Control the Working Process of the Rotor System with Tilting Pad Bearing

Abstract

1. Introduction

2. Objective of Research

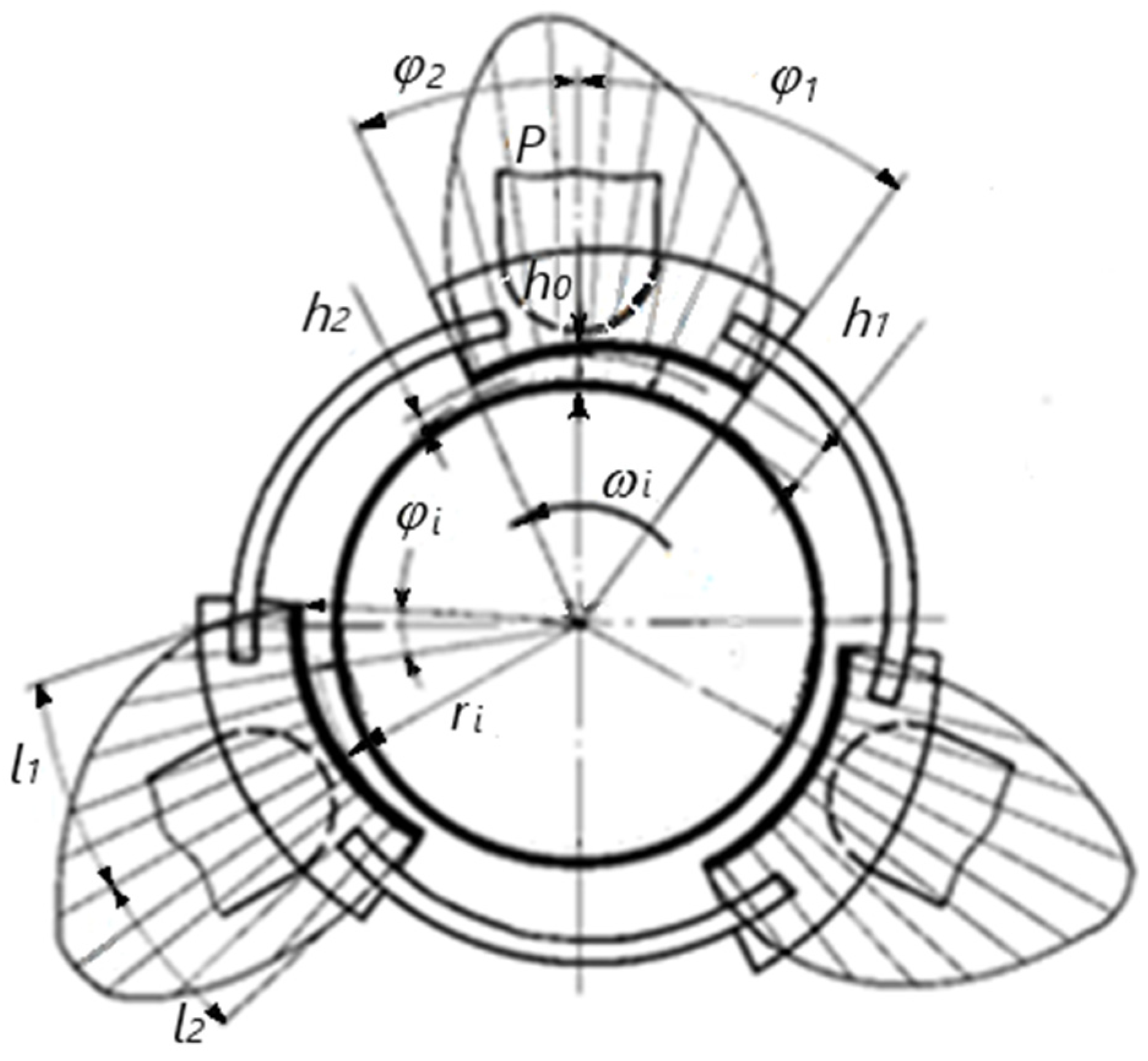

3. Mathematics of Tilting Pad Bearing Adaptivity

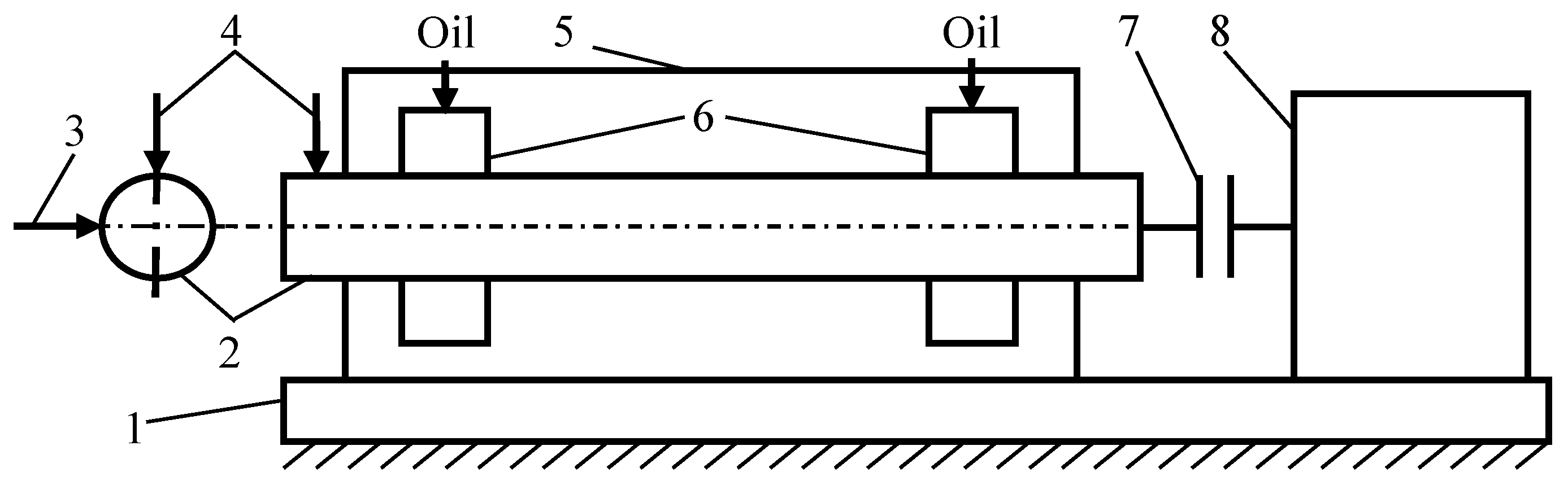

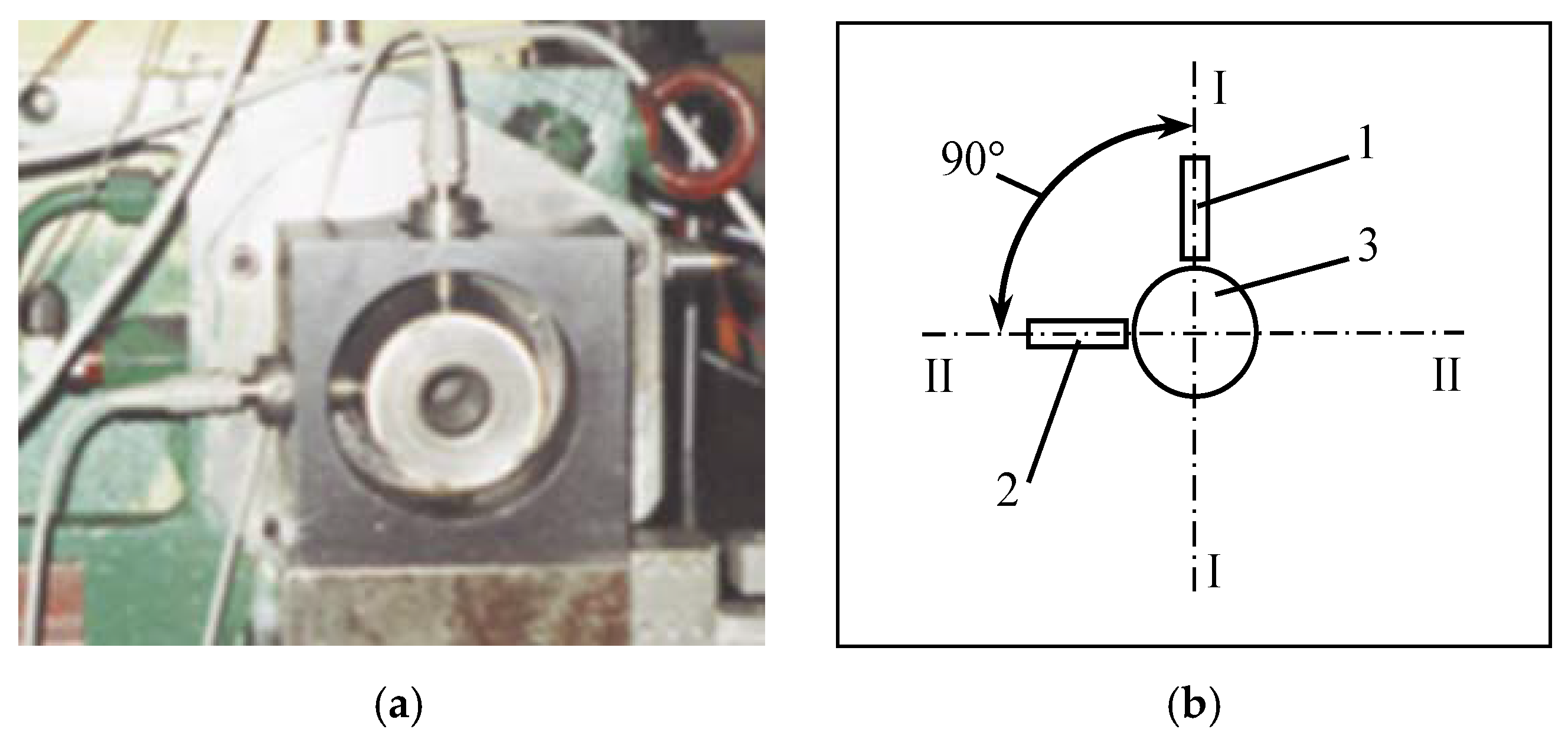

4. Research Equipment and Methodology

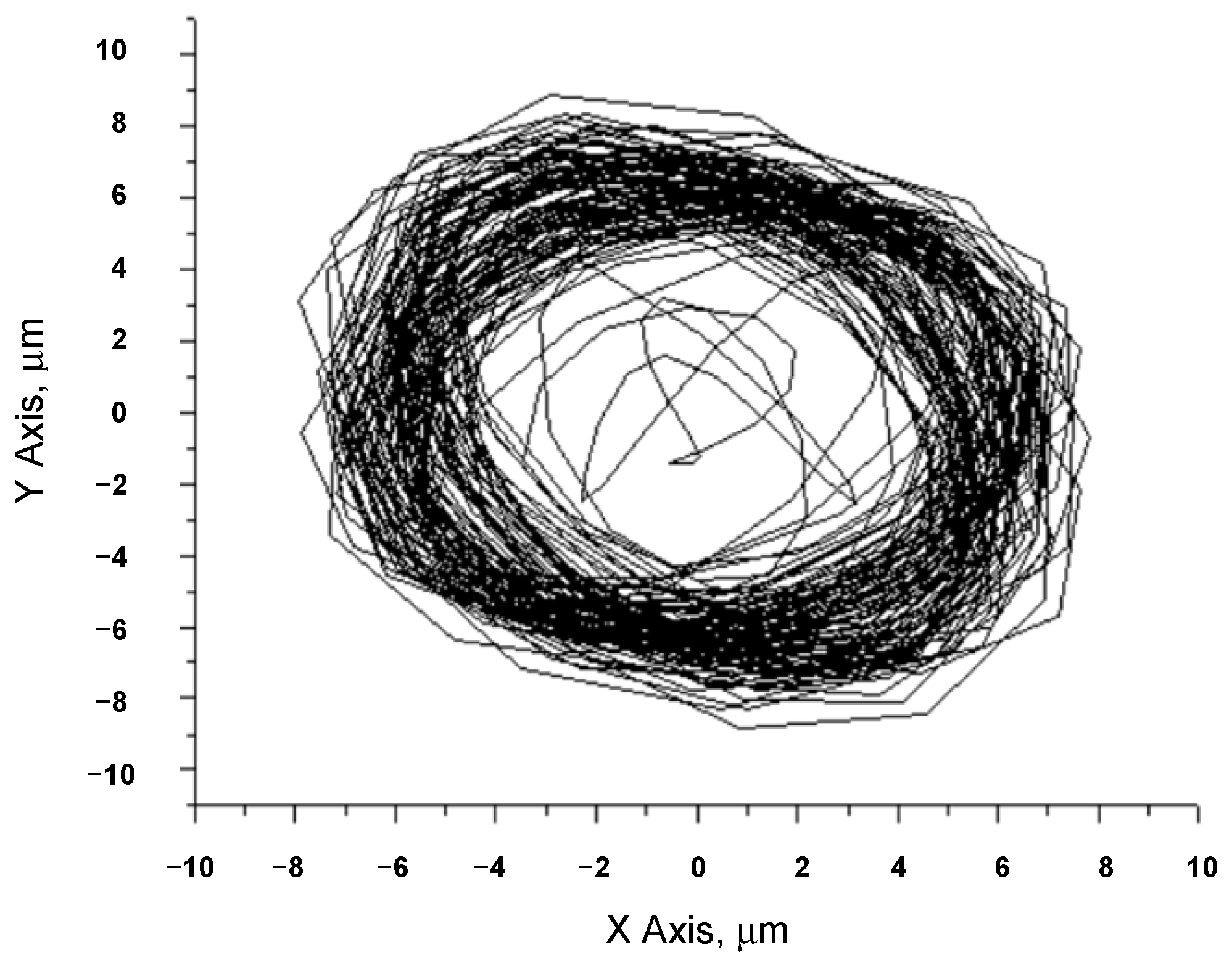

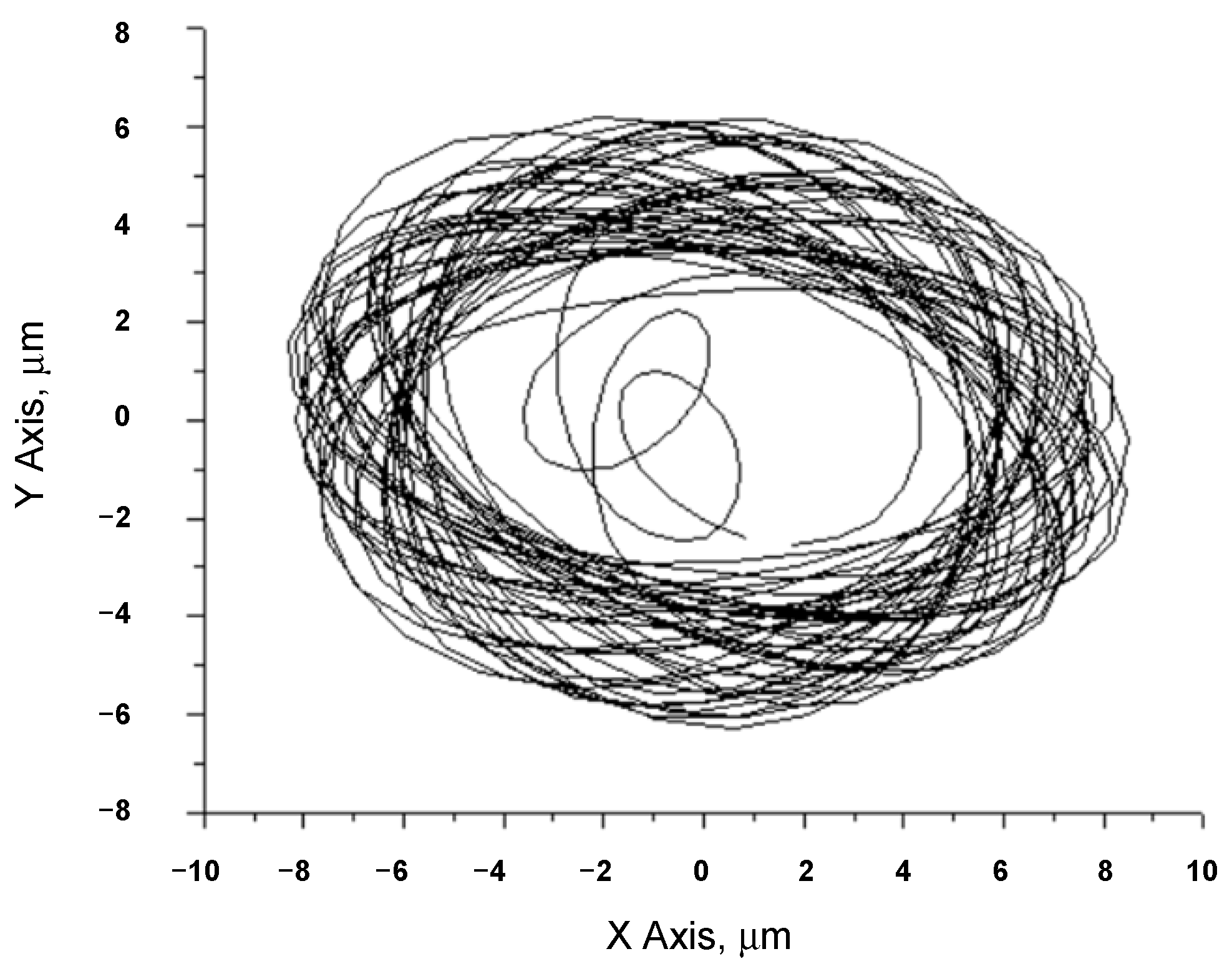

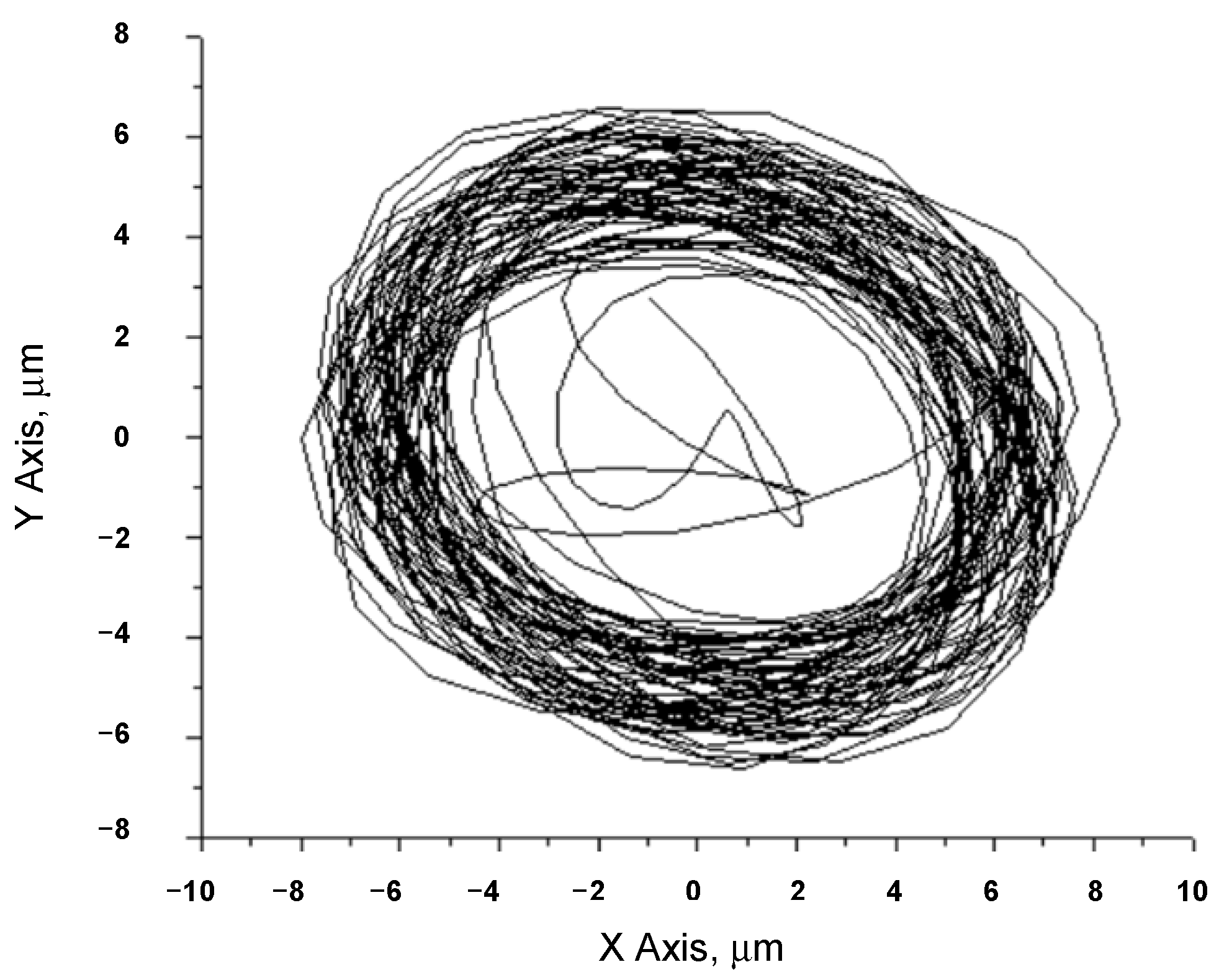

5. Results of Analysis and Discussion

6. Conclusions

- -

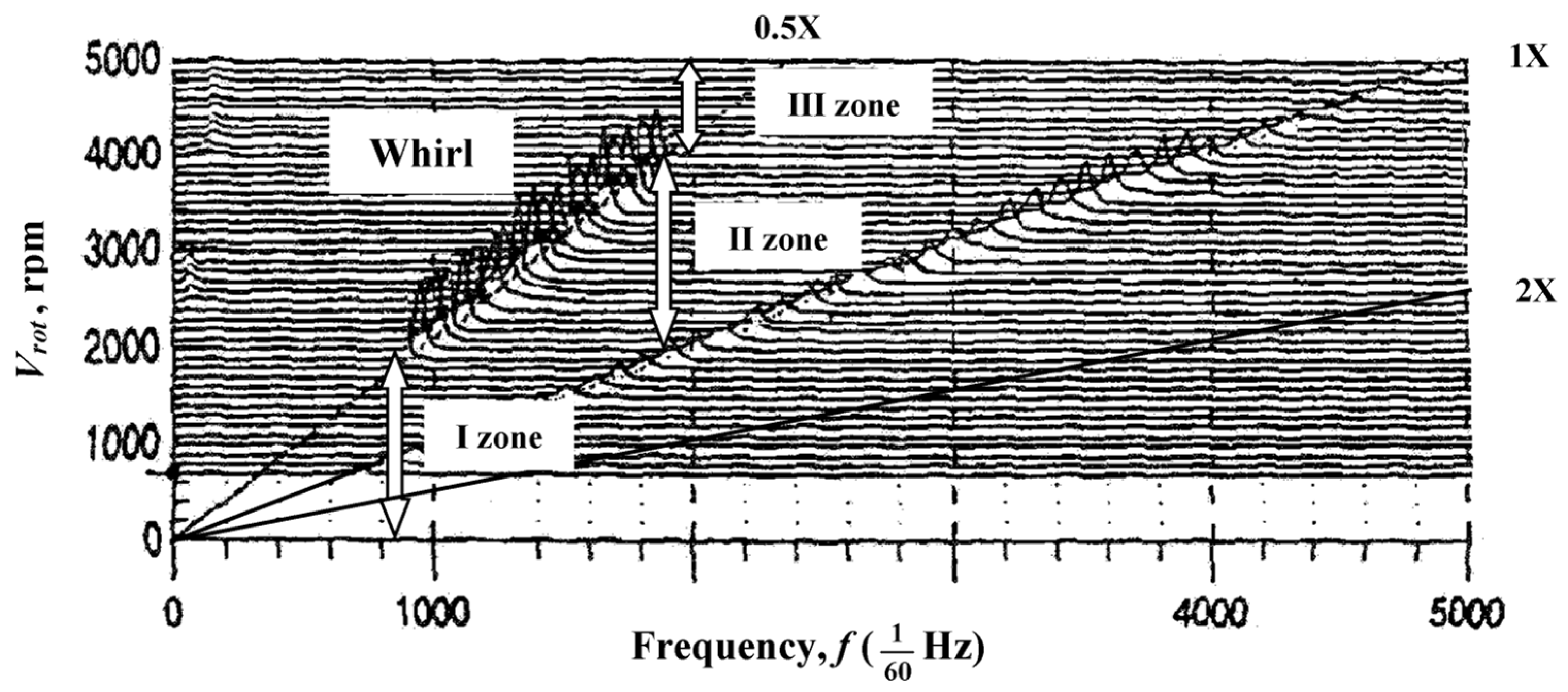

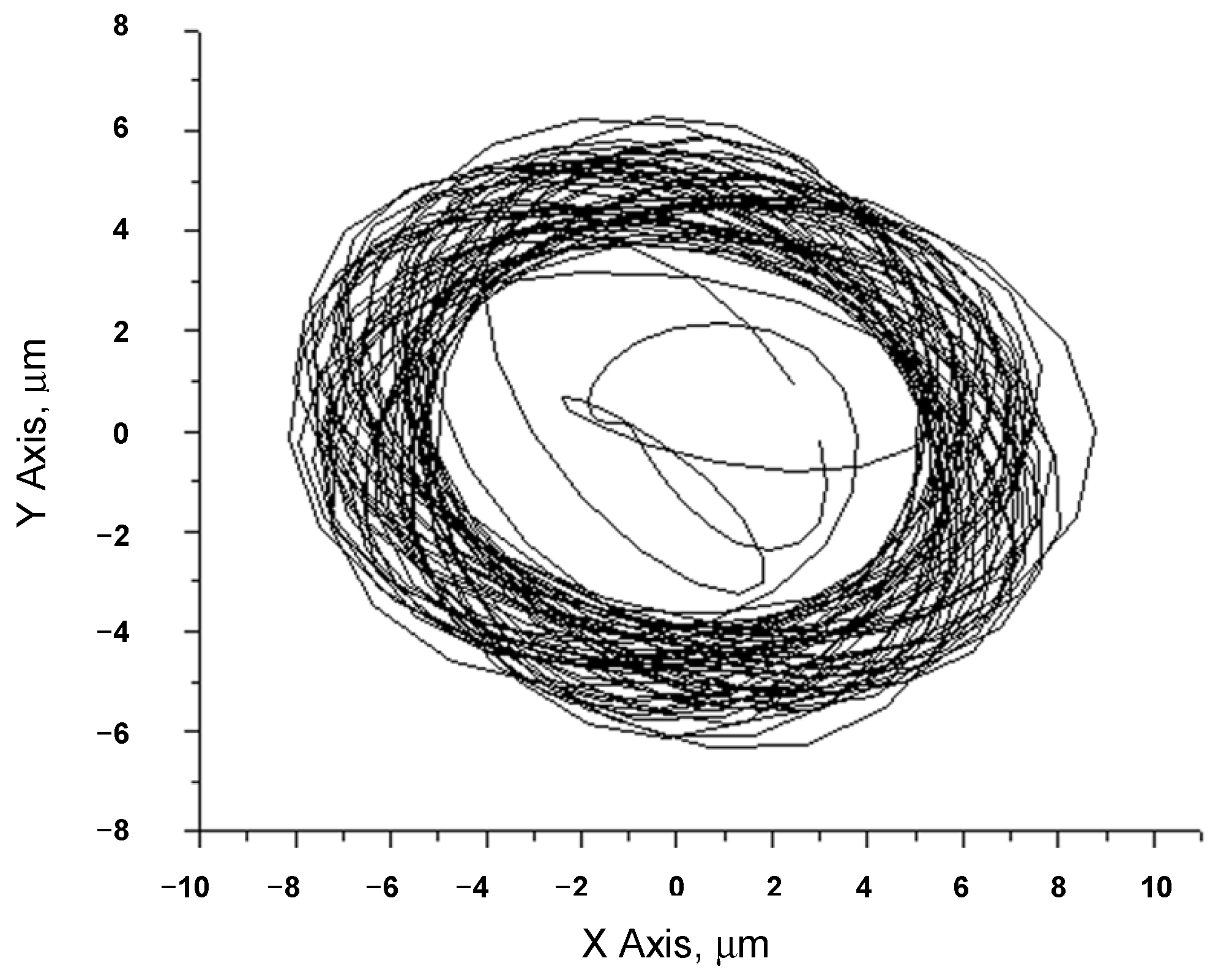

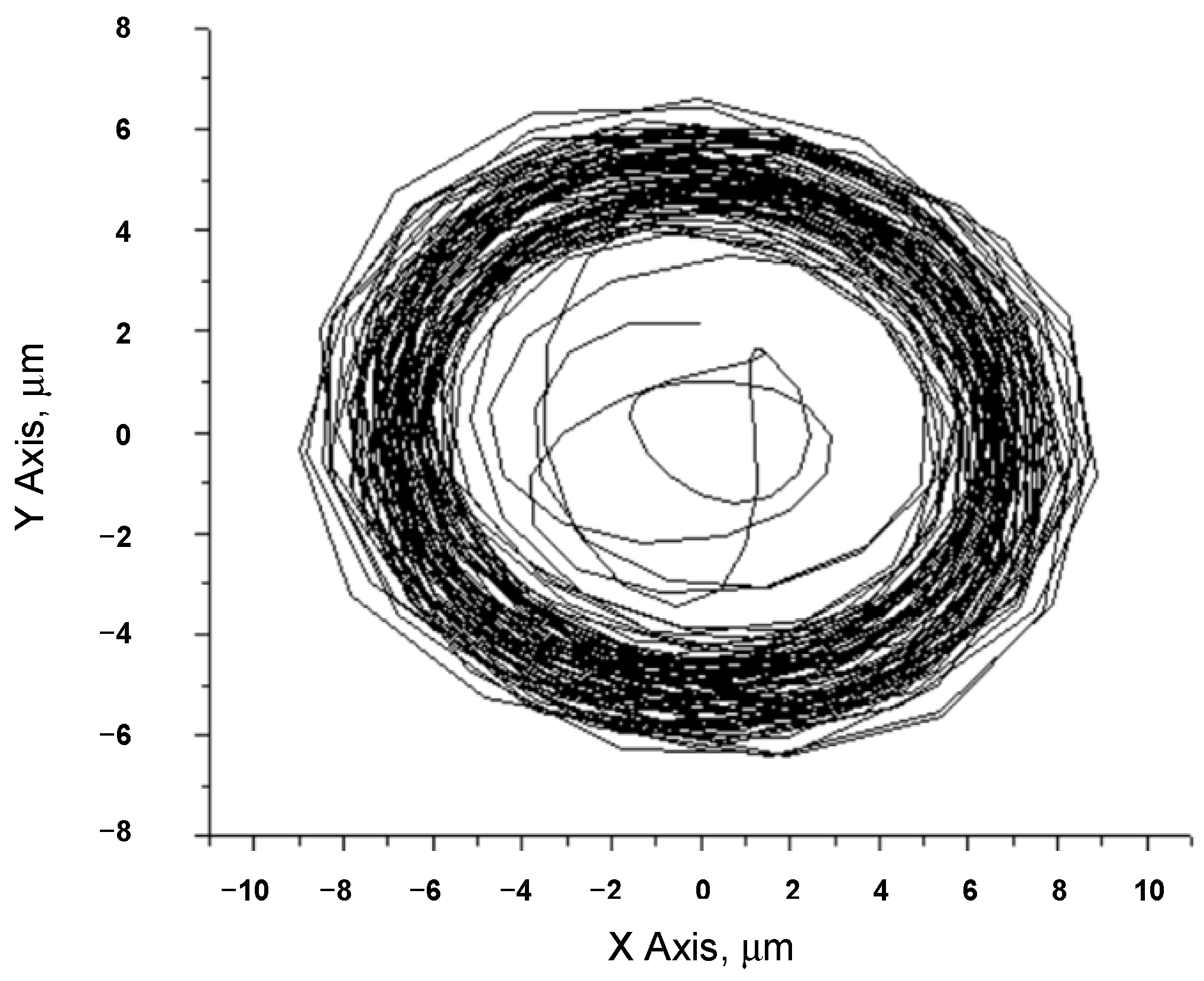

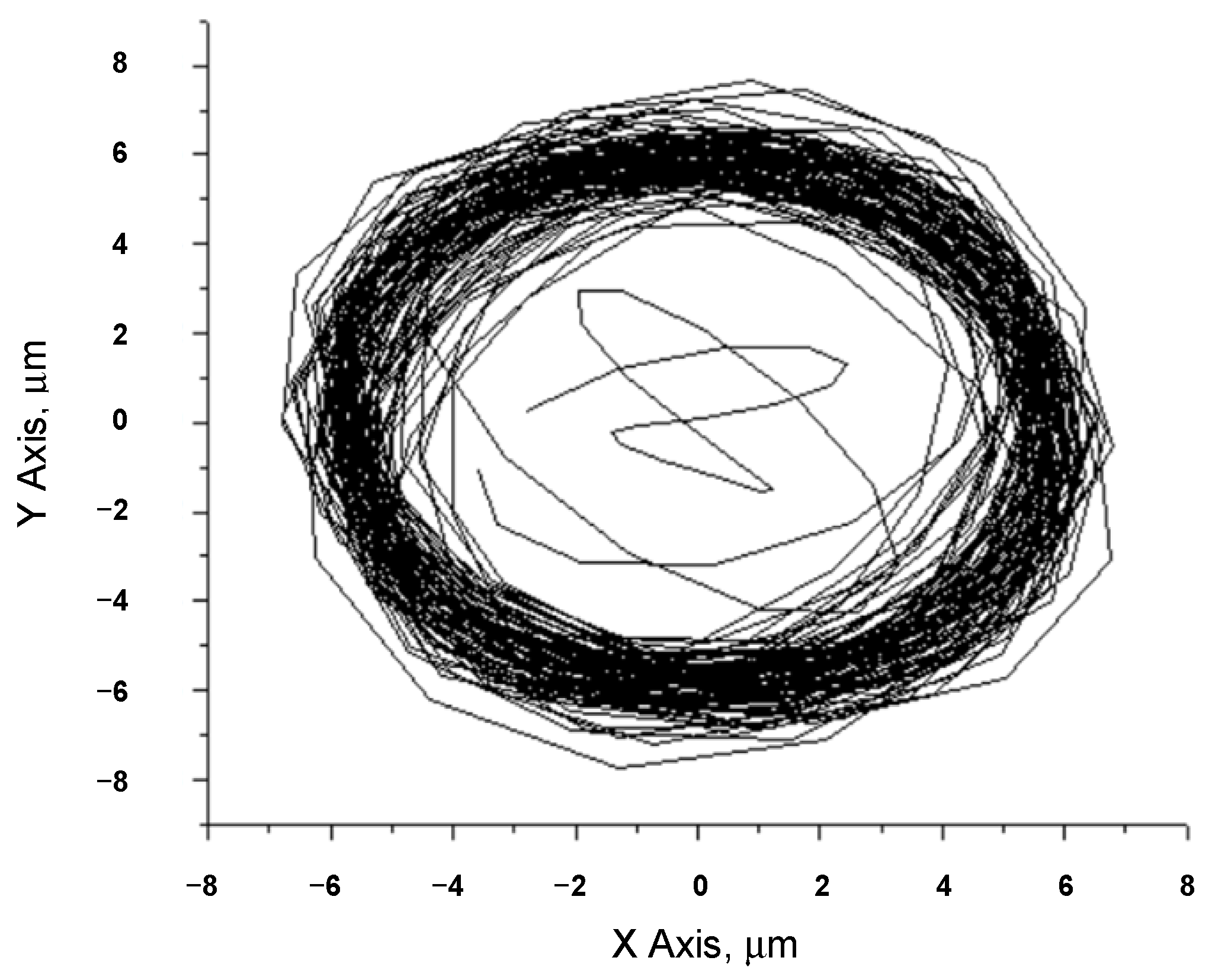

- I zone: 0–1938 rpm—zone of stable work.

- -

- II zone: 1938–3923 rpm—rotor rotation critical zone because the rotor is exposed to oil whirl.

- -

- III zone: 3923–5000 rpm—zone of stable work.

Funding

Data Availability Statement

Conflicts of Interest

References

- Allmaier, H.; Priestner, C.; Six, C.; Priebsch, H.H.; Forstner, C.; Novotny-Farkas, F. Predicting friction reliably and accurately in journal bearings-a systematic validation of simulation results with experimental measurements. Tribol. Int. 2011, 44, 1151–1160. [Google Scholar] [CrossRef]

- Dimond, T.; Younan, A.; Allaire, P. A review of tilting pad bearing theory. Int. J. Rotating Mach. 2011, 2011, 908469. [Google Scholar] [CrossRef]

- Vannini, G.; Cangioli, F.; Ciulli, E.; Nuti, M.; Forte, P.; Kim, J.; Livermore-Hardy, R. Experiments on a Large Flexure Pivot Journal Bearing: Summary of Test Results and Comparison With Predictions. J. Eng. Gas Turbines Power 2020, 142, 031004. [Google Scholar] [CrossRef]

- Liu, S.; Xiao, Z.; Yan, Z.; Chen, Z. Vibration characteristics of rotor system with tilting-pad journal bearing of elastic and damped pivots. J. Cent. South Univ. 2015, 22, 134–140. [Google Scholar] [CrossRef]

- Ondrouch, J.; Ferfecki, P.; Poruba, Z. Active vibration reduction of rigid rotor by kinematic excitation of bushes of journal bearings. Metalurgija 2010, 49, 107–110. [Google Scholar]

- Tejas, H.P.; Darpe, A.K. Vibration response of a cracked rotor in presence of rotor–stator rub. J. Sound Vib. 2008, 317, 841–865. [Google Scholar] [CrossRef]

- Garoli, G.Y.; de Castro, H.F. Analysis of a rotor-bearing nonlinear system model considering fluid-induced instability and uncertainties in bearings. J. Sound Vib. 2019, 448, 108–129. [Google Scholar] [CrossRef]

- Bently, D.E. Rotating Machinery Measurements 101. Orbit 1994, 15, 4–6. [Google Scholar]

- San, A.L.; Koo, B.; Hemmi, M. A Flow Starvation Model for Tilting-Pad Journal Bearings and Evaluation of Frequency Response Functions: A Contribution Toward Understanding the Onset of Low Frequency Shaft Motions. J. Eng. Gas Turbines Powder Trans. ASME 2018, 140, 052506. [Google Scholar] [CrossRef]

- Wu, X.L.; Jiao, Y.H.; Chen, Z.B.; Ma, W.S. Establishment of a contact stiffness matrix and its effect on the dynamic behavior of rod-fastening rotor bearing system. Arch. Appl. Mech. 2021, 91, 3247–3271. [Google Scholar] [CrossRef]

- Safizadeh, M.S.; Golmohammadi, A. Prediction of oil whirl initiation in journal bearings using multi-sensors data fusion. Measurement 2020, 151, 107241. [Google Scholar] [CrossRef]

- Ryu, K.; Ashton, Z. Bump-Type Foil Bearings and Flexure Pivot Tilting-Pad Bearings for Oil-Free Automotive Turbochargers: Highlights in Rotordynamic Performance. J. Eng. Gas Turbines Powder Trans. ASME 2016, 138, 042501. [Google Scholar] [CrossRef]

- Tong, X.; Palazzolo, A. Measurement and Prediction of the Journal Circumferential Temperature Distribution for the Rotordynamic Morton Effect. J. Tribol. Trans. ASME 2018, 140, 031702. [Google Scholar] [CrossRef]

- Galvao, M.M.; Menon, G.J.; Schwarz, V.A. Numerical study of the influence of the pivot position on the steady-state behavior of tilting-pad thrust bearings. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3165–3180. [Google Scholar] [CrossRef]

- Hagemann, T.; Zeh, C.; Proelss, M.; Schwarze, H. The Impact of Convective Fluid Inertia Forces on Operation of Tilting-Pad Journal Bearings. Int. J. Rotating Mach. 2017, 2017, 5683763. [Google Scholar] [CrossRef]

- Wang, L.; Fu, Y.; Pei, S.; Xu, H. Theoretical and Experimental Study on the Axial Oil Film Stiffness of Tilting-Pad Thrust Bearings. Tribol. Trans. 2017, 60, 419–427. [Google Scholar] [CrossRef]

- Fan, C.C.; Syu, J.W.; Pan, M.C.; Tsao, W.C. Study of start-up vibration response for oil whirl, oil whip and dry whip. Mech. Syst. Signal Process. 2011, 25, 3102–3115. [Google Scholar] [CrossRef]

- Ramos, D.J.; Daniel, G.B. A new concept of active hydrodynamic bearing for application in rotating systems. Tribol. Int. 2021, 153, 106592. [Google Scholar] [CrossRef]

- Luo, L.Y.; Fan, Y.H.; Tang, J.H.; Chen, T.Y.; Zhong, N.R.; Feng, P.C.; Kao, Y.C. Frequency Enhancement of Oil Whip and Oil Whirl in a Ferrofluid–Lubricated Hydrodynamic Bearing–Rotor System by Magnetic Field with Permanent Magnets. Appl. Sci. 2018, 8, 1687. [Google Scholar] [CrossRef]

- Silva, H.A.P.; Nicoletti, R. Rotor vibration control using tilting-pad journal bearing with active pads — Numerical and experimental results. J. Sound Vib. 2023, 546, 117441. [Google Scholar] [CrossRef]

- Schweizer, B. Oil whirl, oil whip and whirl/whip synchronization occurring in rotor systems with full-floating ring bearings. Nonlinear Dyn. 2009, 57, 509–532. [Google Scholar] [CrossRef]

- Ding, A.; Ren, X.; Li, X.; Gu, C. Numerical Investigation of Turbulence Models for a Superlaminar Journal Bearing. Adv. Tribol. 2018, 2018, 2841303. [Google Scholar] [CrossRef]

- Zywica, G.; Olszewski, A.; Baginski, P.; Andrearczyk, A.; Zochowski, T.; Klonowicz, P. Theoretical analysis and experimental tests of tilting pad journal bearings with shoes made of polymer material and low-boiling liquid lubrication. Tribol. Int. 2023, 189, 108991. [Google Scholar] [CrossRef]

- Hekmat, M.H.; Biukpour, G.A. Numerical study of the oil whirl phenomenon in a hydrodynamic journal bearing. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 218. [Google Scholar] [CrossRef]

- Li, S.; Zhou, C.; Savin, L.; Shutin, D.; Kornaev, A.; Polyakov, R.; Chen, Z. Theoretical and experimental study of motion suppression and friction reduction of rotor systems with active hybrid fluid-film bearings. Mech. Syst. Signal Process 2023, 182, 109548. [Google Scholar] [CrossRef]

- Chasalevris, A.; Sfyris, D. Evaluation of the finite journal bearing characteristics, using the exact analytical solution of the Reynolds equation. Tribol. Int. 2013, 57, 216–234. [Google Scholar] [CrossRef]

- Liu, H.; Xu, H.; Ellison, P.J.; Jin, Z. Application of computational fluid dynamics and fluid-structure interaction method to the lubrication study of a rotor-bearing system. Tribol. Lett. 2010, 38, 325–336. [Google Scholar] [CrossRef]

- Tong, X.A.; Palazzolo, A.; Suh, J. Review of the Rotordynamic Thermally Induced Synchronous Instability (Morton) Effect. ASME Appl. Mech. Rev. 2017, 69, 060801. [Google Scholar] [CrossRef]

- Muszynska, A.; Bently, D.E. Fluid-induced instabilities of rotors: Whirl and whip—Summary of results. Orbit 1996, 17, 7–15. [Google Scholar]

- Muszynska, A. Alford and the destabilizing forces that lead to fluid whirl/whip. Orbit 1998, 19, 29–31. [Google Scholar]

- Muszynska, A.; Hatch, C.T. Oil whip of a rotor supported in a poorly lubricated bearing. Orbit 1998, 19, 4–8. [Google Scholar]

- Wang, W.M.; Liu, B.B.; Zhang, Y.; Shao, X.; Allaire, P.E. Theoretical and experimental study on the static and dynamic characteristics of tilting-pad thrust bearing. Tribol. Int. 2018, 123, 26–36. [Google Scholar] [CrossRef]

- Shen, J.; Xiong, X.; Li, G.; Wang, X.; Hua, Z.; Nie, Z. Experimental Analysis of Dynamic Oil Film Pressure of Tilting-Pad Journal Bearings. Tribol. Lett. 2016, 63, 36. [Google Scholar] [CrossRef]

- Grigor’ev, B.S.; Fedorov, A.E. A New Improved Method for Calculating Dynamic Coefficients of Fluid Film Bearings. J. Mach. Manuf. Reliab. 2016, 45, 59–64. [Google Scholar] [CrossRef]

- Muszynska, A. Vibrational diagnostics of rotating machinery malfunctions. Int. J. Rotating Mach. 1995, 1, 237–266. [Google Scholar] [CrossRef]

- Marcinkevičius, A.H. Automatic regulation of clearance in a tilting pad journal bearing. Mechanika 2012, 18, 192–195. [Google Scholar] [CrossRef]

- Marcinkevičius, A.H.; Jurevičius, M. Automatic Control of Loading Forces in a Tilting Pad Journal Bearing. Hindawi Publ. Corp. Adv. Mech. Eng. 2014, 6, 590695. [Google Scholar] [CrossRef]

- Tong, X.; Xu, W.; Shi, Y.; Cai, M.; Palazzolo, A. Transient rotordynamic thermal bow (Morton effect) modeling in flexure-pivot tilting pad bearing systems. Tribol. Int. 2023, 177, 107954. [Google Scholar] [CrossRef]

- Rodriguez, L.E.; Childs, D.W. Frequency dependency of measured and predicted rotordynamic coefficients for a load-on-pad flexible-pivot tilting-pad bearing. J. Tribol. 2006, 128, 388–395. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, W.; Chen, S.; Lu, C.; Zhang, Y. Research on trajectory control of rotor systems supported by a combination of rolling and hydrostatic bearings. Precis. Eng. 2024, 88, 475–486. [Google Scholar] [CrossRef]

- Carbonara, A.F.; Duarte, D., Jr.; Bittencourt, M.L. Comparison of journal orbits under hydrodynamic lubrication regime for traditional and Newton-Euler loads in combustion engines. Lat. Am. J. Solids Struct. 2009, 6, 13–33. [Google Scholar]

- Hargreaves, D.J.; Fillon, M. Analysis of a tilting pad journal bearing to avoid pad fluttering. Tribol. Int. 2007, 40, 607–612. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Y.; Wang, Y.; Liu, X.; Wang, Y. Influence of squeezing and interface slippage on the performance of water-lubricated tilting-pad thrust bearing during start-up and shutdown. Lubr. Sci. 2018, 30, 137–148. [Google Scholar] [CrossRef]

- Gropper, D.; Harvey, T.J.; Wang, L. Numerical analysis and optimization of surface textures for a tilting pad thrust bearing. Tribol. Int. 2018, 124, 134–144. [Google Scholar] [CrossRef]

- Suh, J.; Palazzolo, A. Numerical modeling and analysis of flexure-pivot tilting-pad bearing. J. Tribol. 2017, 139, 051704. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, H.; Zhang, S.; Pei, S. A radial clearance adjustable bearing reduces the vibration response of the rotor system during acceleration. Tribol. Int. 2020, 144, 106112. [Google Scholar] [CrossRef]

- Barzdaitis, V.; Cinikas, G. Condition monitoring data formats used in rotating machinery diagnostics. Mechanika 1997, 2, 40–48. [Google Scholar]

- Vasylius, M.; Didžiokas, R.; Mažeika, P.; Barzdaitis, V. The rotating system vibration and diagnostics. Mechanika 2008, 72, 54–58. [Google Scholar]

- Bently, D.E.; Muszynska, A. Role of Circumferential Flow in the Stability of Fluid-Handling Machine Rotors. In Proceedings of the Fifth Workshop on Rotordynamics Instability Problems in High Performance Turbomachinery, Texas A&M University, College Station, TX, USA, 16–18 May 1988. [Google Scholar]

- Tuma, J.; Biloš, J. Fluid Induced Instability of Rotor Systems with Journal Bearings. Eng. Mech. 2007, 14, 69–80. [Google Scholar]

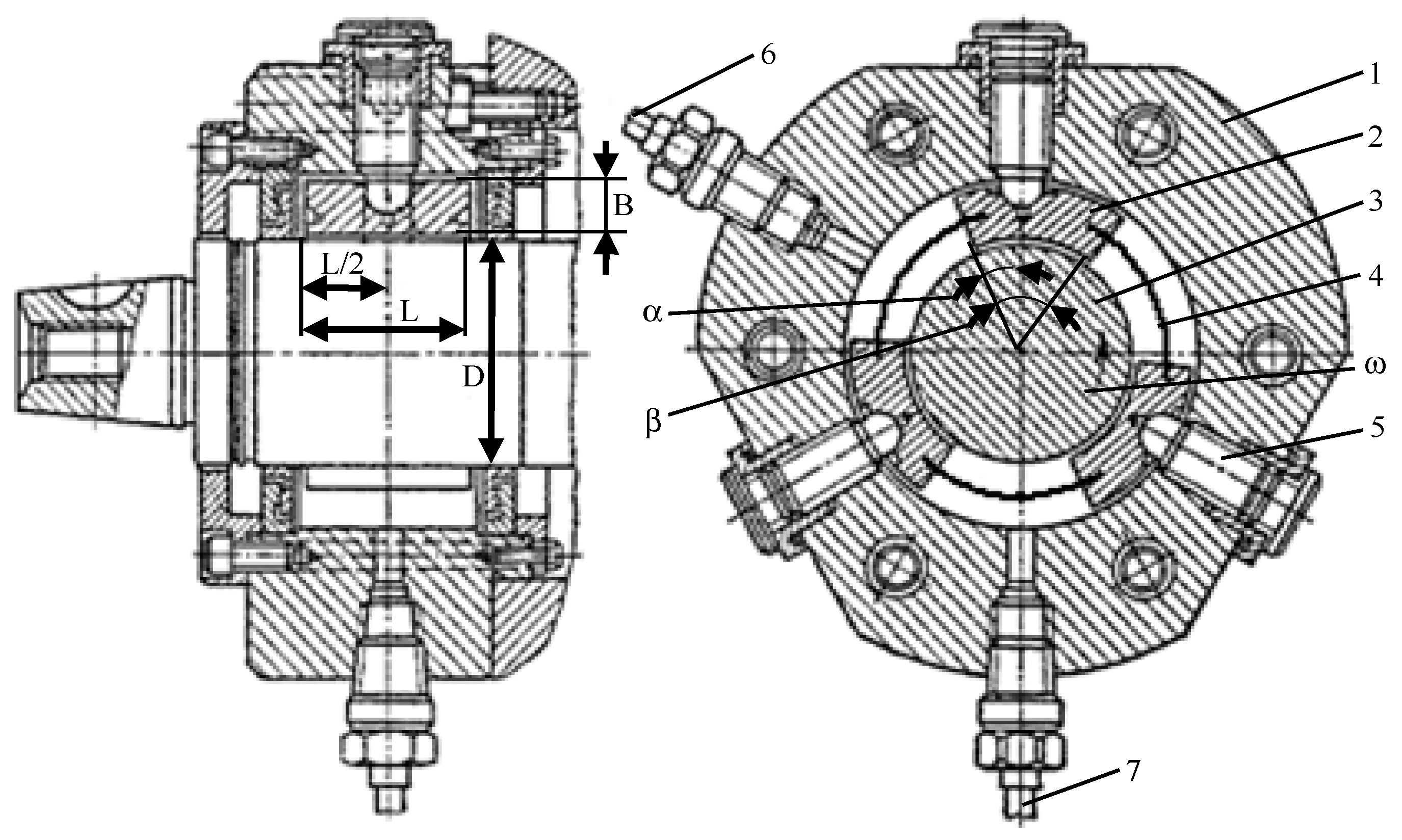

| Parameter | Size, Unit |

|---|---|

| Rotor diameter, D | 90, mm |

| Rotor length, L | 800, mm |

| Rotor roundness deviation | 1.0–0.2 μm |

| Rotor linearity deviation | 2–3, μm |

| Rotor hardness, HV | 850–1050 |

| Rotor surface roughness, Ra | 0.04–0.08, μm |

| Tilting pad width, L | 70, mm |

| Tilting pad half width, L/2 | 35, mm |

| Tilting pad thickness, B | 40, mm |

| Tilting pad angle, β | 60° |

| Tilting pad fastening angle, α | 24°30′ |

| Tilting pad roughness, Ra | 0.32, μm |

| The length of the elastic element, L | 70, mm |

| The hardness of the elastic element, HRC | 42–48 |

| Density of the elastic element, ρ | 7680 kg/m3 (20 °C), 7660 kg/m3 (100 °C) |

| Modulus of elastic element, E | 2.12 × 10−5 MPa (20 °C), 2.06 × 10−5 MPa (100 °C) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Čereška, A. Control the Working Process of the Rotor System with Tilting Pad Bearing. Processes 2024, 12, 2583. https://doi.org/10.3390/pr12112583

Čereška A. Control the Working Process of the Rotor System with Tilting Pad Bearing. Processes. 2024; 12(11):2583. https://doi.org/10.3390/pr12112583

Chicago/Turabian StyleČereška, Audrius. 2024. "Control the Working Process of the Rotor System with Tilting Pad Bearing" Processes 12, no. 11: 2583. https://doi.org/10.3390/pr12112583

APA StyleČereška, A. (2024). Control the Working Process of the Rotor System with Tilting Pad Bearing. Processes, 12(11), 2583. https://doi.org/10.3390/pr12112583