Experimental Research on Behavior of Spontaneous Imbibition and Displacement After Fracturing in Terrestrial Shale Oil Based on Nuclear Magnetic Resonance Measurements

Abstract

:1. Introduction

2. Materials

2.1. Core Samples

- Put the rock samples and toluene and methanol into the Soxhlet extractor.

- Distill until the Soxhlet extractor’s liquid becomes colorless and transparent.

- Soak the rock samples for 8 h. If there is no obvious change in the liquid, stop the experiment; otherwise, repeat Steps 2 and 3.

- Dry the core samples at 105 °C for 48 h.

- Gas porosity was determined by the helium porosity method.

- Gas permeability was determined using a pulse decay permeameter by nitrogen conducted at a net confining pressure of 2.07 MPa at 25 °C.

2.2. Fluid Properties

3. Experiment and Methods

3.1. XRD Analysis

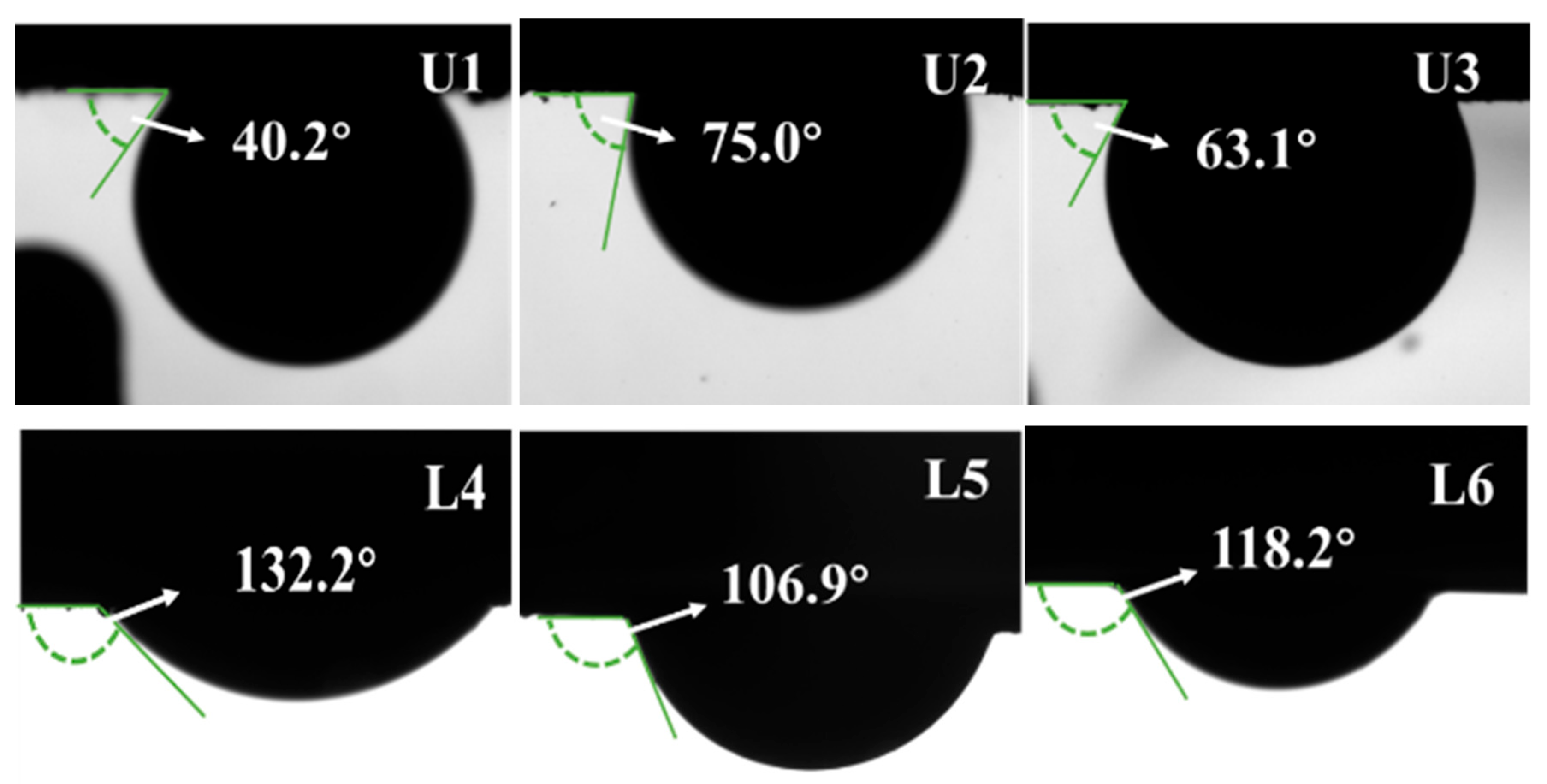

3.2. Contact Angle Measurements

3.3. LF-NMR Measurements

3.4. Oil–Water T2 Contrast Measurements

- Put the core sample into a vacuum dish for vacuum pumping, then add simulated formation water made of H2O to the dish to continue vacuum pumping, and finally, pressurize saturated with formation water.

- Measure the T2 distribution of the core sample after saturated water.

- Dry the core samples at 105 °C for 6 h.

- Put the core sample into a vacuum dish for vacuum pumping, then add simulated formation water, which is made of D2O, to the dish to continue vacuum pumping, and finally, pressurize saturated with formation water.

- The core is saturated to irreducible water saturation by displacement with crude oil after the step.

- Measure the T2 distribution of the core sample with irreducible water saturation.

3.5. SI Measurements

- Put the core sample into a vacuum dish for vacuum pumping, then add simulated formation water made of D2O to the dish to continue vacuum pumping and pressurize saturated with formation water.

- Place the saturated water core sample into the holder and drive it at a constant speed of 0.01 mL/min until continuous crude oil flows out from the outlet and the displacement process is complete. Then, place the displaced saturated core sample into an intermediate container containing crude oil and set a pressure of 40 MPa to pressurize the saturated crude oil. Age in oil for at least 300 h at 80 °C.

- Measure the T2 distribution of the core sample with irreducible water saturation.

- The core is placed into a corresponding vessel containing break fracturing fluids vertically, ensuring the total core is immersed in the fluids. Put the experiment vessel at 80 °C thermostats, and the starting time is recorded for each sample.

- The core is taken out from the vessel at a specific time, and surface fluids are instantly removed using test paper. Seal the core with PTFE tape to reduce fluid evaporation.

- Measure the T2 distribution of the core sample until the core temperature drops to room temperature. Then, put the sample back into the vessel to continue the imbibition process until the next specific time point.

- Repeat Steps 4 through 6 until the end of the experiment. The whole experiment lasts for 21 days.

3.6. Displacement Measurements

- Measure the T2 distribution of the core sample after the SI experiment as the initial displacement spectrum.

- Put the core sample into the core holder. Set constant flow 0.03 mL/min for displacement with tracking confining pressure to 3 MPa at 80 °C; the perfluoro compound oil is used for constant flow displacement. Place a measuring cylinder at the outlet end of the core holder to measure the volume of displaced fracturing fluid.

- Displace 10 PV perfluoro compound oil and take the core sample out of the core holder after the expelled liquid is pure and transparent. Seal the core with PTFE tape to reduce fluid evaporation.

- Measure the T2 distribution of the core sample until the core temperature drops to room temperature.

4. Results and Discussion

4.1. Mineral Composition Result from XRD Experiments

4.2. The Results of Contact Angle Measurements

4.3. Oil–Water T2 Spectrum Contrast from Experiment

4.4. T2 Relaxation Distribution Characterizes the Rock SI Process

4.5. Imbibition Oil Recovery and Imbibition Rate

4.6. Displacement Oil Recovery and Flowback Ratio

5. Conclusions

- The imbibition oil recovery rate is fast in the early stage of SI, and oil recovery begins to increase steadily and slowly after 100 h. The high imbibition recovery indicates that the shale has a specific imbibition potential.

- The crude oil present in the pores is gradually displaced by fracturing fluid because of the capillary force, but the contribution of oil recovery mainly comes from these small mesopores and mesopores. Water-wet core samples’ imbibition oil recovery is about 31.9%; oil-wet core samples’ imbibition oil recovery is about 18.4%.

- The fracturing fluid can effectively change the wettability of oil-wet samples. Oil recovery of water-wet core samples is approximately 40.7%. The oil recovery of oil-wet core samples is about 26%. The wettability significantly affects samples’ imbibition and displacement oil recovery. The additives added to the fracture fluid can effectively alter the wettability of samples from oil-wet to intermediate.

- Oil in small mesopores and mesopores can be effectively displaced. In total, 8% of oil can be flooded from core samples after displacement. After displacement, a large amount of imbibed fracture fluid is trapped in the shale sample pore. Only 12% of fracture fluid flooded from the samples.

- These results demonstrate the imbibition and displacement characteristics of terrestrial shale and several relevant affecting factors and provide guidance for the optimization of fracturing flowback.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mason, G.; Morrow, N.R. Developments in Spontaneous Imbibition and Possibilities for Future Work. J. Pet. Sci. Eng. 2013, 110, 268–293. [Google Scholar] [CrossRef]

- Makhanov, K.; Habibi, A.; Dehghanpour, H.; Kuru, E. Liquid Uptake of Gas Shales: A Workflow to Estimate Water Loss during Shut-In Periods after Fracturing Operations. J. Unconv. Oil Gas. Resour. 2014, 7, 22–32. [Google Scholar] [CrossRef]

- Lin, H.; Zhang, S.; Wang, F.; Pan, Z.; Mou, J.; Zhou, T.; Ren, Z. Experimental Investigation on Imbibition-Front Progression in Shale Based on Nuclear Magnetic Resonance. Energy Fuels 2016, 30, 9097–9105. [Google Scholar] [CrossRef]

- Chen, X.; Liao, K.; Lv, Z.; Zhu, J.; Wang, J.; Li, Y.; Wang, F. Numerical Simulation Study on Optimal Shut-In Time in Jimsar Shale Oil Reservoir. Front. Energy Res. 2022, 10, 849064. [Google Scholar] [CrossRef]

- Progress and development trend of water huff-n-puff technology for horizontal wells in tight oil reservoirs in China Pu, C. Acta Petrolei Sin. 2023, 44, 188–206.

- Ghanbari, E.; Dehghanpour, H. The Fate of Fracturing Water: A Field and Simulation Study. Fuel 2016, 163, 282–294. [Google Scholar] [CrossRef]

- Fu, L.Q.; Chen, H.A.; Lan, Y.B.; Deng, S.; Dong, D. Experimental Research on Transformation from Huff-n-Puff Imbibition to Displacement of Tight Sandstone with NMR; Springer Series in Geomechanics and Geoengineering; Springer Nature: Singapore, 2024; pp. 940–953. [Google Scholar]

- Wijaya, N.; Sheng, J.J. Shut-In Effect in Removing Water Blockage in Shale-Oil Reservoirs with Stress-Dependent Permeability Considered. SPE Reserv. Eval. Eng. 2020, 23, 81–94. [Google Scholar] [CrossRef]

- Hatiboglu, C.U.; Babadagli, T. Primary and Secondary Oil Recovery From Different-Wettability Rocks by Countercurrent Diffusion and Spontaneous Imbibition; Society of Petroleum Engineers: Houston, TX, USA, 2006. [Google Scholar] [CrossRef]

- Yaich, E.; Williams, S.; Bowser, A.; Goddard, P.; Souza OD, D.; Foster, R.A. A Case Study The Impact of Soaking on Well Performance in the Macelts. In Proceedings of the Unconventional Resources Technology Conference, San Antonio, TX, USA, 20–22 July 2015. [Google Scholar] [CrossRef]

- Wang, M.; Leung, J.Y. Numerical Investigation of Coupling Multiphase Flow and Geomechanical Effects on Water Loss During Hydraulic Fracturing Flow Back Operation. SPE Reserv. Eval. Eng. 2015, 19, 520–537. [Google Scholar] [CrossRef]

- Kerunwa, A.; Onyekonwu, M.O.; Anyadiegwu CI, C.; Olafuyi, A.O. Spontaneous Imbibition in Niger Delta Cores; Society of Petroleum Engineers: Houston, TX, USA, 2016. [Google Scholar] [CrossRef]

- Olafuyi, O.A.; Cinar, Y.; Knackstedt, M.A.; Pinczewski, W.V. Spontaneous Imbibition in Small Cores. In Proceedings of the Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 30 October–1 November 2007; p. SPE-109724-MS. [Google Scholar] [CrossRef]

- Habibi, A.; Binazadeh, M.; Dehghanpour, H.; Bryan, D.; Uswak, G. Advances in Understanding Wettability of Tight Oil Formations. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015; p. SPE-175157-MS. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, Q.; Ning, Z.; Li, M.; Lyu, C.; Huang, L.; Wu, X. Experimental Investigation of Countercurrent Spontaneous Imbibition in Tight Sandstone Using Nuclear Magnetic Resonance. Energy Fuels 2018, 32, 6507–6517. [Google Scholar] [CrossRef]

- Handy, L.L. Determination of effective capillary pressures for porous media from imbibition data. Trans. AIME 1960, 219, 75–80. [Google Scholar] [CrossRef]

- Yildiz, H.O.; Gokmen, M.; Cesur, Y. Effect of Shape Factor, Characteristic Length, and Boundary Conditions on Spontaneous Imbibition. J. Pet. Sci. Eng. 2006, 53, 158–170. [Google Scholar] [CrossRef]

- Kim, T.W.; Kovscek, A.R. The Role of Boundary Conditions and Characteristic Length on Imbibition in Both Sandstones and Limestones. In Proceedings of the SPE Western North American and Rocky Mountain Joint Meeting, Denver, CO, USA, 17–18 April 2014; p. SPE-169540-MS. [Google Scholar] [CrossRef]

- Lan, Q.; Ghanbari, E.; Dehghanpour, H.; Hawkes, R. Water Loss versus Soaking Time: Spontaneous Imbibition in Tight Rocks. Energy Technol. 2014, 2, 1033–1039. [Google Scholar] [CrossRef]

- Tinni, A.; Odusina, E.; Sulucarnain, I.; Sondergeld, C.; Rai, C.S. Nuclear-Magnetic-Resonance Response of Brine, Oil, and Methane in Organic-Rich Shales. SPE Res. Eval. Eng. 2015, 18, 400–406, SPE-168971-PA. [Google Scholar] [CrossRef]

- Roychaudhuri, B.; Tsotsis, T.T.; Jessen, K. An Experimental Investigation of Spontaneous Imbibition in Gas Shales. J. Pet. Sci. Eng. 2013, 111, 87–97. [Google Scholar] [CrossRef]

- Cao, G.; Cheng, Q.; Liu, Y.; Bu, R.; Zhang, N.; Wang, P. Influencing Factors of Surfactant Stripping Crude Oil and Spontaneous Imbibition Mechanism of Surfactants in a Tight Reservoir. ACS Omega 2022, 7, 19010–19020. [Google Scholar] [CrossRef]

- Ma, M.; Zhu, J.; Li, J.; Liao, K.; Wang, J.; Wang, F. Imbibition Law of Shale Oil Reservoirs in the Lucaogou Formation in Jimsar Sag. Xing Jiang Pet. Geol. 2021, 42, 702–708. [Google Scholar] [CrossRef]

- Peta, K. Multiscale Wettability of Microtextured Irregular Surfaces. Materials 2024, 17, 5716. [Google Scholar] [CrossRef]

- Sayed, A.M.A.E.; Sayed, N.A.E. Petrophysical Properties of Clastic Reservoirs Using NMR Relaxometry and Mercury Injection Data: Bahariya Formation, Egypt. IOP Conf. Ser. Earth Environ. Sci. 2016, 44, 042018. [Google Scholar] [CrossRef]

- Xu, G.; Shi, Y.; Jiang, Y.; Jia, C.; Gao, Y.; Han, X.; Zeng, X. Characteristics and Influencing Factors for Forced Imbibition in Tight Sandstone Based on Nuclear Magnetic Resonance Measurements. Energy Fuels 2018, 32, 8230–8240. [Google Scholar] [CrossRef]

- Shen, Y.; Ge, H.; Li, C.; Yang, X.; Ren, K.; Yang, Z.; Su, S. Water Imbibition of Shale and Its Potential Influence on Shale Gas Recovery-A Comparative Study of Marine and Continental Shale Formations. J. Nat. Gas. Sci. Eng. 2016, 35, 1121–1128. [Google Scholar] [CrossRef]

- Yang, L.; Ge, H.; Shi, X.; Cheng, Y.; Zhang, K.; Chen, H.; Shen, Y.; Zhang, J.; Qu, X. The Effect of Microstructure and Rock Mineralogy on Water Imbibition Characteristics in Tight Reservoirs. J. Nat. Gas. Sci. Eng. 2016, 34, 1461–1471. [Google Scholar] [CrossRef]

- Andersen, P.; Lohne, A.; Stavland, A.; Hiorth, A.; Brattekås, B. Core Scale Modeling of Polymer Gel Dehydration by Spontaneous Imbibition. SPE J. 2019, 24, 1201–1219. [Google Scholar] [CrossRef]

- Mai, A.; Kantzas, A. Porosity Distributions in Carbonate Reservoirs Using Low-Field NMR. J. Can. Pet. Technol. 2007, 46, 30–36. [Google Scholar] [CrossRef]

- Eslami, M.; Kadkhodaie-Ilkhchi, A.; Sharghi, Y.; Golsanami, N. Construction of Synthetic Capillary Pressure Curves from the Joint Use of NMR Log Data and Conventional Well Logs. J. Pet. Sci. Eng. 2013, 111, 50–58. [Google Scholar] [CrossRef]

- Zhao, H.; Ning, Z.; Zhao, T.; Che, F.; Zhang, R.; Hou, T. Applicability Comparison of Nuclear Magnetic Resonance and Mercury Injection Capillary Pressure in Characterisation Pore Structure of Tight Oil Reservoirs. In Proceedings of the SPE Asia Pacific Unconventional Resources Conference and Exhibition, Brisbane, Australia, 9–11 November 2015; p. SPE-177026-MS. [Google Scholar] [CrossRef]

- Meng, M.; Ge, H.; Ji, W.; Shen, Y.; Su, S. Monitor the Process of Shale Spontaneous Imbibition in Co-Current and Counter-Current Displacing Gas by Using Low Field Nuclear Magnetic Resonance Method. J. Nat. Gas. Sci. Eng. 2015, 27, 336–345. [Google Scholar] [CrossRef]

- Jiang, Y.; Shi, Y.; Xu, G.; Jia, C.; Meng, Z.; Yang, X.; Zhu, H.; Ding, B. Experimental Study on Spontaneous Imbibition under Confining Pressure in Tight Sandstone Cores Based on Low-Field Nuclear Magnetic Resonance Measurements. Energy Fuels 2018, 32, 3152–3162. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H.; Yang, J.; Yang, S. Dynamic Behavior of Salt Dissolution and Its Effect on Imbibition in Inter-Salt Oil Reservoir Due to Fracturing Fluid Injection. In Proceedings of the SPE EuropEC—Europe Energy Conference featured at the 83rd EAGE Annual Conference & Exhibition, Madrid, Spain, 6–9 June 2022; p. SPE-209641-MS. [Google Scholar] [CrossRef]

- Wang, H.T.; Lun, Z. Nuclear Magnetic Resonance Study on Mechanisms of Oil Mobilization in Tight Reservoir Exposed to CO2 in Pore Scale. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016; p. SPE-179554-MS. [Google Scholar] [CrossRef]

- Liu, J.; Sheng, J. Investigation of Countercurrent Imbibition in Oil-Wet Tight Cores Using NMR Technology. SPE J. 2020, 25, 2601–2614, SPE-201099-PA. [Google Scholar] [CrossRef]

- Xu, G.; Han, Y.; Jiang, Y.; Shi, Y.; Wang, M.; Zeng, X. Reducing Residual Oil Saturation: Underlying Mechanism of Imbibition in Oil Recovery Enhancement of Tight Reservoir. SPE J. 2021, 26, 2340–2351, SPE-205491-PA. [Google Scholar] [CrossRef]

- Zou, C.; Zhu, R.; Bai, B.; Yang, Z.; Wu, S.; Su, L.; Quang, Đ.Đ.; Li, X. First Discovery of Nano-pore Throat in Oil and Gas Reservoir in China and Its Scientific Value. Acta Petrol. Sin. 2011, 27, 1857–1864. [Google Scholar]

- Gao, S.; Hu, Z.; Liu, H.; Ye, L.; An, W. Microscopic Pore Characteristics of Different Lithological Reservoirs. Acta Petrol. Sin. 2016, 37, 248–256. [Google Scholar]

- Jackson, M.D.; Valvatne, P.H.; Blunt, M.J. Prediction of wettability variation and its impact on flow using pore- to reservoir-scale simulations. J. Pet. Sci. Eng. 2003, 39, 231–246. [Google Scholar] [CrossRef]

- Valvatne, P.H.; Blunt, M.J. Predictive pore-scale modeling of two-phase flow in mixed wet media. Water Resour. Res. 2004, 40, 187. [Google Scholar] [CrossRef]

- Yang, L.; Ge, H.; Shen, Y.; Zhang, J.; Yan, W.; Wu, S.; Tang, X. Imbibition Inducing Tensile Fractures and Its Influence on In-Situ Stress Analyses: A Case Study of Shale Gas Drilling. J. Nat. Gas. Sci. Eng. 2015, 26, 927–939. [Google Scholar] [CrossRef]

| Sample | Length (cm) | Helium Porosity (%) | Gas Permeability (mD) | Confining Pressure (MPa) |

|---|---|---|---|---|

| U-1 | 3.32 | 9.8 | 0.0365 | 2.07 |

| U-2 | 3.35 | 6.4 | 0.0282 | 2.07 |

| U-3 | 3.34 | 7.3 | 0.0184 | 2.07 |

| L-4 | 3.32 | 13.0 | 0.0085 | 2.07 |

| L-5 | 3.37 | 15.0 | 0.0178 | 2.07 |

| L-6 | 3.35 | 15.0 | 0.0186 | 2.07 |

| Fluid Type | Density (g/cm3) | Viscosity (mPa·s) | Surface Tension (mN/m) |

|---|---|---|---|

| Crude oil (up) | 0.888 | 40 (50 °C) | 51.07 |

| Crude oil (low) | 0.902 | 125 (50 °C) | 43.7 |

| BAF-1 | 1.82 | 1.85 (25 °C) | 26.82 |

| Deuterium oxide | 1.105 | 1.12 (25 °C) | 72.75 |

| Sample | Quartz + Feldspar + Pyrite | Total Carbonated | Total Clay | Smectite | Illite | Chlorite/Smectite |

|---|---|---|---|---|---|---|

| U-1 | 63.3 | 32.5 | 2.3 | 75 | 10 | 15 |

| U-2 | 27.9 | 69.4 | 2.7 | 70 | 15 | 15 |

| U-3 | 77.7 | 19.2 | 3.1 | 50 | 20 | 30 |

| L-4 | 72.4 | 11.4 | 7.9 | 85 | 10 | 5 |

| L-5 | 79.2 | 12.9 | 7.9 | 80 | 10 | 10 |

| L-6 | 75.5 | 19.9 | 4.6 | 75 | 15 | 10 |

| T2 relaxation time, ms | pore radius, μm | pore type |

| ≤1 | ≤2 | micropore |

| 1 < T2 relaxation time ≤ 10 | 2 < pore radius ≤ 10 | small mesopore |

| 10 < T2 relaxation time ≤ 100 | 10 < pore radius ≤ 20 | mesopore |

| 100 < T2 relaxation time ≤ 1000 | 20 < pore radius ≤ 200 | macropore |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Wang, F.; Zhang, S.; Ma, X. Experimental Research on Behavior of Spontaneous Imbibition and Displacement After Fracturing in Terrestrial Shale Oil Based on Nuclear Magnetic Resonance Measurements. Processes 2024, 12, 2685. https://doi.org/10.3390/pr12122685

Zhu J, Wang F, Zhang S, Ma X. Experimental Research on Behavior of Spontaneous Imbibition and Displacement After Fracturing in Terrestrial Shale Oil Based on Nuclear Magnetic Resonance Measurements. Processes. 2024; 12(12):2685. https://doi.org/10.3390/pr12122685

Chicago/Turabian StyleZhu, Jian, Fei Wang, Shicheng Zhang, and Xinfang Ma. 2024. "Experimental Research on Behavior of Spontaneous Imbibition and Displacement After Fracturing in Terrestrial Shale Oil Based on Nuclear Magnetic Resonance Measurements" Processes 12, no. 12: 2685. https://doi.org/10.3390/pr12122685

APA StyleZhu, J., Wang, F., Zhang, S., & Ma, X. (2024). Experimental Research on Behavior of Spontaneous Imbibition and Displacement After Fracturing in Terrestrial Shale Oil Based on Nuclear Magnetic Resonance Measurements. Processes, 12(12), 2685. https://doi.org/10.3390/pr12122685