Numeric Investigation on the Stability of a Preformed Roadway under Backfill Body Subjected to Blasting Load

Abstract

1. Introduction

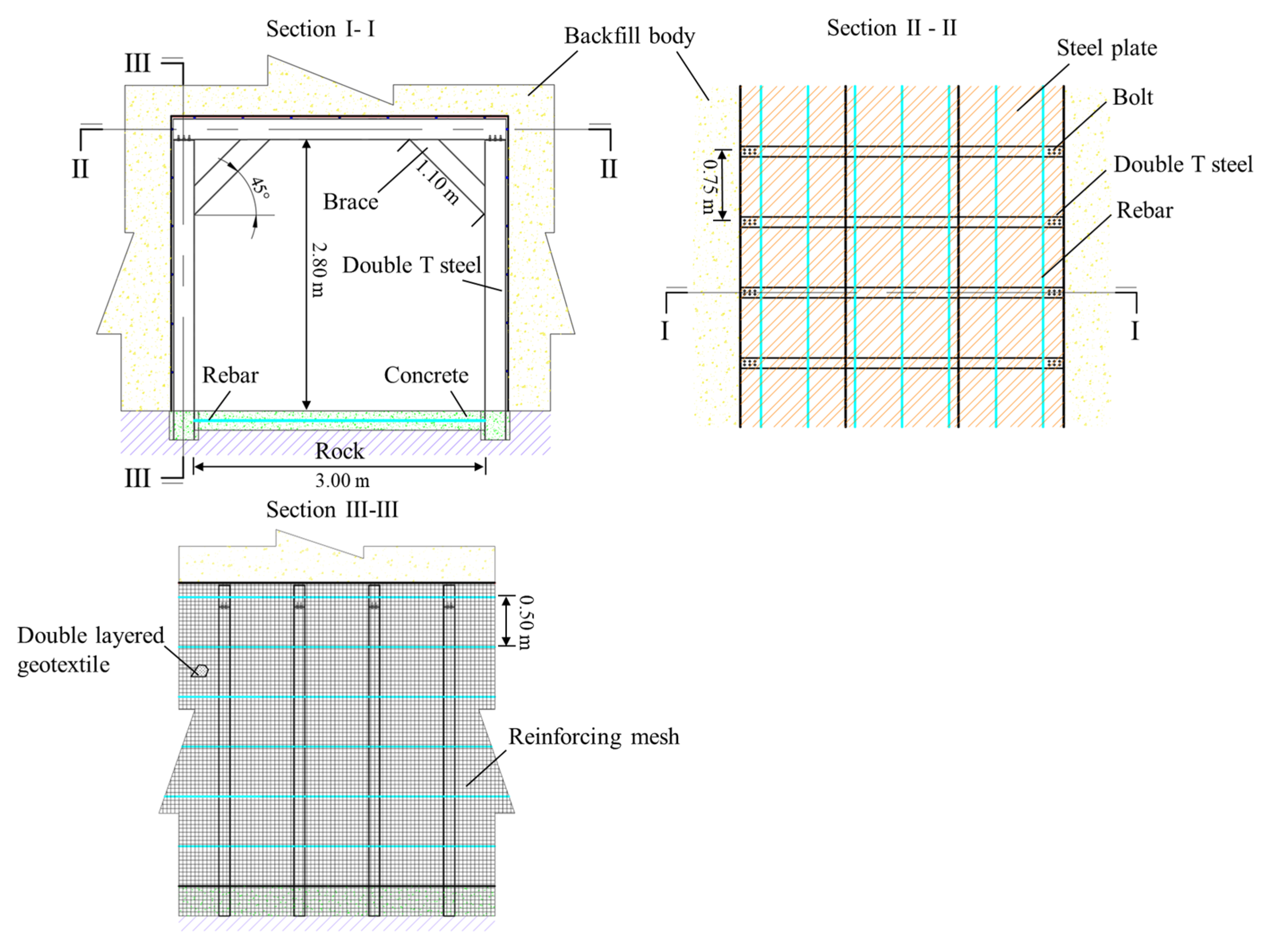

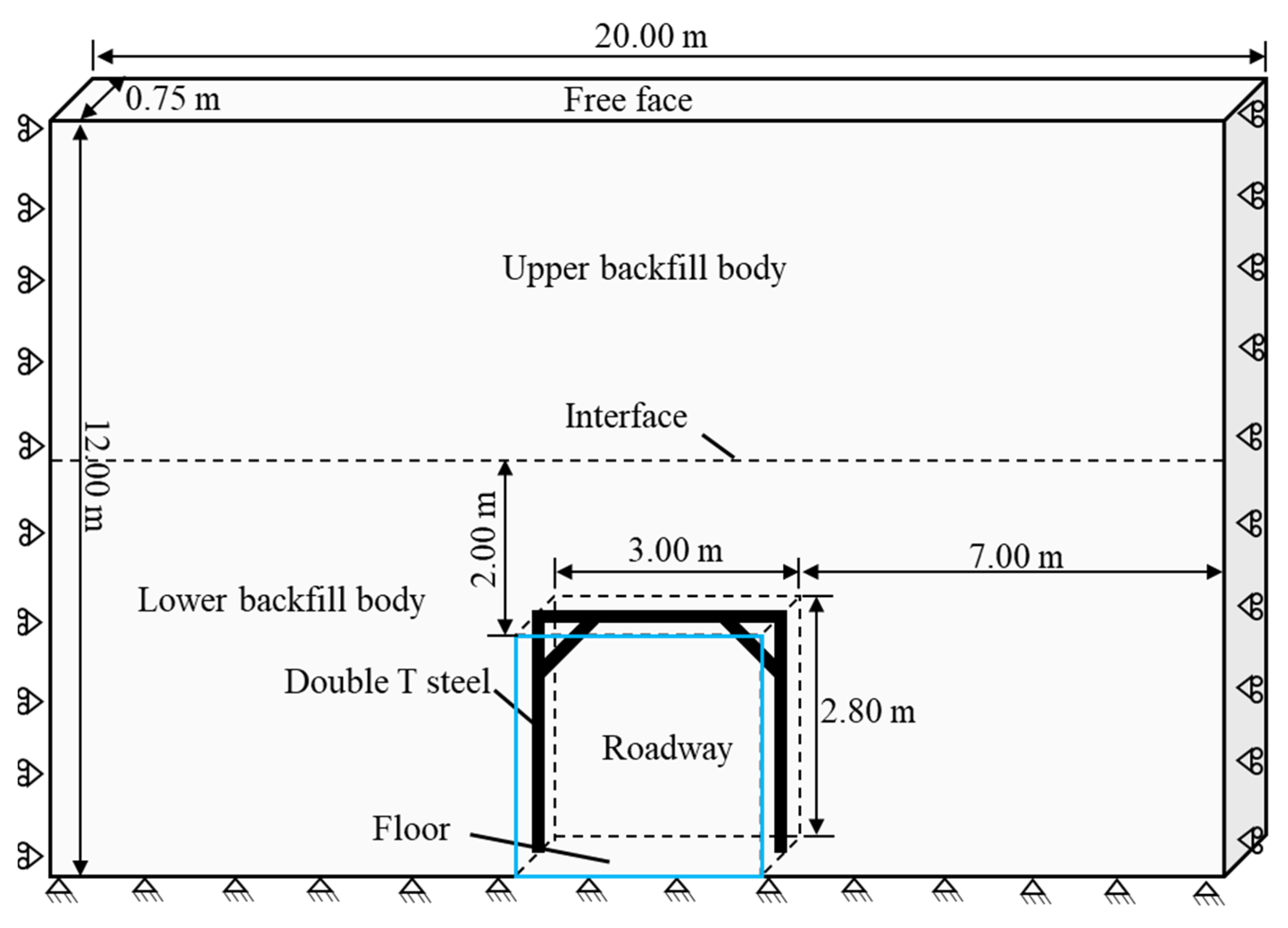

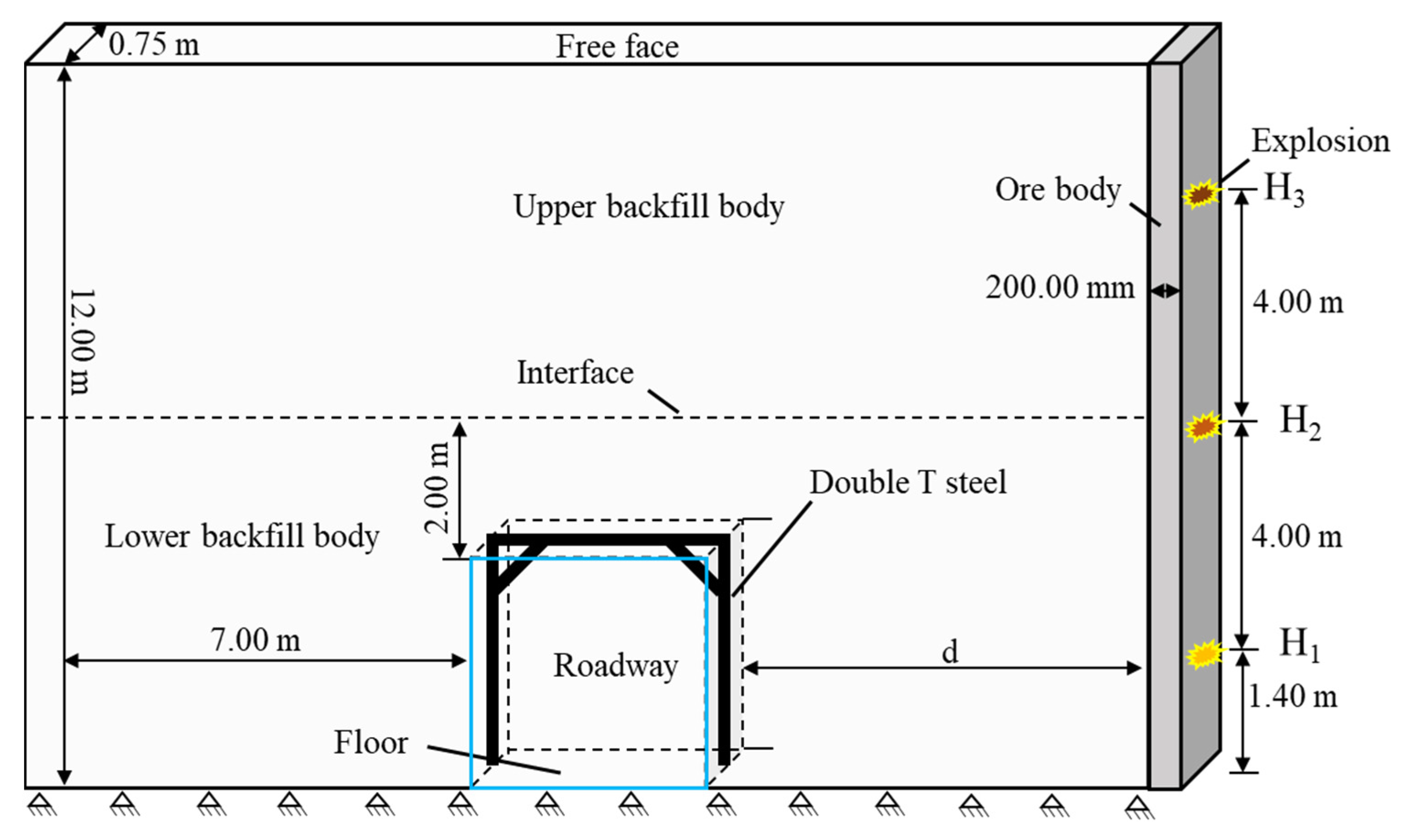

2. Engineering Background

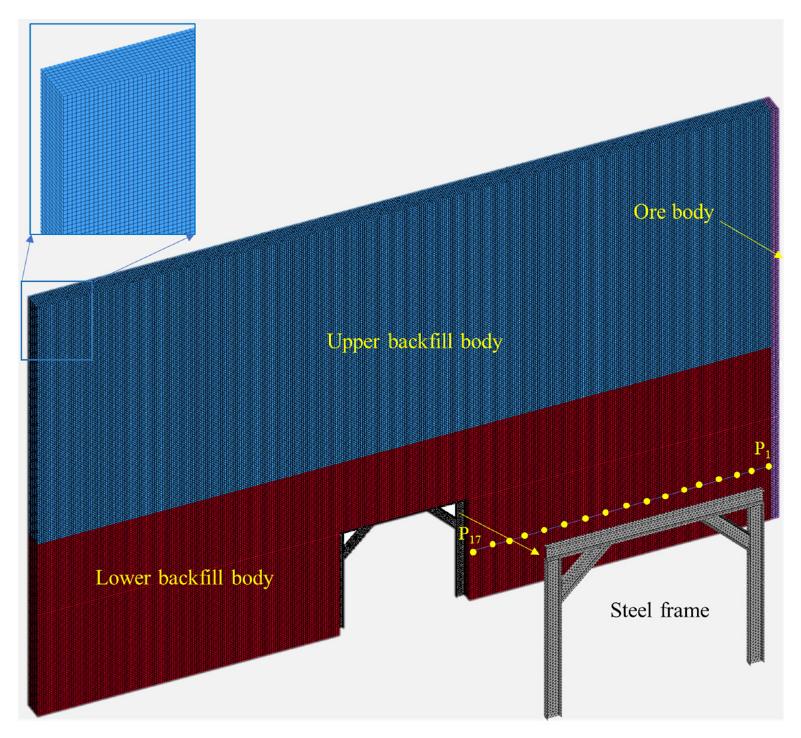

3. Numerical Simulations

3.1. Boundary Conditions of Numerical Model

3.2. Material Model and Parameters

4. Numerical Results and Discussion

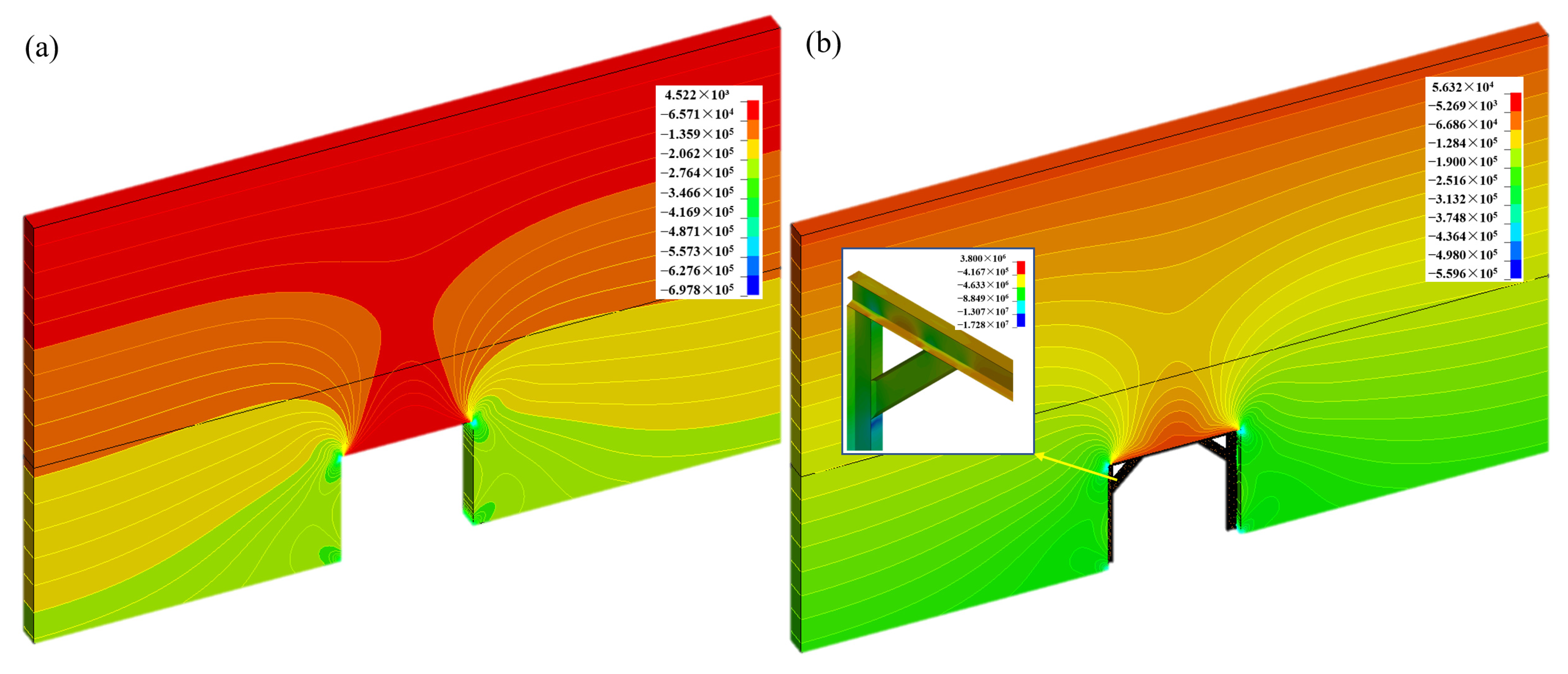

4.1. Static Response of the Roadway under Gravitational Load

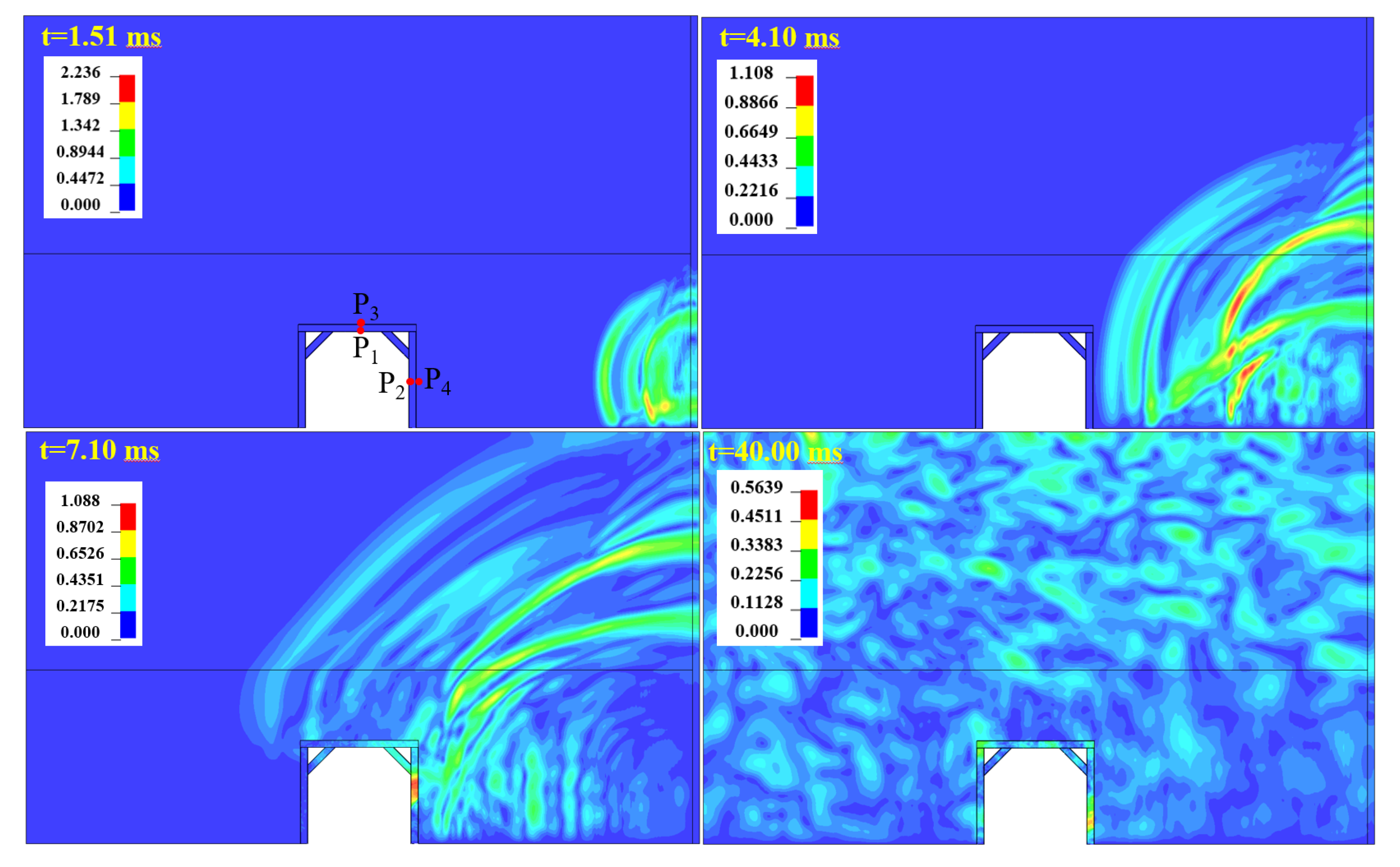

4.2. Dynamic Response of the Roadway Subjected to a Blasting Load

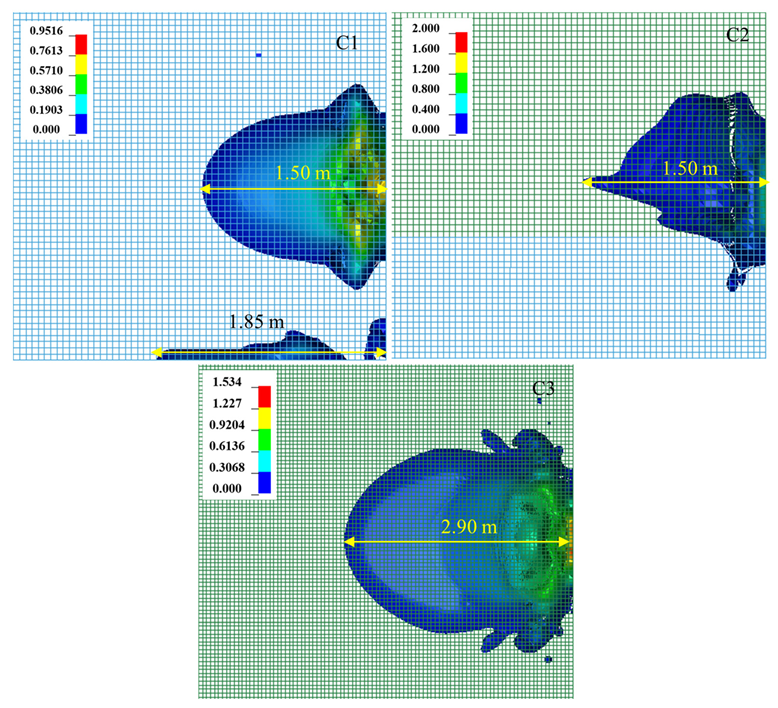

4.3. Blasting-Induced Damage in Backfill Bodies

4.4. Blasting Vibration Velocity

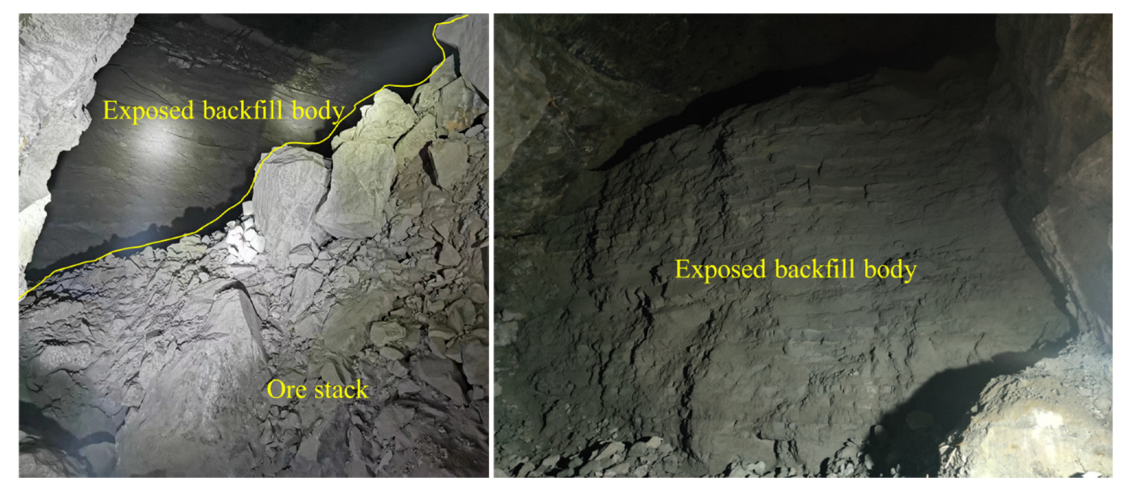

5. Engineering Practice of Mine Pillar Recovery

6. Conclusions

- (1)

- The preformed roadway remained stable under both gravitational load and blasting dynamic impact with a charge of 3.00 kg per blasthole rock emulsion explosive.

- (2)

- The backfill body posed a low risk when subjected to blasting impact. In terms of material failure, the largest failure zone was only a vertical strip zone of 60.00 mm in width near the backfill body, which is totally acceptable in engineering practice.

- (3)

- The blasting vibration attenuation in the steel frame was slower than that in the backfill body, and the vibration frequency in the steel frame was higher than that in the backfill body. Therefore, the quality of the welding spot and screw connection in the steel frame during mine pillar recovery should be carefully considered.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, X.; Zhao, Y.; Guo, Z.; Liu, Y.; Wang, H.; Zhang, J.; Yi, D.; Cao, Y.; Yang, X.; Liu, B.; et al. Influence of different substrates on the microstructure and mechanical properties of WC-12Co cemented carbide fabricated via laser melting deposition. Int. J. Refract. Met. Hard Mater. 2022, 104, 105787. [Google Scholar] [CrossRef]

- Han, Z.; Golev, A.; Edraki, M. A Review of Tungsten Resources and Potential Extraction from Mine Waste. Minerals 2021, 11, 701. [Google Scholar] [CrossRef]

- Leal-Ayala, D.R.; Allwood, J.M.; Petavratzi, E.; Brown, T.J.; Gunn, G. Mapping the global flow of tungsten to identify key material efficiency and supply security opportunities. Resour. Conserv. Recycl. 2015, 103, 19–28. [Google Scholar] [CrossRef]

- Barume, B.; Naeher, U.; Ruppen, D.; Schütte, P. Conflict minerals (3TG): Mining production, applications and recycling. Curr. Opin. Green Sustain. Chem. 2016, 1, 8–12. [Google Scholar] [CrossRef]

- Zhang, Y.; Ni, P. Design optimization of room and pillar mines: A case study of the Xianglushan tungsten mine. Q. J. Eng. Geol. Hydrogeol. 2018, 51, 352–364. [Google Scholar] [CrossRef]

- Navarro Torres, V.F.; Dinis da Gama, C.; Costa e Silva, M.; Neves, P.F.; Xie, Q. Comparative stability analyses of traditional and selective room-and-pillar mining techniques for sub-horizontal tungsten veins. Int. J. Miner. Metall. Mater. 2011, 18, 1–8. [Google Scholar] [CrossRef]

- Mark, C.; Gauna, M. Preventing roof fall fatalities during pillar recovery: A ground control success story. Int. J. Min. Sci. Technol. 2017, 27, 107–113. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, J.; Zhou, N. Study and discussion of short- strip coal pillar recovery with cemented paste backfill. Int. J. Rock Mech. Min. Sci. 2018, 104, 147–155. [Google Scholar] [CrossRef]

- Cao, S.; Xue, G.; Yilmaz, E.; Yin, Z.; Yang, F. Utilizing concrete pillars as an environmental mining practice in underground mines. J. Clean. Prod. 2021, 278, 123433. [Google Scholar] [CrossRef]

- Mallı, T.; Yetkin, M.E.; Özfırat, M.K.; Kahraman, B. Numerical analysis of underground space and pillar design in metalliferous mine. J. Afr. Earth Sci. 2017, 134, 365–372. [Google Scholar] [CrossRef]

- Yang, C.; Zhou, K.; Gao, R.; Xiong, X. Numerical investigation of the dynamic response of a preconditioned roof in an underground mine: A case study of mining environment regeneration. Soil Dyn. Earthq. Eng. 2021, 140, 106457. [Google Scholar] [CrossRef]

- Zhou, N.; Yan, H.; Jiang, S.; Sun, Q.; Ouyang, S. Stability Analysis of Surrounding Rock in Paste Backfill Recovery of Residual Room Pillars. Sustainability 2019, 11, 478. [Google Scholar] [CrossRef]

- Yang, L.; Li, J.; Liu, H.; Jiao, H.; Yin, S.; Chen, X.; Yu, Y. Systematic review of mixing technology for recycling waste tailings as cemented paste backfill in mines in China. Int. J. Miner. Metall. Mater. 2023, 30, 1430–1443. [Google Scholar] [CrossRef]

- Kefeni, K.K.; Msagati, T.A.M.; Mamba, B.B. Acid mine drainage: Prevention, treatment options, and resource recovery: A review. J. Clean. Prod. 2017, 151, 475–493. [Google Scholar] [CrossRef]

- Singalreddy, S.P.; Cui, L.; Fang, K. Spatiotemporal evolution of thermo-hydro-mechanical-chemical processes in cemented paste backfill under interfacial loading. Int. J. Min. Sci. Technol. 2022, 32, 1207–1217. [Google Scholar] [CrossRef]

- Hefni, M.; Hassani, F. Experimental development of a novel mine backfill material: Foam mine fill. Minerals 2020, 10, 564. [Google Scholar] [CrossRef]

- Skrzypkowski, K. Decreasing Mining Losses for the Room and Pillar Method by Replacing the Inter-Room Pillars by the Construction of Wooden Cribs Filled with Waste Rocks. Energies 2020, 13, 3564. [Google Scholar] [CrossRef]

- Kermani, M.; Hassani, F.P.; Aflaki, E.; Benzaazoua, M.; Nokken, M. Evaluation of the effect of sodium silicate addition to mine backfill, Gelfill—Part 1. J. Rock Mech. Geotech. Eng. 2015, 7, 266–272. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, B.; Zhang, Q. Cemented backfill technology based on phosphorous gypsum. J. Cent. South Univ. Technol. 2009, 16, 285–291. [Google Scholar] [CrossRef]

- Zhou, S.; Li, X.; Zhou, Y.; Min, C.; Shi, Y. Effect of phosphorus on the properties of phosphogypsum-based cemented backfill. J. Hazard. Mater. 2020, 399, 122993. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Q.; Qi, C.; Fourie, A.; Xiao, C. Recycling phosphogypsum and construction demolition waste for cemented paste backfill and its environmental impact. J. Clean Prod. 2018, 186, 418–429. [Google Scholar] [CrossRef]

- Cao, S.; Yilmaz, E.; Song, W. Fiber type effect on strength, toughness and microstructure of early age cemented tailings backfill. Constr. Build. Mater. 2019, 223, 44–54. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Yu, Z.; Huang, P. Determination of mechanical, flowability, and microstructural properties of cemented tailings backfill containing rice straw. Constr. Build. Mater. 2020, 246, 118520. [Google Scholar] [CrossRef]

- Dewing, K.; Sharp, R.J.; Muraro, T. Exploration History and Mineral Potential of the Central Arctic Zn-Pb District, Nunavut. Arctic 2006, 59, 415–427. [Google Scholar] [CrossRef][Green Version]

- Cluff, D.L.; Kazakidis, V.N. Opportunities and constraints of engineering frozen backfill for underground mining applications in permafrost. In Proceedings of the ISCORD 2013: Planning for Sustainable Cold Regions, Anchorage, Alaska, 2–5 June 2013; American Society of Civil Engineers: Reston, VI, USA, 2013; pp. 175–190. [Google Scholar]

- Jiang, H.; Fall, M. Yield stress and strength of saline cemented tailings in sub-zero environments: Portland cement paste backfill. Int. J. Miner. Process. 2017, 160, 68–75. [Google Scholar] [CrossRef]

- Hou, C.; Zhu, W.; Yan, B.; Guan, K.; Du, J. The effects of temperature and binder content on the behavior of frozen cemented tailings backfill at early ages. Constr. Build. Mater. 2020, 239, 117752. [Google Scholar] [CrossRef]

- Zhang, Q.; Tao, Z.; Yang, C.; Guo, S.; He, M.; Zhang, C.; Niu, H.; Wang, C.; Wang, S. Experimental and numerical investigation into the non-explosive excavation of tunnels. J. Rock Mech. Geotech. Eng. 2022, 14, 1885–1900. [Google Scholar] [CrossRef]

- Yang, C.; Hassani, F.; Zhou, K.; Zhang, Q.; Wang, F.; Gao, F.; Topa, A. Numerical investigation of TBM disc cutter cutting on microwave-treated basalt with an unrelieved model. Arch. Civ. Mech. Eng. 2022, 22, 147. [Google Scholar] [CrossRef]

- Song, J.; Luo, J.; Zhou, A.; Ou, R.; Ning, Y.; Lin, W. Application of backfill with cofferdam packing bags in Xianglushan tungsten ore. Min. Res. Dev. 2015, 35, 1–4. [Google Scholar]

- Zhu, Z.; Mohanty, B.; Xie, H. Numerical investigation of blasting-induced crack initiation and propagation in rocks. Int. J. Rock Mech. Min. 2007, 44, 412–424. [Google Scholar] [CrossRef]

- Yu, Y.; Ma, L.; Zhang, D. Characteristics of Roof Ground Subsidence While Applying a Continuous Excavation Continuous Backfill Method in Longwall Mining. Energies 2020, 13, 95. [Google Scholar] [CrossRef]

- Emad, M.Z.; Mitri, H.; Kelly, C. Dynamic model validation using blast vibration monitoring in mine backfill. Int. J. Rock Mech. Min. 2018, 107, 48–54. [Google Scholar] [CrossRef]

- Zhou, A.; Luo, J.; Song, J.; Ou, R.; Ning, Y.; Lin, W. Experimental study on filling technology with cofferdam bags in Xianglushan tungsten mine. Min. Res. Dev. 2015, 35, 1–4. [Google Scholar]

- GB 16423-2020; Safety Rerulations for Melal and Non-Metal Mines. Emergency Manaement Department of the People’s Repubic of China, Stae Admimsration for Market Reaulation of the People’s Repubic of China: Beijing, China, 2020.

- Gao, F.; Tang, L.; Yang, C.; Yang, P.; Xiong, X.; Wang, W. Blasting-induced rock damage control in a soft broken roadway excavation using an air deck at the blasthole bottom. Bull. Eng. Geol. Environ. 2023, 82, 97. [Google Scholar] [CrossRef]

- Kiakojouri, F.; Tavakoli, H.R.; Sheidaii, M.R.; De Biagi, V. Numerical analysis of all-steel sandwich panel with drilled I-core subjected to air blast scenarios. Innov. Infrastruct. Solut. 2022, 7, 320. [Google Scholar] [CrossRef]

- Yao, S.; Zhang, D.; Lu, Z.; Lin, Y.; Lu, F. Experimental and numerical investigation on the dynamic response of steel chamber under internal blast. Eng. Struct. 2018, 168, 877–888. [Google Scholar] [CrossRef]

- Guanghong, M.; Yu, H.; Jiuying, A.; Qiuyue, M.; Zhihao, S.; Honghao, M.; Zhaowu, S. Numerical simulation of explosive welding of metal tube and rod based on different algorithms. Trans. China Weld. Inst. 2022, 43, 64–71. [Google Scholar]

- Wang, X.; Li, J.; Zhao, X.; Liang, Y. Propagation characteristics and prediction of blast-induced vibration on closely spaced rock tunnels. Tunn. Undergr. Space Technol. 2022, 123, 104416. [Google Scholar] [CrossRef]

- Li, G.; Deng, G.-Z.; Ma, J. Numerical modelling of the response of cemented paste backfill under the blasting of an adjacent ore stope. Constr. Build. Mater. 2022, 343, 128051. [Google Scholar] [CrossRef]

- Halquist, J. LS-DYNA Keyword User’s Manual Version 971; Livermore Software Technology Corporation: Livermore, CA, USA, 2007. [Google Scholar]

- Deng, X.F.; Zhu, J.B.; Chen, S.G.; Zhao, Z.Y.; Zhou, Y.X.; Zhao, J. Numerical study on tunnel damage subject to blast-induced shock wave in jointed rock masses. Tunn. Undergr. Space Technol. 2014, 43, 88–100. [Google Scholar] [CrossRef]

| Case No. | The Distance between the Right Side of the Preformed Roadway and the Explosion, d (m) | Explosive Position, H (m) |

|---|---|---|

| C1 | 8 | 1.4 |

| C2 | 8 | 5.4 |

| C3 | 8 | 9.4 |

| C4 | 10 | 1.4 |

| C5 | 10 | 5.4 |

| C6 | 10 | 9.4 |

| C7 | 12 | 1.4 |

| C8 | 12 | 5.4 |

| C9 | 12 | 9.4 |

| C10 | 14 | 1.4 |

| C11 | 14 | 5.4 |

| C12 | 14 | 9.4 |

| Material Type | Density (kg/m3) | Elastic Modulus (Gpa) | Poisson’s Ratio | UCS (Mpa) |

|---|---|---|---|---|

| Orebody | 2705.00 | 42.20 | 0.1 | 60.80 |

| Steel | 7850.00 | 210.00 | 0.3 | 235.00 (Yield strength) |

| Upper backfill body | 1540.00 | - | 0.20 | 0.50 (28 day) |

| Lower backfill body | 1780 | - | 0.23 | 1.50 (28 day) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, H.; Wu, F.; Ou, R. Numeric Investigation on the Stability of a Preformed Roadway under Backfill Body Subjected to Blasting Load. Processes 2023, 11, 2548. https://doi.org/10.3390/pr11092548

Deng H, Wu F, Ou R. Numeric Investigation on the Stability of a Preformed Roadway under Backfill Body Subjected to Blasting Load. Processes. 2023; 11(9):2548. https://doi.org/10.3390/pr11092548

Chicago/Turabian StyleDeng, Hongwei, Fei Wu, and Renze Ou. 2023. "Numeric Investigation on the Stability of a Preformed Roadway under Backfill Body Subjected to Blasting Load" Processes 11, no. 9: 2548. https://doi.org/10.3390/pr11092548

APA StyleDeng, H., Wu, F., & Ou, R. (2023). Numeric Investigation on the Stability of a Preformed Roadway under Backfill Body Subjected to Blasting Load. Processes, 11(9), 2548. https://doi.org/10.3390/pr11092548