Abstract

Green chemistry faces a major challenge imposed by the Sustainable Development Goals (6, 14 and 15) defined in the 2030 Agenda. In the case of cleaning products (detergents), the challenges often become a paradox: even if it is biodegradable, no surfactant is harmless to aquatic life. Compared to other studies in the field, this paper covers ultrasound–detergent interactions beyond the cavitation removal process. It also considers synergistic effects with regard to the initial wetting phase and final rinsing. It concludes that the best detergent–ultrasound combination is that which minimises receding and critical sliding angles. At the same time, detergent concentration should be reduced so as to just to capture grease in micelles and avoid reattachment during rinsing. In combination with ultrasound, the concentration of eco-detergents can thus be reduced by up to 10% of their nominal value while attaining the same results.

1. Introduction

Within the framework of the Sustainable Development Goals (SDGs) set by the United Nations and the European Green Deal, the concept of “Safe and Sustainable by Design” (SSbD) is drawing the attention of the scientific community. The European Commission is working on the definitions of “safe” and “sustainable” for the design phase of a wide range of chemicals and materials [1]. In the search for a balance between economic, social and environmental sustainability, the following paradox arises: a chemical will never be safe and/or sustainable if its required physical or chemical properties are essentially harmful. Detergents are a case in point. Whether they are of biological or synthetic origin, they modify surface tension and/or the pH of water in applications such as cleaning and degreasing. Biosurfactants can reduce the surface tension in the same way as synthetic ones, but they biodegrade after a certain time. However, both pH and surface tension changes will always be environmentally harmful [2,3,4]. Aquatic life is sensitive to changes in the pH and surface tension of water, which affect oxygen-exchanging tissues such as the mucus of fish gills [5,6]. Current legislation limits the concentration of these substances in consumer products, so the trend is to develop detergents (eco-detergents) that replace them with less toxic or biodegradable substances. The most realistic alternative is based on the regulation and use of biodetergents that biodegrade in water after a certain time. However, it must be highlighted that until they do, many bio-detergents are still harmful substances [7,8].

The main components of eco-detergents include biosurfactants, enzymes and environmentally friendly solvents, such as water. Biosurfactants are amphiphilic compounds synthesised from plants and microorganisms [9]. In this sense, it is very hard to match the productivity, variety and price of synthetic products [10]. The combination of high-frequency sound (ultrasound) with eco-detergents, however, might provide a way out of this problem [11,12]. Ultrasound can help with physical cleaning principles (cavitation and physically forced wetting) while eco-detergents perform the chemical work (surfactancy and dissolution). This synergy may enable them to attain the same results as synthetic solutions without harming the environment, thus preserving life on land and below water (SDGs 15 and 14) and keeping water clean (SDG 6).

Ultrasonic cleaning is a well-known process based on acoustic cavitation. It has been studied by many authors, including Lauterborn [13,14,15] and Mason [16], who conclude that the size, number and distribution of bubbles depend mainly on the ultrasonic parameters (amplitude and frequency) and the liquid itself (volume, surface tension, density and viscosity). However, another physical phenomenon has been described by several authors [17,18,19,20]: the contact angle is changed when liquids are exposed to low and high frequency vibration. Manor et al. [21] describe a vibration driving force F [N] at megasonic frequency. They formulated Equation (1), where r [m] is the base radius of the droplet, ρ [kg·m−3] is the density, η [N·s·m−2] is the dynamic viscosity, f [Hz] is the frequency, a [m] is the amplitude and θ [rad] is the contact angle:

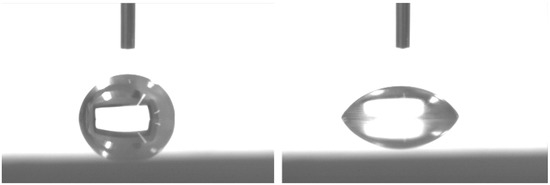

In a previous paper the same authors [19,22] demonstrate that the combination of ultrasonic vibration with contact angle hysteresis results in a non-return mechanism that expands the droplet (Figure 1) until half the acoustic energy introduced is consumed. The non-return mechanism is therefore related to the advancing, receding and critical sliding angles. The critical sliding angle is the minimum angle at which the droplet starts to slide. Once the droplet begins to slide, the advancing angle is the maximum stable contact angle and the receding angle is the minimum angle [23]. The critical sliding angle can be predicted by simulating droplet deformation and equilibrium under gravity forces that depend on the surface tension at each interface, the density and the volume of the droplet [24]. A perfect non-return mechanism is one in which the receding angle is 0 and the advancing angle is the same as the static contact angle.

Figure 1.

Ultrasonic expansion of a 5 µL water droplet [19]. The left image shows the initial state of the droplet. The right image shows its expansion after ultrasonic vibration is applied at 20 kHz.

At this point, instead of increasing wettability, the droplet is atomised. It is therefore a mechanical principle that forces the liquid to wet the surface without changing its chemical composition. The phenomenon is constrained by the atomisation amplitude threshold of each fluid.

Considering the wide variety of industrial dirt (oil, grease, carbon, aggregates, resins, etc.), it is very hard to reach the results, productivity and price of synthetic products via environmentally friendly detergents alone. At this point, the idea of combining high-frequency sound (ultrasound) with eco-detergents emerges as a potential solution. It must be taken into account that depending on the frequency and amplitude of vibration, ultrasonic cavitation can degrade the surfactant [24] in a process called sonolysis. However, rather than being a drawback, this could actually accelerate biodegradation after cleaning.

Finally, once all the dirt has been removed, there is a risk of reattachment if the cleaning solution is not properly removed, i.e., rinsed off. Detergents generate micelles that not only trap dirt but can also repel one another, thus preventing flocculation [25]. When micelles form in a cleaning solution containing surfactants above their critical micelle concentration (CMC), they can encapsulate hydrophobic particles or dirt and keep them suspended in the liquid [26]. This helps to prevent reattachment of dirt onto the cleaned surface [27]. Repulsion forces are especially useful during rinsing, due to the risk of reattachment [28]. However, it should be noted that the ability to prevent reattachment may depend on the nature of the dirt. In some cases, particularly with difficult surfaces, additional cleaning techniques, such as mechanical action or rinsing, may be necessary to ensure complete removal and prevent reattachment. The problem becomes critical during ultrasonic cleaning as ultrasonic cavitation can reduce the size of micelles and consequently increase their number [29]. Previous studies do not focus on this issue, but micelle formation and behaviour between solids have been studied by many authors [30,31]. Thus, for rinsing glass, its own electrical charge and that of the detergent (non-ionic/ionic/anionic) should be considered.

Recent studies have concluded that ultrasound in combination with eco-detergents theoretically has the potential to attain the same results as synthetic detergents. However, there is no specific study demonstrating the mechanisms behind this synergy. Addressing that gap is the main driver of the present study. The experiments reported here focus on the cleaning of tempered glass, which is widely used in the optics and electronics industry. An interesting example is the solar power sector, where energy efficiency depends directly on the reflectance or transmittance of the glass [32,33] and therefore on how clean it is. Most of the relevant literature focuses on the interaction between cavitation and surfactancy. The study reported here goes a step further by studying the ultrasound-detergent synergy in three fundamental cleaning steps:

- -

- Wetting: increased ultrasonic wettability for different detergent solutions;

- -

- Cleaning: removal of soluble (hydrocarbon) and nonsoluble (silicon) grease;

- -

- Rinsing: removal of the dirty solution by gravity alone.

2. Materials and Methods

Three ecological detergents are compared with a synthetic benchmark product that contains potassium hydroxide (Table 1). At high concentrations, the latter can be harmful, strongly irritating and corrosive, and its use can also be harmful to the environment. Even though it is necessary for certain cleaning processes, it would be preferable to minimise its use in favour of more environmentally friendly solutions, so this paper tests more sustainable and ecological solutions. All the ecological solutions considered have the EU Ecolabel. This is a voluntary label intended to promote products with a low environmental impact throughout their life cycle and to provide consumers with accurate, nondeceptive, science-based information on the environmental impact of products.

Table 1.

List of detergents tested.

The whole experimental procedure seeks to explore the synergy between eco-detergents and ultrasonic vibration, but the scope has been extended to address the synergy between synthetic products and even distilled water too. Physicochemical interaction is analysed from three different points of view:

- -

- Increased wettability: ultrasound increases wettability between phases, increasing the contact area and therefore the surface area covered. To that end, the chemical surfactancy and the mechanical increase in wettability for each solution are characterised. Considering the non-return mechanism, the sliding behaviour of each solution is also analysed.

- -

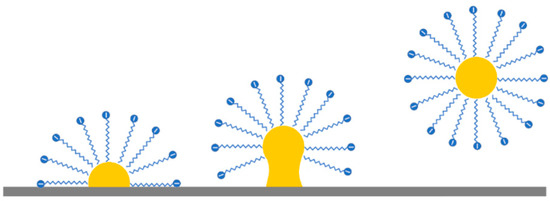

- Removal: ultrasonic cavitation accelerates the removal of dirt and its mechanical capture in micelles (Figure 2). Grease removal is measured by photographic techniques and image analysis. The method compares the effect of dissolution alone and the combination of a solution and ultrasonic cavitation.

- -

- Rinsing: once the grease is detached, it can reattach to the surface if the dirty solution is not rinsed off. The difference between using and not using detergents is studied during gravity-based rinsing.

Figure 2.

Dirt capture in the core of a micelle.

The experimental procedure is split into two aspects, in which different physical principles contribute to the same purpose.

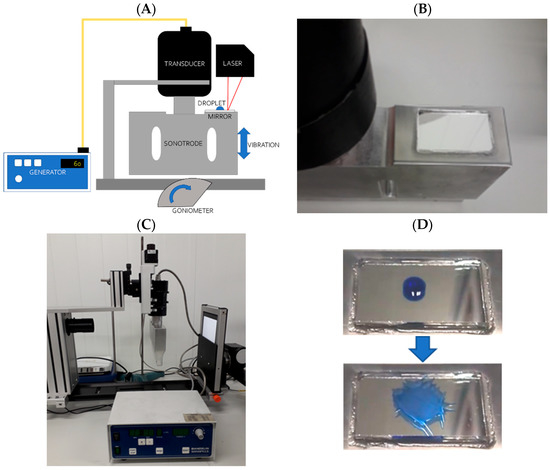

2.1. Wettability Enhancement

To assess the effects of ultrasound on a glass substrate, a 30 × 20 mm tempered glass specimen was bonded with acrylic glue to the upper side of a blade sonotrode. The sonotrode is a metal piece that resonates at 20 kHz in its axial direction. To make it resonate, it is mechanically attached to an ultrasonic transducer that receives an electrical signal from an ultrasonic generator. The generator and the transducer are part of a Bandelin Sonoplus HD 2200 20 kHz homogeniser. The power of the generator can be regulated from 0 to 100 Watts. The power-amplitude relationship of the system was measured with a Keyence LK-G82 triangulation laser (Figure 3). The dropping behaviour of the droplets is characterised by means of a goniometric platform and an Olympus TG400 high dynamic range camera. The critical sliding angle can be measured by increasing the inclination of the whole system degree by degree while the camera captures the beginning of the sliding.

Figure 3.

(A) Schematic view of the experimental set-up. (B) Tempered mirror sample glued to the back of the sonotrode. (C) Actual layout. (D) Example of expansion of the DD4116 reference under ultrasonic vibration.

None of the detergent solutions exceeded a contact angle of 10 degrees, so it was impossible to measure the contact angle. To study wettability behaviour, on the one hand surface tension γ [N/m] was measured via the Du Noüy ring test on a Kruss unit. On the other hand, contrasted photography techniques were applied to analyse droplet expansion under ultrasonic vibration.

2.2. Grease Removal

For the grease removal tests, the same mirror specimen attached to the sonotrode was impregnated with different greases and soiling conditions (Table 2).

Table 2.

List of grease references and impregnation methods.

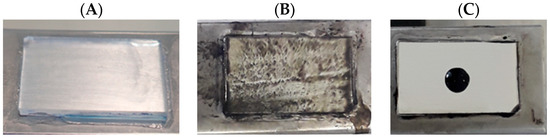

Two types of impregnation method where considered (Figure 4):

- -

- Homogeneous soiling: the grease was homogeneously distributed by drawing a glass microscope holder over the surface of the mirror. A 25 g weight was placed on the holder to ensure constant pressure on the grease during the spreading process.

- -

- Concentrated drop: 0.1 mL of grease was deposited on the surface of the mirror by means of a pipette.

The amount of grease eliminated (cleaning) was quantified using photographic contrast techniques with Matlab software. All the tests were performed for each detergent solution under the same ultrasonic power conditions (60%). Three aspects were compared individually:

- -

- Degreasing due to the inherent surfactant properties of the detergents;

- -

- Degreasing in combination with ultrasonic cavitation;

- -

- Rinsing after cleaning.

Figure 4.

Initial state of each type of grease: (A) silicon grease layer, (B) hydrocarbon grease layer, (C) hydrocarbon grease droplet.

Before and after the cleaning process, pictures of each sample were taken with an Olympus TG4 digital camera. For the silicon grease, a black background was used, and for the hydrocarbon grease, a white one was used. From each picture, the mirror area was trimmed and converted to grey scale. The results were analysed in Matlab R2020b software using image treatment tools. The contrast of the pictures was increased to 50%, so the cleaned surface ratio is the quotient of the black (hydrocarbon) or white (silicon) pixels by the total (whole surface).

2.3. Rinsing

Rinsing was performed by gravity by tilting the sample. The electric charge of the glass was meaured with a Benning MM 1–3 multimeter that measured the capacitance of the sample and its electric potential.

3. Results

3.1. Wettability Enhancement

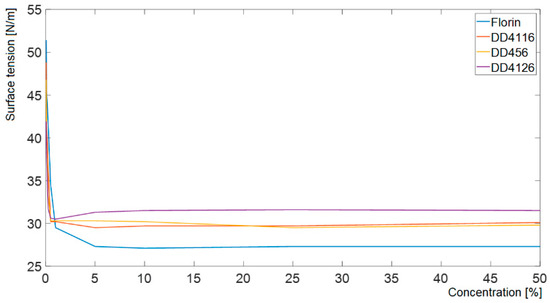

The critical micellar concentration (CMC) of each solution was quantified. Beyond this figure, the surface tension of any solution remains constant. Accordingly, the surface tension of each product was measured at different concentrations. For the concentrated products (Florin 700 and DD 4116), the manufacturer’s recommended concentration (nominal) was set as 25% of nominal in both cases. Table 3 and Figure 5 show the changes in the surface tension of each fluid as a function of its concentration level. All the measurements were repeated automatically 10 times. The equipment does not report results with a standard deviation over 0.1 N/m.

Table 3.

Surface tension of each solution reduced from 100% to 0.05% by volume. The threshold tension before CMC of each solution is underlined and bold.

Figure 5.

Surface tension for each solution below 10%.

The synthetic benchmark product Florin 700 diluted to 25% starts from a lower surface tension than the rest of the eco-detergents. However, it reaches its CMC at higher concentrations than the rest (around 5%). At concentrations lower than 1%, this behaviour is reversed, and the ecological products reach lower surface tensions than the benchmark product. This could be related to the chemical saponification process (potassium hydroxide + grease) of Florin 700.

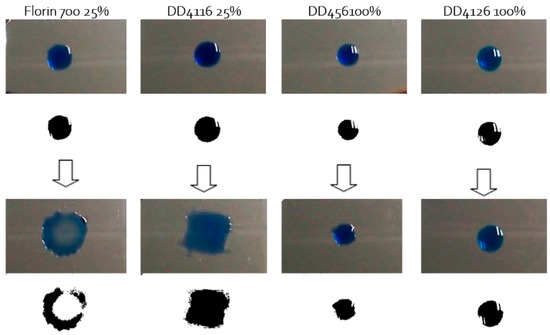

To assess the behaviour of each fluid in the face of ultrasonic vibration, 10 µL of each solution was deposited on a glass probe (Figure 6). The pictures were contrasted at 50% in black and white scale. For all four solutions, the following ultrasonic parameters were used:

- -

- 20 kHz frequency;

- -

- 60 W of power, equivalent to 3 µm of average amplitude (6 µm peak–peak);

- -

- 3 s of exposure.

Figure 6.

Droplets of the different products subjected to 3 s of ultrasonic vibration on a glass substrate. Each picture is contrasted at 50% in black and white scale.

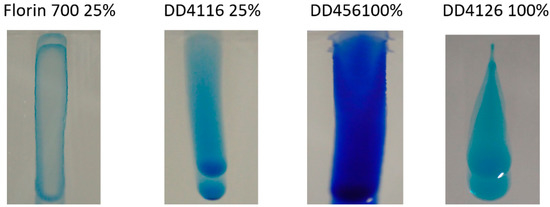

As can be observed, the benchmark product Florin 700 and the eco-detergent DD4116 show a clear tendency to increase their contact surface under ultrasonic vibration. The enzymatic solution DD456 forms capillary waves during exposure to vibration and increases its contact surface, but not sufficiently. Finally, the DD4126 solution does not visibly increase its surface area. According to their data sheets, all the products have dynamic viscosities between 1 and 5 cPs (similar to that of water), so the difference in their behaviour as regards expansion must be mainly due to differences in contact angle hysteresis. As demonstrated by the authors of this study, the difference between the advancing and receding angle can generate a non-return mechanism whereby the droplet expands but does not contract [19]. Due to the high wettability of the four products, it was not possible to measure either of these two angles, but only the critical angle of inclination and the shape of the sliding droplet. Table 4 shows the critical angle of inclination needed for a 5 µL drop of each product to start sliding. The experiment was repeated three times.

Table 4.

Minimum angle required for 5 µL of each solution to start sliding.

As can be seen, the enzymatic solution requires the greatest inclination (DD456 at 45°), and is therefore the one liable to present the greatest resistance to forming a new surface. It begins to slide at about 20° but stops in an intermediate metastable position until the table is tilted to 42°. This could be why the enzymatic solution shows the greatest deviation.

DD4126 starts sliding at a relatively low inclination angle (19°), but it is not altered by the effect of ultrasound. This apparent contradiction is explained by analysing the geometry of the droplet once it starts its descent. As shown in Figure 7, the sliding mechanism of DD4126 is completely different from that of the others. Instead of leaving a trace of wet surface, it slides cleanly. Considering the principle of the non-return mechanism, this fluid cannot expand its contact surface with ultrasonic vibration. Instead, the base of the droplet expands and contracts periodically, but always between the same maximum and minimum values. A perfect scenario would one in which the droplet would begin to slide at a very low inclination (very easy to expand) but would never detach, leaving a wet trace as the droplet advances. The surface stress on the air–fluid interface is quite similar for all the solutions, so behaviour at the solid–liquid interface should be the main factor behind the different sliding angles. Due to the low contact angles of all the fluids (below 10 degrees), it was not possible to characterise this behaviour physically.

Figure 7.

Droplets sliding on tilted mirror.

3.2. Grease Removal

The first grease removal tests focused on removing a complete layer of each grease (silicon- and hydrocarbon-based). To that end, the glass specimen was impregnated and exposed consecutively to the following:

- -

- 20 s of solution (without ultrasound) with a 1 mL detergent layer homogeneously distributed over the entire surface;

- -

- 20 s of ultrasonic vibration at 60 W.

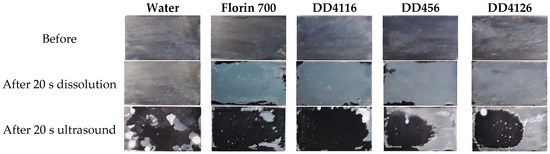

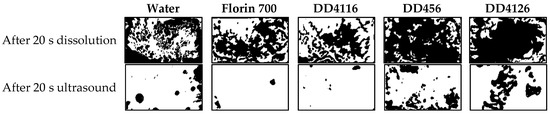

The comparison was made on contrasted photographs before and after cleaning with solution and ultrasound (Figure 8 and Figure 9).

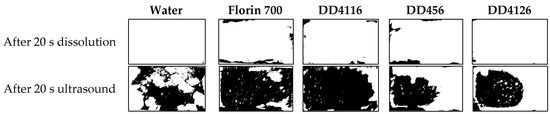

Figure 8.

Effect of each solution on silicone grease with and without ultrasound. The silicon grease is white, and the background is black.

Figure 9.

Contrasted images at 50% for each solution. A total of 20 s of dissolution and 20 s of ultrasound on silicon grease. White shows the remaining grease, and the black background is clean.

Using Matlab R2020b software, the percentages of black (clean) and white (dirty) pixels were determined. Thus, the proportion of surface area cleaned was calculated via the reflection of the mirror on a black background (Table 5). The analysis software reduces the image resolution from 3000 × 4200 pixels to 91 × 151 pixels. This merging induces a 10.9% reduction in the precision of the surface measurement results.

Table 5.

Proportion of surface area cleaned [%] with and without ultrasound.

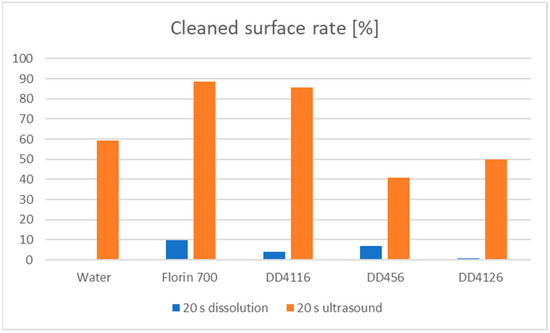

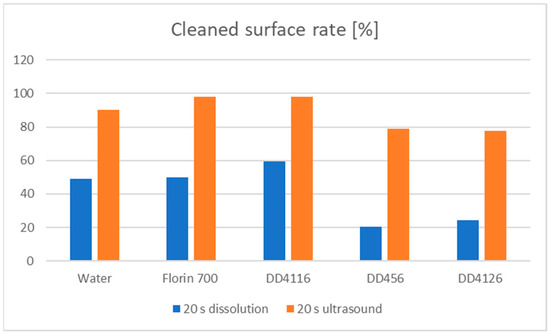

As shown in Figure 10, the cavitation effect predominates over the solubility of the surfactants. Detergents are not effective at removing silicon grease without ultrasound. The Florin 700 benchmark product shows the highest degreasing power but cleans less than 10% of the surface area. This could be because all four products are formulated to clean vegetable or mineral grease (hydrocarbons) and not silicon.

Figure 10.

Proportion of surface area cleaned [%] ultrasonically and non-ultrasonically.

When ultrasonic vibration is activated, all the solutions (even water) remove a large proportion of the silicon grease. Again, the two products with the highest ultrasonic wettability enhancement (Florin 700 and DD4116) are also the best at removing grease, at 88.6 and 85.7%, respectively. It can therefore be concluded that the dynamic wettability between the substrate and the fluid is a critical factor in determining the effectiveness of the synergy between detergents and ultrasound. Thus, cavitation seems to start removing silicon grease partially, starting from the centre of the sample where the ultrasound is concentrated. Once the fluid contacts the glass substrate, the non-return mechanism probably helps to detach the grease through shear forces on the bottom of the silicon layer. This can be observed especially in the poor cleaning results (DD456 and DD4126), in which the cleaning does not cover the whole surface. It begins in the centre of the mirror and expands radially (Figure 8).

Even water, with a higher surface tension, was able to clean up to 59.3%, which is more than the two products whose wettability does not change with ultrasound (DD456 and DD4126). If the cleaning is mainly caused by cavitation and increased wettability, the concentrated detergent DD4114 would be the best compromise between sustainability and efficiency for nonmiscible applications such as silicon grease.

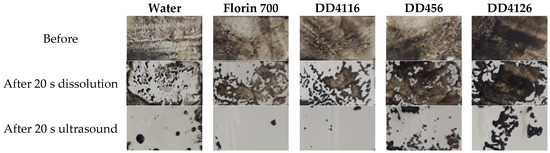

As for the following sample, all detergent references are designed to clean hydrocarbon-based grease. Due to the transparency of the burnt grease, it was necessary to dry the test specimens with a manual dryer before characterising them. Apart from this, the test protocol was exactly the same as that applied to silicone grease. However, the background colour was changed from black to white, since silicone grease is white but burnt hydrocarbon grease is black (Figure 11). The colours in the contrasted photograph are thus reversed, with the dirty area being black and the clean area being white (Figure 12).

Figure 11.

Effect of each solution on hydrocarbon grease with and without ultrasound. The hydrocarbon grease is black, and the background is white.

Figure 12.

Contrasted images at 50% for each solution. A total of 20 s of dissolution and 20 s of ultrasound on hydrocarbon grease. The hydrocarbon grease is black, and the background is white.

Quantitatively (see Table 6 and Figure 13), all the solutions, including water, can eliminate part of the grease by dissolution and/or flotation over 20.6%. In turn, there is a clear improvement after the application of ultrasound in all cases, with 77.7% elimination in the worst case (DD4126). The solutions whose wettability increases with ultrasound (DD456 and DD4126) are the ones that show the worst dissolution capabilities at 20.6% and 24.5%, respectively. In this case, all the detergent solutions wet the grease, so the radial detaching found in the case of silicon is not observed. All the detergent solutions remove all or part of the grease without the help of the ultrasonic wetting mechanism.

Table 6.

Proportion of surface area cleaned [%] with and without ultrasound.

Figure 13.

Proportion of surface area cleaned [%] ultrasonically and non-ultrasonically.

The case of distilled water is of particular interest. The results for water (90.4%) are very similar to those obtained with Florin 700 and DD4116 detergent, but water alone only drags the grease, generating large clusters that remain adhered to the surface after rinsing. Although apparently small, those clusters are spherical and voluminous. An important conclusion is that surfactants are required to prevent the grease from reattaching during rinsing.

In this regard, hydrocarbon-based grease removal calls for a different approach from silicon grease. It requires a combination of water and detergents, but with the minimum concentration of detergent to maintain the surface tension of the water after it comes into contact with the grease.

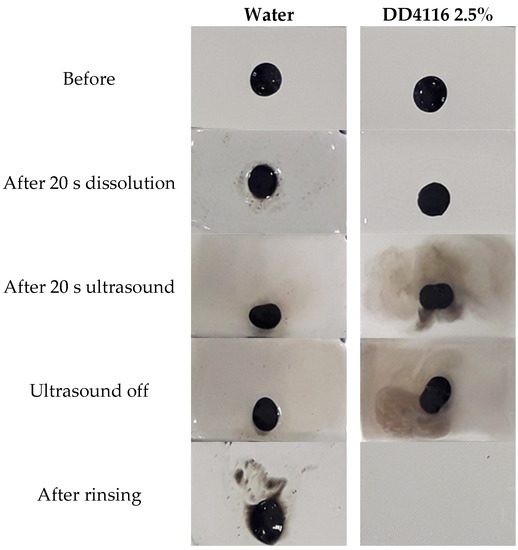

3.3. Rinsing

The combination of water and ultrasound (i.e., cavitation) seems to be the main grease removal mechanism, but it is not sufficient, as reattachment might occur. Therefore, a minimum concentration of detergent is needed during rinsing. To validate this principle and study the contribution of each cleaning mechanism to hydrocarbon grease removal, we studied the cleaning of a 0.1 mL drop of hydrocarbon grease. The 25% solution for reference DD4116 was diluted to 10%, resulting in a concentration of 2.5%. A sequence of dissolution (20 s), sonication (20 s) and gravity rinsing was applied (Figure 14).

Figure 14.

Sequence of removal of a 0.1 mL grease droplet in water and in a 2.5% solution of DD4116. A total of 20 s of ultrasound exposure is applied.

As expected, the main contributor to the removal of built-up grease is ultrasound. Both fluids can remove part of the grease, but the accumulation of degraded agents, such as carbon, means that the dissolution effect is limited to the interface between media. Ultrasonic cavitation increases the contact surface area, so a higher dissolution rata is observed in both cases. However, the main cleaning mechanism is mechanical detachment and displacement of the grease droplet on the glass surface. In both cases, the grease is lifted and displaced. This may be related to the increased wettability between media induced by ultrasonic vibration. Both water and DD4116 show high wettability on glass, while grease does not. When vibration is activated, both fluids are introduced at the base of the grease droplet, detaching it and in turn keeping it in suspension in a single cluster. The difference between the two fluids occurs when vibration is deactivated and the surface is rinsed (Figure 15). The polar molecules of the detergent adhere to the surface of the grease droplet, so that once detached, it does not reattach. Distilled water alone is not capable of generating such an effect; as soon as the vibration is deactivated, the drop falls, wets the substrate and cannot be rinsed by gravity.

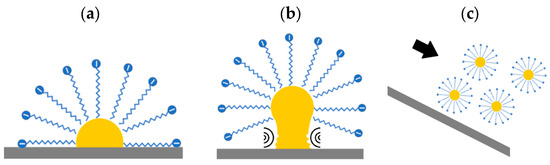

Figure 15.

(a) Polar molecules covering grease droplet. (b) Ultrasonic grease detachment. (c) Rinsing of grease droplets trapped in micelles.

No measurable electric charge is detected on the mirror surface even after rubbing (Table 7).

Table 7.

Electric capacitance, potential and charge of the mirror sample.

Therefore, the most suitable detergent for rinsing should be based on non-ionic surfactants, which, in this case, means the DD4116 ecological product tested.

4. Conclusions

This study reports on the synergy between eco-detergents and ultrasound, seeking to attain the same dirt removal rates as synthetic products but in a more sustainable way. The main conclusions of the study are the following:

- -

- All four detergent references studied reduce the surface tension of distilled water to similar values. However, the dynamic behaviour of each detergent with respect to ultrasound is very different, and sliding behaviour qualitatively coincides with it. Thus, it is the fluids with the highest wetting rate in the face of ultrasound (Florin 700 and ecological product DD4116) that require the smallest angle of inclination to initiate rolling and wet the surface while sliding. This is consistent with the basis of the non-return mechanism.

- -

- In the case of silicon grease, the main elimination principle is mechanical cavitation. The two substances with the best ultrasonic behaviour are, in order, the benchmark product Florin 700 (DD4116) and distilled water. Ultrasonic enhanced wetting helps cavitation to remove silicon grease through shearing forces.

- -

- The same behaviour is found in the case of hydrocarbon grease, but the enhanced wetting effect is not so evident compared to silicon grease.

- -

- Although ultrasound is the main grease removal mechanism, during gravity rinsing, there is a risk of reattachment of the surface. It is therefore necessary to use a detergent that prevents grease from reattaching.

- -

- The optimum solution is to dilute the minimum amount of DD4116 in water. In this way, cavitation and wettability are enhanced, but grease is prevented from re-adhering during rinsing. For this purpose, the concentration can be up to 10 times lower than that recommended by the manufacturer. This figure varies depending on the amount and type of grease present in the substrate.

- -

- With the proper formulation, eco-detergents combined with ultrasound can give better results than synthetic solutions.

Author Contributions

Conceptualisation, J.L.V.V., E.A.B., J.A.S.M. and L.R.R.; methodology, J.A.S.M.; validation, A.T.C., F.B.M. and J.K.I.G.; formal analysis, J.A.S.M., E.A.B., L.R.R.; investigation, J.A.S.M., A.T.C., F.B.M. and J.K.I.G.; writing—original draft preparation, J.A.S.M.; writing—review and editing, E.A.B. and L.R.R.; supervision, L.R.R.; project administration, J.A.S.M.; funding acquisition, J.A.S.M. All authors have read and agreed to the published version of the manuscript.

Funding

The projects leading to this research have received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreements No. 654479 WASCOP and No. 792103 SOLWARIS.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rauscher, H.; Rasmussen, K.; Riego Sintes, J.; Sala, S. Safe and Sustainable by Design Chemicals and Materials; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- Ivanković, T.; Hrenović, J. Surfactants in the Environment. Arch. Ind. Hyg. Toxicol. 2010, 61, 95–110. [Google Scholar] [CrossRef]

- Chowdhury, S.; Rakshit, A.; Acharjee, A.; Saha, B. Biodegradability and Biocompatibility: Advancements in Synthetic Surfactants. J. Mol. Liq. 2021, 324, 115105. [Google Scholar] [CrossRef]

- Chamanfar, A.; Monajati, H.; Rosenbaum, A.; Jahazi, M.; Bonakdar, A.; Morin, E. Microstructure and Mechanical Properties of Surface and Subsurface Layers in Broached and Shot-Peened Inconel-718 Gas Turbine Disc Fir-Trees. Mater. Charact. 2017, 132, 53–68. [Google Scholar] [CrossRef]

- Yi, X.; Wei, Y.; Zhai, W.; Wang, P.; Liu, D.; Zhou, Z. Effects of Three Surfactants on the Degradation and Environmental Risk of Metolachlor in Aquatic Environment. Chemosphere 2022, 300, 134295. [Google Scholar] [CrossRef]

- Kierkegaard, A.; Sundbom, M.; Yuan, B.; Armitage, J.M.; Arnot, J.A.; Droge, S.T.J.; McLachlan, M.S. Bioconcentration of Several Series of Cationic Surfactants in Rainbow Trout. Environ. Sci. Technol. 2021, 55, 8888–8897. [Google Scholar] [CrossRef] [PubMed]

- Rafi, S.; Ravikanth, S.; Basha, D.; Shaik, M.; Rao, K. Impact of detergent toxicity on energy metabolism in liver and gill of the fish channa punctatus. Trends Fish. Res. 2020, 9, 1–6. [Google Scholar]

- Azuokwu, A.A.; Yerima, Y.; Azike, R.U. Production and Performance Evaluation of Biodetergents as an Alternative to Conventional Drilling Detergent. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 2–4 August 2021. [Google Scholar]

- Pott, R.W.M.; Von Johannides, J. Process Development in Biosurfactant Production. In Biosurfactants for the Biobased Economy; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Akbari, S.; Abdurahman, N.H.; Yunus, R.M.; Fayaz, F.; Alara, O.R. Biosurfactants—A New Frontier for Social and Environmental Safety: A Mini Review. Biotechnol. Res. Innov. 2018, 2, 81–90. [Google Scholar] [CrossRef]

- Inui, A.; Honda, A.; Yamanaka, S.; Ikeno, T.; Yamamoto, K. Effect of Ultrasonic Frequency and Surfactant Addition on Microcapsule Destruction. Ultrason. Sonochem. 2021, 70, 105308. [Google Scholar] [CrossRef] [PubMed]

- Javed, M.; Belwal, T.; Ruyuan, Z.; Xu, Y.; Li, L.; Luo, Z. Optimization and Mechanism of Phytochemicals Extraction from Camellia Oleifera Shells Using Novel Biosurfactant Nanobubbles Solution Coupled with Ultrasonication. Food Bioprocess Technol. 2022, 15, 1101–1114. [Google Scholar] [CrossRef]

- Lauterborn, W.; Kurz, T.; Mettin, R.; Ohl, C.D. Experimental and Theoretical Bubble Dynamics. Adv. Chem. Phys. 1999, 110, 295–380. [Google Scholar]

- Lauterborn, W.; Kurz, T.; Geisler, R.; Schanz, D.; Lindau, O. Acoustic Cavitation, Bubble Dynamics and Sonoluminescence. Ultrason. Sonochem. 2007, 14, 484–491. [Google Scholar] [CrossRef]

- Tervo, J.T.; Mettin, R.; Lauterborn, W. Bubble Cluster Dynamics in Acoustic Cavitation. Acta Acust. United Acust. 2006, 92, 178–180. [Google Scholar]

- Mason, T.J. Ultrasonic Cleaning: An Historical Perspective. Ultrason. Sonochem. 2016, 29, 519–523. [Google Scholar] [CrossRef]

- Trapuzzano, M.A. Controlled Wetting Using Ultrasonic Vibration. Doctoral Dissertation, University of South Florida, Tampa, FL, USA, 2019. [Google Scholar]

- Vukasinovic, B.; Smith, M.K.; Glezer, A. Dynamics of a Sessile Drop in Forced Vibration. J. Fluid Mech. 2007, 587, 395. [Google Scholar] [CrossRef]

- Sarasua, J.A.; Ruiz, L.; Aranzabe, E.; Vilas, J.L. Energetic Study of Ultrasonic Wettability Enhancement. Ultrason. Sonochemistry 2021, 79, 105768. [Google Scholar] [CrossRef]

- Trapuzzano, M.; Tejada-Martínez, A.; Guldiken, R.; Crane, N. Volume and Frequency-Independent Spreading of Droplets Driven by Ultrasonic Surface Vibration. Fluids 2020, 5, 18. [Google Scholar] [CrossRef]

- Manor, O.; Dentry, M.; Friend, J.R.; Yeo, L.Y. Substrate Dependent Drop Deformation and Wetting under High Frequency Vibration. Soft Matter 2011, 7, 7976–7979. [Google Scholar] [CrossRef]

- Sarasua Miranda, J.A.; Ruiz-Rubio, L.; Aranzabe Basterrechea, E.; Vilas-Vilela, J.L. Non-Immersion Ultrasonic Cleaning: An Efficient Green Process for Large Surfaces with Low Water Consumption. Processes 2021, 9, 585. [Google Scholar] [CrossRef]

- ElSherbini, A.I.; Jacobi, A.M. Liquid Drops on Vertical and Inclined Surfaces: I. An Experimental Study of Drop Geometry. J. Colloid Interface Sci. 2004, 273, 556–565. [Google Scholar] [CrossRef] [PubMed]

- Nanzai, B.; Suzuki, S.; Okitsu, K. Sonochemical Degradation of Surfactants with Different Charge Types: Effect of the Critical Micelle Concentration in the Interfacial Region of the Cavity. Ultrason. Sonochem. 2021, 71, 105354. [Google Scholar] [CrossRef] [PubMed]

- Rosen, M.J.; Kunjappu, J.T. Micelle Formation by Surfactants. In Surfactants and Interfacial Phenomena; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 123–201. [Google Scholar]

- Shaeiwitz, J.; Chan, A.-C.; Cussler, E.; Evans, D. The Mechanism of Solubilization in Detergent Solutions. J. Colloid Interface Sci. 1981, 84, 47–56. [Google Scholar] [CrossRef]

- Nik Him, N.R.; Hidzir, S.N.M.; Wan Hassan, W.H. Application of CMC from Oil Palm Biomass as Anti-Redeposition Agent in Laundry Detergent. Key Eng. Mater. 2019, 797, 224–229. [Google Scholar] [CrossRef]

- Thompson, C.J.; Ainger, N.; Starck, P.; Mykhaylyk, O.O.; Ryan, A.J. Shampoo Science: A Review of the Physiochemical Processes behind the Function of a Shampoo. Macromol. Chem. Phys. 2023, 224, 2200420. [Google Scholar] [CrossRef]

- Yusof, N.S.M.; Ashokkumar, M. Ultrasonic Transformation of Micelle Structures: Effect of Frequency and Power. Ultrason. Sonochem. 2015, 24, 8–12. [Google Scholar] [CrossRef]

- James, G.K.; Walz, J.Y. Experimental and Theoretical Investigation of the Depletion and Structural Forces Produced by Ionic Micelles. Colloids Surfaces A Physicochem. Eng. Asp. 2014, 441, 406–419. [Google Scholar] [CrossRef]

- Chen, A.; Li, S.-W.; Jing, D.; Xu, J.-H. Interactions between Colliding Oil Drops Coated with Non-Ionic Surfactant Determined Using Optical Tweezers. Chem. Eng. Sci. 2019, 193, 276–281. [Google Scholar] [CrossRef]

- Toth, S.; Muller, M.; Miller, D.C.; Moutinho, H.; To, B.; Micheli, L.; Linger, J.; Engtrakul, C.; Einhorn, A.; Simpson, L. Soiling and Cleaning: Initial Observations from 5-Year Photovoltaic Glass Coating Durability Study. Sol. Energy Mater. Sol. Cells 2018, 185, 375–384. [Google Scholar] [CrossRef]

- Sarasua, J.A.; Sandá, A.; Arguelles-Arizcun, D.; Fernández-García, A. Integration of a Non-Immersion Ultrasonic Cleaning System in a Solar Concentrating Field. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2019; Volume 2126, p. 30050. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).