Abstract

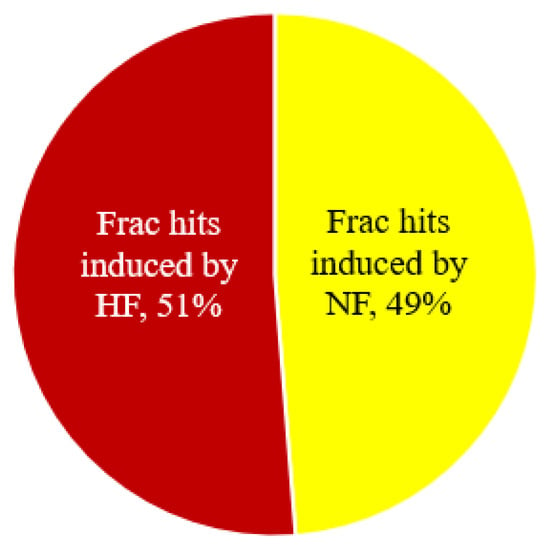

The development of natural fractures (NFs) in shale gas reservoirs is conducive to improving the productivity of shale gas wells. However, NF development leads to high-frequency frac hits between the infill and parent wells, which critically restricts its efficiency. To elucidate the large contribution of hydraulic fractures (HFs) and NFs in frac hits during the production and the development of NF-developed shale gas reservoirs, such reservoirs in the WY area of western China are taken as an example. A total of 197 frac hits well events in this area are systematically classified via the frac-hit discrimination method, and the effects of different factors on HF- and NF- dominated frac hits are classified and studied. Combined with the correlation analysis method and the chart method, the main controlling factors affecting the two types of frac hits are determined, and the corresponding frac-hit prevention countermeasures are proposed. The research demonstrates that (1) the distribution and development of NFs are crucial to production after frac hits. NFs and HFs in the WY area cause 51% and 49%, respectively, of the frac hits. (2) The main controlling factors in NF-dominated frac hits are the approximation angle, fracture linear density, and horizontal stress difference, whereas they are net pressure in fractures, horizontal stress difference, and liquid strength in HF-dominated frac hits. Sensitivity analysis shows that the NF activation difficulty coefficient fluctuates between −35.1% and 47.6%, and the maximum hydraulic fracture length fluctuates between −43.5% and 25.29%. (3) The corresponding frac-hit prevention countermeasures are proposed for the two types of formation mechanisms from different approaches, including frac-hit risk assessment and path planning, production well pressurization and stress diversion, and infill-well fracturing parameter optimization. This paper not only provides a reference for exploring the formation mechanism of frac hits in fractured shale gas reservoirs but also a theoretical basis for the corresponding frac-hit prevention countermeasures.

1. Introduction

The compactness of shale gas reservoirs necessitates combining horizontal drilling and hydraulic fracturing technology for commercial exploitation [1,2]. However, the physical properties of shale produce rich natural fractures (NFs) in the reservoir [3]. The existence of natural fractures is not only conducive to gas seepage in the matrix into the wellbore to improve the productivity of the gas well, but also to increase the probability of pressure channeling between the parent wells and reduce the production of the gas well [4,5]. Frac hits in fractured shale gas reservoirs can be categorized as NF-dominated and HF-dominated frac hits [6].

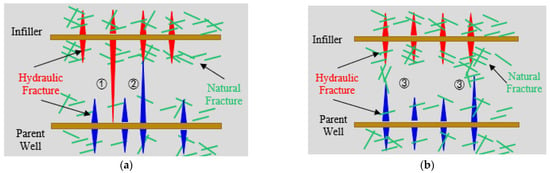

As shown in Figure 1a, ① HFs in the infill well, due to their nonuniformity, directly propagate to the adjacent wells and form a single connection, or ② they interact with the existing hydraulic fractures (HFs) in the parent well. As shown in Figure 1b, ③ HFs in the infill well interact with the fractures in the parent well through NFs. Hazards posed by the frac hit between the shale gas wells include fluctuation in the production of adjacent wells, pressure fluctuation, wellbore blockage, and casing change. Therefore, improving the propagation uniformity of the fractures in infill wells is fundamental to effectively avoiding interwell connectivity due to the single propagation of HFs [7,8].

Figure 1.

Frac hits in fractured shale gas reservoirs. (a) Direct connectivity between the HFs in infill and parent wells; (b) interconnectivity between the HFs in infill and parent wells through NFs.

The technology for identifying and describing frac-hit channels includes the following: ① Type identification of the frac-hit channel. This method classifies the frac-hit channel into the slow-impact type and direct-communication type according to the fluctuation range of the parent well pressure and production during frac hits. ② Identification of main controlling factors of frac hits. Different correlation analysis methods are applied to rank the factors affecting frac hits. ③ Calculation of the degree of frac hits. The degree of frac hits in different intervals between parent wells is calculated using a tracer or well test. ④ The influence of frac hits on productivity is determined via the quantitative calculation method, which is used to calculate the specific influence volume of frac hits on production by applying the rate transient analysis (RTA) method or pressure change integral (PCI) method, which are commonly used in reservoir water breakthrough. ⑤ The qualitative identification technologies of frac hits through the interference well test method, tracer monitoring, and microseismic monitoring to determine whether frac hits exist between the parent wells, as listed in Table 1. These methods are mainly applied to the analysis of frac hits in shale oil and gas reservoirs in North America and western China. However, their calculations are cumbersome, effective periods long, and accuracies low for the field application and classification of frac-hit types. For example, when feature points are present in the factors affecting the frac hits, the grey correlation method and random forest method yield large errors in determining the main control factors of the frac hits channel. Similarly, tracers have a long effective period for monitoring frac hits. Moreover, the accuracy of microseismic monitoring technology is relatively low.

Table 1.

Summary of frac-hit identification and description technology.

Accurately identifying the primary and secondary relationship between NFs and HFs in frac-hit events in fractured shale gas reservoirs is the basis for developing effective frac-hit prevention countermeasures [34,35,36]. To elucidate the prominent role played by HFs and NFs in production and development, this paper considers the development of NF-dominated shale gas reservoirs in the WY area of western China as an example. Through a new method for identifying frac hits, the frac hits in this area are systematically divided, and the effects of different factors on HF- and NF-dominated frac hits are classified. By combining the correlation analysis method and chart method, the main controlling factors affecting the two types of frac hits are determined, and the corresponding frac-hit prevention countermeasures are proposed. This paper not only provides a reference for exploring the formation mechanism of frac hits in fractured shale gas reservoirs, but also provides a theoretical basis for the corresponding frac-hit prevention countermeasures.

2. Identification, Key Factor Analysis, and Countermeasure Development of Frac-Hit

The identification of frac-hit channels is based on seismic data and production dynamic data to determine the type of frac hits between wells. Considering natural/hydraulic fractures as the prerequisite of inter-well pressure channeling, five kinds of weight-analysis methods are used to calculate and analyze the primary and secondary relationship of pressure channeling-related factors on productivity. The sensitivity of natural and hydraulic fractures is analyzed by the difficulty coefficient of NF activation λ and Petrel numerical simulation, and the feasibility of countermeasures is put forward.

2.1. Classification Method of NF/HF Frac Hits

The classification method of NF/HF-dominated frac hits is based on the ant body diagram formed by the seismic monitoring data of NFs in the WY shale gas reservoirs in China. It combines the pressure and production fluctuation in the parent well monitored during hydraulic fracturing to determine the type of frac hits between the child and parent wells. In reservoirs with NF development, the frac hits between the parent wells belong to NF-dominated frac hits if continuous and communicating NFs are present on the frac-hits path. For undeveloped NFs or those without connectivity between the two wells, communication between child and parent wells is the main reason for the nonuniform propagation of HFs to adjacent wells. This type of frac hit is HF-dominated.

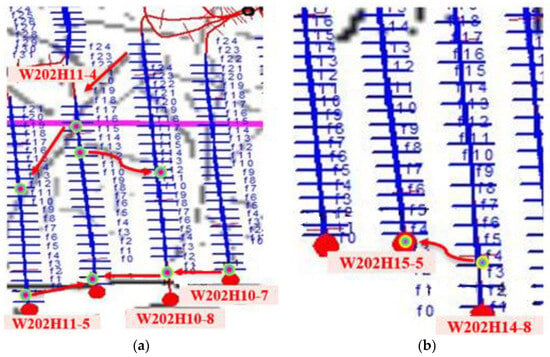

As shown in Figure 2a, W202H11-4, W202H11-5, W202H10-7, and W202H11-8 in the ant body diagram of NF-dominated frac hits communicated with each other through connected NFs, and the pressure and production between the child and parent wells fluctuate greatly during fracturing. Figure 2b shows the dynamic monitoring results under different production parameters: frac hits formed on the W202H15-5 well during the fourth stage fracturing of W202H14-8. However, the ant body diagram reveals that no NF is present on the frac-hit path, indicating that the frac hit between W202H14-8 and W202H15-5 is HF dominated.

Figure 2.

Ant body diagram of frac hits. (a) Ant body diagram of NF-dominated frac hits; (b) ant body diagram of HF-dominated frac hits.

2.2. Determination of Main Controlling Factors and Sensitivity Analysis of Two Types of Frac Hits

Based on Section 2.1, the main influencing factors of NF/HF-dominated frac hits were determined. Combined with the correlation analysis method, the main controlling factors of the two kinds of frac hits between wells were calculated and analyzed, and the sensitivity of different factors to the formation of pressure channeling between wells was analyzed. Finally, two kinds of frac-hit countermeasures corresponding were explored.

2.2.1. Determination of Influencing Factors of NF-Dominated Frac Hits

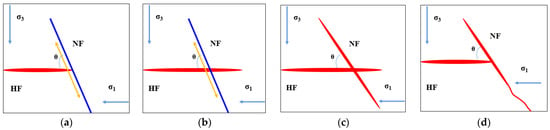

For NFs to form frac-hit channels, they must be “activated” by HFs and in communication with adjacent wells to participate in frac-hits event. The activation mechanisms of NFs mainly include the following: ① Shear activation (shown in Figure 3a). According to Equation (1), the main influencing factors are horizontal in situ stress difference and net pressure in the fracture. ② Through unactivated (shown in Figure 3b). According to Equation (2), the main influencing factors are the net pressure in the fracture and the characteristic NF parameters. ③ Tense activation (shown in Figure 3c). According to Equation (3), the main influencing factors are the net pressure in the fracture and the characteristic NF parameters. ④ Tense activation and end extension (shown in Figure 3d). According to Equation (4), the main influencing factors are the net pressure in the fracture and the characteristic NF parameters. The corresponding theoretical equations of the four NF activation modes are as follows [37,38,39]:

Figure 3.

Four modes of NFs being activated. (a) Mode 1 Shear activation; (b) Mode 2 Through unactivated; (c) Mode 3 Tense activation; and (d) Mode 4 Tense activation and end extension.

Mode 1: Shear activation

where is the horizontal stress difference, MPa; is cohesion, MPa; is the net pressure, MPa; is the friction coefficient, dimensionless; is the approaching angle.

Mode 2: Through Unactivated

where is the tensile strength, MPa.

Mode 3: Tense activation

where is the NF activation stress difference, MPa.

Mode 4: Tense activation and end extension

The main mechanistic factors affecting the formation of HF-dominated frac hits are the horizontal stress difference, net pressure in fracture, and NF characteristic parameters. The characteristic parameters of NFs include fracture width/opening, fracture length, fracture spacing, fracture location, fracture strength/filling, dissolution transformation, approximation angle, fracture linear density, and proportion of NF development section. The horizontal stress difference, net pressure in the fracture, approaching angle, fracture linear density and the proportion of the natural fracture development section are selected as the main factors influencing HF-dominated frac hits of the WY shale gas reservoir while also considering the development of NFs in the shale gas reservoir.

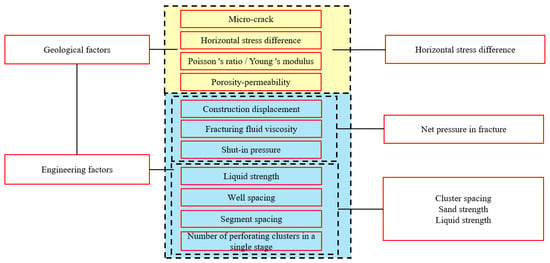

2.2.2. Determination of Influencing Factors in HF-Dominated Frac Hits

A prerequisite for HFs developing into frac-hit channels is the presence of few hydraulic branch fractures, and the main fractures propagate excessively to adjacent wells. The factors affecting HF propagation are geological and engineering factors. The former include microfractures in the reservoir, a horizontal stress difference, Poisson’s ratio/Young’s modulus, reservoir porosity, and permeability. Engineering factors include displacement, fracturing fluid viscosity, pump stop pressure, liquid strength, well spacing, interval spacing, and a single perforation cluster number. Considering the hydraulic fracturing construction and NF distribution of the WY shale gas reservoir (Figure 4), horizontal stress difference, net pressure in fracture, cluster spacing, sanding strength, and liquid strength in WY area were selected.

Figure 4.

Selection route map of influencing factors of HF-dominated frac hits in WY area.

2.2.3. Determination of Main Controlling Factors and Sensitivity Analysis of the Two Types of Frac Hits

The 197 frac-hit well events in the WY shale gas reservoir were classified in Section 2.1, and the influencing factors of NF- and HF-dominated frac hits were determined in Section 2.2.1 and Section 2.2.2. Combined with the correlation analysis method, the main controlling factors of the two types of frac hits were calculated and analyzed, and the sensitivity of different factors to the formation of frac hits was evaluated by combining the formation mechanisms of the two types of frac hits. Some defects in the correlation analysis of the factors affecting frac hits were identified via a single correlation analysis. For example, characteristic values or attributes between parameters in the data greatly affect the calculated correlation coefficient. Therefore, the coefficient of variation, grey correlation, maximum information coefficient, Pearson coefficient, and random forest methods were applied to calculate and analyze the primary and secondary relationships of the influence of frac-hit-related factors on productivity. The influence factors calculated via different methods were assigned and plotted. The main control factors affecting frac hits were selected according to the color distribution in the chart.

2.2.4. Exploration of Frac Hit Countermeasures Corresponding to the Two Types of Frac Hits

After clarifying the main controlling factors for the formation of two types of frac hits in Section 2.2.1, Section 2.2.2 and Section 2.2.3, the corresponding frac-hit countermeasures based on the formation mechanism of NF-dominated and HF-dominated frac hits were proposed to provide a theoretical basis for reducing frac hits during the development of shale gas reservoirs.

3. Results and Analysis

Based on “Section 2 Identification, Key Factor Analysis, and Countermeasure Development of Frac-Hit”, the division of frac-hit types, main controlling factors and sensitivity analysis, as well as the exploration of countermeasures in WY region will be analyzed as follows.

3.1. Proportion and Source of the Different Types of Frac Hits

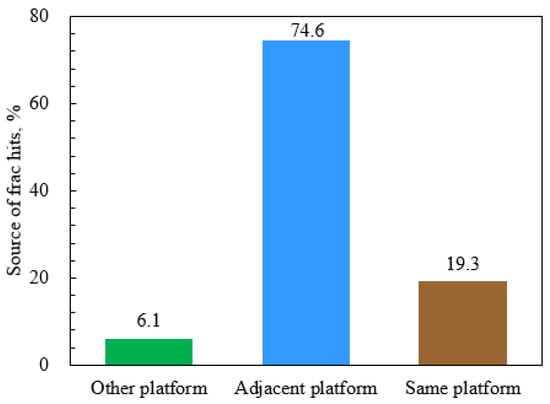

The 197 frac-hit well events in the WY area were classified according to the classification method and criteria of NF- and HF-dominated frac hits in Section 2.1, and the results are shown in Figure 5. NF- and HF-dominated frac hits accounted for 51% and 49% of the frac hits in the WY area. Both types of frac hits, therefore, should be prevented. Figure 6 shows that frac hits were mainly from adjacent platforms (up to 74.6%) followed by branch wells on the same platform (19.3%), whereas the proportion of frac hits between cross-platforms was the smallest (6.1%).

Figure 5.

Statistical results of frac hits according to type.

Figure 6.

Proportion of frac hits according to source.

3.2. Determination of Main Controlling Factors and Sensitivity Analysis of Two Types of Frac Hits

Based on Section 3.1, the main controlling factors corresponding to the two fracture types of frac hits are determined by combining five correlation charts. The change in the up and down amplitude corresponds to the average value of the factors, and the sensitivity of the change in different influencing factors to NF/HF is explored. Finally, considering the geological and engineering factors, the frac-hit prevention countermeasures of the NF/HF-type pressure channeling are put forward.

3.2.1. Main Controlling Factors and Sensitivity Analysis of NF-Dominated Frac Hits

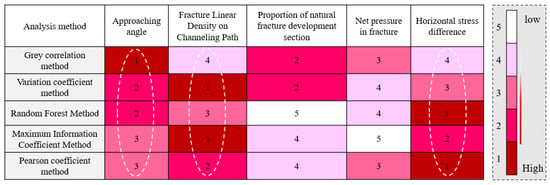

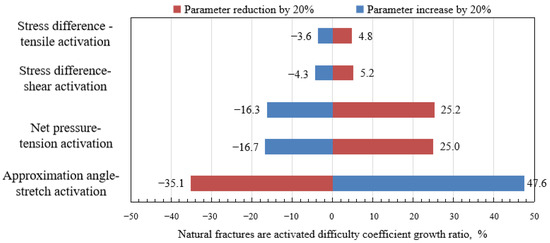

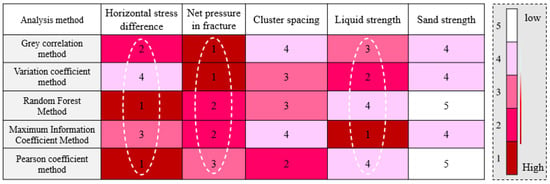

The influence parameters of NF-dominated frac hits (51%) in the well group, as presented in Section 3.1, were analyzed, including horizontal stress difference, net pressure in the fracture, approaching angle, fracture linear density, and the proportion of NF development. Five correlation analysis methods were applied to calculate and analyze the primary and secondary relationships between the influence of frac-hit-related factors on productivity. Moreover, the influence factors calculated using different methods were assigned and plotted. The chart was used to select the main control factors affecting frac hits. The results are shown in Figure 7.

Figure 7.

Analysis chart of influential factors of NF-dominated frac hits.

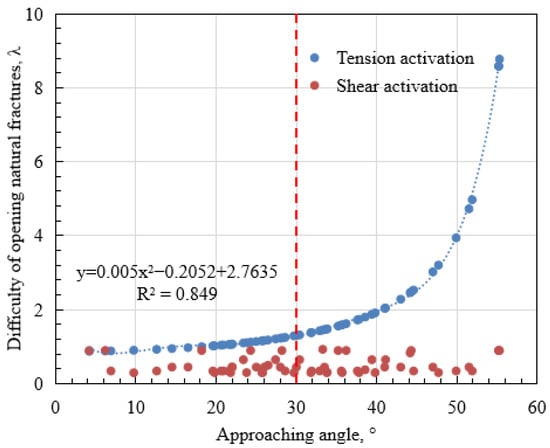

The correlation analysis involved assigning values of 1, 2, 3, 4, and 5, which correspond to darkening shades, in descending order according to the correlation coefficient. That is, the darker the color (the smaller the value), the stronger the correlation between the influencing factors and the productivity. The approach angle, linear density of fractures on the frac-hit path, and the horizontal stress difference are the main factors affecting NF-dominated frac hits, as determined by the color depth distribution map in Figure 7. The secondary factors are the proportion of the NF development section and net pressure in the fracture. NF activation was transformed using Equations (1)–(4). The ratio of horizontal stress difference to influencing factors was defined as the difficulty coefficient of NF activation λ. The larger the λ value is, the greater the probability of NF activation. Because Equations (1)–(4) contain multiple variable parameters, λ corresponding to a change in a certain parameter (such as approximation angle, net pressure in fracture or horizontal stress difference) was calculated, the average value was selected for the remaining parameters for the WY shale gas reservoir, and the corresponding variation amplitude of λ a single factor floated by 20% was observed. The average stress difference of the WY reservoir was 13 MPa, the average approaching angle was 30°, the average net pressure in the fracture was 8.45 MPa, the cohesion was 5.985 MPa, and the friction coefficient was 0.65.

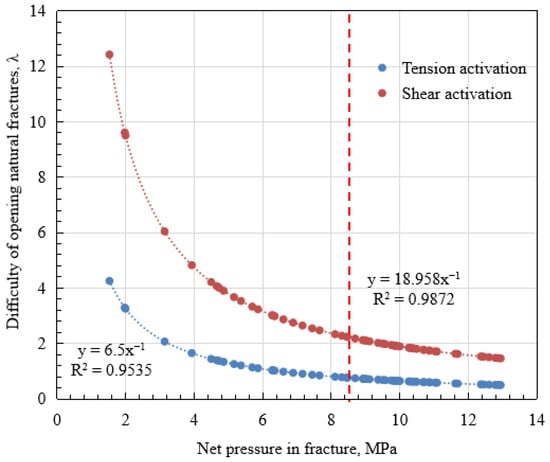

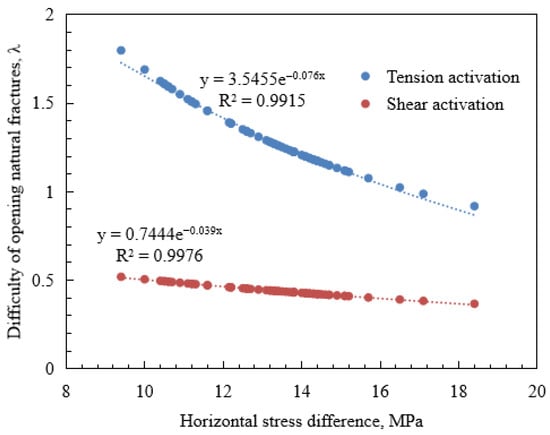

As shown in Figure 8, Figure 9 and Figure 10, when the approaching angle was in the range of 0–60°, the difficulty of NF activation by tension increased parabolically with the approaching angle. When the net pressure in the fracture was between 2 MPa and 14.5 MPa, the difficulty of NF activation decreased exponentially with the increase in the net pressure in the fracture. When the horizontal stress difference was between 9 and 18.5 MPa, the difficulty of NF activation decreased exponentially with the increase in horizontal stress difference, and the curve fitting degree was high. To explore the sensitivity of different influencing factors to the activation of NFs, the average amplitude variation in the corresponding factors was set at 20%, and the change rate of λ was calculated (Figure 11). Noticeably, among the three main controlling factors affecting NF activation, the influence of the approaching angle was the greatest, followed by the net pressure in the fracture, whereas the stress difference had a relatively small influence. The fluctuation ratio of the coefficient representing the difficulty in activating NFs was between −35.1% and 47.6%.

Figure 8.

λ value when the approaching angle changes.

Figure 9.

λ value when the net pressure in the fracture changes.

Figure 10.

λ value when the horizontal stress difference changes.

Figure 11.

λ value floating ratio when the influence factor amplitude is ±20%.

3.2.2. Main Controlling Factors and Sensitivity Analysis of HF-Dominated Frac Hits

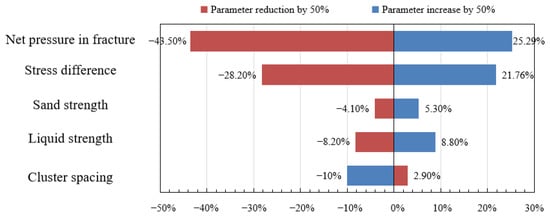

The influence parameters of the HF-dominated frac hits (49%) on the well group were presented in Section 3.1, such as horizontal stress difference, net pressure in the fracture, cluster spacing, sanding strength, and liquid strength. The five correlation analysis methods used to calculate and analyze the primary and secondary relationships between the influence factors of frac hits on productivity and the influence factors calculated by different methods were assigned and plotted. The main control factors affecting frac hits were selected according to the color distribution in the chart. The results are shown in Figure 12. The net pressure in the fracture, the horizontal stress difference, and the liquid strength were the main factors of HF-dominated frac hits, followed by sanding strength and cluster spacing.

Figure 12.

Analysis chart of influential factors of HF-dominated frac hits.

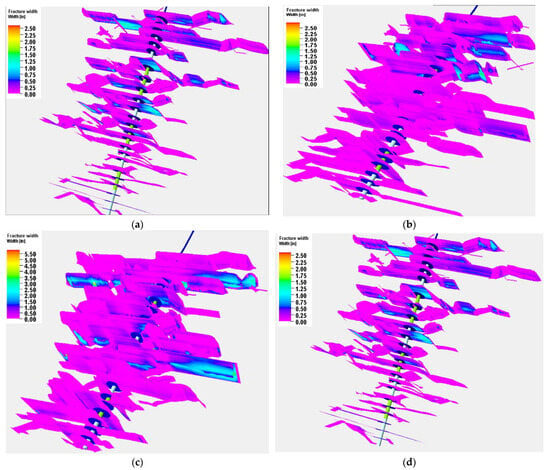

Petrel geological engineering-integrated numerical-simulation software was used to simulate the sensitivity of HF-dominated frac hits in the WY area to the main controlling factors. The relevant parameters for the sensitivity analysis were set as listed in Table 2. The cluster spacing, liquid strength, sand strength, horizontal stress difference, and fracturing fluid construction displacement of the reference group were set as fixed values. The liquid strength, horizontal stress difference, and fracturing fluid construction displacement of the control group were varied to simulate the maximum propagation length of HFs when the three main control factors float up and down by ±50%. As is shown in Figure 13.

Table 2.

HF-dominated frac-hit sensitivity analysis parameter setting.

Figure 13.

Length of the longest HF when the three main controlling factors increase by 50%. (a) Fracture length = 170 m, reference group; (b) fracture length = 223 m, control group 1 (pump rate = 15 m3/min); (c) fracture length = 207 m, control group 2 (horizontal stress difference = 15 MPa); (d) fracture length = 153 m, control group 3 (liquid strength = 30 m3/m).

The longest HF in the control group was compared with that in the reference group when the three main control factors rose ±50%, as shown in Figure 14. Noticeably, ① when the net pressure in the fracture rose ±50% from 4.2 MPa, the fracture length increased from 170 m to 213 m or decreased to 96 m, with approximately a growth rate of 25.29% or a decrease rate of 43.5%, respectively. ② When the horizontal stress difference rose ±50% from 10 MPa, the HF length increased from 170 m to 207 m or decreased to 122 m, with approximately a growth rate of 21.76% or a reduction rate of 28.2%, respectively. ③ When the liquid strength rose ±50% from 20 m3/m, the HF length increased from 170 m to 185 m or decreased to 156 m, with approximately an increase rate of 8.8% or a reduction rate of 8.2%. ④ As shown in Figure 14, when the factors influencing the propagation of HFs rose by ±50%, the net pressure in the fracture had the greatest influence on HF propagation, followed by the horizontal stress difference, cluster spacing, liquid strength, and sand strength, and the maximum HF length generally fluctuated from −43.5% to 25.29%.

Figure 14.

Sensitivity analysis of HF-dominated frac hits.

3.3. Exploration of Frac-Hit Countermeasures

Considering the formation mechanism and main influencing factors of NF- and HF-dominated frac hits presented in Section 2.2 and Section 3.2, the following can be drawn: ① NF-dominated frac hits are fundamentally dependent on whether the fracture is activated and communicating with adjacent wells during hydraulic fracturing, and the mechanism of HF-dominated frac hits is the nonuniform propagation of HFs under the action of geological and engineering factors. ② The analysis results of the NF-dominated frac-hit law in the WY area demonstrated that the risk of NF-dominated frac hits increased with an approaching angle and decreased with an increase in horizontal stress difference and net pressure in the fracture. ③ The analysis results of the HF-dominated frac-hit law in the WY area demonstrated that the root cause of HF-dominated frac is the nonuniform propagation of fractures. With the increase in net pressure, horizontal stress difference, and liquid strength in the fracture, the degree of fracture extension or nonuniform expansion increased, and the risk of pressure channeling increased. The corresponding frac-hit countermeasures are explored in the following by considering the formation mechanism and main control factors of the two types of frac hits.

3.3.1. Frac-Hit Prevention Countermeasures of NF-Dominated Frac Hits

Considering the formation mechanism and influencing factors of NF-dominated frac hits as well as geological and engineering factors, countermeasures for NF-dominated frac hits were proposed from the aspects of frac-hit risk assessment and path planning, production-well pressurization, and stress diversion and infill-well fracturing parameter optimization. ① Frac-hit risk assessment and path planning involve obtaining the ant body diagram of NF development and distribution in the WY shale gas reservoir based on seismic data. When determining the well location layout, areas with more NFs are avoided to reduce the risk of frac hits between wells caused by NFs. ② Production-well pressurization and stress diversion involve increasing reservoir energy by injecting gas or water into the formation, changing the induced stress field and then the inherent in situ stress field of the reservoir, and afterward changing the horizontal in situ stress difference and the degree of activation of NFs. ③ Optimization of fracturing parameters in infill wells involves conducting pressure reductions and fracture control for infill wells. The main methods are temporary plugging and diversion fracturing (TPDF), large-section multicluster + sand control and sand increase, and reducing the influence of net pressure in the HF on the activation of NFs.

3.3.2. Frac-Hit Prevention Countermeasures of NF-Dominated Frac Hits

Ensuring the uniform propagation of HFs can effectively reduce the occurrence of HF-dominated frac hits. Considering the geological and engineering factors affecting the propagation of HFs, the frac-hit prevention countermeasures of HF-dominated frac hits were suggested from the aspects of pressurization and stress diversion in production wells and applying construction technology to ensure the uniform propagation of fractures in infill wells. The ① production-well pressurization and stress diversion method is applicable to NF-dominated frac hits. By changing the induced stress field and then the inherent in situ stress field of the reservoir, the degree of nonuniform propagation of HFs can be reduced. ② Applying construction technology can ensure uniform fracture propagation in infill wells. This method reduces the net pressure in a fracture, ensures uniform fracture propagation, forms a complex fracture network structure, and alleviates frac hits during hydraulic fracturing via TPDF + large section multicluster + liquid control and sand increase.

4. Conclusions

This paper classifies frac hits into NF-dominated and HF-dominated frac hits by considering the WY fractured shale gas reservoir in western China, and a new method for distinguishing frac hits is formulated. Considering the formation mechanism of the two types of frac hits, the factors affecting them were identified. The correlation analysis method and chart method were combined, the main control factors and sensitivity of the two types of frac hits were clarified, and frac-hit prevention countermeasures were proposed. This paper not only provides a reference for exploring the formation mechanism of frac hits in fractured shale gas reservoirs but also provides a theoretical basis for frac-hit prevention countermeasures. The main conclusions are as follows:

(1) The type of frac hits present between the parent wells were determined based on the ant body diagram plotted from seismic monitoring data of NFs in the WY shale gas reservoir in China combined with the pressure and production fluctuation in the parent well monitored during hydraulic fracturing. The paper found that NFs and HFs accounted for 51% and 49%, respectively, of the frac hits in the WY area. Therefore, both types of frac hits should be prevented. Moreover, most of the frac hits were from adjacent platforms, which comprised up to 74.6%.

(2) NF-dominated frac hits depend on whether they are activated and communicating with adjacent wells during hydraulic fracturing. HF-dominated frac hits are attributed to the nonuniform propagation of HFs under geological and engineering factors. The correlation and graph analyses reveal that the approaching angle, fracture linear density, and the horizontal stress difference are the main controlling factors for NF-dominated frac hits. The net pressure, horizontal stress difference, and liquid strength are the main controlling factors for HF-dominated frac hits.

(3) The main prevention countermeasures for NF-dominated frac hits are frac-hit risk assessment and path planning, production well pressurization and stress diversion, and infill-well fracturing parameter optimization. The main frac-hit prevention countermeasures for HF-dominated frac hits are production well pressurization and stress diversion as well as applying construction technology to ensure the uniform expansion of the infill well fracture.

Author Contributions

Writing—original draft, H.X.; writing—review and editing, J.W.; conceptualization, H.J. and J.W.; methodology, J.W.; validation, H.X. and T.W.; formal analysis, H.X.; investigation, K.Z.; visualization, L.Z.; supervision, H.J.; project administration, H.J.; funding acquisition, H.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (No. 52274028); State Key Laboratory of Petroleum Re-sources and Prospecting, China University of Petroleum (No. PRP/open-2205). The APC was funded by Houshun Jiang.

Data Availability Statement

Not applicable.

Acknowledgments

We thank China University of Petroleum (Beijing) for the support of the project experimental equipment. Thank Chuanqing Drilling Company for supporting the experimental materials of the project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Boak, J.; Kleinberg, R. 4—Shale Gas, Tight Oil, Shale Oil and Hydraulic Fracturing. In Future Energy, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 67–95. [Google Scholar]

- He, X.; Chen, G.; Wu, J.; Liu, Y.; Wu, S.; Zhang, J.; Zhang, X. Deep shale gas exploration and development in the southern Sichuan Basin: New progress and challenges. Nat. Gas Ind. B 2023, 10, 32–43. [Google Scholar] [CrossRef]

- Dong, J.-N.; Yuan, G.-J.; Wang, X.Y.; Chen, M.; Jin, Y.; Zeng, C.; Zaman, M. Experimental study of multi-timescale crack blunting in hydraulic fracture. Pet. Sci. 2020, 18, 234–244. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, R.; Shi, W.; Hu, Q.; Xu, X.; Shu, Z.; Yang, Y.; Feng, Q. Structure- and lithofacies-controlled natural fracture developments in shale: Implications for shale gas accumulation in the Wufeng-Longmaxi Formations, Fuling Field, Sichuan Basin, China. Geoenergy Sci. Eng. 2023, 223, 211572. [Google Scholar] [CrossRef]

- Gupta, I.; Rai, C.; Devegowda, D.; Sondergeld, C. A Data-Driven Approach to Detect and Quantify the Impact of Frac-Hits on Parent and Child Wells in Unconventional Formations. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Virtual, 20–22 July 2020. [Google Scholar] [CrossRef]

- Moradi, B.B.; Osouli, A. Effect of Hydraulic Fracture and Natural Fractures Interaction in Fracture Propagation. In Proceedings of the 13th ISRM International Congress of Rock Mechanics, Montréal, QC, Canada, 10–13 May 2015. [Google Scholar]

- Yu, W.; Wu, K.; Zuo, L.; Tian, X.; Weijermars, R. Physical models for inter-well interference in shale reservoirs: Relative impacts of fracture hits and matrix permeability. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, San Antonio, TX, USA, 1–3 August 2016. [Google Scholar]

- Kenomore, M.; Hassan, M.; Malakooti, R.; Dhakal, H.; Shah, A. Shale gas production decline trend over time in the Barnett Shale. J. Pet. Sci. Eng. 2018, 165, 691–710. [Google Scholar] [CrossRef]

- Bommer, P.A.; Bayne, M.A. Active Well Defense in the Bakken: Case Study of a Ten-Well Frac Defense Project, McKenzie County, ND. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 23–25 January 2018. [Google Scholar] [CrossRef]

- Sardinha, C.M.; Petr, C.; Lehmann, J.; Pyecroft, J.F. Determining Interwell Connectivity and Reservoir Complexity through Frac Pressure Hits and Production Interference Analysis. In Proceedings of the SPE/CSUR Unconventional Resources Conference—Canada, Calgary, AB, Canada, 30 September–2 October 2014. [Google Scholar] [CrossRef]

- He, Y.; Guo, J.; Tang, Y.; Xu, J.; Li, Y.; Wang, Y.; Lu, Q.; Patil, S.; Rui, Z.; Sepehrnoori, K. Interwell Fracturing Interference Evaluation of Multi-Well Pads in Shale Gas Reservoirs: A Case Study in WY Basin. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 26–29 October 2020. [Google Scholar] [CrossRef]

- Chen, M.; Tang, J.; Zhu, D.; Hill, A. Classification and Localization of Fracture-Hit Events in Low-Frequency Distributed Acoustic Sensing Strain Rate with Convolutional Neural Networks. SPE J. 2022, 27, 1341–1353. [Google Scholar] [CrossRef]

- Wang, L.; Du, F.; Qiu, K.; Wu, S.; Zhuang, X.; Bai, X.; Wang, L.; Pan, Y. Frac Hit in Complex Tight Oil Reservoir in Ordos Basin: The Challenges, the Root Causes and the Cure. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 26–29 October 2020. [Google Scholar]

- Bommer, P.; Iriarte, J.; Bayne, M.; Cline, C.; Ramirez, A.; Van Domelen, M. Leveraging Cloud-Based Analytics in Active Well Defense Projects and Automated Pressure Response Analyses. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2020. [Google Scholar] [CrossRef]

- He, L.; Yuan, C.; Gong, W. Influencing factors and preventing measures of intra-well frac hit in shale gas. Reserv. Eval. Dev. 2020, 10, 63–69. [Google Scholar]

- Kumar, A.; Shrivastava, K.; Manchanda, R.; Sharma, M. An Efficient Method for Modeling Discrete Fracture Networks in Geomechanical Reservoir Simulation. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, Denver, CO, USA, 22–24 July 2020. [Google Scholar]

- Scherz, R.Y.; Rainbolt, M.F.; Pradhan, Y.; Tian, W. Evaluating the Impact of Frac Communication Between Parent, Child, and Vertical Wells in the Midland Basin Lower Spraberry and Wolfcamp Reservoirs. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 5–7 February 2019. [Google Scholar]

- Daneshy, A. Analysis of Horizontal Well Fracture Interactions, and Completion Steps for Reducing the Resulting Production Interference. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 24–26 September 2018. [Google Scholar] [CrossRef]

- Chris, C. Study Evaluates Fracturing Interference for Multiwell Pads in Shale Gas Reservoirs. J. Pet. Technol. 2021, 73, 67–68. [Google Scholar]

- Kumar, A.; Shrivastava, K.; Elliott, B.; Sharma, M. Effect of Parent Well Production on Child Well Stimulation and Productivity. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2020. [Google Scholar] [CrossRef]

- Anderson, D.; Nobakht, M.; Moghadam, S.; Mattar, L. Analysis of Production Data From Fractured Shale Gas Wells. In Proceedings of the SPE Unconventional Gas Conference, Pittsburgh, PA, USA, 23–25 February 2010. [Google Scholar]

- Yadav, H.; Motealleh, S. Improving Quantitative Analysis of Frac-Hits and Refracs in Unconventional Plays Using RTA. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, Woodlands, TX, USA, 24 January 2017. [Google Scholar] [CrossRef]

- Ibrahim, A.F. Integrated Workflow to Investigate the Effect of Fracture Interference on Well Performance. In Proceedings of the SPE Western Regional Meeting, Bakersfield, CA, USA, 26–28 April 2022. [Google Scholar] [CrossRef]

- Guo, Y.; Ashok, P.; Oort, E.; Isbell, M.; Butler, E.; Riopelle, A. Evaluation of Parent Well Production Changes Caused by Child Well Frac Hits Using A Pressure Integration Approach. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 26–28 July 2021. [Google Scholar] [CrossRef]

- Guo, Y.; Ashok, P.; van Oort, E.; Patterson, R.; Zheng, D.; Isbell, M.; Riopelle, A. A Data Analytics Framework for Analyzing the Effect of Frac Hits on Parent Well Production. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, Virtual, 4–6 May 2021. [Google Scholar] [CrossRef]

- Fan, H.; Zhang, J.; Yue, S. Analysis of influencing factors of interwell interference in shale gas well groups and well spacing optimization. Nat. Gas Geosci. 2022, 33, 512–519. [Google Scholar]

- Uzun, I.; Assiri, W.; Eker, E. Application of Well Interference Test Using Distributed Pressure Sensors to Optimize Well Spacing in Unconventional Shale Reservoirs. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2019. [Google Scholar] [CrossRef]

- Yaich, E.; Diaz De Souza, O.C.; Foster, R.A.; Abou-Sayed, I. A Methodology to Quantify the Impact of Well Interference and Optimize Well Spacing in the Marcellus Shale. In Proceedings of the SPE/CSUR Unconventional Resources Conference, Calgary, Alberta, 30 September–2 October 2014. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, M.M. Diagnosing Fracture-Wellbore Connectivity Using Chemical Tracer Flowback Data. In Proceedings of the The Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018. [Google Scholar] [CrossRef]

- King, G.E.; Rainbolt, M.F.; Swanson, C. Frac Hit Induced Production Losses: Evaluating Root Causes, Damage Location, Possible Prevention Methods and Success of Remedial Treatments. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017. [Google Scholar] [CrossRef]

- Michael, R.; Drew, C.; Timmons, T. Fracture Wing Growth Study Using Synchronized Surface Pressure Data from Monitored Offsetting Wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 26–29 October 2020. [Google Scholar]

- Paryani, M.; Smaoui, R.; Poludasu, S.; Attia, B.; Umholtz, N.; Ahmed, I.; Ouenes, A. Adaptive Fracturing to Avoid Frac Hits and Interference: A Wolfcamp Shale Case Study. In Proceedings of the SPE Unconventional Resources Conference, Calgary, AB, Canada, 15–16 February 2017. [Google Scholar] [CrossRef]

- Moradi, P.M.; Angus, D. Modeling Frac-hits Using Dynamic Microseismicity-Constrained Enhanced Fracture Regions. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Denver, CO, USA, 22–24 July 2019. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, C.; Yang, Y.; Ansari, U.; Han, Y.; Li, X.; Cheng, Y. Preliminary experimental investigation on long-term fracture conductivity for evaluating the feasibility and efficiency of fracturing operation in offshore hydrate-bearing sediments. Ocean Eng. 2023, 281, 114949. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, D.; Yin, J.; Zhou, X.; Li, Y.; Chi, P.; Han, Y.; Ansari, U.; Cheng, Y. Sediment Instability Caused by Gas Production from Hydrate-bearing Sediment in Northern South China Sea by Horizontal Wellbore: Evolution and Mechanism. Nat. Resour. Res. 2023, 32, 1595–1620. [Google Scholar] [CrossRef]

- Wang, F.; Liu, X.; Jiang, B.; Zhuo, H.; Chen, W.; Chen, Y.; Li, X. Low-loading Pt nanoparticles combined with the atomically dispersed FeN4 sites supported by FeSA-NC for improved activity and stability towards oxygen reduction reaction/hydrogen evolution reaction in acid and alkaline media. J. Colloid Interface Sci. 2023, 635, 514–523. [Google Scholar] [CrossRef]

- Jaeger, J.C.; Cook, N. Fundamentals of Rock Mechanics, 3rd ed.; Science Paperbacks; Chapman and Hall: London, UK, 1979; Volume 9, pp. 251–252. [Google Scholar]

- Daneshy, A.A. Fundamental Theories of Hydraulic Fracturing Revisited. Part 1: Single Fractures. HFJ 2015, 2, 8–14. [Google Scholar]

- Daneshy, A.A. Fundamental Theories of Hydraulic Fracturing Revisited. Part 2: Multiple Fractures in Horizontal Wells. HFJ 2015, 2, 3–5. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).