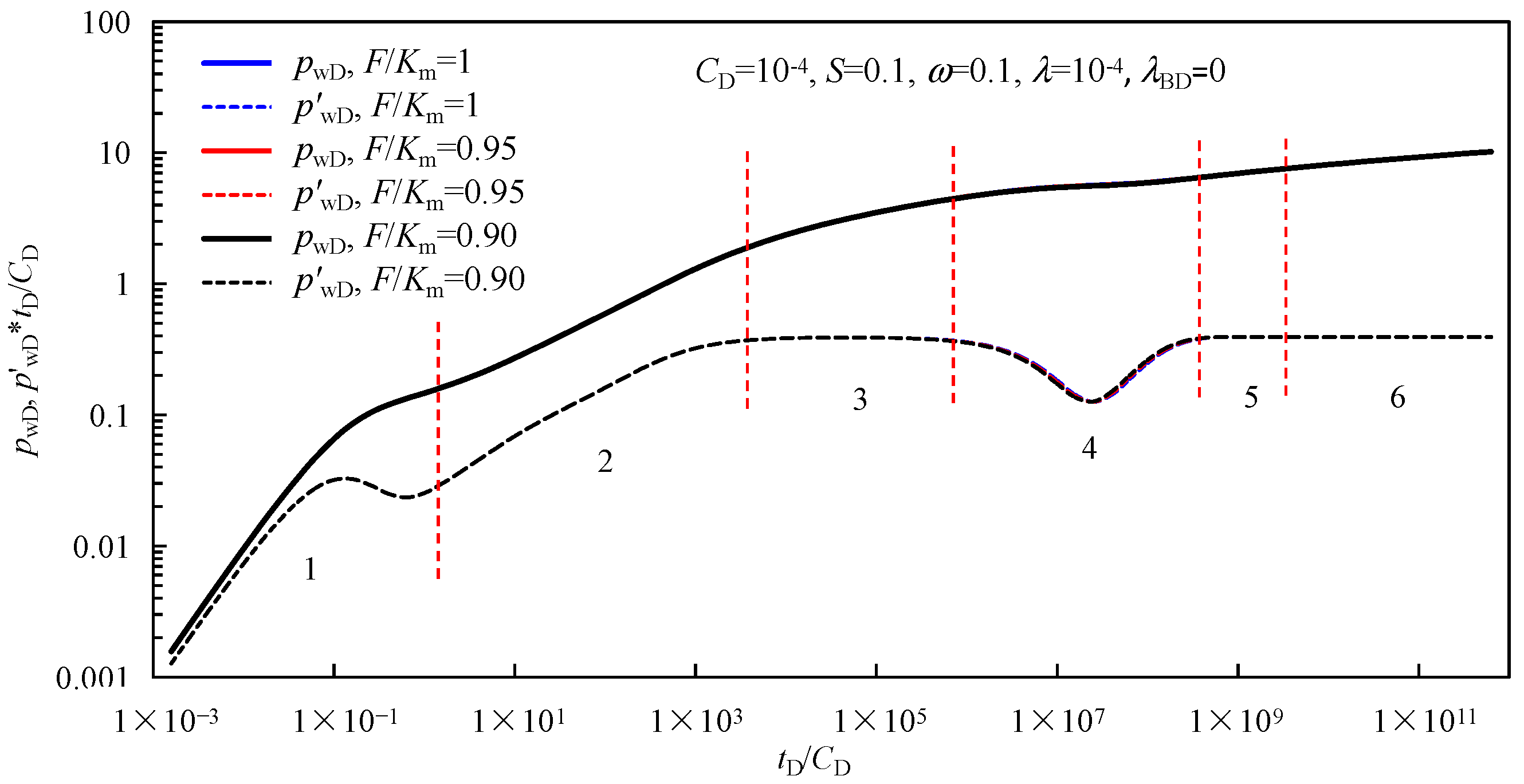

3.1. Flow Regimes Recognition

- Period 1:

- The pure wellbore storage period. The pressure curve and its derivative curve are on an upward-sloping line with a slope of one, which is controlled by oil stored in the wellbore. In skin effect flow periods, an obvious “hump” appears on the derivative curve, and the height and duration of the “hump” are mainly determined by the wellbore storage coefficient and skin factor.

- Period 2:

- The linear flow period of hydraulic fractures. In this flow period, the pressure curve and its derivative curve are parallel to each other, and the derivative curve is an upward straight line with a slope of 0.5.

- Period 3:

- The radial flow period of natural fractures. During this flow period, the pressure derivative curve is represented by a horizontal line at a value of 0.5. This indicates that the flow in the natural fracture system is radial, showing consistent pressure changes over time.

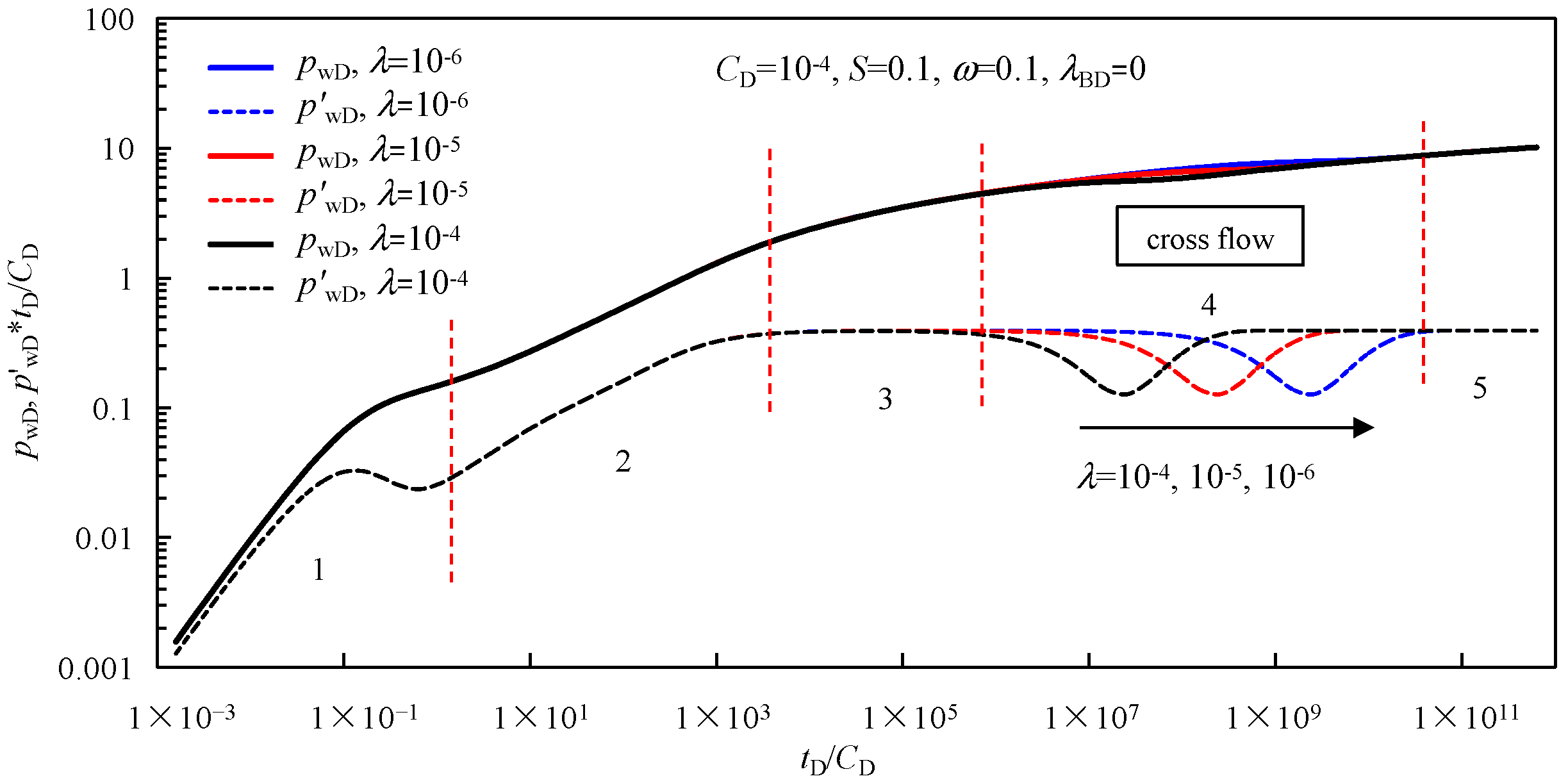

- Period 4:

- The cross-flow period. The most obvious characteristic of this period is the “dip” in the pressure derivative curve. In this stage, the shale oil flows from the matrix to the fracture due to the increasing pressure difference between the fracture system and the matrix system.

- Period 5:

- The late-time compound pseudoradial flow period. The pressure derivative curve is a horizontal line with a value of 0.5, indicating that the entire system is experiencing radial flow.

- Period 6:

- The external boundary response period.

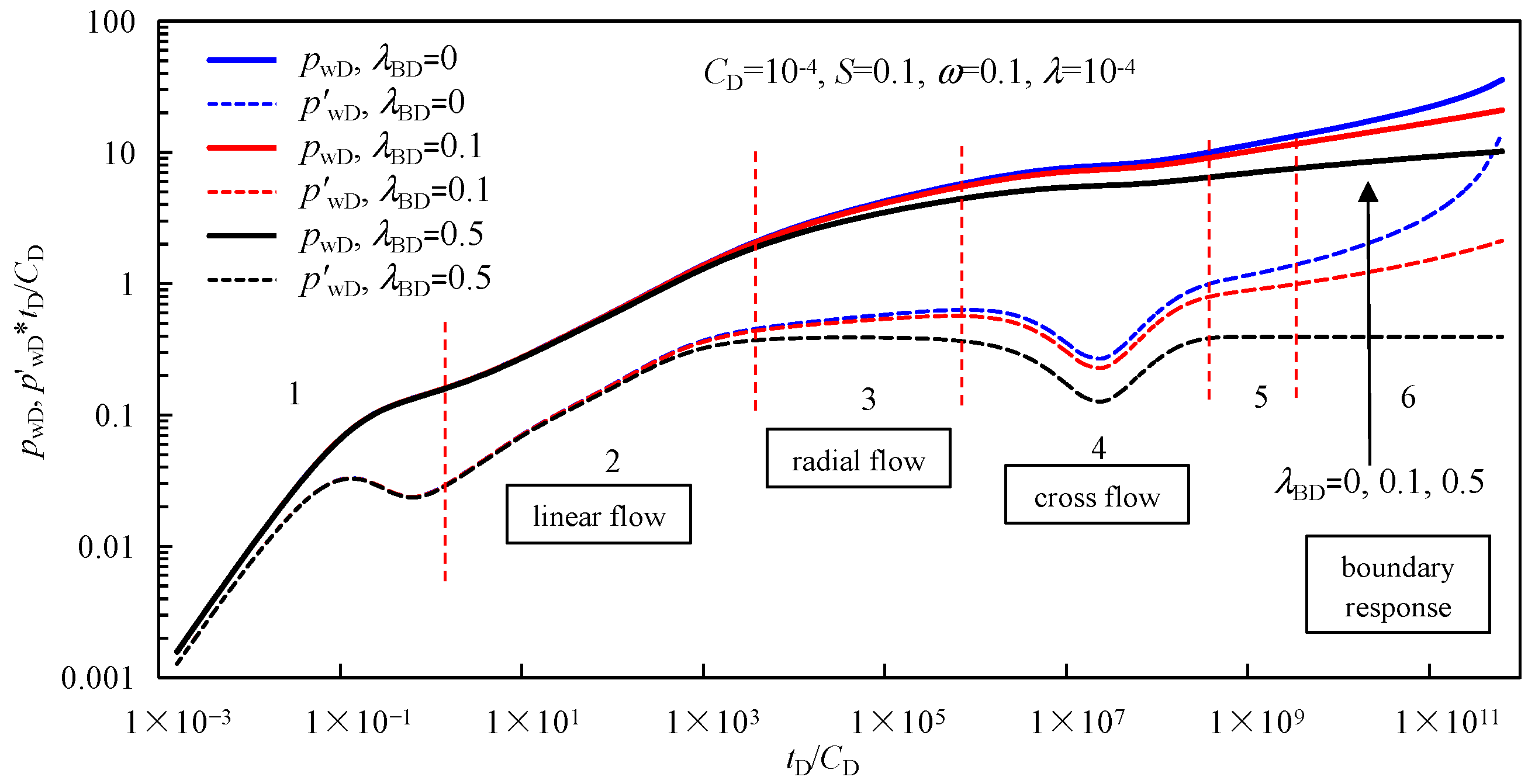

3.2. Parameter Influence

4. Conclusions

- (1)

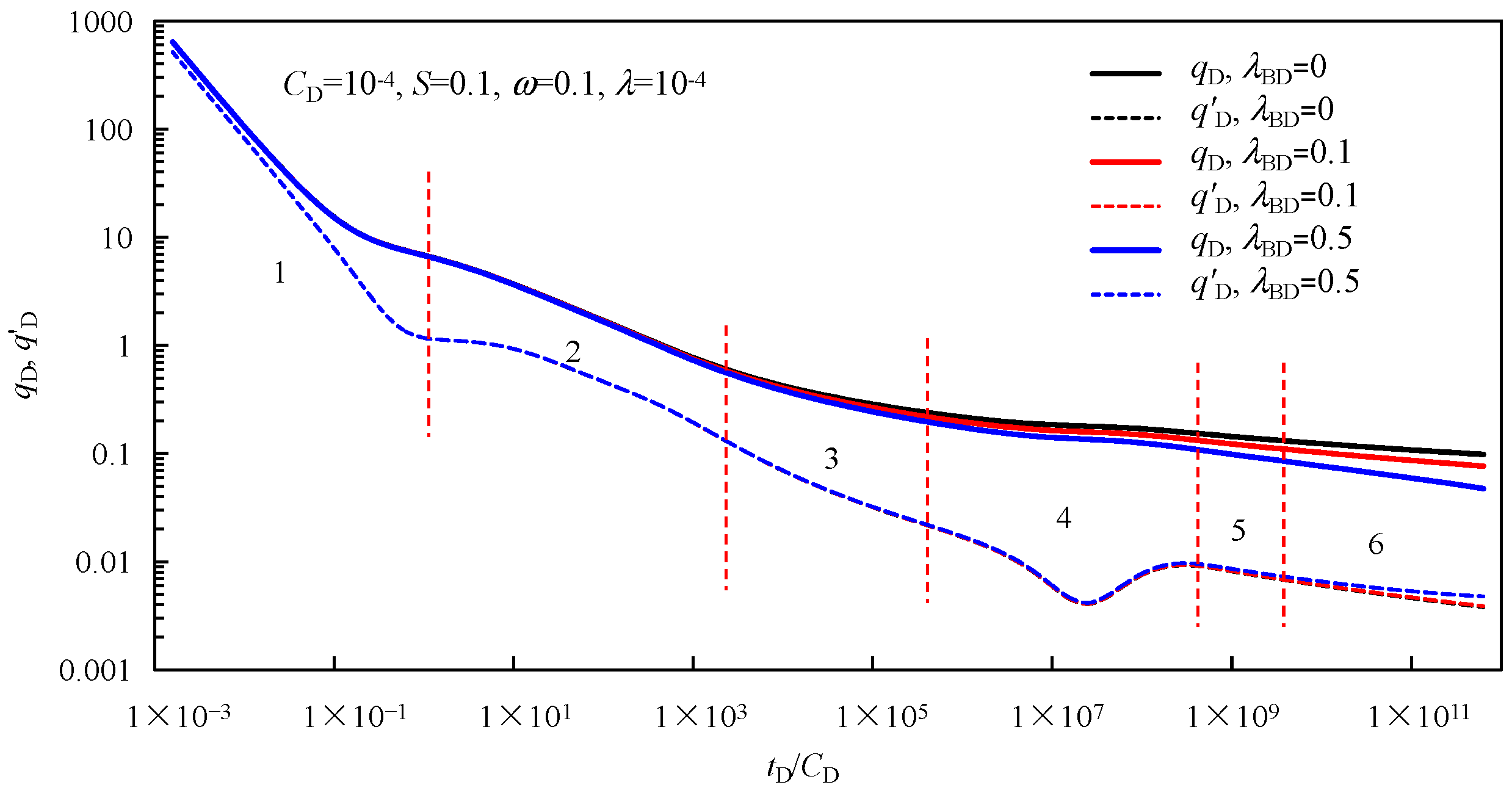

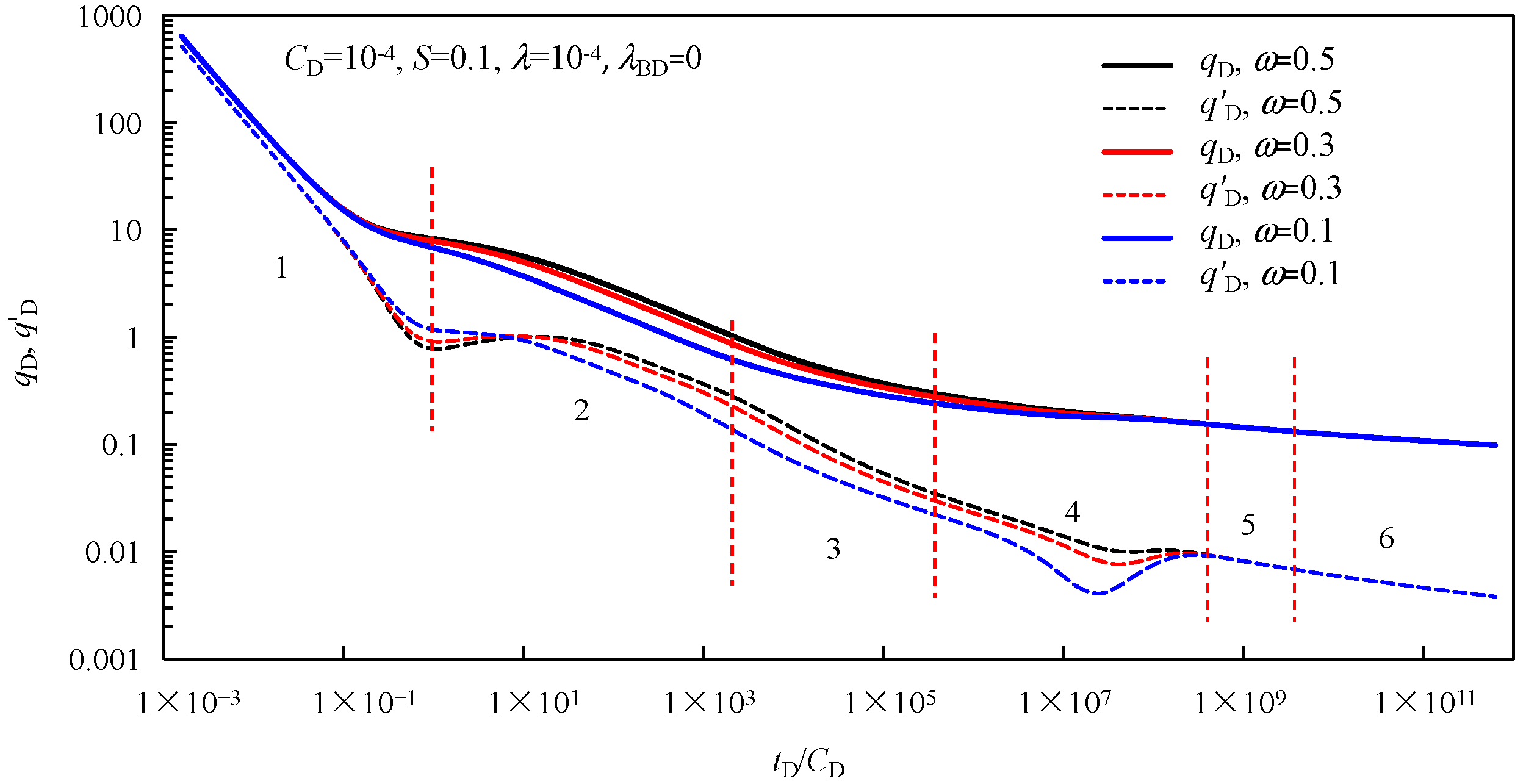

- The pressure response and its pressure derivative of a fractured vertical well in the inter-salt shale oil reservoir with consideration of the threshold pressure gradient are analyzed, and six main transient flow regimes can be observed in type curves of transient pressure.

- (2)

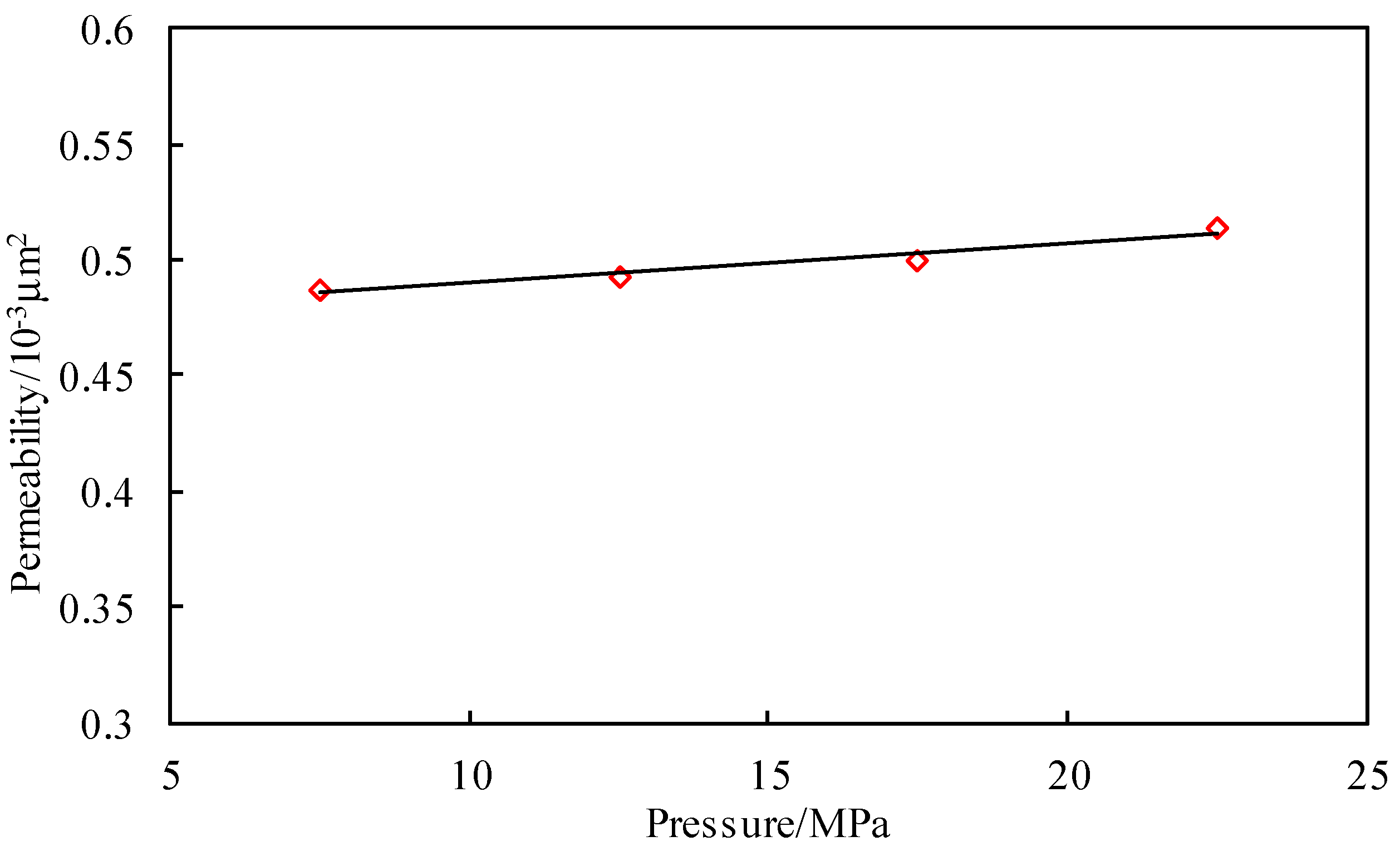

- The impact of salt dissolution on the transient pressure curves and rate decline curves of a fractured well in the inter-salt shale oil reservoir is negligible based on the experimental evaluation of the effect of salt dissolution on shale permeability.

- (3)

- The effect of the threshold pressure gradient on the pressure derivative curves becomes apparent from the radial flow period of natural fractures (Period 3). The pressure curve and its derivative curve begin to deviate and warp up, and the curve will be more warped with the increase in the threshold pressure gradient. Type curves of rate decline curves show that the larger the threshold pressure gradient, the greater the decline of the dimensionless production curve and the greater the upturning of its derivative curve.

- (4)

- The storage capacity ratio ω not only affects the cross-flow period of pressure derivative curves but also affects the curve shape of the linear flow period, and the elastic storativity ratio has the most obvious influence on the middle period of the rate decline curves. In addition, the cross-flow coefficient also has an influence on the transient pressure and rate decline behaviors of fractured wells.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Latin | |

| B | fluid volume factor, m3/sm3 |

| C | wellbore storage coefficient, m3/Pa |

| Cft | total compressibility coefficient of fracture system, Pa−1 |

| Cmt | total compressibility coefficient of matrix system, Pa−1 |

| Cp | rock compressibility coefficient, Pa−1 |

| CL | fluid compressibility coefficient, Pa−1 |

| h | formation thickness, m |

| Kfi | initial permeability of fracture, m2 |

| Kf | permeability of fracture, m2 |

| Kmi | initial permeability of matrix, m2 |

| Km | permeability of matrix, m2 |

| L | Characteristic length, m |

| p | pressure, Pa |

| pi | initial pressure, Pa |

| p0 | reference pressure, Pa |

| pm | matrix pressure, Pa |

| pf | fracture pressure, Pa |

| qsc | surface gas production rate, m3/s |

| qex | cross flow from matrix to fracture, kg/(m3·s) |

| vf | velocity of oil flow in fracture, m/s |

| r | radial distance, m |

| s | Laplace transform variable |

| S | skin factor, dimensionless |

| t | time, s |

| Greek letters | |

| α | matrix block shape factor, 1/m2 |

| λ | cross flow coefficient, dimensionless |

| λB | threshold pressure gradient, Pa/m |

| ω | elastic storativity ratio, dimensionless |

| ϕf | fracture porosity, dimensionless |

| ϕ0 | initial porosity, dimensionless |

| ϕm | matrix porosity, dimensionless |

| ρ0 | reference gas density under reference pressure, kg/m3 |

| ρf | oil density in fracture system, kg/m3 |

| ρm | oil density in matrix system, kg/m3 |

| μ | oil viscosity, Pa·s |

| Superscripts | |

| Laplace transform domain |

Appendix A. Mathematical Model Establishment

Appendix B. Experimental Study on the Effect of the Salt Dissolution on Shale Permeability

| Pressure Difference/MPa | Inlet Pressure/MPa | Outlet Pressure/MPa | Permeability/×10−3 μm2 |

|---|---|---|---|

| 5 | 25 | 20 | 0.514 |

| 5 | 20 | 15 | 0.5 |

| 5 | 15 | 10 | 0.493 |

| 5 | 10 | 5 | 0.488 |

References

- Georgeson, L.; Maslin, M.; Poessinouw, M. Clean up energy innovation. Nature 2016, 538, 27–29. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Su, J.Z.; Chang, X.; Huang, Z.W.; Zhou, T.; Guo, Y.T.; Wu, S.Q. Brittleness evaluation of the inter-salt shale oil reservoir in Jianghan Basin in China. Mar. Pet. Geol. 2019, 102, 109–115. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, F.; He, S.; Zheng, Y.; Wu, S.; Luo, J. The pore structures of the shale about typical inter-salt rhythm in the Paleogene of Qianjiang depression. J. Shenzhen Univ. Sci. Eng. 2019, 36, 289–297. [Google Scholar] [CrossRef]

- Yang, L.; Lu, H.; Fan, X.; Huang, Z.; Zhou, T. Salt occurrence in matrix pores of intersalt shale oil reservoirs. Sci. Technol. Eng. 2020, 20, 1839–1845. [Google Scholar]

- Zhang, Y.; Zhang, M.; Mei, H.; Zeng, F. Study on salt precipitation induced by formation brine flow and its effect on a high-salinity tight gas reservoir. J. Pet. Sci. Eng. 2019, 183, 106384. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, Y.; Wang, H.; Zhao, Q.; Wang, H. Effects of Injection Water Salinity on Physical Properties of Inter-Salt Shale Oil Reservoir. Spec. Oil Gas Reserv. 2020, 27, 131–137. [Google Scholar]

- Yang, X.; Guo, B. Productivity analysis of multi-fractured shale oil wells accounting for the low-velocity non-Darcy effect. J. Pet. Sci. Eng. 2019, 183, 106427. [Google Scholar] [CrossRef]

- Wang, X.; Sheng, J.J. Effect of low-velocity non-Darcy flow on well production performance in shale and tight oil reservoirs. Fuel 2017, 190, 41–46. [Google Scholar] [CrossRef]

- Miller, R.J.; Low, P.F. Threshold gradient for water flow in clay system. Soil Sci. Soc. Am. J. 1963, 27, 605–609. [Google Scholar] [CrossRef]

- Thomas, L.K.; Katz, D.L.; Tek, M.R. Threshold pressure phenomena in porous media. Soc. Petroleum Eng. J. 1968, 8, 174–184. [Google Scholar] [CrossRef]

- Das, A.K. Generalized Darcy’s law including source effect. J. Can. Pet. Technol. 1997, 36, 57–59. [Google Scholar] [CrossRef]

- Boukadi, F.; Bemani, A.; Rumhy, M.; Kalbani, M. Threshold pressure as a measure of degree of rock wettability and diagenesis in consolidated Omani limestone cores. Mar. Pet. Geol. 1998, 15, 33–39. [Google Scholar] [CrossRef]

- Bennion, D.B.; Thomas, F.B.; Ma, T. Recent advances in laboratory test protocols evaluate optimum drilling, completion and stimulation practices for low permeability gas reservoirs. In Paper SPE 60324, Presented at SPE Rocky Mountain Regional/Low-permeability Reservoirs Symposium and Exhibition, Denver, CO, USA, 12–15 March 2000; SPE: Richardson, TX, USA, 2020. [Google Scholar]

- Dey, G.R. Nonlinear flow of gas at low velocity in porous media. J. Nat. Gas Chem. 2007, 16, 217–226. [Google Scholar] [CrossRef]

- Pascal, H. Nonsteady flow through porous media in the presence of a threshold gradient. Acta Mech. 1981, 39, 207–224. [Google Scholar] [CrossRef]

- Lu, J.; Ghedan, S. Pressure behavior of vertical wells in low-permeability reservoirs with threshold pressure gradient. Spec. Top. Rev. Porous Media 2011, 2, 157–169. [Google Scholar] [CrossRef]

- Wu, J.; Xu, P.; Li, L.; Li, Z.; Qi, H.; Wang, C.; Zhang, Y.; Xie, Y.; Tan, D. Multiphase dynamic interfaces and abrasive transport dynamics for abrasive flow machining in shear thickening transition states. Powder Technol. 2024, 446, 120150. [Google Scholar] [CrossRef]

- Tan, Y.; Yesha, N.I.; Weixin, X.U.; Xie, Y.; Lin, L.I.; Tan, D. Key technologies and development trends of the soft abrasive flow finishing method. J. Zhejiang Univ.-Sci. A (Appl. Phys. Eng.) 2023, 24, 1043–1064. [Google Scholar] [CrossRef]

- Song, H.; Liu, Q.; Yang, D.; Yu, M.; Lou, Y.; Zhu, W. Productivity equation of fractured horizontal well in a water-bearing tight gas reservoir with low-velocity non-Darcy flow. J. Nat. Gas Sci. Eng. 2014, 18, 467–473. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, L.; Wu, F.; Zhang, B.; Liu, Q. Analysis of horizontal well pressure behavior in fractured low permeability reservoirs with consideration of the threshold pressure gradient. J. Geophys. Eng. 2013, 10, 035014. [Google Scholar] [CrossRef]

- Cao, L.; Li, X.; Luo, C.; Yuan, L.; Zhang, J.; Tan, X. Horizontal well transient rate decline analysis in low permeability gas reservoirs employing an orthogonal transformation method. J. Nat. Gas Sci. Eng. 2016, 33, 703–716. [Google Scholar] [CrossRef]

- Cao, L.; Li, X.; Zhang, J.; Luo, C.; Tan, X. Dual-porosity model of rate transient analysis for horizontal well in tight gas reservoirs with consideration of threshold pressure gradient. J. Hydrodyn. 2018, 30, 872–881. [Google Scholar] [CrossRef]

- Diwu, P.; Liu, T.; You, Z.; Jiang, B.; Zhou, J. Effect of low velocity non-Darcy flow on pressure response in shale and tight oil reservoirs. Fuel 2018, 216, 398–406. [Google Scholar] [CrossRef]

- Zeng, J.; Wang, X.; Guo, J.; Zeng, F.; Zhang, Q. Composite linear flow model for multi-fractured horizontal wells in tight sand reservoirs with the threshold pressure gradient. J. Pet. Sci. Eng. 2018, 165, 890–912. [Google Scholar] [CrossRef]

- Luo, E.; Wang, X.; Hu, Y.; Wang, J.; Liu, L. Analytical solutions for non-Darcy transient flow with the threshold pressure gradient in multiple-porosity media. Math. Probl. Eng. 2019, 2019, 2618254. [Google Scholar] [CrossRef]

- Wu, Z.; Cui, C.; Lv, G.; Bing, S.; Cao, G. A multi-linear transient pressure model for multistage fractured horizontal well in tight oil reservoirs with considering threshold pressure gradient and stress sensitivity. J. Pet. Sci. Eng. 2019, 172, 839–854. [Google Scholar] [CrossRef]

- Van Everdingen, A.F.; Hurst, W. The application of the Laplace transformation to flow problems in reservoirs. Trans. AIME 1949, 186, 97–104. [Google Scholar] [CrossRef]

- Bumb, A.C.; McKee, C.R. Gas-well testing in the presence of desorption for coalbed methane and devonian shale. SPE Form. Eval. 1988, 3, 179–185. [Google Scholar] [CrossRef]

- Zhan, H.; Zlotnik, V.A. Groundwater flow to horizontal and slanted wells in unconfined aquifers. Wat. Resour. Res. 2002, 38, 1108. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, L.; Zhao, J.; Luo, J.; Zhang, B. “Triple porosity” modeling of transient well test rate decline analysis for multi-fractured horizontal well in shale gas reservoirs. J. Pet. Sci. Eng. 2013, 110, 253–261. [Google Scholar] [CrossRef]

- Stehfest, H. Algorithm 368: Numerical inversion of Laplace transforms. Commun. ACM 1970, 13, 47–49. [Google Scholar] [CrossRef]

| Parameters | Symbols | Values | Units |

|---|---|---|---|

| Formation pressure | pi | 2.34 × 107 | Pa |

| Formation thickness | h | 10 | m |

| Threshold pressure gradient | λB | 5.2 × 104 | Pa/m |

| Matrix permeability | km | 2.4 × 10−19 | m2 |

| Formation thickness | h | 10 | m |

| Fracture permeability | kfh | 2.0 × 10−13 | m2 |

| Fracture porosity | ϕf | 0.039 | dimensionless |

| Oil viscosity | μ | 2.95 × 10−3 | Pa·s |

| Matrix compressibility | cmt | 6.2 × 10−11 | 1/Pa |

| Fracture compressibility | cft | 4.3 × 10−9 | 1/Pa |

| Half-length of hydraulic fracture | xf | 50 | m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Huang, T.; Gao, X.; Song, W.; Hu, C.; Liu, J. Rate Transient Analysis for Fractured Wells in Inter-Salt Shale Oil Reservoirs Considering Threshold Pressure Gradient. Processes 2024, 12, 2833. https://doi.org/10.3390/pr12122833

Guo X, Huang T, Gao X, Song W, Hu C, Liu J. Rate Transient Analysis for Fractured Wells in Inter-Salt Shale Oil Reservoirs Considering Threshold Pressure Gradient. Processes. 2024; 12(12):2833. https://doi.org/10.3390/pr12122833

Chicago/Turabian StyleGuo, Xiao, Ting Huang, Xian Gao, Wenzhi Song, Changpeng Hu, and Jingwei Liu. 2024. "Rate Transient Analysis for Fractured Wells in Inter-Salt Shale Oil Reservoirs Considering Threshold Pressure Gradient" Processes 12, no. 12: 2833. https://doi.org/10.3390/pr12122833

APA StyleGuo, X., Huang, T., Gao, X., Song, W., Hu, C., & Liu, J. (2024). Rate Transient Analysis for Fractured Wells in Inter-Salt Shale Oil Reservoirs Considering Threshold Pressure Gradient. Processes, 12(12), 2833. https://doi.org/10.3390/pr12122833