Artificial Intelligence and Carbon Emissions in Manufacturing Firms: The Moderating Role of Green Innovation

Abstract

:1. Introduction

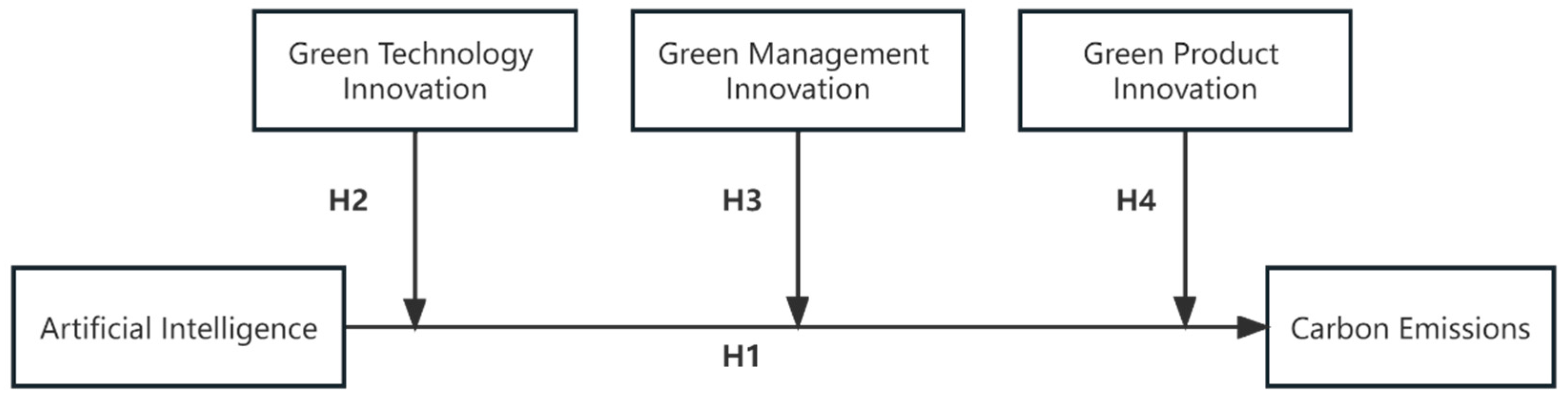

2. Theoretical Background and Hypotheses

2.1. Influence of Enterprise AI Technology on Carbon Emissions

2.2. Moderating Role of Green Technological Innovation

2.3. Moderating Role of Green Management Innovation

2.4. Moderating Effect of Green Product Innovation

3. Methodology

3.1. Sample Selection and Data Sources

3.2. Definitions of the Variables

3.2.1. Dependent Variable

3.2.2. Independent Variable

3.2.3. Moderating Variables

Green Technological Innovation

Green Management Innovation

Green Product Innovation

3.2.4. Control Variables

3.3. Research Model

4. Empirical Analysis Results

4.1. Descriptive Statistics and Correlation Analysis

4.2. Correlation Analysis

4.3. Analysis of Regression Results

4.4. Robustness Tests

Two-Stage Least Squares Test

5. Conclusions and Implications

5.1. Discussion

5.2. Conclusions

5.3. Implications

5.4. Limitations and Future Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiong, J.; Xu, D. Relationship between energy consumption, economic growth and environmental pollution in China. Environ. Res. 2021, 194, 110718. [Google Scholar] [CrossRef]

- Xu, G.; Dong, H.; Xu, Z.; Bhattarai, N. China can reach carbon neutrality before 2050 by improving economic development quality. Energy 2022, 243, 123087. [Google Scholar] [CrossRef]

- Ahad, M.A.; Paiva, S.; Tripathi, G.; Feroz, N. Enabling technologies and sustainable smart cities. Sustain. Cities Soc. 2020, 61, 102301. [Google Scholar] [CrossRef]

- Chatti, W.; Majeed, M.T. Information communication technology (ICT), smart urbanization, and environmental quality: Evidence from a panel of developing and developed economies. J. Clean. Prod. 2022, 366, 132925. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, Y. Study on artificial intelligence: The state of the art and future prospects. J. Ind. Inf. Integr. 2021, 23, 100224. [Google Scholar] [CrossRef]

- Waltersmann, L.; Kiemel, S.; Stuhlsatz, J.; Sauer, A.; Miehe, R. Artificial intelligence applications for increasing resource efficiency in manufacturing companies—A comprehensive review. Sustainability 2021, 13, 6689. [Google Scholar] [CrossRef]

- Ding, T.; Li, J.; Shi, X.; Li, X.; Chen, Y. Is artificial intelligence associated with carbon emissions reduction? Case of China. Resour. Policy 2023, 85, 103892. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Sorooshian, S.; Adeleke, A.Q. Green and low carbon matters: A systematic review of the past, today, and future on sustainability supply chain management practices among manufacturing industry. Clean. Eng. Technol. 2021, 4, 100144. [Google Scholar] [CrossRef]

- Liang, S.; Yang, J.; Ding, T. Performance evaluation of AI driven low carbon manufacturing industry in China: An interactive network DEA approach. Comput. Ind. Eng. 2022, 170, 108248. [Google Scholar] [CrossRef]

- Zhang, C.; Ji, W. Digital twin-driven carbon emission prediction and low-carbon control of intelligent manufacturing job-shop. Procedia CIRP 2019, 83, 624–629. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, Y.; Xing, C.; Liu, J.; He, Y.; Zhou, Y.; Zhang, G. Artificial intelligence powered large-scale renewable integrations in multi-energy systems for carbon neutrality transition: Challenges and future perspectives. Energy Ai 2022, 10, 100195. [Google Scholar] [CrossRef]

- Chen, X.; Wu, X.; Lee, K.Y. The mutual benefits of renewables and carbon capture: Achieved by an artificial intelligent scheduling strategy. Energy Convers. Manag. 2021, 233, 113856. [Google Scholar] [CrossRef]

- Bloomfield, P.S.; Clutton-Brock, P.; Pencheon, E.; Magnusson, J.; Karpathakis, K. Artificial Intelligence in the NHS: Climate and Emissions✰,✰✰. J. Clim. Chang. Health 2021, 4, 100056. [Google Scholar] [CrossRef]

- Liu, L.; Yang, K.; Fujii, H.; Liu, J. Artificial intelligence and energy intensity in China’s industrial sector: Effect and transmission channel. Econ. Anal. Policy 2021, 70, 276–293. [Google Scholar] [CrossRef]

- Chen, C.; Hu, Y.; Karuppiah, M.; Kumar, P.M. Artificial intelligence on economic evaluation of energy efficiency and renewable energy technologies. Sustain. Energy Technol. Assess. 2021, 47, 101358. [Google Scholar] [CrossRef]

- Wu, T.; Zuo, M. Green supply chain transformation and emission reduction based on machine learning. Sci. Prog. 2023, 106, 368504231165679. [Google Scholar] [CrossRef]

- Dauvergne, P. Is artificial intelligence greening global supply chains? Exposing the political economy of environmental costs. Rev. Int. Political Econ. 2022, 29, 696–718. [Google Scholar] [CrossRef]

- Vinuesa, R.; Azizpour, H.; Leite, I.; Balaam, M.; Dignum, V.; Domisch, S.; Felländer, A.; Langhans, S.D.; Tegmark, M.; Fuso Nerini, F. The role of artificial intelligence in achieving the Sustainable Development Goals. Nat. Commun. 2020, 11, 233. [Google Scholar] [CrossRef]

- Gu, R.; Li, C.; Yang, Y.; Zhang, J.; Liu, K. Impact of digital economy development on carbon emission intensity in the Beijing-Tianjin-Hebei region: A mechanism analysis based on industrial structure optimization and green innovation. Environ. Sci. Pollut. Res. 2023, 30, 41644–41664. [Google Scholar] [CrossRef]

- Ch’ng, P.-C.; Cheah, J.; Amran, A. Eco-innovation practices and sustainable business performance: The moderating effect of market turbulence in the Malaysian technology industry. J. Clean. Prod. 2021, 283, 124556. [Google Scholar] [CrossRef]

- Del Río Castro, G.; González Fernández, M.C.; Uruburu Colsa, Á. Unleashing the convergence amid digitalization and sustainability towards pursuing the Sustainable Development Goals (SDGs): A holistic review. J. Clean. Prod. 2021, 280, 122204. [Google Scholar] [CrossRef]

- Qian, Y.; Liu, J.; Shi, L.; Forrest, J.Y.-L.; Yang, Z. Can artificial intelligence improve green economic growth? Evidence from China. Environ. Sci. Pollut. Res. 2023, 30, 16418–16437. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Green supply chain management innovation diffusion and its relationship to organizational improvement: An ecological modernization perspective. J. Eng. Technol. Manag. 2012, 29, 168–185. [Google Scholar] [CrossRef]

- Porter, M.; Van der Linde, C. Green and competitive: Ending the stalemate. Dyn. Eco-Effic. Econ. Environ. Regul. Compet. Advant. 1995, 33, 120–134. [Google Scholar]

- Chen, S.; Zhang, S.; Zeng, Q.; Ao, J.; Chen, X.; Zhang, S. Can artificial intelligence achieve carbon neutrality? Evidence from a quasi-natural experiment. Front. Ecol. Evol. 2023, 11, 1151017. [Google Scholar] [CrossRef]

- Kulkov, I. The role of artificial intelligence in business transformation: A case of pharmaceutical companies. Technol. Soc. 2021, 66, 101629. [Google Scholar] [CrossRef]

- Jose, R.; Panigrahi, S.K.; Patil, R.A.; Fernando, Y.; Ramakrishna, S. Artificial intelligence-driven circular economy as a key enabler for sustainable energy management. Mater. Circ. Econ. 2020, 2, 8. [Google Scholar] [CrossRef]

- Masood, A.; Ahmad, K. A review on emerging artificial intelligence (AI) techniques for air pollution forecasting: Fundamentals, application and performance. J. Clean. Prod. 2021, 322, 129072. [Google Scholar] [CrossRef]

- Pournader, M.; Ghaderi, H.; Hassanzadegan, A.; Fahimnia, B. Artificial intelligence applications in supply chain management. Int. J. Prod. Econ. 2021, 241, 108250. [Google Scholar] [CrossRef]

- Benzidia, S.; Makaoui, N.; Bentahar, O. The impact of big data analytics and artificial intelligence on green supply chain process integration and hospital environmental performance. Technol. Forecast. Soc. Chang. 2021, 165, 120557. [Google Scholar] [CrossRef]

- Sumarliah, E.; Al-hakeem, B. The effects of digital innovations and sustainable supply chain management on business competitive performance post-COVID-19. Kybernetes 2023, 52, 2568–2596. [Google Scholar] [CrossRef]

- Shi, Q.; Lai, X. Identifying the underpin of green and low carbon technology innovation research: A literature review from 1994 to 2010. Technol. Forecast. Soc. Chang. 2013, 80, 839–864. [Google Scholar] [CrossRef]

- Zhang, W.; Li, G. Environmental decentralization, environmental protection investment, and green technology innovation. Environ. Sci. Pollut. Res. 2020, 29, 12740–12755. [Google Scholar] [CrossRef] [PubMed]

- Li, D. Green technology innovation path based on blockchain algorithm. Sustain. Comput. Inform. Syst. 2021, 31, 100587. [Google Scholar] [CrossRef]

- Li, J.; Chen, L.; Chen, Y.; He, J. Digital economy, technological innovation, and green economic efficiency—Empirical evidence from 277 cities in China. Manag. Decis. Econ. 2022, 43, 616–629. [Google Scholar] [CrossRef]

- Shi, R.; Cui, Y.; Zhao, M. Role of low-carbon technology innovation in environmental performance of manufacturing: Evidence from OECD countries. Environ. Sci. Pollut. Res. 2021, 28, 68572–68584. [Google Scholar] [CrossRef]

- Bilal, A.; Li, X.; Zhu, N.; Sharma, R.; Jahanger, A. Green technology innovation, globalization, and CO2 emissions: Recent insights from the OBOR economies. Sustainability 2021, 14, 236. [Google Scholar] [CrossRef]

- Ma, Q.; Tariq, M.; Mahmood, H.; Khan, Z. The nexus between digital economy and carbon dioxide emissions in China: The moderating role of investments in research and development. Technol. Soc. 2022, 68, 101910. [Google Scholar] [CrossRef]

- Du, K.; Li, J. Towards a green world: How do green technology innovations affect total-factor carbon productivity. Energy Policy 2019, 131, 240–250. [Google Scholar] [CrossRef]

- Song, M.; Peng, L.; Shang, Y.; Zhao, X. Green technology progress and total factor productivity of resource-based enterprises: A perspective of technical compensation of environmental regulation. Technol. Forecast. Soc. Chang. 2022, 174, 121276. [Google Scholar] [CrossRef]

- Li, F.; Xu, X.; Li, Z.; Du, P.; Ye, J. Can low-carbon technological innovation truly improve enterprise performance? The case of Chinese manufacturing companies. J. Clean. Prod. 2021, 293, 125949. [Google Scholar] [CrossRef]

- Miao, C.-L.; Duan, M.-M.; Zuo, Y.; Wu, X.-Y. Spatial heterogeneity and evolution trend of regional green innovation efficiency--An empirical study based on panel data of industrial enterprises in China’s provinces. Energy Policy 2021, 156, 112370. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, S.; Zhang, J.; Yang, K. Research on the impact of digital economy on Regional Green Technology Innovation: Moderating effect of digital talent Aggregation. Environ. Sci. Pollut. Res. 2023, 30, 74409–74425. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Xing, C.; Wang, Y. Does green innovation mitigate financing constraints? Evidence from China’s private enterprises. J. Clean. Prod. 2020, 264, 121698. [Google Scholar] [CrossRef]

- Ma, Y.; Hou, G.; Yin, Q.; Xin, B.; Pan, Y. The sources of green management innovation: Does internal efficiency demand pull or external knowledge supply push? J. Clean. Prod. 2018, 202, 582–590. [Google Scholar] [CrossRef]

- Zhang, M.; Zeng, W.; Tse, Y.K.; Wang, Y.; Smart, P. Examining the antecedents and consequences of green product innovation. Ind. Mark. Manag. 2021, 93, 413–427. [Google Scholar] [CrossRef]

- Roberts, R. Managing innovation: The pursuit of competitive advantage and the design of innovation intense environments. Res. Policy 1998, 27, 159–175. [Google Scholar] [CrossRef]

- Fernandez, V. Environmental management: Implications for business performance, innovation, and financing. Technol. Forecast. Soc. Chang. 2022, 182, 121797. [Google Scholar] [CrossRef]

- Zameer, H.; Wang, Y.; Yasmeen, H. Reinforcing green competitive advantage through green production, creativity and green brand image: Implications for cleaner production in China. J. Clean. Prod. 2020, 247, 119119. [Google Scholar] [CrossRef]

- Huong, P.T.; Cherian, J.; Hien, N.T.; Sial, M.S.; Samad, S.; Tuan, B.A. Environmental management, green innovation, and social–open innovation. J. Open Innov. Technol. Mark. Complex. 2021, 7, 89. [Google Scholar] [CrossRef]

- Peters, K.; Buijs, P. Strategic ambidexterity in green product innovation: Obstacles and implications. Bus. Strat. Environ. 2022, 31, 173–193. [Google Scholar] [CrossRef]

- Fleith de Medeiros, J.; Bisognin Garlet, T.; Duarte Ribeiro, J.L.; Nogueira Cortimiglia, M. Success factors for environmentally sustainable product innovation: An updated review. J. Clean. Prod. 2022, 345, 131039. [Google Scholar] [CrossRef]

- Khan, S.J.; Dhir, A.; Parida, V.; Papa, A. Past, present, and future of green product innovation. Bus. Strat. Environ. 2021, 30, 4081–4106. [Google Scholar] [CrossRef]

- Hang, Y.; Sarfraz, M.; Khalid, R.; Ozturk, I.; Tariq, J. Does corporate social responsibility and green product innovation boost organizational performance? a moderated mediation model of competitive advantage and green trust. Econ. Res. Ekon. Istraživanja 2022, 35, 5379–5399. [Google Scholar] [CrossRef]

- Meng, Q.; Li, M.; Liu, W.; Li, Z.; Zhang, J. Pricing policies of dual-channel green supply chain: Considering government subsidies and consumers‘ dual preferences. Sustain. Prod. Consum. 2021, 26, 1021–1030. [Google Scholar] [CrossRef]

- Dugoua, E.; Dumas, M. Green product innovation in industrial networks: A theoretical model. J. Environ. Econ. Manag. 2021, 107, 102420. [Google Scholar] [CrossRef]

- Mariani, M.M.; Machado, I.; Nambisan, S. Types of innovation and artificial intelligence: A systematic quantitative literature review and research agenda. J. Bus. Res. 2023, 155, 113364. [Google Scholar] [CrossRef]

- Zheng, Y.; Sun, X.; Zhang, C.; Wang, D.; Mao, J. Can emission trading scheme improve carbon emission performance? Evidence from China. Front. Energy Res. 2021, 9, 759572. [Google Scholar] [CrossRef]

- Goud, N.N. Corporate governance: Does it matter management of carbon emission performance? An empirical analyses of Indian companies. J. Clean. Prod. 2022, 379, 134485. [Google Scholar] [CrossRef]

- Wei, P.; Li, Y.; Ren, X.; Duan, K. Crude oil price uncertainty and corporate carbon emissions. Environ. Sci. Pollut. Res. 2022, 29, 2385–2400. [Google Scholar] [CrossRef]

- Liu, J.; Liu, L.; Qian, Y.; Song, S. The effect of artificial intelligence on carbon intensity: Evidence from China‘s industrial sector. Socio-Econ. Plan. Sci. 2022, 83, 101002. [Google Scholar] [CrossRef]

- Chen, P.; Gao, J.; Ji, Z.; Liang, H.; Peng, Y. Do artificial intelligence applications affect carbon emission performance?—Evidence from panel data analysis of Chinese cities. Energies 2022, 15, 5730. [Google Scholar] [CrossRef]

- Tao, S.; Wang, Y.; Zhai, Y. Can the application of artificial intelligence in industry cut China’s industrial carbon intensity? Environ. Sci. Pollut. Res. 2023, 30, 79571–79586. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Xu, Y.; Zheng, H.; Wang, Z.; Han, H.; Zeng, L. Artificial intelligence, resource reallocation, and corporate innovation efficiency: Evidence from China‘s listed companies. Resour. Policy 2023, 81, 103324. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, X. The carbon emissions trading scheme and green technology innovation in China: A new structural economics perspective. Econ. Anal. Policy 2022, 74, 365–381. [Google Scholar] [CrossRef]

- Yu, P.; Hao, R.; Cai, Z.; Sun, Y.; Zhang, X. Does emission trading system achieve the win-win of carbon emission reduction and financial performance improvement?—Evidence from Chinese A-share listed firms in industrial sector. J. Clean. Prod. 2022, 333, 130121. [Google Scholar] [CrossRef]

- Li, Y.; Huang, N.; Zhao, Y. The impact of green innovation on enterprise green economic efficiency. Int. J. Environ. Res. Public Health 2022, 19, 16464. [Google Scholar] [CrossRef]

- Xie, Z.; Lu, W.; Yu, J.; Wu, Y.; Liu, Q. Development zones and green innovation: Evidence from Chinese listed companies. China Econ. Rev. 2022, 76, 101874. [Google Scholar] [CrossRef]

- Wang, S.; Abbas, J.; Sial, M.S.; Álvarez-Otero, S.; Cioca, L.I. Achieving green innovation and sustainable development goals through green knowledge management: Moderating role of organizational green culture. J. Innov. Knowl. 2022, 7, 100272. [Google Scholar] [CrossRef]

- Papagiannakis, G.; Voudouris, I.; Lioukas, S.; Kassinis, G. Environmental management systems and environmental product innovation: The role of stakeholder engagement. Bus. Strat. Environ. 2019, 28, 939–950. [Google Scholar] [CrossRef]

- Qi, G.; Jia, Y.; Zou, H. Is institutional pressure the mother of green innovation? Examining the moderating effect of absorptive capacity. J. Clean. Prod. 2021, 278, 123957. [Google Scholar] [CrossRef]

- Lee, K.-H.; Min, B. Green R&D for eco-innovation and its impact on carbon emissions and firm performance. J. Clean. Prod. 2015, 108, 534–542. [Google Scholar] [CrossRef]

- Banker, R.D.; Mashruwala, R.; Tripathy, A. Does a differentiation strategy lead to more sustainable financial performance than a cost leadership strategy? Manag. Decis. 2014, 52, 872–896. [Google Scholar] [CrossRef]

- Visnjic, I.; Wiengarten, F.; Neely, A. Only the brave: Product innovation, service business model innovation, and their impact on performance. J. Prod. Innov. Manag. 2016, 33, 36–52. [Google Scholar] [CrossRef]

- Liu, J.; Qian, Y.; Yang, Y.; Yang, Z. Can artificial intelligence improve the energy efficiency of manufacturing companies? Evidence from China. Int. J. Environ. Res. Public Health 2022, 19, 2091. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhu, Z. Liability structure and carbon emissions abatement: Evidence from Chinese manufacturing enterprises. Environ. Resour. Econ. 2022, 83, 481–507. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Zhang, Q. Does carbon efficiency improve financial performance? Evidence from Chinese firms. Energy Econ. 2021, 104, 105658. [Google Scholar] [CrossRef]

- Zhang, Y.-J.; Shi, W.; Jiang, L. Does China’s carbon emissions trading policy improve the technology innovation of relevant enterprises? Bus. Strat. Environ. 2020, 29, 872–885. [Google Scholar] [CrossRef]

- Yin, K.; Cai, F.; Huang, C. How does artificial intelligence development affect green technology innovation in China? Evidence from dynamic panel data analysis. Environ. Sci. Pollut. Res. 2023, 30, 28066–28090. [Google Scholar] [CrossRef]

- Sharma, M.; Luthra, S.; Joshi, S.; Kumar, A. Implementing challenges of artificial intelligence: Evidence from public manufacturing sector of an emerging economy. Gov. Inf. Q. 2022, 39, 101624. [Google Scholar] [CrossRef]

- Chiarini, A. Industry 4.0 technologies in the manufacturing sector: Are we sure they are all relevant for environmental performance? Bus. Strat. Environ. 2021, 30, 3194–3207. [Google Scholar] [CrossRef]

- Hojageldiyev, D. Artificial intelligence opportunities for environmental protection. In Proceedings of the SPE Gas & Oil Technology Showcase and Conference, Dubai, United Arab Emirates, 21–23 October 2019. [Google Scholar] [CrossRef]

- Bu, H.; Li, G.; Yu, X.; Xun, Z. Is smart carbon emission reduction justified in China? Evidence from national big data comprehensive pilot zones. Heliyon 2023, 9, e17744. [Google Scholar] [CrossRef] [PubMed]

- Bhatti, U.A.; Hashmi, M.Z.; Sun, Y.; Masud, M.; Nizamani, M.M. Editorial: Artificial intelligence applications in reduction of carbon emissions: Step towards sustainable environment. Front. Environ. Sci. 2023, 11, 1183620. [Google Scholar] [CrossRef]

- Mao, S.; Wang, B.; Tang, Y.; Qian, F. Opportunities and challenges of artificial intelligence for green manufacturing in the process industry. Engineering 2019, 5, 995–1002. [Google Scholar] [CrossRef]

| Artificial Intelligence | Artificial Intelligence, Business Intelligence, Image Understanding, Investment Decision Aids, Intelligent Data Analytics, Intelligent Robotics, Machine Learning, Deep Analysis, Semantic Search, Biometrics, Face Recognition, Voice Recognition, Identity Verification, Automatic Driving, Natural Language Processing |

| Variable | Name | Symbol | Definition |

|---|---|---|---|

| Independent variable | Artificial Intelligence Technology Application | AI | Ln (keyword word frequency + 1) |

| Dependent variable | Carbon Emissions Intensity | CEI | Ln (total annual corporate carbon emissions) |

| Moderating variables | Green Technological Innovation | GTI | Number of green invention patent applications/total invention patent applications |

| Green Management Innovation | GMI | Whether ISO 14001 certified | |

| Green Product Innovation | GDI | R&D intensity: R&D investment/revenue | |

| Control variables | Enterprise Size | Size | Ln (book value of total assets at year-end) |

| Return on Assets | ROA | Net profit/total assets | |

| Return On Equity | ROE | Net profit/average balance of shareholders’ equity | |

| Asset–liability Ratio | LEV | Total liabilities/total assets | |

| Total Asset Turnover Ratio | ATO | Operating income/assets | |

| State-owned Enterprise or Not | SOE | 1 for state-owned enterprise, 0 otherwise | |

| Years of Establishment | FirmAge | Ln (current year − year of incorporation + 1) |

| Variables | Mean | Sd | Min | P50 | Max | n |

|---|---|---|---|---|---|---|

| CEI | 11.40 | 1.34 | 8.84 | 11.24 | 15.18 | 9547 |

| AI | 0.18 | 0.45 | 0 | 0 | 2.71 | 9547 |

| GEI | 0.08 | 0.18 | 0 | 0 | 1 | 9547 |

| GMI | 0.33 | 0.47 | 0 | 0 | 1 | 9547 |

| GDI | 4.52 | 3.01 | 0.13 | 3.93 | 20.33 | 9547 |

| Size | 22.04 | 1.17 | 20.12 | 21.86 | 25.61 | 9547 |

| LEV | 0.37 | 0.18 | 0.06 | 0.36 | 0.77 | 9547 |

| ROA | 0.06 | 0.05 | −0.12 | 0.05 | 0.21 | 9547 |

| ROE | 0.09 | 0.09 | −0.28 | 0.09 | 0.34 | 9547 |

| ATO | 0.68 | 0.34 | 0.17 | 0.61 | 2.21 | 9547 |

| SOE | 0.22 | 0.42 | 0 | 0 | 1 | 9547 |

| FirmAge | 2.87 | 0.3 | 1.95 | 2.89 | 3.43 | 9547 |

| Variables | CEI | AI | GEI | GMI | GDI | Size | LEV | ROA | ROE | ATO | SOE | FirmAge |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CEI | 1 | |||||||||||

| AI | 0.049 *** | 1 | ||||||||||

| GEI | 0.063 *** | 0.023 ** | 1 | |||||||||

| GMI | 0.052 *** | 0.009 | −0.002 | 1 | ||||||||

| GDI | −0.365 *** | 0.170 *** | 0.009 | −0.043 *** | 1 | |||||||

| Size | 0.915 *** | 0.070 *** | 0.080 *** | 0.054 *** | −0.266 *** | 1 | ||||||

| LEV | 0.562 *** | 0.045 *** | 0.106 *** | 0.042 *** | −0.270 *** | 0.555 *** | 1 | |||||

| ROA | 0.009 | −0.005 | −0.044 *** | −0.002 | 0.027 *** | −0.071 *** | −0.430 *** | 1 | ||||

| ROE | 0.165 *** | 0.016 | −0.015 | 0.008 | −0.047 *** | 0.078 *** | −0.194 *** | 0.930 *** | 1 | |||

| ATO | 0.473 *** | −0.018 * | −0.022 ** | 0.052 *** | −0.383 *** | 0.188 *** | 0.206 *** | 0.199 *** | 0.272 *** | 1 | ||

| SOE | 0.369 *** | −0.073 *** | 0.021 ** | 0.049 *** | −0.199 *** | 0.388 *** | 0.312 *** | −0.183 *** | −0.120 *** | 0.113 *** | 1 | |

| FirmAge | 0.204 *** | 0.063 *** | −0.054 *** | 0.084 *** | −0.081 *** | 0.208 *** | 0.124 *** | −0.046 *** | −0.013 | 0.065 *** | 0.177 *** | 1 |

| (1) | (2) | (3) | (4) | |

|---|---|---|---|---|

| Variable | CEI | CEI | CEI | CEI |

| AI | −0.022 ** | −0.023 ** | −0.023 ** | −0.031 *** |

| (−2.13) | (−2.23) | (−2.24) | (−2.67) | |

| GEI | −0.043 * | |||

| (−1.67) | ||||

| AI*GEI | −0.110 * | |||

| (−1.82) | ||||

| GMI | −0.032 *** | |||

| (−3.06) | ||||

| AI*GMI | −0.036 ** | |||

| (−1.98) | ||||

| GDI | −0.008 *** | |||

| (−4.74) | ||||

| AI*GDI | −0.006 ** | |||

| (−2.06) | ||||

| Size | 0.888 *** | 0.889 *** | 0.887 *** | 0.887 *** |

| (50.26) | (50.35) | (50.21) | (50.64) | |

| LEV | 0.293 *** | 0.292 *** | 0.297 *** | 0.273 *** |

| (4.79) | (4.79) | (4.87) | (4.49) | |

| ROA | 0.474 | 0.476 | 0.498 | 0.346 |

| (1.21) | (1.21) | (1.27) | (0.90) | |

| ROE | 0.090 | 0.087 | 0.081 | 0.109 |

| (0.43) | (0.42) | (0.39) | (0.53) | |

| ATO | 1.155 *** | 1.154 *** | 1.152 *** | 1.145 *** |

| (26.72) | (26.71) | (26.73) | (26.61) | |

| SOE | −0.044 | −0.044 | −0.041 | −0.039 |

| (−1.18) | (−1.20) | (−1.12) | (−1.06) | |

| FirmAge | 0.133 | 0.132 | 0.131 | 0.141 |

| (1.39) | (1.38) | (1.36) | (1.49) | |

| Constant | −9.522 *** | −9.527 *** | −9.495 *** | −9.519 *** |

| (−22.26) | (−22.31) | (−22.15) | (−22.38) | |

| Observations | 9547 | 9547 | 9547 | 9547 |

| Adjusted R-squared | 0.682 | 0.682 | 0.683 | 0.684 |

| Number of id | 1938 | 1938 | 1938 | 1938 |

| Year FE (Fixed Effect) | YES | YES | YES | YES |

| Variable | First Stage | Second Stage |

|---|---|---|

| AI | CEI | |

| LAI | 0.477 *** | |

| (29.54) | ||

| AI | −0.056 * | |

| (−1.87) | ||

| Size | 0.158 *** | 0.872 *** |

| (2.90) | (40.25) | |

| Lev | 0.385 * | 0.325 *** |

| (1.91) | (4.87) | |

| ROA | −0.089 | 0.409 |

| (−0.07) | (0.98) | |

| ROE | 0.074 | 0.046 |

| (0.12) | (0.20) | |

| ATO | −0.040 | −0.062 * |

| (−0.37) | (−1.75) | |

| SOE | −0.282 ** | 0.233 ** |

| (−2.37) | (2.13) | |

| FirmAge | −0.377 | −0.056 * |

| (−1.08) | (−1.87) | |

| Underidentification test (Kleibergen-Paap rk LM statistic) | 59.333 (Chi-sq(1) p-val = 0.000) | |

| Weak identification test | ||

| (Cragg-Donald Wald F statistic) | 524.712 | |

| (Kleibergen-Paap rk Wald F statistic) | 123.726 | |

| 10% maximal IV size | 16.380 | |

| Observations | 6828 | 6531 |

| Adjusted R-squared | 0.518 | 0.605 |

| Year FE | YES | YES |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Jin, S. Artificial Intelligence and Carbon Emissions in Manufacturing Firms: The Moderating Role of Green Innovation. Processes 2023, 11, 2705. https://doi.org/10.3390/pr11092705

Chen Y, Jin S. Artificial Intelligence and Carbon Emissions in Manufacturing Firms: The Moderating Role of Green Innovation. Processes. 2023; 11(9):2705. https://doi.org/10.3390/pr11092705

Chicago/Turabian StyleChen, Yixuan, and Shanyue Jin. 2023. "Artificial Intelligence and Carbon Emissions in Manufacturing Firms: The Moderating Role of Green Innovation" Processes 11, no. 9: 2705. https://doi.org/10.3390/pr11092705

APA StyleChen, Y., & Jin, S. (2023). Artificial Intelligence and Carbon Emissions in Manufacturing Firms: The Moderating Role of Green Innovation. Processes, 11(9), 2705. https://doi.org/10.3390/pr11092705