Bulk Resistivity of Materials in the Si/FeSi Furnace

Abstract

1. Introduction

2. Materials and Methods

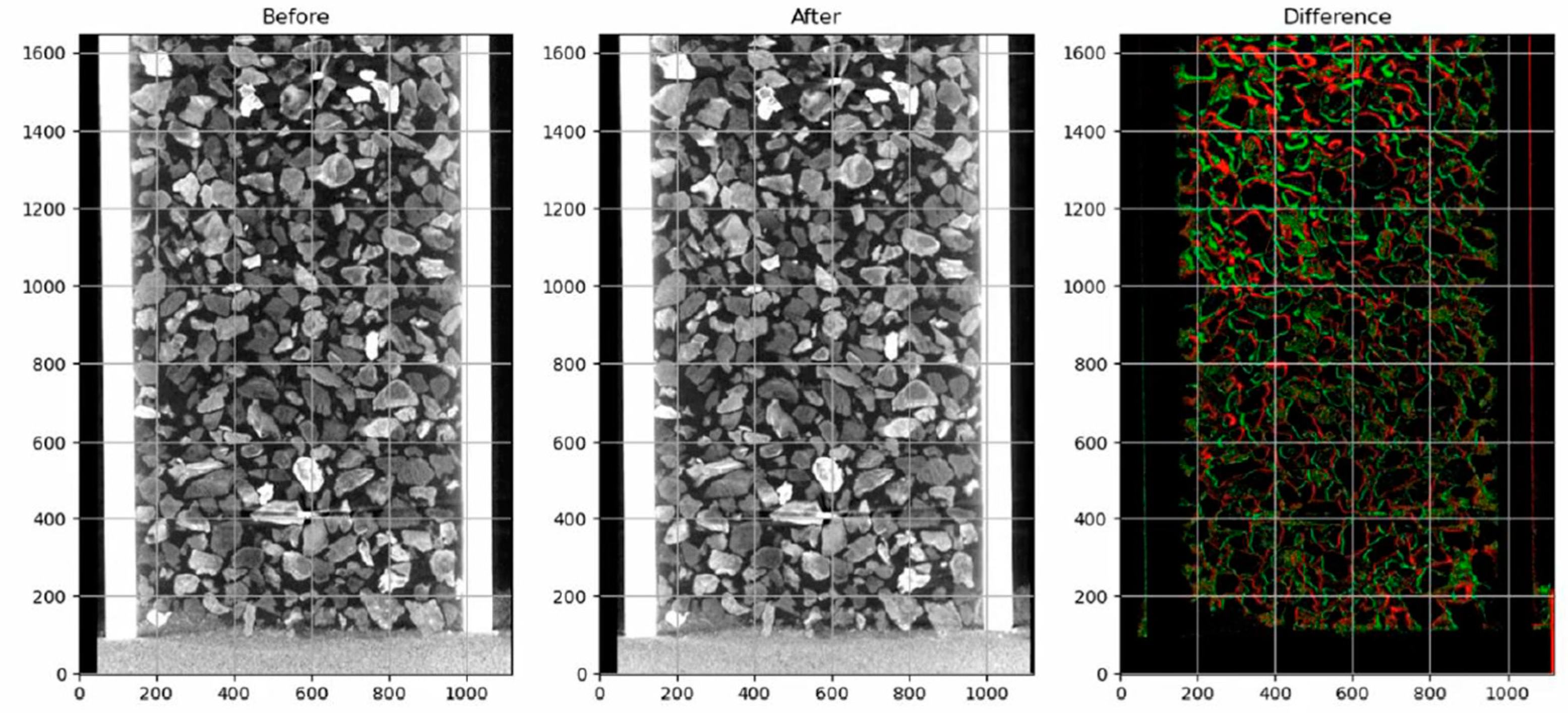

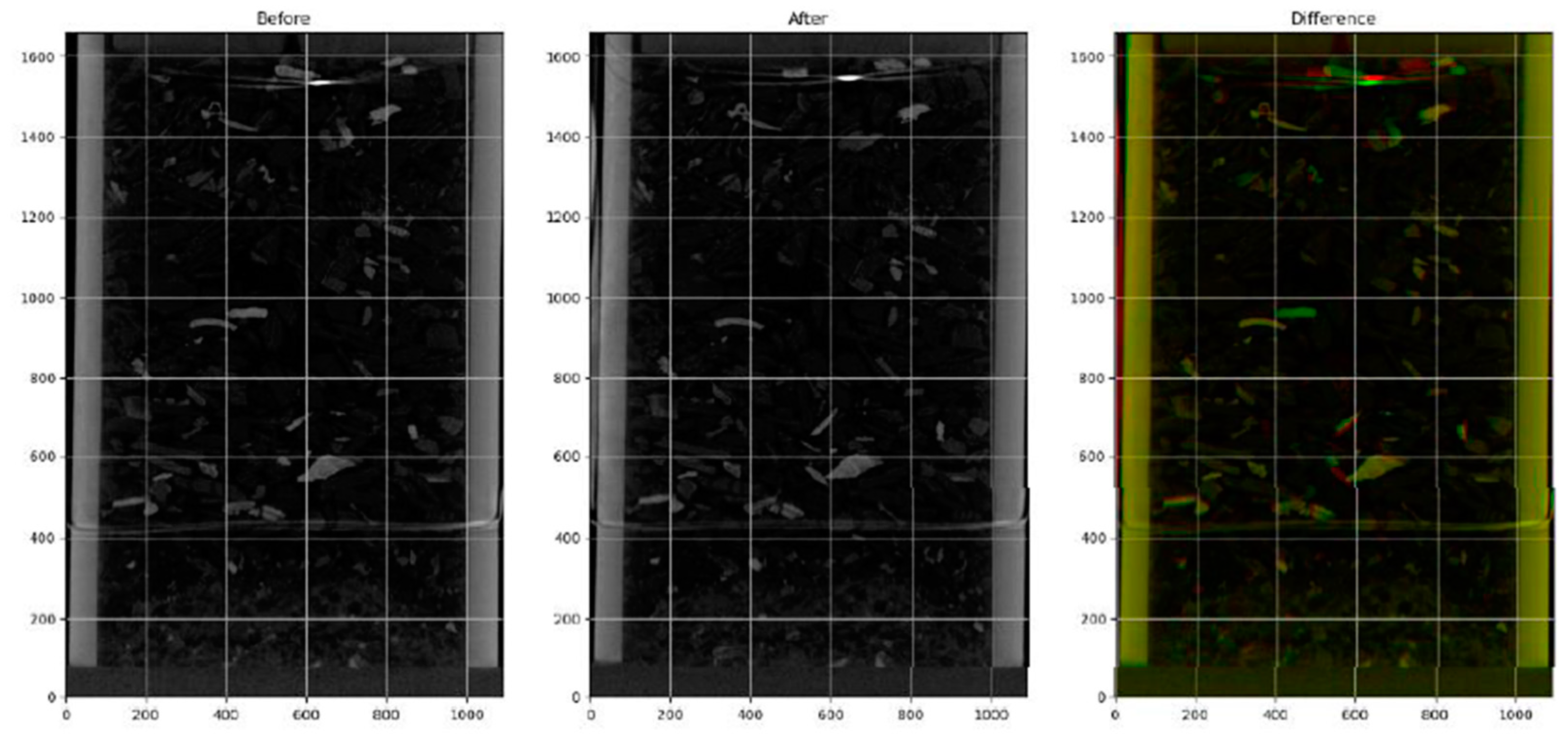

- Aligning the images using landmarks such as the alumina cylinder and the molybdenum wires.

- Converting the dataset to binary using a given threshold to determine if a voxel contained a particle and assigning it a “1” value if yes and a “0” value if not.

- Subtracting the after from the before scan, where if there is no change, black is coded, a particle “appears” in the after is green, and a “disappearing particle” is red.

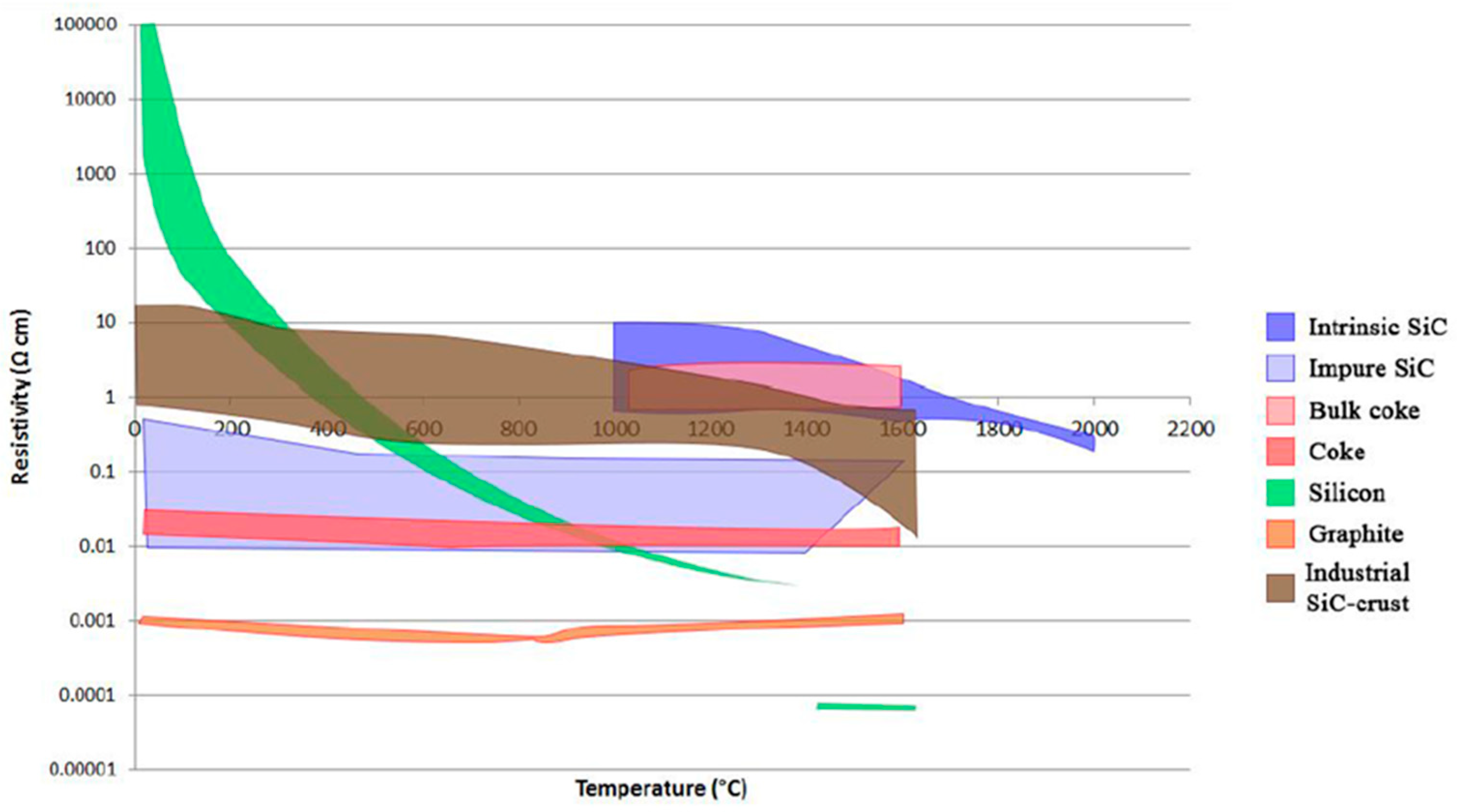

3. Results and Discussions

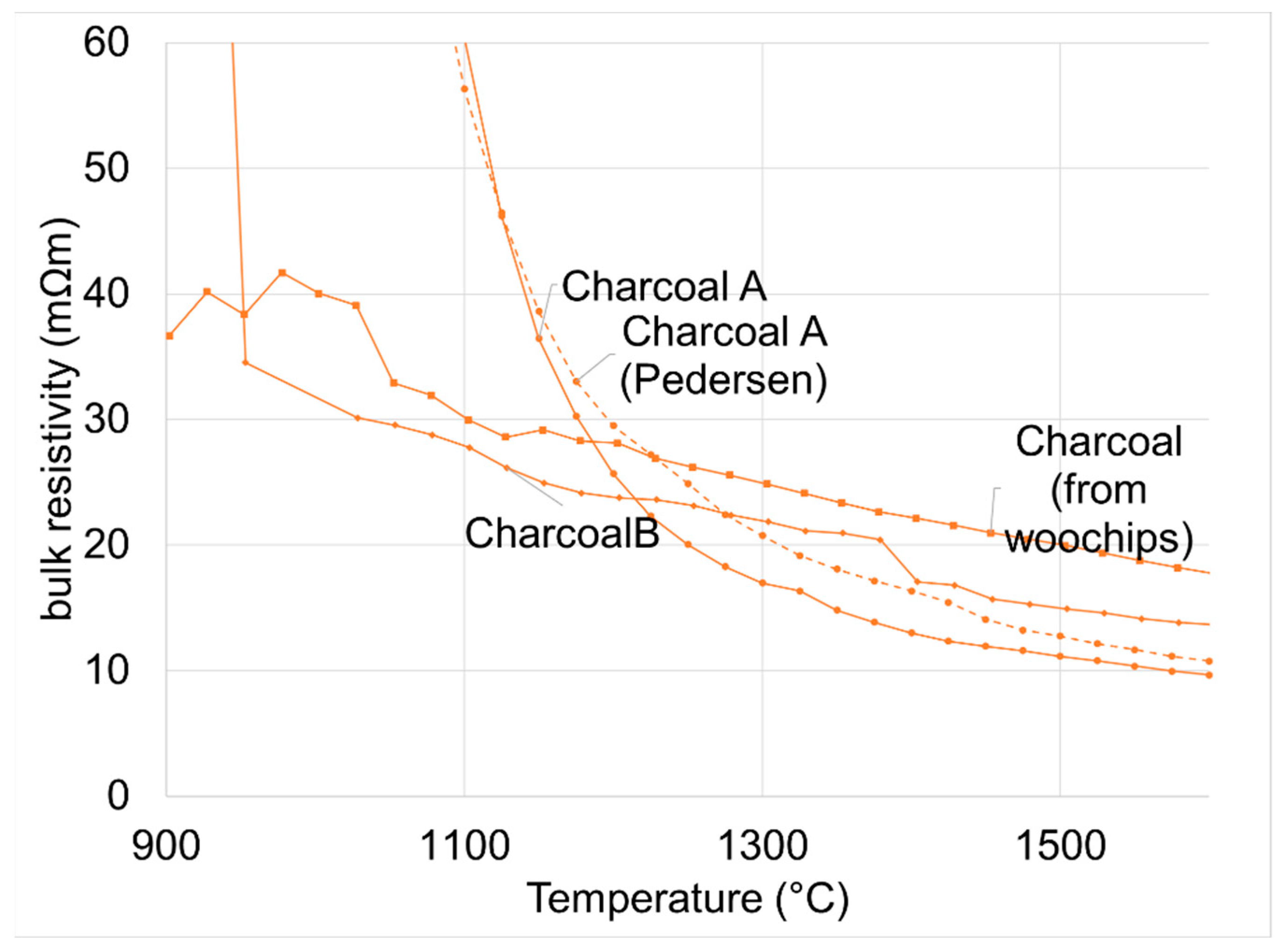

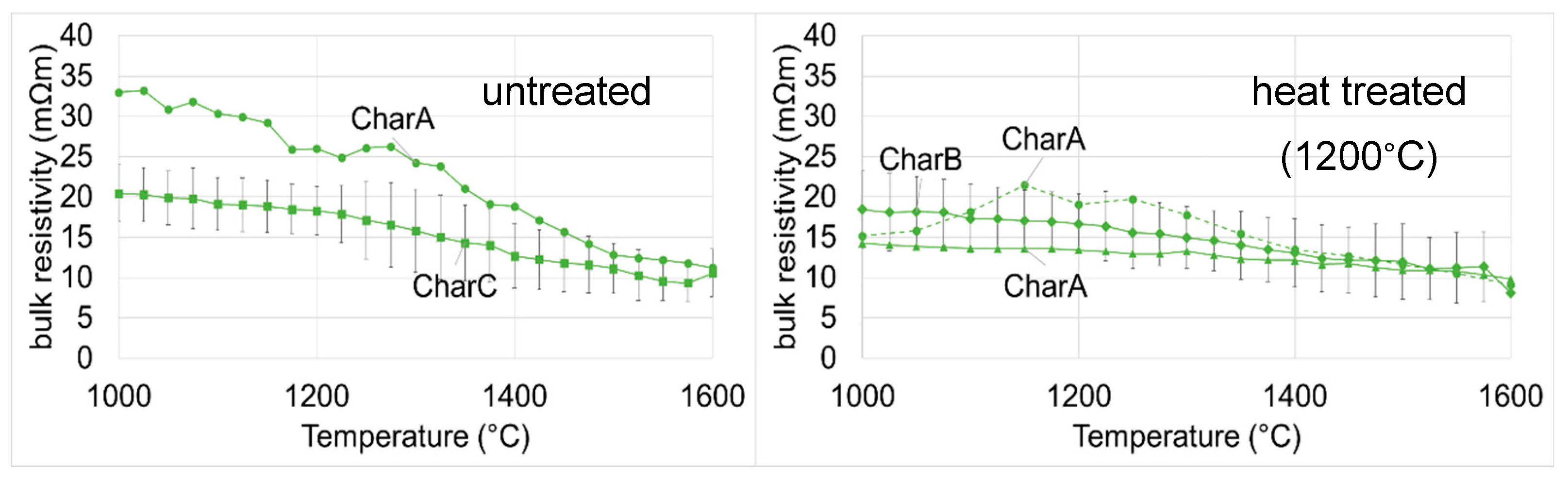

3.1. Resistivity of Carbon Materials

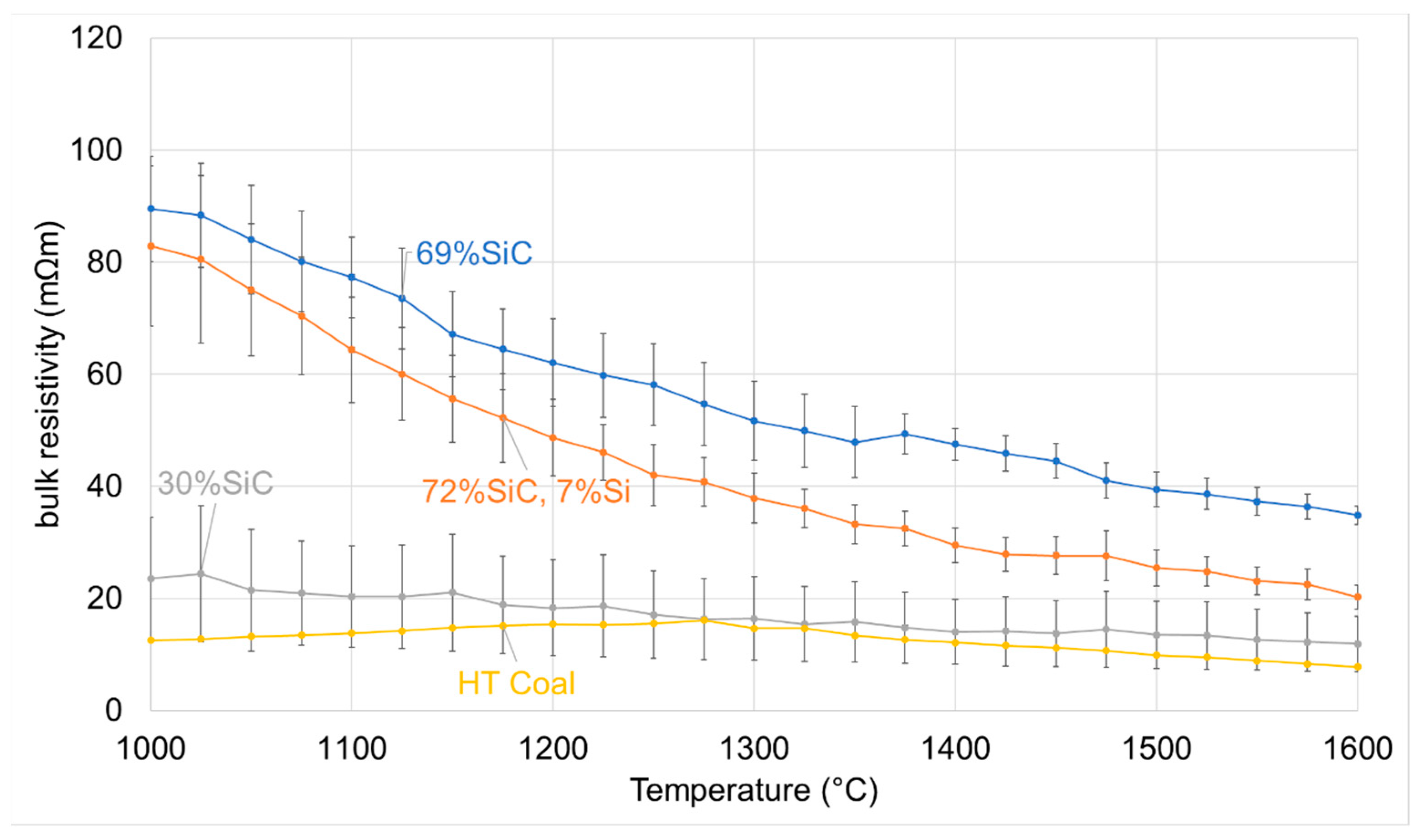

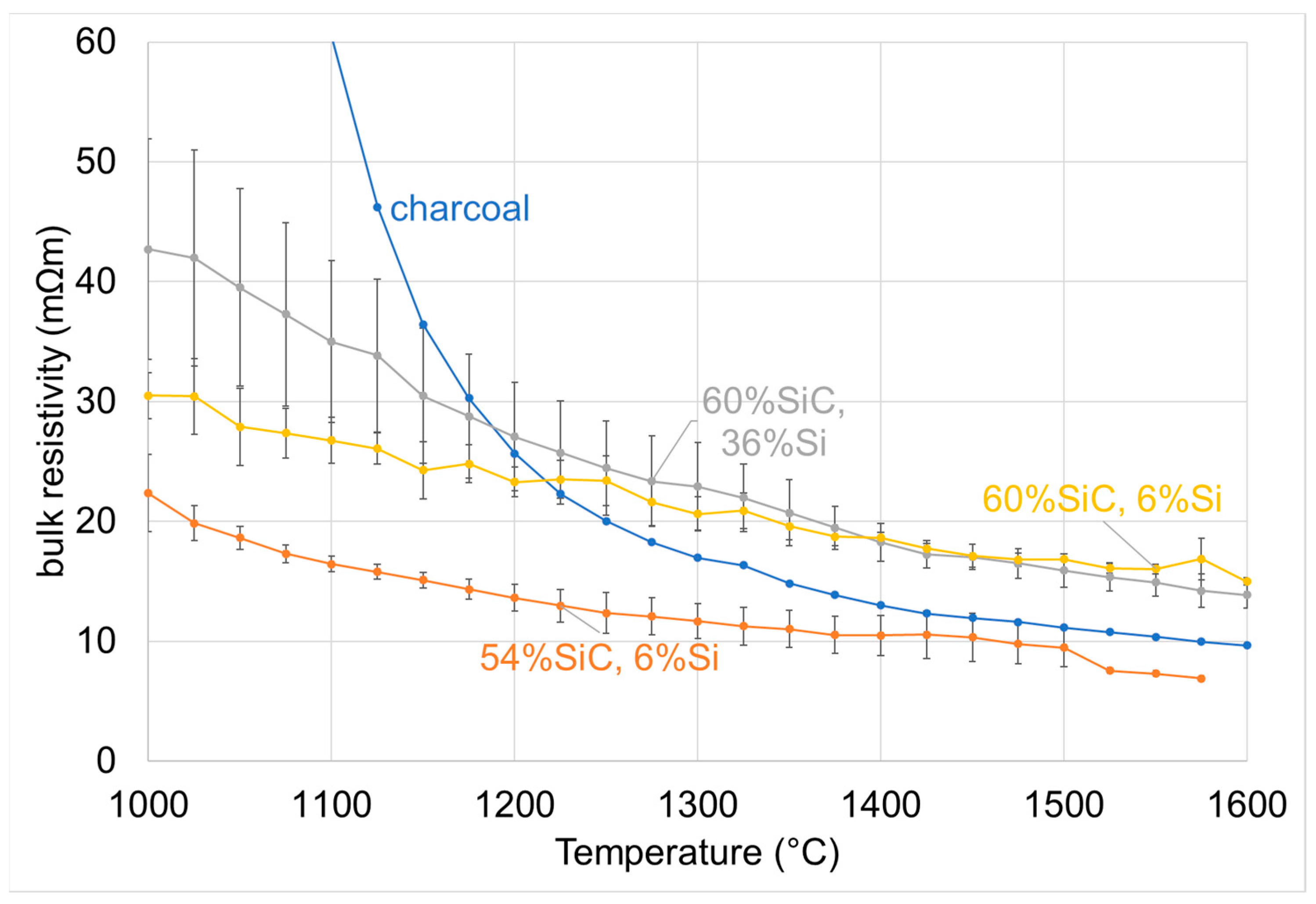

3.2. Resistivity of SiC Materials

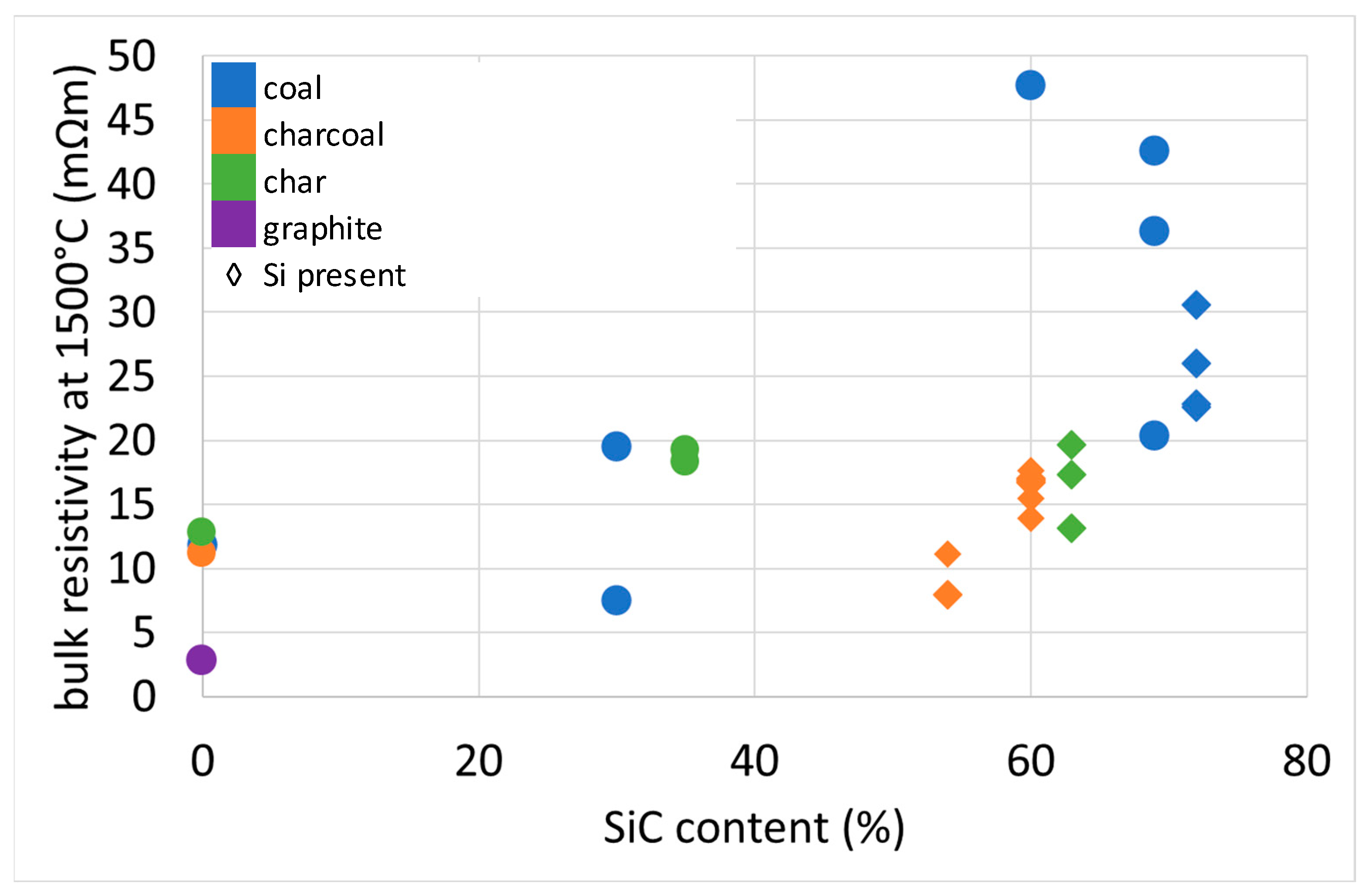

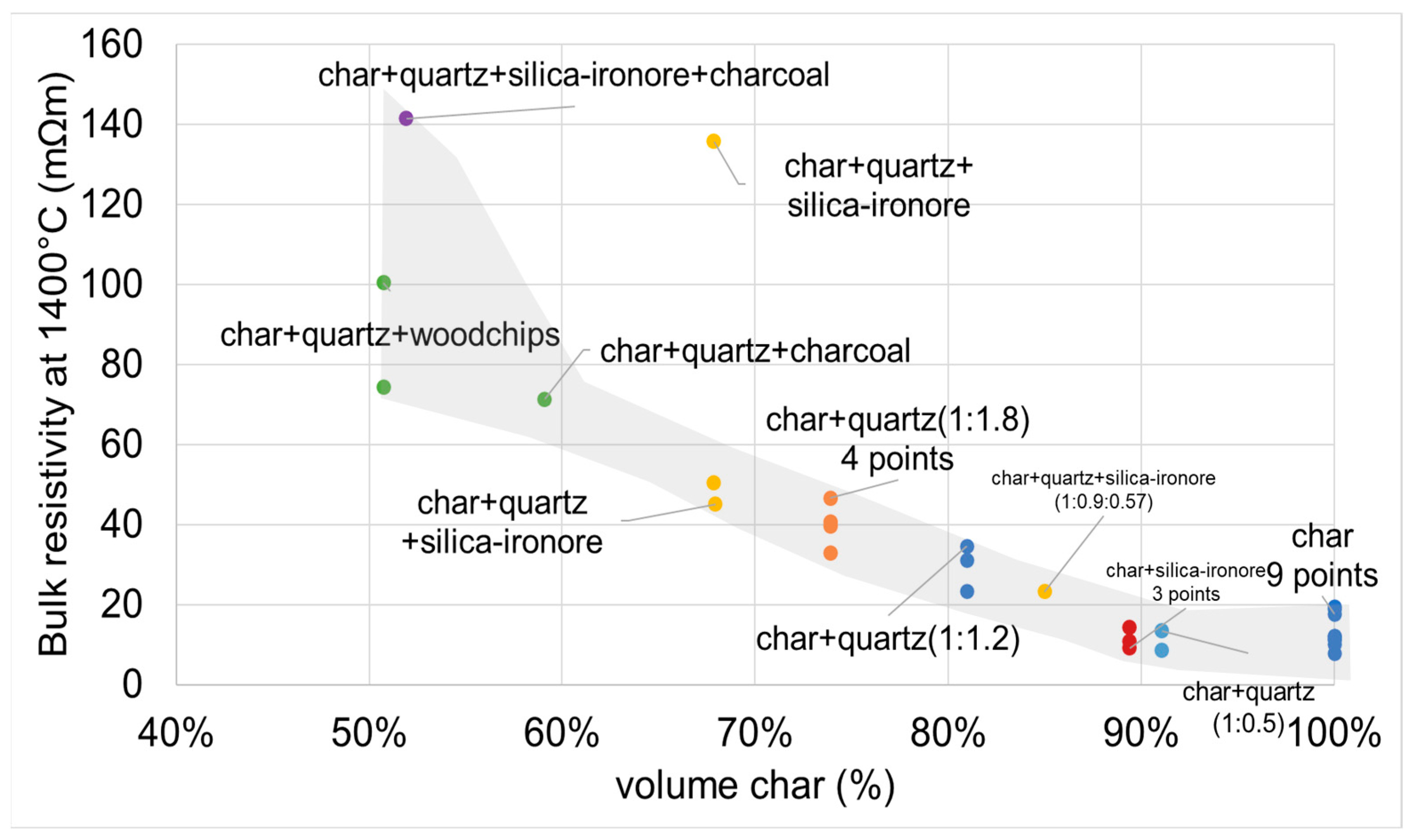

3.3. Resistivity of Charge Materials

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sævarsdottir, G.; Bakken, J. Current distribution in submerged arc furnaces for silicon metal/ferrosilicon production. In Proceedings of the Ferrosilicon Smelting, Helsinki, Finland, 6–9 June 2010; pp. 717–728. [Google Scholar]

- Krokstad, M.A. Electric Resistivity in Industrial SiC-Slag; NTNU: Trondheim, Norway, 2014. [Google Scholar]

- Tesfahungegn, Y.; Magnusson, T.; Tangstad, M.; Sævarsdottir, G.A. Effect of Carbide Configuration on the Current Distribution in Submerged Arc Furnaces for SIlicon Production—A Modelling Approach. In CFD Modeling and SImulation in Materials Processing; Springer: Cham, Switzerland, 2018; pp. 175–185. [Google Scholar]

- Tefsahunegn, Y.; Magnusson, T.; Tangstad, M.; Sævarsdottir, G. The Effect of Side Srcs on Current Distributions in a Submerged Arc Furance for Silicon Production. In Materials Processing Fundamentals 2020, TMS Springer; Springer: Cham, Switzerland, 2020; pp. 177–188. [Google Scholar]

- Schei, A.; Tuset, J.K.; Tveit, H. Production of High Silicon Alloys; Tapir Forlag: Trondheim, Norway, 1998. [Google Scholar]

- Magnussen, T. Basic paramters in the operation and design on submerged arc furnaces, with particular reference to production of high-silicon alloys. J. South. Afr. Inst. Min. Metall. 2018, 118, 631–636. [Google Scholar] [CrossRef]

- Tranell, G.; Andersson, M.; Ringdalen, E.; Ostrovski, O.; Steinmo, J. Reaction zones in a FeSi75 furnace—Results from an industrial excavation. In Proceedings of the Twelfth International Ferroalloys Congress, Helsinki, Finland, 6–9 June 2010. [Google Scholar]

- Westly, J. Resistance and Heat Distribution in a Submerged-arc Furnace. In Proceedings of the INFACON I, Johannesburg, South Africa, 22–26 April 1974; pp. 121–127. [Google Scholar]

- Nurmukhanbetov, Z.; Privalov, O.; Prokopyev, L. Reducibility and electric resistance of carbonaceous materials within ferroalloy smelting processes. In Proceedings of the Thirteenth International Ferroalloys Congress: Efficient Technologies In Ferroalloy Industry, Kazakhstan, Almaty, 9–12 June 2013. [Google Scholar]

- Eidem, P.A. Electrical Resisitivity of Coke Beds; NTNU: Trondheim, Norway, 2008. [Google Scholar]

- Cromarty, R.; Nhiwatiwa, J. Evaluation of coke resistivity for the manganese alloy market. In Proceedings of the INFACON XVI, Trondheim, Norway, 27–29 September 2021. [Google Scholar]

- Krogerus, H.; Lintumma, T.; Jokinen, P. Laboratory Investigations of the Electrical Resistivity of Cokes and Smelting Charge for Optimizing Operation in Large Ferrochrome Furnaces. In Proceedings of the Southern African Pyrometallurgy 2006 International Conference, Johannesburg, South Africa, 5–8 March 2006; pp. 309–328. [Google Scholar]

- Pedersen, T. Electrical Resistivity in Carbon Materials Converting to SiC; NTNU: Trondheim, Norway, 2020. [Google Scholar]

- Pedersen, T. Method for measuring bulk resisitivity in particulate carbon materials. In Proceedings of the Internal NTNU Conference Paper, Trondheim, Norway, 4–6 December 2019. [Google Scholar]

- Surup, G.R.; Pedersen, T.A.; Chaldien, A.; Beukes, J.P.; Tangstad, M. Electrical resistivity of carbonaceous bed material at high temperature. Processes 2020, 8, 933. [Google Scholar] [CrossRef]

- Surup, G.; Smith-Hanssen, N.; Tangstad, M. The properties of carbon blends in submerged arc furnaces. In Proceedings of the INFACON XVI, Trondheim, Norway, 27–29 September 2021. [Google Scholar]

- Hasannezhad, H.; Meysami, A. Effects of Porosity and Electrical Resistance of Metallurgical Coke and Semicoke on Silicon Recovery in a Electric Arc Furnace. JOM 2019, 71, 336–341. [Google Scholar] [CrossRef]

- Bharat, S. Influence of High Temperature Thermal Cycles on the Electrical Resistivity of Charcoal; Faculty of Engineering, University of Pretoria: Pretoria, South Africa, 2022. [Google Scholar]

- Singh, Y. Electrical resistivity measurements: A review. Int. J. Mod. Phys. 2013, 22, 745–756. [Google Scholar] [CrossRef]

- Ketcham, R. X-ray Computed Tomography (CT); SERC, University of Texas: Austin, TX, USA, 2017. [Google Scholar]

- Jayakumari, S. Formation and Characterization of B- and a-Silicon Carbide Produced During Silicon/Ferrosilicon Process; NTNU: Trondheim, Norway, 2020. [Google Scholar]

- Goodge, J. Electron Probe Micro-Analyzer (EPMA); SERC, University of Minnesota Duluth: Duluth, MN, USA, 2019. [Google Scholar]

- Allibert, M.; Gaye, H.; Geiseler, J.; Janke, D.; Keene, B.; Kirner, D.; Kowalski, M.; Lehmann, L.; Mills, K.; Neuschutz, D.; et al. (Eds.) Slag Atlas (Book); ECSC Research: Dusseldorf, Germany, 1995. [Google Scholar]

| Material | Temperature | Resistivity | Particle Size |

|---|---|---|---|

| various cokes [10] | 1500 °C | 4–14 mΩm | 10–30 mm |

| petcoke [10] | 1450 °C | 8–20 mΩm | 10–30 mm |

| charcoal [10] | 1600 °C | 7–16 mΩm | 10–30 mm |

| anthracites [10] | 1400 °C | 9 and 41 mΩm | 10–30 mm |

| coke [9] | 1600 °C | 20–36 mΩm | 3–6 mm |

| char [9] | 1600 °C | 16.6 mΩm | 3–6 mm |

| coke [12] | 1600 °C | 70.9 mΩ * | 5–25 mm |

| char and gas coke [12] | 1600 °C | 164 mΩ * | 5–25 mm |

| coke [17] | 600 °C | 110 mΩm | |

| semicoke [17] | 600 °C | 1250 mΩm | |

| charcoal [13] | 1600 °C | 10.8 mΩm | 4.5–9.5 mm |

| char (treated) [13] | 1600 °C | 9.1 mΩm | 4.5–9.5 mm |

| coal (treated) [13] | 1600 °C | 7.8 mΩm | 4.5–9.5 mm |

| charcoal/SiC/condensate [13] | 1600 °C | 200 mΩm | 4.5–9.5 mm |

| (A) List of the number of experiments done on each of the carbon materials. “HT” denotes heat treatment. Different samples of the same carbon material are differentiated using A, B, or C. | ||||

| Number of Experiments | Carbon Materials | Fixed C (%) | Ash (%) | Volatiles (%) |

| 1 | CharA | 88.5 | 5.87 | 5.4 |

| 1 | CharA_HT | |||

| 1–4 | CharB HT | 96.2 | 1.2 | 2.6 |

| 1–4 | CharC | 86.9 | 11.8 | 1.2 |

| 1 | CharcoalA | 85.9 | 3.97 | 15.9 |

| 1 | Charcoal from woodchips | 91.4 | 4.9 | 3.7 |

| 1 | CharcoalB | 81.8 | 0.03 | 16.2 |

| 1 | Coal_HT | 95.3 | 2.28 | 0.4 |

| (B) List of materials used in the bulk resistivity measurements. | ||||

| SiC Materials from Charcoal A | SiC Materials from CharA | SiC Materials from Coal | ||

| 60% SiC, 6% Si | 32% SiC | 69% SiC | ||

| 60% SiC, 36% Si | 35% SiC | 72% SiC, 7% Si | ||

| 54% SiC, 6% Si | 63% SiC, 2% Si | 30% SiC | ||

| (C) List of the number of experiments done on each of the charge mixtures. Weight ratios are listed in the same order as the materials. | ||||

| Number of Experiments | Charge Mixes | |||

| 1–7 | 1:1.8 char + quartz | |||

| 1–4 | 1:1.2 char + quartz | |||

| 1–2 | 1:0.5 char + quartz | |||

| 1–3 | 1:1.8:0.5 char + quartz + woodchips (charcoal) | |||

| 1–7 | 1:1.8:0.57 char + quartz + silica/iron ore (+charcoal) | |||

| 1–3 | 1:0.57 char + silica/iron ore | |||

| Wt. (%) | |

|---|---|

| SiO2 | 99.8 |

| MgO | 0.02 |

| Al2O3 | 0.04 |

| Fe2O3 | 0.14 |

| Cr2O3 | 0.04 |

| Silica–Iron Ore A wt.(%) | Silica–Iron Ore B wt.(%) | |

|---|---|---|

| SiO2 | 46.3% | 61.8% |

| CaO | 22.5% | 4.96% |

| Al2O3 | 11.4% | 6.91% |

| Fe2O3 | 7.42% | 19.5% |

| MgO | 6.72% | 3.57% |

| Sample | SiO2 | FeO | Al2O3 | MgO | K2O | CaO | Na2O | SO3 | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Average of 6 points (%) | 69.90 ± 1.63 | 5.79 ± 1.17 | 11.21 ± 0.96 | 4.09 ± 0.36 | 2.09 ± 0.22 | 6.43 ± 0.46 | 0.8 ± 0.04 | 0.03 ± 0.01 |

| 2 | Average of 6 points (%) | 69.94 ± 3.29 | 11.16 ± 2.28 | 10.49 ± 2.18 | 3.23 ± 0.74 | 3.13 ± 0.34 | 1.66 ± 0.42 | 0.84 ± 0.12 | 0.18 ± 0.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoover, H.; Fromreide, M.; Sævarsdottir, G.; Tangstad, M. Bulk Resistivity of Materials in the Si/FeSi Furnace. Processes 2023, 11, 2115. https://doi.org/10.3390/pr11072115

Hoover H, Fromreide M, Sævarsdottir G, Tangstad M. Bulk Resistivity of Materials in the Si/FeSi Furnace. Processes. 2023; 11(7):2115. https://doi.org/10.3390/pr11072115

Chicago/Turabian StyleHoover, Haley, Mads Fromreide, Gudrun Sævarsdottir, and Merete Tangstad. 2023. "Bulk Resistivity of Materials in the Si/FeSi Furnace" Processes 11, no. 7: 2115. https://doi.org/10.3390/pr11072115

APA StyleHoover, H., Fromreide, M., Sævarsdottir, G., & Tangstad, M. (2023). Bulk Resistivity of Materials in the Si/FeSi Furnace. Processes, 11(7), 2115. https://doi.org/10.3390/pr11072115