A Comprehensive Overview of the Utilization of Recycled Waste Materials and Technologies in Asphalt Pavements: Towards Environmental and Sustainable Low-Carbon Roads

Abstract

1. Introduction

- ⮚

- Environmental protection: Using recycled waste materials and technologies in asphalt pavement can significantly minimize the negative environmental effects of road construction and maintenance, such as emissions of greenhouse gases and fossil fuel-based resource depletion. It also encourages waste management and reduces the need for dumping sites [16,17].

- ⮚

- Cost-effectiveness: Sustainable asphalt pavement practices can save money in the long term by reducing the need for expensive repairs and replacements over the pavement’s lifespan. Using recycled materials in asphalt pavement, for example, minimizes the need for virgin materials, which can reduce production costs [16,18]. Beyond cost-effectiveness, it is critical to examine the larger benefits of employing recycled products. Recycling aids in the conservation of natural resources, the reduction of energy use, and the reduction of trash output. It also helps to promote a circular economy, which promotes sustainability and reduces dependency on natural resources. Thus, while the initial costs of employing recycled products in road building may be greater, recycling can be a viable and sustainable alternative when considering the long-term environmental advantages and potential cost savings due to lower demand for virgin materials. Recycling technology advancements and quality control procedures can increase the cost-effectiveness and performance of recycled materials in road construction.

- ⮚

- ⮚

- Social responsibility: Sustainable asphalt pavement practices can foster social responsibility by minimizing the detrimental consequences of road construction [21].

2. Methodology

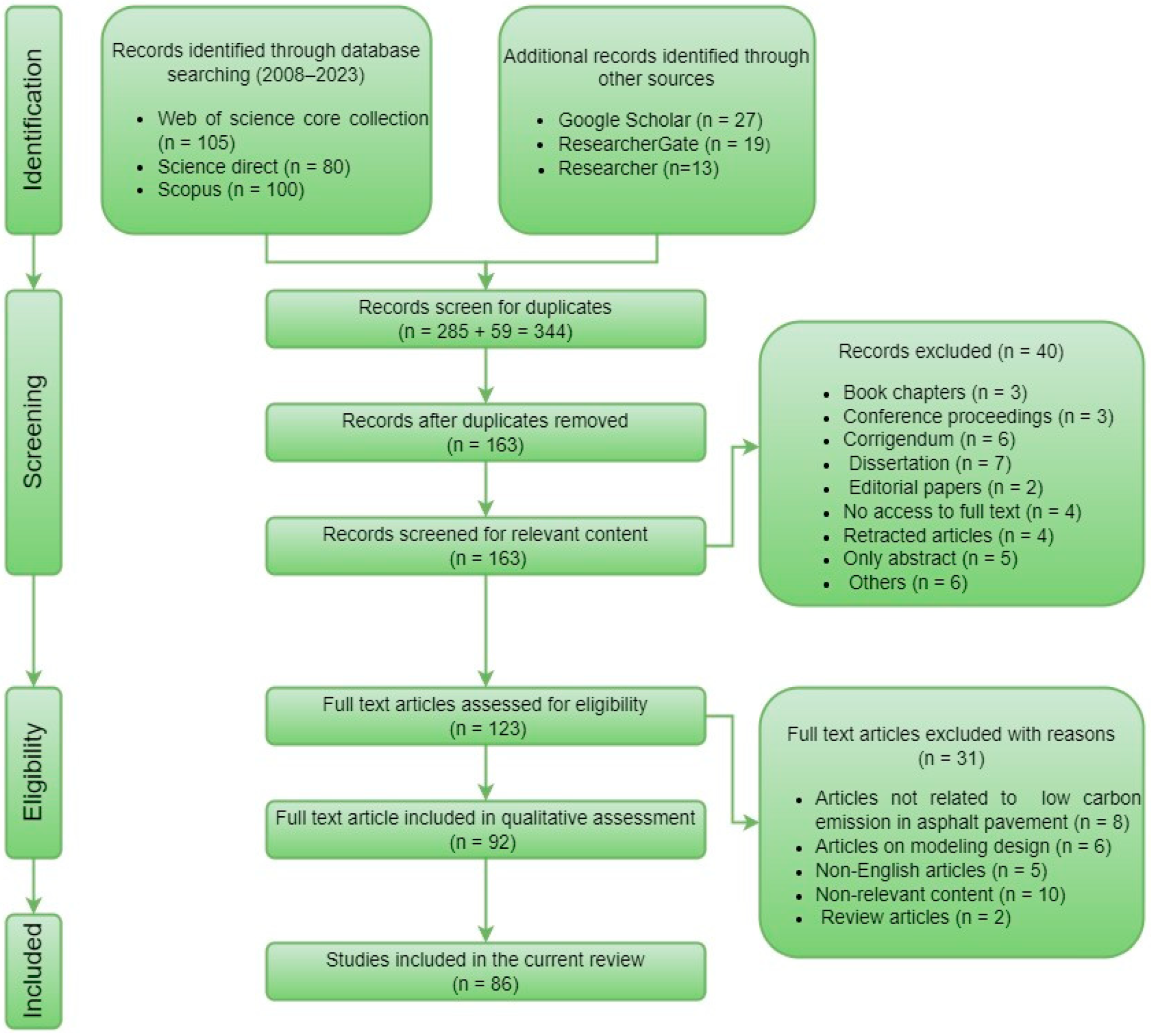

2.1. Qualitative Analysis Using the PRISMA Approach

Study Question

2.2. Quantitative Scientometric Analysis Using VOS Viewer

3. Results and Discussion

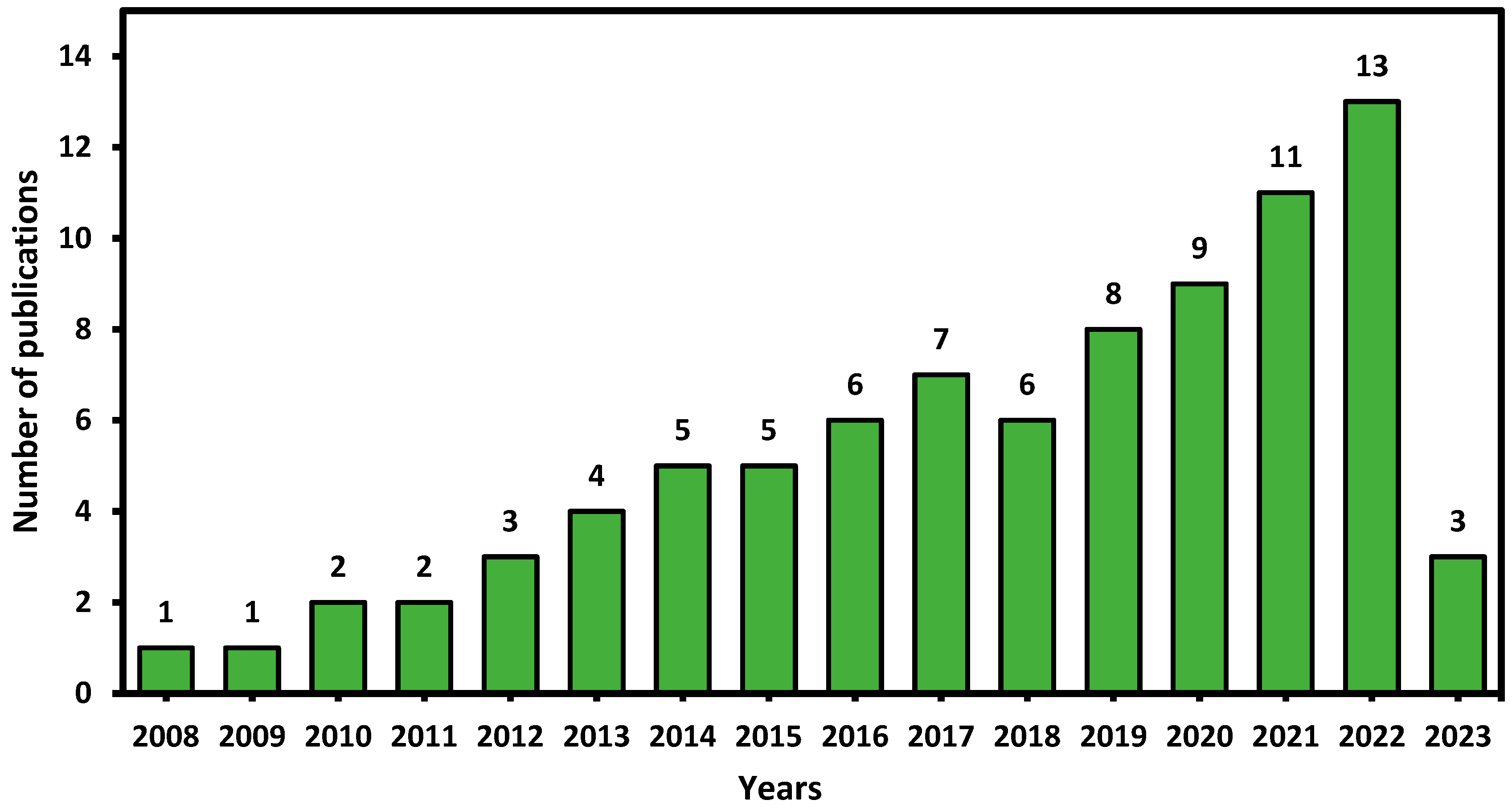

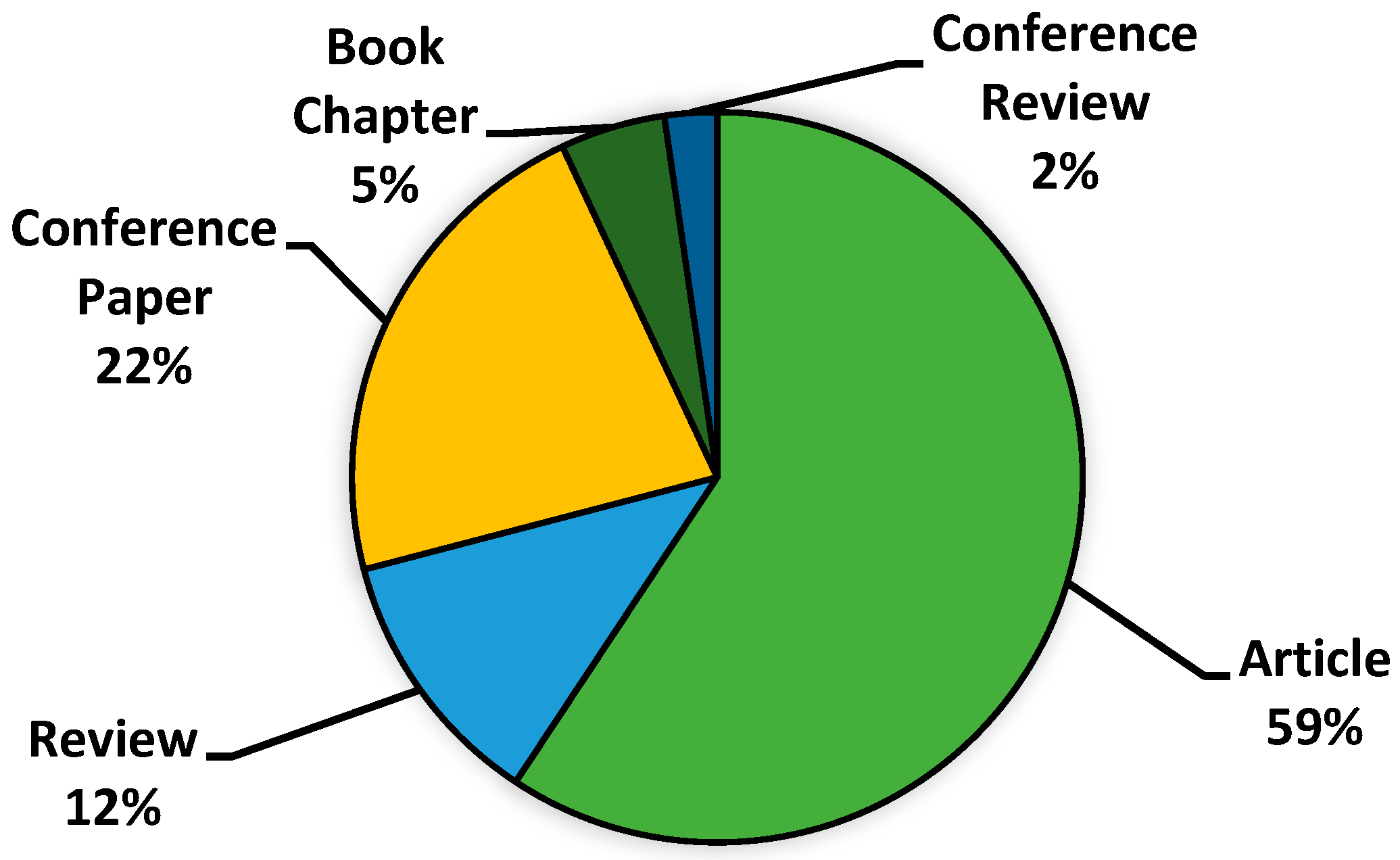

3.1. Descriptive Data Assessment

3.2. Quantitative Scientometric Analysis

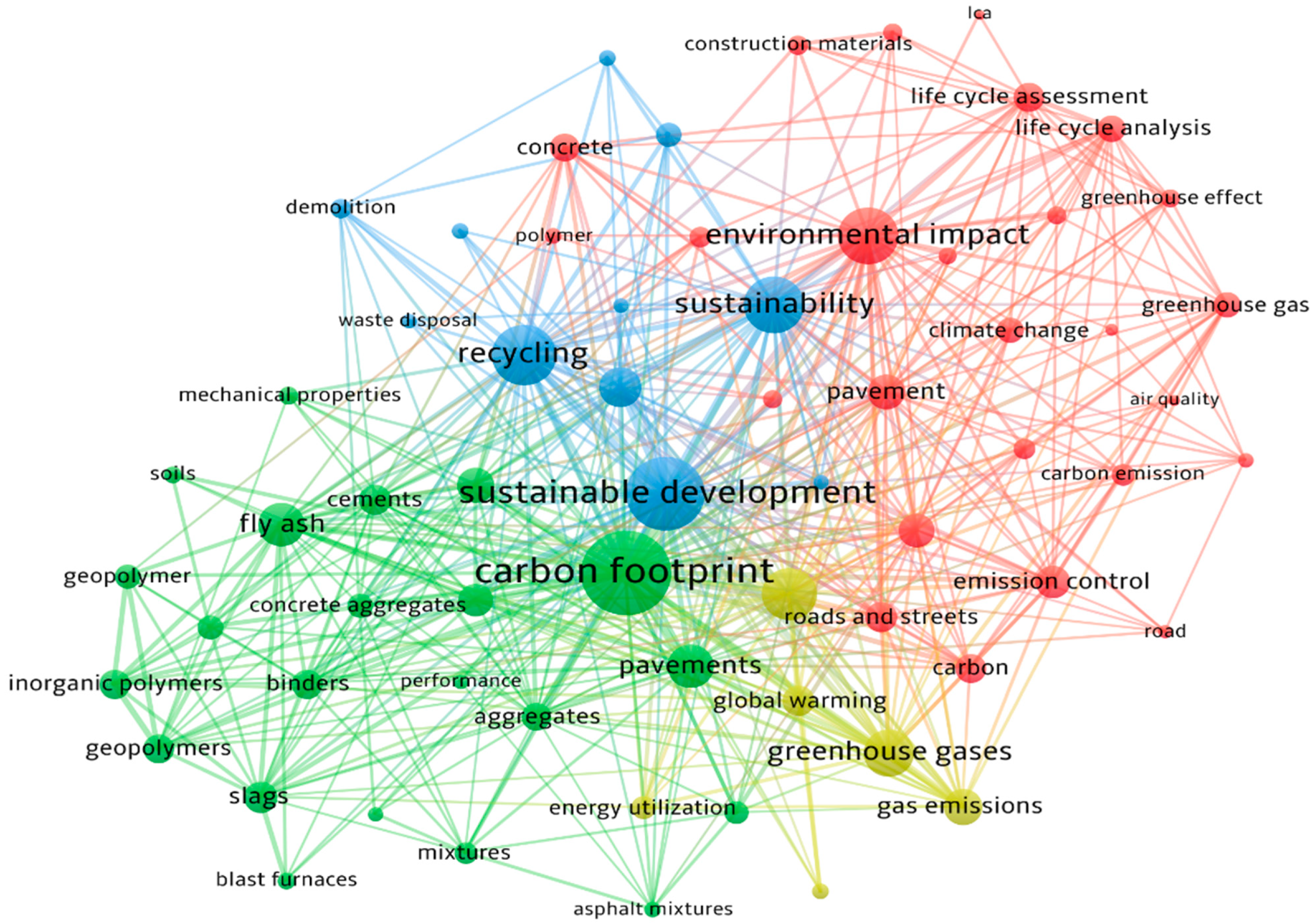

3.2.1. Keywords

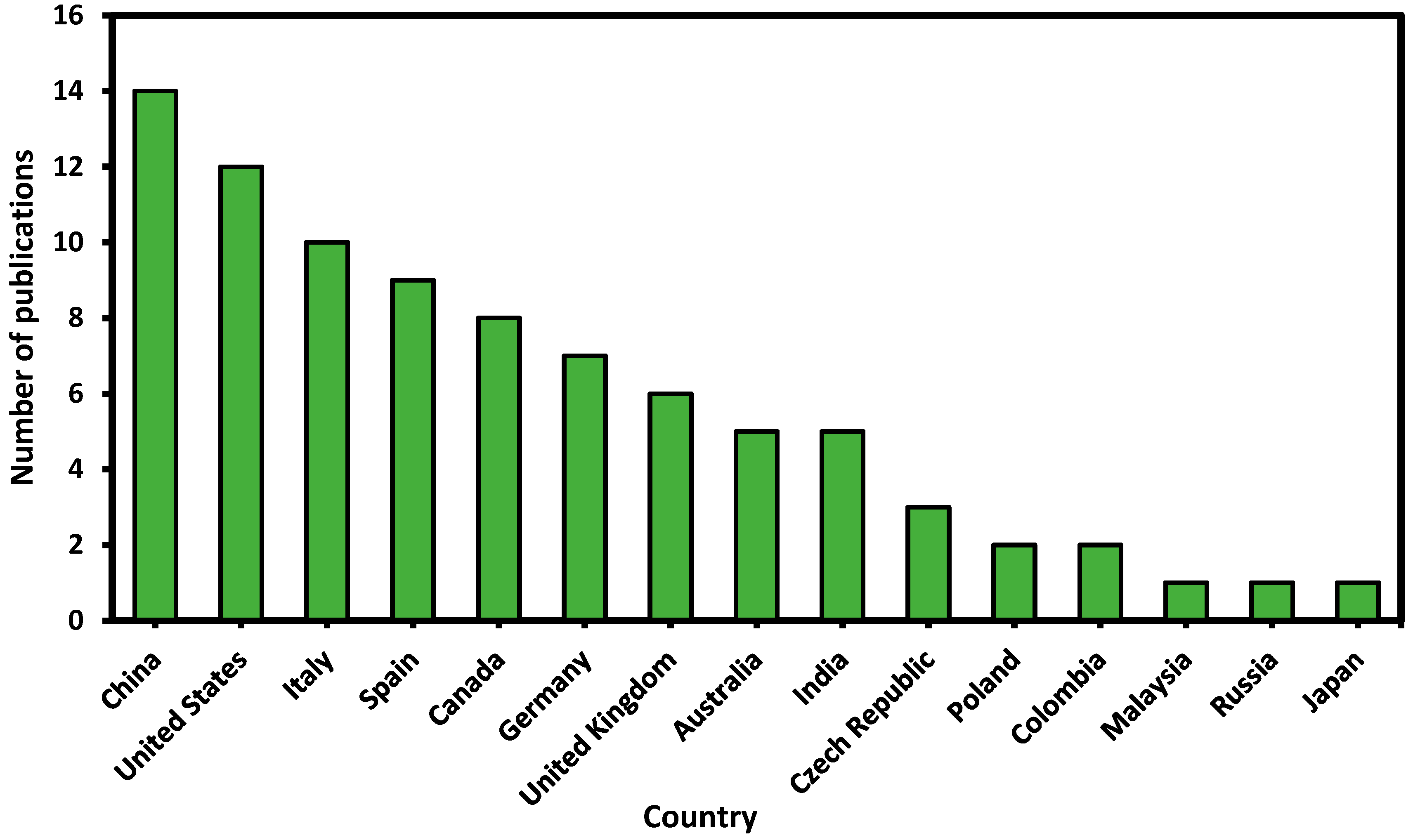

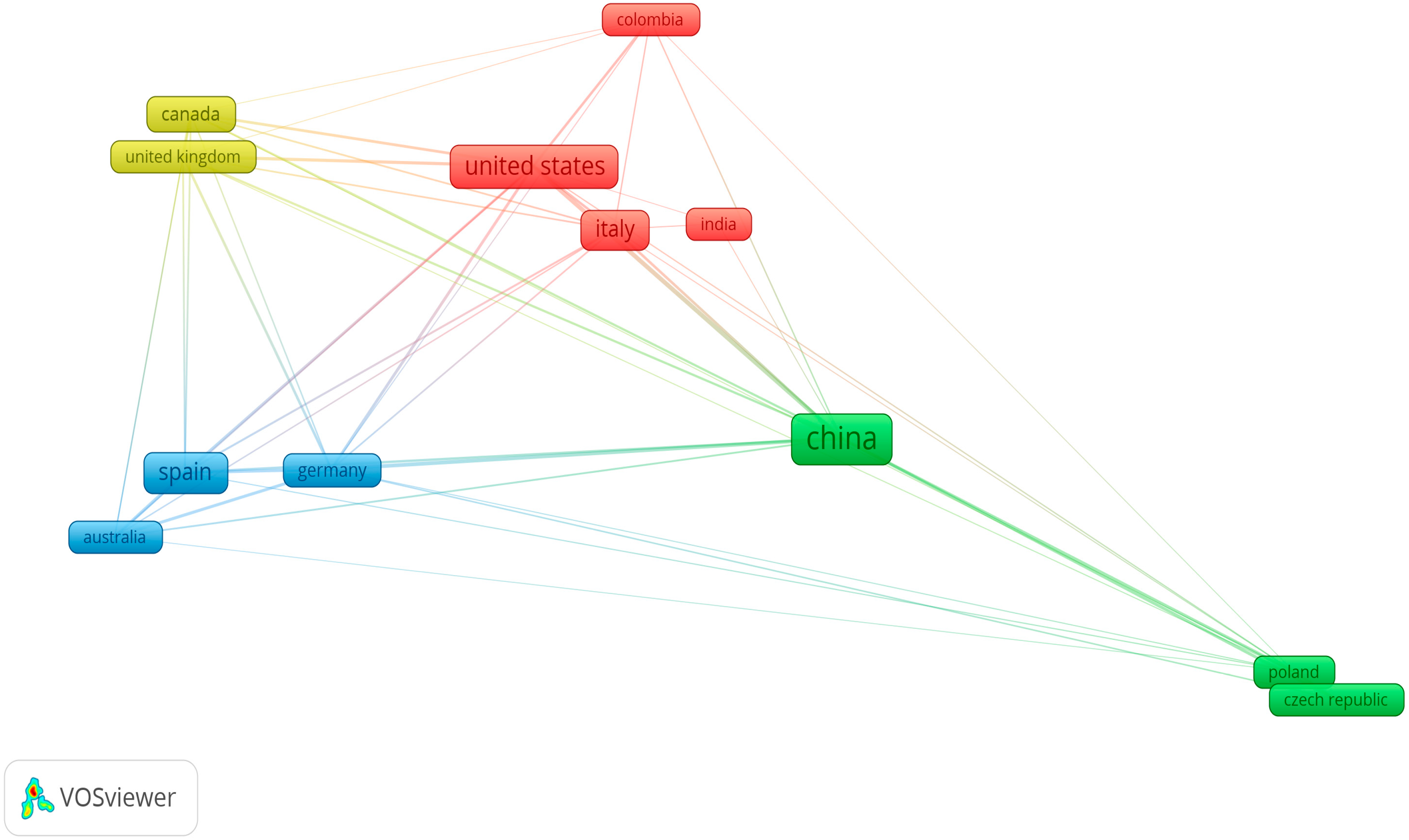

3.2.2. Countries

3.2.3. Sources of Publication

4. Recycled Waste Materials and Technology for Low-Carbon Emission in the Asphalt Pavement

4.1. Waste and Reprocessed Materials

4.1.1. Biochar-Based Materials

4.1.2. Palm Oil Waste

4.1.3. Crumb Rubber

4.1.4. Recycled Asphalt Materials

4.1.5. Industrial Waste Ash and Powder

4.2. Mixing and Production Technology

4.2.1. Warm Mix Asphalt (WMA)

4.2.2. Cold Mix Asphalt (CMA)

4.2.3. Cold Recycling

4.3. Energy Saving and Reduction Technology

4.3.1. Energy Reduction through Moisture Content

4.3.2. Energy Substitution and the Material Heating Process

4.3.3. Emerging Technology and Recycled Waste Materials

5. Discussion

5.1. Key Findings

- ⮚

- It was observed that the incorporation of recycled waste materials and technology in asphalt pavement can help provide considerable environmental benefits by lowering carbon emissions and reducing the total environmental footprint. Additionally, the use of sustainable alternative technologies like WMA and cold recycling reduces energy use and emissions during asphalt manufacture by lowering mixing and compaction temperatures.

- ⮚

- The study found a significant concentration in the field of material-related technologies application for low-carbon asphalt pavement. These technologies employ several strategies, including the use of waste material, mixing procedures, and greener energy. When considered and employed collectively, these methods have a great potential to lower CO2 emissions, with studies predicting a reduction of up to 70% in emissions.

- ⮚

- To ensure the dependable and consistent use of recycled waste materials and technologies for low-carbon asphalt pavements, standardized testing techniques and performance standards should be devised. Technical compatibility investigations should also be conducted to assess the influence of recycled waste materials and technologies on current asphalt production and construction practices.

- ⮚

- When it comes to construction-related technologies, there is much emphasis on strategies to reduce mixing temperatures, as well as on investigating sustainable energy alternatives and improving recycling and low-carbon emission technology. WMA, HWMA, and cold mixes have been developed to replace the high-emission HMA strategy while replacing conventional energy sources with natural gas or electric sources, and biomass fuels can be considered viable measures to lower asphalt plant CO2 emissions.

- ⮚

- There are currently no standardized rules or processes for the development, design, or production of larger-scale mixtures that comprise recycled waste materials and technologies for low-carbon asphalt pavement. The lack of set norms and standards may impede both interested parties and industry professionals from adopting and implementing these recycled waste materials and technologies.

- ⮚

- Furthermore, current studies have depended mostly on experimental trials to identify the optimum proportion of utilizing waste material and technology in mixtures, emphasizing the need for more field-based research to examine the effectiveness and durability of these mixtures in real-world contexts.

- ⮚

- Most research studies on emission reduction methods are limited in scope because they focus on discrete aspects rather than taking a complete whole-life-cycle approach. Furthermore, these studies frequently include inconsistencies in system boundaries and functional units, which makes assessing the efficacy of competing technologies in decreasing emissions difficult.

5.2. Motivations for Adopting Recycled Waste Materials and Technology in Asphalt Pavement to Reduce Carbon Emissions

5.3. Perspectives and Issues Encountered When Implementing Recycled Waste Materials and Technology

6. Conclusions

7. Future Studies and Research Niche

- ⮚

- Based on the review’s findings, scientometric analysis, and discussions, future research should investigate broadening the focus beyond carbon emission studies in most developed countries like China and the United States. Furthermore, more research in underdeveloped nations is required to address the obvious lack of studies in that environment.

- ⮚

- To have a thorough grasp of worldwide low-carbon-emissions asphalt pavement, researchers must widen their investigations to include nations other than the ones currently researched. This approach would allow for a more realistic assessment of the effectiveness, obstacles, and possible possibilities associated with low-carbon-emissions asphalt pavement on a worldwide scale.

- ⮚

- There is a gap between experimental and field performance when it comes to implementing carbon mitigation techniques in asphalt pavement. As a result, to confirm the reliability of the findings, more study is required to focus on the practical implementation of these ideas. Thus, further detailed studies are required before broad full-scale field performance and application.

- ⮚

- Most previous studies focused on adopting one sustainable material or technology for low-carbon asphalt pavement at a time. It is both encouraging and critical to use and combine a variety of waste materials and technology techniques in the asphalt paving sector to improve performance, harness sustainability, and reduce carbon emissions.

- ⮚

- Despite the comprehensive investigation of asphalt pavement CO2 emissions, the prevalence of uncertainties in assessment boundaries, data, and techniques makes cross-comparisons difficult, and needs the development of general evaluation standards, as well as the inclusion of susceptibility and uncertainty assessments, in future studies.

- ⮚

- It is highly advised to use advanced technology such as artificial intelligence for the modeling, and optimization in the field of sustainable and low-carbon technology. These techniques are extremely useful in assessing the CO2 emissions and energy demands of various strategies, both independently and when integrated with other relevant technologies.

- ⮚

- More studies on field investigations in various geographies and climatic situations to validate laboratory research findings about the environmental and economic benefits of using sustainable and low-carbon technologies in asphalt pavement, as recorded in the existing literature, are encouraged.

- ⮚

- Further investigation and testing of WMA technology integration with other asphalt technologies, such as RAP and bio-asphalt technologies, are needed to address and reduce the CO2 emissions and energy consumption associated with the traditional construction process.

- ⮚

- More in-depth examinations and evaluations of road construction techniques/processes, as well as waste materials, are required for low-carbon emission roads. Furthermore, more research is needed on the ultimate physio-mechanical reactivity of asphalt binders and asphalt mixtures to pavement material components.

- ⮚

- The present study considered only a limited number of waste categories/products that allow CO2 emissions reduction. However, other waste products within specific waste categories (such as biochar, bio-oils, polymers, etc.) can provide positive either environmental or economic impacts on the production of paving materials, but these are out of the scope of the present study.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Olhoff, A.; Christensen, J.M. Emissions Gap Report 2020; UNEP DTU Partnership: Copenhagen, Denmark, 2020. [Google Scholar]

- International Energy Agency. World Energy Outlook; International Energy Agency: Paris, France, 2017; Available online: https://www.iea.org/reports/world-energy-outlook-2017 (accessed on 1 June 2023).

- Liu, N.; Wang, Y.; Bai, Q.; Liu, Y.; Wang, P.S.; Xue, S.; Yu, Q.; Li, Q. Road life-cycle carbon dioxide emissions and emission reduction technologies: A review. J. Traffic Transp. Eng. 2022, 9, 532–555. [Google Scholar] [CrossRef]

- Polo-Mendoza, R.; Martinez-Arguelles, G.; Peñabaena-Niebles, R. Environmental optimization of warm mix asphalt (WMA) design with recycled concrete aggregates (RCA) inclusion through artificial intelligence (AI) techniques. Results Eng. 2023, 17, 100984. [Google Scholar] [CrossRef]

- Jagaba, A.H.; Kutty, S.R.M.; Baloo, L.; Birniwa, A.H.; Lawal, I.M.; Aliyu, M.K.; Yaro, N.S.A.; Usman, A.K. Combined treatment of domestic and pulp and paper industry wastewater in a rice straw embedded activated sludge bioreactor to achieve sustainable development goals. Case Stud. Chem. Environ. Eng. 2022, 6, 100261. [Google Scholar] [CrossRef]

- Aryan, Y.; Dikshit, A.K.; Shinde, A.M. A critical review of the life cycle assessment studies on road pavements and road infrastructures. J. Environ. Manag. 2023, 336, 117697. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, H.; Wang, H.; Wang, Y.; Han, S. Integrated Life Cycle Analysis of Cost and CO2 Emissions from Vehicles and Construction Work Activities in Highway Pavement Service Life. Atmosphere 2023, 14, 194. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.M.; Al-Fakih, A.; Noura, S.; Yaghoubi, E.; Alaloul, W.; Al-Mansob, R.A.; Khan, M.I.; Yaro, N.S.A. Utilization of palm oil and its by-products in bio-asphalt and bio-concrete mixtures: A review. Constr. Build. Mater. 2022, 337, 127552. [Google Scholar] [CrossRef]

- Pouranian, M.R.; Shishehbor, M. Sustainability assessment of green asphalt mixtures: A review. Environments 2019, 6, 73. [Google Scholar] [CrossRef]

- Magar, S.; Xiao, F.; Singh, D.; Showkat, B. Applications of reclaimed asphalt pavement in India—A review. J. Clean. Prod. 2022, 335, 130221. [Google Scholar] [CrossRef]

- Vishnu, T.B.; Singh, K.L. A study on the suitability of solid waste materials in pavement construction: A review. Int. J. Pavement Res. Technol. 2021, 14, 625–637. [Google Scholar] [CrossRef]

- Mirhashem, S.A.; Ravanshadnia, M. Carbon Footprint of Road Pavements: A Scientometric Review. Int. J. Pavement Res. Technol. 2022, 15, 221–232. [Google Scholar] [CrossRef]

- Meijer, J.R.; Huijbregts, M.A.J.; Schotten, K.C.G.J.; Schipper, A.M. Global patterns of current and future road infrastructure. Environ. Res. Lett. 2018, 13, 064006. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Sutanto, M.H.; Habib, N.Z.; Napiah, M.; Usman, A.; Jagaba, A.H.; Al-Sabaeei, A.M. Application and circular economy prospects of palm oil waste for eco-friendly asphalt pavement industry: A review. J. Road Eng. 2022, 2, 309–331. [Google Scholar] [CrossRef]

- Ruiz, A.; Guevara, J. Sustainable decision-making in road development: Analysis of road preservation policies. Sustainability 2020, 12, 872. [Google Scholar] [CrossRef]

- Assaf, H.; Abdo, A.A. Life cycle assessment of incorporating recycled materials in pavement design. J. King Saud Univ.-Eng. Sci. 2022; in press. [Google Scholar] [CrossRef]

- Birniwa, A.H.; Abubakar, A.S.; Mahmud, H.N.M.E.; Kutty, S.R.M.; Jagaba, A.H.; Abdullahi, S.S.A.; Zango, Z.U. Application of agricultural wastes for cationic dyes removal from wastewater. In Textile Wastewater Treatment: Sustainable Bio-Nano Materials and Macromolecules; Springer: Berlin/Heidelberg, Germany, 2022; Volume 1, pp. 239–274. [Google Scholar]

- Ai, X.; Pei, Z.; Cao, J.; Zhu, X.; Hu, W.; Gao, L.; Feng, D.; Yi, J. Environmental impact assessment of recycled HMA with RAP materials from the rotary decomposition process compared to virgin HMA and conventional recycled HMA. J. Clean. Prod. 2023, 389, 136078. [Google Scholar] [CrossRef]

- Milad, A.; Babalghaith, A.M.; Al-Sabaeei, A.M.; Dulaimi, A.; Ali, A.; Reddy, S.S.; Bilema, M.; Yusoff, N.I.M. A Comparative Review of Hot and Warm Mix Asphalt Technologies from Environmental and Economic Perspectives: Towards a Sustainable Asphalt Pavement. Int. J. Environ. Res. Public Health 2022, 19, 14863. [Google Scholar] [CrossRef]

- Gruber, M.R.; Hofko, B. Life Cycle Assessment of Greenhouse Gas Emissions from Recycled Asphalt Pavement Production. Sustainability 2023, 15, 4629. [Google Scholar] [CrossRef]

- Copetti Callai, S. High Friction and Acoustic Surface for Pavements: Development of Artificial Engineered Aggregates from Recycled Powders. Ph.D. Thesis, University of Bologna, Bologna, Italy, 2022. [Google Scholar]

- Yaro, N.S.A.; Sutanto, M.H.; Habib, N.Z.; Usman, A.; Kaura, J.M.; Murana, A.A.; Birniwa, A.H.; Jagaba, A.H. A Comprehensive Review of Biochar Utilization for Low-Carbon Flexible Asphalt Pavements. Sustainability 2023, 15, 6729. [Google Scholar] [CrossRef]

- Jagaba, A.H.; Kutty, S.R.M.; Lawal, I.M.; Birniwa, A.H.; Affam, A.C.; Yaro, N.S.A.; Usman, A.K.; Umaru, I.; Abubakar, S.; Noor, A.; et al. Circular economy potential and contributions of petroleum industry sludge utilization to environmental sustainability through engineered processes—A review. Clean. Circ. Bioecon. 2022, 3, 100029. [Google Scholar] [CrossRef]

- Boloy, R.A.M.; Reis, A.D.C.; Rios, E.M.; Martins, J.d.A.S.; Soares, L.O.; Machado, V.A.D.S.; de Moraes, D.R. Waste-to-energy technologies towards circular economy: A systematic literature review and bibliometric analysis. Water Air Soil Pollut. 2021, 232, 306. [Google Scholar] [CrossRef]

- Jagaba, A.H.; Kutty, S.R.M.; Hayder, G.; Baloo, L.; Noor, A.; Yaro, N.S.A.; Saeed, A.A.H.; Lawal, I.M.; Birniwa, A.H.; Usman, A.K. A systematic literature review on waste-to-resource potential of palm oil clinker for sustainable engineering and environmental applications. Materials 2021, 14, 4456. [Google Scholar] [CrossRef] [PubMed]

- Jagaba, A.H.; Kutty, S.R.M.; Noor, A.; Birniwa, A.H.; Affam, A.C.; Lawal, I.M.; Kankia, M.U.; Kilaco, A.U. A systematic literature review of biocarriers: Central elements for biofilm formation, organic and nutrients removal in sequencing batch biofilm reactor. J. Water Process Eng. 2021, 42, 102178. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Sutanto, M.H.; Habib, N.Z.; Napiah, M.; Usman, A.; Muhammad, A. Comparison of Response Surface Methodology and Artificial Neural Network approach in predicting the performance and properties of palm oil clinker fine modified asphalt mixtures. Constr. Build. Mater. 2022, 324, 126618. [Google Scholar] [CrossRef]

- Yang, H.; Liu, L.; Yang, W.; Liu, H.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A comprehensive overview of geopolymer composites: A bibliometric analysis and literature review. Case Stud. Constr. Mater. 2022, 16, e00830. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Lancellotti, I.; Andreola, F.; Barbieri, L.; Belmonte-Ureña, L.J.; Camacho-Ferre, F. Management of agricultural waste biomass as raw material for the construction sector: An analysis of sustainable and circular alternatives. Environ. Sci. Eur. 2022, 34, 70. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Napiah, M.; Sutanto, M.H.; Hainin, M.R.; Usman, A.; Rafindadi, A.D.; Abdulrahman, S.; Saeed, S. Utilization of palm oil mill residue as sustainable pavement materials: A review. Int. J. Integr. Eng. 2021, 13, 66–78. [Google Scholar] [CrossRef]

- Usman, A.; Sutanto, M.H.; Napiah, M.; Zoorob, S.E.; Yaro, N.S.A.; Khan, M.I. Comparison of performance properties and prediction of regular and gamma-irradiated granular waste polyethylene terephthalate modified asphalt mixtures. Polymers 2021, 13, 2610. [Google Scholar] [CrossRef]

- Mantalovas, K.; Di Mino, G.; Jimenez Del Barco Carrion, A.; Keijzer, E.; Kalman, B.; Parry, T.; Lo Presti, D. European national road authorities and circular economy: An insight into their approaches. Sustainability 2020, 12, 7160. [Google Scholar] [CrossRef]

- Birniwa, A.H.; Abdullahi, S.S.; Ali, M.; Mohammad, R.E.A.; Jagaba, A.H.; Amran, M.; Avudaiappan, S.; Maureira-Carsalade, N.; Flores, E.I.S. Recent Trends in Treatment and Fabrication of Plant-Based Fiber-Reinforced Epoxy Composite: A Review. J. Compos. Sci. 2023, 7, 120. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Sutanto, M.H.; Habib, N.Z.; Napiah, M.; Usman, A.; Jagaba, A.H.; Al-Sabaeei, A.M. Modeling and optimization of asphalt content, waste palm oil clinker powder and waste rice straw ash for sustainable asphalt paving employing response surface methodology: A pilot study. Clean. Mater. 2023, 8, 100187. [Google Scholar] [CrossRef]

- Umaru, I.; Alhaji, M.M.; Jagaba, A.H.; Kutty, S.R.M.; Lawal, I.M.; Abubakar, S.; Soja, U.B. The Effect of Groundnut Shell Ash and Metakaolin on Geotechnical Properties of Black Cotton Soils. In Sustainability Challenges and Delivering Practical Engineering Solutions: Resources, Materials, Energy, and Buildings; Springer: Berlin/Heidelberg, Germany, 2023; pp. 177–183. [Google Scholar]

- Abe, A.A.; Rossi, C.O.; Caputo, P. Biomaterials and Their Potentialities as Additives in Asphalt binder Technology: A Review. Molecules 2022, 27, 8826. [Google Scholar] [CrossRef] [PubMed]

- Lehmann, J.; Cowie, A.; Masiello, C.A.; Kammann, C.; Woolf, D.; Amonette, J.E.; Cayuela, M.L.; Camps-Arbestain, M.; Whitman, T. Biochar in climate change mitigation. Nat. Geosci. 2021, 14, 883–892. [Google Scholar] [CrossRef]

- Allen, M.; Babiker, M.; Chen, Y.; Coninck, H.D.; Connors, S.; Diemen, R.V.; Dube, O.P.; Ebi, K.L.; Engelbrecht, F.; Ferrat, M.; et al. Global Warming of 1.5 C. Summary for Policymakers; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2018. [Google Scholar]

- Azzi, E.S.; Karltun, E.; Sundberg, C. Prospective life cycle assessment of large-scale biochar production and use for negative emissions in Stockholm. Environ. Sci. Technol. 2019, 53, 8466–8476. [Google Scholar] [CrossRef] [PubMed]

- Ghasemi, H.; Yazdani, H.; Rajib, A.; Fini, E.H. Toward Carbon-Negative and Emission-Curbing Roads to Drive Environmental Health. ACS Sustain. Chem. Eng. 2022, 10, 1857–1862. [Google Scholar] [CrossRef]

- Zhou, X.; Moghaddam, T.B.; Chen, M.; Wu, S.; Adhikari, S. Biochar removes volatile organic compounds generated from asphalt. Sci. Total Environ. 2020, 745, 141096. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Xiang, W.; Wang, B.; Fang, J.; Zou, W.; He, F.; Li, Y.; Tsang, D.C.; Ok, Y.S.; Gao, B. Adsorption of acetone and cyclohexane onto CO2 activated hydrochars. Chemosphere 2020, 245, 125664. [Google Scholar] [CrossRef]

- Al-dhawi, B.N.S.; Kutty, S.R.M.; Ghaleb, A.A.S.; Almahbashi, N.M.Y.; Saeed, A.A.H.; Al-Mekhlafi, A.B.A.; Alsaeedi, Y.A.A.; Jagaba, A.H. Pretreated palm oil clinker as an attached growth media for organic matter removal from synthetic domestic wastewater in a sequencing batch reactor. Case Stud. Chem. Environ. Eng. 2023, 7, 100294. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Napiah, M.B.; Sutanto, M.H.; Usman, A.; Saeed, S.M. Modeling and optimization of mixing parameters using response surface methodology and characterization of palm oil clinker fine modified bitumen. Constr. Build. Mater. 2021, 298, 123849. [Google Scholar] [CrossRef]

- Kanadasan, J.; Razak, H.A. Engineering and sustainability performance of self-compacting palm oil mill incinerated waste concrete. J. Clean. Prod. 2015, 89, 78–86. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Abutaha, F.; Alqedra, M.A.; Nayaka, R.R. Assessment on engineering properties and CO2 emissions of recycled aggregate concrete incorporating waste products as supplements to Portland cement. J. Clean. Prod. 2018, 203, 822–835. [Google Scholar] [CrossRef]

- Chen, S.; Teng, Y.; Zhang, Y.; Leung, C.K.; Pan, W. Reducing embodied carbon in concrete materials: A state-of-the-art review. Resour. Conserv. Recycl. 2023, 188, 106653. [Google Scholar] [CrossRef]

- Wang, Q.-Z.; Wang, N.-N.; Tseng, M.-L.; Huang, Y.-M.; Li, N.-L. Waste tire recycling assessment: Road application potential and carbon emissions reduction analysis of crumb rubber modified asphalt in China. J. Clean. Prod. 2020, 249, 119411. [Google Scholar] [CrossRef]

- Farina, A.; Zanetti, M.C.; Santagata, E.; Blengini, G.A. Life cycle assessment applied to bituminous mixtures containing recycled materials: Crumb rubber and reclaimed asphalt pavement. Resour. Conserv. Recycl. 2017, 117, 204–212. [Google Scholar] [CrossRef]

- White, P.; Golden, J.S.; Biligiri, K.P.; Kaloush, K. Modeling climate change impacts of pavement production and construction. Resour. Conserv. Recycl. 2010, 54, 776–782. [Google Scholar] [CrossRef]

- Xing, C.; Li, M.; Liu, L.; Lu, R.; Liu, N.; Wu, W.; Yuan, D. A comprehensive review on the blending condition between virgin and RAP asphalt binders in hot recycled asphalt mixtures: Mechanisms, evaluation methods, and influencing factors. J. Clean. Prod. 2023, 398, 136515. [Google Scholar] [CrossRef]

- Giani, M.I.; Dotelli, G.; Brandini, N.; Zampori, L. Comparative life cycle assessment of asphalt pavements using reclaimed asphalt, warm mix technology and cold in-place recycling. Resour. Conserv. Recycl. 2015, 104, 224–238. [Google Scholar] [CrossRef]

- Gulotta, T.; Mistretta, M.; Praticò, F. A life cycle scenario analysis of different pavement technologies for urban roads. Sci. Total Environ. 2019, 673, 585–593. [Google Scholar] [CrossRef]

- Saeedzadeh, R.; Romanoschi, S.A.; Akbariyeh, N.; Khajeh-Hosseini, M.; Abdullah, A.Q. Sustainability assessment of recycled asphalt mixtures based on performance in full-scale testing. J. Transp. Eng. Part B Pavements 2018, 144, 04018024. [Google Scholar] [CrossRef]

- Celauro, C.; Corriere, F.; Guerrieri, M.; Casto, B.L. Environmentally appraising different pavement and construction scenarios: A comparative analysis for a typical local road. Transp. Res. Part D Transp. Environ. 2015, 34, 41–51. [Google Scholar] [CrossRef]

- Karlsson, I.; Rootzén, J.; Johnsson, F. Reaching net-zero carbon emissions in construction supply chains–Analysis of a Swedish road construction project. Renew. Sustain. Energy Rev. 2020, 120, 109651. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Potential utilization of construction wastes in asphalt pavements as fillers using ranking framework. Constr. Build. Mater. 2021, 277, 122262. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Li, D.; Yu, Q. Life cycle assessment for carbon dioxide emissions from freeway construction in mountainous area: Primary source, cut-off determination of system boundary. Resour. Conserv. Recycl. 2019, 140, 36–44. [Google Scholar] [CrossRef]

- Zhou, X.; Moghaddam, T.B.; Chen, M.; Wu, S.; Adhikari, S.; Xu, S.; Yang, C. Life cycle assessment of biochar modified bioasphalt derived from biomass. ACS Sustain. Chem. Eng. 2020, 8, 14568–14575. [Google Scholar] [CrossRef]

- Aurangzeb, Q.; Al-Qadi, I.L.; Ozer, H.; Yang, R. Hybrid life cycle assessment for asphalt mixtures with high RAP content. Resour. Conserv. Recycl. 2014, 83, 77–86. [Google Scholar] [CrossRef]

- Alsubari, B.; Shafigh, P.; Jumaat, M.Z. Utilization of high-volume treated palm oil fuel ash to produce sustainable self-compacting concrete. J. Clean. Prod. 2016, 137, 982–996. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Cheraghian, G.; Falchetto, A.C.; You, Z.; Chen, S.; Kim, Y.S.; Westerhoff, J.; Moon, K.H.; Wistuba, M.P. Warm mix asphalt technology: An up to date review. J. Clean. Prod. 2020, 268, 122128. [Google Scholar] [CrossRef]

- Jamshidi, A.; Hamzah, M.O.; You, Z. Performance of warm mix asphalt containing Sasobit®: State-of-the-art. Constr. Build. Mater. 2013, 38, 530–553. [Google Scholar] [CrossRef]

- Thives, L.P.; Ghisi, E. Asphalt mixtures emission and energy consumption: A review. Renew. Sustain. Energy Rev. 2017, 72, 473–484. [Google Scholar] [CrossRef]

- Vidal, R.; Moliner, E.; Martínez, G.; Rubio, M.C. Life cycle assessment of hot mix asphalt and zeolite-based warm mix asphalt with reclaimed asphalt pavement. Resour. Conserv. Recycl. 2013, 74, 101–114. [Google Scholar] [CrossRef]

- Sharma, A.; Lee, B.-K. Energy savings and reduction of CO2 emission using CaOH2 incorporated zeolite as an additive for warm and hot mix asphalt production. Energy 2017, 136, 142–150. [Google Scholar] [CrossRef]

- Vaitkus, A.; Čygas, D.; Laurinavičius, A.; Perveneckas, Z. Analysis and evaluation of possibilities for the use of warm mix asphalt in Lithuania. Balt. J. Road Bridge Eng. 2009, 4, 80–86. [Google Scholar] [CrossRef]

- Bueche, N. Warm asphalt bituminous mixtures with regards to energy, emissions and performance. In Proceedings of the Young Researchers Seminar (YRS) LAVOC-CONF-2010-002, Torino, Italy, 3–5 June 2009. [Google Scholar]

- Kadhim, M.A.; Al-Busaltan, S.; Dulaimi, A.; Sadique, M.; Al Nageim, H.; Al-Kafaji, M.; Al-Yasari, R. Developing a sustainable, post treated, half warm mix asphalt for structural surface layer. Constr. Build. Mater. 2022, 342, 127926. [Google Scholar] [CrossRef]

- Dulaimi, A.; Al-Busaltan, S.; Sadique, M. The development of a novel, microwave assisted, half-warm mixed asphalt. Constr. Build. Mater. 2021, 301, 124043. [Google Scholar] [CrossRef]

- del Carmen Rubio, M.; Moreno, F.; Martínez-Echevarría, M.J.; Martínez, G.; Vázquez, J.M. Comparative analysis of emissions from the manufacture and use of hot and half-warm mix asphalt. J. Clean. Prod. 2013, 41, 1–6. [Google Scholar] [CrossRef]

- Dash, S.S.; Chandrappa, A.K.; Sahoo, U.C. Design and performance of cold mix asphalt—A review. Constr. Build. Mater. 2022, 315, 125687. [Google Scholar] [CrossRef]

- Jain, S.; Singh, B. Cold mix asphalt: An overview. J. Clean. Prod. 2021, 280, 124378. [Google Scholar] [CrossRef]

- Shanbara, H.K.; Dulaimi, A.; Al-Mansoori, T.; Al-Busaltan, S.; Herez, M.; Sadique, M.; Abdel-Wahed, T. The future of eco-friendly cold mix asphalt. Renew. Sustain. Energy Rev. 2021, 149, 111318. [Google Scholar] [CrossRef]

- Goyer, S.; Dauvergne, M.; Wendling, L.; Gaudefroy, V.; Ropert, C. Environmental data of cold mix using emulsified bitumen for a better selection of road materials. In ISAP 2012: Environmental Data of Cold Mix Using Emulsified Bitumen for a Better Selection of Road Materials; HAL: Lyon, France, 2012. [Google Scholar]

- Chappat, M.; Bilal, J. Energy Consumption and Greenhouse Gas Emissions Sustainable Developmentethe Environmental Road of the Future; Colas Group: Paris, France, 2003. [Google Scholar]

- Saeed, S.M.; Sutanto, M.H.; Napiah, M.; Usman, A.; Batari, A.; Aman, M.Y.; Yaro, N.S.A. Optimization of rubber seed oil content as bio-oil rejuvenator and total water content for cold recycled asphalt mixtures using response surface methodology. Case Stud. Constr. Mater. 2021, 15, e00561. [Google Scholar] [CrossRef]

- Hesham, A.; Aditia, R. Recycling Asphalt Pavements: The State of Practice. In Recycling Strategy, Challenges Associated with Waste Management Towards Sustaining the World; IntechOpen: London, UK, 2023. [Google Scholar]

- Santos, J.; Bryce, J.; Flintsch, G.; Ferreira, A.; Diefenderfer, B. A life cycle assessment of in-place recycling and conventional pavement construction and maintenance practices. Struct. Infrastruct. Eng. 2015, 11, 1199–1217. [Google Scholar] [CrossRef]

- Xiao, F.; Yao, S.; Wang, J.; Li, X.; Amirkhanian, S. A literature review on cold recycling technology of asphalt pavement. Constr. Build. Mater. 2018, 180, 579–604. [Google Scholar] [CrossRef]

- Peng, B.; Fan, X.; Wang, X.; Li, W. Key steps of carbon emission and low-carbon measures in the construction of bituminous pavement. Int. J. Pavement Res. Technol. 2017, 10, 476–487. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Lyu, P.; Hu, S.; Yang, L.; Gao, G. Rethinking the carbon dioxide emissions of road sector: Integrating advanced vehicle technologies and construction supply chains mitigation options under decarbonization plans. J. Clean. Prod. 2021, 321, 128769. [Google Scholar] [CrossRef]

- Fernández-Sánchez, G.; Berzosa, Á.; Barandica, J.M.; Cornejo, E.; Serrano, J.M. Opportunities for GHG emissions reduction in road projects: A comparative evaluation of emissions scenarios using CO2NSTRUCT. J. Clean. Prod. 2015, 104, 156–167. [Google Scholar] [CrossRef]

- Peng, B.; Tong, X.; Cao, S.; Li, W.; Xu, G. Carbon emission calculation method and low-carbon technology for use in expressway construction. Sustainability 2020, 12, 3219. [Google Scholar] [CrossRef]

- Almeida-Costa, A.; Benta, A. Economic and environmental impact study of warm mix asphalt compared to hot mix asphalt. J. Clean. Prod. 2016, 112, 2308–2317. [Google Scholar] [CrossRef]

- Bueche, N.; Dumont, A.-G. Energy in warm mix asphalt. In Proceedings of the Eurasphalt & Eurobitume Congress, Istanbul, Turkey, 13–15 June 2012. [Google Scholar]

- Brown, A. Carbon footprint of HMA and PCC pavements. In Proceeding of The International Conference on Perpetual Pavement, Columbus, OH, USA, 30 September 2009. [Google Scholar]

- Guerrieri, M.; Casto, B.M.L.; Peri, G.; Rizzo, G. Smart vs conventional motorways: Environmental impact assessment under realistic traffic conditions. Sci. Total Environ. 2020, 727, 138521. [Google Scholar] [CrossRef]

- Liu, J.; Li, H.; Wang, Y.; Zhang, H. Integrated life cycle assessment of permeable pavement: Model development and case study. Transp. Res. Part D Transp. Environ. 2020, 85, 102381. [Google Scholar] [CrossRef]

- d’Angelo, J.; Harm, E.; Bartoszek, J.; Baumgardner, G.; Corrigan, M.; Cowsert, J.; Harman, T.; Jamshidi, M.; Jones, W.; Newcomb, D.; et al. Warm-Mix Asphalt: European Practice; United States, Federal Highway Administration, Office of International Programs: Washington, DC, USA, 2008. [Google Scholar]

- Hassan, M. Evaluation of the environmental and economic impacts of warm-mix asphalt using life-cycle assessment. Int. J. Constr. Educ. Res. 2010, 6, 238–250. [Google Scholar] [CrossRef]

| 1 | Objective | To investigate, identify, and assess the current state of research and knowledge, as well as to evaluate different sustainable and recycled materials and technologies that can reduce carbon emissions in asphalt pavement in various contexts, and to render suggestions for future studies. |

| 2 | Question | What are the recycled waste materials and technologies that can be used in asphalt pavement production and construction to minimize carbon emissions while maintaining or improving both durability and performance? |

| S/N | Keyword | Occurrences | Total Link Strength |

|---|---|---|---|

| 1 | Carbon footprint | 42 | 157 |

| 2 | Sustainable development | 37 | 155 |

| 3 | Recycling | 33 | 141 |

| 4 | Sustainability | 31 | 137 |

| 5 | Environmental impact | 30 | 136 |

| 6 | Concrete | 29 | 130 |

| 7 | Pavement | 27 | 126 |

| 8 | Emission control | 26 | 121 |

| 9 | Greenhouse gases | 24 | 114 |

| 10 | Life cycle assessment | 24 | 108 |

| 11 | Fly ash | 23 | 105 |

| 12 | Geopolymer | 21 | 101 |

| 13 | Greenhouse effect | 20 | 98 |

| 14 | Gas emission | 23 | 95 |

| 15 | Life cycle analysis | 20 | 94 |

| 16 | Global warming | 19 | 81 |

| 17 | Climate change | 18 | 77 |

| 18 | Aggregate | 18 | 76 |

| 19 | Mixtures | 18 | 75 |

| 20 | Energy utilization | 17 | 61 |

| 21 | Roads | 16 | 59 |

| 22 | Waste disposal | 16 | 56 |

| 23 | Binders | 15 | 52 |

| 24 | Asphalt mixtures | 14 | 52 |

| 25 | Roads and streets | 14 | 50 |

| 26 | Mechanical properties | 14 | 49 |

| 27 | Construction materials | 14 | 49 |

| 28 | Slag | 13 | 47 |

| 29 | Soils | 13 | 46 |

| 30 | Mixtures | 12 | 44 |

| 31 | Inorganic polymers | 12 | 41 |

| 32 | Demolition | 10 | 40 |

| 33 | Blast furnace | 10 | 39 |

| 34 | Air quality | 10 | 35 |

| S/N | Country | Documents | Citations |

|---|---|---|---|

| 1 | China | 14 | 449 |

| 2 | United States | 12 | 243 |

| 3 | Italy | 10 | 187 |

| 4 | Spain | 9 | 103 |

| 5 | Canada | 8 | 153 |

| 6 | Germany | 7 | 204 |

| 7 | United Kingdom | 6 | 87 |

| 8 | Australia | 5 | 95 |

| 9 | India | 5 | 48 |

| 10 | Czech Republic | 3 | 32 |

| 11 | Poland | 2 | 27 |

| 12 | Colombia | 2 | 14 |

| S/N | Source | Documents | Citations |

|---|---|---|---|

| 1 | Journal of Cleaner Production | 12 | 228 |

| 2 | Construction and Building Materials | 11 | 173 |

| 3 | Materials | 10 | 157 |

| 4 | Journal Central South University | 9 | 114 |

| 5 | Resources, Conservation, and Recycling | 8 | 79 |

| 6 | Renewable and Sustainable Energy Reviews | 7 | 96 |

| 7 | Transportation Research Record | 6 | 84 |

| 8 | Nanotechnology Review | 5 | 56 |

| 9 | Environmental Research | 5 | 37 |

| 10 | Environmental Research Letters | 5 | 74 |

| Materials | Material Quantity (%) | CO2 Emission (%) |

|---|---|---|

| Asphalt binder | 0.7 | 2.3 |

| Aggregates | 74.3 | 2.9 |

| Cement | 4.7 | 84.5 |

| Quick lime | 0.4 | 6.2 |

| Sand | 17.6 | 0.7 |

| Fly ash | 1.4 | 0 |

| Mineral filler | 0.6 | 1.0 |

| Reference | Material | Usage and Content wt.% | Findings | Recommendation |

|---|---|---|---|---|

| [59] | Pinewood and pig manure biochar | Asphalt binder modifier (5%) | Compared to petroleum-based asphalt, bio asphalt binder and binders modified with biochar are more energy-efficient and emit less CO2. Biochar made from wood was more effective. | Biochar has the prospective for the development of environmental and low-carbon asphalt pavement; however, further studies are required to fully comprehend its utilization. |

| [50] | Fly ash | Partial replacement of cement (0.38%) | Using fly ash to partially substitute Portland cement reduces CO2 emissions by 29.6%. | There has been little research and data on the concentration of fly ash leachate in the field and its long-term use. |

| [49] | Crumb rubber | Asphalt binder modifier (18%) | Carbon emission decreased from 36% to 44% compared to conventional mixtures when using asphalt binder with 18% crumb rubber produced using wet technology. | Attention must be paid to the type and nature of rubber used, as this might result in an increase in cost due to the requirement of a higher working temperature. |

| [60] | Recycled asphalt pavement | Aggregate replacement (30%, 40%, and 50%) | The decrease in greenhouse gas was accomplished by increasing the RAP content of asphalt binder; the prospective reduction is up to 12.4%. | Due to limited study on production cost and design life of the mixtures, additional study on life cycle cost estimation is required. |

| [61] | Palm oil fuel ash | Cement replacement (70%) | When palm oil fuel ash was utilized to substitute OPC up to 70%, CO2 emissions were reduced by up to 32–45%. | Future research should concentrate on mechanical performance testing and its long-term effects on the mixture. |

| [41] | Waste wood and straw biochar | Asphalt binder modifier (0%, 2%, 4%, 6%, and 8%) | Biochar was found to reduce VOC production by 50% because of its intrinsic microstructure and carbon negativity. | More research on the long-term and economic feasibility study of various biochar in asphalt pavement is recommended. |

| [56] | Reclaimed steel | Reinforcement bar | Reinforcement steel produced from reclaimed steel reduces GHG emissions by 5–27%. | More research on methods for detecting heavy metals while using such recycled materials in road construction is encouraged to reduce leachate development and environmental contamination. |

| [50] | Crumb rubber | Asphalt binder modifier (1.6%) | Asphalt rubber has a lower carbon footprint compared to Portland cement mixtures but a greater carbon footprint than asphalt mixtures. | The study was limited to dense-graded mixtures. More study using different gradations such as gap, open, and uniform grading is encouraged. |

| [55] | A recycled asphalt pavement and lime stabilization | Aggregate replacement and stabilization (100%) | CO2 emissions from the embankment section are reduced by 48.27% when both RAP and lime stabilization are used, 21.22% when only RAP is used, and 10.96% when only lime stabilization is used. | Further comparative studies are required to buttress the current study and additional studies are needed on life cycle cost assessment. |

| [46] | Recycled aggregate | Aggregate substitution (100%) | When compared to conventional mixes, recycled aggregate mixes reduced CO2 emissions by up to 29%. | Mechanical performance testing and long-term field performance studies are recommended for future research. |

| [57] | Brick, concrete limestone slurry dust, and glass powder | Filler replacement with a mass ratio of water to filler 9:1 | Glass powder and concrete dust emit somewhat more greenhouse gases than brick and limestone dust blends, while stone dust blends emit more greenhouse gases overall. Mixes of limestone dust yield the least amount of GHG emissions of7%. | To limit environmental impact, it is important to evaluate the environmental impact and mitigate heavy metals in waste filler before using it in road construction. |

| [62] | Palm oil fuel ash | Cement substitution (100%) | Palm oil waste-modified mixes can lower CO2 emissions by 44–64% when compared to the conventional asphalt pavement mixture | More research on environmental effects and cost-benefit analyses of various biochars in asphalt pavement is recommended. |

| [48] | Crumb rubber | Asphalt binder modifier Crumb rubber (18% and 25%) and styrene–butadiene–styrene (5%) | Compared to asphalt changed with styrene-butadiene-styrene, crumb rubber-modified asphalt can lower CO2 emissions by 17.06%. | More extensive rheological and performance testing are required to acquire a thorough knowledge of the microscopic and thixotropic behavior of the modified asphalt binder. |

| [52] | Recycled asphalt pavement | Aggregate replacement (10% and 30%) | Carbon emissions were reduced by 6.8% when RAP was combined with a hot asphalt mixture. | The percentage and selected RAP ratio must be carefully considered because they can contribute to an increase in asphalt use. Additional studies and field evaluation are required since the financial and societal impacts of the utilization of reused materials must be considered. |

| Parameters | Heating of Material | ||||

|---|---|---|---|---|---|

| Asphalt Binder | Asphalt Binder | Aggregate | Asphalt Binder | Aggregate | |

| Energy Substitution | Coal to Oil | Coal to Natural Gas | Awning | Oil to Natural Gas | Oil to Natural Gas |

| Energy saving (MJ) | - | 12.24 | 20.44 | 7.36 | 34.55 |

| Reduction in emission (mg) | 955,180 | 2,126,377 | 1,259,370 | 1,171,197 | 6,120,587 |

| Reduction in emission (%) | 18.34 | 40.82 | 5.9 | 27.53 | 28.2 |

| Reference | [82] | [3,85] | [82] | [3,82] | [82] |

| Reference | Technology Utilized | Findings | Recommendation |

|---|---|---|---|

| [52] | Cold recycling | The use of cold in-place recycling reduces the usages of aggregate, transportation, and plant consumption, all of which have advantages to CO2 eq released (a decrease of 9% throughout the entire lifespan and 54% when only the recycling phase is included). | When the method is paired with additional steps such as optimizing pavement roughness and optimizing waste concrete carbonation, CO2 emissions can be significantly reduced. |

| [91] | WMA | WMA has been proven to reduce CO2 emissions by 10–40% at asphalt plants, making it a more sustainable option for pavement construction | More research and consistent statistics on the environmental impact and long-term durability of WMA during its life cycle, as well as its impact on worker health and safety, are needed. |

| [72] | HWMA | The application usage of HWMA can cut CO2 emissions in the production process by up to 58% compared to HMA. | Further research on its long-term viability and performance, potential effects on worker safety and health, and cost-effectiveness, when compared to other asphalt mixtures, is needed. |

| [56] | Energy substitution | Biomass-based fuel and electric construction equipment significantly reduce carbon and GHG emissions, with biomass-based fuel cutting carbon emissions by 36–90% and electrical construction machinery reducing GHG emissions by 67–95%. | More research on the scalability and feasibility of using this construction equipment on larger scales, as well as the fiscal and life cycle analyses, are needed. |

| [81] | Cold recycling | When compared to conventional HMA production, the usage of cold recycling technology results in a 52% reduction in greenhouse gas emissions. | Research on the potential environmental impacts and economic sustainabilities of large-scale cold recycling technologies in the pavement industry is required. |

| [85] | Energy substitution and WMA | Natural gas reduces carbon emissions by 27.68% when compared to heavy oil, and it reduces emissions by 40.92% when compared to coal when heating asphalt binder. Furthermore, by adopting WMA and low-carbon asphalt mixture technologies, carbon emissions from asphalt mixtures can be reduced by 27.3% and 48.6%, respectively. | More research is required on asphalt pavement’s long-term durability and performance, as well as the potential impact of these technologies on pavement design and construction. |

| [80] | Cold recycling | Due to the use of existing materials and decreased energy usage, cold in-place recycling can lower CO2 e emissions by up to 75% when compared to conventional construction processes. | More studies into the most efficient and sustainable combinations of materials and technologies, as well as financial viability and long-term viability in varied geographic and environmental situations, are needed. |

| [92] | WMA | The study reveals that WMA has the potential to reduce CO2 emissions at asphalt binder plants by up to 35% compared to the conventional method. | More research is needed to thoroughly assess the technologies and investigate their long-term performances, as well as optimize the process to achieve higher CO2 reduction rates while maintaining mixture performance. |

| [86] | Energy substitution and WMA | The study indicates the feasiblility to attain a 65% decrease in CO2 emissions by replacing electricity with natural gas, whereas replacing electricity with oil or diesel can result in a 50% to 51% reduction in CO2 emissions. | More research on the field adaptability and practicality of deploying this technology, as well as financial and energy cycle assessments, are necessary. |

| [68] | WMA | According to the study, WMA has the prospect to lower CO2 emissions by up to 30–40% in asphalt plants while also lowering working temperatures by 30 °C. | Further research into the long-term durability and performance of WMA pavement, as well as the economic feasibility of the technology in various regions and asphalt gradations, is needed. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yaro, N.S.A.; Sutanto, M.H.; Baloo, L.; Habib, N.Z.; Usman, A.; Yousafzai, A.K.; Ahmad, A.; Birniwa, A.H.; Jagaba, A.H.; Noor, A. A Comprehensive Overview of the Utilization of Recycled Waste Materials and Technologies in Asphalt Pavements: Towards Environmental and Sustainable Low-Carbon Roads. Processes 2023, 11, 2095. https://doi.org/10.3390/pr11072095

Yaro NSA, Sutanto MH, Baloo L, Habib NZ, Usman A, Yousafzai AK, Ahmad A, Birniwa AH, Jagaba AH, Noor A. A Comprehensive Overview of the Utilization of Recycled Waste Materials and Technologies in Asphalt Pavements: Towards Environmental and Sustainable Low-Carbon Roads. Processes. 2023; 11(7):2095. https://doi.org/10.3390/pr11072095

Chicago/Turabian StyleYaro, Nura Shehu Aliyu, Muslich Hartadi Sutanto, Lavania Baloo, Noor Zainab Habib, Aliyu Usman, Arsalaan Khan Yousafzai, Abdulaziz Ahmad, Abdullahi Haruna Birniwa, Ahmad Hussaini Jagaba, and Azmatullah Noor. 2023. "A Comprehensive Overview of the Utilization of Recycled Waste Materials and Technologies in Asphalt Pavements: Towards Environmental and Sustainable Low-Carbon Roads" Processes 11, no. 7: 2095. https://doi.org/10.3390/pr11072095

APA StyleYaro, N. S. A., Sutanto, M. H., Baloo, L., Habib, N. Z., Usman, A., Yousafzai, A. K., Ahmad, A., Birniwa, A. H., Jagaba, A. H., & Noor, A. (2023). A Comprehensive Overview of the Utilization of Recycled Waste Materials and Technologies in Asphalt Pavements: Towards Environmental and Sustainable Low-Carbon Roads. Processes, 11(7), 2095. https://doi.org/10.3390/pr11072095