Abstract

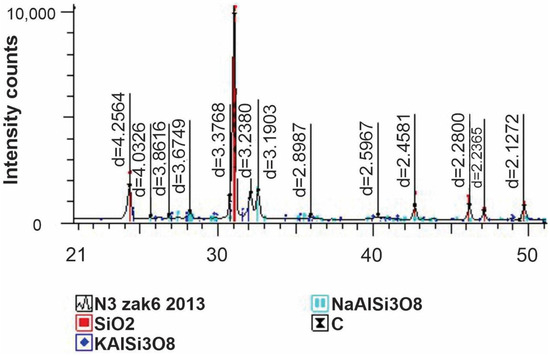

This paper investigates the potential use of coked sands, a byproduct of the thermal processing (pyrolysis) of oil sands, in asphalt concrete mixtures. After pyrolysis extracts the oil from the oil sand, the remaining mineral part becomes coked and changes color to black as solid waste, resulting in a coating of biochar. The coked sand’s X-ray phase analysis (XRD) shows peaks at 4.2564, 3.6749, 3.3768, 3.2380, 3.1903, 2.4581, 2.2800, and 2.2365. Quartz, aluminosilicates, metal oxides, and possibly even carbonates make up the sand’s mineral makeup, as indicated by these peaks. One way to use them is in road construction. In this study, we substituted sand screenings with coked sand in amounts of 5%, 7%, and 10% to examine its impact on the composition of asphalt concrete. This study used 5% paving bitumen (BND 70/100) as a binder for asphalt mineral materials of varying sizes. It concludes that using coked sand to produce asphalt concrete can save 5–10% of sand screenings. The test results showed that adding 5% and 7% of coked sand increases the compressive strength at 50 °C by 8% and 31%, respectively. Adding 10% of coked sand does not increase the strength and actually makes it weaker. The results of the asphalt concrete samples meet type B grade 1 standards of ST RK 1225-2019.

1. Introduction

It is well known that asphalt concrete (AC) is a mixture of inorganic fillers such as crushed stone, sands or gravel, limestone, and bitumen binders derived from petroleum. AC has several synonyms across the globe. Asphalt concrete is commonly called asphalt (or asphaltic) concrete, asphalt, bituminous asphalt concrete, blacktop, and a bituminous mixture, as well as tarmac (in Great Britain and Ireland), pavement (in North America), and asphaltobeton (in Kazakhstan). The durability of AC is greatly influenced by the environmental changes during the year between hot temperatures and cold temperatures, even between day and night. Asphalt pavements have become the main element of urbanization on Earth, and they typically account for more than 30% of typical urban areas [1,2,3,4,5].

By mass, 4–7% bitumen-containing materials serve primarily as a binder in AC; the viscous nature of the bitumen binder allows the asphalt concrete to sustain significant flexibility, creating a very durable surface material. AC is commonly used on road surfaces, revetment, streets, port facilities, runways, bikeways, tracks, hydraulic parking lots, structures, tennis courts, and airports. There are many different types of asphalt pavement around the globe. Each of them, with its own combination of different amounts and types of mineral aggregates and binder, has performance characteristics appropriate for specific applications. The main types of asphalt concrete that have been used in infrastructure are as follows: hot mix asphalt concrete (HMAC), warm mix asphalt concrete (WMAC), cut-back asphalt concrete, cold mix asphalt concrete, mastic asphalt concrete, and natural asphalt concrete. Other asphalt concretes have been developed to meet specific needs, including stone-matrix asphalt [1,6,7,8].

For the purpose of improving the properties of the mineral–asphalt mixtures, additives can be used. These additives are as follows: rubber powder, elastomers, polymers, plastomers, resins, latexes, and others. The modification of asphalt concrete with additives can also be performed with nano-sized materials that better fit the requirements of modern industry. Nanomaterials have a great impact on the properties of the usual material if they are selected properly and implemented correctly into the matrix. A small quantity of nanomaterials could change the material properties or could give new properties to the materials. Nevertheless, some additives are no longer applied or are under very restricted use in many nations for environmental reasons and human health [9,10,11,12,13,14,15].

Phase change materials (PCMs) and asphalt as a matrix are expected to be the new advanced materials for asphalt pavements. The usage of a composite of PCMs in road construction may seem to be not economically justifiable. PCM application in pavements is a promising area for research activity and a new trend. Incorporating phase change materials into pavements can improve their properties, as well as allow the regulation of pavement temperature, avoid the phenomenon of a heat island, and enhance pavement durability on the road surface. The development of this technology for application on a large scale requires knowledge from interdisciplinary fields in the areas of numerical modeling, technology of material sciences, and civil and environmental engineering [16]. Researchers suggested different types of chemical and physical modifiers to be used in asphaltic concrete to enhance the rutting resistance behavior of pavements. However, they have not been fully implemented because of the complex issues associated with their costs and on-site construction [3].

The article investigated the performance of porous asphalt (PA) mixtures experimentally and numerically. It presented the first-ever full-scale test of a PA pavement overlay applied to a bridge deck on a motorway in Thailand. The study optimized the mixture composition for enhanced properties and provided valuable long-term performance data. These findings have the potential to reshape road construction practices, to promote safer and more efficient infrastructure for transportation [17]. Researchers analyzed the cost of reinforcing materials for the national primary road in three different scenarios: new construction, overlay with minimal damage, and overlay with significant damage. There were two types of geosynthetics considered: Polyfelt PGM-G 100/100 geotextile paving fabric (unit area of 430 g/m2) and Miragrid GX100/100 geogrid made from high tenacity polyester (unit area of 335 g/m2). According to their findings, using geosynthetics might prolong the road maintenance cycle by as much as the material’s life, resulting in a road maintenance cycle that is roughly 36.67% less expensive than that of traditional pavement [18].

The sub-base and its load capacity should be considered before road building begins. The major advantages of asphalt concrete are that it is almost 100% recyclable, and recycling processes have increased significantly in the last two decades. Another advantage of asphalt is that it can be mixed with waste or by-products; thus, in preparing asphalt pavement, rubber crumb can be used from worn tires, waste polymer-containing materials, biochar (BC) from pyrolysis, and others. BC is presented in the scientific literature as a novel technique to modify asphalt binders such as hot mix asphalt (HMA). The publication presented the results obtained from an experimental phase designed to evaluate the mechanical performance of hot mix asphalt manufactured with an asphalt binder modified with a BC. A material characterization phase was conducted, and the conventional physical properties of the asphalt concrete modified using BC-OPMF were measured at different mass ratios, such as BC/AC = 5%, 10%, and 15% [19]. The study considered heat-reflective pavement materials by replacing bitumen binders with clear binders and pigment-modified clear binders. There was titanium dioxide white and zinc ferrite yellow; also, iron oxide red pigments were used to give the asphalt the corresponding shades [2].

In this work, the possibilities of using the remaining solid residue after thermal processing (pyrolysis) of oil sands for asphalt concrete mixtures are studied. It is known that Canada, Kazakhstan, and several other countries have a lot of oil sands, and they cannot be processed by traditional oil refining technology due to the heavy oil content. Oil sands contain up to 30% of bitumen or oil; the others are sand soil rocks (mineral parts). In these cases, it is difficult to separate the bitumen of oil–wet-type sands with hot steam, so thermal methods are recommended for the processing. The advantages of pyrolysis are the simplicity of the process, the description of the obtained product, and the shortness of the processing time [20,21,22]. In this case, the mineral parts are coked, in other words, covered with biochar. Therefore, it should be processed according to ecological requirements. It can be seen as a by-product that replaces sand screenings.

2. Materials and Methods

2.1. Materials

To study the effect of coked sand on the properties of asphalt concrete, the hot fine-grained dense asphalt concrete type B grade 1 was prepared. The following source materials were used:

- -

- Crushed stone from gravel fraction of 10–20 mm and 5–10 mm, from LLP “Ozentas” (Talgar, Kazakhstan);

- -

- Sand screenings with the fraction of 0–5 mm, from LLP “Ozentas”;

- -

- Activated mineral powder MP-1, from LLP “Zhartas-SN” (Almaty, Kazakhstan);

- -

- Bitumen grade BND 70/100, from JV “Caspi Bitum” LLP (Aktau, Kazakhstan);

- -

- Coked sand is the solid residue after oil extraction from Munaily Mola oil sand by pyrolysis method. The Munaily Mola oil sand deposits are located in the Atyrau region of Kazakhstan.

2.2. Coked Sand Characterization

An X-ray phase analysis of coked sand obtained from oil sands through pyrolysis was tested using diffractometer DRON-3M (Figure 1). XRD with peaks at 4.2564, 3.6749, 3.3768, 3.2380, 3.1903, 2.4581, 2.2800, and 2.2365 Å provide information on the composition and structural properties of the samples after high-temperature processing. The shown peak at 3.3768 Å is close to the characteristic peak of quartz (SiO2), indicating that quartz remains in the sand. Usually, quartz is very stable at high temperatures; therefore, its presence is common in materials derived from silicate rocks. Next, the peak at 4.2564 Å indicates the presence of aluminosilicates such as zeolites or clays in the tested sample. The mentioned minerals can remain in the material after the pyrolysis processes; however, they may undergo structural changes. Peaks at around 2.4581–2.2365 Å correspond to the metal oxides, which are often found in oil-derived slags. These metal oxides are stable at high temperatures during pyrolysis. The peaks within the range of 3.1903–3.2380 Å can indicate the carbonate minerals (calcite or dolomite). These compositions may exist as residual phases or form through reactions during pyrolysis involving carbon-bearing components. Oil sand undergoes pyrolysis up to a temperature of 580 °C, which has the potential to modify the initial phases and generate new ones. If the X-ray diffraction peaks of coked sand change in intensity or show up as new peaks, it means that the initial mineral structures are changing or that new crystalline phases are forming. The testing results confirm the presence of quartz, aluminosilicates, metal oxides, and carbonates-containing materials, which define the mineralogical composition of the coked sand.

Figure 1.

X-ray phase analyses of mineral part of oil sands.

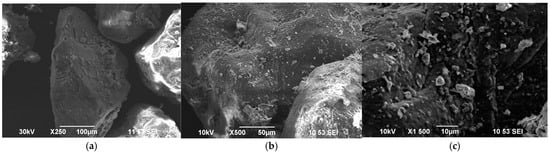

Images of the coked sands were taken with a JSM-6490 LA low-vacuum scanning electron microscope (JEOL Ltd., Tokyo, Japan) for the purpose of studying the interaction between the coked oil fractions and the base mineral materials. The morphological structures of the samples are presented in Figure 2. Scanning electron microscopic (SEM) images were magnified in the range of 250–1500 times. SEM images of the coked sands show some layered structures or granules, reflecting their crystalline nature. The persistence of sand quartz and other phases of transformation highlights the response of the materials to high-temperature conditions and potential chemical interactions during the processes of pyrolysis.

Figure 2.

SEM images of coked sands: (a) magnified 250 times; (b) magnified 500 times; (c) magnified 1500 times.

2.3. Bitumen Characterization

Physical and mechanical characteristics of petroleum bitumen BND 70/100 were determined according to standards GOST 33133-2014, TR TC 014-2011 [23,24]. JV «CASPI BITUM» LLP is one of the largest producers of road bitumen in the Republic of Kazakhstan, which is located in the Mangistau region. Since bitumen is a binder that binds mineral materials in asphalt concrete, all of the characteristics of bitumen are determined according to the following normative documents (standard methods). It is presented in Table 1.

Table 1.

Characteristics of base bitumen.

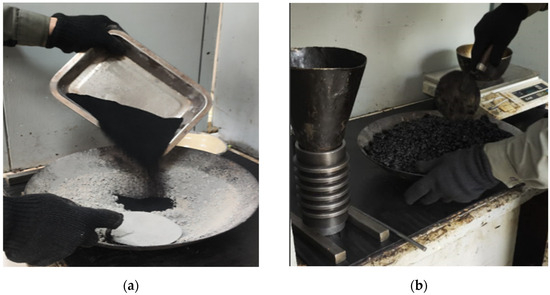

2.4. Asphalt Concrete Preparation with Coked Sands

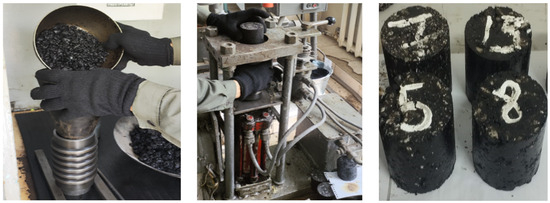

During the asphalt concrete preparation, the materials were mixed using hot technologies (Figure 3). Crushed stone and sand screenings were heated in a drying oven to a temperature of 170–175 °C, bitumen binder was heated to 145 °C, and mineral powder and coked sand were added cold (room temperature).

Figure 3.

Asphalt concrete preparation with coked sands: (a) dry mixing; (b) wet mixing.

Two stages involved mixing the mixture. The first stage involved the “dry” mixing of crushed stone, sand screening, coked sand, and mineral powder. In the second stage, we added hot bitumen and continuously mixed the materials (wet mixing). We continued to mix until we achieved homogeneity. Homogeneity was assessed visually by the degree of coating of grains with bitumen binder. The temperature of the finished asphalt concrete mixture was 150–155 °C.

2.5. Asphalt Concrete Characterization

-Density: Weighed samples from mixtures were immersed for 30 min in a vessel with water at a temperature of 20 ± 2 °C; the water level in the vessel was at least 20 mm higher than the sample surface, after which the samples were weighed in water, ensuring that there are no air bubbles on the samples. After weighing in water, the samples were wiped with a soft cloth and weighed again in air. The average density of a sample from a mixture , g/cm3 was calculated using the following formula:

where —mass of the samples suspended in air, g; —density of the water, g/cm3; —mass of the samples suspended in water, g; —mass of the sample kept in water for 30 min and re-suspended in air, g.

-Water saturation: Weighed samples in air and in water were placed in a vessel with water at a temperature of 20 ± 2 °C. The water level should be above the samples at least 3 cm. The vessel with samples was placed in a vacuum unit, where a residual pressure of no more than 2000 Pa was created and maintained for 1 h when testing samples from mixtures with viscous organic binders. Then, the pressure was brought to atmospheric pressure and the samples were kept in the same vessel with water at a temperature of 20 ± 2 °C for 30 min. After this, the samples were removed from the vessel, weighed in water, and then wiped with a soft cloth and weighed again in air. Water saturation , %, was calculated using the following formula for mixtures:

where —mass of the sample weighed in air, g; —mass of the sample weighed in water, g; —mass of the sample kept in water for 30 min and weighed in air, g; —mass of the sample saturated with water weighed in air, g.

The result of determining water saturation is taken as the arithmetic mean of three determinations, rounded to the first decimal place.

-Compressive strength: The essence of this method was to determine the load required to destroy a sample under specified conditions. Before the test processes, the samples were thermostatically controlled at a specified temperature of 50 ± 2 °C. Samples from hot mixtures were kept at a specified temperature for an hour in water. The compressive strength of the samples was determined on presses at a press plate speed of 3.0 ± 0.3 mm/min. When using hydraulic presses, this speed should be set with the piston idle before testing. The sample was removed from the thermostatic vessel is placed in the center of the lower plate of the press. After that, the upper plate was lowered and stopped above the surface of the samples by 1.5–2 mm. This can also be achieved by appropriately raising the lower press plate. After this, the press electric motor was turned on, and the sample was loaded. The maximum reading of the force meter was taken as the destructive load.

The compressive strength , MPa, was calculated by the following formula:

where —destructive load, N; —initial cross-sectional area of the samples, cm2; 10−2—conversion factor to MPa.

-Crack resistance (tensile strength at splitting): The essence of the method was to determine the load required to split the sample along the generatrix. Before the test process, the samples are thermostatically controlled at a given temperature of 0 ± 2 °C for at least 1 h in water. The temperature of 0 ± 2 °C was created using a mix of water and ice. The tensile strength at the splitting of the sample was determined on presses at a given constant speed of the press plate 50 ± 2 mm/min. When using hydraulic presses, the required speed before testing should be set with the piston idling. The sample removed from the thermostatic vessel is placed in the center of the lower press plate on the side surface, and then the upper plate is lowered and stopped above the surface of the sample by 1.5–2 mm. This can be achieved by appropriately raising the lower press plate. After this, the press electric motor was turned on, and the sample was loaded. The maximum reading of the force meter was taken as the breaking load. The ultimate tensile strength at splitting (, MPa) was calculated by the following formula:

where —destructive load, N; —height of the sample, cm; —diameter of the sample, cm; 10−2—conversion factor to MPa.

The arithmetic mean value of the tests of three samples, rounded to the first decimal place, is taken as the result of the determination.

3. Results

Hot mix asphalt concrete is a widely used material for the construction of highways and other infrastructures. It is crucial to maintain the flow of people and transportation vehicles in a safe and comfortable manner. Crushed stone provides strength and resistance to loads in asphalt. Sand screenings the voids between larger particles and improves the compaction of the mixture. Mineral powder increases the density and water resistance of asphalt concrete.

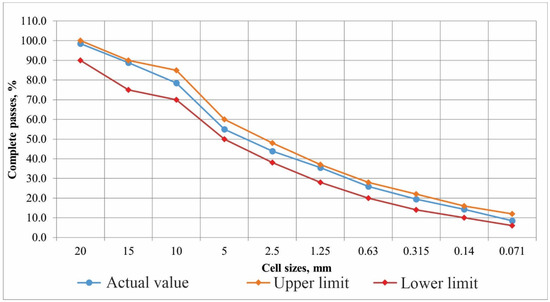

For the investigation of possibilities of using the coked sands from the pyrolysis of oil sands for hot fine-grained asphalt concrete, the compositions of the mineral parts were selected. The curve of the granulometric composition of the mineral part of the mixture is shown in Figure 4.

Figure 4.

Curve of the granulometric composition of the mineral part.

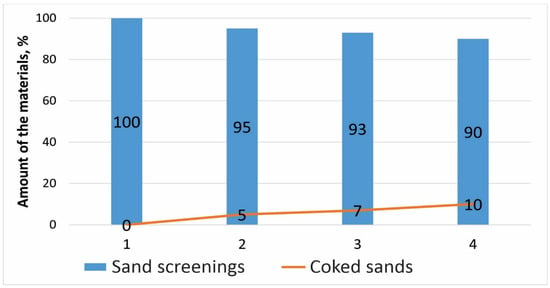

For testing the influence of coked sand on the content of asphalt concrete, the two types of composition were prepared. They are samples without coked sand (control) and samples with the addition of coked sand. Coked sand was added in quantities of 5%, 7%, and 10% of the sand mass from sand screenings. Paving bitumen (BND 70/100) was used as a binder of mineral materials in various sizes. Table 2 presents their exact compositions.

Table 2.

Composition of asphalt concrete.

As can be seen from Table 2, the first sample of asphalt concrete is the control sample (ACCS), which was prepared without adding coked sand. It contains 23% of crushed stone with the size of 10–20 mm, 19% of crushed stone with the size of 5–10 mm, 46% of sand screenings with a size of 0–5 mm, 7% of mineral powder, and 5% of bitumen binder. The other three samples differ from each other in the amount of sand screenings with the size of 0–5 mm and coked sands. All of them contain the same amount of crushed stones, mineral powder, and bitumen as the sample of CS. The second sample is 5% coked sand-added asphalt concrete (5CSAC) that contained 43.7% sand screenings and 2.3% coked sand by mass. As well as the third sample is 7% coked sand-added asphalt concrete (7CSAC), which contained 42.78% sand screenings and 3.22% coked sand. The last sample is 10% coked sand-added asphalt concrete (10CSAC), prepared using 41.4% sand screenings and 4.6% coked sand. Figure 5 illustrates the changes in sand screenings and coked sand contents in the four samples.

Figure 5.

Content of sand screenings and coked sands in the asphalt concrete samples.

According to the results presented in Figure 5, the use of coked sand to produce asphalt concrete can save 5–10% of sand screenings. Conversely, it has the potential to address the issue of utilizing the thermal processing residue of oil sand.

For the purpose of providing analysis of the characteristics of samples, cylindrical asphalt concrete samples were prepared with a height and diameter of 71.4 mm under a constant load of 40 MPa according to ST RK 1218-2003 [32]. After forming, the samples were kept in air-dry conditions for 24 h (Figure 6). While it is possible to mix bitumen with mineral powder at room temperature, it may not be ideal for achieving the best bonding and performance characteristics. Mixing at higher temperatures (170–175 °C) typically promotes better homogeneity, which can lead to improved bonding between the binder and the mineral powder. Room temperature mixing may require more thorough mixing techniques to achieve a uniform blend.

Figure 6.

Forming samples.

The physical and mechanical characteristics of the prepared samples were determined for compliance with the requirements of the Republic of Kazakhstan standard for asphalt concrete mixtures ST RK 1225-2019 [33], on “Asphalt concrete road, airfield and asphalt concrete mixtures. Specifications”. The analyses were conducted under the following conditions: temperature—22 °C, humidity—69%, and pressure—93.3 kPa. The test results are presented in Table 3.

Table 3.

The physical and mechanical characteristics of the asphalt concrete samples.

According to the test results, when adding coked sand to the asphalt concrete in the amount of 5% (sample 5CSAC) and 7% (sample 7CSAC), the compressive strength at 50 °C increases by 8% and 31%, respectively. With the sample of coked sand content reaching 10% (sample 10CSAC), no increase is observed and a decrease in strength occurs. The crack resistance indicator has comparable values. All of the obtained results of asphalt concrete samples comply with the requirements of ST RK 1225-2019 on “Asphalt concrete mixtures for roads, airfields and asphalt concrete. Technical specifications” for type B grade 1.

Previous studies have demonstrated the addition of various waste materials and by-products as modifiers during the preparation of asphalt concrete to enhance its quality. This article employed the oil sand pyrolysis residue as a modifier, resulting in an improvement in asphalt quality. This investigation appreciates the unique feature of using coked sand instead of mineral material, which sets it apart from previous studies.

Thus, studying the phase composition and structure of coked sand, as well as its interaction with pavement composition, is useful for predicting the properties of the materials, like thermal resistance, reactivity, or suitability for industrial applications such as construction materials.

4. Conclusions

In this study, characteristics of the hot fine-grained asphalt concrete with the addition of coked sands were investigated. The used coked sand is the solid residue left over after extracting oil from Munaily Mola oil sand using the pyrolysis method. Based on the results presented in this study, the following conclusions are drawn:

- The X-ray phase analysis (XRD) of coked sand showed that it contains quartz, aluminosilicates, metal oxides, and possibly carbonates. The peaks were found at 4.2564, 3.6749, 3.3768, 3.2380, 3.1903, 2.4581, 2.2800, and 2.2365 Å. These numbers show that the coked sand is made up of these minerals.

- During the sample preparation, the coked sands were added in the amounts of 5%, 7%, and 10% instead of sand screenings in the asphalt concrete mixture. Then, 5% of paving bitumen of BND 70/100 was used as a binder of asphalt mineral materials in various sizes. Test results showed that when adding coked sand in the amounts of 5% (sample 5CSAC) and 7% (sample 7CSAC), the compressive strength at 50 °C increases by 8% and 31%, respectively. With the sample of coked sand content reaching 10% (sample 10CSAC), no increase is observed and a decrease in strength occurs.

- The physical and mechanical characteristics of the prepared asphalt concrete samples were determined to ensure compliance with the requirements of the state standard of the Republic of Kazakhstan. The analyses were conducted under the following conditions: temperature—22 °C, humidity—69%, and pressure—93.3 kPa. All of the obtained results of asphalt concrete samples comply with the requirements of ST RK 1225-2019 on “Asphalt concrete mixtures for roads, airfields and asphalt concrete. Technical specifications” for type B grade 1.

It concludes that using coked sand to produce asphalt concrete can save 5–10% of sand screenings. Coked sand analysis offers insights into its stability, durability, and potential for reuse in various applications, including as construction materials. We can present this work as a solution to potential environmental issues arising from the thermal processing residue of oil sands. It was discovered that coked sands, a by-product of production, enhance the properties of asphalt concrete. These economize natural mineral materials and allow for obtaining high-quality road construction materials.

Author Contributions

Writing—original draft preparation, project administration, and funding acquisition, Y.T.; investigation, Y.O.; writing—review and editing, Z.M.; conceptualization, K.Z.; methodology, K.M.; formal analysis, Y.A. and N.S.; data curation, Y.I. All authors have read and agreed to the published version of the manuscript.

Funding

This study was funded by the Scientific Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Funding number and title: AP19175900 “Extraction of liquid fuels from combustible minerals and reuse of waste from this process”).

Data Availability Statement

The original contributions presented in this study are included in the article, and further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tileuberdi, Y.; Ongarbayev, Y.; Behrendt, F.; Mansurov, Z. Nanostructure of Bitumen Produced from Heavy Oil; Qazaq University: Almaty, Kazakhstan, 2017; 164p. [Google Scholar]

- Badin, G.; Ahmad, N.; Huang, Y.; Mahmood, Y. Evaluation of Pigment-Modified Clear Binders and Asphalts: An Approach towards Sustainable, Heat Harvesting, and Non-Black Pavements. Infrastructures 2024, 9, 88. [Google Scholar] [CrossRef]

- Ghani, U.; Milazzo, S.; Giancontieri, G.; Buttitta, G.; Gu, F.; Presti, D.L. Investigating the Ability of Road Specifications to Discriminate the Rutting Behavior of Rubberized Asphalt Mixtures in Italy. Infrastructures 2024, 9, 113. [Google Scholar] [CrossRef]

- Tsakoumaki, M.; Plati, C. A Critical Overview of Using Reclaimed Asphalt Pavement (RAP) in Road Pavement Construction. Infrastructures 2024, 9, 128. [Google Scholar] [CrossRef]

- Teltayev, B.; Massanov, A.; Aitbayev, Y.; Zhaisanbayev, A. Performance of a Semi-Rigid Pavement: A North Kazakhstan Case Study. Eng. Sci. 2024, 29, 1089. [Google Scholar] [CrossRef]

- Parviz, A. Nano Materials in Asphalt and Tar. Aust. J. Basic Appl. Sci. 2011, 5, 3270–3273. [Google Scholar]

- Mohamed, A.A. A Study on the Physical and Mechanical Properties of Asphaltic Concrete Incorporating Crumb Rubber Produced Through Dry Process. Ph.D. Thesis, Universiti Sains Malaysia, George Town, Malaysia, 2007; 48p. [Google Scholar]

- Teltayev, B.; Iskakbayev, A.; Oliviero Rossi, C.; Abu, B. Unsteady-State Creep of an Asphalt Concrete. Appl. Sci. 2022, 12, 1615. [Google Scholar] [CrossRef]

- Austruy, F.; Tileuberdi, Y.; Ongarbaev, Y.; Mansurov, Z. Study of Production of Rubber-Bitumen Compounds. Eurasian Chem.-Technol. J. 2012, 14, 133–138. [Google Scholar] [CrossRef]

- Korniejenko, K.; Nykiel, M.; Choinska, M.; Jexembayeva, A.; Konkanov, M.; Aruova, L. An Overview of Micro- and Nano-Dispersion Additives for Asphalt and Bitumen for Road Construction. Buildings 2023, 13, 2948. [Google Scholar] [CrossRef]

- Imanbayev, Y.; Bussurmanova, A.; Ongarbayev, Y.; Serikbayeva, A.; Sydykov, S.; Tabylganov, M.; Akkenzheyeva, A.; Izteleu, N.; Mussabekova, Z.; Amangeldin, D.; et al. Modification of Bitumen with Recycled PET Plastics from Waste Materials. Polymers 2022, 14, 4719. [Google Scholar] [CrossRef] [PubMed]

- Roco, M.C.; Mirkin, C.A.; Hersam, M.C. Nanotechnology research directions for societal needs in 2020: Summary of international study. J. Nanopart. Res. 2011, 13, 897–919. [Google Scholar] [CrossRef]

- Partl, M.N.; Gubler, R.; Hugener, M. Nano-Science and -Technology for Asphalt Pavements. Available online: http://www.empa.ch (accessed on 18 September 2024).

- Firoozi, A.A.; Taha, M.R.; Firoozi, A.A. Nanotechnology in Civil Engineering. Electron. J. Geotech. Eng. 2014, 19, 4673–4682. [Google Scholar]

- Saurav. Application of nanotechnology in building materials. Int. J. Eng. Res. Appl. 2012, 2, 1077–1082. [Google Scholar]

- Korniejenko, K.; Nykiel, M.; Choinska, M.; Jexembayeva, A.; Konkanov, M.; Aruova, L. An Overview of Phase Change Materials and Their Applications in Pavement. Energies 2024, 17, 2292. [Google Scholar] [CrossRef]

- Imjai, T.; Garcia, R.; Rassameekobkul, W.; Sofri, L.A.; Wicaksono, A. Service Performance of Porous Asphalt Mixtures in Thailand: Laboratory and Full-Scale Field Tests. Int. J. Pavement Res. Technol. 2024. [Google Scholar] [CrossRef]

- Mahdi, A.N.; Imjai, T.; Wattanapanich, C.; Garcia, R.; Kaur, H.; Musarat, M.A. Life Cycle Cost Analysis of Flexible Pavements Reinforced with Geo-Synthetics: A Case Study of New Construction or Repair Overlays in Thailand’s Roads. Eng. Sci. 2024, 28, 1071. [Google Scholar] [CrossRef]

- Chaves-Pabón, S.B.; Rondón-Quintana, H.A.; Bastidas Martínez, J.G. Mechanical Performance of a Hot Mix Asphalt Modified with Biochar Obtained from Oil Palm Mesocarp Fiber. Infrastructures 2024, 9, 156. [Google Scholar] [CrossRef]

- Tileuberdi, Y.; Ongarbayev, Y.; Imanbayev, Y.; Yermekova, A.; Behrendt, F.; Ismailova, A.; Zhanbekov, K.; Seilkhan, A.; Mansurov, Z. Studying Characteristics of Natural Bitumen of Oil Sand with Comparison to Heavy Crude Oil. ES Mater. Manuf. 2023, 22, 1035. [Google Scholar] [CrossRef]

- Liu, P.; Zhu, M.; Zhang, Z.; Zhang, D. Pyrolysis of an Indonesian oil sand on a thermogravimetric analyser and a fixed-bed reactor. J. Anal. Appl. Pyrolysis 2016, 117, 191–198. [Google Scholar] [CrossRef]

- Zhang, Z.; Ma, X.; Li, H.; Li, X.; Gao, X. Understanding the pyrolysis progress physical characteristics of Indonesian oil sands by visual experimental investigation. Fuel 2018, 216, 29–35. [Google Scholar] [CrossRef]

- GOST 33133-2014; Automobile Roads of General Use on “Viscous Road Petroleum Bitumens. Technical Requirements”. Interstate Council for Standardization, Metrology and Certification (ISC): Moscow, Russia, 2015.

- TR TS 014-2011; Technical Regulations of the Customs Union on “Road Safety”. Eurasian Economic Commission, Department for Technical Regulation and Accreditation: Moscow, Russia, 2011.

- GOST 33136-2014; Automobile Roads of General Use on “Viscous Road Petroleum Bitumens. Method for Determination of Needle Penetration Depth”. Interstate Council for Standardization, Metrology and Certification (ISC): Moscow, Russia, 2015.

- GOST 33142-2014; Automobile Roads of General Use on “Viscous Road Petroleum Bitumens. Determination of the Softening Point. Ring and Ball Method”. Interstate Council for Standardization, Metrology and Certification (ISC): Moscow, Russia, 2019.

- GOST 33138-2014; Automobile Roads of General Use on “Viscous Road Petroleum Bitumens. Method for Determination of Tensile Properties”. Interstate Council for Standardization, Metrology and Certification (ISC): Moscow, Russia, 2015.

- GOST 33141-2014; Automobile Roads of General Use on “Viscous Road Petroleum Bitumens. Determination of Flash Points. Cleveland Open Cup Method”. Interstate Council for Standardization, Metrology and Certification (ISC): Moscow, Russia, 2015.

- GOST 33143-2014; Automobile Roads of General Use on “Viscous Road Petroleum Bitumens. Method for Determination of Fraas Brittleness Temperature”. Interstate Council for Standardization, Metrology and Certification (ISC): Moscow, Russia, 2015.

- GOST 33134-2014; Automobile Roads of General Use on “Viscous Road Petroleum Bitumens. Determination of the Penetration Index”. Interstate Council for Standardization, Metrology and Certification (ISC): Moscow, Russia, 2015.

- GOST 33135-2014; Automobile Roads of General Use on “Viscous Road Petroleum Bitumens. Method for Determination of Solubility”. Interstate Council for Standardization, Metrology and Certification (ISC): Moscow, Russia, 2015.

- ST RK 1218-2003; Organic Binding Materials for Road and Airfield Construction. Test Methods. National Standard of Republic of Kazakhstan: Astana, Kazakhstan, 2003.

- ST RK 1225-2019; Asphalt Concrete Mixtures for Roads, Airfields and Asphalt Concrete. Technical Conditions. National Standard of Republic of Kazakhstan: Nur-Sultan, Kazakhstan, 2019.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).