Abstract

In this paper, we explore the suggestions of the results of experimental studies on low-dimensional layered systems in FeNi/V2O3/FeNi film structures. The multifunctional material V2O3 is used as an interlayer between the magnetically active FeNi layers. The films were obtained by ultrahigh vacuum magnetron sputtering on a glass substrate with a base size of 10−10 Torr. It has been found that for V2O3 films, the decrease in the metal–semiconductor transition temperature increases significantly. Magnetic characteristics were studied on the MPMS-XL SQUID magnetometer. The exchange effect occurs both in the region where the oxide has a magnetic order and in the paramagnetic region. The latter is due to the effect of the magnetic panel in the oxide package. The phenomenon of oscillation of the exchange field occurs depending on the phenomenon of intermediate observation observed experimentally.

1. Introduction

Film materials and heterostructures have been paid much attention due to the wide range of properties they possess and the development of technologies for their production. Such systems are then used as building blocks for the fabrication of various advanced technologies, including spintronics devices. In this direction, materials called “multifunctional” become interesting, designed to perform several functions through a reasonable combination of various functionalities. For the direction of spintronics, multifunctional materials are used as sensor elements, magnetic memory elements, etc. [1,2].

For example, for structures in which control elements are based on multifunctional materials, FeBiO3 and (La,Sr)MnO3 are widely used: thermistor devices, bolometer-type infrared detectors, multiple-state memory elements and others. In such devices, controlled doping is an effective tool. It can be used, eventually in combination with deformation or other structural distortions, to adapt material properties at the nanoscale [3].

Many properties for film systems are determined by interactions at the interface of various materials [4]. Interfaces change not only the bulk magnetic properties but are also capable of inducing magnetism in non-magnetic layers, changing the nature of the magnetic state. Non-collinearity, interface anisotropy, interface-induced spin textures, etc., occur at the interfaces in heterostructures. The most well-known effects are exchange displacement, magnetic springs, the spin Hall effect and topological insulators. In general, the magnetic characteristics of a material (MS, TC, etc.) change whenever its dimensions become comparable to the corresponding magnetic correlation length [5]. Moreover, changes in properties can be associated with structural changes in the vicinity of the interface, with the thickness of layers or interfacial effects such as mutual diffusion, roughness and deformation.

External electric or magnetic fields, elastic stresses, light irradiation, electric current, etc., can be the methods of controlling properties. In this case, external influences can affect the volumetric properties and/or interfaces. Interfaces play a fundamental role in the development of applied technologies. It has been shown that they can create new types of magnetic states and new means for their rapid manipulation [6]. Most of the research is devoted to films, interfaces and heterostructures based on metals and metal alloys.

Advances in the study of metallic systems have stimulated the study of magnetic heterostructures based on other materials, including semiconductors and oxides, for example [7]. In this regard, structures including layers with a metal–insulator transition (MIT) are of particular interest. Canonical examples of materials in which MIT and structural phase transitions occur are vanadium oxides VO2 and V2O3. In the VO2 material, a first-order phase transition occurs at a temperature of about 340 K. In this case, a transition occurs from a dielectric low-temperature phase to a high-temperature metal phase, with a change in resistance up to four orders of magnitude. On the other hand, the transition in the V2O3 material occurs at a temperature of about 160 K. In this case, there is a transition from a dielectric antiferromagnetic low-temperature phase to a high-temperature paramagnetic metal phase, with a change in resistance up to five orders of magnitude.

There are many works that have studied the magnetic properties of VO2/Ni [8,9] and V2O3/Ni [10,11,12] two-layer films and the Ni/V2O3/FeNi [13] spin-valve structure.

In the case of V2O3/Ni bilayers, insulating regions appear during a structural transition with decreasing temperature. Due to this small area of Ni, the layer becomes stressed; hence, a decrease in the coercive force is observed below Tc. In addition, the formation of the V2O3 layer is likely to occur, and the formation of cell formation between the stressed and weakened portions of the Ni layer is accelerated. During magnetization and demagnetization, this boundary freely acts as a pinning center for the motion of the domain tissue. For samples with lower magnetic roughness, the Ni domains are larger than the V2O3 domains. Thus, phase coexistence creates additional magnetic domains, domain walls and pinning in the Ni film [8].

Some work on thin-film vanadium oxide–ferromagnetic structures has shown that interfacial coupling between a ferromagnetic material (Ni, Fe and Co) and vanadium oxide leads to additional strain anisotropy due to the effect of inverse magnetostriction. Therefore, the change in the hysteresis loop of the system due to phase separation strongly depends on the quality of the interface, since there is a coexistence of phases caused by additional pinning of domains at the grain boundaries.

Our work is devoted to the study of interfaces and magnetic properties of a three-layer structure: FeNi/V2O3/FeNi with a metal–insulator transition in V2O3, which is promising as a multifunctional material. Interest in the study of these particular samples is due to the fact that the use of a material as an interlayer between magnetically active layers, which simultaneously has the properties of a metal–semiconductor transition and has a magnetic–paramagnetic transition, opens up new possibilities in the design of structures with desired properties and is practically unexplored. It is important to elucidate the role of the interface between the magnetically active layer and the interlayer in the formation of the magnetic structure, depending on the thickness of the interlayer, the sequence of deposition of layers and the technological conditions for deposition of various layers of the structure. These studies may be important in matters of spin-dependent transport, since the conditions for the injection of spin-polarized electrons, along with the degree of polarization of conduction electrons in magnetic layers, strongly depend on the conjugation of energy bands and scattering processes at interfaces.

2. Materials and Methods

We have tried to study FeNi/V2O3/FeNi three-layer structures with a layer of vanadium oxide V2O3 and permalloy (FeNi) magnetic layers.

The films were sputtered onto a glass substrate using an ultrahigh vacuum magnetron sputtering system from Omicron NanoTechnology (Taunusstein, Germany) with Pfeiffer Vacuum turbomolecular pumps. The substrate was placed in the elevator of the working chamber through the sluice system for loading samples. The position of the substrate in the elevator relative to the magnetron was set to 20 cm. The deposition was carried out at a base pressure of 10−10 Torr in an argon atmosphere at a pressure of 3 m Torr (with film thickness control system during growth). The substrate was preliminarily cleaned by ion-plasma etching in the working chamber, immediately before the deposition process. All layers were deposited onto a rotating substrate at its temperature T ≈ 373 K. The vanadium oxide layer was deposited from an AC magnetron using a V2O3 target. The permalloy layer was deposited from a DC magnetron using a Fe14Ni86 alloy target.

Electron microscopic images and electron microdiffraction patterns are performed using a special JEOL JEM-2100 transmission microscope equipped with an Oxford Inca x-sight energy dispersive spectrometer at a fast voltage of 200 kV (when preparing samples for installing Gatan PIPS). Additional refinement of the layer thicknesses was performed using electron microscopic images. The phase composition was studied by X-ray diffraction analysis (XRD) on a DRON-4-07 instrument (Cu-Kα radiation). Analysis of the intensity of diffraction reflections on electron diffraction patterns and their interpretation were made using the Gatan Digital Micrograph software and the ICDD PDF 4+ database.

Magnetic characteristics were studied on the MPMS-XL SQUID magnetometer in fields up to 50 kOe. The measurements were made in the temperature range from 4.2 K to 300 K. The magnetic field lay in the plane of the film. Before each measurement, the film was first placed in a demagnetizer and then cooled in a zero magnetic field (ZFC mode). The four-probe method was used for magnetotransport measurements. The external field was set by an electromagnet when measuring R(T) above 100 K. The external field was perpendicular to the macroscopic transport current (H ⊥ Imacro). The critical current was determined by the criterion of 1 µV/cm, and the sample was immersed in liquid nitrogen.

As a result, the following sets of samples were obtained, investigated and analyzed:

1. Three-layer FeNi/V2O3/FeNi films with thicknesses tFeNi ≈ 15 nm, tV2O3 = from 3 nm up to 19 nm, with a step of 2 nm.

2. In order to study the features of the V2O3/FeNi and FeNi/V2O3 interfaces, two-layer films with different sequences of V2O3 and FeNi layers: SiO2(substrate)/V2O3/FeNi and SiO2 (substrate)/FeNi/V2O3 with thicknesses tFeNi ≈ 15 nm, tV2O3 ≈ 30 nm were obtained.

3. To determine the transition region of vanadium oxide, a series of single-layer V2O3 films with thicknesses tV2O3 = 20, 30, 40, 50, 80 and 100 nm was produced.

3. Results

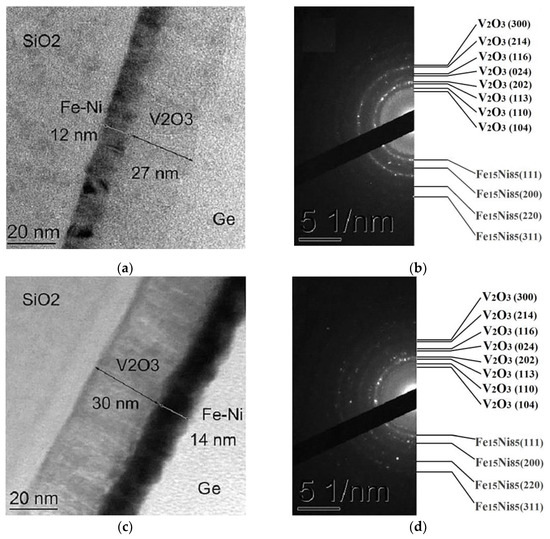

Figure 1a–d show electron microscopic images and electron microdiffraction patterns obtained from cross sections of two-layer SiO2 (substrate)/V2O3/FeNi and SiO2 (substrate)/FeNi/V2O3 films. Interpretation of the diffraction reflexes observed in electron microdiffraction patterns (Figure 1b,d) shows that, regardless of the deposition sequence of the V2O3 and FeNi layers, crystalline phases are formed in the films, V2O3 having a rhombohedral lattice (spatial R-3c group, lattice parameters: a = 4.95 Å, c = 14.0 Å, PDF 4+ card #00-034-0187) and an unordered solid solution of Fe-Ni having a cubic face-centered lattice (spatial Fm-3m group, lattice parameter: a = 3.54 Å, PDF 4+ card #04-003-2245). The analysis of electron microscopic images suggests that in the case of a SiO2 (substrate)/V2O3/FeNi sample (see Figure 1a), the FeNi/V2O3 interface is more blurred, which indicates a diffusive interpenetration of materials at the interface. In the case of the SiO2 (substrate)/FeNi/V2O3 sample (see Figure 1c), the V2O3/FeNi interface is more pronounced, which indicates the absence of significant materials mixing in the V2O3 and FeNi layers. It is natural to expect that such an asymmetry will result in a difference in the physical properties of the FeNi/V2O3 and V2O3/FeNi interfaces.

Figure 1.

Electron microscopic image (a,c) and electron microdiffraction pattern (b,d) of the cross section. (a,c) SiO2 film (substrate)/V2O3/Fe-Ni; (b,d) SiO2 film (substrate)/Fe-Ni/V2O3.

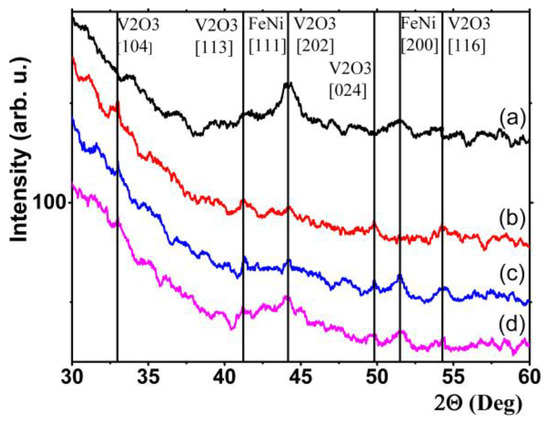

Figure 2 shows the XRD patterns of the samples: SiO2 (substrate)/FeNi (50 nm) (a), SiO2 (substrate)/V2O3 (50 nm) (b), SiO2 (substrate)/V2O3 (5 nm)/FeNi (15 nm) (c) and SiO2 (substrate)/FeNi (15 nm)/V2O3 (5 nm)/FeNi (15 nm) (d). The rather thin thicknesses of the film structures make it difficult to obtain better X-ray diffraction patterns of the samples, despite the longer data acquisition times (about five hours or more). However, despite this, the spectra of the film show peaks corresponding to the phases of vanadium oxide V2O3 (see Figure 2b–d) and permalloy (FeNi) (see Figure 2a,c,d). Thus, the analysis and interpretation of the X-ray diffraction patterns of the samples show the presence of crystallographic structures corresponding to diffraction reflections obtained from electron microscopic measurements.

Figure 2.

XRD patterns for samples: SiO2 (substrate)/FeNi (50 nm) (a), SiO2 (substrate)/V2O3 (50 nm) (b), SiO2 (substrate)/V2O3 (5 nm)/FeNi (15 nm) (c) and SiO2 (substrate)/FeNi (15 nm)/V2O3 (5 nm)/FeNi (15 nm) (d).

It is known [14] that the magnitude and temperature dependence of electrical resistance vary depending on thickness in metal films. Moreover, at small thicknesses for the V2O3 composites [15], the temperature behavior of electrical resistance in the vicinity of the metal–insulator transition temperature (TMD) changes depending on the layer thickness and stoichiometry of the material. For bulk crystals of V2O3, the value of TMD is 150 K approximately, while at temperatures of T > 150 K a paramagnetic state is realized, and below the transition temperature an antiferromagnetic state takes place. Thus, the state of vanadium oxide (in terms of its electrical resistance) is not unambiguous. Therefore, additional research was carried out to determine this condition.

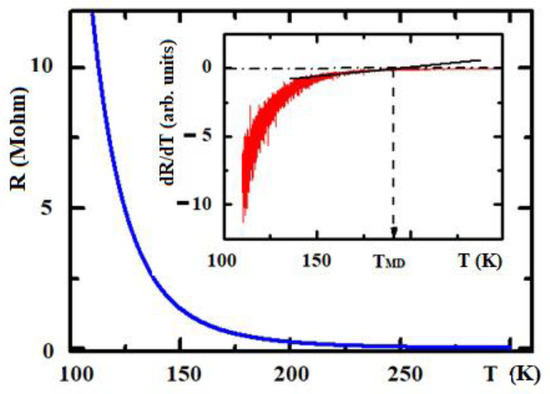

The curve in Figure 3 represents the experimental temperature dependence of the resistance R(T) of a 30 nm thick V2O3 film in the transition region and the TMD determination procedure. The TMD transition temperature is defined as the intersection point of the derivative (dR/dT) with a straight line, which corresponds to the R(T) curve asymptote at the temperature increasing (insert in Figure 3). Thus, the transition temperature MIT corresponds to 191 K for a V2O3 film 30 nm thick.

Figure 3.

Electron temperature dependence of the film resistance with tV2O3 = 30 nm. The insert shows the temperature dependence of the dR/dT derivative used to determine the transition temperature.

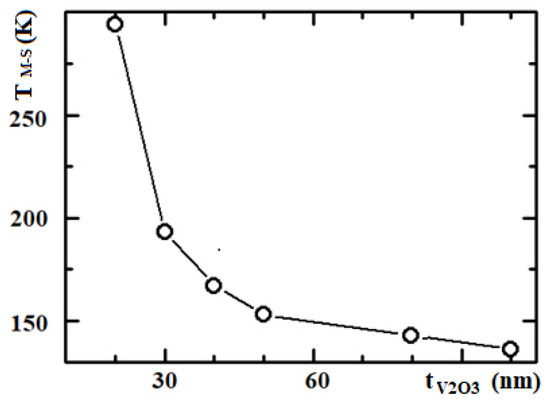

The behavior of the MIT temperature of all obtained single-layer films of the V2O3 composites depending on thickness has been studied. The data are shown in Figure 4. It can be seen that at vanadium oxide layer thicknesses of more than 100 nm, the transition temperature practically approaches the transition temperature for a bulk crystal. A sharp increase in the transition temperature takes place when the film thickness decreases less than 50 nm. This result made it possible to determine the maximum thickness of the intermediate layer of vanadium oxide V2O3 in the FeNi/V2O3/FeNi three-layer composition, at which V2O3 can be considered a non-conductive layer for further research.

Figure 4.

Dependence of the V2O3 metal–semiconductor transition temperature on the film thickness.

Below are the results of measurements of the magnetic properties of three-layer systems.

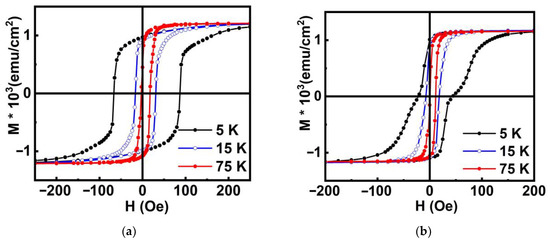

Figure 5 shows the field dependencies of magnetization for FeNi/V2O3/FeNi films with intermediate layer thicknesses of t V2O3 = 3, 7 and 11 nm (parts a, b and c, respectively), which were taken at different temperatures. It can be seen that the shape of the hysteresis loop depends on the interlayer thickness, while an exchange displacement effect takes place. The presented field dependencies of the magnetization were taken at temperatures T = 5, 15 and 75 K.

Figure 5.

Field dependencies of FeNi/V2O3/FeNi films magnetization. tV2O3 = 3 (a), 7 (b) and 11 (c) nm. T = 5, 15 and 75 K.

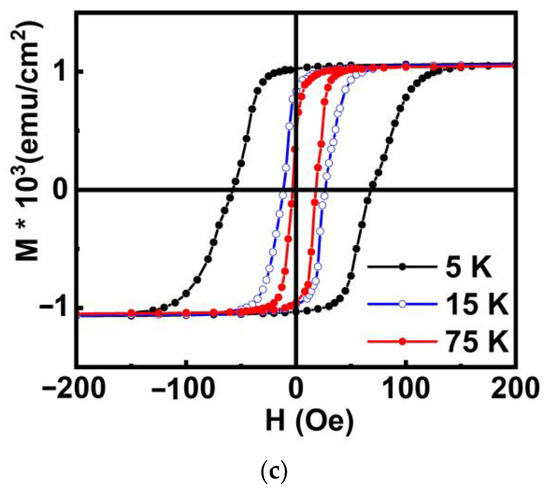

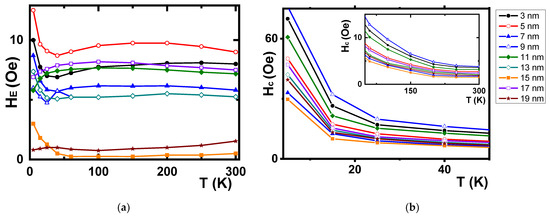

The temperature dependencies of the exchange displacement field (HE) and the coercive force (HC) of three-layer films are shown in Figure 6 (parts a and b, respectively). Figure 6b shows the dependence at temperatures up to 50 K. Figure 6b shows the dependence of HC at higher temperatures.

Figure 6.

Temperature dependencies of FeNi/V2O3/FeNi films: (a) exchange displacement (HE); (b) coercive force (HC). tV2O3 = 3, 5, 7, 9, 11, 13, 15, 17, 19 nm. The insert shows the HC dependencies at high temperatures.

All temperature dependencies of the coercive forces demonstrate an increase in the value of HC with decreasing temperature. In this case, up to a temperature of about 15 K, the value of HC changes only slightly. Further, the coercive force increases more sharply with decreasing temperature for all thicknesses of the V2O3 interlayer. The coercive force of the structure is by one order greater than that of the nominal permalloy layer [16]. Figure 6b also shows that, depending on the thickness of the vanadium oxide layer, HC oscillations take place. The value of the coercive force decreases from 60 Oe to 15 Oe, with an increase in the thickness of the V2O3 interlayer from 3 nm up to 7 nm. Then, the value of the coercive force increases to 45 Oe at the thickness of the V2O3 interlayer of 4 nm. Further, as the thickness of the interlayer increases to 15 nm, the coercive force starts to decrease to 8 Oe again.

The curves of the temperature dependencies of exchange displacement fields (Figure 6a) can be divided into two groups according to the nature of behavior in the region of low temperatures during heating.

In the first group of films, the HE value noticeably decreases with increasing temperature in the range from 4.2 K to 60 K, and then there is a slight increase in the region of T ≈ 150–250 K. In the second group of films, the HE value increases at first to a temperature of about 50 K, and then it reaches a plateau.

In our case, the significant influence of the interlayer on the magnetic properties of ferromagnetic layers (including the values of coercive forces and exchange bias fields) is obvious at temperatures of T < 40 K. No changes are observed in the vicinity of the temperature of the proposed electrical transition. The peculiarity of this system is that the effect of exchange displacement is observed in the entire temperature range of measurements, even where no magnetic order in the interlayer V2O3 should be. For all films, the sign of the exchange displacement field is positive. As noted above, a state with high electrical resistance is realized throughout the studied area.

4. Discussion

It was previously found [17] that oscillations of the exchange bias field were detected in the Fe/Cr structure, where the authors attribute the observed effect to similar oscillations of the interlayer interaction in Fe/Cr (2 1 1) superlattices. The authors believe that this is an indication of the linear dependence of the exchange displacement field on the interlayer interaction energy.

The exchange displacement field in the simplest case in two-layer ferromagnetic/antiferromagnetic systems is described by the expression [18]

where SF and SAF are spins in ferromagnetic and antiferromagnetic materials, Jex is the constant of exchange interaction at the interface, MF and tF are the magnetization and thickness of the ferromagnetic layer, respectively, and α is the structural factor at the interface. It is known [19] that the effect of positive exchange displacement (HE > 0) is realized in systems (1) when cooling occurs in a negative magnetic field (hf < 0) and positive interlayer interaction (Jex > 0) under the condition (Jex•SAF) < 0 (with the direction of spin in the antiferromagnet) or in the case (2) when hf > |J•SAF|, but the interlayer exchange is negative (J < 0).

HE = (α•Jex•|SF|•|SAF|)/(MF•tF)

Be that as it may, in the evaluation of the flow rate, the structure factor α and the constant interchangeability of Jex at the interface are of interest, given the special multilayer nature of the system. It is realized that, in reality, interfaces are never atomically smooth. Indeed, interface features can be detected in terms of structures, roughness, magnetic properties and domain walls of the ferromagnetic and weakly magnetic layers.

It is known that the deposition of V2O3 on permalloy at 750 °C can provoke the appearance of magnetite Fe3O4 (111) at the interface, which is the cause of the exchange bias in the Py/V2O3 layers [20]. However, in our case, the skin temperature was lower (373 K). The electron microscopic and X-ray diffraction data do not contain traces of Fe3O4 (111) in the films. Therefore, we associate the appearance of the exchange bias with other reasons.

In our case, the cooling of the structure was carried out in a residual magnetic field, when the ferromagnetic layer was in an ordered state, and the V-containing layer was in a paramagnetic state, with a small spin value on the vanadium ion. There, the molecular field of the ferromagnetic layer acts as a cooling field for the vanadium oxide layer. Thus, it is concluded that the exchange between the layers is negative at the beginning of cooling. An exchange displacement in the paramagnetic region of the oxide layer arises due to the fact that in this layer there is a near-surface layer with a magnetic moment other than zero, i.e., there is a bond between the magnetic ions in the permalloy and the V ions at the interface, and the V interphase atoms have an induced magnetic moment.

Such a layer is suggested to arise due to the effect of magnetic proximity, similar to the process in a two-layer V2O3/Co system [21]. In this case, the structure of magnetic domains at the interface during magnetization reversal of the ferromagnetic layer controls the effects: fields of the exchange bias, coercive force or blocking temperature. As it is shown in [22], in such systems the exchange is dependent on spatial coordinates, and it decreases with distance from the plane of materials separation and has the form J ~ exp(−t/L), where L determines the scale of interaction.

Another interesting point is the oscillating dependence of HC on the thickness of the vanadium-containing layer. For example [23], this behavior is observed in the LaMnO3/LaNiO3 structure, where LaMnO3 is a ferromagnet and LaNiO3 is a paramagnet, and both have metallic conductivity. Here, according to calculations from the first principles, the resemblance of induced magnetic ordering in LaNiO3 to a spin density wave has been concluded. However, we demonstrate how interlayer interactions can induce a complex magnetic structure in the low-temperature region, in which the V2O3 interlayer is not a metal and is in a non-magnetic state.

Initially, a FeNi material with very low anisotropy was used as a ferromagnetic layer, in order to avoid the obscurement of the interactions induced by conjugation with the V2O3 layer. As it is known [24], the coercive field is proportional to the anisotropy of the material HC = 2•K/(MS•γ(θ)), where, γ(θ) is a parameter depending on the angle θ between the light axis and the direction of the magnetic field; the other designations are traditional. As it can be seen in Figure 5b, the coercive field decreases rapidly, and changes are very small at temperatures T > 20 K. Therefore, the behavior of the coercive force depending on the thickness of the nonmagnetic layer leads to the need to take into account the interface anisotropy.

As a result, the anisotropy at the FeNi/V2O3/FeN interfaces may be the sum of one-ion anisotropy of the vanadium ion subsystem and the arising interface anisotropy. According to [25], the constant of one-ion anisotropy (standard designations) is D = 8.34 cm−1 (≈12.07 K), which is consistent in magnitude with the temperature of significant changes in HC. However, this mechanism alone is not sufficient to explain the behavior of both HC and HE at higher temperatures.

All these features in FeNi/V2O3/FeNi three-layer films, i.e., an increase in coercivity at low temperature, a positive exchange bias and the presence of coercive force oscillations, are signs of interlayer exchange effects. Apparently, the explanation of such effects in FeNi/V2O3/FeNi films is the simultaneous presence of two effects: exchange bias and magnetic proximity.

5. Conclusions

Thus, it has been established in this work that the presence of a V2O3 interlayer between permalloy layers leads to a change in the magnetic state. Despite the fact that there should not be magnetic order in the interlayer over the entire temperature range, in this case, the layer has a high electrical resistance.

The main facts and effects found in this study are listed below.

It has been found that the metal–semiconductor transition temperature of the V2O3 composites increases strongly at film thicknesses of tVO < 50 nm, and at tVO > 100 nm it tends to the value inherent in the bulk material.

It was found that the V2O3/FeNi interface is more pronounced than the interface obtained by reverse deposition of FeNi/V2O3 layers under the same conditions. In this case, the presence of crystalline phases does not change, but only diffusion interpenetration of permalloy and vanadium oxide materials occurs at the interface.

It has been found that the shape of the hysteresis loop depends on the thickness of the oxide interlayer.

There is an effect of exchange displacement in the entire temperature range, both in the region of magnetic ordering of vanadium oxide and in the paramagnetic region.

It should be noted that, in general, there are many reports on the change in HC with temperature for AFM/FM heterostructures, even for similar ones. Our results reflect the behavior of the effect of oscillations of the coercive force depending on the thickness of the interlayer in the FeNi/V2O3/FeNi three-layer structure.

The presence of the effect of exchange displacement in the disordered region of vanadium oxide is associated with the effect of magnetic proximity.

These experimental results can be useful for the development of new layered structures for practical applications.

Author Contributions

G.S.P.: conceptualization, methodology, software; A.V.K.: data curation, writing—original draft preparation; V.I.Y.: visualization, investigation; I.O.A.: investigation, validation; S.M.Z.: writing—reviewing and editing, investigation; S.V.S.: investigation, validation; E.T.M.: software, validation. All authors have read and agreed to the published version of the manuscript.

Funding

The research was conducted according to the state assignment of the Ministry of Science and Higher Education of the Russian Federation and the Federal State Autonomous Educational Institution of Higher Education Siberian Federal University (No. FSRZ-2023-0008).

Data Availability Statement

Not applicable.

Acknowledgments

Cross sections of the samples were obtained at the Krasnoyarsk Regional Research Equipment Sharing Center of the FRC KSC Siberian Branch Russian Academy of Sciences and Electron Microscopy Laboratory of the Research Equipment Sharing Center of the Siberian Federal University (RESC SFU). Electron microscopic studies were carried out at the RESC SFU.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Lu, C.; Hu, W.; Tian, Y.; Wu, T. Multiferroic oxides thin films and heterostructures. Appl. Phys. Rev. 2015, 2, 021304. [Google Scholar] [CrossRef]

- Lendlein, A.; Trask, R.S. Multifunctional materials: Concepts, function-structure relationships, knowledge-based design, translational materials research. Multifunct. Mater. 2018, 1, 010201. [Google Scholar] [CrossRef]

- Ben, H.; Gajek, M.; Bibes, M.; Barthelemy, A. Spintronics with multiferroics. J. Phys. Condens. Matter. 2008, 20, 434221. [Google Scholar] [CrossRef]

- Hellman, F.; Hoffman, A.; Tserkovnyak, Y.; Beach, G.S.D.; Fullerton, E.E.; Leighton, C.; MacDonald, A.H.; Ralph, D.C.; Arena, D.A.; Durr, H.A.; et al. Interface-induced phenomena in magnetism. Rev. Mod. Phys. 2017, 89, 025006. [Google Scholar] [CrossRef]

- Vaz, C.A.F.; Bland, J.A.C.; Lauhoff, G. Magnetism in ultrathin film structures. Rep. Prog. Phys. 2008, 71, 056501. [Google Scholar] [CrossRef]

- Hoffmann, A.; Bader, S.D. Opportunities at the Frontiers of Spintronics. Phys. Rev. Appl. 2015, 4, 047001. [Google Scholar] [CrossRef]

- Lee, H.-J.; Bordel, C.; Karel, J.; Cooke, D.W.; Charilaou, M.; Hellman, F. Electron-Mediated Ferromagnetic Behavior in CoO/ZnO Multilayers. Phys. Rev. Lett. 2013, 110, 087206. [Google Scholar] [CrossRef]

- de la Venta, J.; Wang, S.; Ramirez, J.G.; Schuller, I.K. Control of magnetism across metal to insulator transitions. Appl. Phys. Lett. 2013, 102, 122404. [Google Scholar] [CrossRef]

- Lauzier, J.; Sutton, L.; de la Venta, J. Coercivity enhancement in VO2/Ni bilayers due to interfacial stress. J. Appl. Phys. 2017, 122, 173902. [Google Scholar] [CrossRef]

- de la Venta, J.; Wang, S.; Saerbeck, T.; Ramírez, J.G.; Valmianski, I.; Schuller, I.K. Coercivity enhancement in V2O3/Ni bilayers driven by nanoscale phase coexistence. Appl. Phys. Lett. 2014, 104, 062410. [Google Scholar] [CrossRef]

- Urban, C.; Quesada, A.; Saerbeck, T.; Garcia, M.A.; de la Rubia, M.A.; Valmianski, I.; Fernandez, J.F.; Schuller, I.K. Two state coercivity driven by phase coexistence in vanadium sesquioxides/nickel bulk hybrid material. Appl. Phys. Lett. 2016, 109, 112401. [Google Scholar] [CrossRef]

- Sutton, L.; Lauzier, J.; la Venta, J.D. Magnetic properties of hybrid V2O3/Ni composites. J. Appl. Phys. 2018, 123, 083902. [Google Scholar] [CrossRef]

- Erekhinsky, M.; de la Venta, J.; Schuller, K. Spin valve effect across the metal-insulator transition in V2O3. J. Appl. Phys. 2013, 114, 143901. [Google Scholar] [CrossRef]

- Coffey, K. Electron scattering in metallic thin films. In Metallic Films for Electronic, Optical and Magnetic Applications. Structure, Processing and Properties; Barmak, K., Coffey, K., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2014; p. 422. [Google Scholar] [CrossRef]

- Dillemans, L.; Smets, T.; Lieten, R.R.; Menghini, M.; Su, C.-Y.; Locquett, J.-P. Evidence of the metal-insulator transition in ultrathin unstrained V2O3 thin films. Appl. Phys. Lett. 2014, 104, 071902. [Google Scholar] [CrossRef]

- Patrin, G.S.; Turpanov, I.A.; Yushkov, V.I.; Kobyakov, A.V.; Patrin, K.G.; Yurkin, G.Y.; Zhivaya, Y.A. Effect of the Semiconductor Spacer on Positive Exchange Bias in the CoNi/Si/FeNi Three-Layer Structure. JETP Lett. 2019, 109, 320. [Google Scholar] [CrossRef]

- Lazar, L.; Jiang, J.S.; Felcher, G.P.; Inomata, A.; Bader, S.D. Oscillatory exchange bias in Fe/Cr double superlattices. J. Magn. Magn. Mater. 2001, 223, 299–303. [Google Scholar] [CrossRef]

- van der Zaag, P.J.; Ijiri, Y.; Borchers, J.A.; Feiner, L.F.; Wolf, R.M.; Gaines, J.M.; Erwin, R.W.; Verheijen, M.A. Difference between Blocking and Néel Temperatures in the Exchange Biased Fe3O4CoO System. Phys. Rev. Lett. 2000, 84, 6105. [Google Scholar] [CrossRef] [PubMed]

- Binek, C. Tunable Exchange Bias Effects. In Nanoscale Magnetic Materials and Applications; Liu, J.P., Fullerton, E., Gutfleih, O., Sellmer, D.J., Eds.; Springer: New York, NY, USA, 2009; p. 159. [Google Scholar] [CrossRef]

- de la Venta, J.; Erekhinsky, M.; Wang, S.; West, K.G.; Morales, R.; Schuller, I.K. Exchange bias induced by the Fe3O4 Verwey transition. Phys. Rev. B 2012, 85, 134447. [Google Scholar] [CrossRef]

- Diez, J.M.; Cunado, J.L.F.; Lapa, P.; Arnay, I.; Pedraz, P.; Perna, P.; Bollero, A.; Miranda, R.; Schuller, I.K.; Camarero, J. Interfacial Exchange Phenomena Driven by Ferromagnetic Domains. Adv. Mater. Interfaces 2022, 9, 2200331. [Google Scholar] [CrossRef]

- Gökemeijer, N.J.; Ambrose, T.; Chien, C.L. Long-Range Exchange Bias across a Spacer Layer. Phys. Rev. Lett. 1997, 79, 4270. [Google Scholar] [CrossRef]

- Gibert, M.; Zubko, P.; Scherwitzl, R.; Íñiguez, J.; Triscone, J.-M. Exchange bias in LaNiO3–LaMnO3 superlattices. Nat. Mater. 2012, 11, 195. [Google Scholar] [CrossRef] [PubMed]

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; p. 275. [Google Scholar]

- Kuwamoto, H.; Robinson, W.R.; Honig, J.M. Magnetic Structure of the Low Temperature Antiferromagnetic Phase of V2O3. J. Sol. St. Chem. 1978, 24, 389. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).