Study on the Influence of Geological Parameters of CO2 Plume Geothermal Systems

Abstract

1. Introduction

2. Modeling

2.1. Geological Conditions in the Study Area

2.2. Control Equations and Performance Evaluation Equations for Geometric Models

2.3. Mesh Generation and Parameter Setting

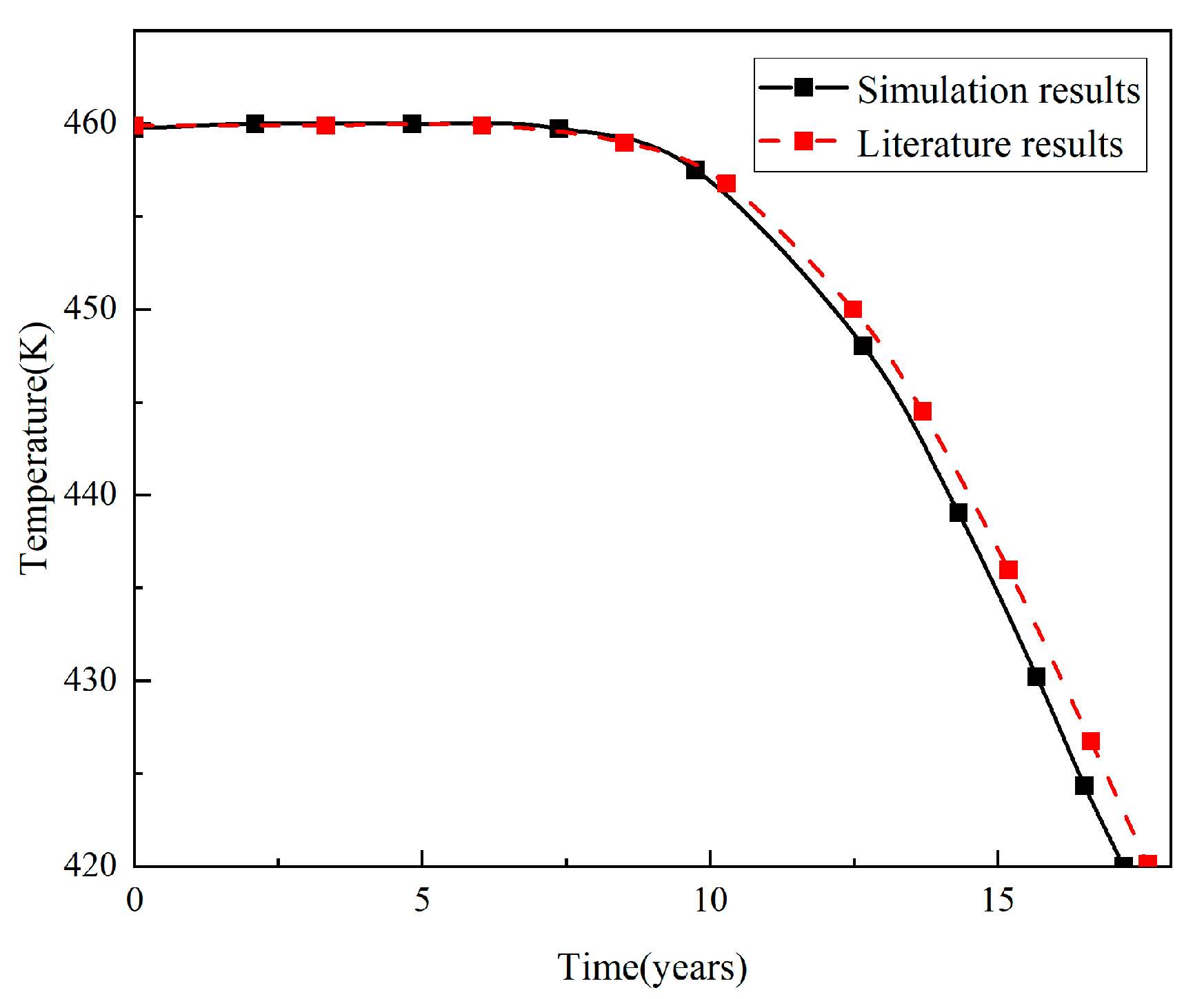

2.4. Numerical Calculations and Model Validation

3. Sensitivity Analysis of Geological Parameters

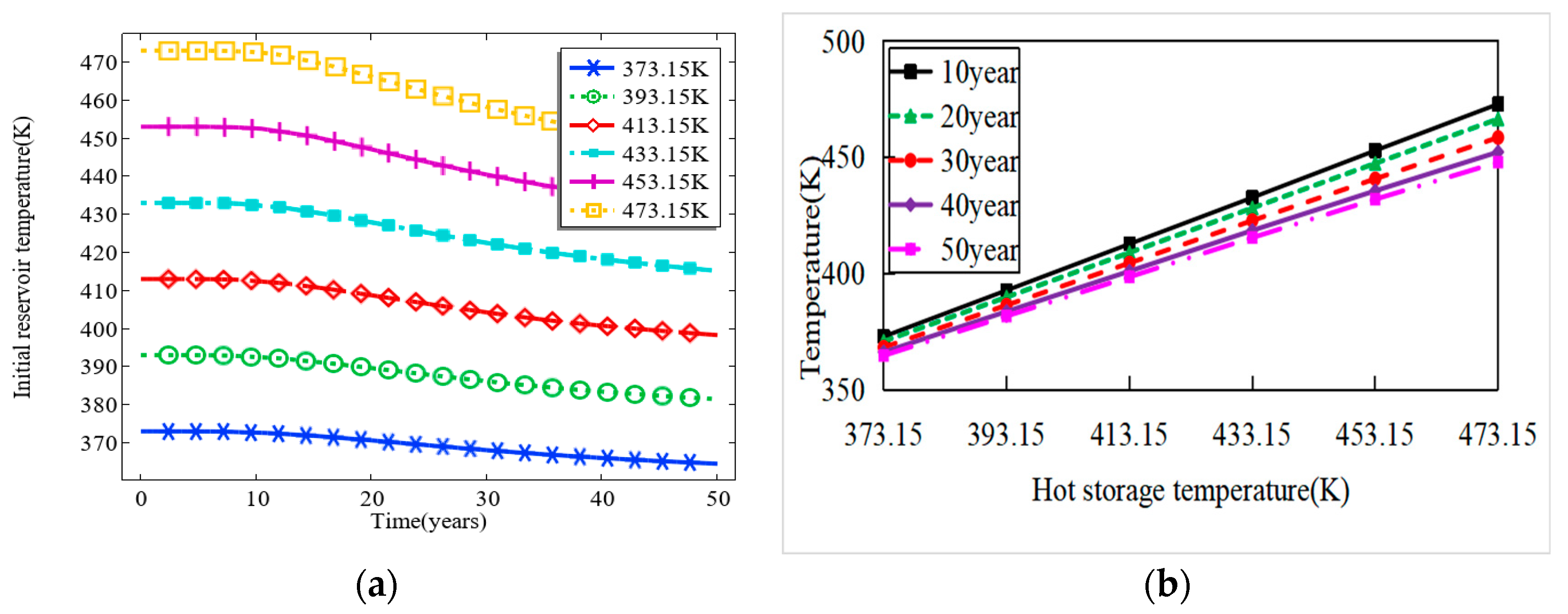

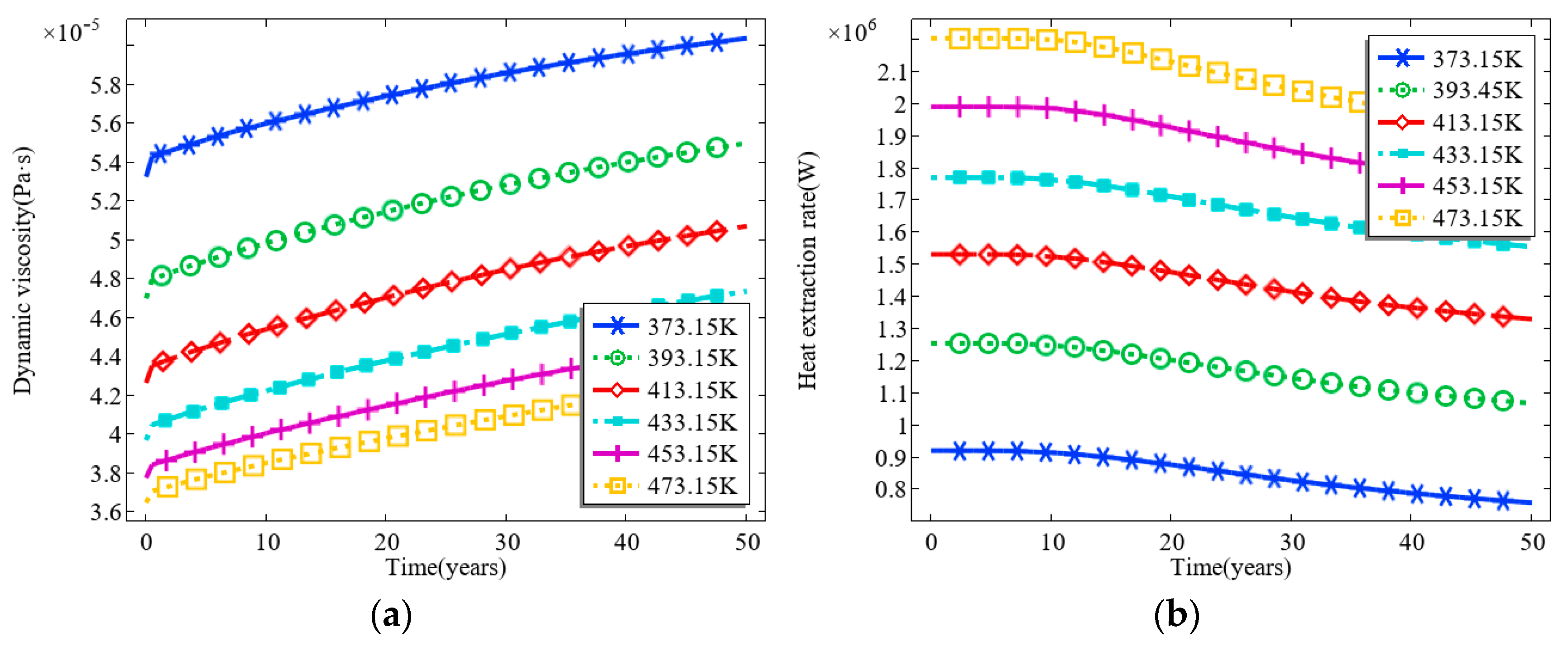

3.1. Effect of Initial Temperature of the Thermal Reservoir

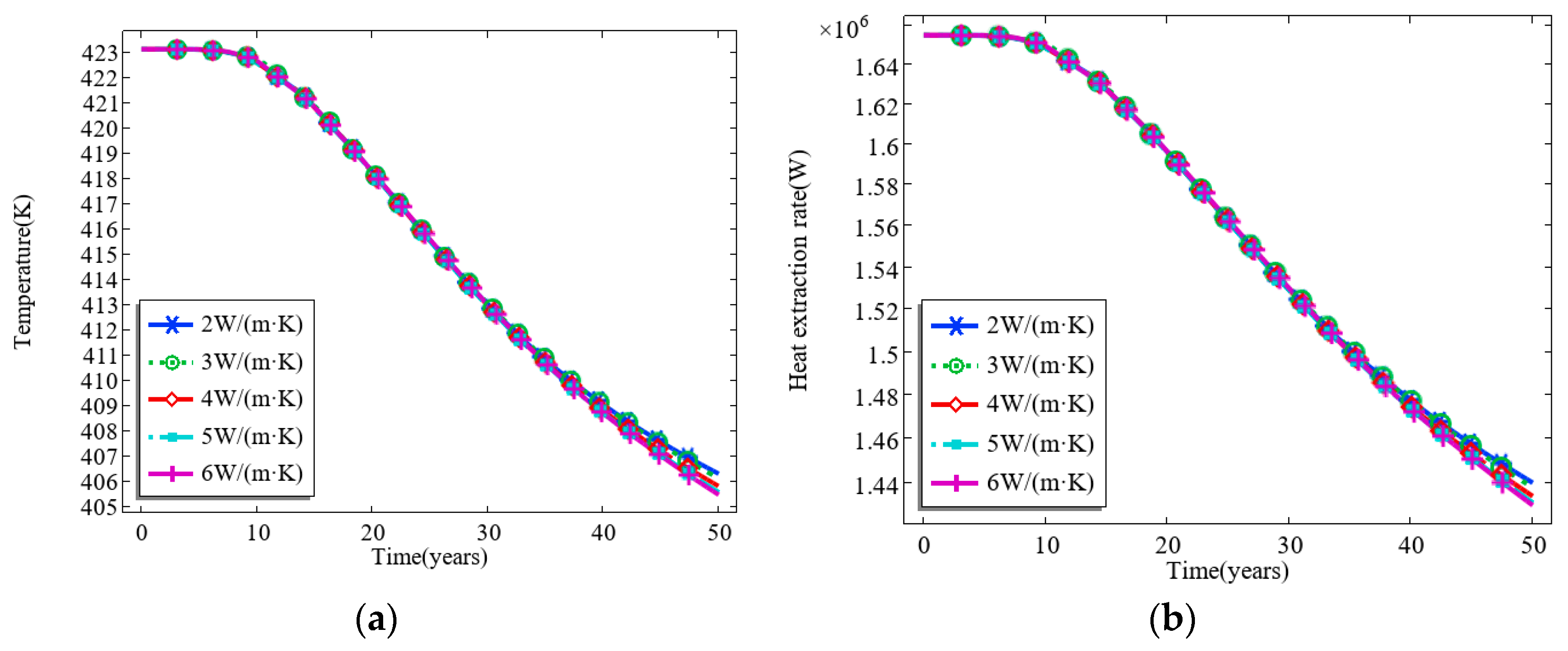

3.2. Effect of the Thermal Conductivity of the Thermal Reservoir

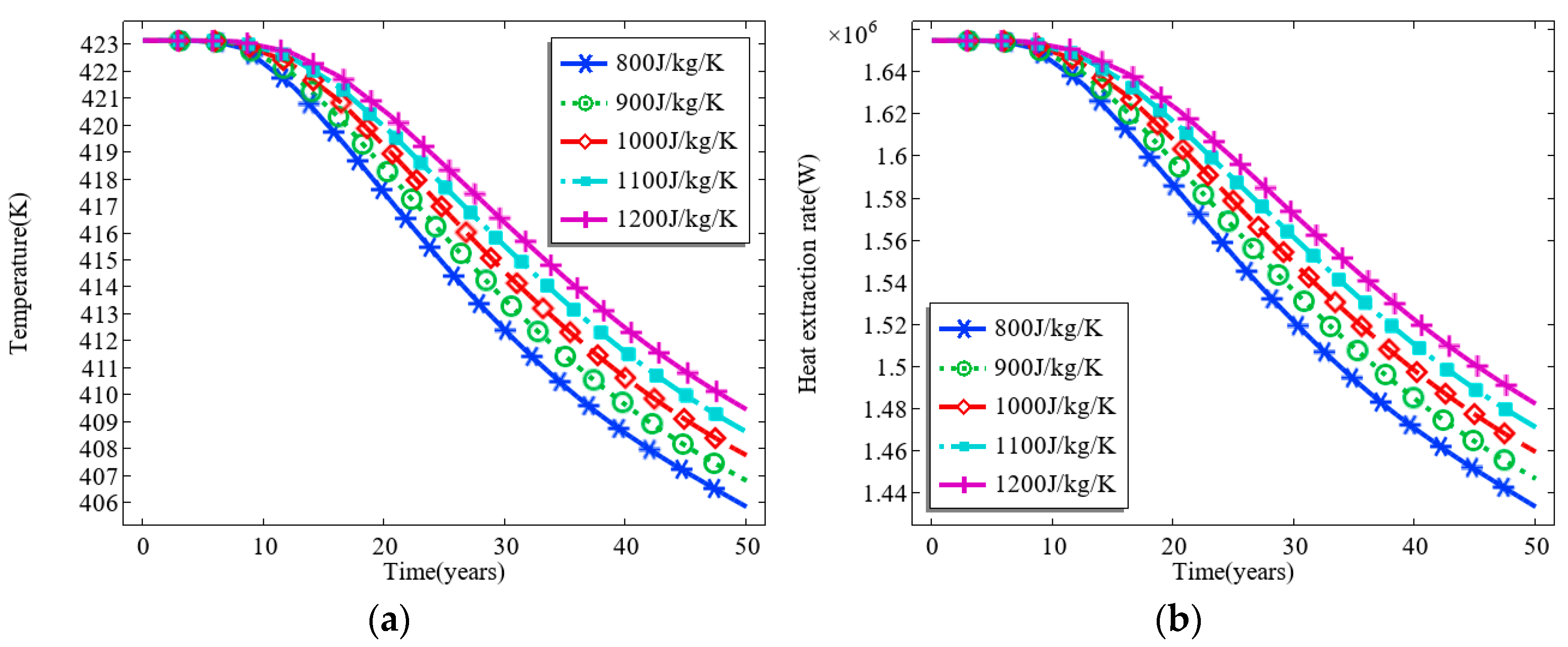

3.3. Effect of the Specific Heat Capacity of the Thermal Reservoir

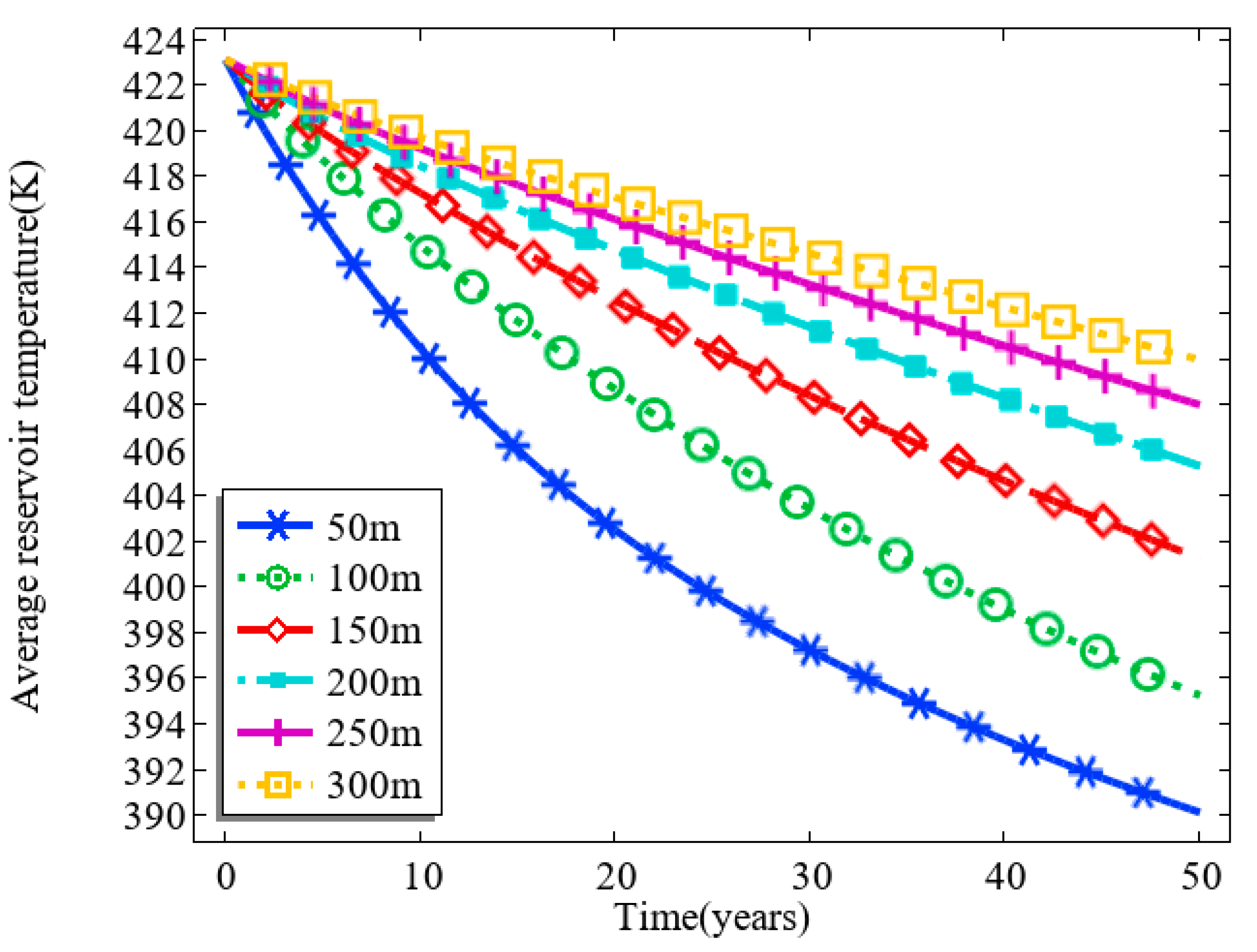

3.4. Effect of the Thickness of the Thermal Reservoir

4. Conclusions

- The increase in the initial temperature of the thermal storage significantly increases the fluid temperature and the rate of heat recovery in the production well; however, the service life of the thermal storage at these high temperatures is shortened compared to that of the medium and low temperature thermal storage. In contrast, the thermal conductivity of thermal storage has a negligible to almost negligible effect on the heat extraction process. On the other hand, the increased specific heat capacity of the thermal storage means that the thermal storage is able to release more heat energy per unit of temperature change. This directly leads to a more significant increase in the temperature of the injected CO2, which in turn increases the temperature of the fluid in the production well, extends the operational life of the reservoir, and increases the rate of heat recovery.

- A reduction in thermal storage thickness accelerates the drop in production fluid temperature and shortens the time to thermal breakthrough. Therefore, when selecting reservoirs for geothermal extraction, thicker reservoirs should be prioritized to ensure long-term heat recovery effectiveness. In addition, the length of the shot hole section is a key factor in determining the controllable thickness of thermal reservoir development. Under the initial conditions of this study, the thickness of the thermal reservoir that can be effectively controlled and developed reaches 250 m when the length of the shot hole section is set at 50 m.

- Going forward, when CO2 is used as a heat-carrying medium for heat recovery from high temperature gas reservoirs, the key metrics for site selection will focus on the initial temperature, specific heat capacity, and thickness of the thermal reservoir. These parameters are essential to ensure the efficiency and sustainability of the heat recovery process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rubin, E.; De Coninck, H. IPCC special report on carbon dioxide capture and storage. In TNO (2004) Cost Curves for CO2 Storage, Part; Cambridge University Press: Cambridge, UK, 2005; Volume 2, p. 14. [Google Scholar]

- Global Status of CCS: Targeting Climate Change; Global CCS Institute: Docklands, Australia, 2019.

- Townsend, A.; Raji, N.; Zapantis, A. The Value of Carbon Capture and Storage (CCS); Global CCS Institute: Docklands, Australia, 2020. [Google Scholar]

- Zinsalo, J.M.; Lamarche, L.; Raymond, J. Injection strategies in an enhanced geothermal system based on discrete fractures model. Appl. Therm. Eng. 2020, 169, 114812. [Google Scholar] [CrossRef]

- Ezekiel, J.; Kumbhat, D.; Ebigbo, A.; Adams, B.M.; Saar, M.O. Sensitivity of reservoir and operational parameters on the energy extraction performance of combined CO2-egr–cpg systems. Energies 2021, 14, 6122. [Google Scholar] [CrossRef]

- Borgia, A.; Pruess, K.; Kneafsey, T.J.; Oldenburg, C.M.; Pan, L. Simulation of CO2-EGS in a fractured reservoir with salt precipitation. Energy Procedia 2013, 37, 6617–6624. [Google Scholar] [CrossRef]

- Cao, W.; Chen, J.; Jiang, F. Numerical simulation of the influence of working fluid variables on EGS thermal mining process. J. Jilin Univ. (Earth Sci. Ed.) 2015, 45, 1180–1188. [Google Scholar]

- Zhang, L.; Pei, J.J.; Ren, S.R. Heat mining capacity and energy utilization efficiency of SCCO2-HDR geothermal system. Renew. Energy Resour. 2014, 32, 114–119. [Google Scholar]

- Randolph, J.B.; Saar, M.O. Coupling geothermal energy capture with carbon dioxide sequestration in naturally permeable, porous geologic formations: A comparison with enhanced geothermal systems. In Proceedings of the Geothermal Resources Council Annual Meeting 2010 Geothermal, Sacramento, CA, USA, 24–27 October 2010; pp. 401–405. [Google Scholar]

- Zhang, L.; Ezekiel, J.; Li, D.; Pei, J.; Ren, S. Potential assessment of CO2 injection for heat mining and geological storage in geothermal reservoirs of China. Appl. Energy 2014, 122, 237–246. [Google Scholar] [CrossRef]

- Cao, W.; Huang, W.; Chen, J.; Li, Z.; Jiang, F. Numerical study on the heat extraction performance of enhanced geothermal systems with a well-fracture-reservoir combined model. Renew. Energy 2023, 202, 370–380. [Google Scholar] [CrossRef]

- Liu, G.; Pu, H.; Zhao, Z.; Liu, Y. Coupled thermo-hydro-mechanical modeling on well pairs in heterogeneous porous geothermal reservoirs. Energy 2019, 171, 631–653. [Google Scholar] [CrossRef]

- Tian, H.; Pan, F.; Xu, T.; McPherson, B.J.; Yue, G.; Mandalaparty, P. Impacts of hydrological heterogeneities on caprock mineral alteration and containment of CO2 in geological storage sites. Int. J. Greenh. Gas Control. 2014, 24, 30–42. [Google Scholar] [CrossRef]

- Bu, F.; Xu, T.; Wang, F.; Yang, Z.; Tian, H. Influence of highly permeable faults within a low-porosity and low-permeability reservoir on migration and storage of injected CO2. Geofluids 2016, 16, 769–781. [Google Scholar] [CrossRef]

- Feng, G.; Li, J.; Xu, T. Effect of reservoir physical parameters on heat extraction rate in carbon dioxide plume geothermal system. Renew. Energy 2013, 31, 85–92. [Google Scholar]

- Xu, T.; Feng, G.; Hou, Z.; Tian, H.; Shi, Y.; Lei, H. Wellbore–reservoir coupled simulation to study thermal and fluid processes in a CO2-based geothermal system: Identifying favorable and unfavorable conditions in comparison with water. Environ. Earth Sci. 2015, 73, 6797–6813. [Google Scholar] [CrossRef]

- Xu, T.; Pruess, K.; Apps, J. Numerical studies of fluid-rock interactions in enhanced geothermal systems (EGS) with CO2 as working fluid. In Proceedings of the Thirty-Third Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 28–30 January 2008. [Google Scholar]

- Garapati, N.; Randolph, J.B.; Valencia, J.L.; Saar, M.O. CO2-plume geothermal (CPG) heat extraction in multi-layered geologic reservoirs. Energy Procedia 2014, 63, 7631–7643. [Google Scholar] [CrossRef]

- Zhang, G.; Wu, K.; Fan, C. Calculation and significance of rock mechanical parameters of deep reservoirs in key areas of Yingqiong Basin. Geol. J. Chin. Univ. 2021, 27, 616–624. [Google Scholar]

- Yuan, A. Research on Heat Transfer Characteristics of Enhanced Geothermal System Based on Heat-Flow Coupling; Anhui Jianzhu University: Hefei, China, 2023. [Google Scholar]

- Qu, Z.; Zhang, W.; Guo, T. Influence of geological parameters and bedding fractures on geothermal productivity based on COMSOL. Prog. Geophys. 2017, 32, 2374–2382. [Google Scholar]

- Singh, H.K.; Chandrasekharam, D.; Raju, N.J. Geothermal energy potential in relation to black carbon reduction and CO2 mitigation of Himalayan geothermal belt—A review. Geothermics 2024, 119, 102962. [Google Scholar] [CrossRef]

- Huang, Y.; Kong, Y.; Cheng, Y. Evaluating the long-term sustainability of geothermal energy utilization from deep coal mines. Geothermics 2023, 107, 102584. [Google Scholar] [CrossRef]

- Rajabi, M.M.; Chen, M.; Bozorgpour, A. Stochastic techno-economic analysis of CO2-circulated geothermal energy production in a closed reservoir system. Geothermics 2021, 96, 102202. [Google Scholar] [CrossRef]

- Song, G. Multi-Field Coupling Mechanism and Optimization of Heat Extraction Performance of EGS Circulating Injection and Production in Hot Dry Rock; China University of Petroleum (Beijing): Beijing, China, 2023. [Google Scholar]

- Xiao, X.; Li, W.; Gong, P. Study on the CO2-EGS coupling model of the porosity of hot dry rock. Energy Sci. Eng. 2024, 12, 2992–3007. [Google Scholar] [CrossRef]

- Zhang, T. Study on the Flow Heat Transfer Law of Heat Extraction Working Fluid in Deep Geothermal Single Fracture; China University of Petroleum (Beijing): Beijing, China, 2023. [Google Scholar]

| Number of Meshes | Outlet Temperature/K | Running Time/s |

|---|---|---|

| 35,824 | 422.57 | 610 |

| 115,283 | 422.89 | 819 |

| 229,423 | 423.15 | 1026 |

| 303,415 | 423.15 | 1249 |

| 440,819 | 423.15 | 1807 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Reservoir thickness | 100 m | Thicknesses of caprock and bedrock | 100 m |

| Initial reservoir temperature | 150 °C | Porosity of caprock and bedrock | 0.05 |

| Specific heat capacity of the reservoir | 900 J/(kg°C) | Density of caprock and bedrock | 2800 kg/m3 |

| Density of the reservoir | 2600 kg/m3 | Thermal conductivity of caprock and bedrock | 3 W/(m°C) |

| Thermal conductivity of the reservoir | 2.5 W/(m°C) | Permeability of caprock and bedrock | 0.01 mD |

| Porosity of the reservoir | 0.155 | Specific heat capacity of caprock and bedrock | 1000 J/(kg°C) |

| Geothermal gradient | 0.0398 °C/m | Length of injection–production perforation section | 50 m |

| Surface temperature | 25 °C | Injection production well spacing | 250 m |

| Injection temperature | 55 °C | Injection–production well diameter | 0.3 m |

| Injection rate | 10 kg/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, J.; Zheng, H.; Zhou, Y.; Liang, Y.; Zeng, Q.; Fu, M. Study on the Influence of Geological Parameters of CO2 Plume Geothermal Systems. Processes 2024, 12, 2808. https://doi.org/10.3390/pr12122808

Song J, Zheng H, Zhou Y, Liang Y, Zeng Q, Fu M. Study on the Influence of Geological Parameters of CO2 Plume Geothermal Systems. Processes. 2024; 12(12):2808. https://doi.org/10.3390/pr12122808

Chicago/Turabian StyleSong, Jifeng, Huaan Zheng, Yuxia Zhou, Yukai Liang, Qianyi Zeng, and Meilong Fu. 2024. "Study on the Influence of Geological Parameters of CO2 Plume Geothermal Systems" Processes 12, no. 12: 2808. https://doi.org/10.3390/pr12122808

APA StyleSong, J., Zheng, H., Zhou, Y., Liang, Y., Zeng, Q., & Fu, M. (2024). Study on the Influence of Geological Parameters of CO2 Plume Geothermal Systems. Processes, 12(12), 2808. https://doi.org/10.3390/pr12122808