Investigation into the Perforation Optimization in Conglomerate Reservoir Based on a Field Test

Abstract

:1. Introduction

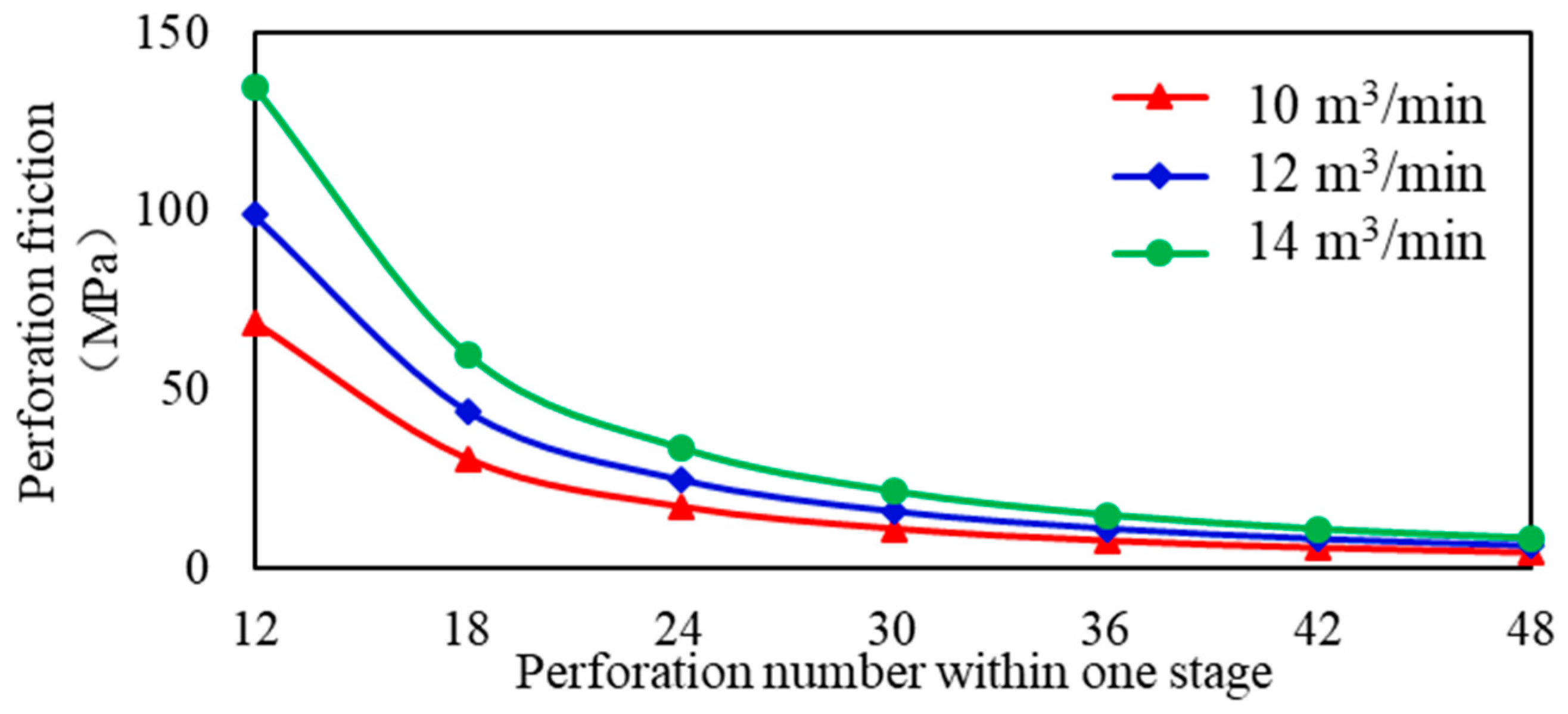

2. Perforation Optimization Based on the Theoretical Model

3. Experimental Design

3.1. The Properties of the Test Well

3.2. Perforating Scheme

4. Analysis of Test Results

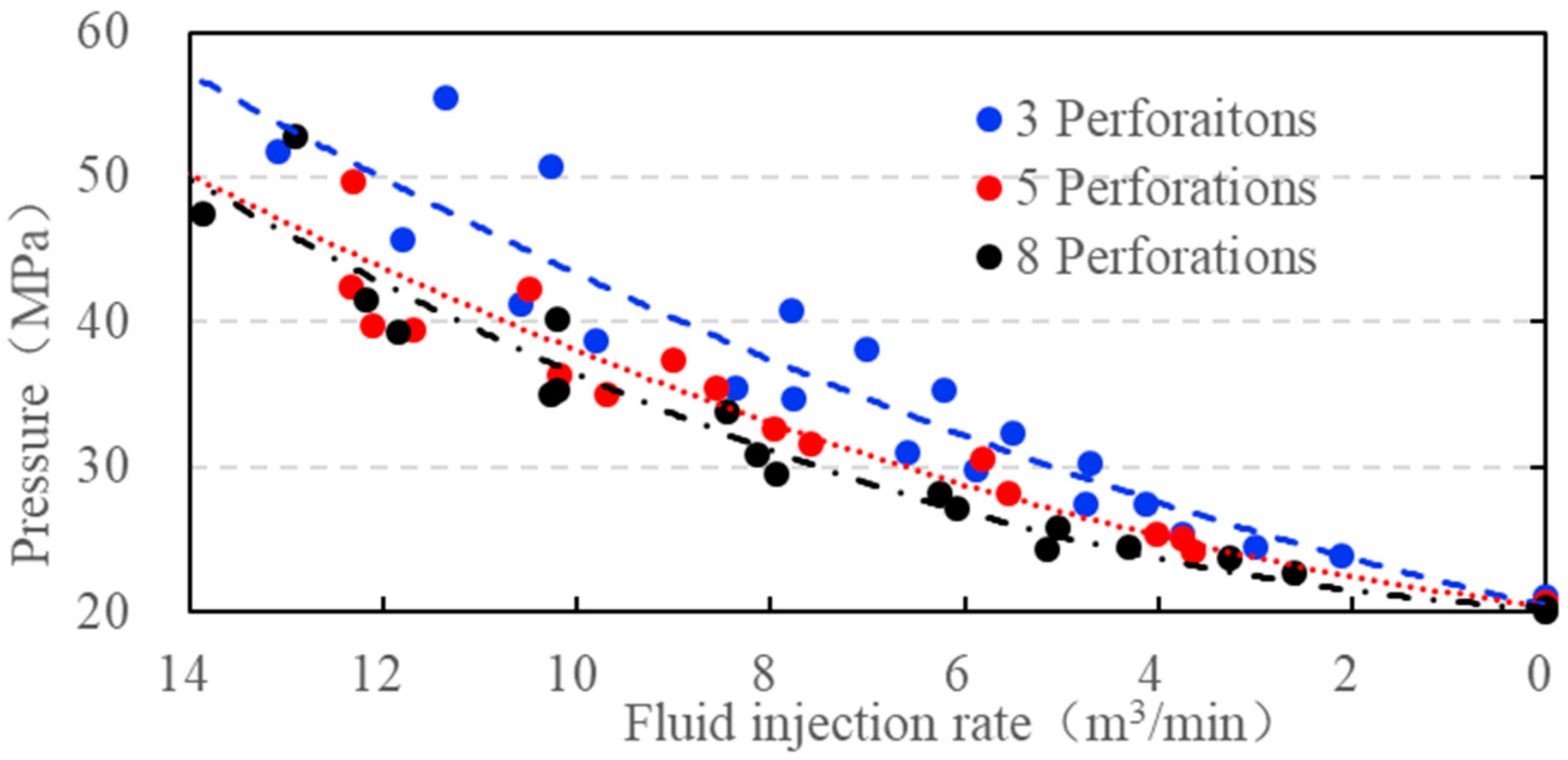

4.1. Analysis of the Step-Down Test Results

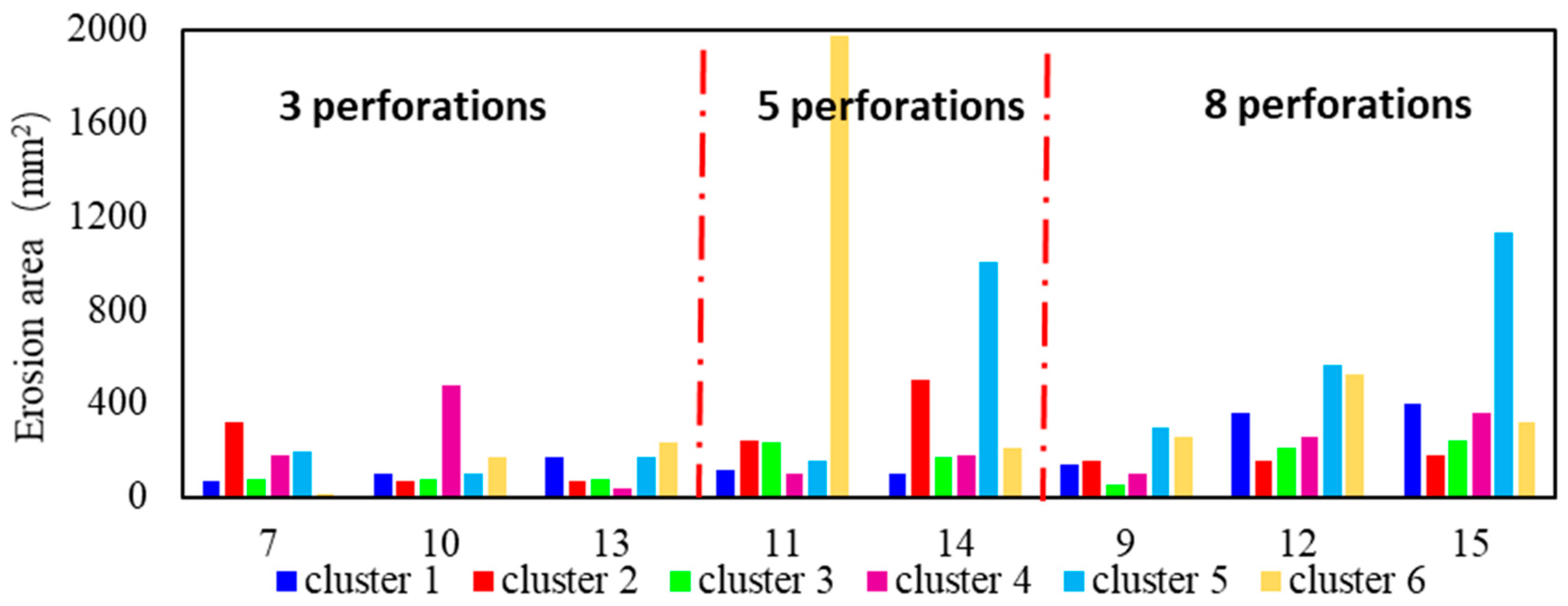

4.2. Analysis of Perforation Erosion Measurements

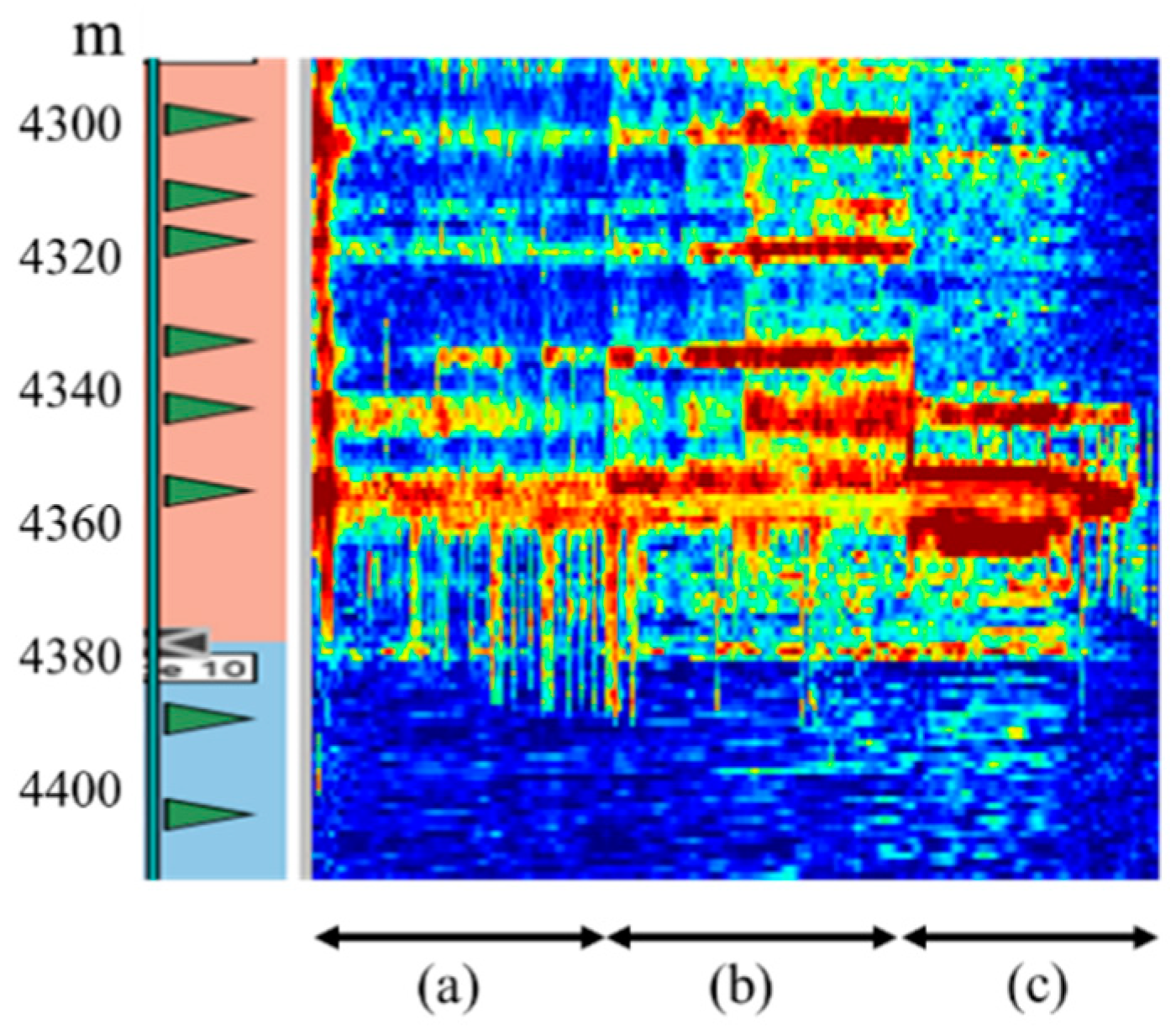

5. Verification of Optimized Perforation Scheme

6. Conclusions

- (1)

- It is necessary to optimize the perforation number per cluster because it not only improves the net wellbore pressure of the wellbore and balances the property difference among multiple fractures but also avoids excessive perforation erosion. Multiple fractures can propagate uniformly through reducing the perforation number while the super fracture may generate if the perforation number is extremely small.

- (2)

- The initial perforation friction of the three-perforation scheme is much higher than that of the eight-perforation scheme. After the injection of proppant, the difference in the perforation friction between the two schemes gradually decreases due to the perforation erosion. Based on downhole video monitoring results, the stimulation effect of the eight-perforation scheme is much better than that of the three-perforation scheme. It is suggested that the perforation number per cluster should be designed as eight in the Mahu conglomerate reservoir.

- (3)

- The optical fiber monitoring results show that the eight-perforation scheme can realize the simultaneous initiation of multiple fractures and more than 80% of the perforation clusters can receive fracturing fluid. With the injection of proppant, some perforation clusters stop receiving fracturing fluid due to the perforation erosion. The temporary plugging technology can be applied to plug the dominant perforation clusters and promote the poor perforation cluster to receive enough fracturing fluid.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, G.; Qin, J.; Xian, C.; Fan, X.; Zhang, J.; Ding, Y. Theoretical understandings, key technologies and practices of tight conglomerate oilfield efficient development: A case study of the Mahu oilfield, Junggar Basin, NW China. Pet. Explor. Dev. 2020, 47, 1275–1290. [Google Scholar] [CrossRef]

- Jiangwen, X.U.; Jianmin, L.I.; Yuanyue, W.; Kun, D.; Hong, J. Exploration and practice of volume fracturing technology in the horizontal well of Mahu tight conglomerate reservoirs. China Pet. Explor. 2019, 24, 241. [Google Scholar]

- Zhang, W.; Gao, Y.; Liang, L.X. Rock mechanics characteristics of conglomerate reservoir and its effects on fracturing treatment. Fault-Block Oil Gas Field 2021, 28, 5. [Google Scholar]

- Li, M.H.; Zhou, F.J.; Huang, G.P. A finite element simulation method for multi-fracture propagation in horizontal wells based on fluid pipe element. J. China Univ. Pet. Ed. Nat. Sci. 2022, 046, 105–112. [Google Scholar]

- Liu, J.; Ge, H.; Mou, S.; Wang, X.; Wang, J. Characterization of meso-structure of glutenite reservoirs by ultrasonic characteristics and the velocity heterogeneity. J. Pet. Sci. Eng. 2022, 208, 109436. [Google Scholar] [CrossRef]

- Liu, J.; Ge, H.; Zhang, Z.; Wang, X.; Wang, J. Influence of mechanical contrast between the matrix and gravel on fracture propagation of glutenite. J. Pet. Sci. Eng. 2022, 208, 109639. [Google Scholar] [CrossRef]

- Li, J.M.; Wu, B.C.; Zhao, H.Y. Adaptability of horizontal well volume fracturing to tight conglomerate reservoirs in Mahu oilfield. China Pet. Explor. 2019, 24, 10. [Google Scholar]

- Liao, S.M.; Sang, Y.; Song, Y.; Zeng, B.; Liu, W.; Yang, L. Research and field tests on staged fracturing technology for casing deformation stage in horizontal shale gas wells. Nat. Gas Ind. 2017, 37, 40–45. [Google Scholar]

- Barree, R.D. Potential Issues with Extreme Limited Entry in Horizontal Wells. In Proceedings of the Unconventional Resources Technology Conference (URTEC), Virtual, 20–22 July 2020; pp. 713–733. [Google Scholar] [CrossRef]

- Long, G.; Xu, G. The effects of perforation erosion on practical hydraulic-fracturing applications. SPE J. 2017, 22, 645–659. [Google Scholar] [CrossRef]

- Wu, K.; Olson, J.E. Mechanisms of Simultaneous Hydraulic-Fracture Propagation From Multiple Perforation Clusters in Horizontal Wells. SPE J. 2016, 21, 1000–1008. [Google Scholar] [CrossRef]

- Lu, W.J.; Sun, Z.L.; Liu, B.W. Optimization of Perforation Friction during Limited Fracturing in Jimsar Shale Oil Reservoir. J. Xi’an Shiyou Univ. Nat. Sci. Ed. 2022, 37, 49–57. [Google Scholar]

- Li, Y.; Deng, J.G.; Liu, W. Numerical simulation of limited entry technique in multi-stage and multi-cluster horizontal well fracturing. Fault-Block Oil Gas Field 2017, 24, 69–73. [Google Scholar]

- Zhou, Z.L.; Zhang, G.Q.; Xiong, W.X. Perforating parameter optimization of limit entry fracturing for horizontal wells. Fault-Block Oil Gas Field 2015, 22, 374–378. [Google Scholar]

- Zhang, R.X.; Hou, B.; Dan, Q.L. Parameter optimization of spiral perforations in horizontal well with tight sandstone reservoir. Chin. J. Geotech. Eng. 2018, 40, 2143–2147. [Google Scholar]

- Li, Q.; Zhang, C.; Yang, Y.; Ansari, U.; Han, Y.; Li, X.; Cheng, Y. Preliminary experimental investigation on long-term fracture conductivity for evaluating the feasibility and efficiency of fracturing operation in offshore hydrate-bearing sediments. Ocean. Eng. 2023, 281, 114949. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, D.; Yin, J.; Zhou, X.; Li, Y.; Chi, P.; Han, Y.; Ansari, U.; Cheng, Y. Sediment Instability Caused by Gas Production from Hydrate-bearing Sediment in Northern South China Sea by Horizontal Wellbore: Evolution and Mechanism. Nat. Resour. Res. 2023, 32, 1595–1620. [Google Scholar] [CrossRef]

- Wang, F.; Liu, X.; Jiang, B.; Zhuo, H.; Chen, W.; Chen, Y.; Li, X. Low-loading Pt nanoparticles combined with the atomically dispersed FeN4 sites supported by FeSA-NC for improved activity and stability towards oxygen reduction reaction/hydrogen evolution reaction in acid and alkaline media. J. Colloid Interface Sci. 2023, 635, 514–523. [Google Scholar] [CrossRef] [PubMed]

- Somanchi, K.; Brewer, J.; Reynolds, A. Extreme Limited-Entry Design Improves Distribution Efficiency in Plug-and-Perforate Completions: Insights From Fiber-Optic Diagnostics. SPE Drill. Complet. 2018, 33, 298–306. [Google Scholar] [CrossRef]

- Weddle, P.; Griffin, L.; Pearson, C.M. Mining the Bakken II—Pushing the Envelope with Extreme Limited Entry Perforating. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 23–25 January 2018. [Google Scholar]

- Cramer, D.; Friehauf, K.; Roberts, G.; Whittaker, J. Integrating DAS, treatment pressure analysis and video-based perforation imaging to evaluate limited entry treatment effectiveness. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, OnePetro, Oklahoma City, OK, USA, 9–10 April 2019. [Google Scholar]

- Zang, C.; Jiang, H.; Shi, S.; Li, J.; Zou, Y.; Zhang, S.; Tian, G.; Yang, P. An analysis of the uniformity of multi-fracture initiation based on downhole video imaging technology: A case study of Mahu tight conglomerate in Junggar Basin, NW China. Pet. Explor. Dev. 2022, 49, 448–457. [Google Scholar] [CrossRef]

- Roberts, G.; Whittaker, J.; McDonald, J.; Paxson, T. Proppant Distribution Observations from 20,000+ Perforation Erosion Measurements. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, OnePetro, The Woodlands, TX, USA, 4–6 February 2020. [Google Scholar]

- Wang, B.; Zhou, F.; Yang, C.; Wang, D.; Yang, K.; Liang, T. Experimental study on injection pressure response and fracture geometry during temporary plugging and diverting fracturing. SPE J. 2020, 25, 573–586. [Google Scholar] [CrossRef]

| Perforation Number Per Cluster | Cluster Number Per Stage | Perforation Number in One Stage | Fracturing Stage Number |

|---|---|---|---|

| 3 | 6 | 18 | Stage 7, Stage 10, Stage 13; |

| 5 | 30 | Stage 8, Stage 11, Stage 14; | |

| 8 | 48 | Stage 9, Stage 12, Stage 15; |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Q.; Ma, Y.; Wang, J.; Chen, L.; Ye, Z.; Xu, Y.; Li, H.; Wang, B. Investigation into the Perforation Optimization in Conglomerate Reservoir Based on a Field Test. Processes 2023, 11, 2446. https://doi.org/10.3390/pr11082446

Fan Q, Ma Y, Wang J, Chen L, Ye Z, Xu Y, Li H, Wang B. Investigation into the Perforation Optimization in Conglomerate Reservoir Based on a Field Test. Processes. 2023; 11(8):2446. https://doi.org/10.3390/pr11082446

Chicago/Turabian StyleFan, Qinghu, Yonggui Ma, Junping Wang, Liang Chen, Zhiquan Ye, Yajun Xu, Huan Li, and Bo Wang. 2023. "Investigation into the Perforation Optimization in Conglomerate Reservoir Based on a Field Test" Processes 11, no. 8: 2446. https://doi.org/10.3390/pr11082446

APA StyleFan, Q., Ma, Y., Wang, J., Chen, L., Ye, Z., Xu, Y., Li, H., & Wang, B. (2023). Investigation into the Perforation Optimization in Conglomerate Reservoir Based on a Field Test. Processes, 11(8), 2446. https://doi.org/10.3390/pr11082446