The Characterization and Application of Flow Units in Tight Reservoirs Considering Stimulation Treatments

Abstract

1. Introduction

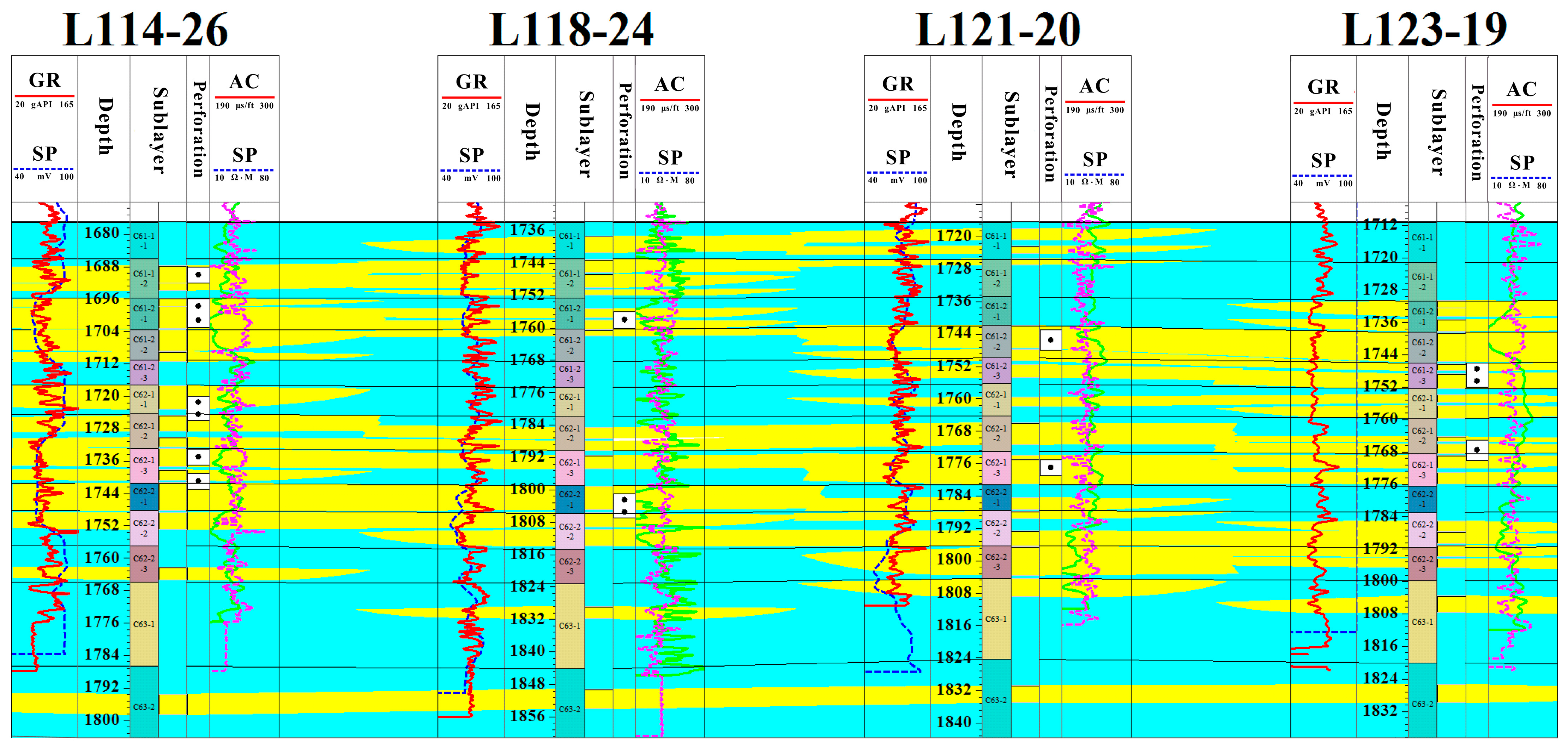

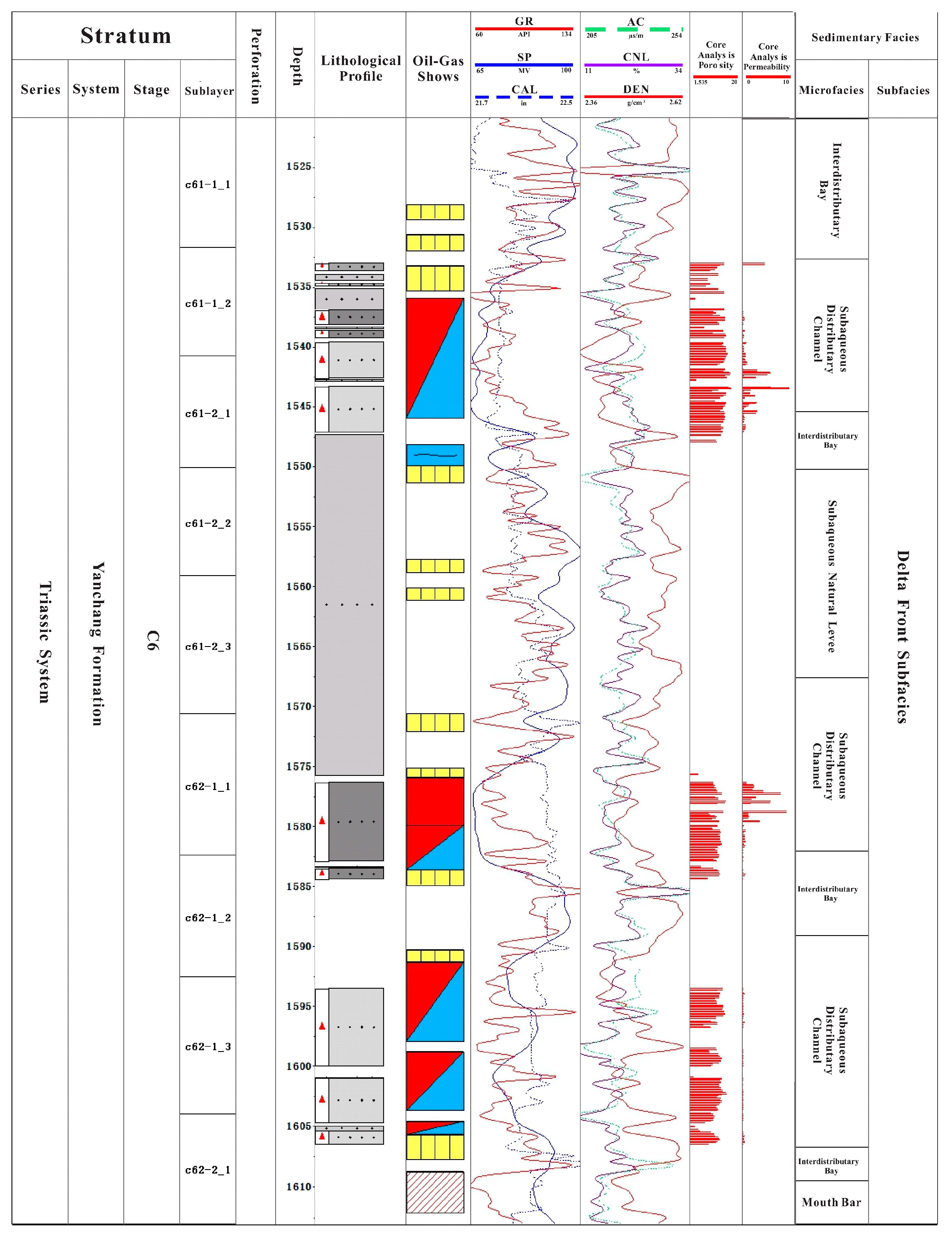

2. Regional Geological Overview

3. Selection of Flow Unit Characterization Parameters

3.1. Static Parameter Selection Based on GRA

- Set cumulative production as the reference series x0 (k), and select permeability, sand body thickness, mud content, porosity, median grain size, permeability variation coefficient, permeability gradient coefficient, permeability contrast, permeability coefficient, and distribution density of barrier interlayers as the comparison series xi (k).

- Normalize the data of both the reference and comparison series using Equation (1):

- Use Equation (2) to calculate the correlation coefficient εi (k) between the reference series and comparison series:where η is the distinguishing coefficient, typically between 0 and 1, with a common value of 0.5.

- Use Equation (3) to obtain the overall grey correlation degree:

3.2. Dynamic Parameter Selection Based on GRA

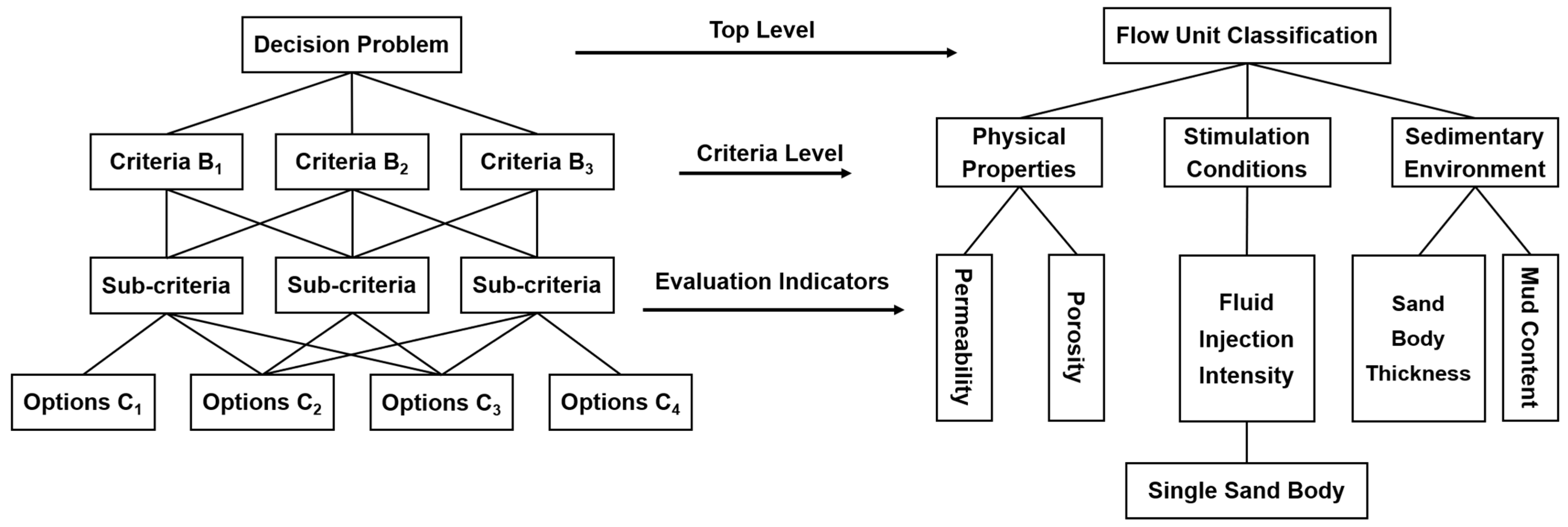

4. Method for Characterizing Flow Units in Tight Reservoirs

4.1. Subjective Weight Calculation Based on the AHM Method

- Top level: contains only one element, representing the overall goal of the decision analysis, also known as the general objective level.

- Middle level: comprises several sub-objectives, representing the main goal and various sub-goals, often called the goal level.

- Bottom level: presents feasible methods to achieve each administrative decision objective, also known as the option level.

4.1.1. Constructing the Judgment Matrix

- AHP Judgment Matrix of the Criteria Level

- AHP Judgment Matrix for Physical Properties

- AHP Judgment Matrix for Stimulation Conditions

- AHP Judgment Matrix for Sedimentary Environment

4.1.2. Constructing the Attribute Judgment Matrix

- AHM Attribute Judgment Matrix of the Criteria Level

- AHM Attribute Judgment Matrix for Physical Properties

- AHM Attribute Judgment Matrix for Stimulation Conditions

- AHM Attribute Judgment Matrix for Sedimentary Environment

4.1.3. Attribute Weight Calculation

4.1.4. Calculation of Combined Weights

4.2. Objective Weight Calculation Based on Entropy Weight Method

4.2.1. Constructing the Initial Indicator Matrix

4.2.2. Matrix Normalization

4.2.3. Calculating Information Entropy

4.2.4. Calculating Indicator Divergence

4.2.5. Calculating Indicator Weights

4.3. Comprehensive Weight Calculation Based on the Entropy Weight–AHM Method

4.4. Reliability Demonstration

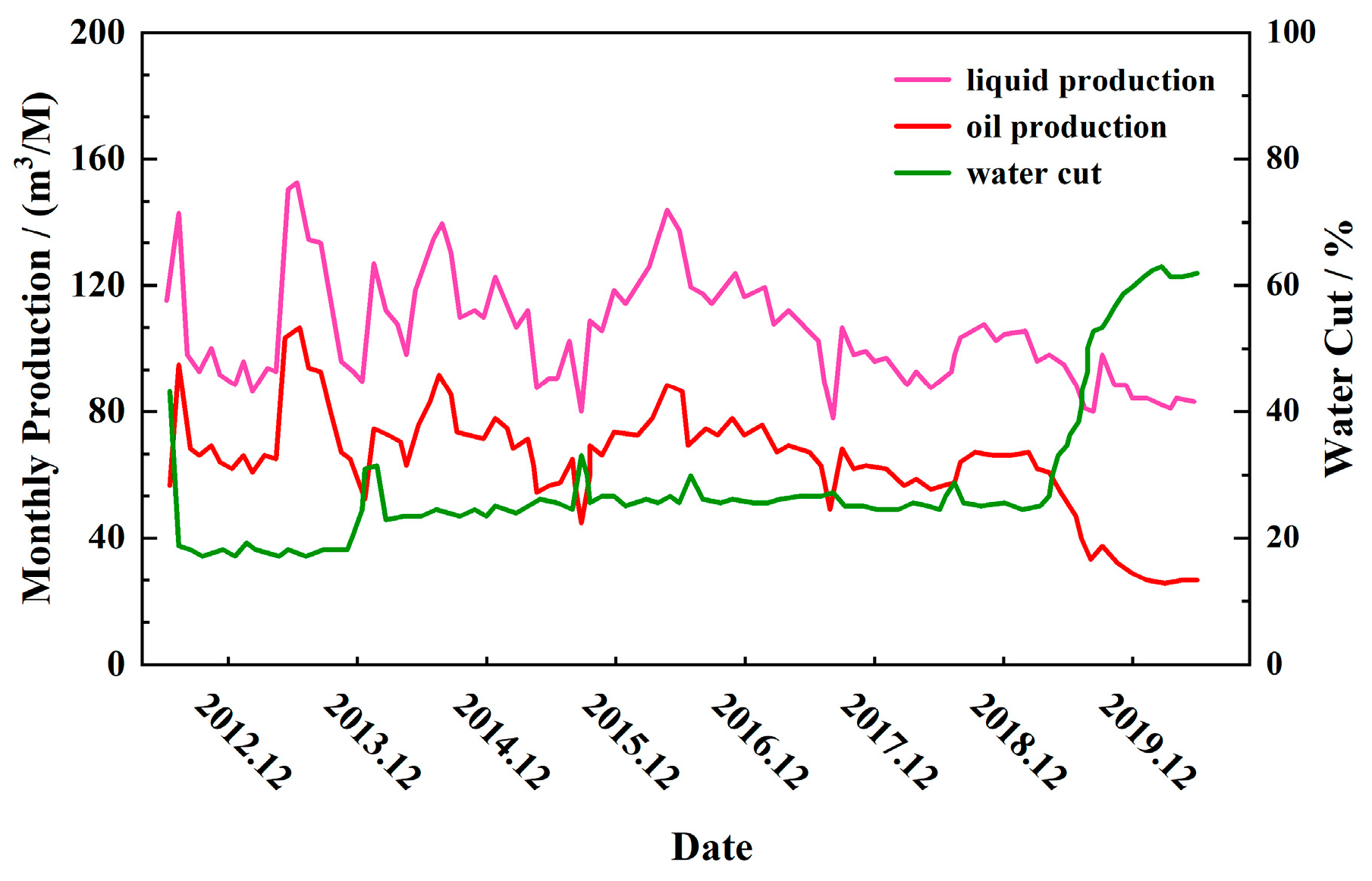

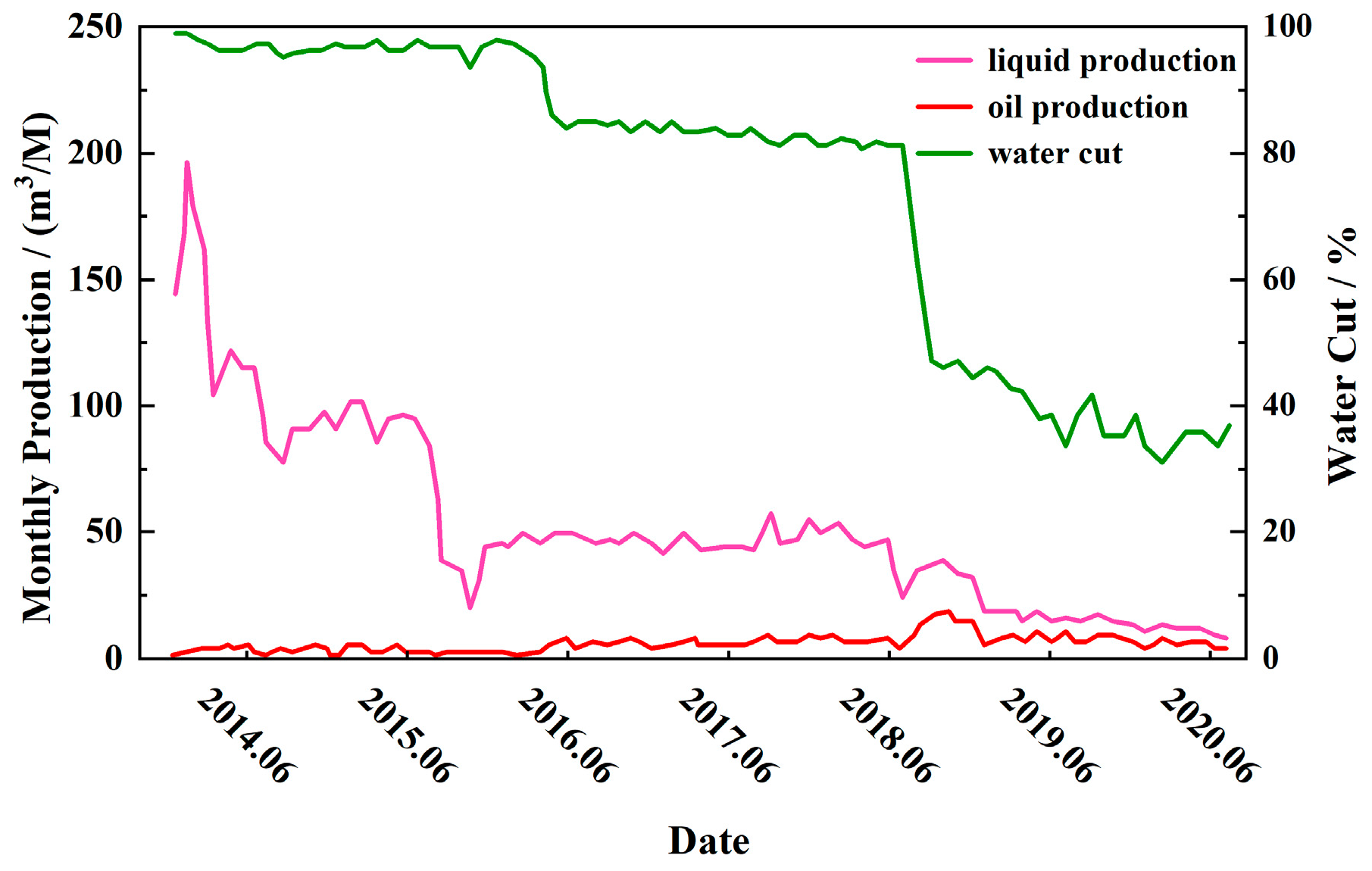

4.4.1. Testing with Production Dynamics Parameters

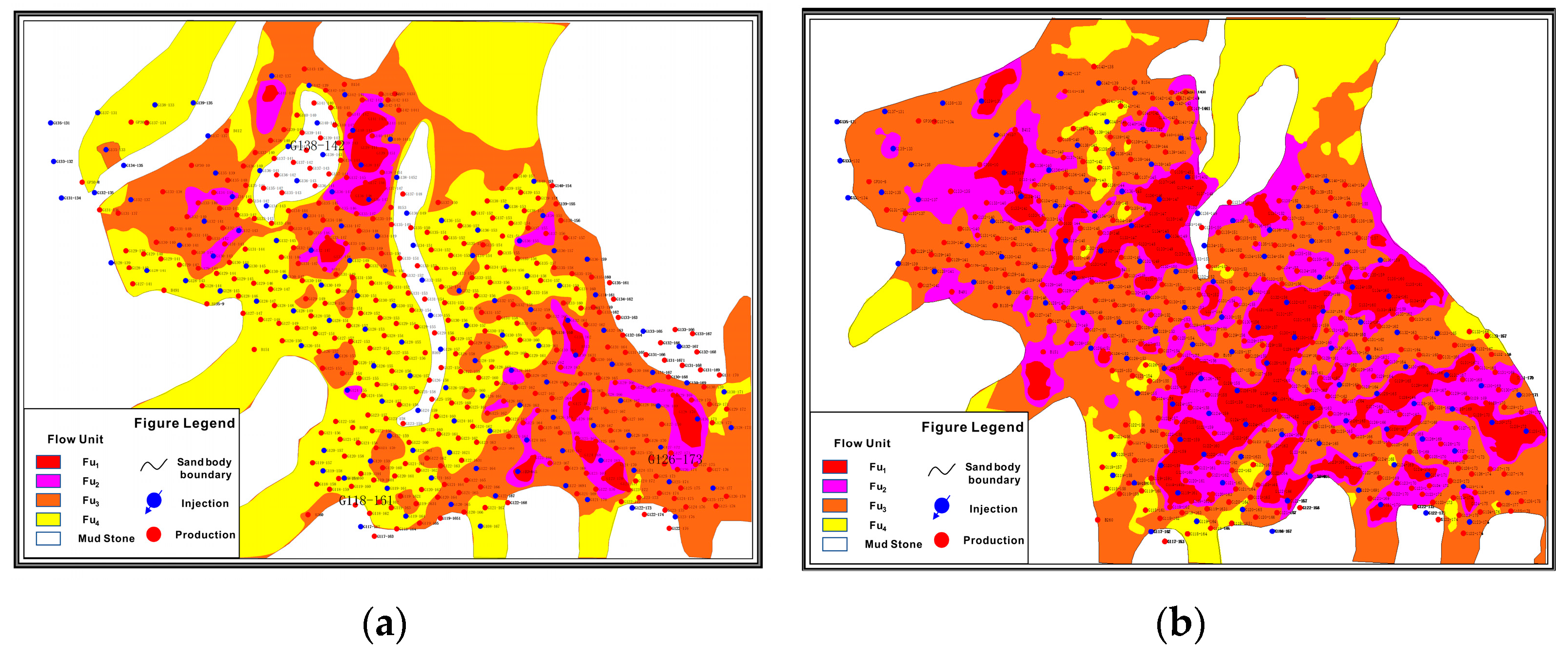

4.4.2. Testing the Distribution of Flow Units

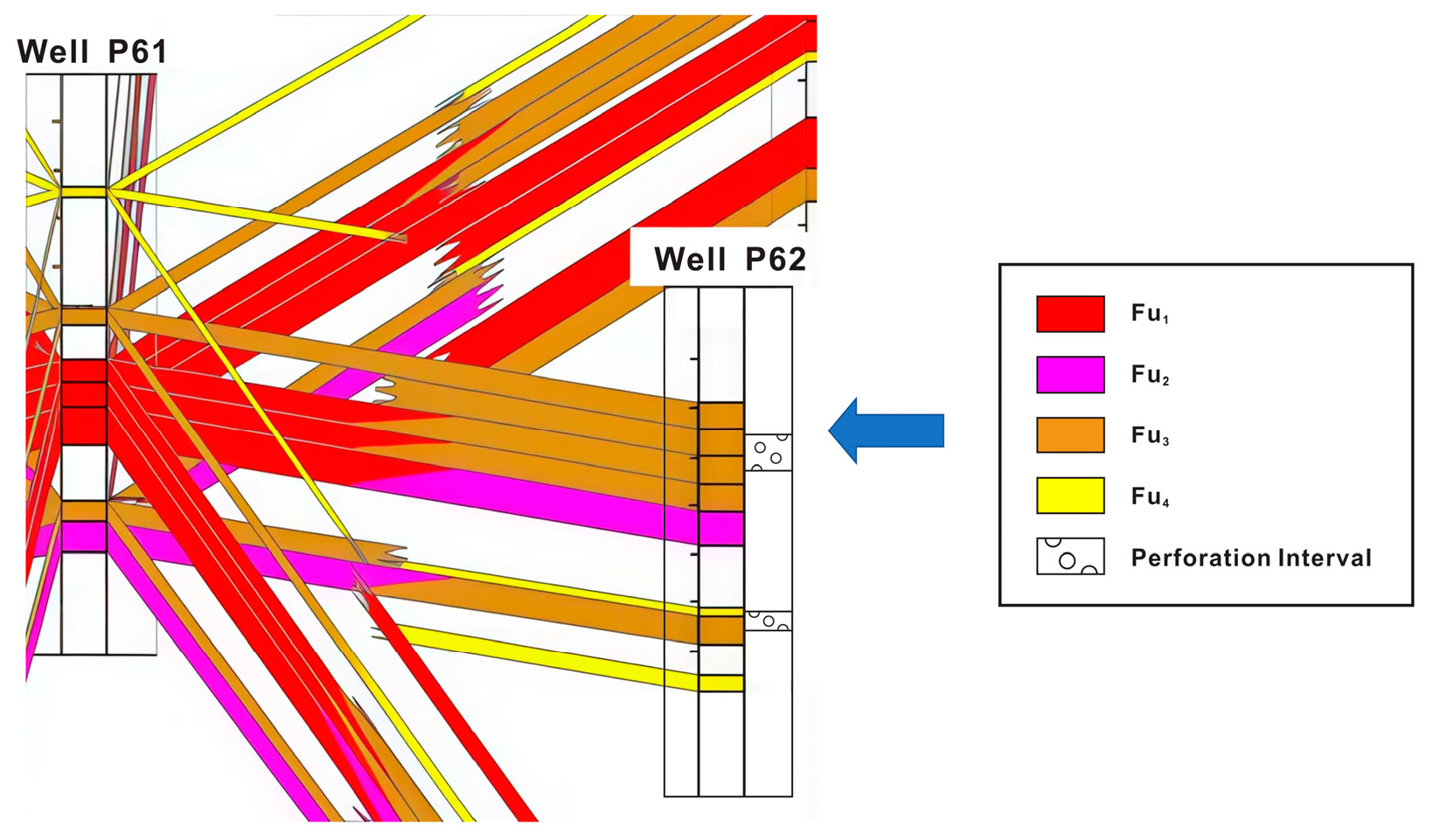

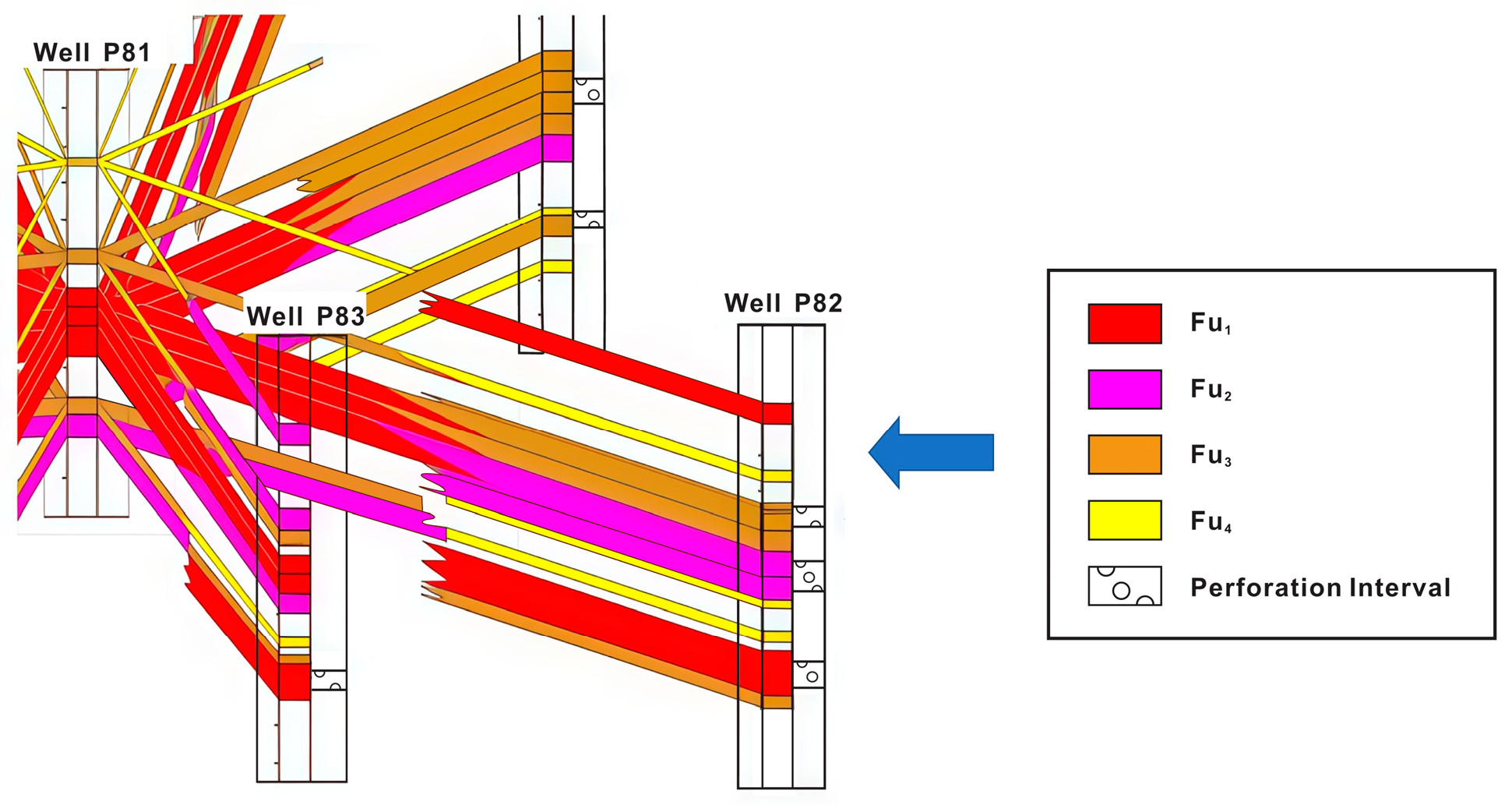

4.4.3. Testing Flow Unit Comparison

5. Application

5.1. Analysis of Stimulation Measure Compatibility

5.1.1. Poor Compatibility

5.1.2. Moderate Compatibility

5.1.3. Good Compatibility

5.2. Differential Adjustment Strategies for the Target Area

- The method relies on static geological parameters and dynamic artificial stimulation intensity parameters. However, in practical applications, difficulties in data acquisition and high data noise may arise, affecting the accuracy and reliability of the model.

- During long-term reservoir production, fracture systems may become blocked or closed, affecting the distribution of flow units. However, the model has limitations in dynamically reflecting fracture changes.

- The model uses the entropy-weighting method to assign weights to static and dynamic parameters, simplifying the complex interactions between them, which may introduce errors.

6. Conclusions

- (1)

- By integrating the seepage mechanism of tight oil reservoirs and field practices, the Grey Relational Analysis method was used to select the key static parameters (sand body thickness, permeability, mud content, and porosity) and stimulation parameter (fluid injection intensity) that affect the properties of flow units in tight reservoirs.

- (2)

- This study establishes the entropy weight–AHM method, which incorporates both subjective and objective weights to achieve comprehensive flow unit characterization in tight reservoirs. This method calculated the comprehensive weights and scores for flow unit indicators in Block W, enabling the interactive characterization of flow units in tight reservoirs. Flow unit classification standards were provided based on normal distribution, and the method’s reliability was verified through production dynamics and other factors.

- (3)

- Based on the flow unit characterization results for Block W, key flow unit maps were created. Combined with existing stimulation treatments and production dynamics data, these maps were used to evaluate the compatibility of measures with production wells. A compatibility evaluation standard was established, guiding the next steps in development adjustments for Block W.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gunter, G.W.; Finneran, J.M.; Hartmann, D.J.; Miller, J.D. Early determination of reservoir flow units using an integrated petrophysical method. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 5–8 October 1997. [Google Scholar]

- Aguilera, R. Flow units: From conventional to tight-gas to shale-gas to tight-oil to shale-oil reservoirs. SPE Reserv. Eval. Eng. 2014, 17, 190–208. [Google Scholar] [CrossRef]

- Rodriguez, A. Facies modeling and the flow unit concept as a sedimentological tool in reservoir description: A case study. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 2–5 October 1988. [Google Scholar]

- Nooruddin, H.A.; Hossain, M.E. Modified kozeny–carmen correlation for enhanced hydraulic flow unit characterization. J. Pet. Sci. Eng. 2011, 80, 107–115. [Google Scholar] [CrossRef]

- Kassab, M.A.; Teama, M.A. Hydraulic flow unit and facies analysis integrated study for reservoir characterisation: A case study of Middle Jurassic rocks at Khashm EI-Galala, Gulf of Suez, Egypt. Arab. J. Geosci. 2018, 11, 294. [Google Scholar] [CrossRef]

- Wang, H.; Kou, Z.; Bagdonas, D.A.; Phillips, E.H.; Alvarado, V.; Johnson, A.C.; Jiao, Z.; McLaughlin, J.F.; Quillinan, S.A. Multiscale petrophysical characterization and flow unit classification of the minnelusa eolian sandstones. J. Hydrol. 2022, 607, 127466. [Google Scholar] [CrossRef]

- Amaefule, J.O.; Altunbay, M.; Keelan, D.K. Enhanced Reservoir Description: Using Core and Log Data to Identify Hydraulic (Flow) Units and Predict Permeability in Uncored Intervals/Wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 3–6 October 1993. [Google Scholar]

- Silseth, J.K.; MacDonald, A.C.; Alvestad, J.; Buller, A.T.; Torp, S.B. Impact of Flow-Unit Reservoir Description on Simulated Waterflood Performance. SPE Reserv. Eng. 1993, 8, 27–33. [Google Scholar] [CrossRef]

- Ti, G.; Ogbe, D.O.; Munly, W.; Hatzignatiou, D.G. Use of Flow Units as a Tool for Reservoir Description: A Case Study. SPE Form. Eval. 1995, 10, 122–128. [Google Scholar] [CrossRef]

- Li, H.; Peng, S. Reservoir dynamic flow unit models of Jing11 block in Bieguzhuang oilfield. Pet. Geol. Recovery Effic. 2007, 149, 67–70. [Google Scholar]

- Song, G.; Sun, W.; Gao, H.; Mo, J. The classification of flow units and its influence on deliverability performance: A case of the Chang 1 formation of Yuan 54 Areas in Ordos Basin. J. Northwest Univ. (Nat. Sci. Ed.) 2010, 40, 299–303. [Google Scholar]

- Xu, S.; Lu, Y.; Wang, Y. Study on Flow Units of Turbidite Fan Low Permeability Reservoir Based on Support Vector Machine. J. Jilin Univ. (Earth Sci. Ed.) 2018, 48, 1330–1341. [Google Scholar]

- Yu, P. An integrated method of data mining and flow unit identification for typical low permeability reservoir prediction. World J. Eng. Technol. 2018, 7, 122–128. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, K.; Xu, S.; Wang, Y.; Zhang, Q. Identifying flow units by FA-assisted SSOM—An example from the eocene basin-floor-fan turbidite reservoirs in the daluhu oilfield, dongying depression, bohai bay basin, china. J. Pet. Sci. Eng. 2020, 186, 106695. [Google Scholar] [CrossRef]

- Yuan, B.; Zhang, H.; Ye, Q.; Zhang, L.; Chen, Z.; Yao, C.; Dong, D.; Lai, J. Flow-unit Classification Based on Compound Sand-Body Architecture of Delta and Distribution Pattern of Remaining Oil. Acta Sedimentol. Sin. 2021, 39, 1253–1263. [Google Scholar]

- Liu, R.; Sun, Y.; Yan, B. Reservoir Flow Units for Dynamic and Static Combinations: Case study of Neogene Guantao Formation in block M, Gudao oilfield. Acta Sedimentol. Sin. 2023, 41, 1170–1180. [Google Scholar]

- Ding, Y.; Guo, X.; Chang, S. Research on identification of flow units based on FZI. EDP Sci. 2021, 248, 01005. [Google Scholar]

- Farzi, R.; Bolandi, V.; Yarmohammadi, S.; Mosalmannejad, H.; Ezati, M. Intelligent and Statistical Analysis to Estimating the Hydraulic Flow Units: A Case Study from the Kupal Oilfield, SW Iran. J. Appl. Geophys. 2022, 206, 104814. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, D.; Zhou, S.; Wang, H.; Deng, Y.; Liu, E.; Song, G. Sedimentological and Diagenetic Effects on Petrophysical Characteristics and Hydraulic Flow Units of Zhujiang Sandstones in the Pearl River Mouth Basin, South China Sea. Energy 2023, 282, 128942. [Google Scholar] [CrossRef]

- Foroshani, J.S.; Mehrabi, H.; Rahimpour-Bonab, H. Reservoir Heterogeneity of Upper Cretaceous Sarvak Formation in the Dezful Embayment, SW Iran: Implications of Flow Unit Distribution, Electrofacies Analysis and Geological-Based Reservoir Zonation. J. Afr. Earth. Sci. 2023, 200, 104882. [Google Scholar] [CrossRef]

- Cabrera Ruiz, M.L.; Batezelli, A. Correlation between Geomechanical and Sedimentary Facies and Their Implications for Flow Unit Definition in the Pre-Salt Carbonate Reservoir, Brazil. J. South Am. Earth Sci. 2024, 141, 104958. [Google Scholar] [CrossRef]

- Xu, Z.; Fu, Q.; Hui, X.; Jing, L.; Shixiang, J.; Xiangtong, L. Division and distribution of flow units of Chang 613reservoir in Huaqing area, Ordos Basin. Nat. Gas Geosci. 2018, 29, 1757–1766. [Google Scholar]

- Yan, W.; Bao, H.; Si, X.; Yu, Y. Optimization of fracturing parameters for horizontal wells based on grey correlation method. Math. Pract. Theory 2021, 51, 145–151. [Google Scholar]

- Yang, J.; Jiang, Z. Application of Grey Relational Analysis in Urumqi Mining Area Reservoir Assessment. Coal Geol. China 2017, 29, 36–40. [Google Scholar]

- Dong, F.; Lu, X.; Jin, W. The Comprehensive Evaluation of Low Permeability Sandstone Reservoirs Based on the AHM Method. Ground Water 2016, 38, 168–170. [Google Scholar]

- Harker, P.T.; Vargas, L.G. The theory of ratio scale estimation: Saaty’ analytic hierarchy process. Manag. Sci. 1987, 33, 1383–1403. [Google Scholar] [CrossRef]

- Dong, F.; Lu, X.; Ju, H.; Wei, S. Division of Flow Units of the Low Permeability Sandstone Reservoir Based on Entropy-Weighting TOPSIS Method. Bull. Geol. Sci. Technol. 2012, 31, 124–128. [Google Scholar]

- Zhang, T.; Yan, H. Optimization and Application of Multi-attribute Decision Algorithm Based on Entropy Weight Method. J. North China Univ. Sci. Technol. (Nat. Sci. Ed.) 2022, 44, 82–88. [Google Scholar]

- Li, F.; Li, D. Combination Evaluation Model Based on the Entropy Weight Method. Technol. Informatiz. 2021, 148–150. [Google Scholar]

- Yang, W.; Wu, Y.; Wang, J. Grey Confidence Interval Estimation of Small Samples Based on Entropy-weight Method. J. Zhengzhou Univ. (Nat. Sci. Ed.) 2016, 48, 51–56. [Google Scholar]

- Zhou, R.; Fan, F.; He, D.; Qiu, W.H. Integrated entropy weight method based on data stability and subjective preference in multi-attribute group decision-making. Control Decis. 2012, 27, 1169–1174. [Google Scholar]

- Cao, C.; Zhou, F.; Cheng, L.; Liu, S.; Lu, W.; Wang, Q. A comprehensive method for acid diversion performance evaluation in strongly heterogeneous carbonate reservoirs stimulation using CT. J. Pet. Sci. Eng. 2021, 203, 108614. [Google Scholar] [CrossRef]

- Xue, Y.; Cheng, L.; Mou, J.; Zhao, W. A new fracture prediction method by combining genetic algorithm with neural network in low-permeability reservoirs. J. Pet. Sci. Eng. 2014, 121, 159–166. [Google Scholar] [CrossRef]

- Cao, C.; Cheng, L.; Zhang, X.; Shi, J. Numerical simulation investigation on well performance integrated stress sensitivity and sand production. Geofluids 2021, 2021, 9925866. [Google Scholar] [CrossRef]

- Liu, X.; Shen, N.; Feng, H. Application of the AHM Model Based on Entropy Weight in the Selection of Third-Party Logistics Carriers. China-Today Forum 2013, 56–57. [Google Scholar]

- Dong, F.; Lu, X.; Chen, X.; Xin, T. Optimum Program for Underground Gas Storage Projects Based on Entropy-weight AHM. J. Yangtze Univ. (Nat. Sci. Ed.) 2012, 9, 133–136. [Google Scholar]

- Zhang, L.; Li, R.; Deng, H.; Fu, M.; Hu, L.; Guo, X.; Xie, X.; Zhao, C. Identification, Distribution Characteristics, and Effects on Production of Interlayers in Carbonate Reservoirs: A Case Study from the Cretaceous Mishrif Formation in Halfaya Oilfield. Iraq. J. Pet. Sci. Eng. 2021, 202, 108571. [Google Scholar] [CrossRef]

- Chen, H. Flow Unit Characteristics of Fan Delta Front Deposits and Its Influence on Reservoir Development-Taking Yulou Oil Bearing Sets in Some Experimental Area in West Depression in Liaohe Basin in China as an Example. J. Pet. Sci. Eng. 2019, 179, 44–55. [Google Scholar] [CrossRef]

- Fan, Z.; Li, K.; Li, J.; Song, H.; He, L.; Wu, X. A Study on Remaining Oil Distribution in a Carbonate Oil Reservoir Based on Reservoir Flow Units. Pet. Explor. Dev. 2014, 41, 634–641. [Google Scholar] [CrossRef]

- Chen, X.; Xiao, P.; Duan, R.; Lu, W.; Zhang, X.; Chen, G. Study on flow unit division and remaining oil tapping in deep-water turbidite gas injection reservoir. Unconv. Oil Gas 2023, 10, 103–111. [Google Scholar]

- Chu, F.; Zhang, X.; Zhang, G.; Dong, C. Deep Learning Prediction of Waterflooding-Based Alteration of Reservoir Hydraulic Flow Unit. Geoenergy Sci. Eng. 2023, 231, 212396. [Google Scholar] [CrossRef]

- Oliveira, G.P.; Araújo, E.A.; Santos, M.D.; Roque, W.L. Non-Uniform Injector/Producer Well Pattern Designs Induced by Morphology and Anisotropy of Flow Units. J. Pet. Sci. Eng. 2020, 186, 106680. [Google Scholar] [CrossRef]

| Indicator Comprehensive Score | Type |

|---|---|

| >0.54 | Fu1 |

| 0.48~0.54 | Fu2 |

| 0.38~0.48 | Fu3 |

| <0.38 | Fu4 |

| Flow Units | Sand Body Thickness (m) | Permeability (10−3 μm2) | Mud Content (%) | Porosity (%) | Fluid Injection Intensity (m3/m) | Comprehensive | Type |

|---|---|---|---|---|---|---|---|

| S1-1 | 3.28 | 0.23 | 19.17 | 11.18 | 33.80 | 0.30 | Fu4 |

| S1-2 | 4.58 | 0.21 | 25.71 | 11.03 | 38.95 | 0.33 | Fu4 |

| S1-3 | 6.76 | 0.28 | 19.40 | 11.14 | 25.40 | 0.37 | Fu4 |

| S2-1 | 6.88 | 0.12 | 17.28 | 9.27 | 48.63 | 0.46 | Fu3 |

| S2-2 | 5.89 | 0.59 | 22.91 | 12.67 | 30.53 | 0.51 | Fu2 |

| S3-1 | 6.4 | 0.45 | 22.45 | 11.17 | 26.80 | 0.43 | Fu3 |

| S3-2 | 4.1 | 0.26 | 22.22 | 10.31 | 26.80 | 0.26 | Fu4 |

| S3-3 | 4.31 | 0.75 | 21.54 | 12.83 | 20.65 | 0.48 | Fu2 |

| S4-1 | 4.69 | 0.61 | 20.54 | 11.95 | 33.74 | 0.52 | Fu2 |

| … | … | … | … | … | … | … | … |

| S7-1 | 6.78 | 0.44 | 23.02 | 11.59 | 12.27 | 0.33 | Fu4 |

| S7-2 | 5.39 | 0.43 | 13.34 | 11.70 | 12.27 | 0.34 | Fu4 |

| S8-1 | 6.23 | 0.81 | 21.77 | 13.11 | 30.88 | 0.64 | Fu1 |

| S8-2 | 4.75 | 0.75 | 20.53 | 12.12 | 38.55 | 0.62 | Fu1 |

| S8-3 | 10.89 | 0.31 | 16.46 | 10.44 | 38.85 | 0.62 | Fu1 |

| S9-1 | 5.59 | 0.21 | 10.72 | 10.69 | 40.87 | 0.46 | Fu3 |

| S9-2 | 5.59 | 0.53 | 25.99 | 12.45 | 31.60 | 0.46 | Fu3 |

| S9-3 | 9.85 | 0.63 | 16.78 | 13.25 | 13.70 | 0.57 | Fu1 |

| S10-1 | 4.23 | 0.48 | 12.69 | 12.93 | 24.88 | 0.44 | Fu3 |

| S10-2 | 6 | 0.46 | 19.96 | 11.73 | 40.23 | 0.53 | Fu2 |

| S10-3 | 3.94 | 0.71 | 16.15 | 14.17 | 23.75 | 0.51 | Fu2 |

| Flow Unit | Sand Body Thickness (m) | Permeability (10−3 μm2) | Porosity | Mud Content (%) |

|---|---|---|---|---|

| Fu1 | 14.1 | 4.24 | 0.14 | 11.5 |

| Fu2 | 7.2 | 2.45 | 0.11 | 13.4 |

| Fu3 | 2.4 | 3.24 | 0.13 | 15.7 |

| Fu4 | 2.1 | 0.86 | 0.08 | 21.3 |

| Treatments Compatibility | Evaluation Standard | Adjustment Strategy |

|---|---|---|

| Poor | Perforation positions do not match; stimulation intensity is inadequate | Adjust perforation positions and increase stimulation intensity |

| Moderate | Perforation positions or stimulation intensity do not match | Increase stimulation intensity and adjust perforation positions |

| Good | Perforation positions and stimulation intensity both match | No adjustment; use parameters as a referencefor other wells |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, J.; Liu, X.; Wu, X.; Xue, Y.; Yang, G. The Characterization and Application of Flow Units in Tight Reservoirs Considering Stimulation Treatments. Processes 2024, 12, 2706. https://doi.org/10.3390/pr12122706

Hou J, Liu X, Wu X, Xue Y, Yang G. The Characterization and Application of Flow Units in Tight Reservoirs Considering Stimulation Treatments. Processes. 2024; 12(12):2706. https://doi.org/10.3390/pr12122706

Chicago/Turabian StyleHou, Jingtao, Xiaoqi Liu, Xinwei Wu, Yongchao Xue, and Guobin Yang. 2024. "The Characterization and Application of Flow Units in Tight Reservoirs Considering Stimulation Treatments" Processes 12, no. 12: 2706. https://doi.org/10.3390/pr12122706

APA StyleHou, J., Liu, X., Wu, X., Xue, Y., & Yang, G. (2024). The Characterization and Application of Flow Units in Tight Reservoirs Considering Stimulation Treatments. Processes, 12(12), 2706. https://doi.org/10.3390/pr12122706