Experimental Study on Gas Explosion Propagation in Porous Metal Materials

Abstract

1. Introduction

2. Attenuation Theory of Gas Explosion by Porous Metal Material

3. Materials and Methods

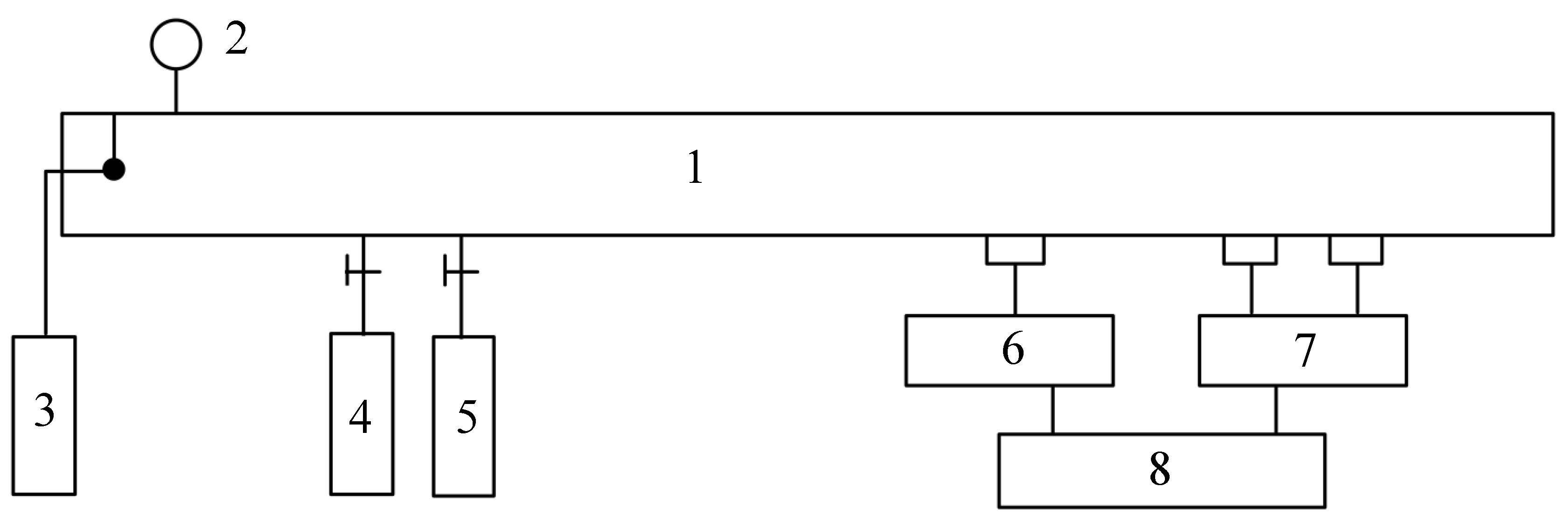

3.1. Experimental System

3.2. Experimental Scheme

- (1)

- Selection of porous materials

- (2)

- Experimental parameters

- (3)

- Experimental steps

4. Result Analyses and Discussion

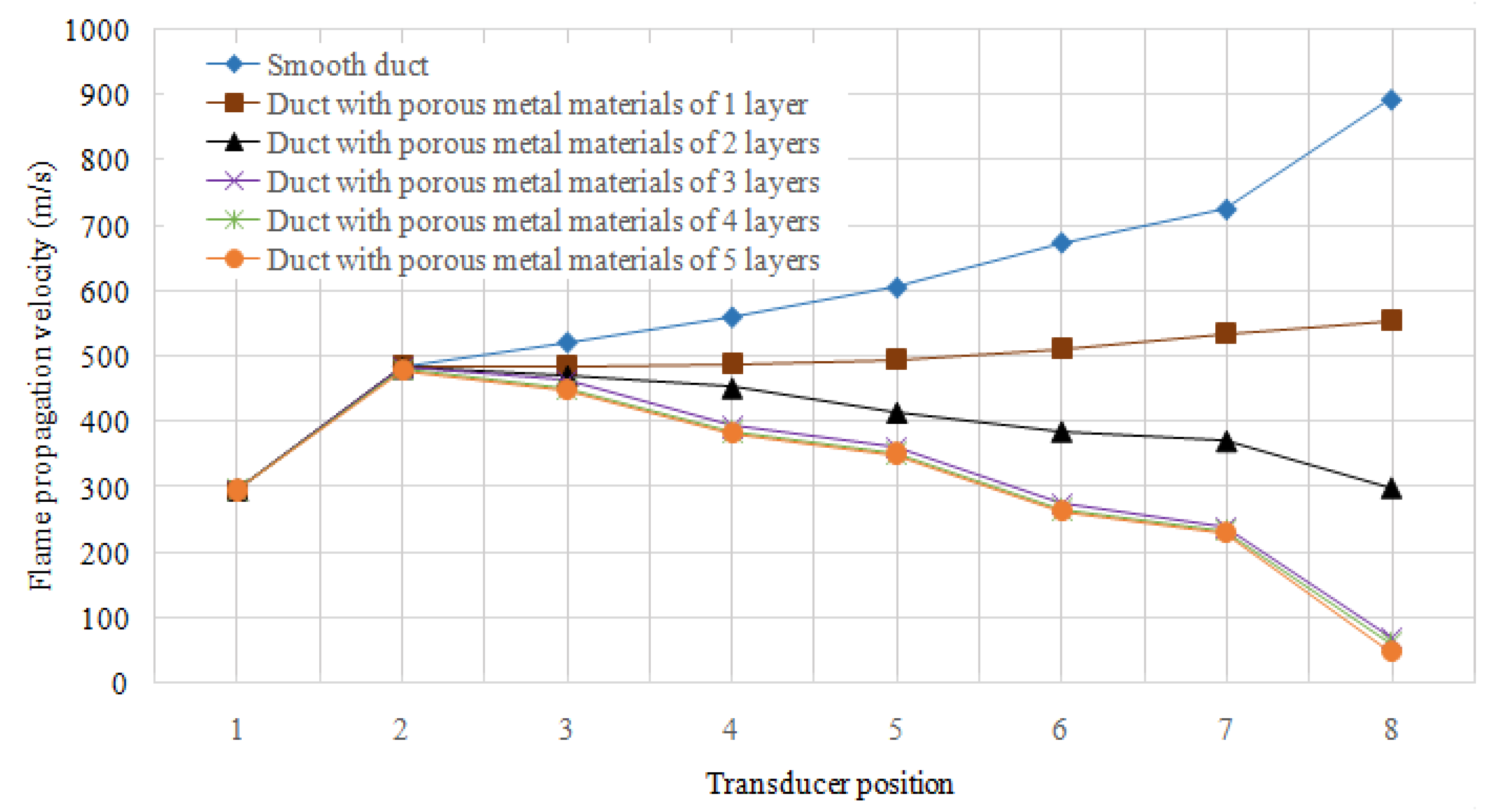

4.1. Influence of Porous Metal Materials on Flame Propagation Velocity

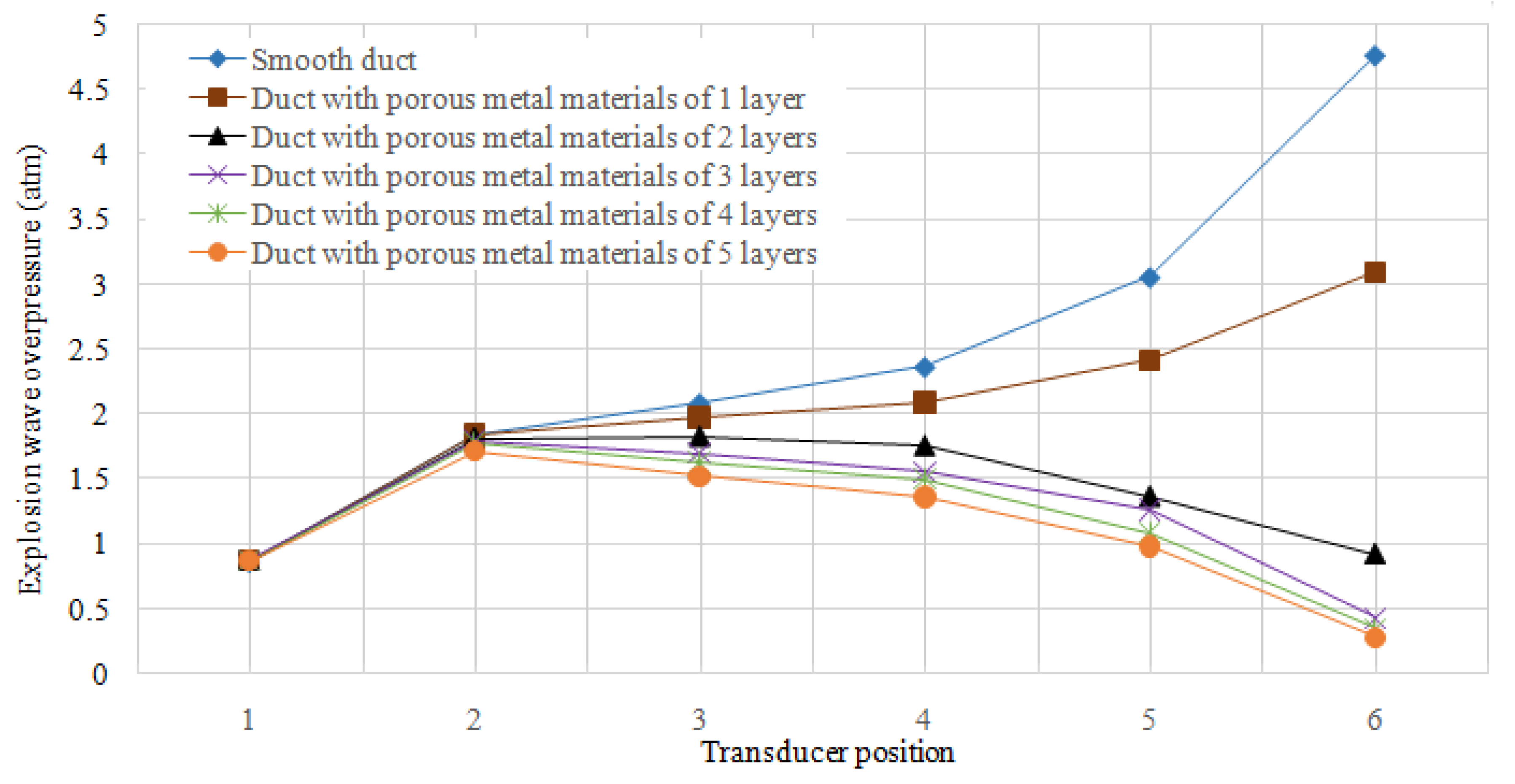

4.2. Influence of Porous Metal Material on Overpressure of Explosion Wave

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhenzhen, J.; Qing, Y. Analysis of the response characteristics of a roadway wall under the impact of gas explosion. Energy Sci. Eng. 2023, 11, 2486–2504. [Google Scholar] [CrossRef]

- Ye, Q.; Wang, G.G.; Jia, Z.; Zheng, C. Experimental study on the influence of wall heat effect on gas explosion and its propagation. Appl. Therm. Eng. 2017, 118, 392–397. [Google Scholar] [CrossRef]

- Zhang, H.; Jia, Z.; Ye, Q.; Cheng, Y.; Li, S. Numerical simulation on influence of initial pressures on gas explosion propagation characteristics in roadway. Front. Energy Res. 2022, 10, 913045. [Google Scholar] [CrossRef]

- Ye, Q.; Jia, Z.; Zheng, C. Study on hydraulic-controlled blasting technology for pressure relief and permeability improvement in a deep hole. J. Pet. Sci. Eng. 2017, 159, 433–445. [Google Scholar] [CrossRef]

- Saki, S.A.; Brune, J. Prevention of gob ignitions and explosions in long wall mining using dynamic seals. Int. J. Min. Sci. Technol. 2017, 27, 999–1003. [Google Scholar]

- Ye, Q.; Jia, Z. Effect of the bifurcating duct on the gas explosion propagation characteristics. Combust. Explos. Shock. Waves 2014, 50, 424–428. [Google Scholar] [CrossRef]

- Yang, Z.; Ye, Q.; Jia, Z.; Li, H. Numerical simulation of pipeline-pavement damage caused by explosion of leakage gas in buried PE pipelines. Adv. Civ. Eng. 2020, 2020, 4913984. [Google Scholar]

- Zhang, J.; Sun, Z.; Zheng, Y. Coupling effects of foam ceramics on the flame and shock wave of gas explosion. Saf. Sci. 2012, 50, 797–800. [Google Scholar] [CrossRef]

- Guo, X.; Jia, Z.; Ye, Q. Numerical study on influence of wall thermal effect on thermal impact of gas explosion. Sustainability 2023, 15, 7792. [Google Scholar] [CrossRef]

- Vasil’ev, A.A. Near limiting detonation in channels with porous walls. Combust. Explos. Shock. Waves 1994, 30, 101–106. [Google Scholar] [CrossRef]

- Teodorczyk, A.; Lee, J.H.S. Detonation attenuation by foams and wire meshes lining the walls. Shock. Waves 1995, 4, 225–236. [Google Scholar] [CrossRef]

- Fedorov, A.V.; Fedorchenko, I.A. Interaction of a normally incident shock wave with a porous material layer on a solid wall. Combust. Explos. Shock. Waves 2010, 46, 89–95. [Google Scholar] [CrossRef]

- Mehrjoo, N.; Gao, Y.; Kiyanda, C.B.; Ng, H.D.; Lee, J.H. Effects of porous walled tubes on detonation transmission into unconfined space. Proc. Combust. Inst. 2014, 35, 1981–1987. [Google Scholar] [CrossRef]

- Mazaheri, K.; Mahmoudi, Y.; Sabzpooshani, M.; Radulescu, M.I. Experimental and numerical investigation of propagation mechanism of gaseous detonations in channels with porous walls. Combust. Flame 2015, 162, 2638–2659. [Google Scholar] [CrossRef]

- Zhang, Z.; Lin, B.; Li, G. Coke oven gas explosion suppression. Saf. Sci. 2013, 55, 81–87. [Google Scholar] [CrossRef]

- Nie, B.; He, X.; Zhang, R. The roles of foam ceramics in suppression of gas explosion overpressure and quenching of flame propagation. J. Hazard. Mater. 2011, 192, 741–747. [Google Scholar] [CrossRef]

- Chen, P.; Huang, F.; Sun, Y.; Chen, X. Effects of metal foam meshes on premixed methane-air flame propagation in the closed duct. J. Loss Prev. Process Ind. 2017, 47, 22–28. [Google Scholar] [CrossRef]

- Ciccarelli, G.; Johansen, C.; Parravani, M. Transition in the propagation mechanism during flame acceleration in porous media. Proc. Combust. Inst. 2011, 33, 2273–2278. [Google Scholar] [CrossRef]

- Ji, C. Research on new technology on obstructing diffusion of mine gas explosion. Coal Technol. 2010, 29, 110–113. (In Chinese) [Google Scholar]

- Wen, X.; Xie, M.; Yu, M. Porous media quenching behaviors of gas deflagration in the presence of obstacles. Exp. Therm. Fluid Sci. 2013, 50, 37–44. (In Chinese) [Google Scholar] [CrossRef]

- Wang, B.; Jing, J.; Gong, Y.; Liu, T. Experimental study on the reproduction of serious gas explosions in coal mines. Fire Sci. Technol. 2004, 23, 513–516. [Google Scholar]

- Bivol, G.Y.; Golovastov, S.V.; Golub, V.V. Propagation of detonation wave in hydrogen–air mixture in channels with sound-absorbing surfaces. Tech. Phys. Lett. 2015, 41, 1167–1169. [Google Scholar] [CrossRef]

- Bivol, G.Y.; Golovastov, S.V.; Golub, V.V. Attenuation and recovery of detonation wave after passing through acoustically absorbing section in hydrogen-air mixture at atmospheric pressure. J. Loss Prev. Process Ind. 2016, 43, 311–314. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, Y.; Wei, C. The comparative experimental study of the porous materials suppressing the gas explosion. Procedia Eng. 2011, 26, 1049–1055. [Google Scholar]

- Yu, J.; Cai, T.; Li, Y. Experiment to quench explosive gas with structure of wire mesh. J. Combust. Sci. Technol. 2008, 14, 97–100. [Google Scholar]

- Wang, Z.; Terushige, O. The optimum choice of the design parameter on wire gauze. China Saf. Sci. J. 1995, 5, 176–182. (In Chinese) [Google Scholar]

- Duan, Y.; Wang, S.; He, S.; Wan, L. Characteristics of gas explosion to diffusion combustion under porous materials. Explos. Shock. Wave 2020, 40, 095401.1–095401.7. [Google Scholar] [CrossRef]

- Han, F. The Experiment and Numerical Simulation of the Flame Spread in Tubes with Porous Material. Master’s Thesis, Dalian University of Technology, Dalian, China, 2008. (In Chinese). [Google Scholar]

- Cui, Y.Y.; Wang, Z.R.; Zhou, K.B.; Ma, L.S.; Liu, M.H.; Jiang, J.C. Effect of wire mesh on double-suppression of CH4/air mixture explosions in a spherical vessel connected to pipelines. J. Loss Prev. Process Ind. 2017, 45, 69–77. [Google Scholar] [CrossRef]

- Jin, K.; Duan, Q.; Chen, J.; Liew, K.M.; Gong, L.; Sun, J. Experimental study on the influence of multi-layer wire mesh on dynamics of premixed hydrogen-air flame propagation in a closed duct. Int. J. Hydrog. Energy 2017, 42, 148–159. [Google Scholar] [CrossRef]

- Jia, Z.; Feng, T. Numerical simulation on methane explosion propagation in a one-dimensional straight duct with porous metal materials. Comput. Model. New Technol. 2014, 18, 275–281. [Google Scholar]

- Wei, C.; Xu, M.; Wang, S. Experiment of porous materials for suppressing the gas explosion flame wave. J. China Univ. Min. Technol. 2013, 42, 206–213. [Google Scholar]

- Peng, R.; Wang, F. Effect of porous media on flame propagation velocity and pressure. Coal Technol. 2016, 35, 195–197. [Google Scholar] [CrossRef]

- Lin, B.Q. Mechanism and Control Technology for Gas Explosion in Coal Mines; China University of Science and Technology Press: Xuzhou, China, 2012. [Google Scholar]

- Jia, Z.; Ye, Q.; Yang, Z. Influence ofwall heat effect on gas explosion and its propagation. Processes 2023, 11, 1326. [Google Scholar] [CrossRef]

| Serial Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|

| Measuring point position (m) | 4.3 | 5.2 | 5.4 | 5.6 | 5.8 | 6.1 | 6.3 | 7.2 | |

| Layer number | 0 | 297.5 | 485.4 | 521.7 | 560.4 | 605.8 | 674.5 | 725.7 | 893.6 |

| 1 | 296.1 | 485.3 | 485.6 | 489.3 | 495.7 | 512.3 | 535.9 | 554.2 | |

| 2 | 296.1 | 483.3 | 471.2 | 452.6 | 415.2 | 386.3 | 371.8 | 300.5 | |

| 3 | 296.1 | 483.3 | 463.6 | 392.6 | 361.2 | 275.9 | 239.1 | 70.5 | |

| 4 | 296.1 | 480.3 | 451.1 | 385.9 | 352.9 | 266.2 | 234.8 | 61.8 | |

| 5 | 295.8 | 479.1 | 449.6 | 383.1 | 351.7 | 264.2 | 230.9 | 49.1 | |

| Serial Number | 1 | 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|---|---|

| Measuring point position (m) | 4.3 | 5.2 | 5.4 | 5.6 | 6.1 | 7.2 | |

| Layer number | 0 | 0.86 | 1.84 | 2.08 | 2.36 | 3.05 | 4.76 |

| 1 | 0.87 | 1.84 | 1.97 | 2.09 | 2.41 | 3.09 | |

| 2 | 0.87 | 1.81 | 1.82 | 1.75 | 1.36 | 0.92 | |

| 3 | 0.87 | 1.79 | 1.69 | 1.55 | 1.26 | 0.43 | |

| 4 | 0.87 | 1.77 | 1.62 | 1.49 | 1.08 | 0.35 | |

| 5 | 0.87 | 1.71 | 1.52 | 1.36 | 0.98 | 0.28 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, Z.; Ye, Q. Experimental Study on Gas Explosion Propagation in Porous Metal Materials. Processes 2023, 11, 2081. https://doi.org/10.3390/pr11072081

Jia Z, Ye Q. Experimental Study on Gas Explosion Propagation in Porous Metal Materials. Processes. 2023; 11(7):2081. https://doi.org/10.3390/pr11072081

Chicago/Turabian StyleJia, Zhenzhen, and Qing Ye. 2023. "Experimental Study on Gas Explosion Propagation in Porous Metal Materials" Processes 11, no. 7: 2081. https://doi.org/10.3390/pr11072081

APA StyleJia, Z., & Ye, Q. (2023). Experimental Study on Gas Explosion Propagation in Porous Metal Materials. Processes, 11(7), 2081. https://doi.org/10.3390/pr11072081