Enhancement of Anti-UV Aging Performance of Asphalt Modified by UV-531/Pigment Violet Composite Light Stabilizers

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of Modified Asphalt

2.3. UV Aging Test

2.4. Characterization Methods

2.4.1. Characterization of Asphalt Conventional Performance

2.4.2. FTIR Test

2.4.3. GPC Test

2.4.4. Dynamic Shear Rheometer (DSR) Test

3. Results and Discussion

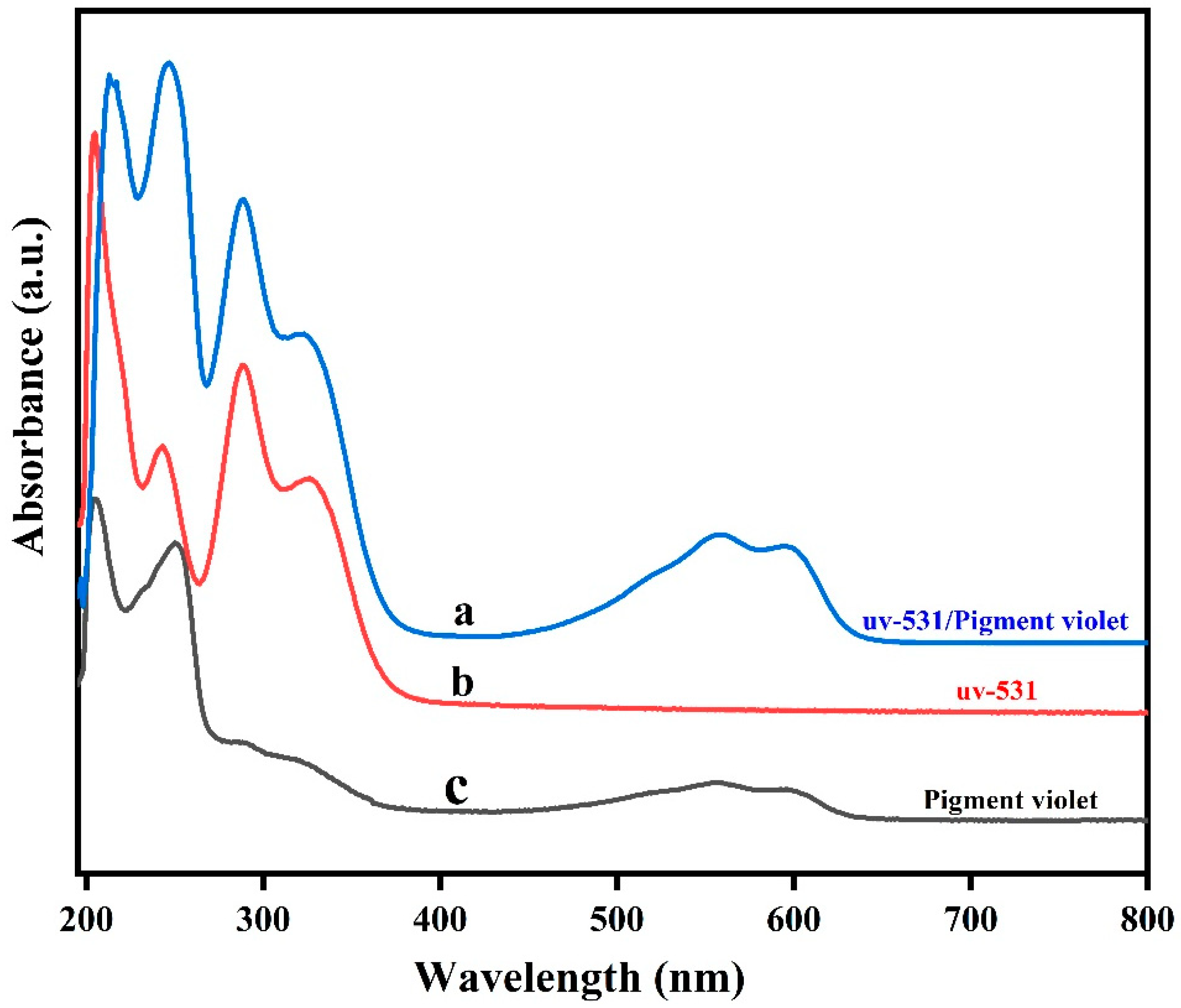

3.1. UV-Vis Spectra Analysis of Anti-UV Agents

3.2. Effect of Anti-UV Agents on the Conventional Performance of Asphalt Before and After UV Aging

3.3. Functional Group Analysis of the Modified Asphalts After UV Aging

3.4. Analysis of Changes in Asphalt Molecular Weight

3.5. Rheological Property Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

References

- Jiang, W.; Li, P.; Ye, W.; Shan, J.; Li, Y.; Xiao, J. The effect and mechanism of La2O3 on the anti-ultraviolet aging characteristics of virgin bitumen. Constr. Build. Mater. 2020, 230, 116967. [Google Scholar] [CrossRef]

- Li, Y.; Feng, J.; Yang, F.; Wu, S.; Liu, Q.; Bai, T.; Liu, Z.; Li, C.; Gu, D.; Chen, A.; et al. Gradient aging behaviors of asphalt aged by ultraviolet lights with various intensities. Constr. Build. Mater. 2021, 295, 123618. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, A.; Wu, S.; Li, Y.; Song, Y. Laboratory and field performance investigation of anti-ultraviolet aging of warm-mixed asphalt concretes. Constr. Build. Mater. 2023, 409, 134032. [Google Scholar] [CrossRef]

- He, Z.; Xie, T.; Yu, H.; Ge, J.; Dai, W. Evaluation of quantum dot composite graphene /Titanium oxide enhanced UV aging resistance modified asphalt. Constr. Build. Mater. 2023, 408, 133732. [Google Scholar] [CrossRef]

- Peng, C.; Guo, C.; You, Z.; Xu, F.; Ma, W.; You, L.; Li, T.; Zhou, L.; Huang, S.; Ma, H.; et al. The Effect of Waste Engine Oil and Waste Polyethylene on UV Aging Resistance of Asphalt. Polymers 2020, 12, 602. [Google Scholar] [CrossRef] [PubMed]

- Jamal, M.; Martinez-Arguelles, G.; Giustozzi, F. Effect of waste tyre rubber size on physical, rheological and UV resistance of high-content rubber-modified bitumen. Constr. Build. Mater. 2021, 304, 124638. [Google Scholar] [CrossRef]

- He, B.; Li, Y.; Chen, J.; Fu, M.; Zhang, X.; Li, W.; Yu, J.; Zhu, L. Evaluation of UV aging resistance of bitumen containing lignosulfonate grafted layered double hydroxides. Constr. Build. Mater. 2023, 403, 133026. [Google Scholar] [CrossRef]

- Rajib, A.; Saadeh, S.; Katawal, P.; Mobasher, B.; Fini, E.H. Enhancing Biomass Value Chain by Utilizing Biochar as A Free Radical Scavenger to Delay Ultraviolet Aging of Bituminous Composites Used in Outdoor Construction. Resour. Conserv. Recycl. 2021, 168, 105302. [Google Scholar] [CrossRef]

- Xiao, X.Y.; Liu, W.; Zhang, D.K.; Wan, C.X. Effect of organic montmorillonite on microstructure and properties of the OMMT/EVA/Asphalt composites. Polym. Compos. 2016, 39, 1959–1966. [Google Scholar] [CrossRef]

- Tur Rasool, R.; Wang, S.; Zhang, Y.; Li, Y.; Zhang, G. Improving the aging resistance of SBS modified asphalt with the addition of highly reclaimed rubber. Constr. Build. Mater. 2017, 145, 126–134. [Google Scholar] [CrossRef]

- Yang, J.; Muhammad, Y.; Yang, C.; Liu, Y.; Su, Z.; Wei, Y.; Li, J. Preparation of TiO2/PS-rGO incorporated SBS modified asphalt with enhanced resistance against ultraviolet aging. Constr. Build. Mater. 2021, 276, 121461. [Google Scholar] [CrossRef]

- Ma, R.; Zhao, M.; Mo, Y.; Tang, P.; Feng, Y.; Li, D. HALS intercalated layered double hydroxides as an efficient light stabilizer for polypropylene. Appl. Clay Sci. 2019, 180, 105196. [Google Scholar] [CrossRef]

- Zhong, B.; Tang, Y.; Chen, Y.; Luo, Y.; Jia, Z.; Jia, D. Improvement of UV aging resistance of PBAT composites with silica-immobilized UV absorber prepared by a facile method. Polym. Degrad. Stab. 2023, 211, 110337. [Google Scholar] [CrossRef]

- Zhengang, F.; Fengjie, C.A.I.; Dongdong, Y.A.O.; Xinjun, L.I. FM analysis of aging properties of UV531/SBS modified bitumen. IOP Conf. Ser. Mater. Sci. Eng. 2020, 758, 012068. [Google Scholar] [CrossRef]

- Souza, P.M.S.; Morales, A.R.; Sanchez, E.M.S.; Mei, L.H.I. Study of PBAT Photostabilization with Ultraviolet Absorber in Combination with Hindered Amine Light Stabilizer and Vitamin E, Aiming Mulching Film Application. J. Polym. Environ. 2018, 26, 3422–3436. [Google Scholar] [CrossRef]

- Sun, X.; Yuan, J.; Liu, Z.; Qin, X.; Yin, Y. Evaluation and characterization on the segregation and dispersion of anti-UV aging modifying agent in asphalt binder. Constr. Build. Mater. 2021, 289, 123204. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Z.; Hong, L.; Huang, Y. Effect of ultraviolet absorber (UV-531) on the properties of SBS-modified asphalt with different block ratios. Constr. Build. Mater. 2020, 234, 117388. [Google Scholar] [CrossRef]

- Chen, S.; Liu, Y.; Chen, S.; Zhao, G.; Wu, Y. Triazole ultraviolet absorbers with enrichment performance for material surfaces protection from ultraviolet rays. Mater. Lett. 2021, 291, 129496. [Google Scholar] [CrossRef]

- Thetford, D.; Chorlton, A.P. Investigation of vat dyes as potential high performance pigments. Dye. Pigment. 2004, 61, 49–62. [Google Scholar] [CrossRef]

- Li, J.; Yu, J.; Wu, S.; Pang, L.; Amirkhanian, S.; Zhao, M. Effect of inorganic ultraviolet resistance nanomaterials on the physical and rheological properties of bitumen. Constr. Build. Mater. 2017, 152, 832–838. [Google Scholar] [CrossRef]

- Pipintakos, G.; Vincent Ching, H.Y.; Soenen, H.; Sjövall, P.; Mühlich, U.; Van Doorslaer, S.; Varveri, A.; Van den Bergh, W.; Lu, X. Experimental investigation of the oxidative ageing mechanisms in bitumen. Constr. Build. Mater. 2020, 260, 119702. [Google Scholar] [CrossRef]

- Wang, Z.; Ye, F. Experimental investigation on aging characteristics of asphalt based on rheological properties. Constr. Build. Mater. 2020, 231, 117158. [Google Scholar] [CrossRef]

- Hu, J.; Wu, S.; Liu, Q.; García Hernández, M.I.; Wang, Z.; Nie, S.; Zhang, G. Effect of ultraviolet radiation in different wavebands on bitumen. Constr. Build. Mater. 2018, 159, 479–485. [Google Scholar] [CrossRef]

- Li, B.; Han, J.; Wei, D.; Ji, H.; Yao, T.; Wang, H.; Han, J.; Zhang, Y. A molecular dynamics simulation study on the recovery performance of aged asphalt binder by waste vegetable oil rejuvenators. J. Clean. Prod. 2024, 442, 140796. [Google Scholar] [CrossRef]

- Wang, F.; Xiao, Y.; Cui, P.; Lin, J.; Li, M.; Chen, Z. Correlation of asphalt performance indicators and aging Degrees: A review. Constr. Build. Mater. 2020, 250, 118824. [Google Scholar] [CrossRef]

- Wen, Y.; Guo, N.; You, Z.; Wang, L.; Tan, Y. Comparative evaluation of rheological properties and micromechanics of non-foamed and foamed asphalt mastic. Constr. Build. Mater. 2018, 193, 654–664. [Google Scholar] [CrossRef]

- T0628-2011; Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2012.

- Matthews, Y.J.; Halliday, G.M.; Phan, T.A.; Damian, D.L. Wavelength dependency for UVA-induced suppression of recall immunity in humans. J. Dermatol. Sci. 2010, 59, 192–197. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, H.; Chen, Y.; Ji, J.; You, Z.; Zhang, Y. A review on compatibility between crumb rubber and asphalt binder. Constr. Build. Mater. 2021, 297, 123820. [Google Scholar] [CrossRef]

- Li, Z.; Fa, C.; Zhao, H.; Zhang, Y.; Chen, H.; Xie, H. Investigation on evolution of bitumen composition and micro-structure during aging. Constr. Build. Mater. 2020, 244, 118322. [Google Scholar] [CrossRef]

- Liu, Q.; Yi, X.; Cannone Falchetto, A.; Cai, M.; Yu, B. UV-induced gradient aging of bitumen films: A comprehensive study. Fuel 2024, 357, 130088. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, H.; Duan, H. Investigation of ultraviolet radiation aging gradient in asphalt binder. Constr. Build. Mater. 2020, 246, 118501. [Google Scholar] [CrossRef]

- Feng, Z.; Cai, F.; Yao, D.; Li, X. Aging properties of ultraviolet absorber/SBS modified bitumen based on FTIR analysis. Constr. Build. Mater. 2021, 273, 121713. [Google Scholar] [CrossRef]

- Zhou, Y.; Du, L.; Liu, X.; Zhang, K.; Xu, P.; Zhang, Y. Microscopic performance of modified asphalt based on aging. Constr. Build. Mater. 2021, 279, 122429. [Google Scholar] [CrossRef]

- Huang, W.; Guo, Y.; Zheng, Y.; Ding, Q.; Sun, C.; Yu, J.; Zhu, M.; Yu, H. Chemical and rheological characteristics of rejuvenated bitumen with typical rejuvenators. Constr. Build. Mater. 2021, 273, 121525. [Google Scholar] [CrossRef]

- Hu, J.; Wu, S.; Liu, Q.; García Hernández, M.I.; Zeng, W. Effect of ultraviolet radiation on bitumen by different ageing procedures. Constr. Build. Mater. 2018, 163, 73–79. [Google Scholar] [CrossRef]

- Ding, Y.; Deng, M.; Cao, X.; Yu, M.; Tang, B. Investigation of mixing effect and molecular aggregation between virgin and aged asphalt. Constr. Build. Mater. 2019, 221, 301–307. [Google Scholar] [CrossRef]

- Jiang, W.; Bao, R.; Lu, H.; Yuan, D.; Lu, R.; Sha, A.; Shan, J. Analysis of rheological properties and aging mechanism of bitumen after short-term and long-term aging. Constr. Build. Mater. 2021, 273, 121777. [Google Scholar] [CrossRef]

- Zhang, D.; Zheng, Y.; Yuan, G.; Qian, G.; Zhang, H.; You, Z.; Li, P. Chemical characteristics analyze of SBS-modified bitumen containing composite nanomaterials after aging by FTIR and GPC. Constr. Build. Mater. 2022, 324, 126522. [Google Scholar] [CrossRef]

- Kumar, K.; Singh, A.; Maity, S.K.; Srivastava, M.; Sahai, M.; Singh, R.K.; Garg, M.O. Rheological studies of performance grade bitumens prepared by blending elastomeric SBS (styrene butadiene styrene) co-polymer in base bitumens. J. Ind. Eng. Chem. 2016, 44, 112–117. [Google Scholar] [CrossRef]

- Omairey, E.L.; Zhang, Y.; Gu, F.; Ma, T.; Hu, P.; Luo, R. Rheological and fatigue characterisation of bitumen modified by anti-ageing compounds. Constr. Build. Mater. 2020, 265, 120307. [Google Scholar] [CrossRef]

- Yan, C.; Huang, W.; Lin, P.; Zhang, Y.; Lv, Q. Chemical and rheological evaluation of aging properties of high content SBS polymer modified asphalt. Fuel 2019, 252, 417–426. [Google Scholar] [CrossRef]

| Items | Test Values | Test Methods |

|---|---|---|

| Penetration (25 °C, 0.1 mm) | 66 | T0604 |

| Softening point (°C) | 47 | T0606 |

| Ductility (10 °C, cm) | 39 | T0605 |

| Viscosity (60 °C, Pa·s) | 207 | T0602 |

| Asphalt | C=O | S=O | IC=O | IS=O |

|---|---|---|---|---|

| Matrix asphalt (UV-0 h) | 0.03 | 0.15 | 0.0076 | 0.0379 |

| Matrix asphalt (UV-108 h) | 0.4 | 0.32 | 0.1028 | 0.0804 |

| UV-531/asphalt (UV-0 h) | 0.0738 | 0.0503 | 0.0489 | 0.0333 |

| UV-531/asphalt (UV-108 h) | 0.2 | 0.364 | 0.0517 | 0.094 |

| PV/asphalt (UV-0 h) | 0.0143 | 0.1467 | 0.0026 | 0.027 |

| PV/asphalt (UV-144 h) | 0.2126 | 1.1572 | 0.0131 | 0.0712 |

| UV-531/PV/asphalt (UV-0 h) | 0.0178 | 0.0503 | 0.0118 | 0.0333 |

| UV-531/PV/asphalt (UV-144 h) | 0.028 | 0.0755 | 0.0154 | 0.0414 |

| Sample | Aging Time (h) | Mn | Mw | PDI |

|---|---|---|---|---|

| Matrix asphalt | 0 | 1165 | 1339 | 1.1495 |

| 108 | 1310 | 1657 | 1.2647 | |

| UV-531/PV modified asphalt | 0 | 1136 | 1335 | 1.1753 |

| 144 | 1122 | 1354 | 1.2067 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Liu, Y.; Cao, Z.; Liu, Y.; Ren, Y.; Liang, H.; Wang, K.; Zhang, Y.; Wang, J.; Li, X. Enhancement of Anti-UV Aging Performance of Asphalt Modified by UV-531/Pigment Violet Composite Light Stabilizers. Processes 2024, 12, 2758. https://doi.org/10.3390/pr12122758

Zhang F, Liu Y, Cao Z, Liu Y, Ren Y, Liang H, Wang K, Zhang Y, Wang J, Li X. Enhancement of Anti-UV Aging Performance of Asphalt Modified by UV-531/Pigment Violet Composite Light Stabilizers. Processes. 2024; 12(12):2758. https://doi.org/10.3390/pr12122758

Chicago/Turabian StyleZhang, Fa, Yang Liu, Zhenhao Cao, Yifan Liu, Yufang Ren, Haishan Liang, Kunyu Wang, Yanyan Zhang, Jia Wang, and Xue Li. 2024. "Enhancement of Anti-UV Aging Performance of Asphalt Modified by UV-531/Pigment Violet Composite Light Stabilizers" Processes 12, no. 12: 2758. https://doi.org/10.3390/pr12122758

APA StyleZhang, F., Liu, Y., Cao, Z., Liu, Y., Ren, Y., Liang, H., Wang, K., Zhang, Y., Wang, J., & Li, X. (2024). Enhancement of Anti-UV Aging Performance of Asphalt Modified by UV-531/Pigment Violet Composite Light Stabilizers. Processes, 12(12), 2758. https://doi.org/10.3390/pr12122758