Review of the Chinese Aluminum Industry’s Low-Carbon Development Driven by Carbon Tariffs: Challenges and Strategic Responses

Abstract

1. Introduction

2. Current Development Status of China’s Aluminum Industry

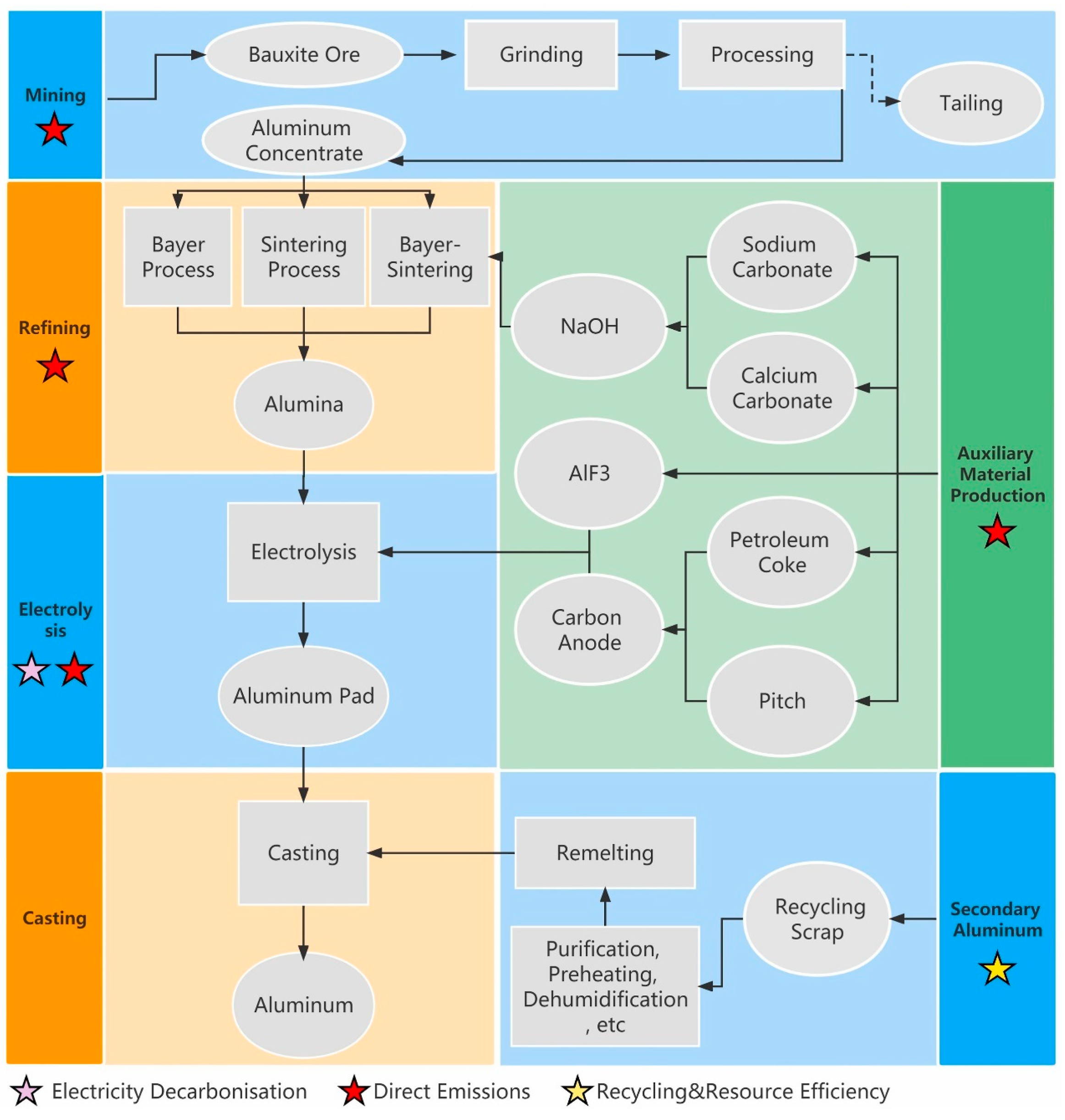

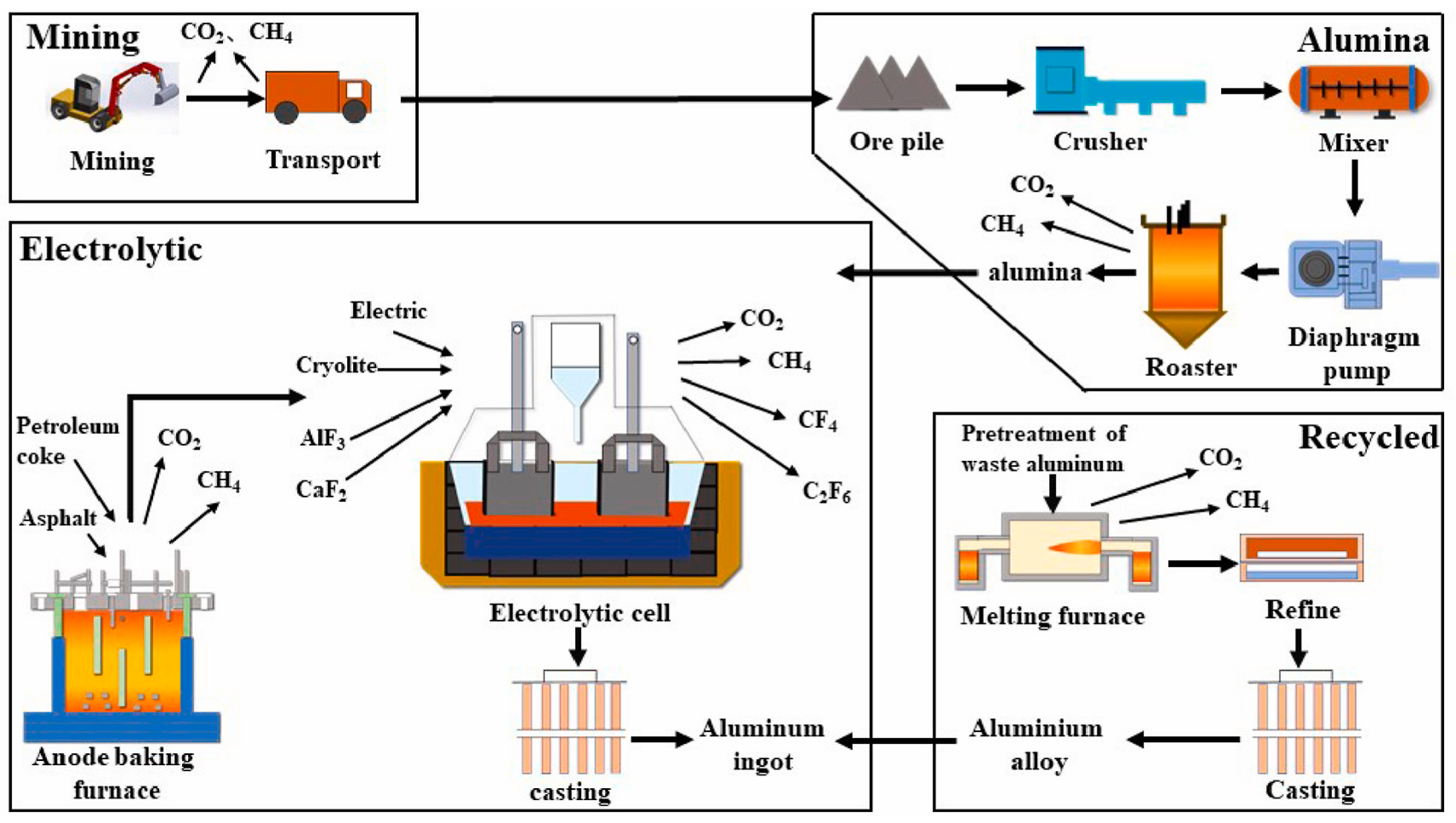

2.1. Production Process of Aluminum

2.2. Energy Structure and Carbon Emissions Status of China’s Aluminum Industry

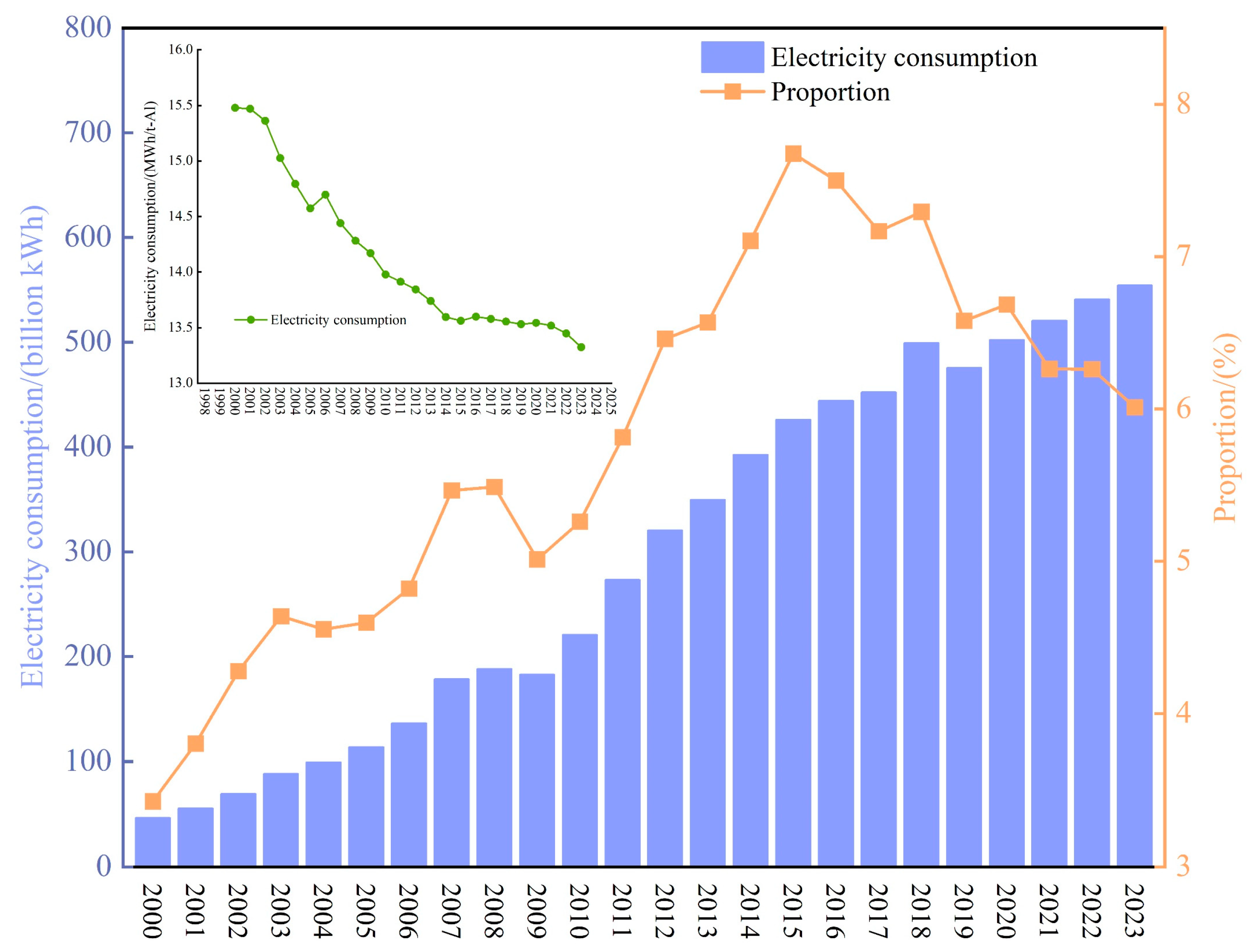

2.2.1. Energy Structure of China’s Aluminum Industry

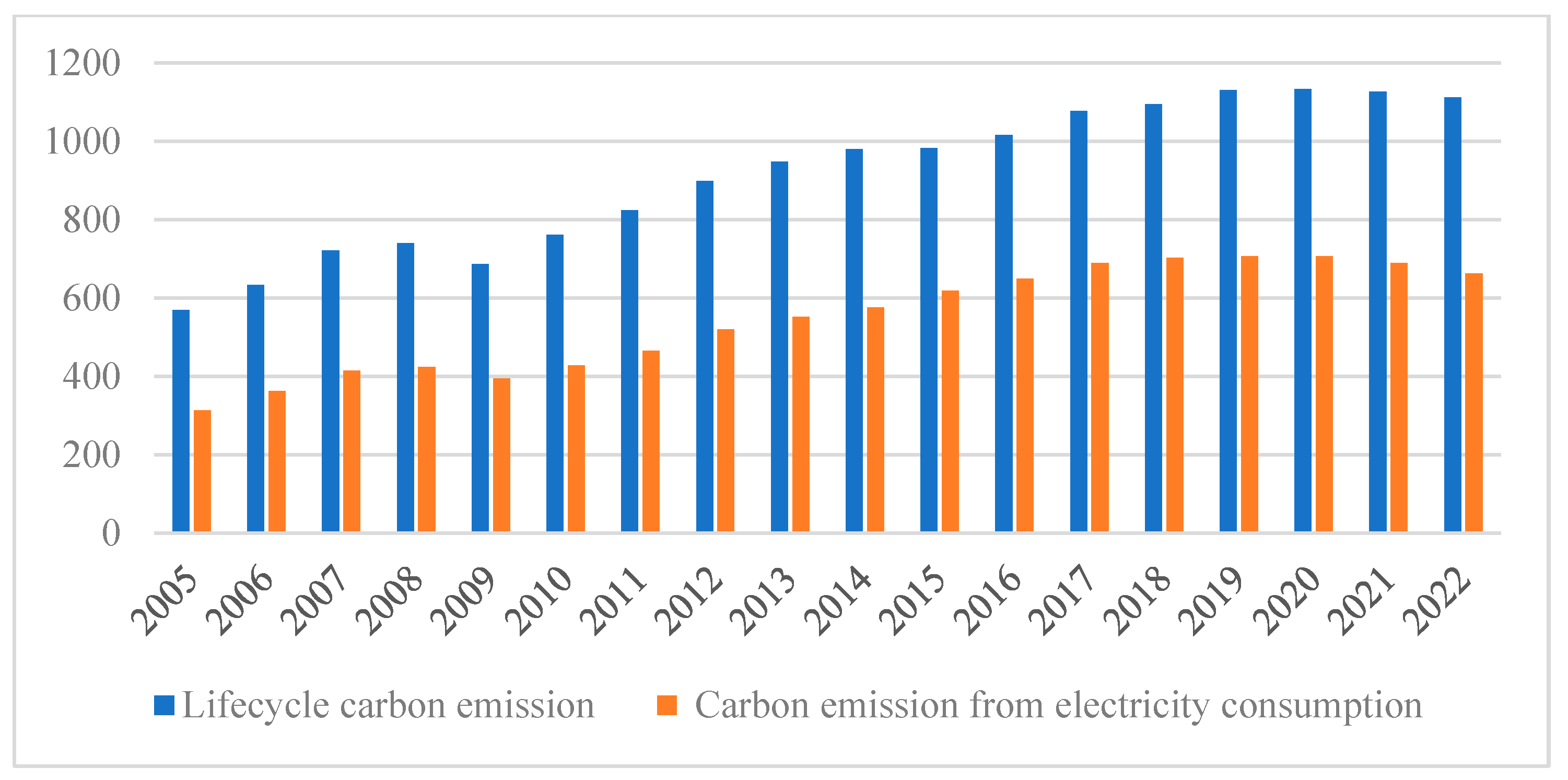

2.2.2. Current Situation of Carbon Emissions in China’s Aluminum Industry

2.3. Current Status of Carbon Emissions in the Aluminum Production Enterprise

2.3.1. Carbon Accounting Method Based on LCA

2.3.2. Carbon Emission Sources and Situation in Aluminum Production

3. Challenges and Dilemmas in the Development of the Chinese Aluminum Industry

3.1. Irrationality of the Cleaner Power Structure

3.2. Insufficient Supply of Low-Carbon Raw Materials

3.3. Trade Risks Arising from the Carbon Border Mechanism

3.3.1. Impact on Export Costs of Aluminum Products

- (1)

- Purchase of additional carbon certificates. The implementation of a carbon tariff necessitates that importers acquire electronic certificates that correspond to the carbon emissions embedded in imported products. This regulatory requirement is designed to hold importers accountable for the environmental impact of their products. Since China’s current carbon market lacks a robust carbon pricing mechanism for high-carbon industries [46,47] and has not yet aligned with international markets, Chinese aluminum products cannot benefit from foreign carbon offset policies, which indirectly increases the costs and prices of Chinese aluminum in the foreign market.

- (2)

- Expansion of carbon tariff coverage. Carbon tariffs currently exclude indirect carbon emissions, focusing only on the direct emissions from the production and processing of products, and they do not yet account for the wider emissions generated throughout the upstream and downstream supply chains. Once indirect emissions from electricity consumption are incorporated into the carbon accounting framework, aluminum exporters will be required to pay additional carbon taxes based on their electricity usage. As carbon tariffs gradually extend their sectoral coverage to downstream products in the supply chain, the cost burden placed on the aluminum industry will likely continue to expand. The cumulative effect of these changes could lead to a substantial increase in the overall cost burden placed on the aluminum sector.

- (3)

- Purchase advanced technology. In order to meet the carbon emission standards for aluminum exports, Chinese companies may invest in advanced foreign production equipment and technologies, further driving up costs, which will translate into higher export costs for aluminum products [48]. However, such investments often come with substantial financial implications. Although these investments are crucial for compliance and long-term sustainability, they also bring immediate financial challenges that could affect market share and profit margins.

- (4)

- Potential price advantage. Chinese aluminum products that are exported are already subject to stringent environmental standards, and even exceed the regulations, and so adherence to high environmental standards could reverse the current situation and yield competitive price advantages [7]. By demonstrating compliance with rigorous environmental criteria, Chinese manufacturers could attract customers who are willing to pay a premium for products that align with their sustainability goals. In addition, regarding the CBAM, the additional costs are more likely to be passed on to consumers in other regions.

3.3.2. Impact on Export Volume of Aluminum Products

- (1)

- Price increases cause reductions in capacity and export volumes. An increase in aluminum product prices will result in the loss of competitive pricing advantages for exported aluminum products, which may lead to a decrease in international market demand and a potential loss of orders [49,50]. Consequently, market contraction could cause overcapacity and insufficient demand, leading to significant issues related to idle capacity and inventory buildup in China’s aluminum industry [51]. Consequently, the anticipated reduction in orders could pose serious challenges for Chinese aluminum exporters and supply chains.

- (2)

- Elimination of outdated production capacity. The implementation of carbon tariffs will drive an overall low-carbon transformation within the industry, including the elimination of outdated production capacities. In the short term, a series of changes will directly affect aluminum production levels, resulting in a reduction in exportable quantities. This transition may initially result in a decrease in the quantity of aluminum available for export, as production facilities are restructured and optimized to align with new regulatory requirements.

- (3)

- Develop low-carbon industries and expand domestic demand. The carbon tariff may also stimulate China to accelerate the development of low-carbon industries, such as new energy vehicles, thereby increasing domestic demand for aluminum products and alleviating export pressures. The demand for materials that support these initiatives, like green aluminum, is expected to rise significantly. By redirecting resources and innovation efforts towards the production of high-quality aluminum and other green technologies, Chinese companies can strengthen their competitive position both domestically and internationally.

3.3.3. Impact on the Competitive Position

- (1)

- A late start for technological systems and carbon markets leads to a decline in initial competitiveness. The implementation of carbon tariffs will lead to disadvantages for aluminum products from developing countries with relatively less advanced industrialization, including China. Green barriers and trade friction caused by the CBAM will intensify, causing Chinese aluminum products to lose their competitiveness compared to those from more developed economies, which benefit from advanced recycling processes and lower carbon footprints [52].

- (2)

- Transition to high-quality supply chains. The implementation of carbon border mechanisms will impose additional carbon regulation costs on high-carbon products throughout the supply chain. To mitigate these costs, superior supply chain segments may shift from high-carbon to low-carbon countries. Such a shift in supply chain dynamics may lead to disruptions in established trade relationships, logistical inefficiencies, and reduced economies of scale.

- (3)

- Chain reactions exacerbate the complexity and competition of exportation. The adoption of carbon border mechanisms may prompt other countries to consider similar carbon tariff policies. As more nations follow suit, the ripple effect may intensify, creating additional layers of complexity and costs for Chinese exporters and exacerbate the impact on China’s export trade, leading to further challenges for the aluminum industry in maintaining its market position. Consequently, maintaining competitiveness and market share will become increasingly difficult for China’s aluminum industry as it contends with heightened regulatory barriers and rising production costs.

4. Strategies for the Chinese Aluminum Industry in Response to Low-Carbon Development Regulated by Carbon Tariffs

4.1. Source Substitution: Transformation to a Cleaner Energy Structure

4.2. Source Replacement: Low-Carbon Materials Substitution

4.2.1. Adopting Low-Carbon Anodes During the Electrolysis Process

- (1)

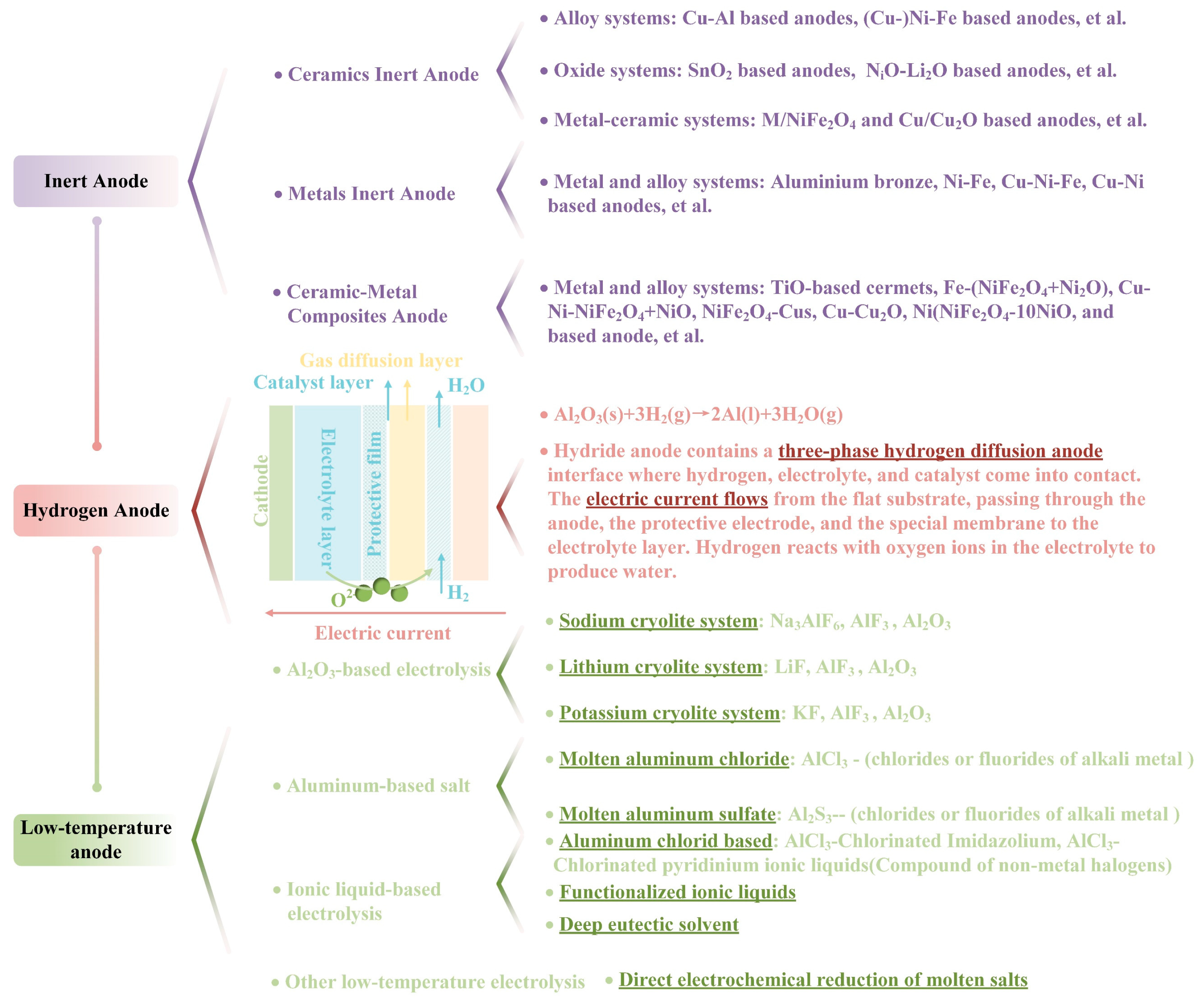

- Inert anode materials. The types of inert anode materials mainly include three systems: ceramics, metals, and metal ceramics [23]. The ideal inert anode material should have a good electrical conductivity, high chemical stability and corrosion resistance, excellent mechanical properties, and cost advantages [65,66].

- (2)

- Hydrogen anode. Hydrogenated anode technology adopts appropriate cathodes and hydrogen diffusion anodes for electrochemical reactions [67].

- (3)

- Low-temperature electrolysis anode. The electrolytic aluminum process can achieve approximately 140 kW·h/kg of energy-savings for every 10 °C decrease in temperature. Simultaneously, the physicochemical properties of the electrolyte will be severely affected during the process of reducing the electrolysis temperature and voltage. The current temperature for aluminum electrolysis has reached 950 °C, while the melting point of aluminum is 660 °C and such a high temperature is not necessary. Theoretically, low-temperature technologies such as Al2O3-based, aluminum-based salt, and ionic liquid-based electrolysis have been proposed and developed to achieve energy conservation and carbon reduction.

4.2.2. Enhancing Aluminum Recycling Efficiency and the Utilization of Recycled Aluminum

4.3. Intermediate Process Control: Innovation of Key Technologies and Production Processes

4.4. End-of-Pipe Treatment: Applications of Carbon Capture and Utilization

4.4.1. Carbon Capture Technologies

4.4.2. Carbon Utilization Technologies

4.5. Policy Incentive: Optimize the Management of the Supply Chain and Policy Implementation

5. Conclusions

- (1)

- This study highlights the current status of China’s aluminum industry from three critical perspectives: energy consumption, carbon emissions, and trade dynamics. The aluminum industry has demonstrated significant progress but is poised to face ongoing challenges. Coal-fired power generation continues to dominate the energy consumption landscape in the aluminum sector. Despite improvements in energy efficiency driven by technological innovation, the persistent reliance on coal has still resulted in elevated carbon emissions. Furthermore, since 2000, the trade dynamics of Chinese aluminum products have exhibited a robust growth trajectory, indicating a deep integration of the aluminum value chain into the global supply chain. As carbon tariffs are implemented and China’s carbon market aligns with international standards, the aluminum industry will encounter substantial challenges that necessitate strategic adaptations to maintain competitiveness and sustainability in an evolving regulatory environment.

- (2)

- The implementation of carbon tariffs presents significant challenges and opportunities for China’s aluminum industry. Firstly, the expected increase in aluminum export costs may undermine the pricing competitiveness of Chinese aluminum products in international markets. However, this situation simultaneously incentivizes enterprises to transition towards low-carbon production methods. The additional operational costs incurred to meet carbon emission standards could initially lead to a decline in export volumes and exacerbate existing overcapacity issues. Nevertheless, adherence to stringent environmental regulations may gradually confer competitive advantages in a global market that is increasingly attuned to sustainability concerns. Thus, the Chinese aluminum industry must formulate strategic responses to carbon tariffs to navigate the dual pressures of compliance and competitiveness effectively.

- (3)

- China’s aluminum industry must adopt a comprehensive approach to address the challenges posed by carbon tariffs, encompassing upstream low-carbon materials and energy management, intermediate process control, end-point governance, and policy incentives. Transitioning to clean energy and optimizing raw material usage are critical to reducing the carbon footprint of aluminum production. The industry must invest in technological innovations to enhance energy efficiency and strengthen carbon capture and utilization efforts. Furthermore, establishing robust recycling systems and adopting advanced recycling technologies can significantly reduce emissions and operational costs. Simultaneously, optimizing the policy framework is essential to promote sustainable practices and incentivize the industry’s low-carbon transition.

Author Contributions

Funding

Conflicts of Interest

References

- Zhao, L.-T.; Chen, Z.-Y.; Duan, Y.-X.; Qiu, R.-X. How will CBAM affect the decarbonisation of steel industry in China? A system dynamics approach. Int. J. Prod. Res. 2023, 62, 6859–6880. [Google Scholar] [CrossRef]

- Chu, L.; Do, T.N.; Le, T.H.L.; Ho, Q.A.; Dang, K. Carbon border adjustment mechanism, carbon pricing, and within-sector shifts: A partial equilibrium approach to Vietnam’s steel sector. Energy Policy 2024, 193, 114293. [Google Scholar] [CrossRef]

- Ambec, S.; Esposito, F.; Pacelli, A. The economics of carbon leakage mitigation policies. J. Environ. Econ. Manag. 2024, 125, 102973. [Google Scholar] [CrossRef]

- Healy, S.; Schumacher, K.; Eichhammer, W. Analysis of carbon leakage under phase III of the eu emissions trading system: Trading patterns in the cement and aluminium sectors. Energies 2018, 11, 1231. [Google Scholar] [CrossRef]

- Yi, X.; Lu, Y.; He, G.; Li, H.; Chen, C.; Cui, H. Global carbon transfer and emissions of aluminum production and consumption. J. Clean. Prod. 2022, 362, 132513. [Google Scholar] [CrossRef]

- Ali, J. Road map for sustainable and effective carbon pricing: Bridging the gap of realities and ambitions. Environ. Sci. Pollut. Res. 2023, 30, 94070–94080. [Google Scholar] [CrossRef]

- Zhou, X.; Zhu, Q.; Xu, L.; Wang, K.; Yin, X.; Mangla, S.K. The effect of carbon tariffs and the associated coping strategies: A global supply chain perspective. Omega 2024, 122, 102960. [Google Scholar] [CrossRef]

- Shen, A.; Zhang, J. Technologies for CO2 emission reduction and low-carbon development in primary aluminum industry in China: A review. Renew. Sustain. Energy Rev. 2024, 189, 113965. [Google Scholar] [CrossRef]

- International Aluminium Institute. Available online: https://international-aluminium.org (accessed on 2 September 2024).

- Lin, B.; Zhao, H. Evaluating current effects of upcoming EU Carbon Border Adjustment Mechanism: Evidence from China’s futures market. Energy Policy 2023, 177, 113573. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment of the People’s Republic of China. National Carbon Emission Trading Market Coverage for the Cement, Steel, and Electrolytic Aluminum Industries Work Plan (Draft for Comments). Available online: https://www.mee.gov.cn/xxgk2018/xxgk/xxgk06/202409/t20240909_1085452.html (accessed on 14 October 2024).

- Cho, B.-K.; Jung, H.; Chung, J.-B.; Song, C.-K. Implications of the Carbon Border Adjustment Mechanism on South Korean industries: Challenges and policy recommendations. J. Clean. Prod. 2024, 444, 141278. [Google Scholar] [CrossRef]

- Chang, J. Implementation of the EU carbon border adjustment mechanism and China’s policy and legal responses. Environ. Impact Assess. Rev. 2025, 110, 107683. [Google Scholar] [CrossRef]

- Li, K.; Luo, Z.; Hong, L.; Wen, J.; Fang, L. The role of China’s carbon emission trading system in economic decarbonization: Evidence from Chinese prefecture-level cities. Heliyon 2024, 10, e23799. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, J.; Wu, Z.; Li, Y. Study on the effectiveness and influencing factors of China’s carbon emissions trading policy from industries’ perspective. Clean. Techn. Environ. Policy 2024. [Google Scholar] [CrossRef]

- Evro, S.; Oni, B.A.; Tomomewo, O.S. Global strategies for a low-carbon future: Lessons from the US, China, and EU’s pursuit of carbon neutrality. J. Clean. Prod. 2024, 461, 142635. [Google Scholar] [CrossRef]

- Eheliyagoda, D.; Li, J.; Geng, Y.; Zeng, X. The role of China’s aluminum recycling on sustainable resource and emission pathways. Resour. Policy 2022, 76, 102552. [Google Scholar] [CrossRef]

- The Aluminum Association. Abundant Clean Energy, New Tech Investment Key to Aluminum Industry Decarbonization by 2050. Available online: https://www.aluminum.org/news/abundant-clean-energy-new-tech-investment-key-aluminum-industry-decarbonization-2050 (accessed on 14 October 2024).

- International Aluminium Institute. Primary Aluminium Smelting Power Consumption. Available online: https://international-aluminium.org/statistics/primary-aluminium-smelting-power-consumption/ (accessed on 14 October 2024).

- Hassan, Q.; Algburi, S.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. A review of hybrid renewable energy systems: Solar and wind-powered solutions: Challenges, opportunities, and policy implications. Results Eng. 2023, 20, 101621. [Google Scholar] [CrossRef]

- Brough, D.; Jouhara, H. The aluminium industry: A review on state-of-the-art technologies, environmental impacts and possibilities for waste heat recovery. Int. J. Thermofluids 2020, 1–2, 100007. [Google Scholar] [CrossRef]

- The Central People’s Government of the People’s Republic of CHINA. 2024–2025 Energy Conservation and Carbon Reduction Action Plan. Available online: https://www.gov.cn/yaowen/liebiao/202405/content_6954373.htm (accessed on 10 September 2024).

- Padamata, S.K.; Yasinskiy, A.; Polyakov, P.V. Progress of inert anodes in aluminium industry: Review. J. Sib. Fed. Univ. Chem. 2018, 11, 18–30. [Google Scholar] [CrossRef]

- Lassagne, O.; Gosselin, L.; Désilets, M.; Iliuta, M.C. Techno-economic study of CO2 capture for aluminum primary production for different electrolytic cell ventilation rates. Chem. Eng. J. 2013, 230, 338–350. [Google Scholar] [CrossRef]

- Mathisen, A.; Sørensen, H.; Eldrup, N.; Skagestad, R.; Melaaen, M.; Müller, G.I. Cost optimised CO2 capture from aluminium production. Energy Procedia 2014, 51, 184–190. [Google Scholar] [CrossRef]

- National Bureau of Statistics. 2023 National Economic and Social Development Statistical Bulletin. Available online: https://www.stats.gov.cn/sj/zxfb/202402/t20240228_1947915.html (accessed on 10 September 2024).

- International Aluminium Institute. Greenhouse Gas Emissions Intensity—Primary Aluminium. Available online: https://international-aluminium.org/statistics/greenhouse-gas-emissions-aluminium-sector/?publication=greenhouse-gas-emissions-aluminium-sector (accessed on 2 September 2024).

- Zheng, Y.; Shan, R.; Xu, W.; Qiu, Y. Effectiveness of carbon dioxide emission target is linked to country ambition and education level. Commun. Earth Environ. 2024, 5, 209. [Google Scholar] [CrossRef]

- Burke, J.; Gambhir, A. Policy incentives for greenhouse gas removal techniques: The risks of premature inclusion in carbon markets and the need for a multi-pronged policy framework. Energy Clim. Chang. 2022, 3, 100074. [Google Scholar] [CrossRef]

- Li, X.; Lin, J.; Liu, C.; Liu, A.; Shi, Z.; Wang, Z.; Jiang, S.; Wang, G.; Liu, F. Research on Aluminum Electrolysis from 1970 to 2023: A Bibliometric Analysis. JOM 2024, 76, 3265–3274. [Google Scholar] [CrossRef]

- Li, S.; Zhang, T. The development scenarios and environmental impacts of China’s aluminum industry: Implications of import and export transition. J. Sustain. Met. 2022, 8, 1472–1484. [Google Scholar] [CrossRef]

- Xin, H.; Wang, S.; Chun, T.; Xue, X.; Long, W.; Xue, R.; Zhang, R. Effective pathways for energy conservation and emission reduction in iron and steel industry towards peaking carbon emissions in China: Case study of Henan. J. Clean. Prod. 2023, 399, 136637. [Google Scholar] [CrossRef]

- Dutta, D.; Arya, S.; Kumar, S. Industrial wastewater treatment: Current trends, bottlenecks, and best practices. Chemosphere 2021, 285, 131245. [Google Scholar] [CrossRef]

- Singh, B.J.; Chakraborty, A.; Sehgal, R. A systematic review of industrial wastewater management: Evaluating challenges and enablers. J. Environ. Manag. 2023, 348, 119230. [Google Scholar] [CrossRef]

- International Aluminium Institute. Primary Aluminium Smelting Energy Intensity. Available online: https://international-aluminium.org/statistics/primary-aluminium-smelting-energy-intensity/ (accessed on 2 September 2024).

- Ingarao, G.; Deng, Y.; Marino, R.; Di Lorenzo, R.; Lo Franco, A. Energy and CO2 life cycle inventory issues for aluminum based components: The case study of a high speed train window panel. J. Clean. Prod. 2016, 126, 493–503. [Google Scholar] [CrossRef]

- Palazzo, J.; Geyer, R. Consequential life cycle assessment of automotive material substitution: Replacing steel with aluminum in production of North American vehicles. Environ. Impact Assess. Rev. 2019, 75, 47–58. [Google Scholar] [CrossRef]

- Cheng, K.; Zhang, J.; Yi, P.; Zhu, G.; Hao, W.; Ji, W.; Tian, H.; Wang, Y. Exploring the emission characteristics and reduction potential of air pollutants from Chinese aluminum industry: 2005–2025. Earth Future 2020, 8, e2019EF001440. [Google Scholar] [CrossRef]

- Farjana, S.H.; Huda, N.; Mahmud, M.A.P. Impacts of aluminum production: A cradle to gate investigation using life-cycle assessment. Sci. Total Environ. 2019, 663, 958–970. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Zhu, W.; Yang, Y.; Cheng, H. Carbon reduction potential based on life cycle assessment of China’s aluminium industry-a perspective at the province level. J. Clean. Prod. 2019, 239, 118004. [Google Scholar] [CrossRef]

- Li, M.; Gao, F.; Sun, B.; Liu, Y.; Gong, X.; Nie, Z. Zero carbon-emission technology route construction and multifactor analysis of aluminum production in China. J. Clean. Prod. 2022, 370, 133535. [Google Scholar] [CrossRef]

- Gao, F.; Nie, Z.; Wang, Z.; Li, H.; Gong, X.; Zuo, T. Greenhouse gas emissions and reduction potential of primary aluminum production in China. Sci. China Ser. E-Technol. Sci. 2009, 52, 2161–2166. [Google Scholar] [CrossRef]

- Yu, B.; Zhao, Z.; Zhang, S.; An, R.; Chen, J.; Li, R.; Zhao, G. Technological development pathway for a low-carbon primary aluminum industry in China. Technol. Forecast. Soc. Chang. 2021, 173, 121052. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Zhu, H.; Zhou, P.; Liu, S.; Lei, X.; Li, Y.; Li, B.; Ning, P. Life cycle assessment of pollutants and emission reduction strategies based on the energy structure of the nonferrous metal industry in China. Energy 2022, 261, 125148. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Q.; Ning, P.; Wen, S. Greenhouse gas contribution and emission reduction potential prediction of China’s aluminum industry. Energy 2024, 290, 130183. [Google Scholar] [CrossRef]

- Wang, H.; Tan, Z.; Zhang, A.; Pu, L.; Zhang, J.; Zhang, Z. Carbon market price prediction based on sequence decomposition-reconstruction-dimensionality reduction and improved deep learning model. J. Clean. Prod. 2023, 425, 139063. [Google Scholar] [CrossRef]

- Ji, C.-J.; Hu, Y.-J.; Tang, B.-J.; Qu, S. Price drivers in the carbon emissions trading scheme: Evidence from Chinese emissions trading scheme pilots. J. Clean. Prod. 2021, 278, 123469. [Google Scholar] [CrossRef]

- Zhu, N.; Qian, L.; Jiang, D.; Mbroh, N. A simulation study of China’s imposing carbon tax against American carbon tariffs. J. Clean. Prod. 2020, 243, 118467. [Google Scholar] [CrossRef]

- Zhao, B.; Yarime, M. The impacts of carbon tariffs on international trade flows and carbon emissions: An analysis integrating trade elasticities with an application to US-China trade. Energy Econ. 2022, 115, 106337. [Google Scholar] [CrossRef]

- Li, W.; Liu, X.; Lu, C. Analysis of China’s steel response ways to EU CBAM policy based on embodied carbon intensity prediction. Energy 2023, 282, 128812. [Google Scholar] [CrossRef]

- Cheng, X.; Wang, W.; Chen, X.; Zhang, W.; Song, M. Carbon tariffs and energy subsidies: Synergy or antagonism? Energy 2024, 306, 132563. [Google Scholar] [CrossRef]

- Ramadhani, D.P.; Koo, Y. Comparative analysis of carbon border tax adjustment and domestic carbon tax under general equilibrium model: Focusing on the Indonesian economy. J. Clean. Prod. 2022, 377, 134288. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, X.; Zeng, A. Decoupling analysis between economic growth and aluminum cycle: From the perspective of aluminum use and carbon emissions. J. Environ. Manag. 2023, 344, 118461. [Google Scholar] [CrossRef]

- Sorknæs, P.; Johannsen, R.M.; Korberg, A.D.; Nielsen, T.B.; Petersen, U.R.; Mathiesen, B.V. Electrification of the industrial sector in 100% renewable energy scenarios. Energy 2022, 254, 124339. [Google Scholar] [CrossRef]

- Deng, L.; Johnson, S.; Gencer, E. Environmental-Techno-Economic analysis of decarbonization strategies for the Indian aluminum industry. Energy Convers. Manag. 2022, 274, 116455. [Google Scholar] [CrossRef]

- Pedneault, J.; Majeau-Bettez, G.; Krey, V.; Margni, M. What future for primary aluminium production in a decarbonizing economy? Glob. Environ. Chang. 2021, 69, 102316. [Google Scholar] [CrossRef]

- de Lange, D.E. Climate action now: Energy industry restructuring to accelerate the renewable energy transition. J. Clean. Prod. 2024, 443, 141018. [Google Scholar] [CrossRef]

- Jamali, M.-B.; Rasti-Barzoki, M.; Altmann, J. An evolutionary game-theoretic approach for investigating the long-term behavior of the industry sector for purchasing renewable and non-renewable energy: A case study of Iran. Energy 2023, 285, 129245. [Google Scholar] [CrossRef]

- Sgouridis, S.; Ali, M.; Sleptchenko, A.; Bouabid, A.; Ospina, G. Aluminum smelters in the energy transition: Optimal configuration and operation for renewable energy integration in high insolation regions. Renew. Energy 2021, 180, 937–953. [Google Scholar] [CrossRef]

- Wang, Z.; Sheng, K.; Zhu, X.; Chen, H.; Wang, X. Photovoltaic system modeling and primary frequency modulation technique based on DIgSILENT. Int. Conf. Optoelectron. Mater. Devices 2022, 12164, 329–334. [Google Scholar]

- Wu, N.; Xu, J.; Linghu, J.; Huang, J. Real-time optimal control and dispatching strategy of multi-microgrid energy based on storage collaborative. Int. J. Electr. Power Energy Syst. 2024, 160, 110063. [Google Scholar] [CrossRef]

- Chen, X.; Dong, W.; Yang, Q. Robust optimal capacity planning of grid-connected microgrid considering energy management under multi-dimensional uncertainties. Appl. Energy 2022, 323, 119642. [Google Scholar] [CrossRef]

- Long, Y.; Liu, X. Optimal green investment strategy for grid-connected microgrid considering the impact of renewable energy source endowment and incentive policy. Energy 2024, 295, 131073. [Google Scholar] [CrossRef]

- Saevarsdottir, G.; Kvande, H.; Welch, B.J. Reducing the Carbon Footprint: Aluminium Smelting with Changing Energy Systems and the Risk of Carbon Leakage. In Light Metals 2020; Tomsett, A., Ed.; Springer International Publishing: Cham, Switzerland, 2020; pp. 726–734. [Google Scholar]

- He, Y.; Zhou, K.; Zhang, Y.; Xiong, H.; Zhang, L. Recent progress of inert anodes for carbon-free aluminium electrolysis: A review and outlook. J. Mater. Chem. A 2021, 9, 25272–25285. [Google Scholar] [CrossRef]

- Feng, L.-C.; Xie, N.; Shao, W.-Z.; Zhen, L.; Ivanov, V.V. Exploring Cu2O/Cu cermet as a partially inert anode to produce aluminum in a sustainable way. J. Alloys Compd. 2014, 610, 214–223. [Google Scholar] [CrossRef]

- Namboothiri, S.; Taylor, M.P.; Chen, J.J.J.; Hyland, M.M.; Cooksey, M. Aluminium production options with a focus on the use of a hydrogen anode: A review. Asia-Pacific J. Chem. Eng. 2007, 2, 442–447. [Google Scholar] [CrossRef]

- Makwana, A.; Sa, V.; Kabarowski, J.; Huang, Y.; Da Silva Junior, R.P.; He, X. Pathways to Reduce Operational Carbon Footprint in Secondary Aluminum Melting. In Energy Technology 2024; Iloeje, C., Alam, S., Guillen, D.P., Tesfaye, F., Zhang, L., Hockaday, S.A.C., Neelameggham, N.R., Peng, H., Haque, N., Yücel, O., et al., Eds.; Springer: Cham, Switzerland, 2024; pp. 17–27. [Google Scholar]

- Yang, C.; Zhang, L.; Chen, Z.; Gao, Y.; Xu, Z. Dynamic material flow analysis of aluminum from automobiles in China during 2000–2050 for standardized recycling management. J. Clean. Prod. 2022, 337, 130544. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, Y.; Xi, J.; Sun, J.; Yan, S.; Du, T.; Na, H.Y.; Xi, J.; Sun, J.; Yan, S.; et al. Synergistic enhancement for energy-saving, emission reduction and profit improvement in iron and steel manufacturing system: Strategies for parameter regulation and technologies integration. Energy Convers. Manag. 2024, 322, 119101. [Google Scholar] [CrossRef]

- Vallejo Olivares, A.; Pastor-Vallés, E.; Pettersen, J.B.; Tranell, G. LCA of recycling aluminium incineration bottom ash, dross and shavings in a rotary furnace and environmental benefits of salt-slag valorisation. Waste Manag. 2024, 182, 11–20. [Google Scholar] [CrossRef] [PubMed]

- Capuzzi, S.; Timelli, G. Preparation and melting of scrap in aluminum recycling: A review. Metals 2018, 8, 249. [Google Scholar] [CrossRef]

- Kamavaram, V.; Mantha, D.; Reddy, R.G. Recycling of aluminum metal matrix composite using ionic liquids:: Effect of process variables on current efficiency and deposit characteristics. Electrochim. Acta 2005, 50, 3286–3295. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, Z.; Hiraki, T.; Takeda, O.; Zhu, H.; Matsubae, K.; Nagasaka, T. A solid-state electrolysis process for upcycling aluminium scrap. Nature 2022, 606, 511–515. [Google Scholar] [CrossRef]

- Adhikari, B.; Lister, T.E.; Reddy, R.G. Techno-economic and life cycle assessment of aluminum electrorefining from mixed scraps using ionic liquid. Sustain. Prod. Consum. 2022, 33, 932–941. [Google Scholar] [CrossRef]

- Chen, Q.; Guo, Y.; Lai, X.; Han, X.; Liu, X.; Lu, L.; Ouyang, M.; Zheng, Y. Chemical-free recycling of cathode material and aluminum foil from waste lithium-ion batteries by combining plasma and ultrasonic technology. ACS Appl. Mater. Interfaces 2024, 16, 31076–31084. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Y.; Yang, J.; Di, Y.; Peng, J. Study on the cathodic behavior of impurities in the process of aluminum extraction by soluble anode electrolysis. J. Electrochem. Soc. 2022, 169, 063505. [Google Scholar] [CrossRef]

- Hou, W.; Li, H.; Li, M.; Cheng, B. Recycling of spent refractory materials to produce Al–Si master alloys via the aluminum reduction cell. J. Clean. Prod. 2021, 289, 125162. [Google Scholar] [CrossRef]

- Liu, F.; Lv, H.; Zuo, Z.; Xie, M.; Li, R.; Zhao, H.A. denitrification-phase transition and protection rings (dpp) process for recycling electrolytic aluminum dross. ACS Sustain. Chem. Eng. 2021, 9, 13751–13760. [Google Scholar] [CrossRef]

- Hagelüken, C.; Goldmann, D. Recycling and circular economy—Towards a closed loop for metals in emerging clean technologies. Miner. Econ. 2022, 35, 539–562. [Google Scholar] [CrossRef]

- Yang, T.; Luo, D.; Yu, A.; Chen, Z. Enabling future closed-loop recycling of spent lithium-ion batteries: Direct cathode regeneration. Adv. Mater. 2023, 35, 2203218. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Chen, G.; Chen, S.; Zhu, C.; Chen, K. Inhibiting segregation enabled outstanding combination of mechanical and corrosion properties in precipitation-strengthened aluminum alloys. J. Mater. Sci. Technol. 2024, 179, 240–250. [Google Scholar] [CrossRef]

- Raabe, D.; Ponge, D.; Uggowitzer, P.J.; Roscher, M.; Paolantonio, M.; Liu, C.; Antrekowitsch, H.; Kozeschnik, E.; Seidmann, D.; Gault, B.; et al. Making sustainable aluminum by recycling scrap: The science of “dirty” alloys. Prog. Mater. Sci. 2022, 128, 100947. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, Y.; Liu, S.; Su, Z.; Jiang, T. Life cycle assessment of aluminum-silicon alloy production from secondary aluminum in China. J. Clean. Prod. 2023, 392, 136214. [Google Scholar] [CrossRef]

- Moghimian, P.; Poirié, T.; Habibnejad-Korayem, M.; Zavala, J.A.; Kroeger, J.; Marion, F.; Larouche, F. Metal powders in additive manufacturing: A review on reusability and recyclability of common titanium, nickel and aluminum alloys. Addit. Manuf. 2021, 43, 102017. [Google Scholar] [CrossRef]

- Du, S.; Zhang, S.; Wang, J.; Lv, Z.; Xu, Z.; Liu, C.; Liu, J.; Liu, B. Energy flow of aerospace aluminum scraps cycle and advanced integration principles for upcycling technologies: A review. J. Clean. Prod. 2024, 448, 141176. [Google Scholar] [CrossRef]

- Krall, P.; Weißensteiner, I.; Pogatscher, S. Recycling aluminum alloys for the automotive industry: Breaking the source-sink paradigm. Resour. Conserv. Recycl. 2024, 202, 107370. [Google Scholar] [CrossRef]

- Díaz-Romero, D.; Van den Eynde, S.; Zaplana, I.; Zhou, C.; Sterkens, W.; Goedemé, T.; Peeters, J. Classification of aluminum scrap by laser induced breakdown spectroscopy (LIBS) and RGB + D image fusion using deep learning approaches. Resour. Conserv. Recycl. 2023, 190, 106865. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Wang, N.; Liu, Y.; Xin, H.; Sun, H.; Zhang, R. Exploring the paths of energy conservation and emission reduction in aluminum industry in Henan province, China. J. Clean. Prod. 2024, 467, 142997. [Google Scholar] [CrossRef]

- Sun, J.; Qiu, Z.; Yuan, Y.; Che, Z.; Zhang, L.; Du, T.; Na, H.; Li, Y. Decarbonization potential collaborated with source industries for China’s iron and steel industry towards carbon neutrality. J. Clean. Prod. 2023, 429, 139643. [Google Scholar] [CrossRef]

- Guo, Y.; Yu, Y.; Ren, H.; Xu, L. Scenario-based DEA assessment of energy-saving technological combinations in aluminum industry. J. Clean. Prod. 2020, 260, 121010. [Google Scholar] [CrossRef]

- Zhang, L.; Na, H.; Yuan, Y.; Sun, J.; Yang, Y.; Qiu, Z.; Che, Z.; Du, T. Integrated optimization for utilizing iron and steel industry’s waste heat with urban heating based on exergy analysis. Energy Convers. Manag. 2023, 295, 117593. [Google Scholar] [CrossRef]

- Yuan, Y.; Na, H.; Du, T.; Qiu, Z.; Sun, J.; Yan, T.; Che, Z. Multi-objective optimization and analysis of material and energy flows in a typical steel plant. Energy 2023, 263, 125874. [Google Scholar] [CrossRef]

- Sun, W.; Wang, Q.; Zhou, Y.; Wu, J. Material and energy flows of the iron and steel industry: Status quo, challenges and perspectives. Appl. Energy 2020, 268, 114946. [Google Scholar] [CrossRef]

- Na, H.; Qiu, Z.; Sun, J.; Yuan, Y.; Zhang, L.; Du, T. Revealing cradle-to-gate CO2 emissions for steel product producing by different technological pathways based on material flow analysis. Resour. Conserv. Recycl. 2024, 203, 107416. [Google Scholar] [CrossRef]

- Na, H.; Sun, J.; Yuan, Y.; Qiu, Z.; Zhang, L.; Du, T. Theoretical Energy Consumption Analysis for Sustainable Practices in Iron and Steel Industry. Metals 2024, 14, 563. [Google Scholar] [CrossRef]

- Yuan, Y.; Na, H.; Chen, C.; Qiu, Z.; Sun, J.; Zhang, L.; Du, T.; Yang, Y. Status, challenges, and prospects of energy efficiency improvement methods in steel production: A multi-perspective review. Energy 2024, 304, 132047. [Google Scholar] [CrossRef]

- Na, H.; Sun, J.; Qiu, Z.; Yuan, Y.; Du, T. Optimization of energy efficiency, energy consumption and CO2 emission in typical iron and steel manufacturing process. Energy 2022, 257, 124822. [Google Scholar] [CrossRef]

- Fan, C.; Wei, R.; Cheng, T.; Sun, R.; Zhang, H.; Long, H. The positive contributions of steel slag in reducing carbon dioxide emissions in the steel industry: Waste heat recovery, carbon sequestration, and resource utilization. Chem. Eng. J. 2024, 498, 155379. [Google Scholar] [CrossRef]

- Jouhara, H.; Nieto, N.; Egilegor, B.; Zuazua, J.; González, E.; Yebra, I.; Igesias, A.; Delpech, B.; Almahmoud, S.; Brough, D.; et al. Waste heat recovery solution based on a heat pipe heat exchanger for the aluminium die casting industry. Energy 2023, 266, 126459. [Google Scholar] [CrossRef]

- HAARBERG, G. Electrowinning of Aluminum—Challenges and Possibilities for Reducing the Carbon Footprint. Electrochemistry 2024, 92, 043002. [Google Scholar] [CrossRef]

- Senanu, S.; Hassel, M.; Solheim, A.; Skybakmoen, E. Sustainability of Different Aluminium Production Technologies. In Light Metals 2024; Wagstaff, S., Ed.; Springer: Cham, Switzerland, 2024; pp. 696–702. [Google Scholar]

- Su, S.; Pal, U.; Pal, U.; Guan, X.; Guan, X. Zero-Direct-Carbon-Emission Aluminum Production by Solid Oxide Membrane-Based Electrolysis Process. In Advances in Molten Slags, Fluxes, and Salts; John Wiley & Sons, Ltd.: Chichester, UK, 2016; pp. 781–790. ISBN 978-1-119-33319-7. [Google Scholar]

- Xu, Y.; Jiao, H.; Wang, M.; Jiao, S. Direct preparation of V-Al alloy by molten salt electrolysis of soluble NaVO3 on a liquid Al cathode. J. Alloys Compd. 2019, 779, 22–29. [Google Scholar] [CrossRef]

- Zuo, Z.; Lv, H.; Li, R.; Liu, F.; Zhao, H. A new approach to recover the valuable elements in black aluminum dross. Resour. Conserv. Recycl. 2021, 174, 105768. [Google Scholar] [CrossRef]

- Kong, W.; Han, Z.; Lu, S.; Ni, M. A simple but effective design to enhance the performance and durability of direct carbon solid oxide fuel cells. Appl. Energy 2021, 287, 116586. [Google Scholar] [CrossRef]

- Chen, Q.; Qiu, Q.; Yan, X.; Zhou, M.; Zhang, Y.; Liu, Z.; Cai, W.; Wang, W.; Liu, J. A compact and seal-less direct carbon solid oxide fuel cell stack stepping into practical application. Appl. Energy 2020, 278, 115657. [Google Scholar] [CrossRef]

- Tian, S.; Di, Y.; Dai, M.; Chen, W.; Zhang, Q. Comprehensive assessment of energy conservation and CO2 emission reduction in future aluminum supply chain. Appl. Energy 2022, 305, 117796. [Google Scholar] [CrossRef]

- Shokrollahi, M.; Teymouri, N.; Navarri, P. Identification and evaluation of most promising CO2 utilization technologies: Multi criteria decision analysis and techno-economic assessment. J. Clean. Prod. 2024, 434, 139620. [Google Scholar] [CrossRef]

- Cleeton, C.; Farmahini, A.H.; Sarkisov, L. Performance-based ranking of porous materials for PSA carbon capture under the uncertainty of experimental data. Chem. Eng. J. 2022, 437, 135395. [Google Scholar] [CrossRef]

- Yan, L.; Wang, L.; Wang, Z.; Cao, Y.; He, B. Comparison of three biomass-based carbon-negative power generation systems. J. Clean. Prod. 2021, 285, 125424. [Google Scholar] [CrossRef]

- del Río, J.I.; Almarza, M.; Martín, Á.; Bermejo, M.D. CO2-rich and CO2-lean streams as activators of reducing metals for the green hydrogen generation and the catalytic production of formate. Fuel 2024, 372, 132146. [Google Scholar] [CrossRef]

- Han, Y.; Lin, R.; Wang, X.-Y. Preparation of Nano Calcite by the Carbon Capture Technology to Improve the Performance of Ultrahigh-Performance Concrete Containing Calcined Clay. ACS Sustain. Chem. Eng. 2023, 11, 4531–4542. [Google Scholar] [CrossRef]

- Evans, H.A.; Mullangi, D.; Deng, Z.; Wang, Y.; Peh, S.B.; Wei, F.; Wang, J.; Brown, C.M.; Zhao, D.; Canepa, P.; et al. Aluminum formate, Al(HCOO)3: An earth-abundant, scalable, and highly selective material for CO2 capture. Sci. Adv. 2022, 8, eade1473. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Zhu, B.; Wang, L.; Yu, J. Triethanolamine-modified layered double oxide for efficient CO2 capture with low regeneration energy. J. Colloid. Interface Sci. 2024, 659, 486–494. [Google Scholar] [CrossRef] [PubMed]

- Jahandar Lashaki, M.; Ziaei-Azad, H.; Sayari, A. Unprecedented improvement of the hydrothermal stability of amine-grafted MCM-41 silica for CO2 capture via aluminum incorporation. Chem. Eng. J. 2022, 450, 138393. [Google Scholar] [CrossRef]

- Geissler, C.H.; Maravelias, C.T. Analysis of alternative bioenergy with carbon capture strategies: Present and future. Energy Environ. Sci. 2022, 15, 2679–2689. [Google Scholar] [CrossRef]

- Singh, S.P.; Ohara, B.; Ku, A.Y. Prospects for cost-competitive integrated gasification fuel cell systems. Appl. Energy 2021, 290, 116753. [Google Scholar] [CrossRef]

- Lakzian, E.; Yazdani, S.; Salmani, F.; Mahian, O.; Kim, H.D.; Ghalambaz, M.; Ding, H.; Yang, Y.; Li, B.; Wen, C. Supersonic separation towards sustainable gas removal and carbon capture. Prog. Energy Combust. Sci. 2024, 103, 101158. [Google Scholar] [CrossRef]

- Tian, Z.; Zhou, J.; Zhang, Y.; Gao, W. Targeting zero energy increment for an onboard CO2 capture system: 4E analyses and multi-objective optimization. Energy Convers. Manag. 2024, 301, 117890. [Google Scholar] [CrossRef]

- Qiao, Y.; Chen, Z.; Wu, X.; Li, Z. Investigation on co-combustion of semi-coke and bituminous coal in oxygen-enriched atmosphere: Combustion, thermal conversion, and kinetic analyses. Energy 2023, 269, 126816. [Google Scholar] [CrossRef]

- Fordoei, E.E.; Mazaheri, K.; Mohammadpour, A. Numerical study on the heat transfer characteristics, flame structure, and pollutants emission in the MILD methane-air, oxygen-enriched and oxy-methane combustion. Energy 2021, 218, 119524. [Google Scholar] [CrossRef]

- Nhuchhen, D.R. Integrated gasification carbon capture plant using molten carbonate fuel cell: An application to a cement industry. Energy 2023, 282, 128614. [Google Scholar] [CrossRef]

- Jahromi, F.B.; Elhambakhsh, A.; Keshavarz, P.; Panahi, F. Insight into the application of amino acid-functionalized MIL-101(Cr) micro fluids for high-efficiency CO2 absorption: Effect of amine number and surface area. Fuel 2023, 334, 126603. [Google Scholar] [CrossRef]

- Yu, S.; Zhao, X.; Zhang, J.; Liu, S.; Yuan, Z.; Liu, X.; Liu, B.; Yi, X. A novel combining strategy of cellulose aerogel and hierarchically porous metal organic frameworks (HP-MOFs) to improve the CO2 absorption performance. Cellulose 2022, 29, 6783–6796. [Google Scholar] [CrossRef]

- Shen, M.; Kong, F.; Guo, W.; Zuo, Z.; Guo, C.; Tong, L.; Yin, S.; Wang, L.; Kawi, S.; Chu, P.K.; et al. Enhanced Direct Air Carbon Capture on NaX Zeolite by Electric-Field Enhanced Physical Adsorption and In Situ CO2 Synergistic Effects of Cold Plasma. Adv. Funct. Mater. 2024, 2408922. [Google Scholar] [CrossRef]

- Gao, Y.; He, X.; Mao, K.; Russell, C.K.; Toan, S.; Wang, A.; Chien, T.; Cheng, F.; Russell, A.G.; Zeng, X.C.; et al. Catalytic CO2 Capture via Ultrasonically Activating Dually Functionalized Carbon Nanotubes. ACS Nano 2023, 17, 8345–8354. [Google Scholar] [CrossRef]

- Chen, L.; E, J.; Ma, Y.; Deng, Y.; Han, D. Investigation on the influence of modified zeolite molecular sieve on the hydrocarbon adsorbent and adsorption performance during cold-start conditions based on Monte Carlo simulation and grey relational analysis. Fuel 2022, 319, 123846. [Google Scholar] [CrossRef]

- Cui, J.; Zhang, Z.; Yang, L.; Hu, J.; Jin, A.; Yang, Z.; Zhao, Y.; Meng, B.; Zhou, Y.; Wang, J.; et al. A molecular sieve with ultrafast adsorption kinetics for propylene separation. Science 2024, 383, 179–183. [Google Scholar] [CrossRef]

- Vannak, H.; Osaka, Y.; Tsujiguchi, T.; Kodama, A. The efficacy of carbon molecular sieve and solid amine for CO2 separation from a simulated wet flue gas by an internally heated/cooled temperature swing adsorption process. Appl. Therm. Eng. 2024, 239, 122145. [Google Scholar] [CrossRef]

- Mano, P.; Namuangruk, S. Theory-based design principles for unprecedentedly high two-level CO2 utilization of CO2-derived metal-organic frameworks. Chem. Eng. J. 2024, 486, 150248. [Google Scholar] [CrossRef]

- Zeng, P.; Zhao, C.; Liang, C.; Li, P.; Zhang, H.; Wang, R.; Guo, Y.; Xia, H.; Sun, J. Comparative study on low-temperature CO2 adsorption performance of metal oxide-supported, graphite-casted K2CO3 pellets. Sep. Purif. Technol. 2023, 306, 122608. [Google Scholar] [CrossRef]

- Guo, Y.; Zhao, C.; Li, C.; Wu, Y. CO2 sorption and reaction kinetic performance of K2CO3/AC in low temperature and CO2 concentration. Chem. Eng. J. 2015, 260, 596–604. [Google Scholar] [CrossRef]

- Xu, H.; Miao, J.; Wang, J.; Deng, J.; Zhang, J.; Kou, Q.; Xiong, X.; Holmes, D.E. Integrated CO2 capture and conversion via H2-driven CO2 biomethanation: Cyclic performance and microbial community response. Bioresour. Technol. 2024, 393, 130055. [Google Scholar] [CrossRef] [PubMed]

- Torres, D.; Pérez-Rodríguez, S.; Cesari, L.; Castel, C.; Favre, E.; Fierro, V.; Celzard, A. Review on the preparation of carbon membranes derived from phenolic resins for gas separation: From petrochemical precursors to bioresources. Carbon 2021, 183, 12–33. [Google Scholar] [CrossRef]

- Fan, Y.; Yu, W.; Wu, A.; Shu, W.; Zhang, Y. Recent progress on CO2 separation membranes. RSC Adv. 2024, 14, 20714–20734. [Google Scholar] [CrossRef]

- Álvarez, A.; Borges, M.; Corral-Pérez, J.J.; Olcina, J.G.; Hu, L.; Cornu, D.; Huang, R.; Stoian, D.; Urakawa, A. CO2 Activation over Catalytic Surfaces. ChemPhysChem 2017, 18, 3135–3141. [Google Scholar] [CrossRef]

- Kim, J.; Seong, A.; Yang, Y.; Joo, S.; Kim, C.; Jeon, D.H.; Dai, L.; Kim, G. Indirect surpassing CO2 utilization in membrane-free CO2 battery. Nano Energy 2021, 82, 105741. [Google Scholar] [CrossRef]

- Gustafsson, M.; Cordova, S.S.; Svensson, N.; Eklund, M. Climate performance of liquefied biomethane with carbon dioxide utilization or storage. Renew. Sustain. Energy Rev. 2024, 192, 114239. [Google Scholar] [CrossRef]

- Jeffry, L.; Ong, M.Y.; Nomanbhay, S.; Mofijur, M.; Mubashir, M.; Show, P.L. Greenhouse gases utilization: A review. Fuel 2021, 301, 121017. [Google Scholar] [CrossRef]

- Haider, S.N.-U.-Z.; Qureshi, W.A.; Ali, R.N.; Shaosheng, R.; Naveed, A.; Ali, A.; Yaseen, M.; Liu, Q.; Yang, J. Contemporary advances in photocatalytic CO2 reduction using single-atom catalysts supported on carbon-based materials. Adv. Colloid. Interface Sci. 2024, 323, 103068. [Google Scholar] [CrossRef]

- Ding, L.; Bai, F.; Borjigin, B.; Li, Y.; Li, H.; Wang, X. Embedding Cs2AgBiBr6 QDs into Ce-UiO-66-H to in situ construct a novel bifunctional material for capturing and photocatalytic reduction of CO2. Chem. Eng. J. 2022, 446, 137102. [Google Scholar] [CrossRef]

- Ramadhan Ikreedeegh, R.; Arif Hossen, M.D.; Sherryna, A.; Tahir, M. Recent advances on synthesis and photocatalytic applications of MOF-derived carbon materials: A review. Coord. Chem. Rev. 2024, 510, 215834. [Google Scholar] [CrossRef]

- Oh, V.B.-Y.; Ng, S.-F.; Ong, W.-J. Is photocatalytic hydrogen production sustainable?—Assessing the potential environmental enhancement of photocatalytic technology against steam methane reforming and electrocatalysis. J. Clean. Prod. 2022, 379, 134673. [Google Scholar] [CrossRef]

- Luan, L.; Ji, X.; Guo, B.; Cai, J.; Dong, W.; Huang, Y.; Zhang, S. Bioelectrocatalysis for CO2 reduction: Recent advances and challenges to develop a sustainable system for CO2 utilization. Biotechnol. Adv. 2023, 63, 108098. [Google Scholar] [CrossRef] [PubMed]

- Francis Kurisingal, J.; Kim, H.; Hyeak Choe, J.; Seop Hong, C. Covalent organic framework-based catalysts for efficient CO2 utilization reactions. Coord. Chem. Rev. 2022, 473, 214835. [Google Scholar] [CrossRef]

- Ruan, J.; Chen, L.; Qi, Z. Deep eutectic solvents as a versatile platform toward CO2 capture and utilization. Green Chem. 2023, 25, 8328–8348. [Google Scholar] [CrossRef]

- Li, S.; Niu, L.; Yue, Q.; Zhang, T. Trajectory, driving forces, and mitigation potential of energy-related greenhouse gas (GHG) emissions in China’s primary aluminum industry. Energy 2022, 239, 122114. [Google Scholar] [CrossRef]

- Wang, J.; Liu, W.; Chen, L.; Li, X.; Wen, Z. Analysis of China’s non-ferrous metals industry’s path to peak carbon: A whole life cycle industry chain based on copper. Sci. Total Environ. 2023, 892, 164454. [Google Scholar] [CrossRef]

- Masoomi, B.; Sahebi, I.G.; Ghobakhloo, M.; Mosayebi, A. Do industry 5.0 advantages address the sustainable development challenges of the renewable energy supply chain? Sustain. Prod. Consum. 2023, 43, 94–112. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, L.; Wu, F.; Xia, R. Role of sustainable management policy and carbon neutral processes in improving sustainable performance: Study of China’s aluminium sector. Resour. Policy 2024, 88, 104347. [Google Scholar] [CrossRef]

- Chu, W.-J.; Fan, L.-W.; Zhou, P. Extreme spillovers across carbon and energy markets: A multiscale higher-order moment analysis. Energy Econ. 2024, 138, 107833. [Google Scholar] [CrossRef]

- Qiu, L.; Chu, L.; Zhou, R.; Xu, H.; Yuan, S. How do carbon, stock, and renewable energy markets interact: Evidence from Europe. J. Clean. Prod. 2023, 407, 137106. [Google Scholar] [CrossRef]

- Otto, S.; Oberthür, S. International cooperation for the decarbonization of energy-intensive industries: Unlocking the full potential. Climate Policy 2024, 1–17. [Google Scholar] [CrossRef]

- Jia, Z.; Wu, R.; Liu, Y.; Wen, S.; Lin, B. Can carbon tariffs based on domestic embedded carbon emissions reduce more carbon leakages? Ecol. Econ. 2024, 220, 108163. [Google Scholar] [CrossRef]

- Fang, Y.; Yu, Y.; Shi, Y.; Liu, J. The effect of carbon tariffs on global emission control: A global supply chain model. Transp. Res. Part. E Logist. Transp. Rev. 2020, 133, 101818. [Google Scholar] [CrossRef]

- Haites, E.; Bertoldi, P.; König, M.; Bataille, C.; Creutzig, F.; Dasgupta, D.; de la rue du Can, S.; Khennas, S.; Kim, Y.-G.; Nilsson, L.J.; et al. Contribution of carbon pricing to meeting a mid-century net zero target. Clim. Policy 2024, 24, 1–12. [Google Scholar] [CrossRef]

- Hao, X.; Sun, W.; Zhang, X. How does a scarcer allowance remake the carbon market? An evolutionary game analysis from the perspective of stakeholders. Energy 2023, 280, 128150. [Google Scholar] [CrossRef]

- Qi, S.; Zhou, C.; Li, K.; Tang, S. The impact of a carbon trading pilot policy on the low-carbon international competitiveness of industry in China: An empirical analysis based on a DDD model. J. Clean. Prod. 2021, 281, 125361. [Google Scholar] [CrossRef]

| Countries | Current Progress in Carbon Border Mechanism | Characteristics and Content | Implementation Time |

|---|---|---|---|

| European Union | Carbon Border Adjustment Mechanism (CBAM) | The CBAM applies to products exported from other countries to the European Union and requires importers of goods to purchase certificates at the price of the European carbon market; includes six industries: electricity, steel, cement, fertilizers, aluminum, and hydrogen. | Started its transition in October 2023; will be officially implemented in 2026, and fully operational by 2034. |

| The United States | Clean Competition Act (CCA) | The CCA imposes a carbon emission fee on imported goods and allocates the revenue to developing countries, covering multiple industrial sectors such as cement, steel, aluminum, and glass. Since the United States lacks a unified carbon pricing system, the CCA stipulates that relevant companies only need to pay a carbon fee. The subjects of the levy include not only importers but also domestic producers in the United States. | Since 2024, CCA will impose a carbon tax of USD 55 per tonne on emissions that exceed the baseline level. Subsequently, the price of the carbon tax will increase by 5% on top of the previous year’s price, adjusted for inflation. |

| Canada | Border Carbon Adjustments (Not yet implemented) | The Canadian government is seeking domestic and international dialog and cooperation to integrate the BCA mechanism into the trade system, aiming to achieve climate goals while maintaining competitiveness. | Since 2021, there has been an exploration to add BCA to Canada’s climate policy toolbox. |

| United Kingdom | Carbon Border Adjustment Mechanism (Not yet implemented) | The initially covered product categories include aluminum, cement, ceramics, fertilizers, glass, hydrogen, and steel. | The UK’s carbon border adjustment mechanism will be implemented from 2027. |

| Aluminum Production Process | Energy Consumption (kgce/t-Al) | CO2e Emission (t-CO2e/t-Al) |

|---|---|---|

| Primary aluminum | 3086.48 | 14.98 |

| Recycled aluminum | 146.00 | 0.32 |

| Type | Material | Unit | Production Process of Primary Aluminum | Primary Aluminum | ||||

|---|---|---|---|---|---|---|---|---|

| Mining | Refining | Anode Production | Electrolysis | Casting | ||||

| Energy Import | Fuel Oil | kg/t | 7.73 | 21 | 69 | 0 | 0 | 114.11 |

| Electricity | kWh/t | 16.5 | 289 | 211 | 13,543 | 411 | 15,817.04 | |

| Raw Coal | kg/t | 12.2 | 276 | 0 | 0 | 0 | 625.78 | |

| Natural Gas | M3/t | 0.247 | 85 | 79.3 | 0 | 1.05 | 217.78 | |

| Coal Gas | m3/t | 0 | 0 | 1.3 | 0 | 0 | 0.66 | |

| Coke | kg/t | 0 | 32 | 0 | 0 | 0 | 66.01 | |

| Dissolvent | kg/t | 0 | 0 | 0 | 0 | 4 | 4 | |

| Aluminum Pad | t/t | 0 | 0 | 0 | 0 | 1.08 | 1.08 | |

| Pollution Export | CO2 | kg/t | 59.54 | 1089.06 | 862.34 | 10,384.77 | 284.13 | 14,459.42 |

| CO | kg/t | 0.145 | 1.52 | 400 | 659 | 0.71 | 919.28 | |

| SO2 | kg/t | 0.16 | 1.43 | 3.03 | 16.8 | 0.93 | 24.3 | |

| NOX | kg/t | 0.008 | 0.17 | 0.855 | 0.0015 | 0.00066 | 0.82 | |

| CH4 | kg/t | 0.0002 | 0.005 | 0.005 | 0 | 0.00004 | 0.01 | |

| PM10 | kg/t | 0.04 | 0.08 | 0.16 | 5.48 | 0.27 | 6.62 | |

| PM2.5 | kg/t | 0.18 | 5.87 | 0.1 | 3.15 | 0.16 | 16.55 | |

| HF | kg/t | 0 | 0.01 | 0.05 | 15 | 0 | 16.25 | |

| C2F6 | kg/t | 0 | 0 | 0 | 0.0034 | 0 | 0 | |

| CF4 | kg/t | 0 | 0 | 0 | 0.034 | 0 | 0.04 | |

| PAHs | kg/t | 0 | 0 | 0.027 | 0 | 0 | 0.01 | |

| Total | CO2e | kg/t | 120.12 | 1137.36 | 1113.03 | 10,385.2 | 296.62 | 14,979.55 |

| Technologies | Energy Saving (GJ/t-Al) | CO2 Reduction (kg/t-Al) | Annualized Capital Cost (CNY/t) | Ref. |

|---|---|---|---|---|

| Tubular falling film evaporator technology | 0.92 | 87.33 | 2130 | [89] |

| High-efficient and energy-saving kiln technology for use in alumina baking process | 0.66 | 62.66 | 2788 | [89] |

| Novel cathode structure of aluminum rebate cell | 3.69 | 90.00 | 583.99 | [108] |

| Aluminum abatement cell structure optimization techniques with low temperatures | 0.58 | 91.25 | 60.00 | [108] |

| Comprehensive technology of current intensifying and high-efficiency energy-saving | 3.60 | 570.30 | 20.00 | [108] |

| New energy saving technology of stable current insulation aluminum electrolytic cell | 1.80 | 285.15 | 45.00 | [89] |

| Pipe heating and pot holding technology | 0.60 | 56.56 | 11,216 | [89] |

| Gas-operated anode for prebaked aluminum abatement cell with low voltage | 0.45 | 71.29 | 35.00 | [89] |

| Starting up and closing down cell appliances of aluminum reduction cell without a cut-off | 0.27 | 42.77 | 30.00 | [108] |

| New cathode casting technology | 1.80 | 285.15 | 45.00 | [89] |

| Carbon-free slag anode technology | 0.36 | 57.03 | 25 | [89] |

| Aluminum electrolysis waste heat recovery technology | 3.60 | 570.30 | 367.00 | [108] |

| New type of coke particle roasting starting technology for aluminum reduction cells | 1.74 | 275.45 | 150.00 | [89] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, T.; Zhang, L.; Yuan, Y.; Yang, Y.; Na, H. Review of the Chinese Aluminum Industry’s Low-Carbon Development Driven by Carbon Tariffs: Challenges and Strategic Responses. Processes 2024, 12, 2707. https://doi.org/10.3390/pr12122707

Hou T, Zhang L, Yuan Y, Yang Y, Na H. Review of the Chinese Aluminum Industry’s Low-Carbon Development Driven by Carbon Tariffs: Challenges and Strategic Responses. Processes. 2024; 12(12):2707. https://doi.org/10.3390/pr12122707

Chicago/Turabian StyleHou, Tianshu, Lei Zhang, Yuxing Yuan, Yuhang Yang, and Hongming Na. 2024. "Review of the Chinese Aluminum Industry’s Low-Carbon Development Driven by Carbon Tariffs: Challenges and Strategic Responses" Processes 12, no. 12: 2707. https://doi.org/10.3390/pr12122707

APA StyleHou, T., Zhang, L., Yuan, Y., Yang, Y., & Na, H. (2024). Review of the Chinese Aluminum Industry’s Low-Carbon Development Driven by Carbon Tariffs: Challenges and Strategic Responses. Processes, 12(12), 2707. https://doi.org/10.3390/pr12122707