1. Introduction

The pig farming industry plays a crucial role in meeting the global demand for pork. However, maintaining a clean and hygienic environment in pigsties is of paramount importance to ensure the health of pigs, improve the quality of pork, and prevent the spread of diseases [

1,

2]. Traditional cleaning and disinfection methods in pigsties are often labor-intensive, inefficient, and may not achieve the desired level of hygiene [

3,

4]. China is currently the world’s largest market for pork production and consumption, with pork production accounting for 60% of total meat production in the last several years, indicating a huge market size. The rapid expansion of the market has promoted the development of pig farming from decentralized breeding to specialization, scale, and intensification. At the same time, with the increase in breeding density, animal diseases, cleaning, and disinfection problems have emerged. How to build a “firewall” for the prevention and control of major diseases in large-scale pig farms, gradually complete the disinfection and purification of pig farms and pigs, ensure the smooth and sustainable development of pig farm production, and maintain the high health status of pig herds have become major issues facing all breeding practitioners.

In recent years, there has been a growing interest in the development of intelligent systems for pigsty cleaning and disinfection. A large number of studies have focused on the application of advanced technologies such as sensors, robotics, and automated control systems to improve the effectiveness and efficiency of these processes. For example, Mahfuz et al. [

5] considered the beneficial role of intelligent technology in the pig farming industry and suggested applying intelligent technology to the pig farming industry. Juszkiewicz et al. [

6] believed that although African Swine Fever (ASF) has been known for nearly 100 years, an effective vaccine or treatment is still lacking. Currently, only appropriate biosecurity measures, such as disinfection, are being implemented to prevent disease outbreaks. Alejo et al. [

7] found that due to the stability of ASFV in blood and excreta, exposure to substances containing a large amount of the virus can also lead to viral infection. Feng and Wang [

8] explored a disinfection robot system and intelligent disinfection mode to improve the efficiency and safety of livestock and poultry breeding disinfection.

Traditional pig farms generally use cleaning machines to clean the farm and pigs. Existing cleaning machines mainly use manual or semi-automatic methods, lacking highly automated, intelligent, and efficient technological innovation, and have relatively singular functions. The following problems often arise during use: ① High labor costs: traditional pig washing and farm cleaning, disinfection, and other work usually require a large amount of manpower input, high labor intensity, and can easily lead to a waste of human resources. ② Incomplete cleaning: due to limitations in manual operation, it is difficult to ensure thorough cleaning using traditional methods. ③ Water resource waste: traditional cleaning methods often use a large amount of water resources, and the use of cleaning agents may also be excessive. ④ The cleaning cycle is difficult to determine: Traditional cleaning methods have low efficiency and lack timely perception of environmental changes. The cleaning cycle is usually fixed and cannot be intelligently adjusted according to actual needs.

In order to improve the intelligence level of cleaning pigs and pig farms, solve problems such as labor costs, water resource waste, and difficulties in adjusting cleaning cycles according to actual situations, our team have collected relevant data. Then, a user demand-oriented model composed of AHP [

9] and QFD [

10] methods is used for data analysis. Finally, based on practical production, we innovatively designed an intelligent washing and disinfection integrated system that meets user needs and is suitable for the current breeding environment.

2. Preliminary Research

2.1. Field Research

The project team of four went to the Zhuhao Livestock Breeding Base in Shaoguan, Guangdong in July 2023 for this research, to understand the structure of the pig farm, environmental control, feeding management, disease prevention and control, breeding equipment, technical applications, etc. The on-site scene shot by the team is shown in

Figure 1. Our project team observed and recorded the workflow and status of pig cleaning, communicated with pig farm personnel, and learned about the specific problems encountered during pig cleaning. After returning, a research report was formed by combining observation and recording data and conducting an in-depth analysis of the application, industrial development, application prospects, and technological trends of foreign cleaning machines, as well as the use of cleaning machines in pig farms in various parts of China (Sichuan, Jiangxi, Gansu, Heilongjiang, etc.).

2.2. Questionnaire Survey

The project team conducted research on the intelligent cleaning of pigs. The respondents included contractors of breeding farms, individual pig farmers, researchers in breeding technology, and livestock workers. A total of 100 questionnaires were distributed to the research subjects, and 97 valid questionnaires were collected. According to the results, 68.04% of pig farms do not have a dedicated place to clean pigs, and only 31.96% have a place to clean them. In the multiple-choice question “What methods do you use to clean pigs? (Options are not limited to one item)”, 75.26% of respondents chose to wash pigs by splashing water, 50.52% chose to rinse them with water pipes, and 35.05% chose to wash pigs by soaking. The frequency of pig washing in the pig farm is 2–4 times a day in summer and 3–4 times a week in winter. Cleaning a pig requires 2–3 workers, with 18.56% taking less than 10 min, 57.73% taking 10–30 min, and 23.71% taking over 30 min. A total of 84.53% of people are willing to use intelligent equipment instead of manual pig washing. A total of 64.95% of people believe that intelligent pig washing equipment can save time, 69.92% of people believe that intelligent pig washing can reduce skin disease problems in pigs, and 50.52% of people believe that it can save costs; 42.27% of people expect a set of intelligent pig washing equipment to be controlled within 5000 yuan.

2.3. Competitive Analysis

This competitive analysis mainly analyzes the equipment commonly used for cleaning pigs and pig farms, comparing factors such as price, heating function, disinfection function, etc. The list comparison is given in

Table 1.

2.4. Research and Development of Intelligent Manure Cleaning and Disinfection Systems for Pig Farms

At present, there is no intelligent system specifically designed for cleaning pigs and pig farms. Research on intelligent systems for pig farms mainly focuses on intelligent manure cleaning and disinfection systems. Currently, the advanced pig farm automatic manure cleaning system information platform is developed using the Delta DOPSoft 2.00.07 and WPLSoft 2.48 software. Compared with the old system, it improves the stability and maintenance efficiency of the equipment, as well as the efficiency of manure cleaning. It can solve the problems of insufficient data acquisition, untimely warnings, and frequent maintenance during the pig farm manure cleaning process due to insufficient information technology [

11,

12].

The existing intelligent disinfection system for pigsties can use humidity, temperature, and harmful gas sensors to continuously monitor the environmental indicators of the pigsty, and can complete the feedback function of pigsty temperature, humidity, and PM2.5 values. On the premise of implementing the intelligent control of temperature and humidity in the pigsty, if the pigsty needs disinfection, the disinfection equipment can work according to the instructions to reduce the total suspended solids content and toxic and harmful gas concentration in the pigsty, thereby ensuring the health of the breeding environment [

13].

From the preliminary research, it can be concluded that three-quarters of the breeding personnel still use water splashing to clean pigs. The vast majority of practitioners are willing to try using intelligent devices instead of manual pig washing. The prices of pig washing equipment on the market range from 300 yuan/set to 28,000 yuan/set. The equipment is generally manual or semi-automatic, lacking highly automated, intelligent, and efficient technological innovation. There are not many machines with disinfection functions. The research and development of intelligent systems for pig farms mainly focus on intelligent manure cleaning and disinfection systems, without intelligent systems for cleaning pigs and pig farms. The breeding industry is developing rapidly, but it is difficult for pig farms to achieve standardization and automation in pig washing. By addressing the shortcomings of existing products in the market, our developed intelligent cleaning and disinfection integrated system for pig farms will bring a new cleaning management experience to the breeding industry, meeting the urgent market demand for intelligence, efficiency, and environmental protection.

3. Analysis of User Requirement Weights Based on AHP

3.1. Overview of Analytic Hierarchy Process

The Analytic Hierarchy Process [

14,

15] is a decision-making method that structures complex problems into a hierarchy and assigns weights to factors for comparisons and prioritization. It helps make rational choices in various fields. It is widely used in fields such as supply chain management [

16], risk assessment [

17], environmental management [

18], etc. The brief steps of AHP are as follows: Firstly, construct a judgment matrix based on the 1–9 scale method. Then, calculate the criterion weight vector by

where

.

Finally, determine the consistency ratio (

CR) via

where

RI is the random consistency index and

. For more details on AHP, please refer to references [

19,

20].

3.2. Construction of Analytic Hierarchy Process Model

By using the affinity diagram (KJ) method [

21], the survey results were integrated and classified into four categories, functional, usage, safety, and styling requirements, which were used as the criterion layer, and 14 specific requirements as the indicator layer. The user demand hierarchy analysis model for the intelligent washing and disinfection integrated equipment in the pig farm constructed is shown in

Figure 2.

3.3. User Demand Weight Calculation for Intelligent Washing and Disinfection Integrated Equipment in Pigsties

To ensure the scientific validity of the research results, the project team invited 17 relevant personnel to fill out the AHP questionnaire, including 7 industrial design teachers, 4 product designers, and 6 users.

We first compared user needs pairwise using a scale of 1–9 and assigned scores accordingly. Using the geometric mean method, the user demand weights for intelligent washing and disinfection integrated equipment in pig farms are obtained as shown in

Table 2. The consistency test was conducted on the calculation results, and the

CR values of the criterion layer and sub criterion layer were both less than 0.1. This indicates that the data are true and reliable, providing a basis for the research in this article.

4. Design Requirement Analysis Based on QFD

QFD [

22,

23,

24] is a quality management instrument which is capable of effectively converting customer demands into the engineering characteristics of products or services. By using QFD after AHP analysis, the relationship between user requirements and design requirements can be clarified, providing accurate support and guidance for product design. By mapping user requirements to specific design requirements, we ensure the objectivity and rationality of design requirements and construct a QFD for user and design requirements to obtain important design requirements.

Based on previous field research and competitor analysis, it can be concluded that the current pig washing equipment on the market lacks highly automated, intelligent, and efficient technological innovation, and there are not many machines that also have disinfection functions. These deficiencies can correspond to user needs, leading to design requirements such as the coexistence of cleaning and disinfection functions, intelligent recognition systems, and fast response times. In addition, the team used Google Scholar to accurately search for 403 pieces of information by entering the keyword “Intelligent Washing” and used web crawling software to collect webpage information. The team also segmented the relevant information crawled and obtained 1038 words. Then, three professionals in industrial design were invited to screen words and select a total of 42 words related to intelligent cleaning equipment. The results are presented in the form of a word cloud map, as shown in

Figure 3.

By analyzing the keywords, the design requirements can be summarized as follows: cleaning nozzle, disinfection nozzle, stable structure, modular design, standardized design, etc. The analysis results were then summarized, organized, and combined with user needs to determine the mapping of the 15 user requirements for intelligent washing and disinfection integrated equipment in pig farms to the design requirements, as shown in

Table 3.

5. Construction of QFD Quality House

We next input the weight values of the user requirements obtained from AHP into the Quality Function Deployment and invited experts to score the correlation between user requirements and design requirements. A “●” indicates a significant correlation with a value of 5; “○” indicates correlation with a value of 3; “∆” represents a weak correlation with a value of 1; and spaces represent no correlation. Based on this, a matrix of the relationship between user requirements and design requirements is constructed, and the quality house of the intelligent washing and disinfection integrated equipment in the pig farm is shown in

Figure 4.

6. Design Example of Intelligent Washing and Disinfection Integrated System for Pigsties

6.1. Scheme Design

Based on the weight calculation and analysis results of the design requirements, the project team broke the traditional design thinking of pig washing and disinfection equipment, researched the technology of fire sprinkler systems and pig positioning, and designed an intelligent washing and disinfection integrated system that is more suitable for modern aquaculture. This system tracks the cleaning target through a movable nozzle and achieves automated control and monitoring of the entire cleaning and disinfection process through an integrated intelligent control system, as shown in

Figure 5. The advantages are very obvious: ① the cleaning and disinfection system uses electronic control for intelligent cleaning, reducing a large amount of labor input; ② the intelligent disinfection system in the pig farm can achieve comprehensive coverage of the entire site, with multiple nozzles activated simultaneously for blind spot cleaning; ③ it can accurately control the nozzle water output, disinfectant ratio, and water pressure, effectively reducing resource waste; ④ the program sets the cycle for cleaning pigs and disinfecting the site, and the system will intelligently sense environmental changes and adjust the cycle accordingly; ⑤ in addition to pig washing and disinfection functions, the system also has fire protection functions, making it versatile and cost-effective. The intelligent washing and disinfection integrated system provides a safer, more efficient, and environmentally friendly solution for pig farms, integrating washing, disinfection, and firefighting.

6.2. Automatic Nozzle Structure

As shown in

Figure 6, the automatic nozzle used in the intelligent washing and disinfection integrated system mainly consists of an electric tube, a water tube, three drivers, sensors, and two nozzles. The electrical conduit is mainly connected to the power supply of the pig farm, while the water pipe is mainly connected to the water pipe of the pig farm. Nozzle 1 can spray clean water, mainly for cleaning pigs and firefighting purposes. Nozzle 2 mainly sprays pre prepared disinfectant to disinfect the pigs and the pig farm. The entire mobile nozzle can rotate left and right, and both nozzle 1 and nozzle 2 can swing up and down, capable of spraying in various directions in the pig farm.

The nozzle parameters are shown in

Table 4.

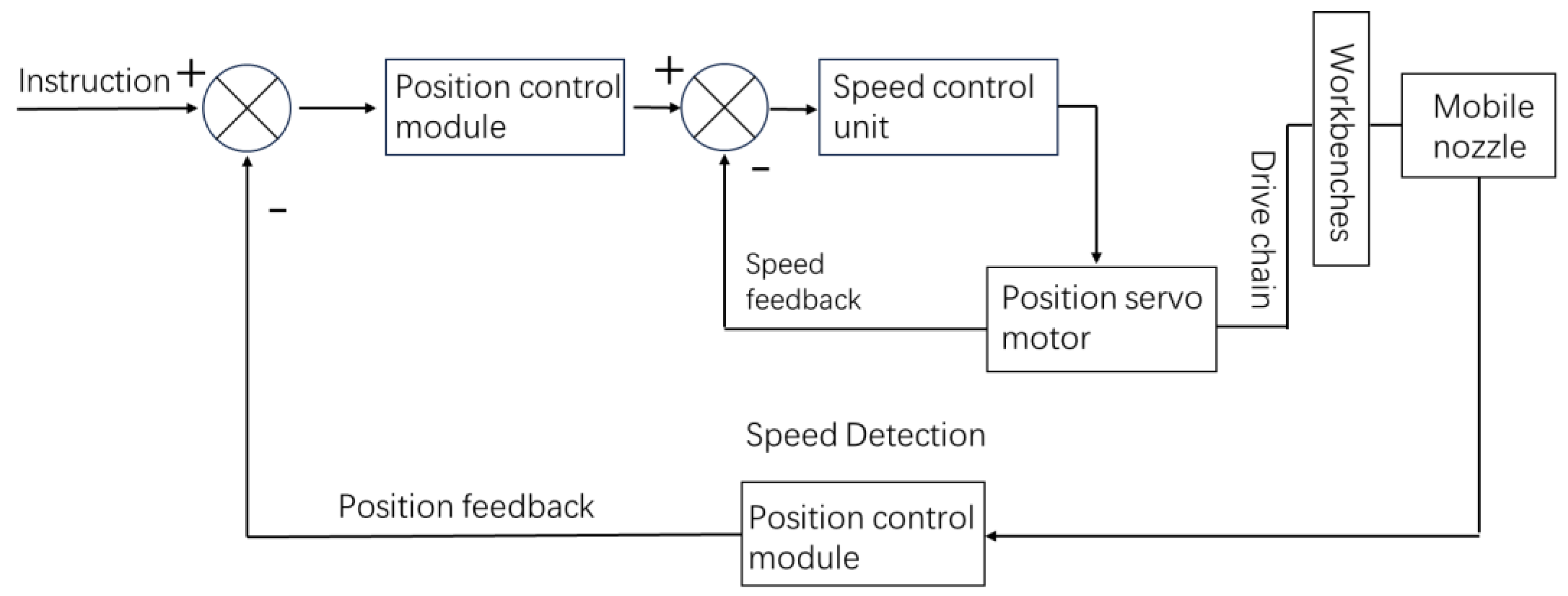

6.3. Automatic Control System

The mobile nozzle mainly relies on the point-to-point control system in the automation control system to achieve precise water spraying. Point-to-point control is a control system that integrates electronic technology, computer technology, automatic control, and detection to enable the controlled end to reach the destination according to a given trajectory and speed [

25,

26]. The point-to-point control system generally includes the final mechanical actuator, mechanical transmission mechanism, power components, controller, position measuring device, etc. The intelligent washing and disinfection integrated system is designed for cleaning and disinfecting pigs, which can move. Therefore, it not only requires high positioning accuracy for point control, but also dynamic performance requirements. So, the team added position servo motors to the point control system during the design process, as shown in

Figure 7. Servo motors can control speed and position accuracy very accurately and can convert voltage signals into torque and speed to drive control objects. After adding the servo motor, whether the pig is just standing or walking, the moving nozzle can quickly locate it and perform accurate cleaning.

In addition, the point-to-point control system needs to be paired with Radio Frequency Identification (RFID) ear tags based on Radio Frequency Identification [

27,

28]. Radio Frequency Identification (RFID) ear tags consist of chips and antennas inside and use radio wave technology to transmit data. Its important advantage is non-contact recognition, which can read data quickly in harsh environments. This technology has achieved traceability in animal disease monitoring and has mature applications in automation such as automatic feeding, automatic weighing, and estrus detection in the pig industry, all of which are key foundational technologies for these applications. The mobile nozzle can automatically recognize the position of pigs with electronic ear tags and whether they have been cleaned and disinfected, avoiding repeated handling of the same pig. Pig farm personnel can also set cleaning cycles for mobile nozzles and regularly clean and disinfect each pig with a high degree of intelligence.

6.4. System Architecture Layout

Figure 8 shows the structural layout and operation process of the intelligent washing and disinfection integrated system in the pig farm and marks and explains each component. From the diagram, it can be seen that the entire system consists of 13 parts, including a liquid pump, water valve, pressure pump, controller, PVC water pipe, wire, disc wheel, waterproof wire, electric water valve, high-pressure water pipe, guide rail, roller, automatic nozzle and hydraulic telescopic rod. In order to ensure good ventilation conditions and facilitate the renewal of air and temperature regulation in the pigsty, the ideal height of a pigsty is generally around 3.5–4.0 m. So, in order to adapt to the height of the pigs and better clean the parts below the pigs’ backs, the team has installed a hydraulic telescopic rod (Part 13) above the automatic cleaning decoration, which can extend down to a maximum distance of 1.5 m. The combination of the hydraulic telescopic rod, point control system, and servo motor can achieve centimeter-level cleaning accuracy. Whether the pig is static or dynamic, it can be easily positioned and rinsed with very high accuracy.

6.5. Schematic Diagram of Nozzle Spray Range

The plan view in

Figure 9 shows the nozzle layout and range of the intelligent washing and disinfection integrated system. The red dots represent the nozzles, the yellow lines represent the tracks, and the light red circles represent a nozzle range. The range radius of each nozzle is about 7 m. The pig farm manager can determine the number of nozzles to be installed based on the indoor area of the farm. After setting up the program, the nozzles will be cleaned and disinfected within an effective range. Every four nozzles can cover 200 square m of cleaning and disinfection. Traditional cleaning requires an average of 2–3 cleaners per pig farm, and it takes 5 min to bathe a pig using 60 L of water. Taking 100 pigs as an example, cleaning takes 8 h and uses six tons of water. By using an intelligent disinfection system to clean a single pig, it only takes 1.5 min and uses 30 L of water, which saves 50% of water compared to traditional methods. It only takes 2.5 h to clean 100 pigs, reducing the cleaning time by 5.5 h and avoiding the possibility of drug spraying poisoning incidents every year. Efficient modern intelligent aquaculture technology is an inevitable development trend, and it is expected that the market capacity of intelligent washing and disinfection integrated systems will be over 100,000 sets.

7. Conclusions

With the rapid expansion of the market and the increase in breeding density in recent years, the importance of pig diseases, cleaning, and disinfection has become increasingly prominent, and improving the automation and intelligence of pig farms has become a key issue. In this study, the project team first obtained user needs through survey questionnaires and interviews. Then, based on the research data, the affinity diagram (KJ) method was used to integrate and classify the research results, and a demand analysis was conducted on four aspects: functionality, usage, design, and price. Then, the Analytic Hierarchy Process (AHP) was used to calculate the weights of each of the user requirements. Combined with competitor analysis and literature research methods to obtain design keywords, the quality function was used to obtain the quality house, and the design requirements of the intelligent washing and disinfection integrated system for pig farms were quantitatively analyzed, making the design process more scientific. Finally, based on the design parameters, an intelligent washing and disinfection integrated system for pig farms was designed that meets users’ functional, usage, styling, and safety requirements. The drawback is that a large number of requirement descriptions can be obtained through research and analysis in the early stage. Although the judgment matrix has a certain degree of standardization, it cannot completely solve the subjectivity of the internal element settings of the judgment matrix. At the same time, due to the numerous design elements of the intelligent washing and disinfection integrated system for pig farms in this project, it is difficult to comprehensively and clearly classify and establish a reasonable demand system when dividing the requirements into levels. This study has currently completed the production of a mobile nozzle 3D printing model. We will create a 1:1 physical model of the entire system in a later stage and conduct experiments in the actual environment of the pig farm to further verify the feasibility of its structure and debug the operating system.

8. Applications and Impact

In 2022, the Chinese Ministry of Animal Husbandry and the Ministry of Environmental Protection jointly issued the “Guiding Plan for the Ecological Development of Animal Husbandry”, which clearly proposes to support and promote the promotion and application of intelligent breeding equipment to improve the ecological environment quality of animal husbandry. In addition, the government also provides support in fiscal policy by setting up subsidies for the purchase of intelligent breeding equipment and encouraging farms to introduce intelligent pig washing systems to promote the green upgrading of animal husbandry.

The design of the intelligent washing and disinfection integrated system aims to improve the hygiene level of pig farms, reduce labor intensity, achieve intelligent and efficient pig farm management, improve pork quality, and produce healthier and more reliable pork. It also reduces labor risks, minimizes the risks of workers coming into contact with pigs during the cleaning process, and improves work safety. This project mainly targets consumer entities such as animal husbandry companies, animal husbandry cooperative organizations, large-scale breeders, intelligent breeders, rural breeders, and farmers’ cooperatives. Based on the characteristics of pig farm operations and modern intelligent breeding protection, innovative design research is conducted on the functions, shapes, and usage methods of the decontamination system, as well as how to improve work efficiency and safety efficiency. It is expected that intelligent farming will continue to replace traditional farming methods in the next 10–20 years, and this project has huge market potential. The promotion and application of new generation information technologies such as big data and cloud computing have made intelligent and precise aquaculture a reality, providing an effective way for high-quality, high-yield, and the sustainable development of aquaculture.