Evaluation and Application of Wellbore Stability of Deep Oil Wells in the Southern Margin of Junggar Basin

Abstract

1. Introduction

2. Reservoir Rock Mechanics Experiment and Stress Prediction

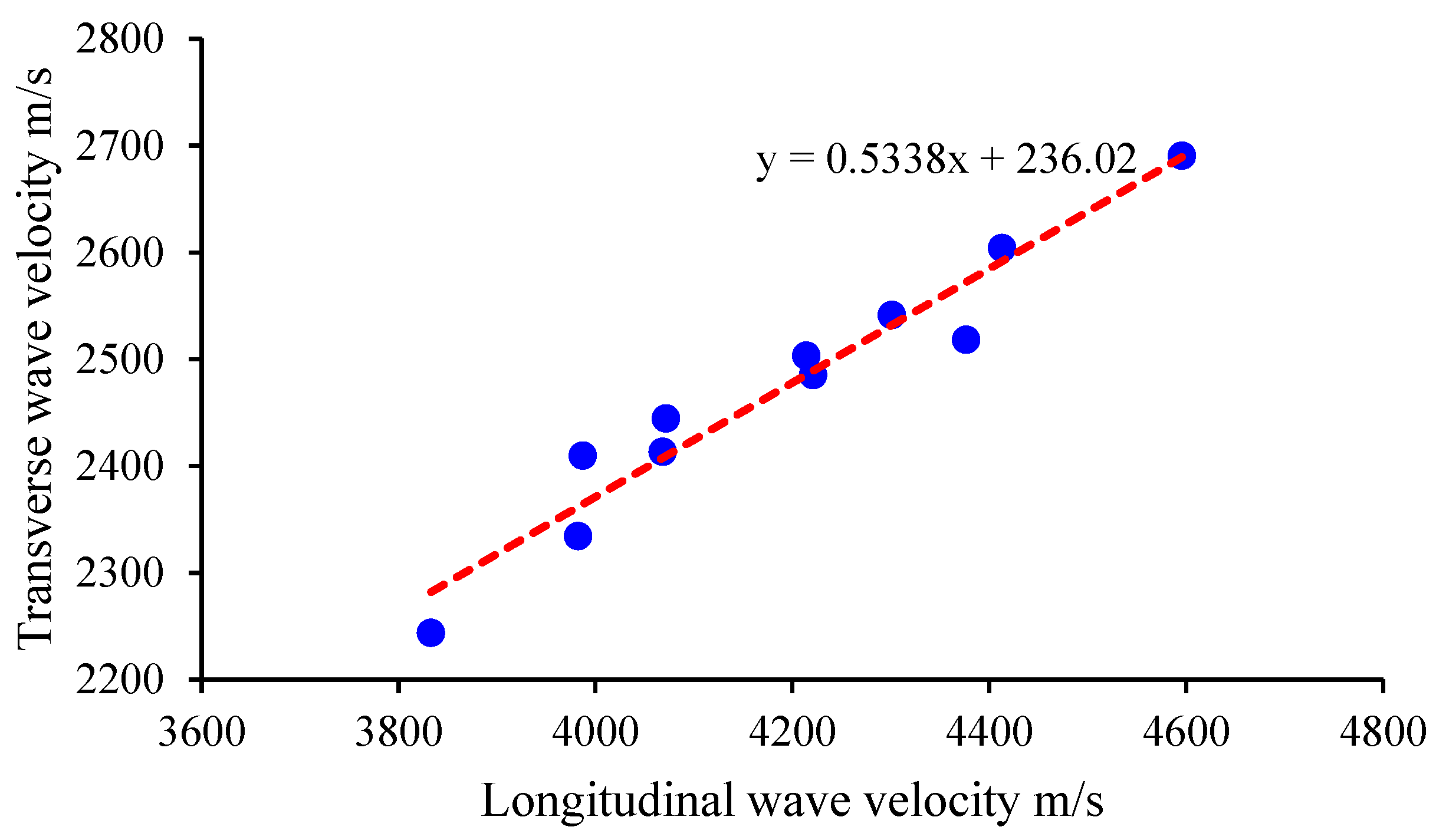

2.1. Acoustic Time Difference Measurement

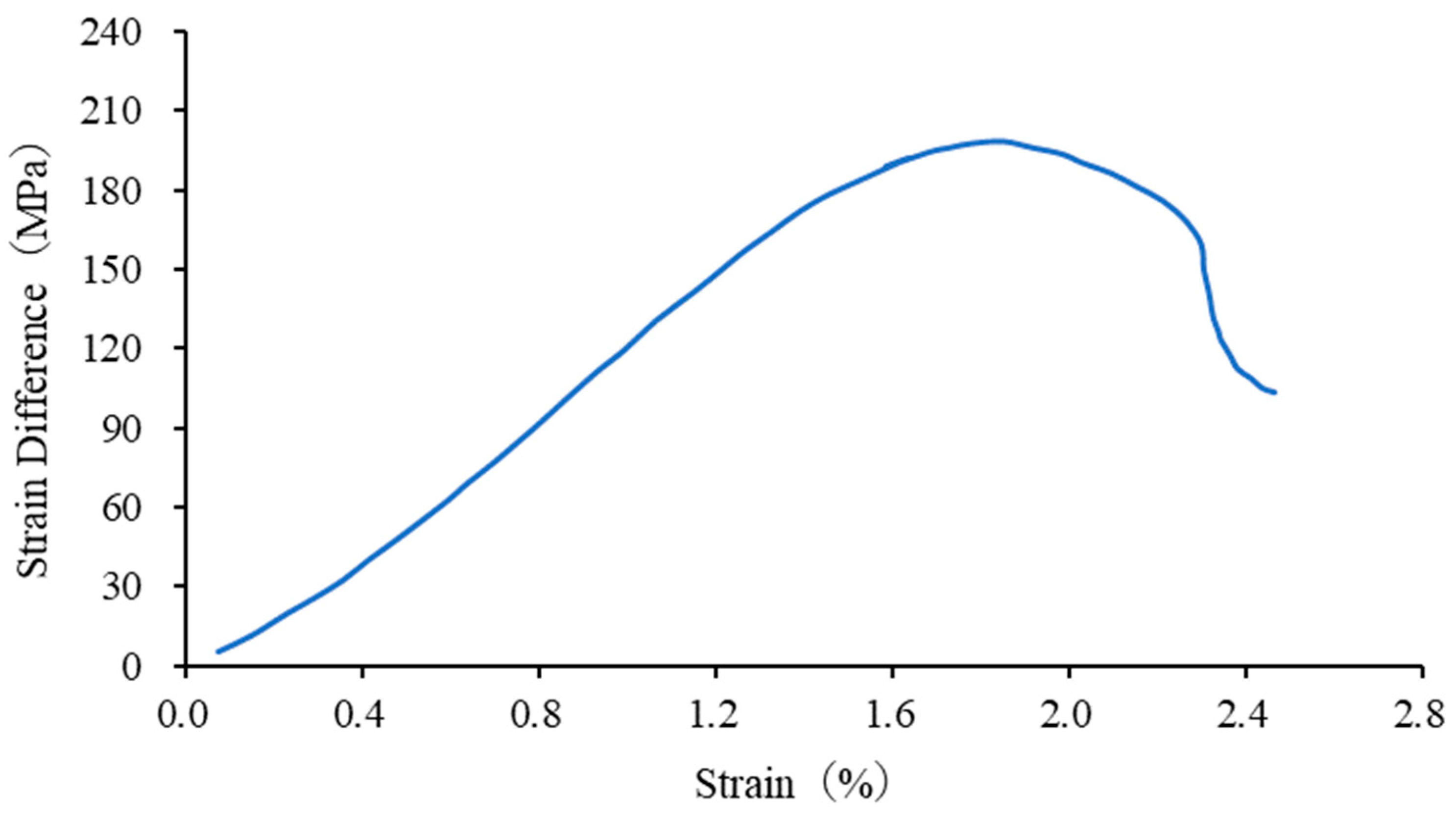

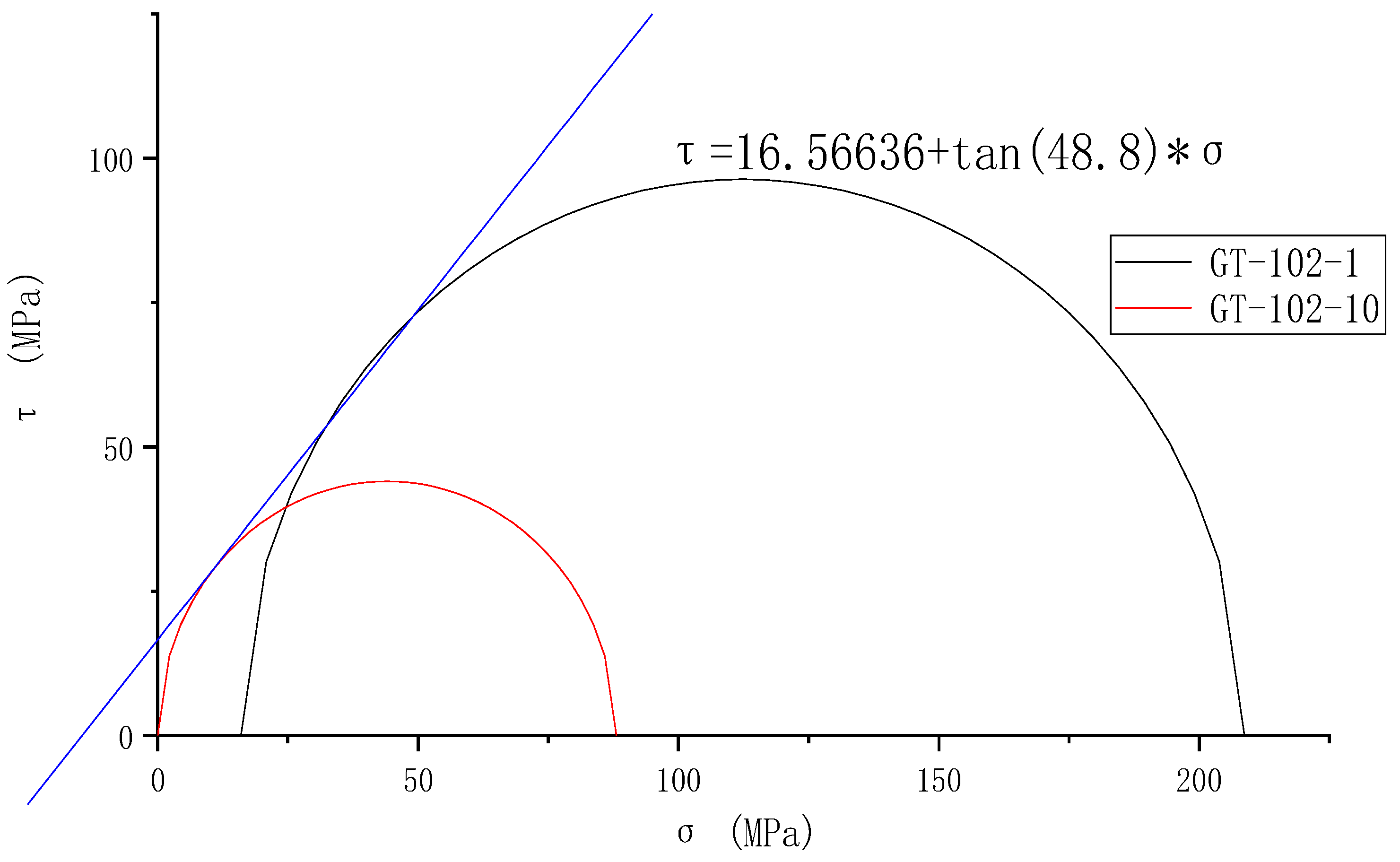

2.2. Triaxial Stress Experiment

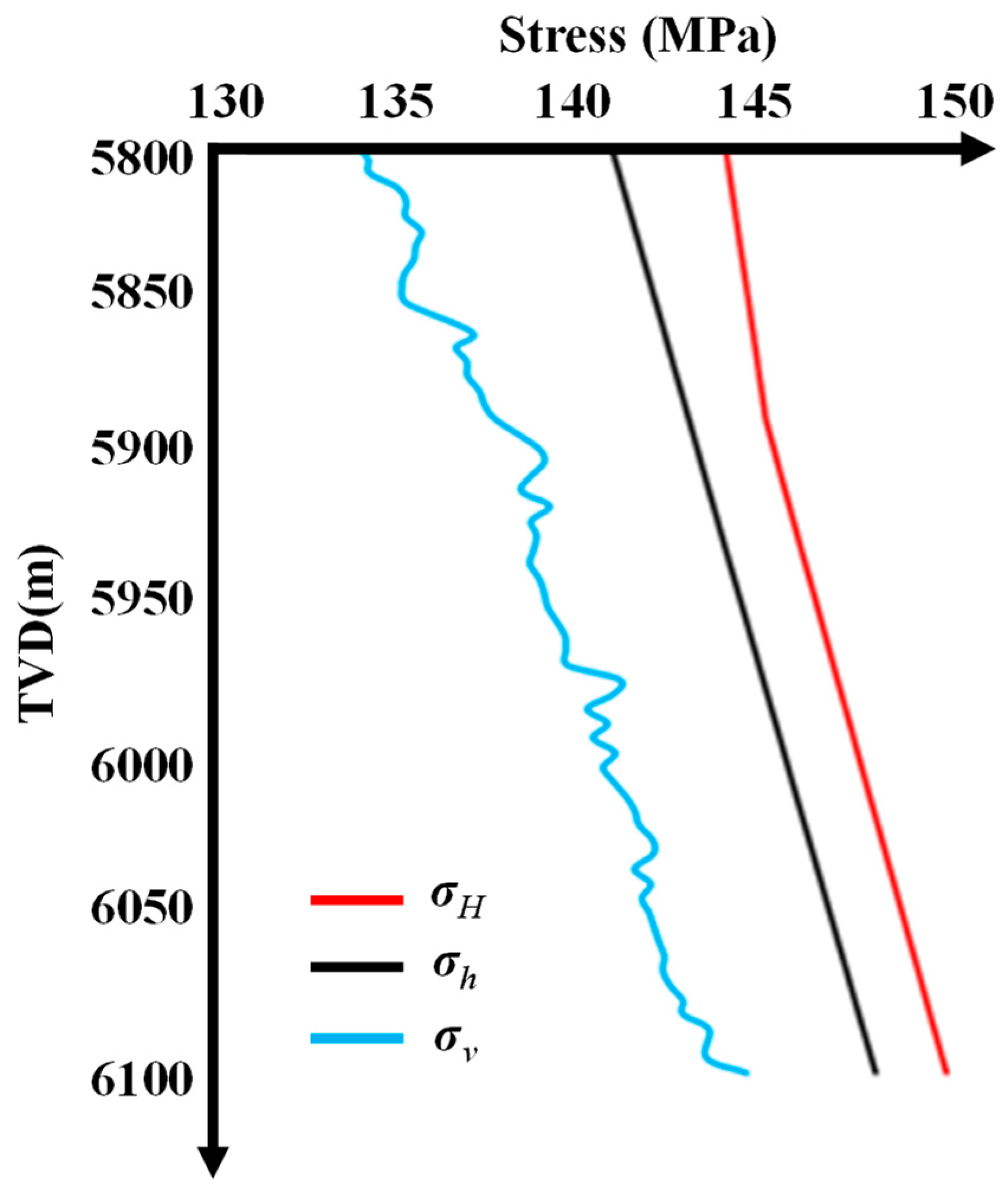

2.3. Geostress Parameter Profile

3. Evaluation Model for Wellbore Stability

4. Evaluation of the Stability of the Wellbore

4.1. Stability of Wellbore under Original Formation Pressure

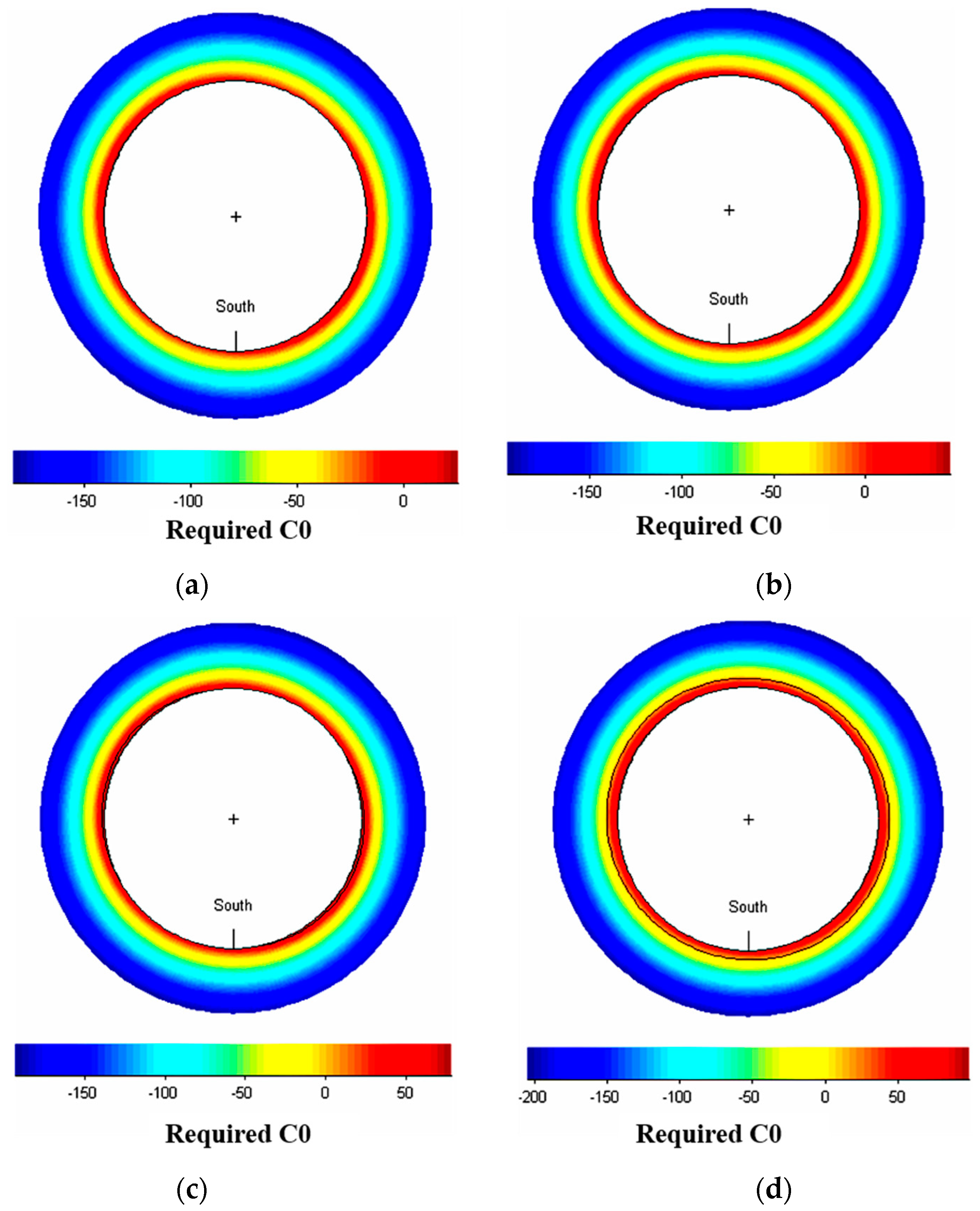

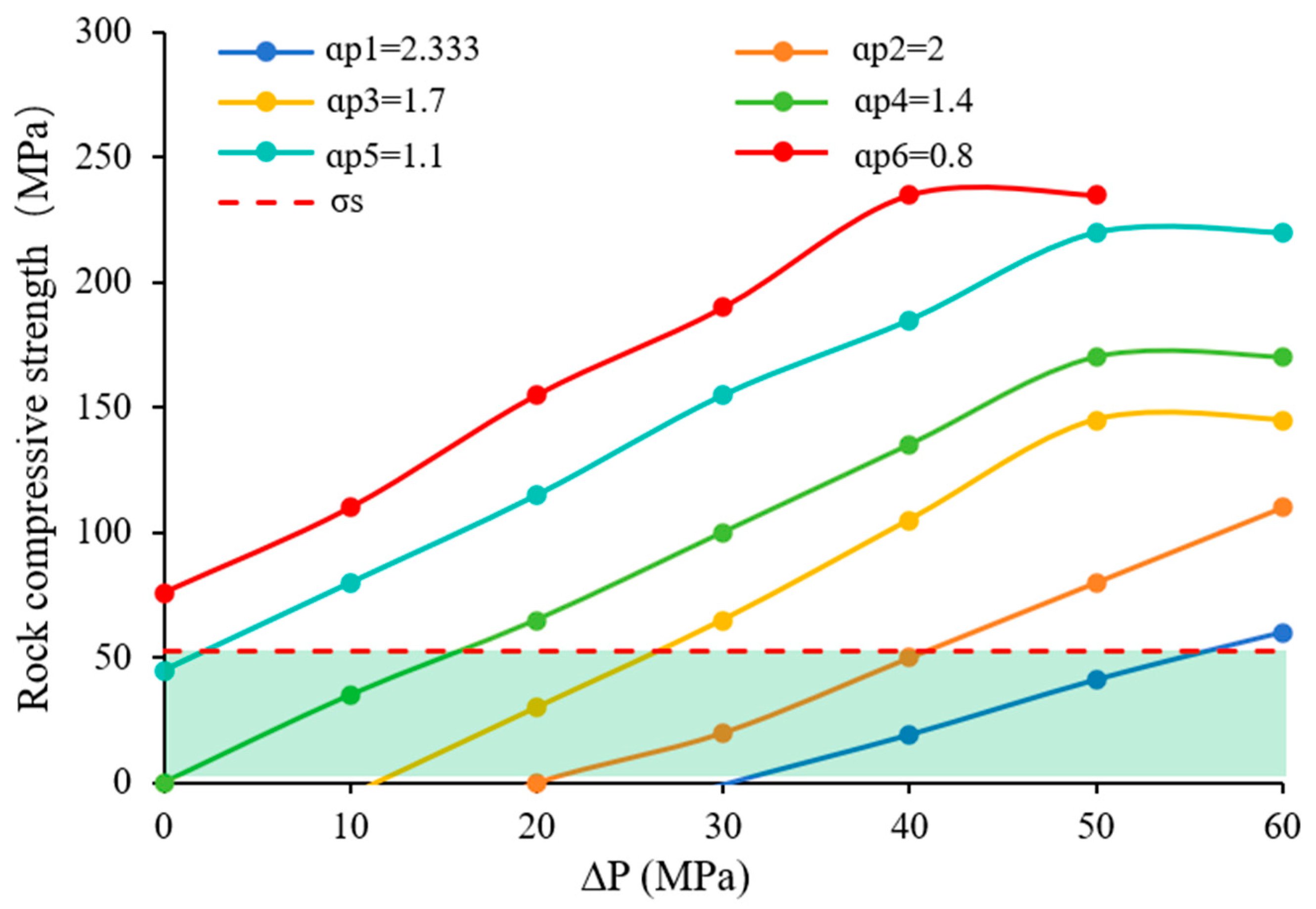

4.2. Impact of Formation Pressure Drop on Wellbore Stability

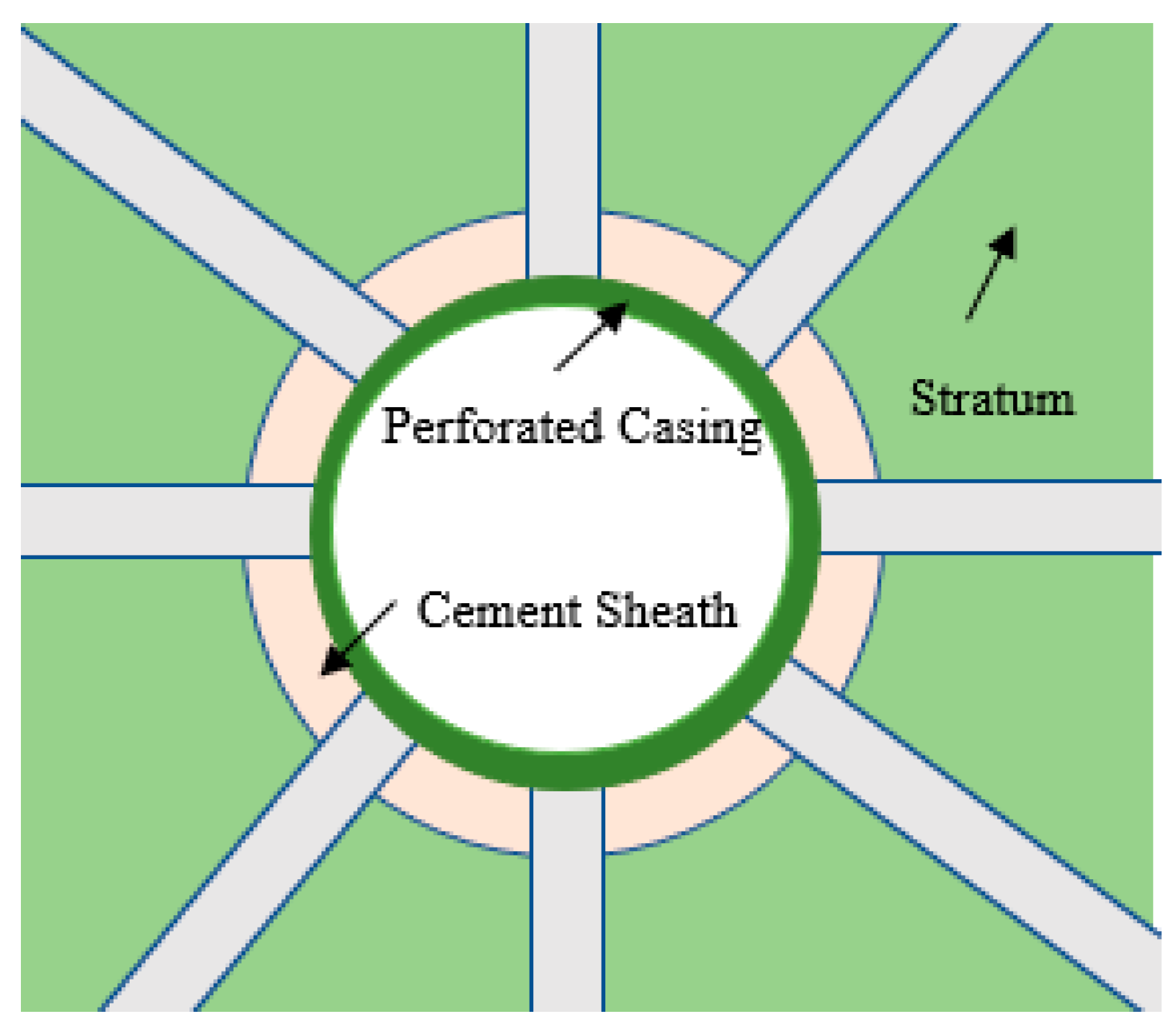

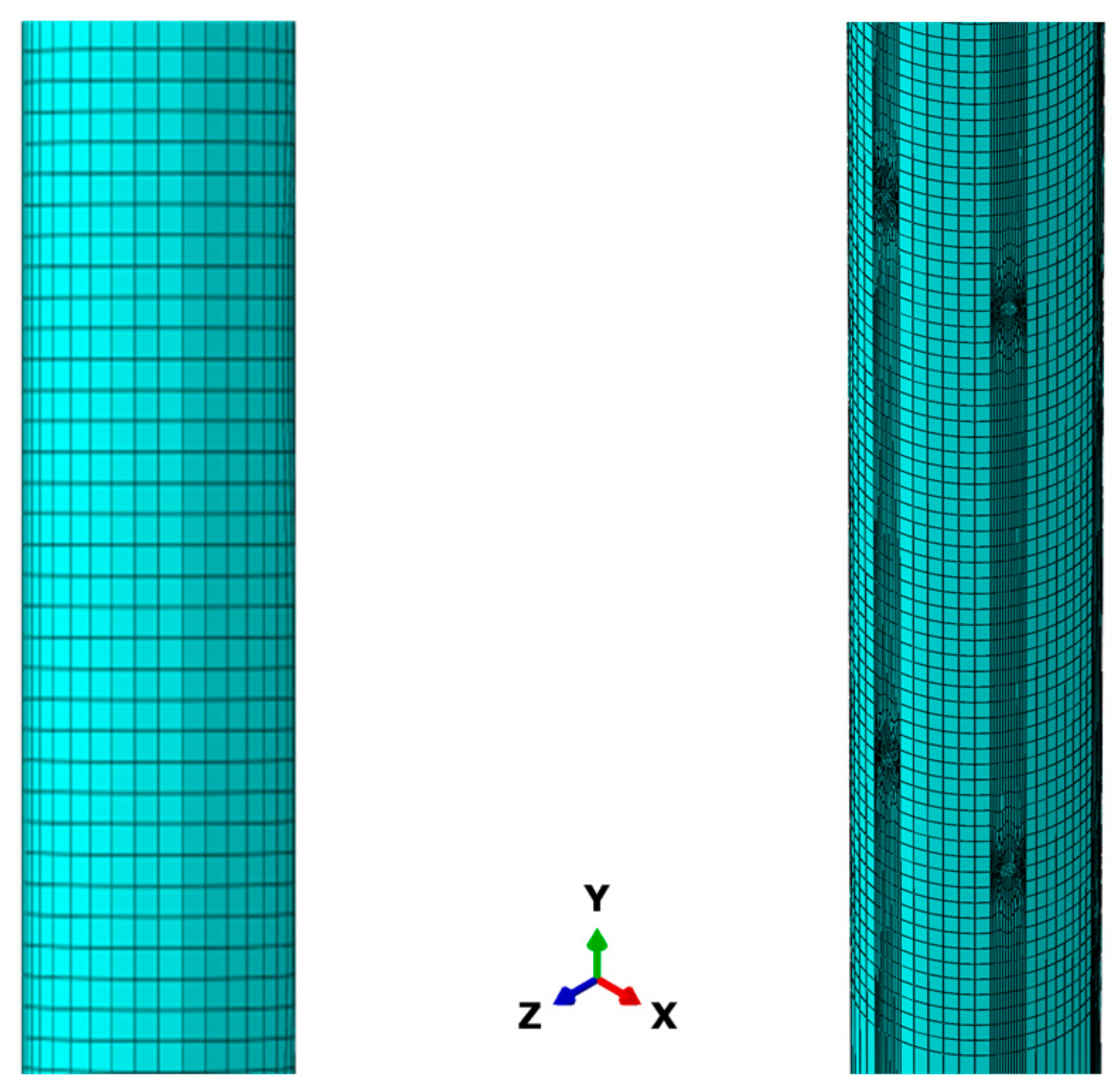

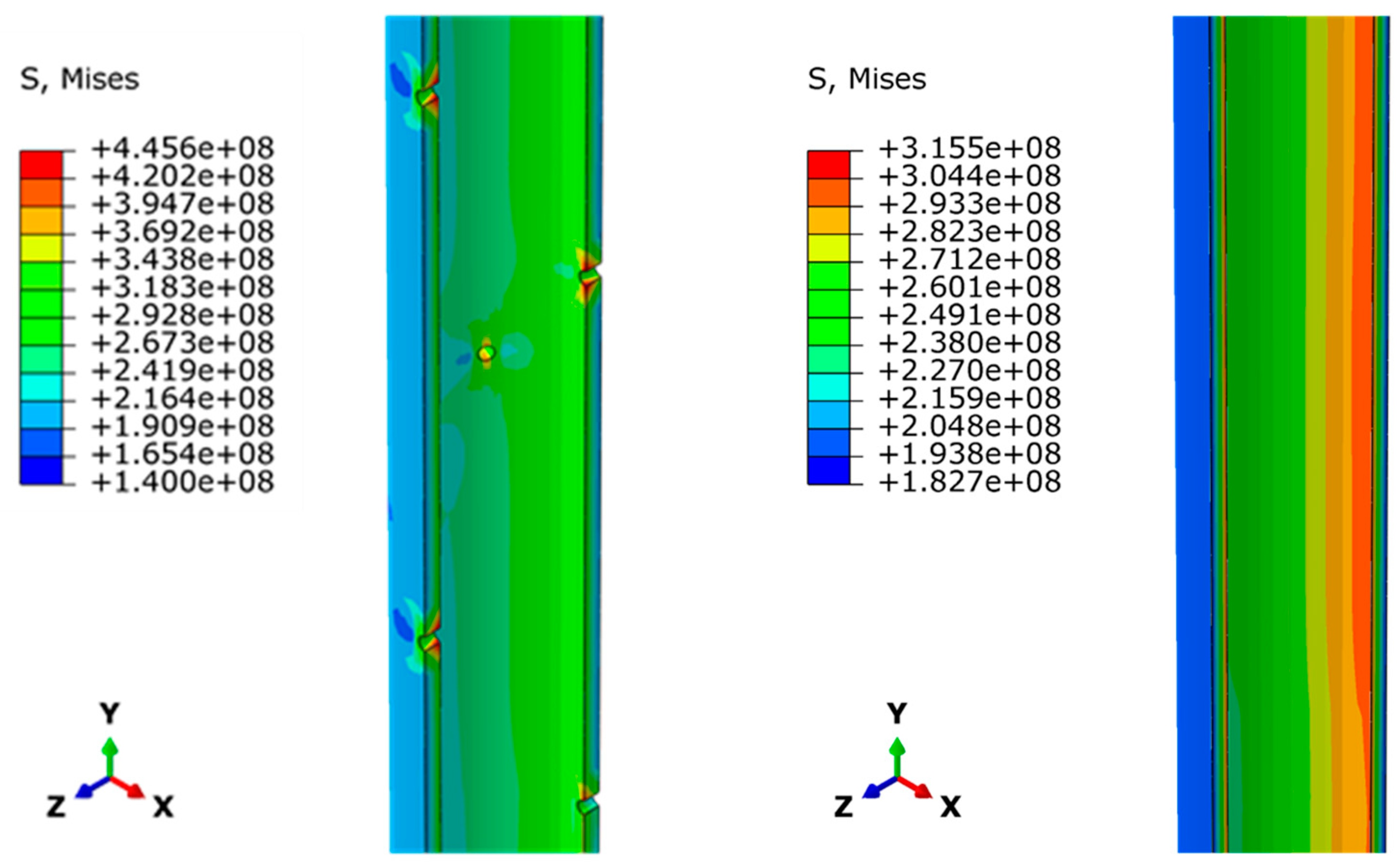

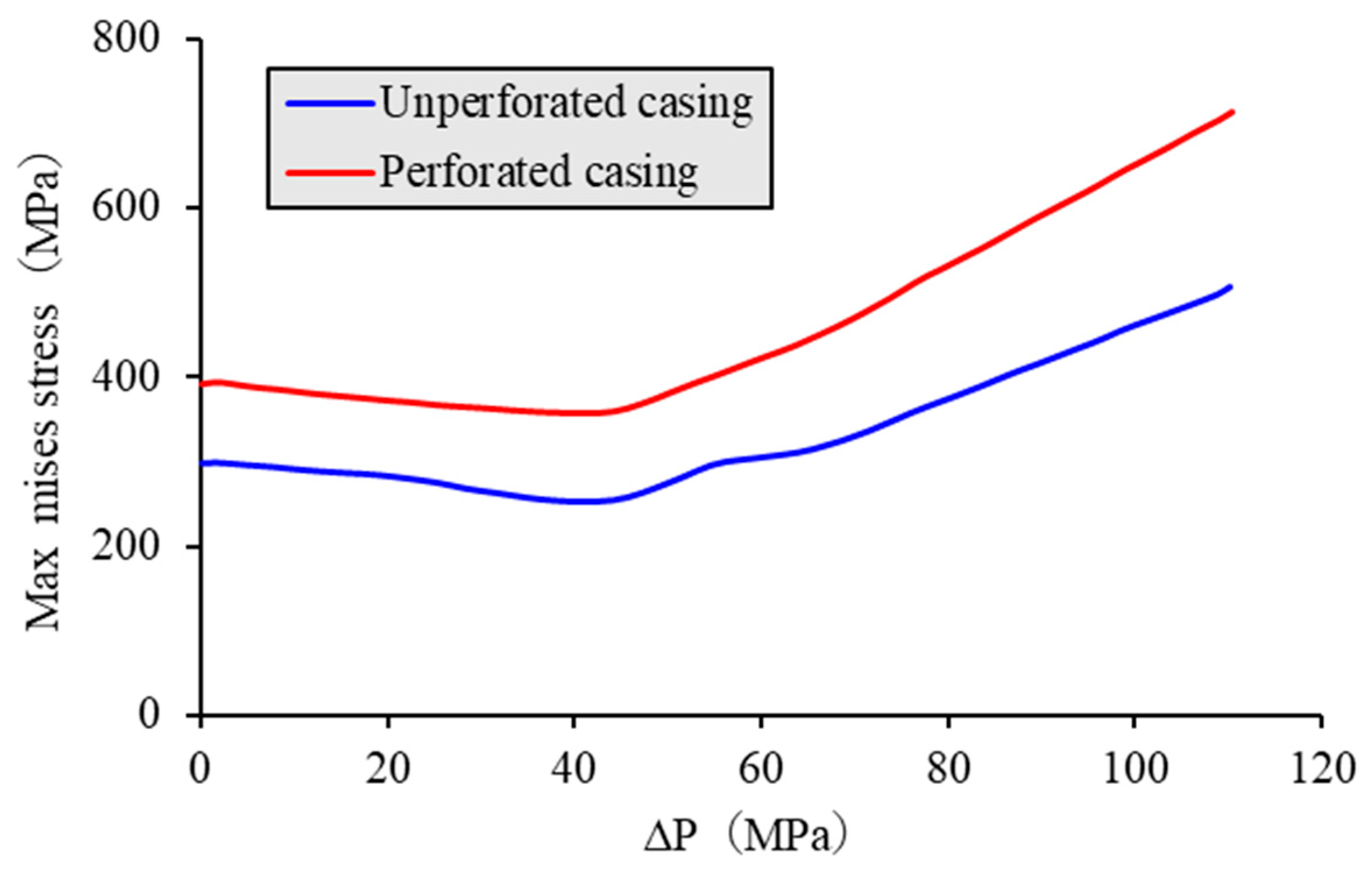

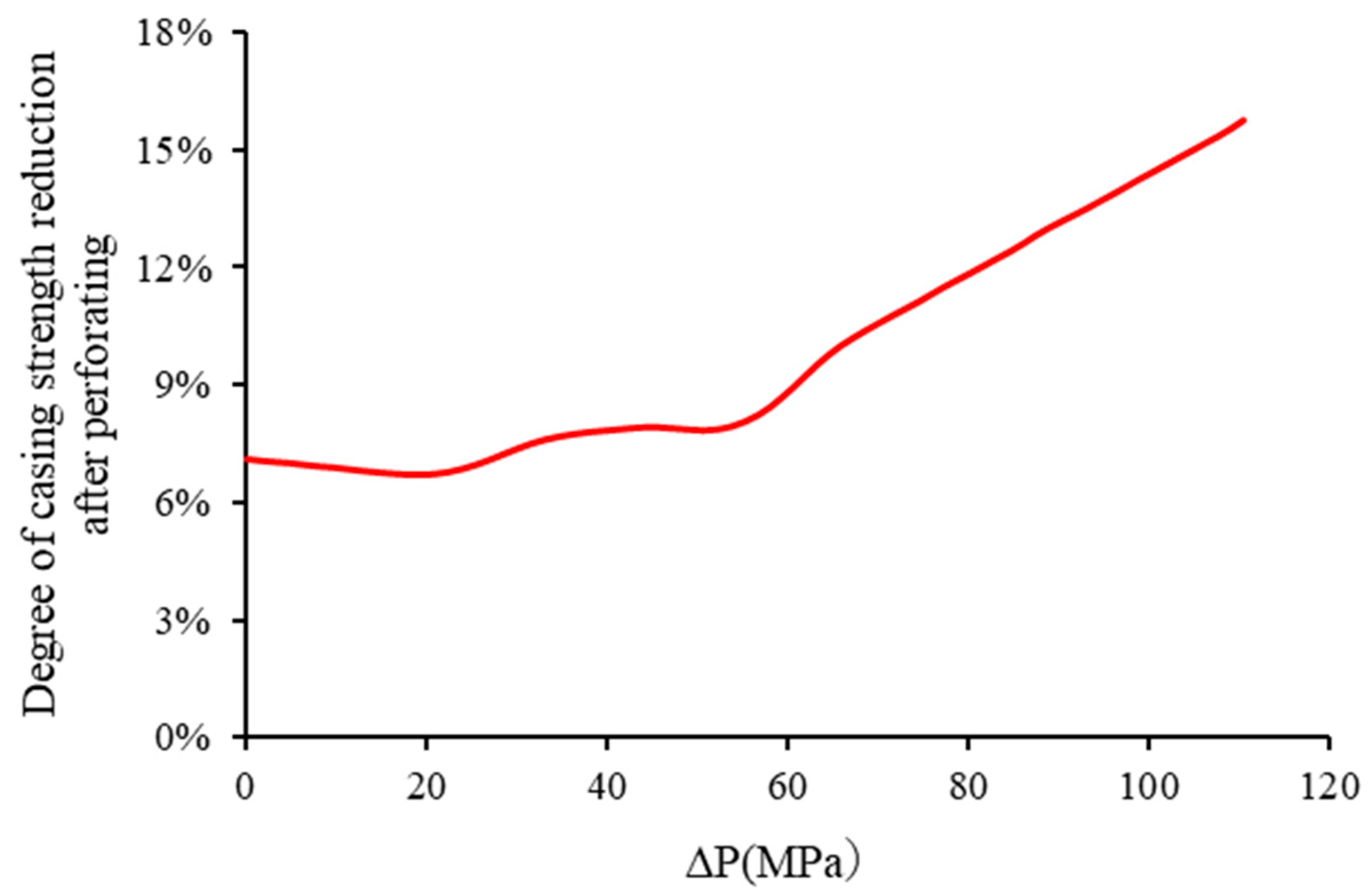

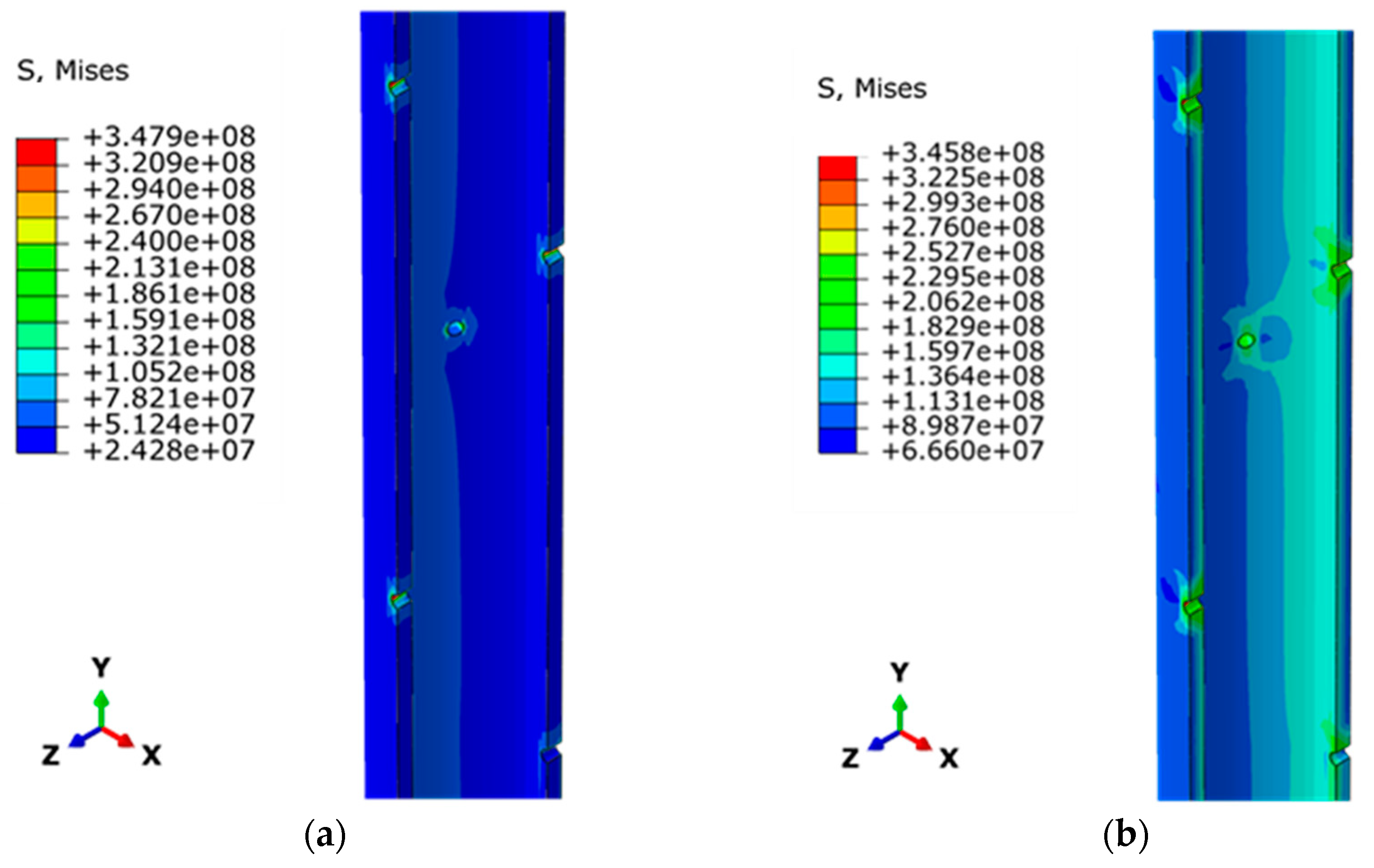

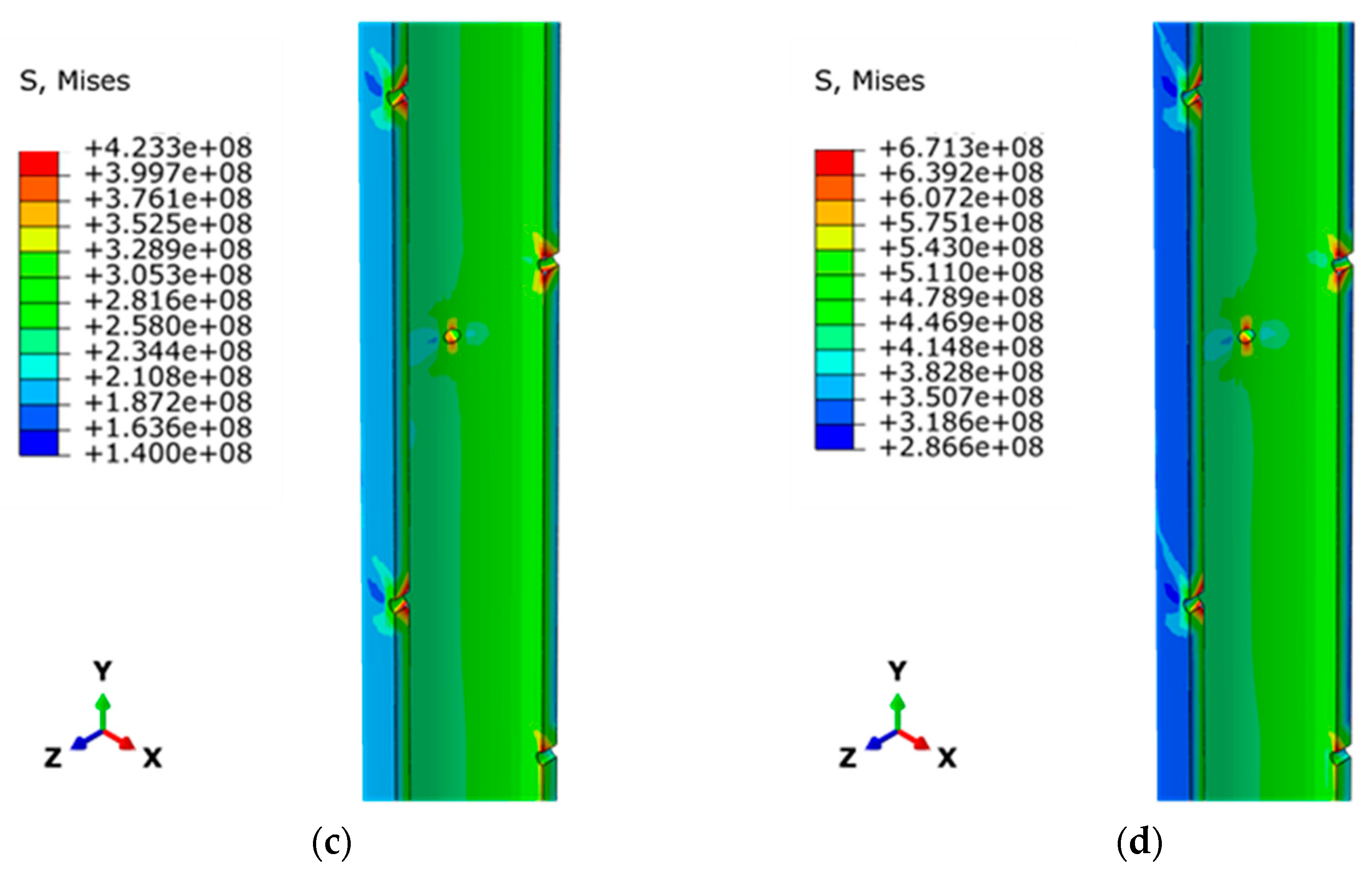

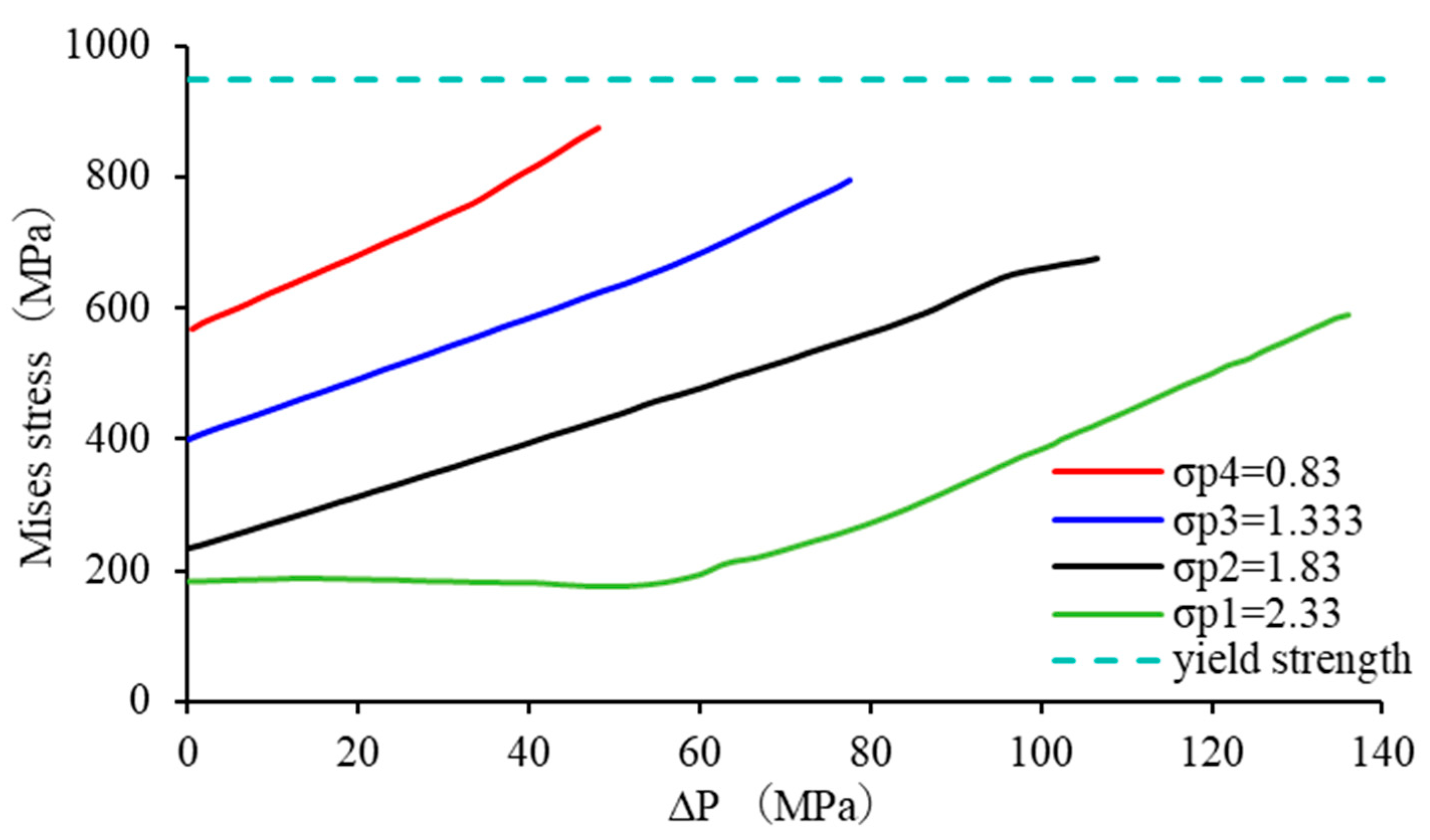

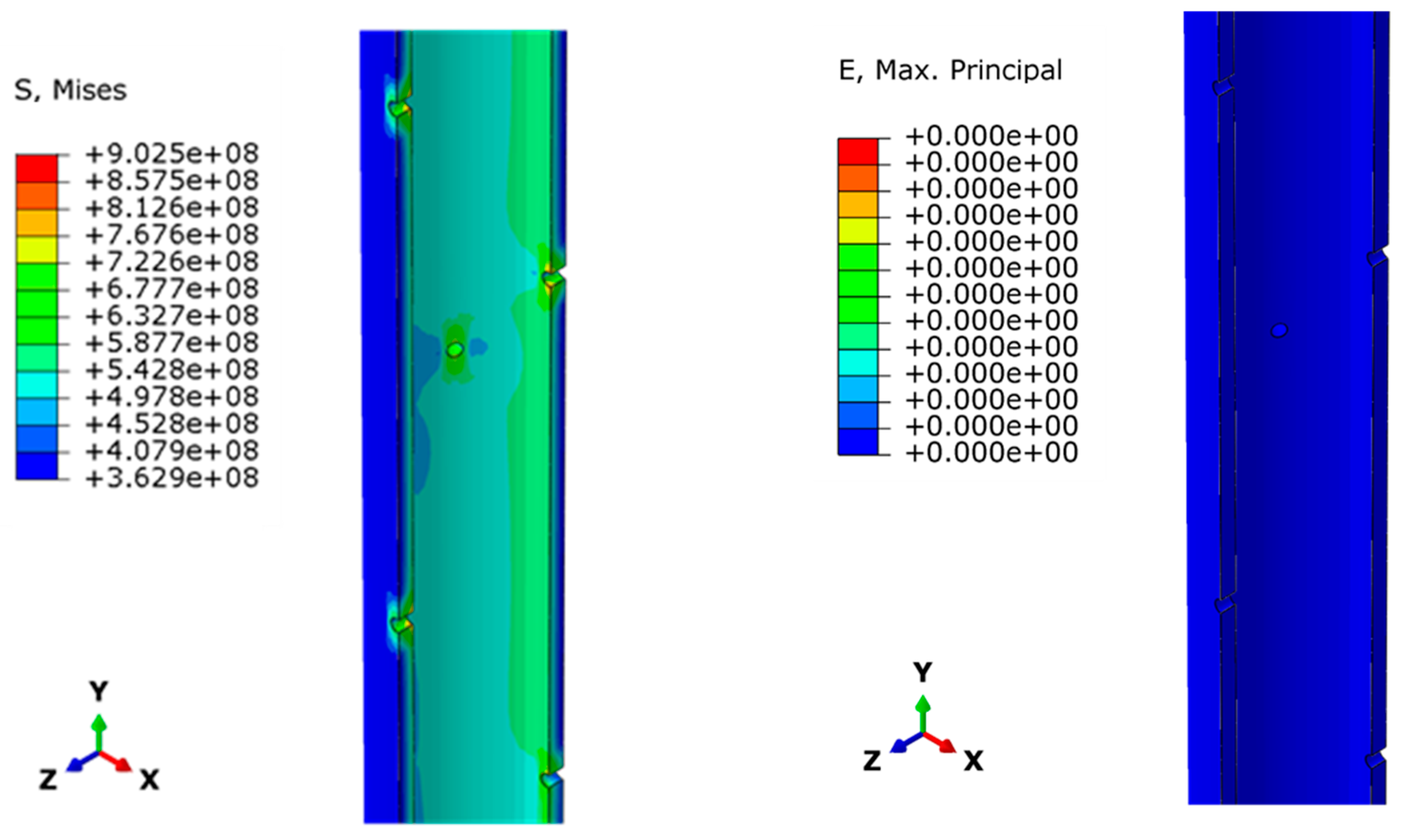

4.3. Effect of Perforation on Casing Strength

4.4. Evaluation of Perforation Completion Casing Stability

5. Conclusions

- (1)

- Based on the target deep core samples, longitudinal and transverse wave acoustic testing and rock mechanics parameter testing were conducted. Based on the logging curve and mechanical correction relationship of the G102 well, the static rock mechanics parameters and stress distribution profile of the target well were accurately predicted.

- (2)

- During the production process, as the formation pressure decreases, the critical collapse pressure difference in the wellbore rock decreases significantly. The greater the production pressure difference, the greater the possibility of rock damage to the wellbore.

- (3)

- Due to the small elastic modulus of the cement sheath and its buffering effect between the formation and casing, the stress on the casing slightly decreases and then increases again with the increase in the production pressure difference during perforation completion. The stress concentration on the perforation casing mainly occurs at the perforation hole. When the pressure inside the wellbore decreases, the higher the formation pressure coefficient, the greater the maximum stress on the perforated casing.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, B.; Xu, C.; Zhang, H.; Guo, Y.; Yang, J.; Li, Y.; Zhao, J. Research progress and countermeasures for wellbore instability mechanism in deep fractured formations. Acta Pet. Sin. 2024, 45, 875–888. [Google Scholar]

- Meng, H.; Ge, H.; Fu, D.; Wang, X.; Shen, Y.; Jiang, Z.; Wang, J. Numerical investigation of casing shear deformation due to fracture/fault slip during hydraulic fracturing. Energy Sci. Eng. 2020, 8, 3588–3601. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, X.; Liang, L.; Xiong, J.; Li, W.; Wei, X.; Duan, X.; Hou, L. Wellbore stability model in shale formation under the synergistic effect of stress unloading-hydration. Pet. Explor. Dev. 2023, 50, 1478–1486. [Google Scholar] [CrossRef]

- Wang, H.; Ge, Y.; Shi, L. Technologies in deep and ultra-deep well drilling: Present status, challenges and future trend in the 13th Five-Year Plan period (2016–2020). Nat. Gas Ind. B 2017, 4, 319–326. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, Y.; Yang, Y. Wellbore stability of deep well in western margin thrust belt of Ordos Basin. Sci. Technol. Eng. 2024, 24, 6691–6700. [Google Scholar]

- Zhang, M.; Li, D.; Fan, X. Study on collapse pressure and instability area around wellbore in fault zone. Fault-Block Oil Gas Field 2024, 6, 1–11. [Google Scholar]

- Du, J.; Zhi, D.; Li, J.; Yang, D.; Tang, Y.; Qi, X.; Xiao, L.; Wei, L. Major breakthrough of Well Gaotan 1 and exploration prospects of lower assemblage in southern margin of Junggar Basin, NW China. Pet. Explor. Dev. 2019, 46, 205–215. [Google Scholar] [CrossRef]

- Bu, C.; Xiong, Y.; Zhu, C.; Qing, X.; Xie, Y. Optimization of completion modes in deep formation of west Sichuan basin. Nat. Gas Ind. 2008, 28, 95–97. [Google Scholar]

- Jiang, T.; Sun, X. Development of Keshen ultra-deep and ultra-high pressure gas reservoirs in the Kuqa foreland basin, Tarim Basin: Understanding points and technical countermeasures. Nat. Gas Ind. B 2018, 6, 16–24. [Google Scholar] [CrossRef]

- Zhang, Y. Yangs Staged fracturing for ultra—Deep and ultra—Low permeability horizontal wells in Shun—9 wellblock. Spec. Oil Gas Reserv. 2013, 20, 134–137. [Google Scholar]

- Law, D.; Dundas, A.S.; Reid, D.J. HPHT horizontal sand control completion. In Proceedings of the SPE/CIM International Conference on Horizontal Well Technology, Calgary, AB, Canada, 6–8 November 2000; SPE-65515-MS. SPE: Richardson, TX, USA, 2000. [Google Scholar]

- Biot, M.A. Theory of Elasticity and Consolidation for a Porous Anisotropic Solid. J. Appl. Phys. 1955, 26, 182–185. [Google Scholar] [CrossRef]

- Hubbert, M.K.; Willis, D.G. Mechanics of Hydraulic Fracting. Trans. Soc. Pet. Eng. AIME 1957, 210, 153–163. [Google Scholar] [CrossRef]

- Fairhurst, C. The phenomenon of rock splitting parallel to a free surface under compressive stress. In Proceedings of the First Congress of the International Society of Rock Mechanics, Lisbon, Portugal, 25 September–1 October 1968. [Google Scholar]

- Bradley, W.B. Failure of inclined boreholes. J. Energy Resour. Technol. 1979, 101, 232–239. [Google Scholar] [CrossRef]

- Lee, H.; Ong, S.H.; Azeemuddin, M.; Goodman, H. A wellbore stability model for formations with anisotropic rock strengths. J. Pet. Sci. Eng. 2012, 96–97, 109–119. [Google Scholar] [CrossRef]

- Ma, T.; Chen, P.; Yang, C.; Zhao, J. Wellbore stability analysis and well path optimization based on the breakout width model and Mogi–Coulomb criterion. J. Pet. Sci. Eng. 2015, 135, 678–701. [Google Scholar] [CrossRef]

- Far, P.B.; Hassani, A.H.; Al-Ajmi, A.M.; Heydari, H. A novel model for wellbore stability analysis during reservoir depletion. J. Nat. Gas Sci. Eng. 2016, 35, 935–943. [Google Scholar]

- Reisabadi, M.Z.; Haghighi, M.; Sayyafzadeh, M.; Khaksar, A. Effect of matrix shrinkage on wellbore stresses in coal seam gas: An example from Bowen Basin, east Australia. J. Nat. Gas Sci. Eng. 2020, 77, 103280. [Google Scholar] [CrossRef]

- Mansourizadeh, M.; Jamshidian, M.; Bazargan, P.; Mohammadzadeh, O. Wellbore stability analysis and breakout pressure prediction in vertical and deviated boreholes using failure criteria—A case study. J. Pet. Sci. Eng. 2016, 145, 482–492. [Google Scholar] [CrossRef]

- Xu, K.; Liu, Z.; Chen, Q.; Zhang, Q.; Ling, X.; Cai, X.; He, Q.; Yang, M. Application of machine learning in wellbore stability prediction: A review. Geoenergy Sci. Eng. 2023, 232, 212409. [Google Scholar] [CrossRef]

- Udegbunam, J.E.; Aadnøy, B.S.; Fjelde, K.K. Uncertainty evaluation of wellbore stability model predictions. J. Pet. Sci. Eng. 2014, 124, 254–263. [Google Scholar] [CrossRef]

- Guo, Y.; Blanford, M.; Candella, J.D. Evaluating the risk of casing failure caused by high-density perforation: A 3D finite-element-method study of compaction-induced casing deformation in a deepwater reservoir, Gulf of Mexico. SPE Drill. Complet. 2015, 30, 141–151. [Google Scholar] [CrossRef]

- Liu, L.J.L.; Li, G.; Luo, J.; Peng, Y.; Xia, X.; Wang, F. Strength analysis of perforated casing under non-uniform in-situ stress in ultra-deep wells. In Proceedings of the Second International Conference on Applied Statistics, Computational Mathematics, and Software Engineering (ASCMSE 2023), Zhengzhou, China, 12–14 May 2023; SPIE: Richardson, TX, USA, 2023; Volume 12784, pp. 6–13. [Google Scholar]

- Yu, R.; Yin, M.; Ran, Y. Analysis of mechanical property of screw drilling and perforated casing in open hole completion. CPM 2008, 36, 30–32, 35. [Google Scholar]

- Abdollahipour, A.; Soltanian, H.; Pourmazaheri, Y.; Kazemzadeh, E.; Fatehi-Marji, M. Sensitivity analysis of geomechanical parameters affecting a wellbore stability. J. Cent. South Univ. 2019, 26, 768–778. [Google Scholar] [CrossRef]

- Song, D.; Liu, Q.; Qiu, L.; Zhang, J.; Majid, K.; Peng, Y.; Zhao, Y.; Wang, M.; Guo, M.; Hong, T. Experimental study on resistivity evolution law and precursory signals in the damage process of gas-bearing coal. Fuel 2024, 362, 130798. [Google Scholar]

- Qiu, L.; Zhu, Y.; Liu, Q.; Guo, M.; Song, D.; Wang, A. Response law and indicator selection of seismic wave velocity for coal seam outburst risk. Adv. Geo-Energy Res. 2023, 9, 198–210. [Google Scholar] [CrossRef]

- Lin, J.E. Proceedings of the International Field Exploration and Development Conference 2019; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Rahman, K.; Khaksar, A.; Kayes, T. Minimizing sanding risk by optimizing well and perforation trajectory using an integrated geomechanical and passive sand-controlapproach. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008; Society of Petroleum Engineers: Richardson, TX, USA, 2008. [Google Scholar]

| Core Number | Porosity | Confining Pressure (MPa) | Temperature (°C) | Poisson’s Ratio | Elastic Modulus (MPa) | Differential Stress (MPa) |

|---|---|---|---|---|---|---|

| GT-102-1 | 0.0162 | 16.0 | 140 | 0.161 | 14,786.6 | 192.7 |

| GT-102-2 | 0.0307 | 0.145 | 14,283 | 223.4 | ||

| GT-102-3 | 0.0488 | 26.0 | 0.146 | 15,123 | 192.0 | |

| GT-102-4 | 0.0297 | 0.167 | 17,901.8 | 242.7 | ||

| GT-102-5 | 0.0658 | 53.0 | 0.156 | 16,869 | 262.2 | |

| GT-102-6 | 0.058 | 0.134 | 16,293 | 281.9 | ||

| GT-102-7 | 0.0403 | 140.0 | 0.102 | 26,546 | 680.3 | |

| GT-102-8 | 0.0544 | 0.101 | 27,116 | 720.8 | ||

| GT-102-9 | 0.1077 | 0.0 | 25 °C | 0.181 | 3644 | 35.4 |

| GT-102-10 | 0.0263 | 0.172 | 8201.8 | 88.1 | ||

| GT-102-11 | 0.0489 | 0.16 | 5873 | 74.0 | ||

| GT-102-12 | 0.082 | 0.172 | 7834.8 | 45.4 |

| Sample Number | Group Number | Confining Pressure (MPa) | Differential Stress (MPa) | Cohesion (MPa) | Internal Friction Angle (°) |

|---|---|---|---|---|---|

| GT-102-1 | (1) | 16 | 192.7 | 16.6 | 48 |

| GT-102-10 | 0 | 88.1 | |||

| GT-102-2 | (2) | 16 | 223.4 | 14.6 | 53.4 |

| GT-102-10 | 0 | 88.1 | |||

| GT-102-3 | (3) | 26 | 192 | 15.5 | 44.6 |

| GT-102-11 | 0 | 74 | |||

| GT-102-4 | (4) | 26 | 242.7 | 13.9 | 48.8 |

| GT-102-11 | 0 | 74 | |||

| average value | 15.2 | 48.7 | |||

| Formation Pressure Coefficient | Formation Pressure (MPa) | Critical Collapse Pressure Difference (MPa) |

|---|---|---|

| 2.33 | 135.5 | 55 |

| 2 | 116.3 | 41 |

| 1.7 | 98.8 | 26 |

| 1.4 | 81.4 | 15 |

| 1.1 | 64.8 | 2 |

| 0.8 | 46.5 | -15 |

| Casing parameters | Wellbore diameter | 215.9 | mm |

| Inner diameter of casing | 111.16 | mm | |

| Outer diameter of casing | 139.7 | mm | |

| Wall thickness of casing | 14.27 | mm | |

| Elastic modulus of casing | 210 | GPa | |

| Shear modulus of casing | 82 | GPa | |

| Elastic modulus of cement sheath | 10 | GPa | |

| Poisson’s ratio of cement sheath | 0.25 | ||

| Cement ring cohesion | 12 | MPa | |

| Friction angle inside cement ring | 24 | ° | |

| Cement stone shear dilation angle | 12 | ° | |

| Tensile strength of cement sheath | 8 | MPa | |

| Perforation parameters | Perforation depth | 0.6 | m |

| Perforation phase | 60 | ° | |

| Perforation aperture | 10 | mm | |

| Perforation density | 16 | hole/m |

| Plastic strain | 0 | 0.00824 | 0.02203 | 0.02606 | 0.03195 | 0.04274 | 0.05746 | 1 |

| Stress (MPa) | 950 | 1107.5 | 1139.3 | 1147.4 | 1160.6 | 1172.9 | 1180.5 | 1300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, T.; Lu, Y.; Hou, P.; Xue, C.; Chi, M.; Yu, J.; Gao, H.; Xu, X.; Li, H.; Qian, K. Evaluation and Application of Wellbore Stability of Deep Oil Wells in the Southern Margin of Junggar Basin. Processes 2024, 12, 2145. https://doi.org/10.3390/pr12102145

Liu T, Lu Y, Hou P, Xue C, Chi M, Yu J, Gao H, Xu X, Li H, Qian K. Evaluation and Application of Wellbore Stability of Deep Oil Wells in the Southern Margin of Junggar Basin. Processes. 2024; 12(10):2145. https://doi.org/10.3390/pr12102145

Chicago/Turabian StyleLiu, Tao, Yu Lu, Pingwei Hou, Chengwen Xue, Ming Chi, Jie Yu, Han Gao, Xiaohui Xu, Haitao Li, and Keming Qian. 2024. "Evaluation and Application of Wellbore Stability of Deep Oil Wells in the Southern Margin of Junggar Basin" Processes 12, no. 10: 2145. https://doi.org/10.3390/pr12102145

APA StyleLiu, T., Lu, Y., Hou, P., Xue, C., Chi, M., Yu, J., Gao, H., Xu, X., Li, H., & Qian, K. (2024). Evaluation and Application of Wellbore Stability of Deep Oil Wells in the Southern Margin of Junggar Basin. Processes, 12(10), 2145. https://doi.org/10.3390/pr12102145