Thermo-Mechanical Behavior of Green Sandwich Structures for Building and Construction Applications

Abstract

1. Introduction

2. Materials and Method

2.1. Materials

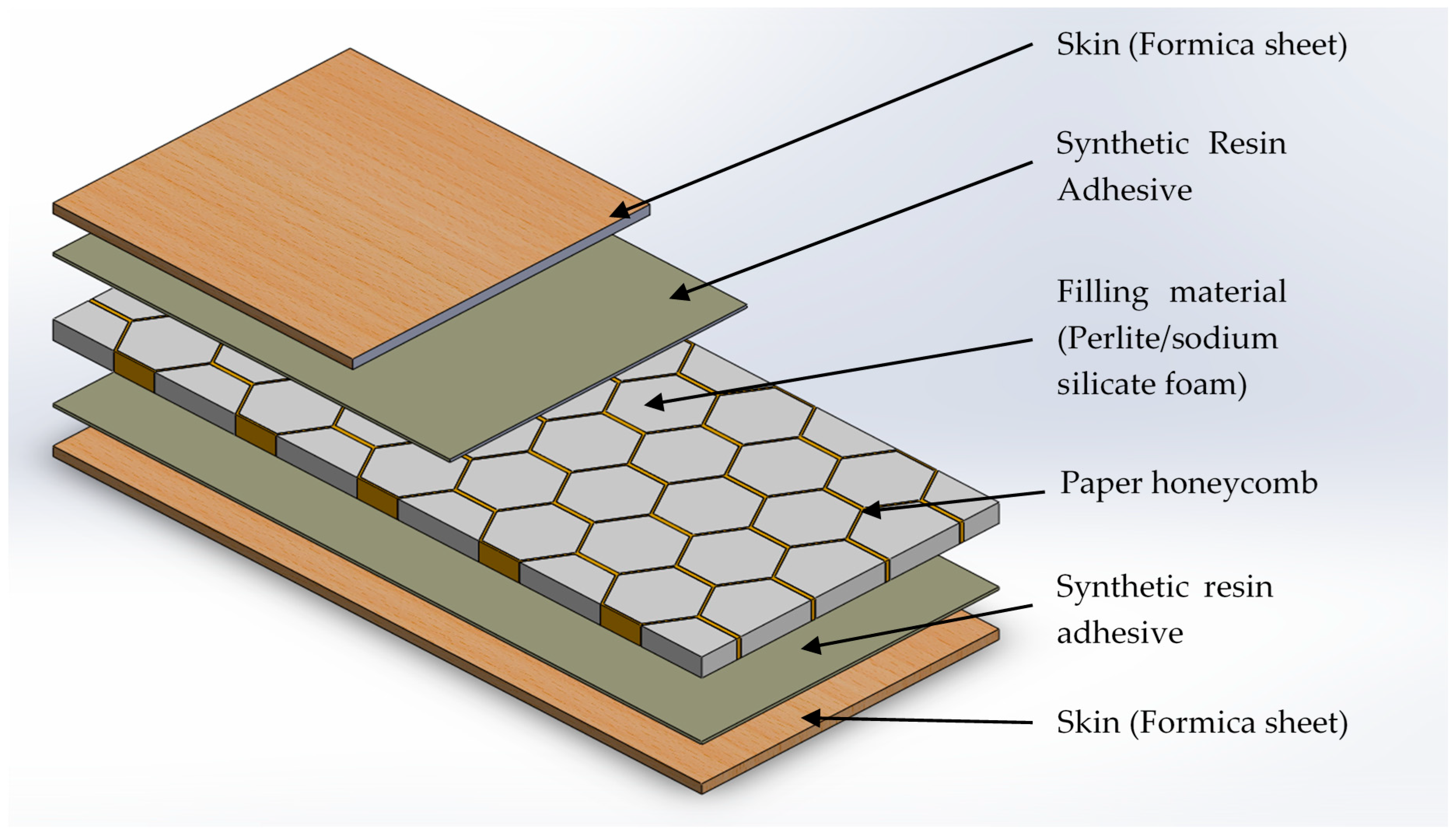

2.2. Specimen Preparation

2.2.1. Fabrication of Honeycomb Structure

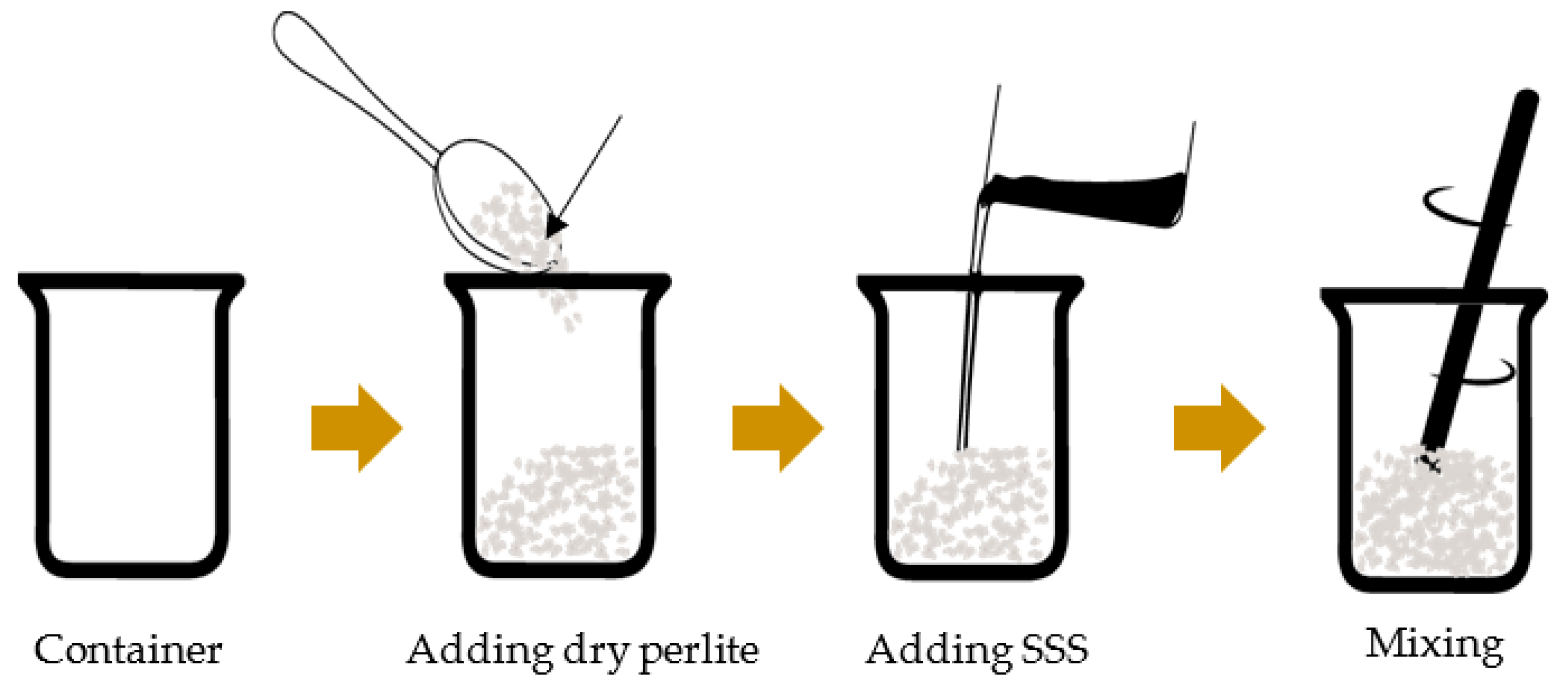

2.2.2. Preparation of Perlite Foam Mixture

2.2.3. Core Manufacturing

2.2.4. Fabrication of Sandwich

2.3. Density Measurement

2.4. Flexural Testing

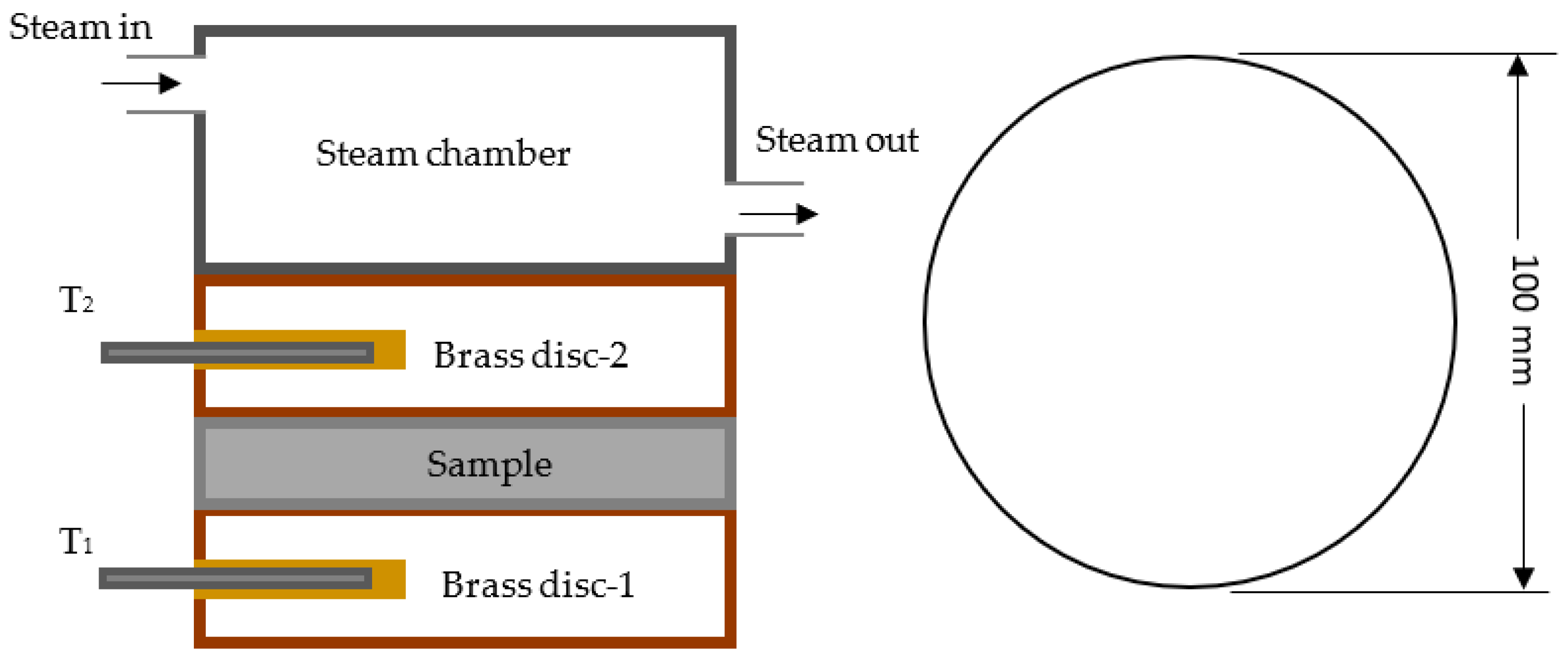

2.5. Thermal Conductivity Testing

3. Results and Discussion

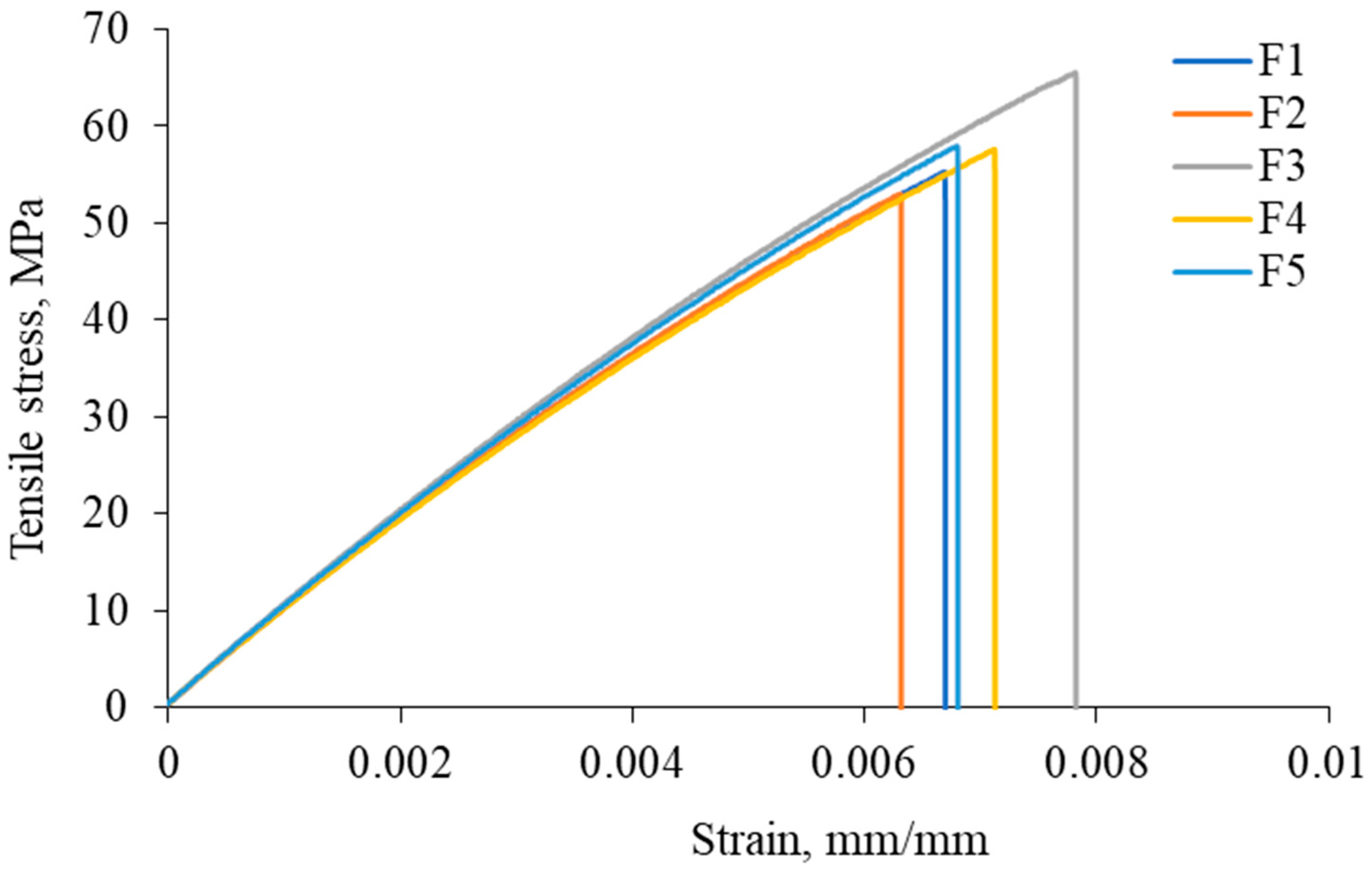

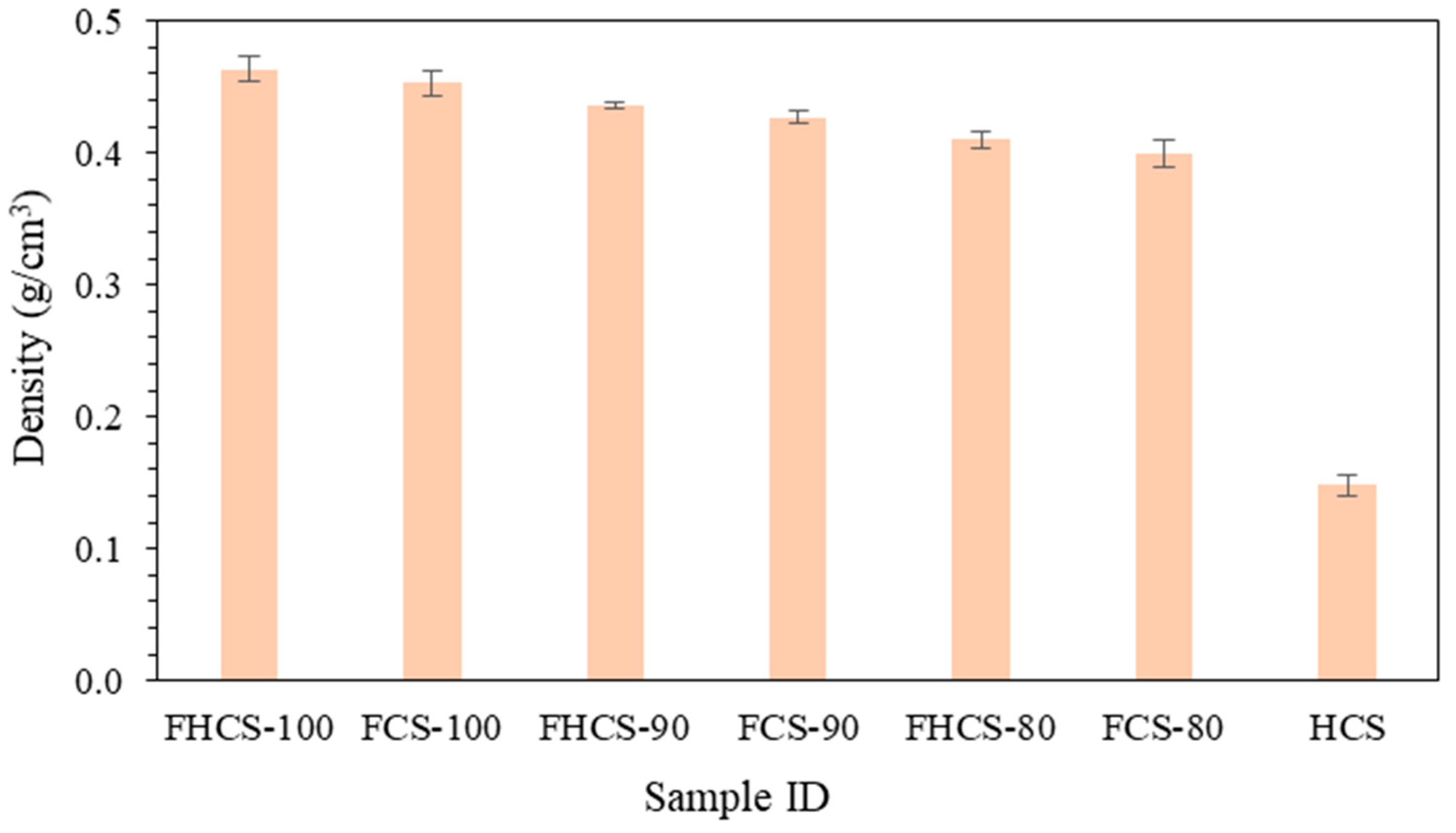

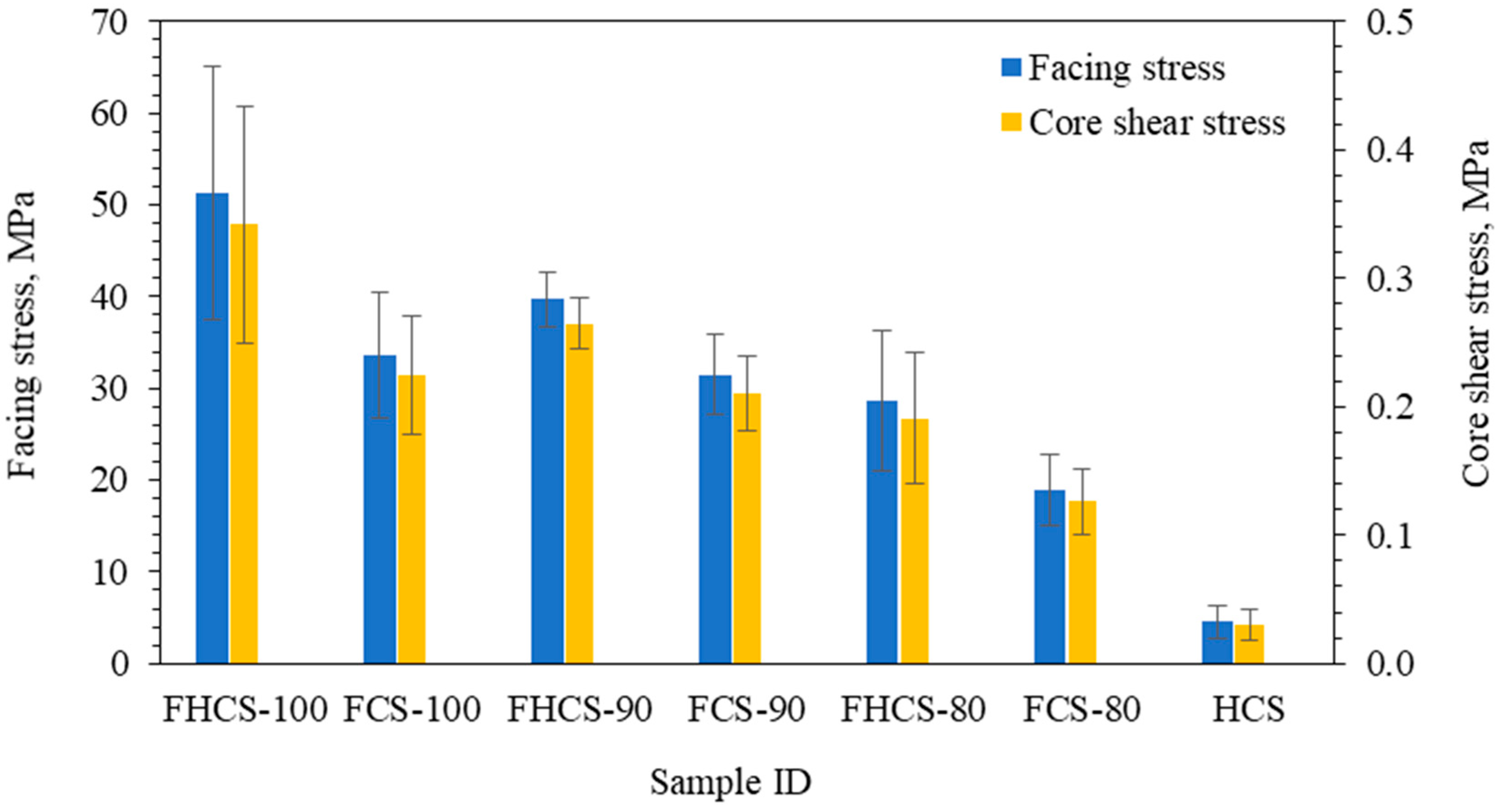

3.1. Flexural Properties

| Sample ID | Density (g/cm3) | Sp. Flexural Strength, [MPa/(g/cm3)] | Sp. Flexural Modulus, [GPa/(g/cm3)] |

|---|---|---|---|

| FHCS-100 | 0.47 | 23.77 | 3.78 |

| FHCS-90 | 0.44 | 19.62 | 3.69 |

| FHCS-80 | 0.42 | 15.25 | 3.16 |

| FCS-100 | 0.46 | 17.18 | 3.17 |

| FCS-90 | 0.43 | 17.44 | 2.79 |

| FCS-80 | 0.40 | 10.15 | 2.68 |

| HCS | 0.15 | 6.77 | 1.42 |

| Portland cement skin with kraft paper honeycomb core [26] | 0.99 | 0.88 | - |

| Flax-reinforced Portland cement skin with kraft paper honeycomb core [26] | 0.89 | 1.74 | - |

| Oriented strand boards or plywood [37] | 0.55 | 29.82 | 8.97 |

| Gypsum-fiber boards [37] | 1.15 | 3.48 | 3.30 |

| Chips board urea-formaldehyde bonded [38] | 0.72 | 15.97 | 2.68 |

| MDF [38] | 0.68 | 27.50 | - |

| Coconut coir cement board [39] | 1.13 | 17.64 | 4.70 |

| Commercial flake board [39] | 1.40 | 8.43 | 4.29 |

| Commercial cellulose board [39] | 1.56 | 12.24 | 4.22 |

| Gypsum panel [11] | 1.00 | 2.26 | 2.12 |

| Jute-fiber-reinforced gypsum panel [11] | 0.97 | 2.03 | 2.24 |

| Perlite/sodium silicate foam panel [22] | 0.41 | 2.37 | 0.87 |

| Syntactic foam panel [40] | 0.37 | 21.32 | 2.86 |

| Syntactic foam panel [40] | 0.44 | 17.20 | 2.57 |

| Nylon-fiber-reinforced perlite/sodium silicate panel [18] | 0.41 | 2.68 | 0.61 |

| Perlite/sodium silicate foam with jute-fiber-reinforced epoxy composite skin [31] | 0.59 | 6.50 | 0.61 |

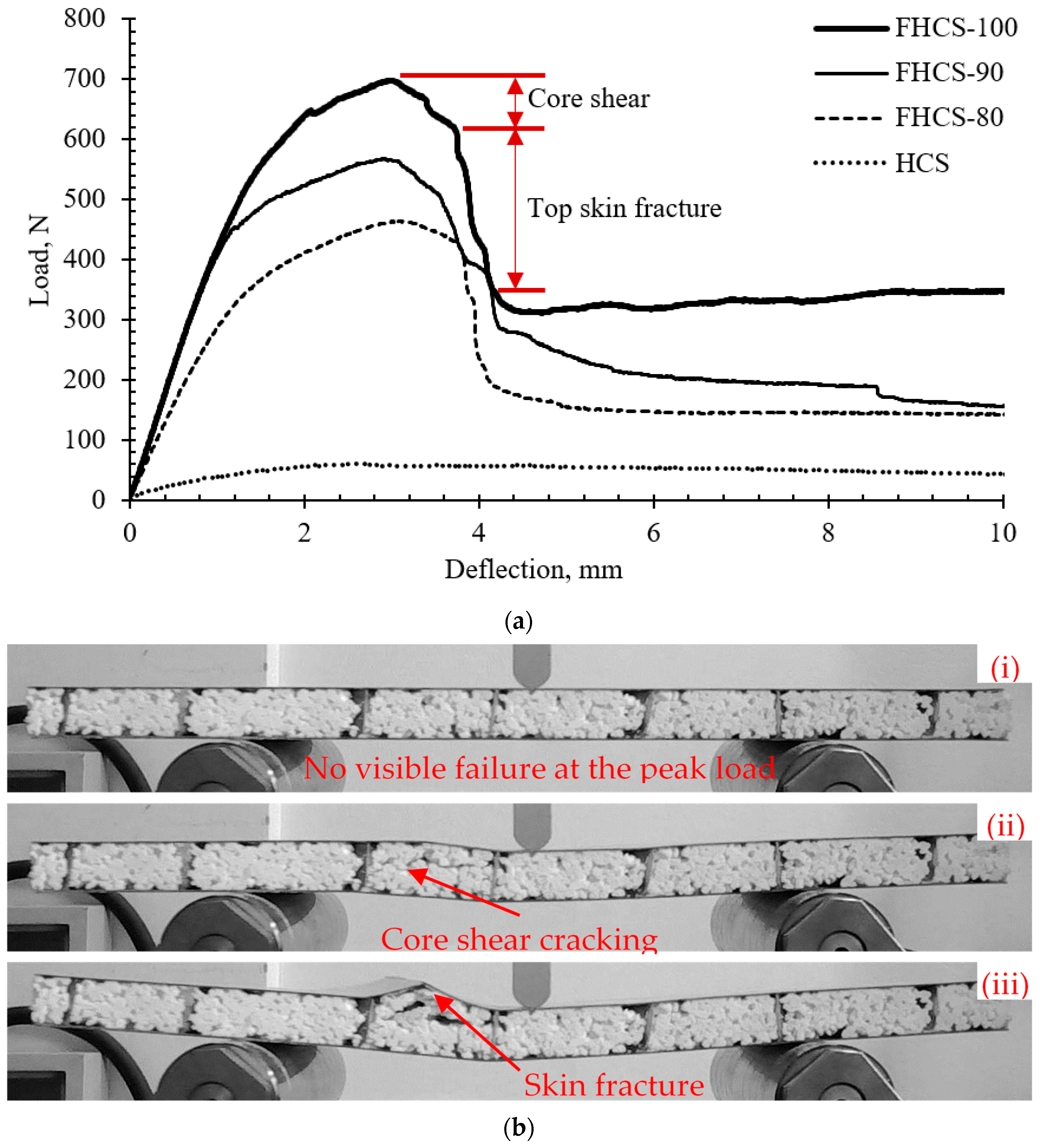

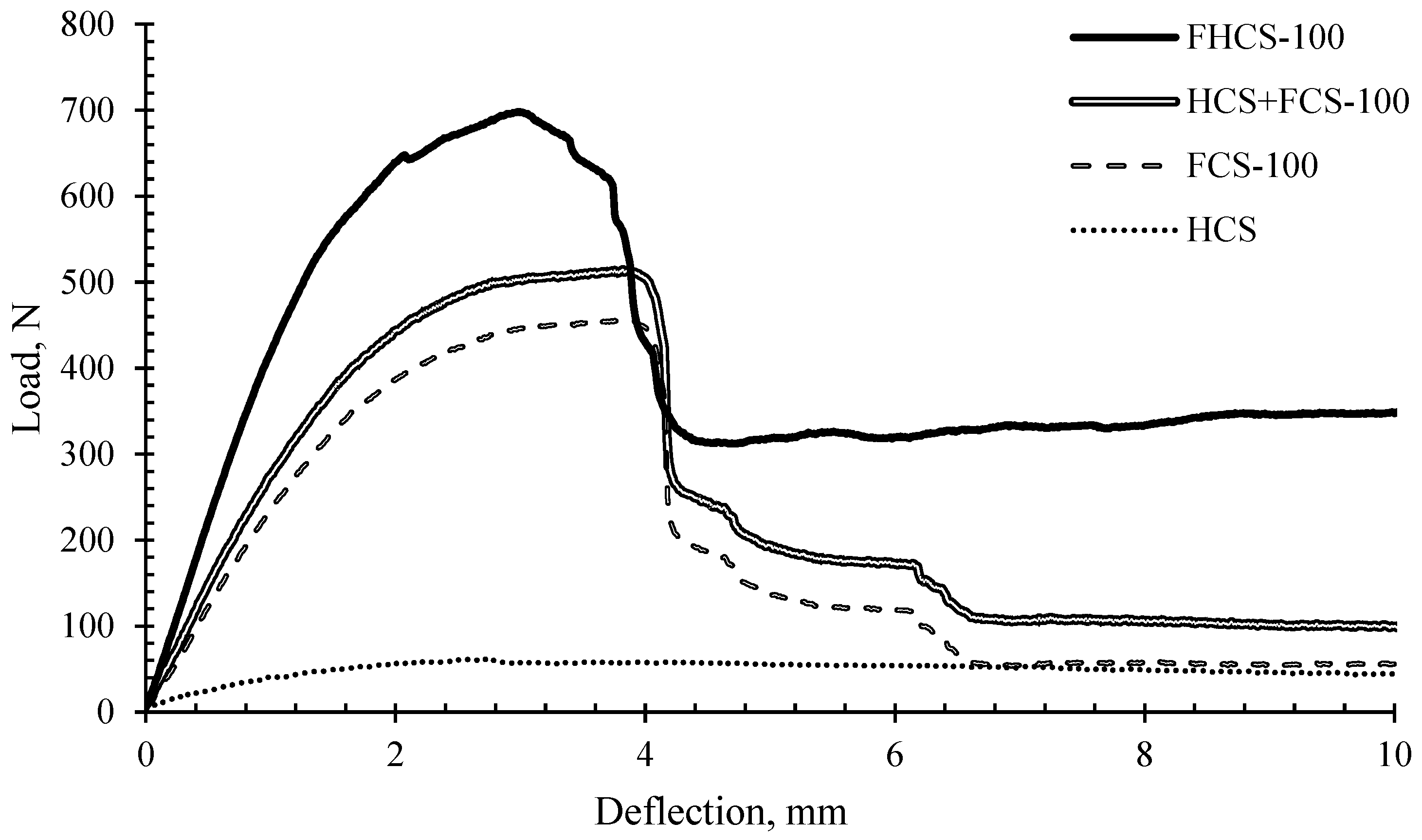

3.2. Flexural Load-Deflection Curves and Failure Mechanism

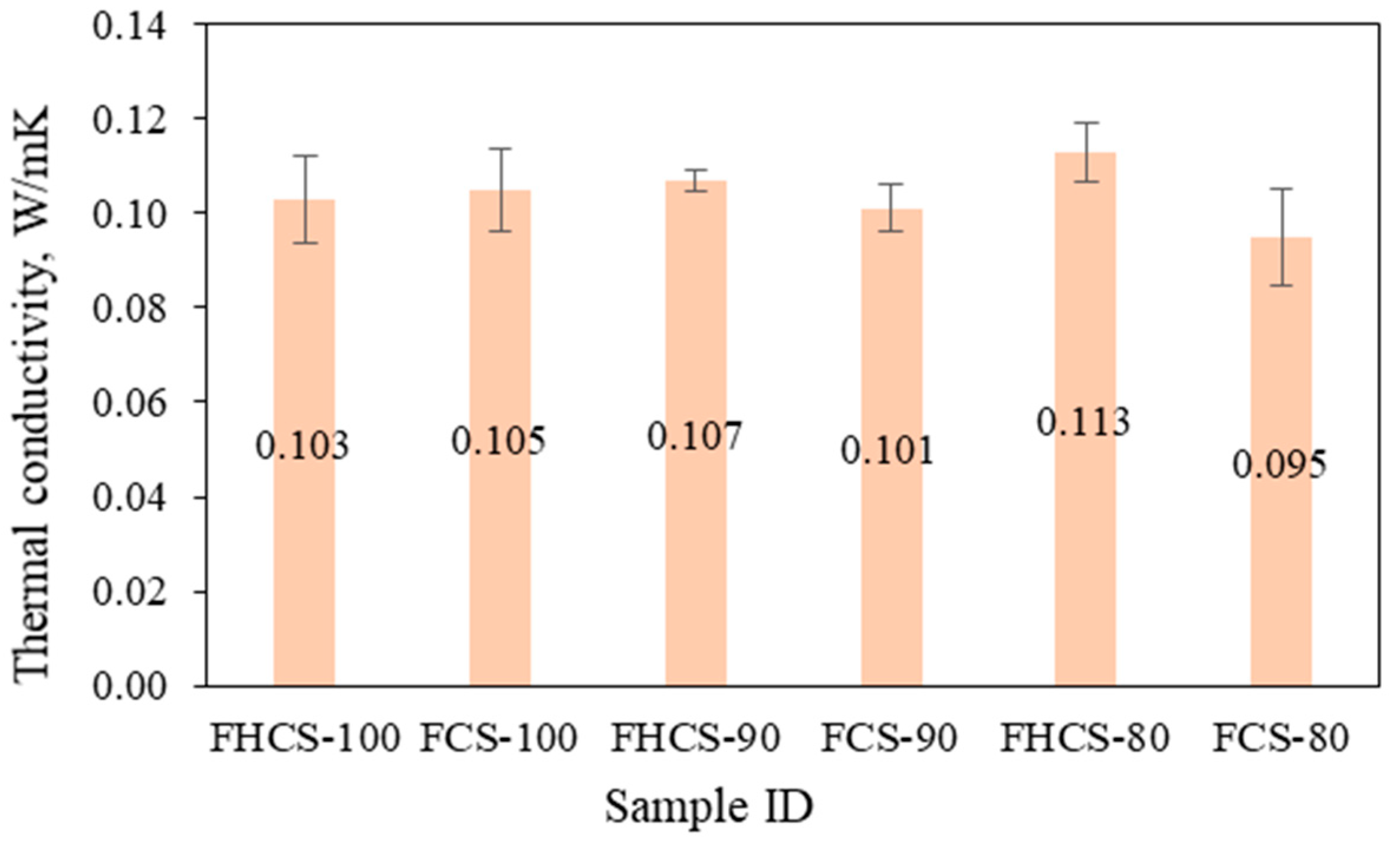

3.3. Thermal Behavior

4. Conclusions

- The flexural properties of the foam-only sandwich structures improved significantly with paper honeycomb reinforcement. Paper honeycomb reinforcement can be an effective method for enhancing foam-core-based sandwich structures. Furthermore, the perlite/sodium silicate composite foam filling in the cells of the paper honeycomb core increased the flexural properties of the sandwich structures remarkably.

- The paper honeycomb core-based sandwich structure exhibited a reasonable flexural strength of 1.01 MPa, making it suitable for non-load-bearing structures.

- The density of the sandwich structures increased with the foam filling, but the specific flexural properties were substantially greater than those of the paper honeycomb core-based sandwiches.

- The failure initiation due to flexural loading in foam-only and foam-filled paper honeycomb sandwich structures occurred by core shear cracking. In contrast, the failure in the paper honeycomb core-based sandwich was found to be local deformation, due to core buckling.

- The highest facing stress developed in the sandwich structures was lower than the tensile strength of the Formica sheets. Therefore, the performance of the sandwich structures could be further improved by enhancing the shear strength of the cores.

- Core shear failure did not significantly impact the load-bearing capacity of the sandwiches. Instead, the second stages of failure, such as delamination or skin fracture, led to a rapid drop in load-bearing capacity.

- The concentration of sodium silicate and the presence of paper honeycomb reinforcement in the perlite/sodium silicate foam core-based sandwich structures had an insignificant effect on thermal conductivity.

- The thermal conductivity of the foam core-based sandwiches, with or without paper honeycomb, ranged from 0.095 to 0.113 W/mK, which was significantly lower than that of many existing building materials found in the literature.

- Additionally, the specific flexural properties of the sandwiches studied in this work were comparable to those of common building materials used in non-load-bearing applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Berge, B. The Ecology of Building Materials; Routledge: London, UK, 2009. [Google Scholar]

- Lanzón, M.; García-Ruiz, P. Lightweight cement mortars: Advantages and inconveniences of expanded perlite and its influence on fresh and hardened state and durability. Constr. Build. Mater. 2008, 22, 1798–1806. [Google Scholar] [CrossRef]

- Dube, W.; Sparks, L.; Slifka, A. Thermal conductivity of evacuated perlite at low temperatures as a function of load and load history. Cryogenics 1991, 31, 3–6. [Google Scholar] [CrossRef]

- Ennis, D. Perlite mining and reclamation in the no aqua peaks, Taos County, New Mexico. In Proceedings of the 62nd Field Conference Geology of the Tusas Mountains–Ojo Caliente: New, Mexico, USA, New Mexico Geological Society Guidebook, Espanola, NM, USA, 28 September–1 October 2011. [Google Scholar]

- Yilmazer, S.; Ozdeniz, M.B. The effect of moisture content on sound absorption of expanded perlite plates. Build. Environ. 2005, 40, 311–318. [Google Scholar] [CrossRef]

- Rashad, A.M. A synopsis about perlite as building material—A best practice guide for Civil Engineer. Constr. Build. Mater. 2016, 121, 338–353. [Google Scholar] [CrossRef]

- Jack, M.; Rahr, C.E. Building Board of Fiber and Asphalt Coated Perlite. U.S. Patent 2,626,864, 27 January 1953. [Google Scholar]

- Sherman, N.; Cameron, J.H. Method of Manufacturing Improved Mineral Board. U.S. Patent 4,297,311, 27 October 1981. [Google Scholar]

- Shastri, D.; Kim, H.S. A new consolidation process for expanded perlite particles. Constr. Build. Mater. 2014, 60, 1–7. [Google Scholar] [CrossRef]

- Vimmrová, A.; Keppert, M.; Svoboda, L.; Černý, R. Lightweight gypsum composites: Design strategies for multi-functionality. Cem. Concr. Compos. 2011, 33, 84–89. [Google Scholar] [CrossRef]

- Karua, P.; Arifuzzaman, M.; Islam, M.S. Effect of jute fiber reinforcement on the mechanical properties of expanded perlite particles-filled gypsum composites. Constr. Build. Mater. 2023, 387, 131625. [Google Scholar] [CrossRef]

- Arifuzzaman, M.; Kim, H.S. Novel mechanical behaviour of perlite/sodium silicate composites. Constr. Build. Mater. 2015, 93, 230–240. [Google Scholar] [CrossRef]

- Arifuzzaman, M.; Kim, H.S. Flatwise Compression and Flexural Behaviour of Perlite/Sodium Silicate Composite Foam. Appl. Mech. Mater. 2017, 860, 19–24. [Google Scholar] [CrossRef]

- Arifuzzaman, M.; Kim, H.S. Prediction and evaluation of density and volume fractions for the novel perlite composite affected by internal structure formation. Constr. Build. Mater. 2017, 141, 201–215. [Google Scholar] [CrossRef]

- Arifuzzaman, M.; Kim, H.S. Plane Stress/Strain Compressive Behavior of Perlite Composite Foam. J. Test. Eval. 2019, 47, 2905–2925. [Google Scholar] [CrossRef]

- Adhikary, P.; Arifuzzaman, M.; Kabir, E. Compressive properties of expanded perlite based particulate composite for the application in building insulation Board. J. Eng. Adv. 2020, 1, 1–5. [Google Scholar] [CrossRef]

- Karua, P.; Arifuzzaman, M. Compressive behavior of perlite/sodium silicate composite foam modified by boric acid. Metall. Mater. Eng. 2022, 28, 103–124. [Google Scholar] [CrossRef]

- Aziz Naser Takey, A.S.M.; Hossain, G.M.I.; Sarker, S.; Arifuzzaman, M. Effect of Nylon Fiber Reinforcement on Mechanical Behavior of Expanded Perlite/Sodium Silicate Composites. In Proceedings of the 2nd International Conference on Mechanical Engineering and Applied Sciences (ICMEAS), MIST, Dhaka, Bangladesh, 8–12 December 2022. [Google Scholar]

- Tian, Y.L.; Guo, X.L.; Wu, D.L.; Sun, S.B. A study of effect factors on sodium silicate based expanded perlite insulation board strength. Appl. Mech. Mater. 2013, 405, 2771–2777. [Google Scholar] [CrossRef]

- Al Abir, A.; Faruk, M.O.; Arifuzzaman, M. Novel expanded perlite based composite using recycled expanded polystyrene for building material applications. In Proceedings of the 6th International Conference on Mechanical, Industrial and Energy Engineering (ICMIEE), KUET, Khulna, Bangladesh, 19–21 December2020. [Google Scholar]

- Yew, M.C.; Yew, M.K.; Yuen, R.K.K. Experimental analysis of lightweight fire-rated board on fire resistance, mechanical, and acoustic properties. Fire 2023, 6, 221. [Google Scholar] [CrossRef]

- Arifuzzaman, M.; Kim, H.S. Novel flexural behaviour of sandwich structures made of perlite foam/sodium silicate core and paper skin. Constr. Build. Mater. 2017, 148, 321–333. [Google Scholar] [CrossRef]

- Wang, D. Impact behavior and energy absorption of paper honeycomb sandwich panels. Int. J. Impact Eng. 2009, 36, 110–114. [Google Scholar] [CrossRef]

- Dongmei, W. Cushioning properties of multi-layer corrugated sandwich structures. J. Sandw. Struct. Mater. 2009, 11, 57–66. [Google Scholar] [CrossRef]

- Chen, Z.; Yan, N. Investigation of elastic moduli of Kraft paper honeycomb core sandwich panels. Compos. Part B Eng. 2012, 43, 2107–2114. [Google Scholar] [CrossRef]

- Shahbazi, S.; Singer, N.; Majeed, M.; Kavgic, M.; Foruzanmehr, R. Cementitious Insulated Drywall Panels Reinforced with Kraft-Paper Honeycomb Structures. Buildings 2022, 12, 1261. [Google Scholar] [CrossRef]

- Fu, Y.; Sadeghian, P. Flexural and shear characteristics of bio-based sandwich beams made of hollow and foam-filled paper honeycomb cores and flax fiber composite skins. Thin-Walled Struct. 2020, 153, 106834. [Google Scholar] [CrossRef]

- Abd Kadir, N.; Aminanda, Y.; Ibrahim, M.S.; Mokhtar, H. Experimental study on energy absorption of foam filled kraft paper honeycomb subjected to quasi-static uniform compression loading. IOP Conf. Ser. Mater. Sci. Eng. 2016, 152, 012048. [Google Scholar] [CrossRef]

- Abd Kadir, N.; Aminanda, Y.; Ibrahim, M.S.; Mokhtar, H. Experimental study of low-velocity impact on foam-filled Kraft paper honeycomb structure. IOP Conf. Ser. Mater. Sci. Eng. 2018, 290, 012082. [Google Scholar] [CrossRef]

- Safarabadi, M.; Haghighi-Yazdi, M.; Sorkhi, M.; Yousefi, A. Experimental and numerical study of buckling behavior of foam-filled honeycomb core sandwich panels considering viscoelastic effects. J. Sandw. Struct. Mater. 2021, 23, 3985–4015. [Google Scholar] [CrossRef]

- Sarkar, S.; Aziz Naser Takey, A.S.M.; Ahammad, R.; Islam, M.S.; Arifuzzaman, M. Mechanical behavior of sandwich structure made of perlite foam core and JFRP skin. In Proceedings of the 7th International Conference on Mechanical, Industrial and Energy Engineering (ICMIEE), KUET, Khulna, Bangladesh, 22–24 December 2022. [Google Scholar]

- Hossain, G.M.I.; Karua, P.; Arifuzzaman, M. Mechanical Characterization of Novel Sandwich Structures Made of Perlite/Epoxy Core with JFRP Facings. In Proceedings of the 7th International Conference on Engineering Research, Innovation and Education (ICERIE), SUST, Sylhet, Bangladesh, 12–14 January 2023. [Google Scholar]

- Zenkert, D. An Introduction to Sandwich Structures, Student Edition; DTU Mechanical Engineering, Technical University of Denmark: Lyngby, Denmark, 2005. [Google Scholar]

- Pflug, J.; Vangrimde, B.; Verpoest, I.; Bratfisch, P.; Vandepitte, D. Continuously produced honeycomb cores. In Proceedings of the International SAMPE Symposium and Exhibition, Long Beach, CA, USA, 11–15 May 2003. [Google Scholar]

- ASTM C393/C393M-11; Standard Test Method for Core Shear Properties of Sandwich Constructions by Beam Flexure. ASTM International: West Conshohocken, PA, USA, 2016.

- Barragán, V.M.; Maroto, J.C.; Pastuschuk, E.; Muñoz, S. Testing a simple Lee’s disc method for estimating throuh-plane thermal conductivity of polymeric ion-exchange membranes. Int. J. Heat Mass Transf. 2022, 184, 122295. [Google Scholar] [CrossRef]

- Casagrande, D.; Grossi, P.; Tomasi, R. Shake table tests on a full-scale timber-frame building with gypsum fibre boards. Eur. J. Wood Wood Prod. 2016, 74, 425–442. [Google Scholar] [CrossRef]

- Thoemen, H.; Irle, M.; Sernek, M. (Eds.) Wood-Based Panels: An Introduction for Specialists; Brunel University Press: London, UK, 2010. [Google Scholar]

- Asasutjarit, C.; Hirunlabh, J.; Khedari, J.; Charoenvai, S.; Zeghmati, B.; Cheul Shin, U. Development of coconut coir-based lightweight cement board. Constr. Build. Mater. 2007, 21, 277–288. [Google Scholar] [CrossRef]

- Islam, M.M.; Kim, H.S. Sandwich composites made of syntactic foam core and paper skin: Manufacturing and mechanical behavior. J. Sandw. Struct. Mater. 2012, 14, 111–127. [Google Scholar] [CrossRef]

- Demirkir, C.; Colakoglu, G.; Colak, S.; Aydin, I.; Candan, Z. Influence of aging procedure on bonding strength and thermal conductivity of plywood panels. Acta Phys. Pol. A 2016, 129, 1230–1234. [Google Scholar] [CrossRef]

- Haseli, M.; Layeghi, M.; Hosseinabadi, H.Z. Characterization of blockboard and battenboard sandwich panels from date palm waste trunks. Measurement 2018, 124, 329–337. [Google Scholar] [CrossRef]

- Sayadi, A.A.; Tapia, J.V.; Neitzert, T.R.; Charles Clifton, G. Effects of expanded polystyrene (EPS) particles on fire resistance, thermal conductivity and compressive strength of foamed concrete. Constr. Build. Mater. 2016, 112, 716–724. [Google Scholar] [CrossRef]

- Cherki, A.-b.; Remy, B.; Khabbazi, A.; Jannot, Y.; Baillis, D. Experimental thermal properties characterization of insulating cork–gypsum composite. Constr. Build. Mater. 2014, 54, 202–209. [Google Scholar] [CrossRef]

- San-Antonio-González, A.; Del Río Merino, M.; Arrebola, C.V.; Villoria-Sáez, P. Lightweight material made with gypsum and extruded polystyrene waste with enhanced thermal behaviour. Constr. Build. Mater. 2015, 93, 57–63. [Google Scholar] [CrossRef]

- Ng, S.-C.; Low, K.-S. Thermal conductivity of newspaper sandwiched aerated lightweight concrete panel. Energy Build. 2010, 42, 2452–2456. [Google Scholar] [CrossRef]

- Lesiecki, M.; Kawalerczyk, J.; Derkowski, A.; Wieruszewski, M.; Dziurka, D.; Mirski, R. Properties of lightweight insulating board produced from triticale straw particles. Materials 2023, 16, 5272. [Google Scholar] [CrossRef]

| Sample | Tensile Strength (MPa) | Tensile Modulus (GPa) | Failure Strain (%) |

|---|---|---|---|

| Formica sheet | 57.89 ± 4.73 | 8.91 ± 0.23 | 0.69 ± 0.05 |

| Sample ID | Sodium Silicate Solution, wt.% | Water, wt.% |

|---|---|---|

| FHCS-100, FCS-100 | 100 | 0 |

| FHCS-90, FCS-90 | 90 | 10 |

| FHCS-80, FCS-80 | 80 | 20 |

| Sample ID | Mass of Perlite (g) | Mass of SSS as Received (g) | Mass of Water (g) | Mass of Diluted SSS (g) |

|---|---|---|---|---|

| FHCS-100 | 85 | 365.00 | 0 | 365.00 |

| FCS-100 | 90 | 386.47 | 0 | 386.47 |

| FHCS-90 | 85 | 328.50 | 36.50 | 365.00 |

| FCS-90 | 90 | 347.82 | 38.65 | 386.47 |

| FHCS-80 | 85 | 292.00 | 73.00 | 365.00 |

| FCS-80 | 90 | 309.18 | 77.29 | 386.47 |

| Sample ID | Density, g/cm3 | Core Shear Stress, MPa | Facing Stress, MPa | Flexural Modulus, GPa | Flexural Strength, MPa | Thermal Conductivity, W/mK |

|---|---|---|---|---|---|---|

| FHCS-100 | 0.47 ± 0.010 | 0.35 ± 0.10 | 51.26 ± 13.81 | 1.76 ± 0.09 | 11.03 ± 2.95 | 0.10 ± 0.010 |

| FHCS-90 | 0.44 ± 0.003 | 0.27 ± 0.02 | 39.72 ± 3.00 | 1.61 ± 0.07 | 8.55 ± 0.64 | 0.11 ± 0.003 |

| FHCS-80 | 0.42 ± 0.007 | 0.20 ± 0.06 | 28.64 ± 7.65 | 1.30 ± 0.09 | 6.26 ± 1.70 | 0.10 ± 0.010 |

| FCS-100 | 0.46 ± 0.009 | 0.23 ± 0.05 | 33.69 ± 6.86 | 1.44 ± 0.09 | 7.79 ± 1.62 | 0.11 ± 0.010 |

| FCS-90 | 0.43 ± 0.006 | 0.22 ± 0.03 | 31.53 ± 4.36 | 1.19 ± 0.14 | 7.45 ± 1.08 | 0.11 ± 0.010 |

| FCS-80 | 0.40 ± 0.011 | 0.13 ± 0.03 | 18.95 ± 3.85 | 1.07 ± 0.21 | 4.06 ± 0.82 | 0.09 ± 0.004 |

| HCS | 0.15 ± 0.008 | 0.04 ± 0.02 | 4.59 ± 1.81 | 0.22 ± 0.12 | 1.01 ± 0.40 | - |

| Sample ID | Failure Sequence |

|---|---|

| FHCS-100 | Core shear–top skin fracture |

| FHCS-90 | Core shear–top skin fracture |

| FHCS-80 | Core shear–top skin fracture |

| FCS-100 | Core shear–delamination-top skin fracture |

| FCS-90 | Core shear–delamination |

| FCS-80 | Core shear–delamination |

| HCS | Local buckling of honeycomb core |

| Reference | Materials | Density (g/cm3) | Thermal Conductivity (W/m.K) |

|---|---|---|---|

| [26] | Gypsum board | 0.65 | 0.159 |

| [37] | Gypsum fiberboard | 1.15 | 0.32 |

| [38] | MDF | 0.696 | 0.0974 |

| [38] | Thin MDF | 0.802 | 0.1104 |

| [42] | Date Palm Waste-MDF sandwich panel | 0.456 | 0.1357 |

| [37] | Oriented strand boards (OSB) or plywood (PWD) | 0.65 | 0.13 |

| [38] | Plywood (Beech) | 0.679 | 0.1304 |

| [41] | Plywood (Scots pine) | 0.58 | 0.10 |

| [41] | Plywood (Black pine) | 0.60 | 0.11 |

| [38] | Particleboard | 0.597 | 0.0965 |

| [26] | Flax-reinforced Portland cement skin with kraft paper honeycomb core | 0.89 | 0.097 |

| [39] | Coconut coir cement board | 1.04 | 0.40 |

| [39] | Commercial flakeboard | 1.04 | 0.36 |

| [39] | Commercial cellulose board | 1.56 | 0.68 |

| [43] | Polystyrene foamed concrete | 0.4 | 0.157 |

| [44] | Cork–gypsum composite | 0.472 | 0.124 |

| [45] | Gypsum composite | 0.88 | 0.13 |

| [46] | Newspaper sandwiched ALC panel | 1.1 | 0.30 |

| [47] | Triticale straw board | 0.15–0.20 | 0.033–0.046 |

| Current study | Perlite/sodium silicate foam-based sandwich with Formica sheet skin | 0.40–0.47 | 0.095–0.113 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hossain, F.; Arifuzzaman, M.; Islam, M.S.; Islam, M.M. Thermo-Mechanical Behavior of Green Sandwich Structures for Building and Construction Applications. Processes 2023, 11, 2456. https://doi.org/10.3390/pr11082456

Hossain F, Arifuzzaman M, Islam MS, Islam MM. Thermo-Mechanical Behavior of Green Sandwich Structures for Building and Construction Applications. Processes. 2023; 11(8):2456. https://doi.org/10.3390/pr11082456

Chicago/Turabian StyleHossain, Forhad, Md Arifuzzaman, Md Shariful Islam, and Md Mainul Islam. 2023. "Thermo-Mechanical Behavior of Green Sandwich Structures for Building and Construction Applications" Processes 11, no. 8: 2456. https://doi.org/10.3390/pr11082456

APA StyleHossain, F., Arifuzzaman, M., Islam, M. S., & Islam, M. M. (2023). Thermo-Mechanical Behavior of Green Sandwich Structures for Building and Construction Applications. Processes, 11(8), 2456. https://doi.org/10.3390/pr11082456