Experimental Study on the Stress Sensitivity Characteristics of Wave Velocities and Anisotropy in Coal-Bearing Reservoir Rocks

Abstract

1. Introduction

2. Sample Preparation and Experimental Methods

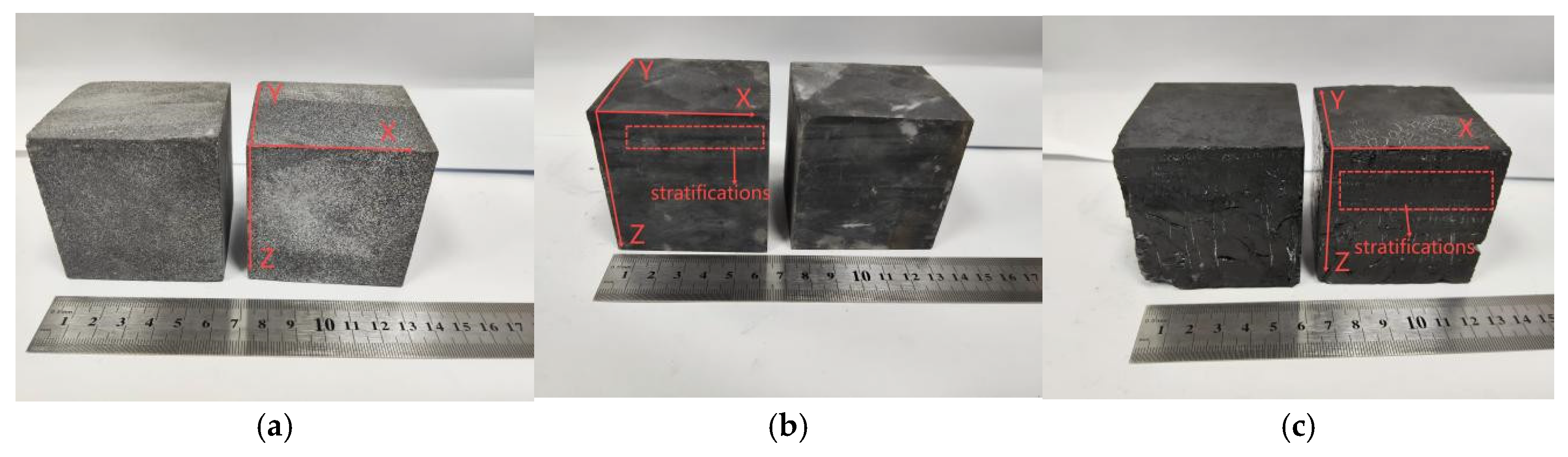

2.1. Rock Sample Collection and Specimen Preparation

2.2. Experimental Instruments and Equipment

2.3. Main Experimental Methods and Procedures

2.3.1. Main Experimental Method

2.3.2. Main Experimental Steps

- (1).

- Uniaxial loading experiments were conducted on cylindrical samples, gradually and slowly increasing the axial pressure until the samples failed. This produced stress–strain curves for each type of coal rock sample and determined their compressive strength. The stress–strain curves were analyzed to ascertain the elastic deformation range and yield point (Pmax) of the coal rock samples selected. Specific testing information for the Pmax of the measured rock samples is presented in Table 2.

- (2).

- For each direction, tests of transverse and longitudinal wave velocities were performed on the rock samples under atmospheric pressure, obtaining the wave speed information of the tested samples at this stage.

- (3).

- For each rock sample, the X direction was selected as the first testing direction. Starting from the initial loading pressure point of 0.5 MPa, axial pressure loading was applied to the sample with an incremental pressure of 0.5 MPa. Each pressure point was stabilized for 1 min. before performing ultrasonic tests to acquire waveform data of the longitudinal and transverse transmitted waves under that pressure state. The pressure was then increased to the next pressure point, and the ultrasonic testing process was repeated until Pmax was reached or approached.

- (4).

- The above steps were repeated, sequentially conducting loading-ultrasonic experiments in the Y and Z directions. At this point, the experimental testing of one sample was completed. The same procedures were repeated to complete the uniaxial loading-ultrasound measurement experiments for each rock sample in the three orthogonal directions.

3. Experimental Results

4. Analysis and Discussion of Experimental Results

4.1. Ultrasonic Response Characteristics of Rocks Under Normal Pressure Conditions

4.2. Influence Characteristics of Loading Pressure on Wave Velocity Magnitude

4.2.1. Sandstone

4.2.2. Mud Shale

4.2.3. Anthracite

4.2.4. Dynamic Elasticity Parameters

4.3. Influence Characteristics of Loading Pressure on Wave Velocity Anisotropy

4.3.1. Sandstone

4.3.2. Mud Shale

4.3.3. Anthracite

5. Conclusions

- (1).

- In different directions, the longitudinal wave velocity (Vp), transverse wave velocity (Vs), and wave velocity ratio of sandstone, mud shale, and anthracite all exhibit a distinct stage-wise increase with rising pressure. During the initial phase of pressure increase, the rate of wave velocity increase is rapid, but it gradually slows down and approaches a stable maximum value (theoretical rock skeleton wave velocity). This phenomenon aligns with the stress–strain behavior of rocks prior to yielding and failure under uniaxial loading conditions. The wave velocity of anthracite is relatively low, and compared to sandstone, the sensitivity of mud shale and anthracite wave velocities to loading pressure is reduced. Among the three types of reservoir rocks, Vp is generally more sensitive to loading pressure than Vs, indicating that Vp can serve as a good elastic wave indicator for predicting in situ stress states.

- (2).

- During the pressure loading process, the measured wave velocities and wave velocity ratios of sandstone, mud shale, and anthracite display certain anisotropic characteristics, with an overall trend of weakening and stabilizing anisotropy. The anisotropic features of wave velocities and wave velocity ratios in mud shale are stronger than those in sandstone. Conversely, the anisotropic strength of the longitudinal wave velocity (Vp) and wave velocity ratio in anthracite is significantly lower than that of mud shale, while the transverse wave velocity (Vs) demonstrates a very high degree of anisotropy. However, the sensitivity of the anisotropy of wave velocities and wave velocity ratios in mud shale and anthracite to loading pressure is relatively weak.

- (3).

- The anisotropic characteristics of the longitudinal wave velocity in sandstone and mud shale are stronger than those of the transverse wave velocity, whereas the anisotropic characteristics of the transverse wave velocity in anthracite are stronger than those of the longitudinal wave velocity. This is due to the higher sensitivity of transverse waves to anisotropic media with fractures. Layering structure is the primary factor contributing to the anisotropy of sandstone and mud shale, while in anthracite, the presence of numerous (micro-)fractures, in addition to layering structure, is another significant factor influencing its anisotropy.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.G.; Qin, Y.; You, Z.J.; Yang, Z.B. Distribution Characteristics of In Situ Stress Field and Vertical Development Unit Division of CBM in Western Guizhou, China. Nat. Resour. Res. 2021, 30, 3659–3679. [Google Scholar] [CrossRef]

- Li, M.; Li, M.J.; Pan, J.N.; Gao, D.; Cao, Y.X. Coalbed methane accumulation, in-situ stress, and permeability of coal reservoirs in a complex structural region (Fukang area) of the southern Junggar Basin, China. Front. Earth Sci. 2023, 10, 1076076. [Google Scholar] [CrossRef]

- Markov, A.; Markov, M.; Levin, V.; Jarillo, G.R. Electromagnetic field excitation during the scattering of an acoustic wave on an inhomogeneity in a poroelastic medium. Int. J. Eng. Res. Sci. 2013, 182, 103784. [Google Scholar] [CrossRef]

- Khosrow, N.; Tayfun, B. Pore-scale investigation of immiscible displacement process in porous media under high-frequency sound waves. J. Fluid Mech. 2011, 680, 336–360. [Google Scholar] [CrossRef]

- Buishvili, T.; Kekutia, S.; Tkeshelashvili, O.; Tkeshelashvili, L. Theory of sound propagation in superfluid-filled porous media. Phys. Lett. A 2002, 300, 672–686. [Google Scholar] [CrossRef]

- Pothana, P.; Garcia, E.F.; Ling, K. Effective Elastic Properties and Micro-mechanical Damage Evolution of Composite Granular Rocks: Insights from Particulate Discrete Element Modelling. Rock Mech. Rock Eng. 2024, 57, 6567–6611. [Google Scholar] [CrossRef]

- Pothana, P.; Ifrene, G.; Ling, K. Stress-Dependent Petrophysical Properties of the Bakken Unconventional Petroleum System: Insights from Elastic Wave Velocities and Permeability Measurements. Fuels 2023, 4, 397–416. [Google Scholar] [CrossRef]

- Pothana, P.; Ifrene, G.; Ling, K. Integrated Petrophysical Evaluation and Rock Physics Modeling of Broom Creek Deep Saline Aquifer for Geological CO2 Storage. Fuels 2024, 5, 53–74. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Wu, J.; Wang, Y. The Carrying Behavior of Water-Based Fracturing Fluid in Shale Reservoir Fractures and Molecular Dynamics of Sand-Carrying Mechanism. Processes 2024, 12, 2051. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Han, Y. A Numerical Investigation on Kick Control with the Displacement Kill Method during a Well Test in a Deep-Water Gas Reservoir: A Case Study. Processes 2024, 12, 2090. [Google Scholar] [CrossRef]

- Zheng, L.J.; Zhang, Z.P.; Peng, Y.; Ai, T.; Zhang, R.; Ren, L. Stress wave propagation law and dynamic elastic parameters of marble with different occurrence depth. Res. Explor. Lab. 2020, 39, 9–13. [Google Scholar] [CrossRef]

- Cheng, Y.; Song, Z.P.; Jin, J.F.; Chang, X.X.; Yuan, W. Variation of p-wave velocity and stress wave amplitude in sandstone under static stress. J. Yangtze River Sci. Res. Inst. 2018, 35, 115–119. [Google Scholar] [CrossRef]

- Zheng, G.P.; Zhao, X.D.; Liu, J.P.; Li, Y.H. Experimental study on change in acoustic wave velocity when rock is loading. J. Northeastern Univ. Nat. Sci. 2009, 30, 1197–1200. [Google Scholar] [CrossRef]

- Guo, F.; Yang, X.D.; Guo, L.; Lai, S.H. Multi-attribute Probabilistic Neural Network Reservoir Prediction Based on Mudstone Acoustic Time Difference Decompaction Correction. Energy Explor. Exploit. 2024, 42, 82–102. [Google Scholar] [CrossRef]

- Wang, P.; Xu, J.Y.; Liu, S.; Liu, S.H. Mechanical properties and ultrasonic time-frequency characteristics of thermally damaged sandstone. Chin. J. Rock Mech. Eng. 2014, 33, 1897–1904. [Google Scholar] [CrossRef]

- Kong, B.; Zhong, J.; Wei, J. Study on sound wave kinematic characteristics and temperature sensing mechanism during the warming process of loose coals. Energy 2024, 307, 132753. [Google Scholar] [CrossRef]

- Si, W.P.; Di, B.R.; Wei, J.X.; Li, Q. Experimental study of water saturation effect on acoustic velocity of sandstones. J. Nat. Gas Sci. Eng. 2016, 33, 37–43. [Google Scholar] [CrossRef]

- Hu, S.; Liu, W.N.; Liu, Y.M.; Liu, K. Acoustic logging response law in shales based on petrophysical model. Pet. Sci. 2022, 19, 2120–2130. [Google Scholar] [CrossRef]

- Guo, J.; Chen, C.M.; Cai, G.B.; Wen, H.; Li, S. Exploring Acoustic Wave Propagation and Equivalent Path in Quasi-Porous Medium of Loose Coal Mass. Nat. Resour. Res. 2024, 33, 389–403. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, X.K.; Zhang, Y.G. Ultrasonic elastic characteristics of six kinds of metamorphic coals in China under room temperature and pressure conditions. Chin. J. Geophys. 2016, 59, 2726–2738. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Liu, L.; Du, J.G. Research progress of rock wave velocity under high temperature and high pressure. Chin. J. Geophys. 2023, 38, 1999–2022. [Google Scholar] [CrossRef]

- Jana, A.; Stuedlein, A.W. Dynamic in Situ Nonlinear Inelastic Response of a Deep Medium Dense Sand Deposit. J. Geotech. Geoenviron. Eng. 2021, 147, 04021039. [Google Scholar] [CrossRef]

- Jiang, P.; Apfel, E.R. Measuring the frequency-dependent ultrasonic attenuation of liquids with a pulse transmission method. J. Acoust. Soc. Am. 2005, 89, 1971. [Google Scholar] [CrossRef]

- Zhang, J.L.; Wang, Y.; Zhang, Y.G. Application of shear wave polarization method in ultrasonic measurement of coal samples. J. China Coal. Soc. 2013, 38, 1220–1226. [Google Scholar] [CrossRef]

- Wang, C.; Yuan, X.P.; Wang, K.W. Constitutive equation of loading-induced elastic-plastic damage of coal and sandstone. Coal. Geol. Explor. 2017, 45, 105–111. [Google Scholar] [CrossRef]

- Chen, P.; Wang, E.; Chen, X.; Zhen, T.L.; Zhong, H.L.; Rong, X.S. Regularity and mechanism of coal resistivity response with different conductive characteristics in complete stress–strain process. Int. J. Min. Sci. Technol. 2015, 25, 779–786. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, T.F. Rock Phys; Peking University Press: Beijing, China, 2001. [Google Scholar]

- Nikolenko, P.V.; Shkuratnik, V.L.; Chepur, M.D. The effect of limestone porosity on the velocity of p- and s-waves under mechanical and thermal loading. J. Min. Sci. 2021, 56, 695–705. [Google Scholar] [CrossRef]

- Bai, J.J.; Si, S.H.; Kang, Y.L.; Chen, M.J.; You, L.J.; Tao, L.; Zhu, Q.J. Investigation on the propagation characteristic of shale ultrasonic in the stress loading procedure. Prog. Geophys. Chin. 2022, 37, 2351–2363. [Google Scholar] [CrossRef]

- Lei, J. Impact of anisotropic and inhomogeneous medium on measuring seismic shear-wave splitting. Chin. Sci. Bull. 2017, 62, 2619–2629. (In Chinese) [Google Scholar] [CrossRef]

- Xu, H.; Yu, Q.Z.; Liu, J.P.; Xiao, H.J.; Cheng, F. Study on the propagation characteristics of seismic waves perpendicular to the earth-rock dam axis. Soil. Dyn. Earthquake. Eng. 2024, 186, 108907. [Google Scholar] [CrossRef]

- Zang, H.L.; Feng, M.; An, M.J. Evaluation and determination of anisotropic parameters using multiple shear-wave splitting analysis methods. Chin. J. Geophys. 2023, 66, 3258–3272. [Google Scholar] [CrossRef]

- Xu, T.; Ai, Y.S.; Wu, C.L.; Chen, L.; Fan, E.B.; Li, L.; Dong, W.Y. Subduction-Induced Asthenospheric Flow Around the Songliao Basin in NE China Revealed by Shear Wave Splitting Measurements of Dense Seismic Arrays. J. Geophys. Res. Solid Earth 2023, 128, e2022JB026075. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.H. Investigation of the P- and S-wave velocity anisotropy of a Longmaxi formation shale by real-time ultrasonic and mechanical experiments under uniaxial deformation. J. Pet. Sci. Eng. 2017, 158, 253–267. [Google Scholar] [CrossRef]

- Wei, J.X.; Zhao, J.G.; Shuai, D.; Di, B.B.; Qin, S.Y. Estimations of P- and S-wave velocities and anisotropy from measurements on artificial fractured samples. Explor. Geophys. 2018, 83, MR107–MR121. [Google Scholar] [CrossRef]

- Shi, P.D.; Yuan, S.Y.; Wang, T.Y.; Wang, Y.Y.; Liu, T. Fracture Identification in a Tight Sandstone Reservoir:A Seismic Anisotropy and Automatic Multisensitive Attribute Fusion Framework. IEEE Geosci. Remote Sens. Lett. 2018, 15, 1525–1529. [Google Scholar] [CrossRef]

- Wang, B.; Li, W.; Lu, J.; Jin, W.J.; Hu, S. Study on acoustic logging response of fractured reservoirs using a novel equivalent medium model. Acta Geophys. 2022, 6, 2695–2704. [Google Scholar] [CrossRef]

| Test Sample | Side Length (mm) | Quality/m (g) | Density/ρ (g/cm3) | ||

|---|---|---|---|---|---|

| X | Y | Z | |||

| S1 | 62.09 | 62.17 | 62.05 | 630.3 | 2.631 |

| S2 | 62.55 | 63 | 61.98 | 642.6 | 2.631 |

| Y1 | 62.05 | 62 | 61.53 | 618.8 | 2.614 |

| Y2 | 62.6 | 61.68 | 62.11 | 624.8 | 2.605 |

| M1 | 62.15 | 62.6 | 62.2 | 361.7 | 1.495 |

| M2 | 62.65 | 62.86 | 63.48 | 372.1 | 1.488 |

| Sandstone | Mud Shale | Anthracite | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample | Pmax(MPa) | Sample | Pmax(MPa) | Sample | Pmax(MPa) | ||||||

| X | Y | Z | X | Y | Z | X | Y | Z | |||

| S1 | 46 | 46 | 46 | Y1 | 36 | 36 | 36 | M1 | 12 | 12 | 12 |

| S2 | 50 | 38 | 50 | Y2 | 30 | 30 | 30 | M2 | 10 | 10 | 10 |

| Sample | Pressure Range (MPa) | Vp (m/s) | Vs (m/s) | r | AV (m/s) | AVs (m/s) | (m/s/MPa) | (m/s/MPa) |

|---|---|---|---|---|---|---|---|---|

| S1 | 0.5~46 | 3927~5174 | 2857~3289 | 1.45~1.58 | ||||

| S2 | 0.5~50 | 3948~5213 | 2695~3336 | 1.45~1.6 | ||||

| Y1 | 0.5~36 | 3995~4980 | 2664~3333 | 1.48~1.53 | ||||

| Y2 | 0.5~30 | 3981~5048 | 2610~3295 | 1.41~1.59 | ||||

| M1 | 0.5~12 | 2330~2494 | 1196~1388 | 1.76~1.97 | ||||

| M2 | 0.5~10 | 2351~2494 | 1211~1385 | 1.76~1.98 |

| Sample | Vp (m/s) | Vs (m/s) | ρ/g/cm3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| X | Y | Z | Average | X | Y | Z | Average | ||

| S1 | 4373 | 4288 | 3927 | 4196 | 2915 | 2852 | 2686 | 2818 | 2.631 |

| S2 | 4314 | 4257 | 3948 | 4173 | 2882 | 2864 | 2695 | 2814 | 2.631 |

| Y1 | 4773 | 4844 | 3995 | 4537 | 3215 | 3229 | 2664 | 3036 | 2.614 |

| Y2 | 4815 | 4569 | 4141 | 4508 | 3162 | 3163 | 2610 | 2978 | 2.605 |

| M1 | 2400 | 2436 | 2330 | 2389 | 1360 | 1370 | 1196 | 1309 | 1.495 |

| M2 | 2410 | 2418 | 2351 | 2393 | 1362 | 1361 | 1211 | 1311 | 1.488 |

| Sample | Pressure Range (MPa) | A(Vp) | a(Vp) | A(Vs) | a(Vs) | A(r) | a(r) |

|---|---|---|---|---|---|---|---|

| S1 | 0.5~46 | ||||||

| S2 | 0.5~50 | ||||||

| Y1 | 0.5~36 | ||||||

| Y2 | 0.5~30 | ||||||

| M1 | 0.5~12 | ||||||

| M2 | 0.5~10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Xu, X.; Jian, K.; Xu, L.; Li, J.; Zhao, D.; Xue, Z.; Xin, Y. Experimental Study on the Stress Sensitivity Characteristics of Wave Velocities and Anisotropy in Coal-Bearing Reservoir Rocks. Processes 2024, 12, 2819. https://doi.org/10.3390/pr12122819

Zhang Z, Xu X, Jian K, Xu L, Li J, Zhao D, Xue Z, Xin Y. Experimental Study on the Stress Sensitivity Characteristics of Wave Velocities and Anisotropy in Coal-Bearing Reservoir Rocks. Processes. 2024; 12(12):2819. https://doi.org/10.3390/pr12122819

Chicago/Turabian StyleZhang, Zehua, Xiaokai Xu, Kuo Jian, Liangwei Xu, Jian Li, Dongyuan Zhao, Zhengzheng Xue, and Yue Xin. 2024. "Experimental Study on the Stress Sensitivity Characteristics of Wave Velocities and Anisotropy in Coal-Bearing Reservoir Rocks" Processes 12, no. 12: 2819. https://doi.org/10.3390/pr12122819

APA StyleZhang, Z., Xu, X., Jian, K., Xu, L., Li, J., Zhao, D., Xue, Z., & Xin, Y. (2024). Experimental Study on the Stress Sensitivity Characteristics of Wave Velocities and Anisotropy in Coal-Bearing Reservoir Rocks. Processes, 12(12), 2819. https://doi.org/10.3390/pr12122819