A Low-Carbon Scheduling Method of Flexible Manufacturing and Crane Transportation Considering Multi-State Collaborative Configuration Based on Hybrid Differential Evolution

Abstract

:1. Introduction

2. Literature Review

2.1. Low-Carbon Manufacturing Scheduling Optimization

2.2. Manufacturing Scheduling Optimization Considering Transportation

3. Formulation

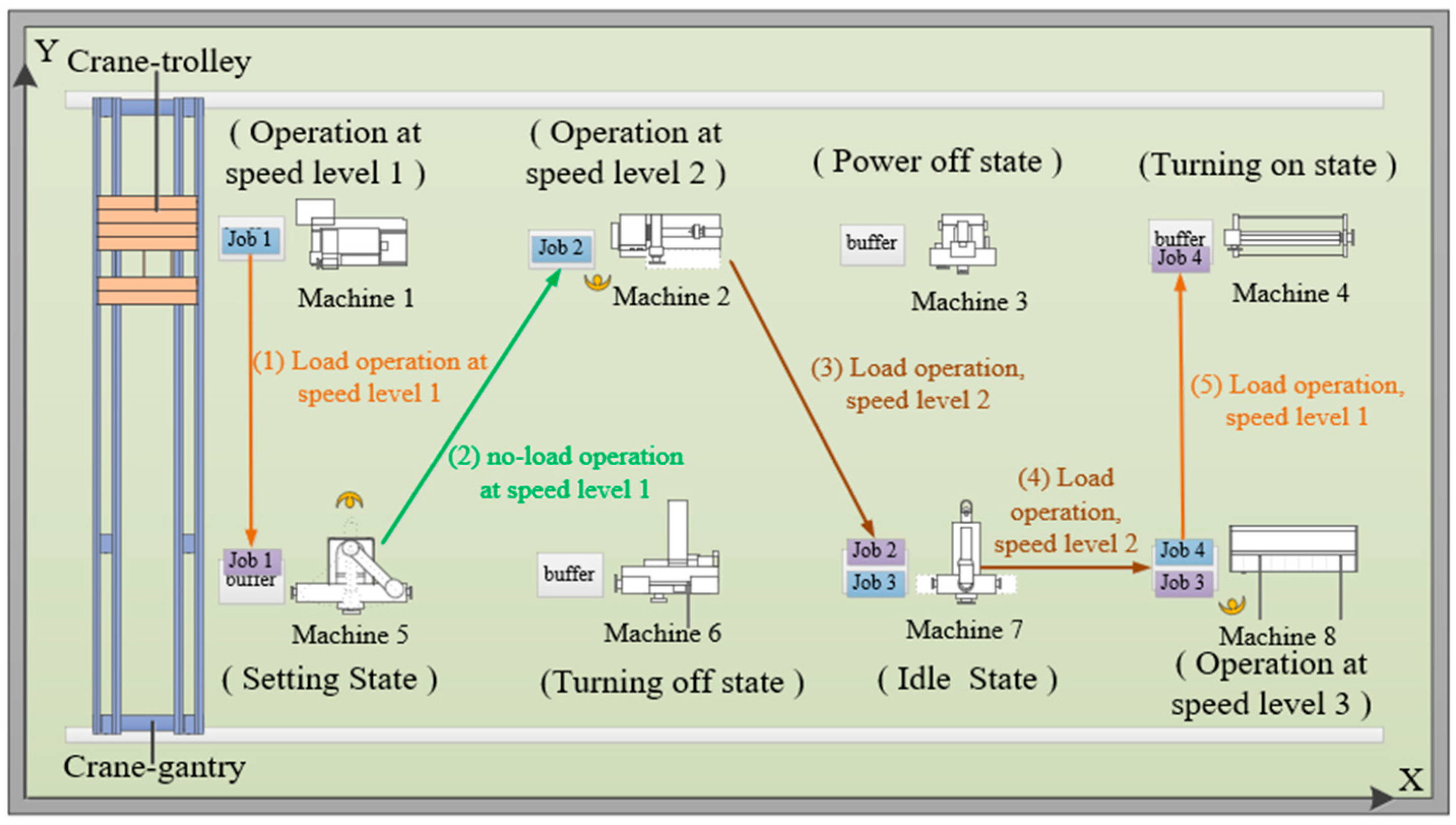

3.1. Problem Description

3.2. Assumptions

- Each workpiece can only be processed on one of the available machines with a certain speed at a certain time.

- Each machine can only process one workpiece at a certain time.

- The crane can only transport one workpiece at a certain time.

- The gantry and trolley cannot run at the same time for safety.

- The workpiece does not occupy the current machine after completing a certain process.

- When a certain process is completed, the transportation must be started after the next machine is idle for safety; otherwise, the crane needs to wait in place.

3.3. The Comprehensive Energy Consumption Model

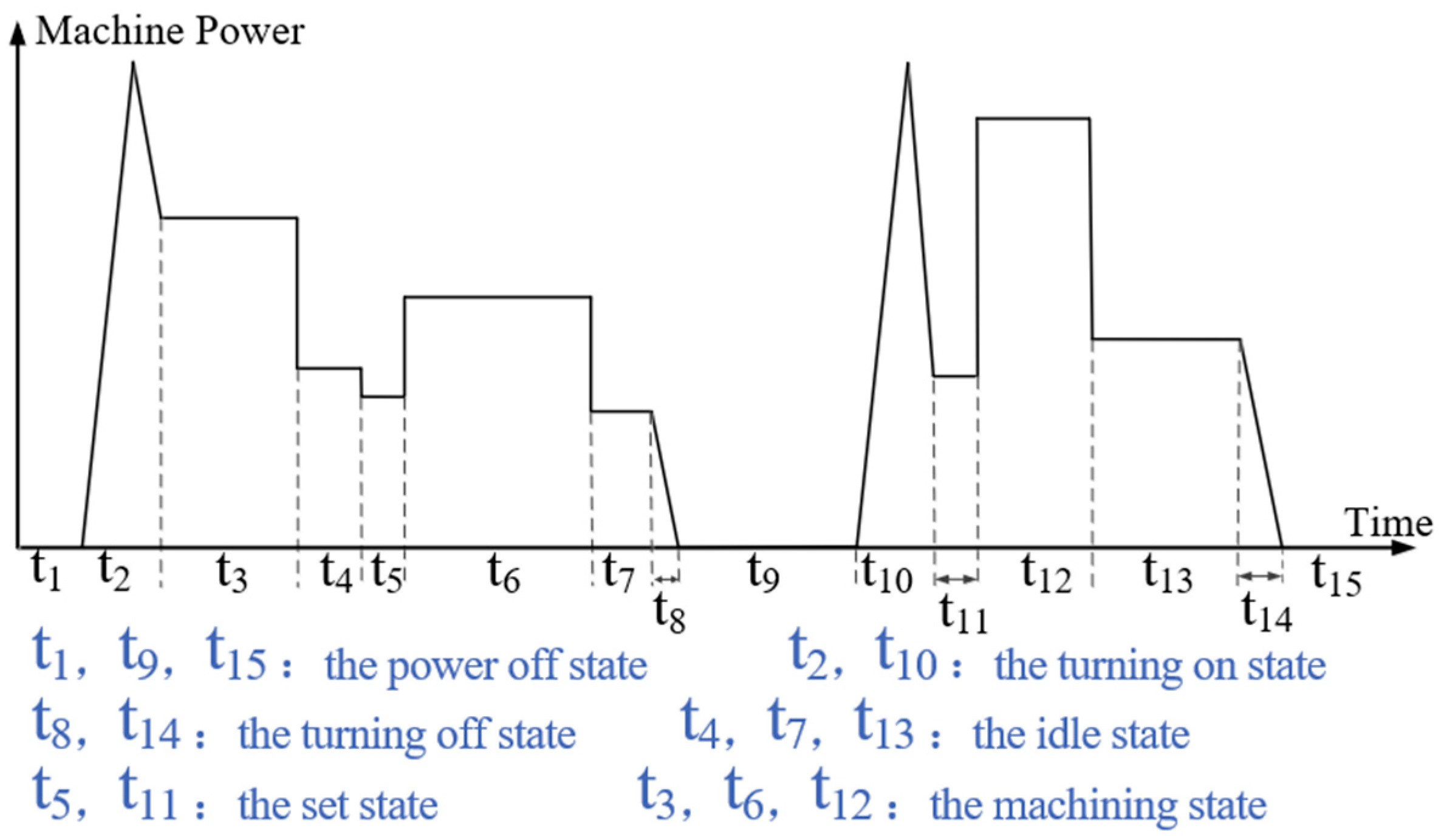

3.3.1. The Energy Consumption of the Machine Operation Process

- The energy consumption of the set state of the machine.

- II.

- The energy consumption of the machining state.

- III.

- The energy consumption of idle state

- IV.

- The energy consumption of turn-on/off state.

- V.

- The total energy consumption of the machine operation process.

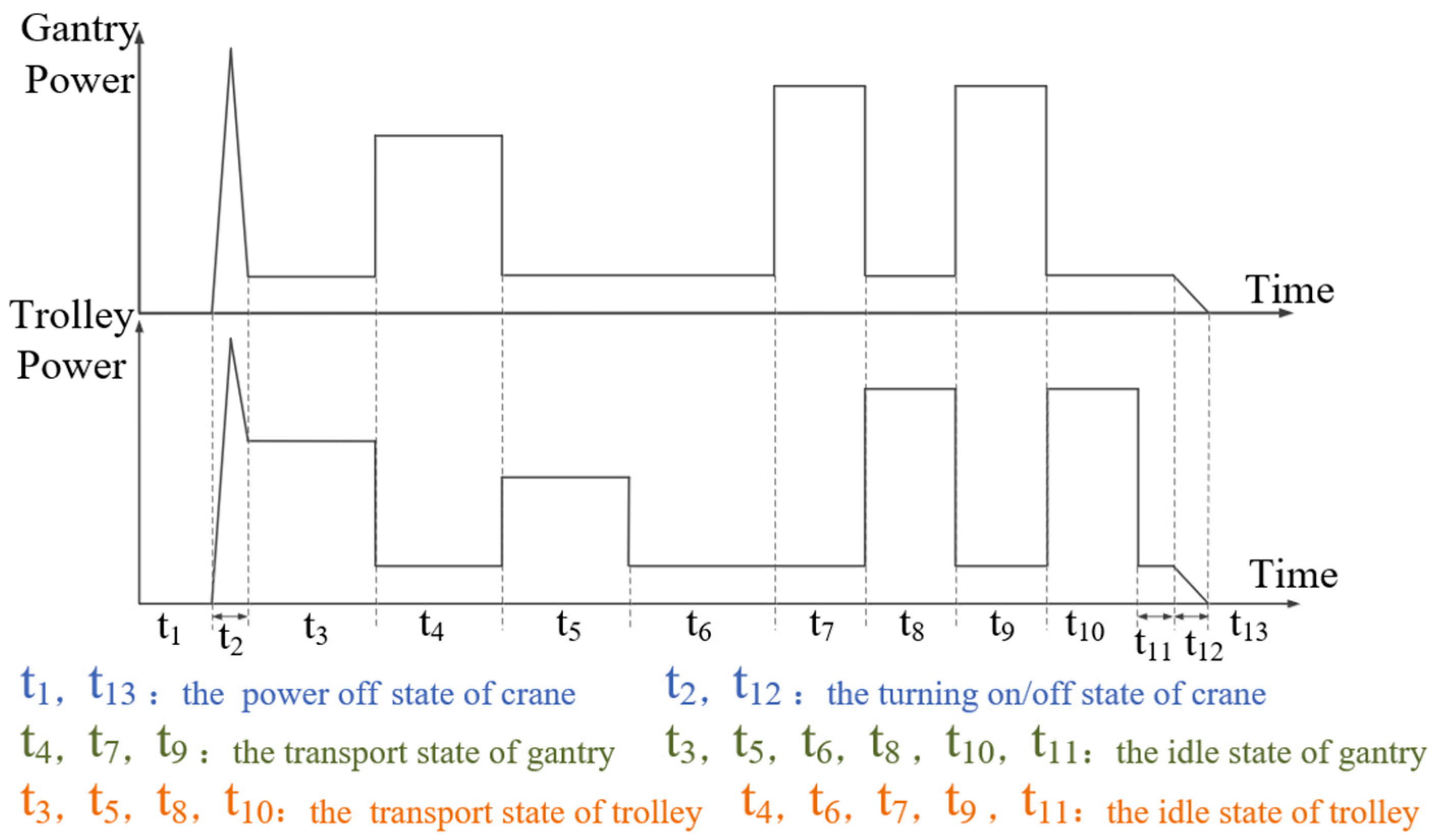

3.3.2. The Energy Consumption of Crane Operation Process

- The energy consumption of the crane idle state.

- II.

- The energy consumption of crane turning on/off state.

- III.

- The energy consumption of crane operation state.

- IV.

- Total energy consumption of crane transportation process

3.4. The Formulation of the Mixed-Integer Programming Model

4. Methodology

| Algorithm 1 Framework of DE-FA-CSOS | |

| Input: task set, population size per task (R) | |

| Output: optimal solution | |

| 1 | Initialization |

| 2 | While Terminate iteration is not satisfied do |

| 3 | Output populations |

| 4 | Input DE population |

| 5 | Update the fluorescence of all individuals |

| 6 | for i ← 1 to n do |

| 7 | Select two firefly individuals |

| 8 | Compare the fitness of two individuals |

| 9 | The firefly with poor fitness moves to another |

| 10 | Update the location of fireflies |

| 11 | Mutation |

| 12 | Crossover |

| 13 | Selection |

| 14 | CSOS # Optimization by strategy 1 and strategy2 |

| 15 | Update population |

| 16 | End |

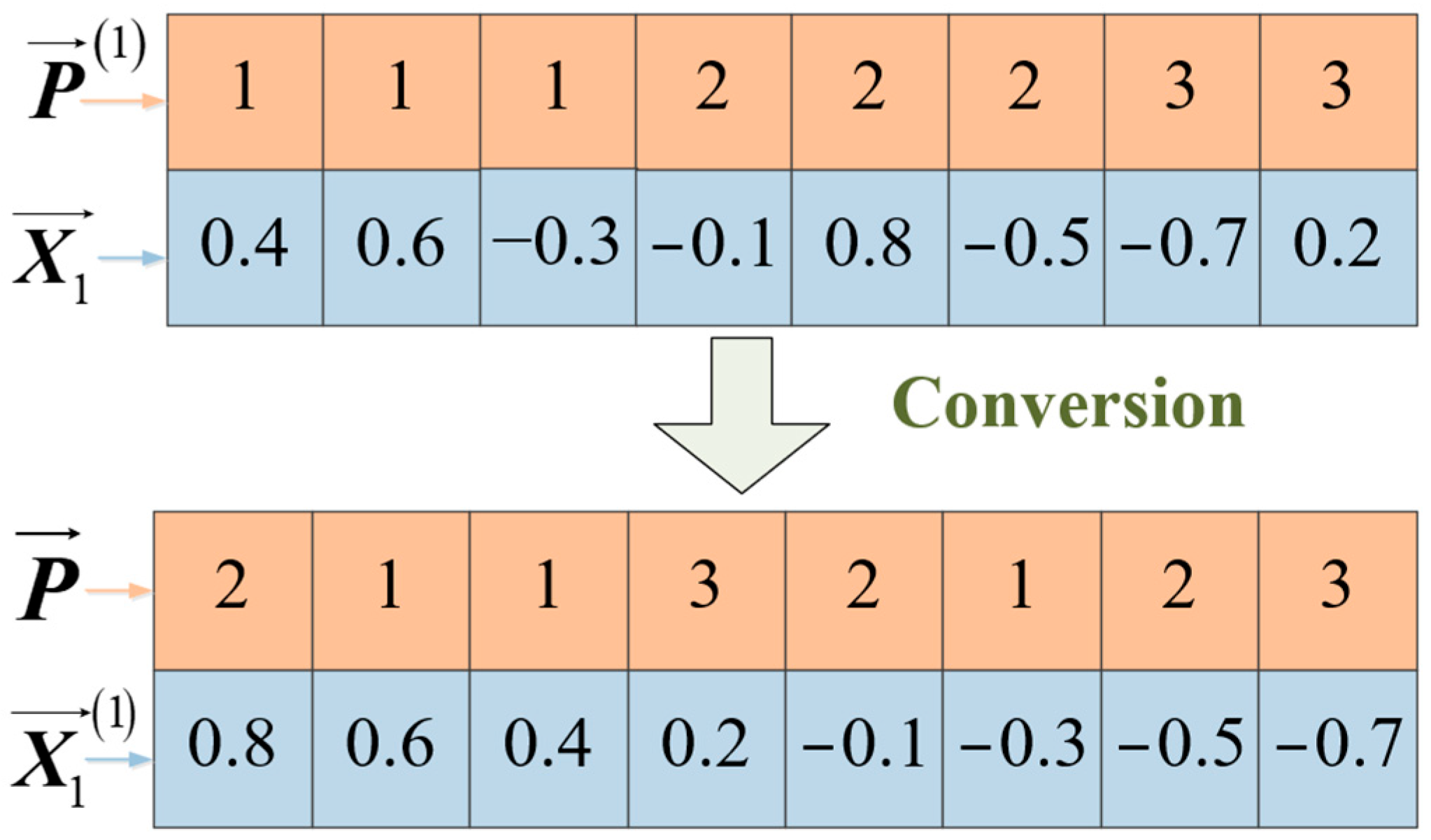

4.1. Representation and Encoding

4.2. The Transformation of Chromosome

4.2.1. Positive Transformation

4.2.2. Negative Transformation

4.3. The Collaborative State Optimization Strategy

4.3.1. Strategy 1: Load Transportation State Optimization Strategy

4.3.2. Strategy 2: Machining State Optimization Strategy

4.4. The Differential Evolution Algorithm

4.4.1. Initialization

4.4.2. Mutation

4.4.3. Crossover

4.4.4. Selection

4.5. The Firefly Algorithm

4.5.1. Algorithm Rules

4.5.2. Parameter Properties

4.6. Complexity Analysis

5. Case Study

5.1. Data Source

| Machine | Level 1 Power (W) | Level 2 Power (W) | Level 3 Power (W) | Location (m) | Set Up | Startup Energy (kJ) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Operating | Idle | Operating | Idle | Operating | Idle | Dxm | Dym | Time (min) | Power (W) | ||

| 1 | 1120 | 220 | 1690 | 280 | 1960 | 390 | 30 | 20 | 1 | 240 | 141.6 |

| 2 | 1340 | 240 | 1870 | 310 | 2320 | 340 | 30 | 80 | 2 | 190 | 133.8 |

| 3 | 1050 | 180 | 1520 | 290 | 1920 | 350 | 130 | 20 | 1 | 210 | 124.8 |

| 4 | 1210 | 210 | 1780 | 330 | 2070 | 410 | 130 | 80 | 1 | 230 | 165.6 |

| 5 | 1170 | 230 | 1590 | 270 | 2260 | 320 | 230 | 20 | 1 | 210 | 118.2 |

| 6 | 1290 | 190 | 1810 | 320 | 2470 | 310 | 230 | 80 | 2 | 180 | 150.6 |

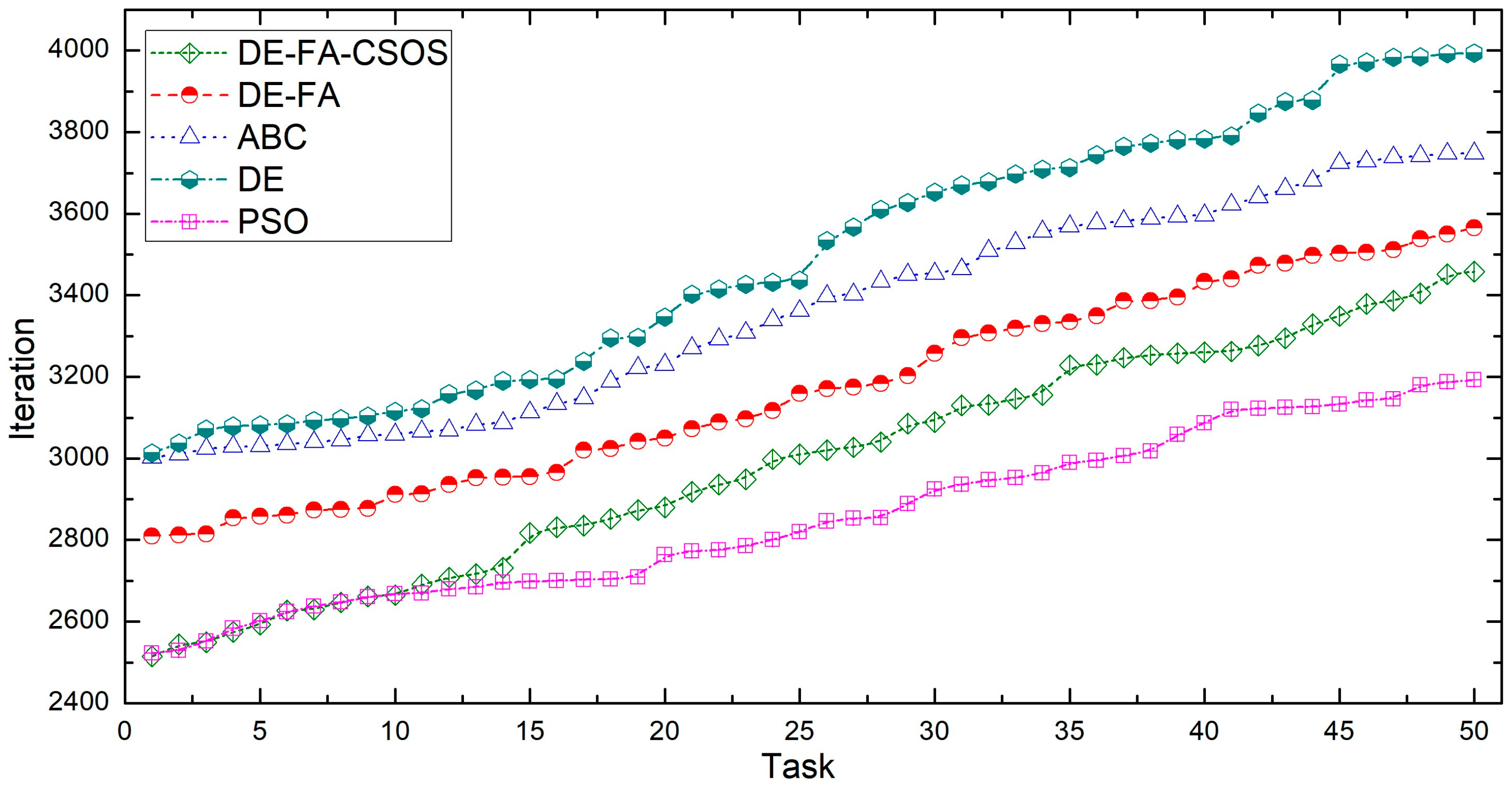

5.2. Performance Comparison Analysis

5.2.1. Parameter Setting

5.2.2. Comparison Results Analysis

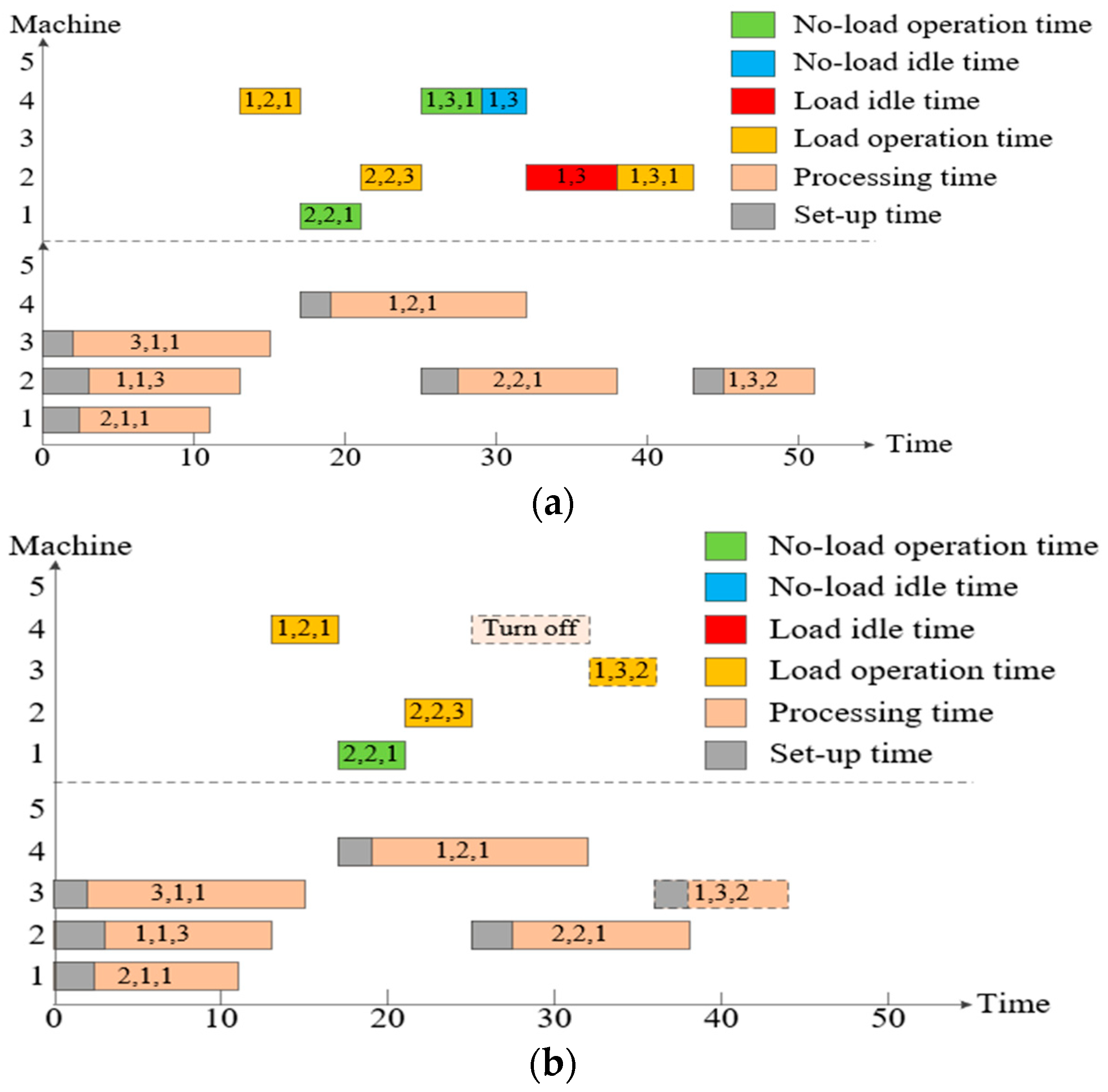

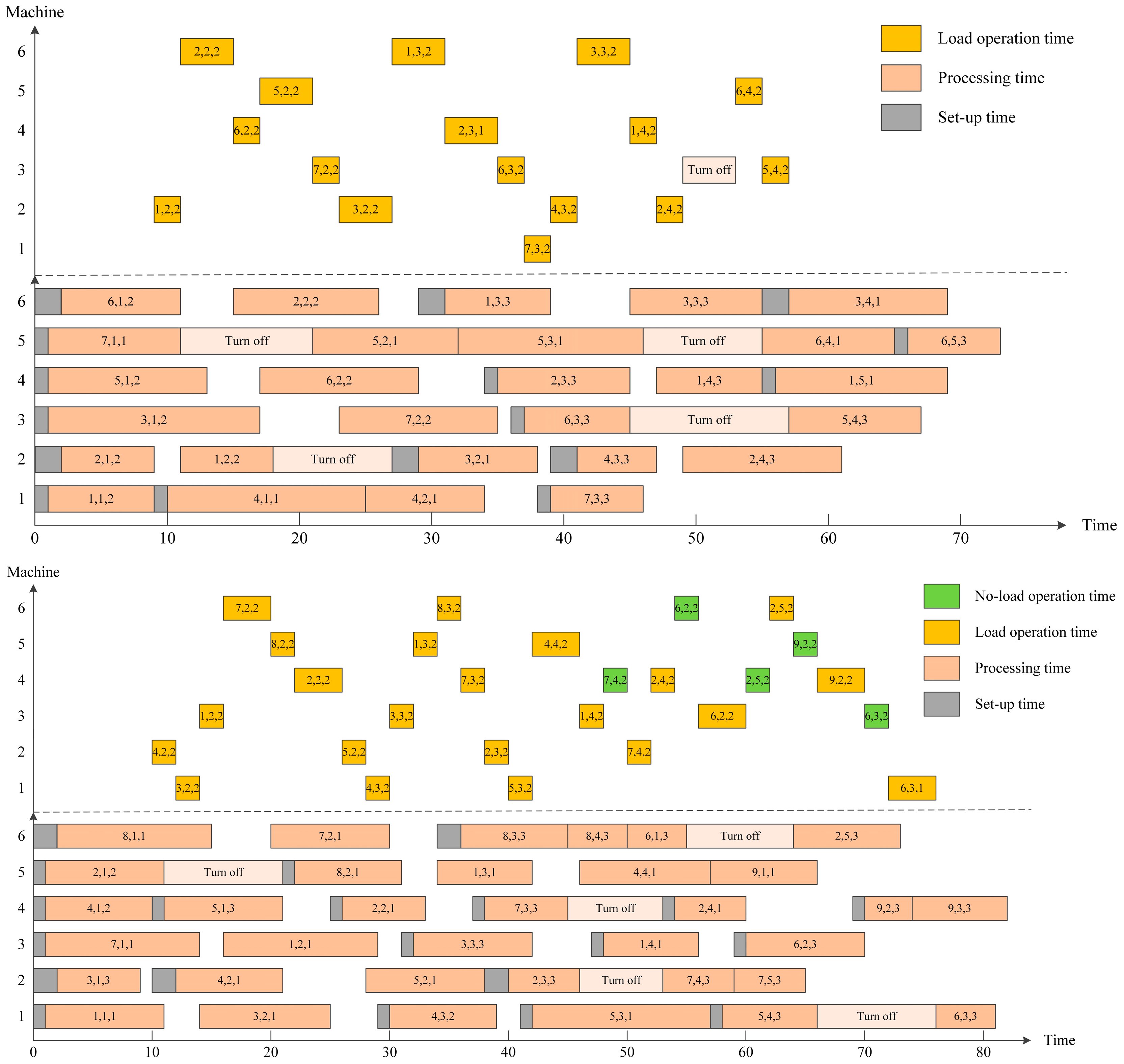

5.3. Scheduling Solution Analysis

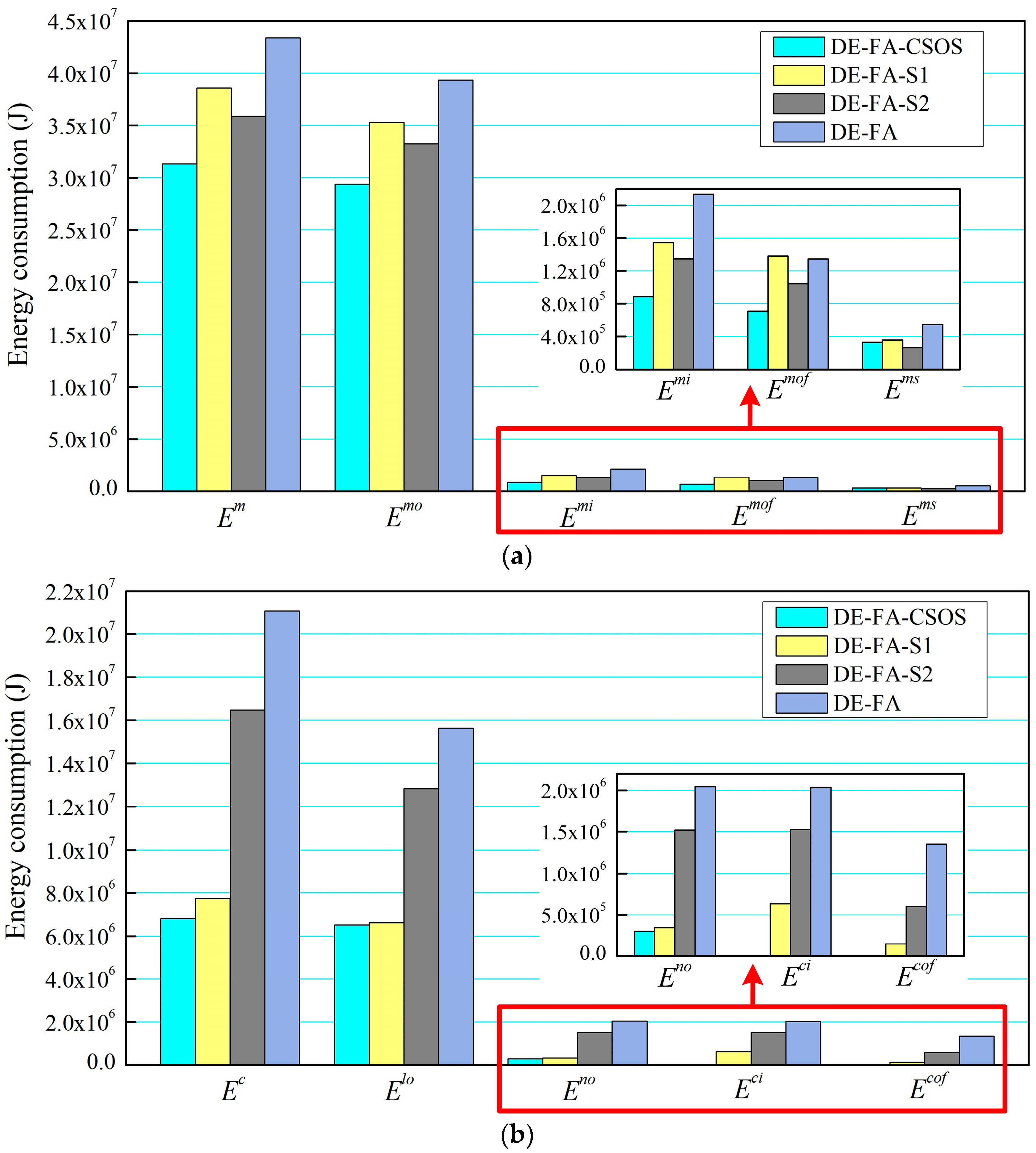

5.4. Low-Carbon Optimization Effect Analysis

5.5. Algorithm Robustness Analysis

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| The quantity of machines | |

| The quantity of workpieces | |

| The quantity of machine’s operation speed level | |

| The quantity of crane’s operation speed level | |

| The index of machine, m = 1, 2, 3, …, M | |

| The index of workpiece, n = 1, 2, 3, …, N | |

| The index of machine’s operation speed level, q = 1, 2, 3, …, Q | |

| The index of crane’s operation speed level | |

| The process quantity of workpiece n | |

| The i-th process of workpiece n, i = 1, 2, 3, …Pn | |

| The first process | |

| The operation speed level of machine m for Pi,n | |

| The available machine set for Pi,n | |

| The set of the first process on each machine | |

| The set of the first process of each workpiece | |

| The operation machine for Pi,n | |

| The operation machine for the first process | |

| The crane’s no-load operation target machine for Pi,n | |

| The crane’s load operation target machine for Pi,n | |

| The set-up time of Pi,n on machine m with speed q | |

| The operation time of Pi,n on machine m with speed q | |

| The idle time of machine m before Pi,n starts to operate | |

| The processing start time of Pi,n | |

| The processing completion time of Pi,n | |

| The gantry’s no-load operation time for Pi,n | |

| The trolley’s no-load operation time for Pi,n | |

| The gantry’s load operation time for Pi,n | |

| The trolley’s load operation time for Pi,n | |

| The crane’s no-load idle time for Pi,n | |

| The crane’s load idle time for Pi,n | |

| The set-up power of machine m | |

| The operation power of machine m with speed q | |

| The idle power of machine m with speed q | |

| The energy that machine m starts up once | |

| The rated power of the gantry at r-th speed level | |

| The rated power of the trolley at s-th speed level | |

| The idle power of the crane | |

| The energy that the crane starts up once | |

| The gantry’s operation speed with r-th level | |

| The trolley’s operation speed with r-th level | |

| The weight of workpiece n | |

| The lifting weight of the crane | |

| The weight of the lifting appliance | |

| The weight of the gantry | |

| The weight of the trolley | |

| The horizontal distance of machine m | |

| The vertical distance of machine m | |

| The initial location of the crane | |

| The crane’s no-load operation location for Pi,n | |

| The crane’s load operation location for Pi,n | |

| The decision variable of the machining process | |

| The decision variable of the machine’s shutdown status | |

| The decision variable of the crane’s operation speed level | |

| The decision variable of the crane’s shutdown status at the no-load idle phase | |

| The decision variable of the crane’s shutdown status at the load idle phase | |

| The decision variable of the adjacent process | |

| The decision variable of adjacent process on a machine | |

| The decision variable of the machine’s operation speed |

References

- China Statistical Yearbook; National Bureau of Statistics of China: Beijing, China, 2022.

- Peng, C.; Guo, X.; Long, H. Carbon Intensity and Green Transition in the Chinese Manufacturing Industry. Energies 2022, 15, 6012. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, R.; Pan, W. Evaluation of Carbon Emission Efficiency and Spatial Relevance in the Thermal Power Industry: Evidence from China. Environ. Dev. Sustain. 2023. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, S.; Wang, L. Integrated Green Scheduling Optimization of Flexible Job Shop and Crane Transportation Considering Comprehensive Energy Consumption. J. Clean. Prod. 2019, 211, 765–786. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Goli, A.; Weber, G.-W. Fuzzy Mathematical Programming and Self-Adaptive Artificial Fish Swarm Algorithm for Just-in-Time Energy-Aware Flow Shop Scheduling Problem with Outsourcing Option. IEEE Trans. Fuzzy Syst. 2020, 28, 2772–2783. [Google Scholar] [CrossRef]

- Yu, T.-S.; Han, J.-H. Scheduling Proportionate Flow Shops with Preventive Machine Maintenance. Int. J. Prod. Econ. 2021, 231, 107874. [Google Scholar] [CrossRef]

- Fu, Y.; Zhou, M.; Guo, X.; Qi, L. Scheduling Dual-Objective Stochastic Hybrid Flow Shop with Deteriorating Jobs via Bi-Population Evolutionary Algorithm. IEEE Trans. Syst. Man Cybern.-Syst. 2020, 50, 5037–5048. [Google Scholar] [CrossRef]

- Han, Y.; Li, J.; Sang, H.; Liu, Y.; Gao, K.; Pan, Q. Discrete Evolutionary Multi-Objective Optimization for Energy-Efficient Blocking Flow Shop Scheduling with Setup Time. Appl. Soft. Comput. 2020, 93, 106343. [Google Scholar] [CrossRef]

- Shao, W.; Shao, Z.; Pi, D. An Ant Colony Optimization Behavior-Based MOEA/D for Distributed Heterogeneous Hybrid Flow Shop Scheduling Problem Under Nonidentical Time-of-Use Electricity Tariffs. IEEE Trans. Autom. Sci. Eng. 2022, 19, 3379–3394. [Google Scholar] [CrossRef]

- Huang, J.-P.; Pan, Q.-K.; Miao, Z.-H.; Gao, L. Effective Constructive Heuristics and Discrete Bee Colony Optimization for Distributed Flowshop with Setup Times. Eng. Appl. Artif. Intell. 2021, 97, 104016. [Google Scholar] [CrossRef]

- Li, Y.; Li, X.; Gao, L.; Meng, L. An Improved Artificial Bee Colony Algorithm for Distributed Heterogeneous Hybrid Flowshop Scheduling Problem with Sequence-Dependent Setup Times. Comput. Ind. Eng. 2020, 147, 106638. [Google Scholar] [CrossRef]

- Wu, X.; Yuan, Q.; Wang, L. Multiobjective Differential Evolution Algorithm for Solving Robotic Cell Scheduling Problem with Batch-Processing Machines. IEEE Trans. Autom. Sci. Eng. 2021, 18, 757–775. [Google Scholar] [CrossRef]

- Pan, Y.; Gao, K.; Li, Z.; Wu, N. Improved Meta-Heuristics for Solving Distributed Lot-Streaming Permutation Flow Shop Scheduling Problems. IEEE Trans. Autom. Sci. Eng. 2023, 20, 361–371. [Google Scholar] [CrossRef]

- Qin, M.; Wang, R.; Shi, Z.; Liu, L.; Shi, L. A Genetic Programming-Based Scheduling Approach for Hybrid Flow Shop with a Batch Processor and Waiting Time Constraint. IEEE Trans. Autom. Sci. Eng. 2021, 18, 94–105. [Google Scholar] [CrossRef]

- Afsar, S.; Jose Palacios, J.; Puente, J.; Vela, C.R.; Gonzalez-Rodriguez, I. Multi-Objective Enhanced Memetic Algorithm for Green Job Shop Scheduling with Uncertain Times. Swarm Evol. Comput. 2022, 68, 101016. [Google Scholar] [CrossRef]

- Wei, Z.; Liao, W.; Zhang, L. Hybrid Energy-Efficient Scheduling Measures for Flexible Job-Shop Problem with Variable Machining Speeds. Expert Syst. Appl. 2022, 197, 116785. [Google Scholar] [CrossRef]

- Duan, J.; Wang, J. Energy-Efficient Scheduling for a Flexible Job Shop with Machine Breakdowns Considering Machine Idle Time Arrangement and Machine Speed Level Selection. Comput. Ind. Eng. 2021, 161, 107677. [Google Scholar] [CrossRef]

- Wu, X.; Peng, J.; Xiao, X.; Wu, S. An Effective Approach for the Dual-Resource Flexible Job Shop Scheduling Problem Considering Loading and Unloading. J. Intell. Manuf. 2021, 32, 707–728. [Google Scholar] [CrossRef]

- Luo, S.; Zhang, L.; Fan, Y. Real-Time Scheduling for Dynamic Partial-No-Wait Multiobjective Flexible Job Shop by Deep Reinforcement Learning. IEEE Trans. Autom. Sci. Eng. 2022, 19, 3020–3038. [Google Scholar] [CrossRef]

- Jiang, S.-L.; Liu, Q.; Bogle, I.D.L.; Zheng, Z. A Self-Learning Based Dynamic Multi-Objective Evolutionary Algorithm for Resilient Scheduling Problems in Steelmaking Plants. IEEE Trans. Autom. Sci. Eng. 2023, 20, 832–845. [Google Scholar] [CrossRef]

- Feng, Y.; Hong, Z.; Li, Z.; Zheng, H.; Tan, J. Integrated Intelligent Green Scheduling of Sustainable Flexible Workshop with Edge Computing Considering Uncertain Machine State. J. Clean. Prod. 2020, 246, 119070. [Google Scholar] [CrossRef]

- He, L.; Chiong, R.; Li, W.; Dhakal, S.; Cao, Y.; Zhang, Y. Multiobjective Optimization of Energy-Efficient JOB-Shop Scheduling with Dynamic Reference Point-Based Fuzzy Relative Entropy. IEEE Trans. Ind. Inform. 2022, 18, 600–610. [Google Scholar] [CrossRef]

- Wang, J.; Yang, J.; Zhang, Y.; Ren, S.; Liu, Y. Infinitely Repeated Game Based Real-Time Scheduling for Low-Carbon Flexible Job Shop Considering Multi-Time Periods. J. Clean. Prod. 2020, 247, 119093. [Google Scholar] [CrossRef]

- Li, L.; Li, C.; Tang, Y.; Li, L.; Chen, X. An Integrated Solution to Minimize the Energy Consumption of a Resource-Constrained Machining System. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1158–1175. [Google Scholar] [CrossRef]

- Kovalenko, I.; Balta, E.C.; Tilbury, D.M.; Barton, K. Cooperative Product Agents to Improve Manufacturing System Flexibility: A Model-Based Decision Framework. IEEE Trans. Autom. Sci. Eng. 2023, 20, 440–457. [Google Scholar] [CrossRef]

- Kung, L.-C.; Liao, Z.-Y. Optimization for a Joint Predictive Maintenance and Job Scheduling Problem with Endogenous Yield Rates. IEEE Trans. Autom. Sci. Eng. 2022, 19, 1555–1566. [Google Scholar] [CrossRef]

- Wang, C.-N.; Porter, G.A.; Huang, C.-C.; Nguyen, V.T.; Husain, S.T. Flow-Shop Scheduling with Transportation Capacity and Time Consideration. CMC-Comput. Mat. Contin. 2022, 70, 3031–3048. [Google Scholar] [CrossRef]

- Lei, C.; Zhao, N.; Ye, S.; Wu, X. Memetic Algorithm for Solving Flexible Flow-Shop Scheduling Problems with Dynamic Transport Waiting Times. Comput. Ind. Eng. 2020, 139, 105984. [Google Scholar] [CrossRef]

- Xin, X.; Jiang, Q.; Li, S.; Gong, S.; Chen, K. Energy-Ef Fi Cient Scheduling for a Permutation Fl Ow Shop with Variable Transportation Time Using an Improved Discrete Whale Swarm Optimization. J. Clean. Prod. 2021, 293, 126121. [Google Scholar] [CrossRef]

- Yuan, S.; Li, T.; Wang, B. A Discrete Differential Evolution Algorithm for Flow Shop Group Scheduling Problem with Sequence-Dependent Setup and Transportation Times. J. Intell. Manuf. 2021, 32, 427–439. [Google Scholar] [CrossRef]

- Goli, A.; Tirkolaee, E.B.; Aydin, N.S. Fuzzy Integrated Cell Formation and Production Scheduling Considering Automated Guided Vehicles and Human Factors. IEEE Trans. Fuzzy Syst. 2021, 29, 3686–3695. [Google Scholar] [CrossRef]

- Zhou, B.; Lei, Y. Bi-Objective Grey Wolf Optimization Algorithm Combined Levy Flight Mechanism for the FMC Green Scheduling Problem. Appl. Soft. Comput. 2021, 111, 107717. [Google Scholar] [CrossRef]

- Ren, W.; Yan, Y.; Hu, Y.; Guan, Y. Joint Optimisation for Dynamic Flexible Job-Shop Scheduling Problem with Transportation Time and Resource Constraints. Int. J. Prod. Res. 2022, 60, 5675–5696. [Google Scholar] [CrossRef]

- Li, J.-Q.; Du, Y.; Gao, K.-Z.; Duan, P.-Y.; Gong, D.-W.; Pan, Q.-K.; Suganthan, P.N. A Hybrid Iterated Greedy Algorithm for a Crane Transportation Flexible Job Shop Problem. IEEE Trans. Autom. Sci. Eng. 2022, 19, 2153–2170. [Google Scholar] [CrossRef]

- Li, M.; Lei, D. An Imperialist Competitive Algorithm with Feedback for Energy-Efficient Flexible Job Shop Scheduling with Transportation and Sequence-Dependent Setup Times. Eng. Appl. Artif. Intell. 2021, 103, 104307. [Google Scholar] [CrossRef]

- Zhao, N.; Fu, Z.; Sun, Y.; Pu, X.; Luo, L. Digital-Twin Driven Energy-Efficient Multi-Crane Scheduling and Crane Number Selection in Workshops. J. Clean. Prod. 2022, 336, 130175. [Google Scholar] [CrossRef]

- Sun, Y.; Chung, S.-H.; Wen, X.; Ma, H.-L. Novel Robotic Job-Shop Scheduling Models with Deadlock and Robot Movement Considerations. Transp. Res. Pt. e-Logist. Transp. Rev. 2021, 149, 102273. [Google Scholar] [CrossRef]

- Zou, W.-Q.; Pan, Q.-K.; Wang, L.; Miao, Z.-H.; Peng, C. Efficient Multiobjective Optimization for an AGV Energy-Efficient Scheduling Problem with Release Time. Knowl.-Based Syst. 2022, 242, 108334. [Google Scholar] [CrossRef]

- Li, Y.; Gu, W.; Yuan, M.; Tang, Y. Real-Time Data-Driven Dynamic Scheduling for Flexible Job Shop with Insufficient Transportation Resources Using Hybrid Deep Q Network. Robot. Comput.-Integr. Manuf. 2022, 74, 102283. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, J.; Tang, L.; Zhao, R.; Dong, Y. Model and Heuristic Solutions for the Multiple Double-Load Crane Scheduling Problem in Slab Yards. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1307–1319. [Google Scholar] [CrossRef]

- Wu, X.; Sun, Y. A Green Scheduling Algorithm for Flexible Job Shop with Energy-Saving Measures. J. Clean. Prod. 2018, 172, 3249–3264. [Google Scholar] [CrossRef]

- Gao, D.; Wang, G.-G.; Pedrycz, W. Solving Fuzzy Job-Shop Scheduling Problem Using DE Algorithm Improved by a Selection Mechanism. IEEE Trans. Fuzzy Syst. 2020, 28, 3265–3275. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Yang, X.-S.; Talatahari, S.; Alavi, A.H. Firefly Algorithm with Chaos. Commun. Nonlinear Sci. Numer. Simul. 2013, 18, 89–98. [Google Scholar] [CrossRef]

- Civicioglu, P.; Besdok, E. A Conceptual Comparison of the Cuckoo-Search, Particle Swarm Optimization, Differential Evolution and Artificial Bee Colony Algorithms. Artif. Intell. Rev. 2013, 39, 315–346. [Google Scholar] [CrossRef]

- Nekouie, N.; Yaghoobi, M. A New Method in Multimodal Optimization Based on Firefly Algorithm. Artif. Intell. Rev. 2016, 46, 267–287. [Google Scholar] [CrossRef]

- Goli, A.; Ala, A.; Hajiaghaei-Keshteli, M. Efficient Multi-Objective Meta-Heuristic Algorithms for Energy-Aware Non-Permutation Flow-Shop Scheduling Problem. Expert Syst. Appl. 2023, 213, 119077. [Google Scholar] [CrossRef]

- Li, H.; Wang, X.; Peng, J.B. A Hybrid Differential Evolution Algorithm for Flexible Job Shop Scheduling with Outsourcing Operations and Job Priority Constraints. Expert Syst. Appl. 2022, 201, 117182. [Google Scholar] [CrossRef]

- Baysal, M.E.; Sarucan, A.; Buyukozkan, K.; Engin, O. Artificial Bee Colony Algorithm for Solving Multi-Objective Distributed Fuzzy Permutation Flow Shop Problem. J. Intell. Fuzzy Syst. 2022, 42, 439–449. [Google Scholar] [CrossRef]

- Tan, W.H.; Yuan, X.F.; Huang, G.M.; Liu, Z.X. Low-Carbon Joint Scheduling in Flexible Open-Shop Environment with Constrained Automatic Guided Vehicle by Multi-Objective Particle Swarm Optimization. Appl. Soft. Comput. 2021, 111, 107695. [Google Scholar] [CrossRef]

| Task | DE-FA-CSOS | DE-FA | ABC | DE | PSO | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Std | Mean | Std | Mean | Std | Mean | Std | Mean | Std | |

| 1 | 40.06 | 0.902 | 40.10 | 1.091 | 41.01 | 1.079 | 40.37 | 1.343 | 40.25 | 1.110 |

| 2 | 40.39 | 0.992 | 40.55 | 1.174 | 41.16 | 1.098 | 40.40 | 1.178 | 40.39 | 1.341 |

| 3 | 40.60 | 0.883 | 41.35 | 1.118 | 41.27 | 1.378 | 41.60 | 1.352 | 42.20 | 1.176 |

| 4 | 41.30 | 0.954 | 41.87 | 1.014 | 41.36 | 1.293 | 41.76 | 1.317 | 42.70 | 1.175 |

| 5 | 41.81 | 0.911 | 41.67 | 1.007 | 41.51 | 1.196 | 42.32 | 1.248 | 43.12 | 1.253 |

| 6 | 41.93 | 0.849 | 41.73 | 1.048 | 41.93 | 1.379 | 42.77 | 1.277 | 43.77 | 1.277 |

| 7 | 42.01 | 1.064 | 42.27 | 1.089 | 42.31 | 1.356 | 42.96 | 1.181 | 44.61 | 1.181 |

| 8 | 42.51 | 0.808 | 43.37 | 1.020 | 42.61 | 1.307 | 43.73 | 1.138 | 44.71 | 1.200 |

| 9 | 42.62 | 1.037 | 43.61 | 1.147 | 42.92 | 1.110 | 44.45 | 1.237 | 45.16 | 1.437 |

| 10 | 43.04 | 0.878 | 43.64 | 1.145 | 44.42 | 1.379 | 44.74 | 1.347 | 45.30 | 1.122 |

| 11 | 43.52 | 1.059 | 44.51 | 1.001 | 44.54 | 1.075 | 44.77 | 1.242 | 45.77 | 1.481 |

| 12 | 43.77 | 0.912 | 44.90 | 1.061 | 45.81 | 1.237 | 45.31 | 1.156 | 45.92 | 1.307 |

| 13 | 43.97 | 0.939 | 45.33 | 1.163 | 46.13 | 1.193 | 46.03 | 1.139 | 45.98 | 1.210 |

| 14 | 44.19 | 1.063 | 45.60 | 1.118 | 46.16 | 1.227 | 46.91 | 1.397 | 46.42 | 1.304 |

| 15 | 44.45 | 0.905 | 45.93 | 1.025 | 46.66 | 1.072 | 47.02 | 1.124 | 47.08 | 1.338 |

| 16 | 44.57 | 0.902 | 46.02 | 1.147 | 47.47 | 1.236 | 47.24 | 1.390 | 47.50 | 1.149 |

| 17 | 45.37 | 0.806 | 46.31 | 1.102 | 47.91 | 1.267 | 47.28 | 1.206 | 48.40 | 1.391 |

| 18 | 45.44 | 0.963 | 46.80 | 1.124 | 48.50 | 1.354 | 47.33 | 1.234 | 48.47 | 1.386 |

| 19 | 45.95 | 0.801 | 46.90 | 1.053 | 48.63 | 1.066 | 47.61 | 1.278 | 48.93 | 1.277 |

| 20 | 46.13 | 0.903 | 46.92 | 1.049 | 48.83 | 1.201 | 48.00 | 1.161 | 48.95 | 1.462 |

| 21 | 46.80 | 1.054 | 47.09 | 1.119 | 49.09 | 1.078 | 48.40 | 1.288 | 49.04 | 1.214 |

| 22 | 47.20 | 1.056 | 47.12 | 1.085 | 49.39 | 1.287 | 48.69 | 1.374 | 49.83 | 1.102 |

| 23 | 47.29 | 1.029 | 47.37 | 1.067 | 49.43 | 1.368 | 48.81 | 1.299 | 49.84 | 1.104 |

| 24 | 47.53 | 1.019 | 47.93 | 1.059 | 49.76 | 1.118 | 49.32 | 1.114 | 51.16 | 1.294 |

| 25 | 48.08 | 0.976 | 48.34 | 1.066 | 49.78 | 1.012 | 49.95 | 1.307 | 51.49 | 1.258 |

| 26 | 48.53 | 0.954 | 48.55 | 1.116 | 49.90 | 1.170 | 50.00 | 1.207 | 52.54 | 1.186 |

| 27 | 48.91 | 0.925 | 48.99 | 1.158 | 50.28 | 1.142 | 50.02 | 1.176 | 52.65 | 1.443 |

| 28 | 49.20 | 0.935 | 50.56 | 1.149 | 50.40 | 1.232 | 50.67 | 1.288 | 53.02 | 1.423 |

| 29 | 50.78 | 1.027 | 51.20 | 1.029 | 50.83 | 1.239 | 51.60 | 1.291 | 53.14 | 1.330 |

| 30 | 50.95 | 1.054 | 51.80 | 1.022 | 51.33 | 1.220 | 51.69 | 1.108 | 53.33 | 1.240 |

| 31 | 51.17 | 0.816 | 51.89 | 1.108 | 51.45 | 1.373 | 51.95 | 1.155 | 54.36 | 1.494 |

| 32 | 51.46 | 0.844 | 52.63 | 1.073 | 52.75 | 1.020 | 52.26 | 1.246 | 54.91 | 1.405 |

| 33 | 51.82 | 0.803 | 53.22 | 1.151 | 52.84 | 1.106 | 52.52 | 1.326 | 54.98 | 1.347 |

| 34 | 51.93 | 0.823 | 53.81 | 1.131 | 53.05 | 1.355 | 52.53 | 1.163 | 55.18 | 1.103 |

| 35 | 52.74 | 0.994 | 53.94 | 1.028 | 53.43 | 1.264 | 53.48 | 1.285 | 55.48 | 1.226 |

| 36 | 53.49 | 0.845 | 54.48 | 1.115 | 53.57 | 1.097 | 53.58 | 1.243 | 55.50 | 1.238 |

| 37 | 53.80 | 1.075 | 54.67 | 1.065 | 54.24 | 1.023 | 53.80 | 1.150 | 55.59 | 1.402 |

| 38 | 53.97 | 1.003 | 54.70 | 1.006 | 56.77 | 1.144 | 54.28 | 1.242 | 55.68 | 1.242 |

| 39 | 54.49 | 0.806 | 54.99 | 1.145 | 56.92 | 1.174 | 54.96 | 1.163 | 55.94 | 1.423 |

| 40 | 55.43 | 0.990 | 55.26 | 1.143 | 56.95 | 1.092 | 55.84 | 1.369 | 56.31 | 1.465 |

| 41 | 55.67 | 1.031 | 55.82 | 1.120 | 57.21 | 1.012 | 55.93 | 1.384 | 57.51 | 1.245 |

| 42 | 55.84 | 0.910 | 55.98 | 1.191 | 57.34 | 1.120 | 56.17 | 1.245 | 57.61 | 1.312 |

| 43 | 56.16 | 1.059 | 56.54 | 1.001 | 57.36 | 1.043 | 56.37 | 1.175 | 57.64 | 1.284 |

| 44 | 56.76 | 0.837 | 56.87 | 1.173 | 57.72 | 1.327 | 57.69 | 1.252 | 57.75 | 1.294 |

| 45 | 56.81 | 0.998 | 56.95 | 1.159 | 57.95 | 1.009 | 57.74 | 1.271 | 58.04 | 1.273 |

| 46 | 57.53 | 1.090 | 57.93 | 1.160 | 58.07 | 1.150 | 57.95 | 1.102 | 58.54 | 1.402 |

| 47 | 57.77 | 0.930 | 58.20 | 1.132 | 58.84 | 1.232 | 58.09 | 1.108 | 58.84 | 1.312 |

| 48 | 58.31 | 0.910 | 59.03 | 1.087 | 59.25 | 1.184 | 58.89 | 1.178 | 58.91 | 1.139 |

| 49 | 58.97 | 1.025 | 59.18 | 1.062 | 59.41 | 1.346 | 59.55 | 1.284 | 59.44 | 1.292 |

| 50 | 59.21 | 0.843 | 59.72 | 1.048 | 59.64 | 1.214 | 59.77 | 1.328 | 59.48 | 1.158 |

| Best/All | 46/50 | 45/50 | 3/50 | 3/50 | 1/50 | 2/50 | 0/50 | 0/50 | 0/50 | 0/50 |

| Friedman | 1.13 | 1.14 | 2.56 | 2.32 | 3.46 | 3.36 | 3.25 | 3.91 | 4.60 | 4.27 |

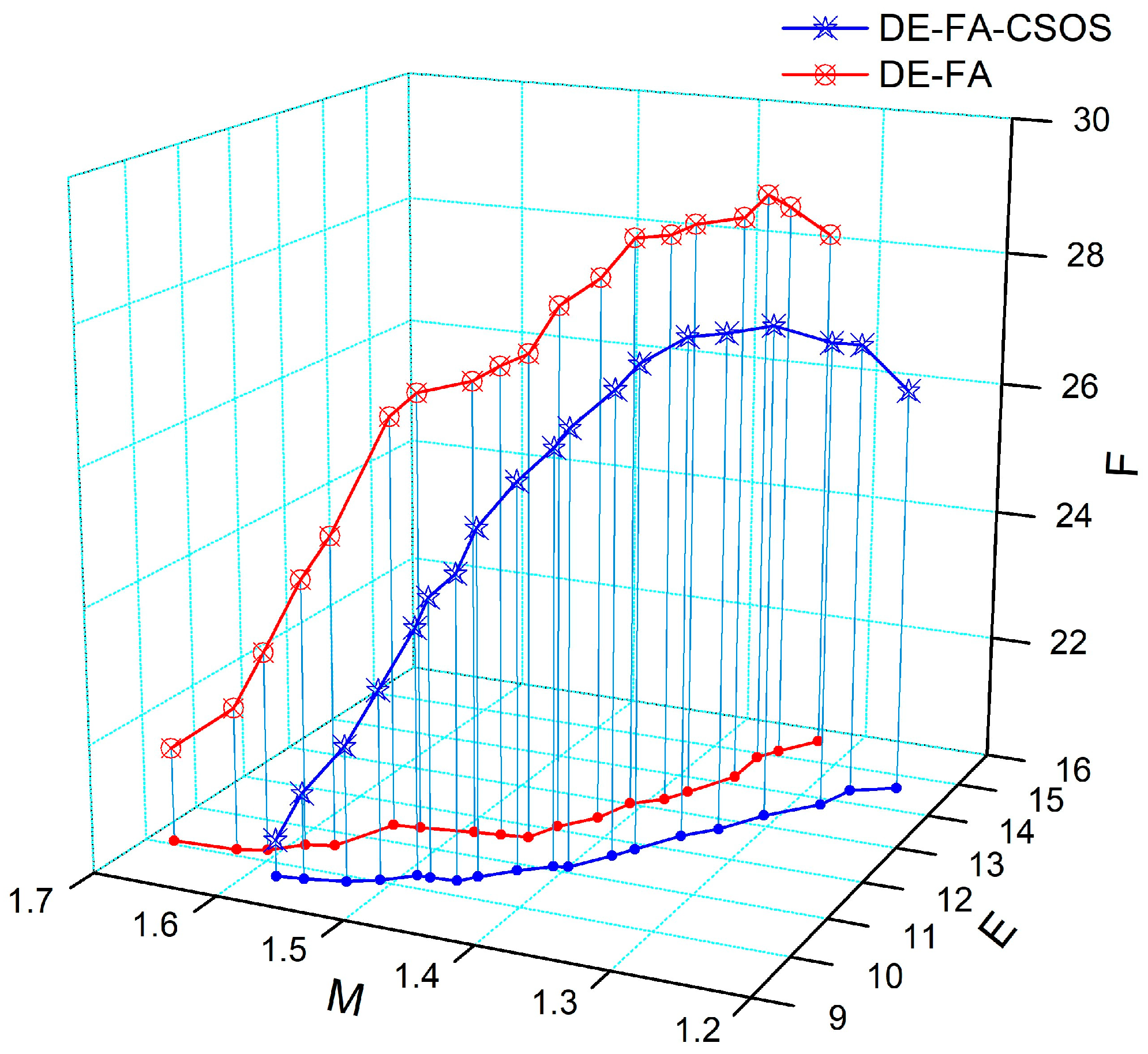

| No. | DE-FA-CSOS | Solution Gap (%) | DE-FA | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| E | M | F | GapE | GapM | GapF | E | M | F | ||

| 1 | 0.05 | 14.62 | 1.24 | 26.25 | 6.91 | 7.26 | 7.24 | 15.63 | 1.33 | 28.14 |

| 2 | 0.10 | 14.34 | 1.27 | 26.96 | 5.72 | 6.30 | 6.24 | 15.16 | 1.35 | 28.64 |

| 3 | 0.15 | 13.83 | 1.28 | 27.13 | 7.52 | 6.25 | 6.45 | 14.87 | 1.36 | 28.88 |

| 4 | 0.20 | 13.28 | 1.31 | 27.48 | 7.00 | 3.82 | 4.45 | 14.21 | 1.36 | 28.71 |

| 5 | 0.25 | 12.72 | 1.33 | 27.50 | 6.76 | 3.76 | 4.47 | 13.58 | 1.38 | 28.74 |

| 6 | 0.30 | 12.39 | 1.35 | 27.51 | 7.18 | 2.96 | 4.14 | 13.28 | 1.39 | 28.65 |

| 7 | 0.35 | 11.85 | 1.37 | 27.25 | 9.79 | 2.92 | 5.08 | 13.01 | 1.41 | 28.64 |

| 8 | 0.40 | 11.59 | 1.38 | 26.95 | 7.77 | 2.90 | 4.63 | 12.49 | 1.42 | 28.19 |

| 9 | 0.45 | 11.14 | 1.40 | 26.51 | 8.62 | 2.86 | 5.10 | 12.10 | 1.44 | 27.86 |

| 10 | 0.50 | 11.08 | 1.41 | 26.23 | 5.51 | 2.84 | 4.00 | 11.69 | 1.45 | 27.28 |

| 11 | 0.55 | 10.83 | 1.43 | 25.80 | 7.39 | 2.80 | 4.98 | 11.63 | 1.47 | 27.08 |

| 12 | 0.60 | 10.52 | 1.45 | 25.20 | 10.08 | 2.76 | 6.54 | 11.58 | 1.49 | 26.84 |

| 13 | 0.65 | 10.34 | 1.46 | 24.59 | 10.93 | 4.79 | 8.25 | 11.47 | 1.53 | 26.62 |

| 14 | 0.70 | 10.31 | 1.48 | 24.21 | 10.77 | 4.73 | 8.44 | 11.42 | 1.55 | 26.25 |

| 15 | 0.75 | 10.30 | 1.49 | 23.75 | 3.50 | 5.37 | 4.11 | 10.66 | 1.57 | 24.73 |

| 16 | 0.80 | 10.04 | 1.51 | 22.90 | 5.08 | 5.30 | 5.14 | 10.55 | 1.59 | 24.08 |

| 17 | 0.85 | 9.86 | 1.53 | 22.10 | 4.16 | 5.23 | 4.39 | 10.27 | 1.61 | 23.07 |

| 18 | 0.90 | 9.75 | 1.56 | 21.37 | 4.00 | 4.49 | 4.07 | 10.14 | 1.63 | 22.24 |

| 19 | 0.95 | 9.69 | 1.58 | 20.64 | 4.02 | 6.33 | 4.21 | 10.08 | 1.68 | 21.51 |

| Mean | 11.50 | 1.41 | 25.28 | 6.98 | 4.40 | 5.36 | 12.31 | 1.47 | 26.64 | |

| Std | 1.60 | 0.10 | 2.21 | 2.31 | 1.47 | 1.41 | 1.75 | 0.11 | 2.37 | |

| Task | DE-FA-CSOS | Result Gap (%) | Dispatcher Mode | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Em | Ec | M | GapEm | GapEc | GapM | Em | Ec | M | |

| 1 | 8.69 | 1.89 | 1.37 | 34.46 | 28.41 | 29.38 | 13.26 | 2.64 | 1.94 |

| 2 | 11.38 | 3.52 | 1.52 | 25.03 | 27.12 | 29.95 | 15.18 | 4.83 | 2.17 |

| 3 | 9.18 | 3.46 | 1.45 | 34.29 | 36.86 | 38.30 | 13.97 | 5.48 | 2.35 |

| 4 | 11.08 | 2.03 | 1.48 | 23.95 | 45.28 | 40.08 | 14.57 | 3.71 | 2.47 |

| 5 | 13.03 | 2.85 | 1.38 | 19.91 | 39.87 | 43.44 | 16.27 | 4.74 | 2.44 |

| 6 | 12.64 | 3.77 | 1.47 | 26.64 | 21.13 | 39.26 | 17.23 | 4.78 | 2.42 |

| 7 | 11.61 | 3.23 | 1.39 | 22.13 | 30.69 | 39.30 | 14.91 | 4.66 | 2.29 |

| 8 | 12.75 | 3.56 | 1.41 | 18.01 | 33.46 | 33.80 | 15.55 | 5.35 | 2.13 |

| 9 | 12.79 | 2.51 | 1.42 | 17.59 | 45.79 | 36.61 | 15.52 | 4.63 | 2.24 |

| 10 | 11.66 | 2.57 | 1.54 | 29.63 | 36.54 | 40.08 | 16.57 | 4.05 | 2.57 |

| Mean gap | 25.17 | 34.52 | 37.02 | ||||||

| Max gap | 34.46 | 45.79 | 43.44 | ||||||

| Min gap | 17.59 | 21.13 | 29.38 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Xu, L.; Pan, C.; Gao, X.; Xiong, W.; Tang, H.; Lei, D. A Low-Carbon Scheduling Method of Flexible Manufacturing and Crane Transportation Considering Multi-State Collaborative Configuration Based on Hybrid Differential Evolution. Processes 2023, 11, 2737. https://doi.org/10.3390/pr11092737

Liu Z, Xu L, Pan C, Gao X, Xiong W, Tang H, Lei D. A Low-Carbon Scheduling Method of Flexible Manufacturing and Crane Transportation Considering Multi-State Collaborative Configuration Based on Hybrid Differential Evolution. Processes. 2023; 11(9):2737. https://doi.org/10.3390/pr11092737

Chicago/Turabian StyleLiu, Zhengchao, Liuyang Xu, Chunrong Pan, Xiangdong Gao, Wenqing Xiong, Hongtao Tang, and Deming Lei. 2023. "A Low-Carbon Scheduling Method of Flexible Manufacturing and Crane Transportation Considering Multi-State Collaborative Configuration Based on Hybrid Differential Evolution" Processes 11, no. 9: 2737. https://doi.org/10.3390/pr11092737

APA StyleLiu, Z., Xu, L., Pan, C., Gao, X., Xiong, W., Tang, H., & Lei, D. (2023). A Low-Carbon Scheduling Method of Flexible Manufacturing and Crane Transportation Considering Multi-State Collaborative Configuration Based on Hybrid Differential Evolution. Processes, 11(9), 2737. https://doi.org/10.3390/pr11092737