A Novel Pattern Recognition based Kick Detection Method for Offshore Drilling Gas Kick and Overflow Diagnosis

Abstract

1. Introduction

2. The Basic Overflow Pattern

- (1)

- Reduces the number of false alarms. The use of a threshold value alone cannot distinguish excess events from similar events.

- (2)

- Significantly decreases the dependence on the accuracy of calculation software. To achieve high calculation accuracy, it is necessary to precisely describe the physical processes and calculation parameters, and even a minor deviation can result in significant errors, which is frequently challenging in deepwater drilling environments. For instance, when the friction coefficient is 0.001 and 0.0011, the calculated value of the bottom hole pressure will result in significant errors, but the influence of the changing trend of the calculated value of the bottom hole pressure can be neglected.

- (3)

- Other stratigraphic information can be retrieved. For example, the increment pressure and mud pool increment trend can be utilized to retrieve formation pressure data. The gas invasion process is like the unstable well test process. Therefore, stratigraphic information can be represented based on the change in gas invasion response parameters (standpipe pressure (SPP), outlet flow rate, mud pool increment, etc.), thus realizing stratigraphic information inversion before shut-in, which plays an important role in the density design of kill fluid.

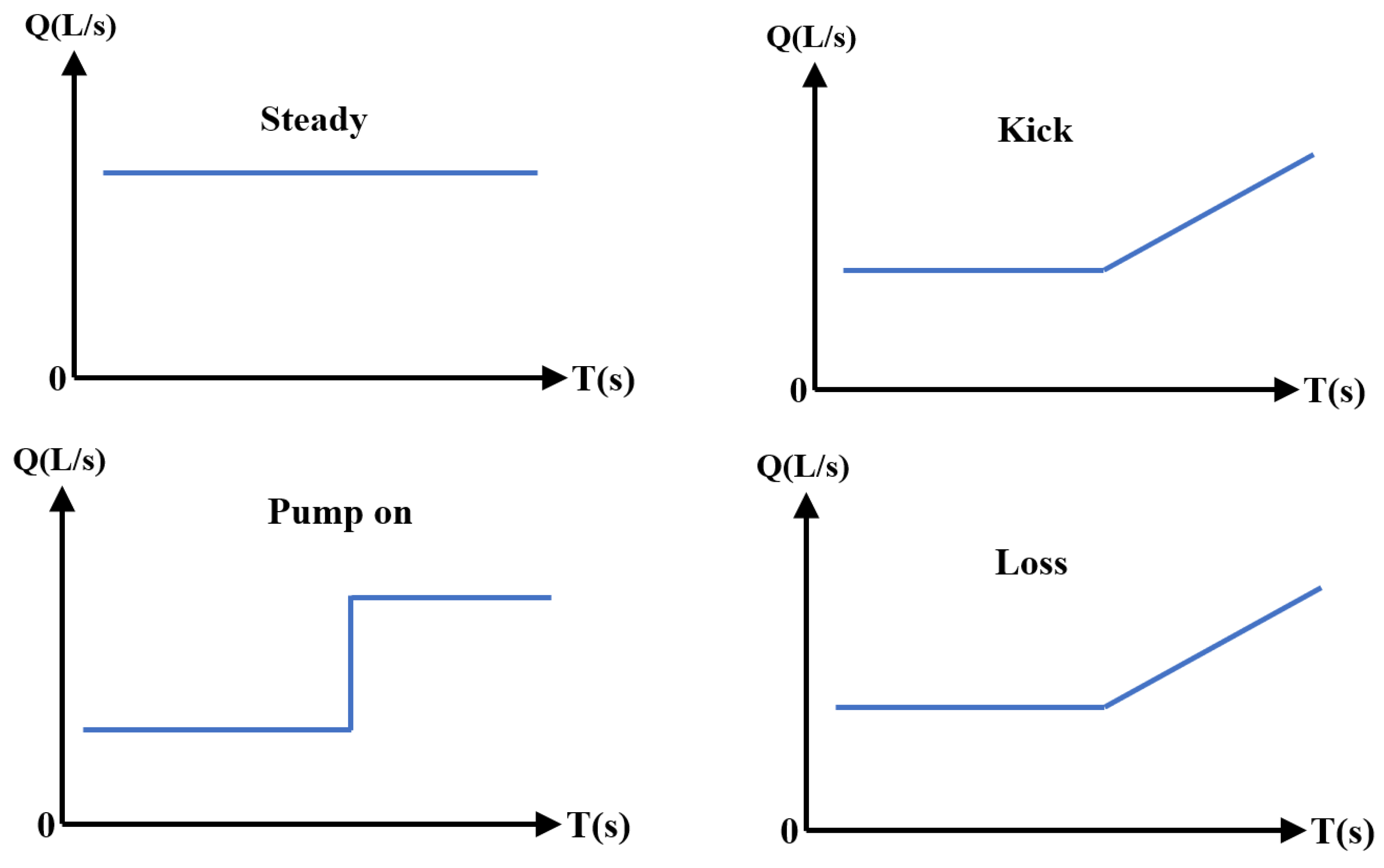

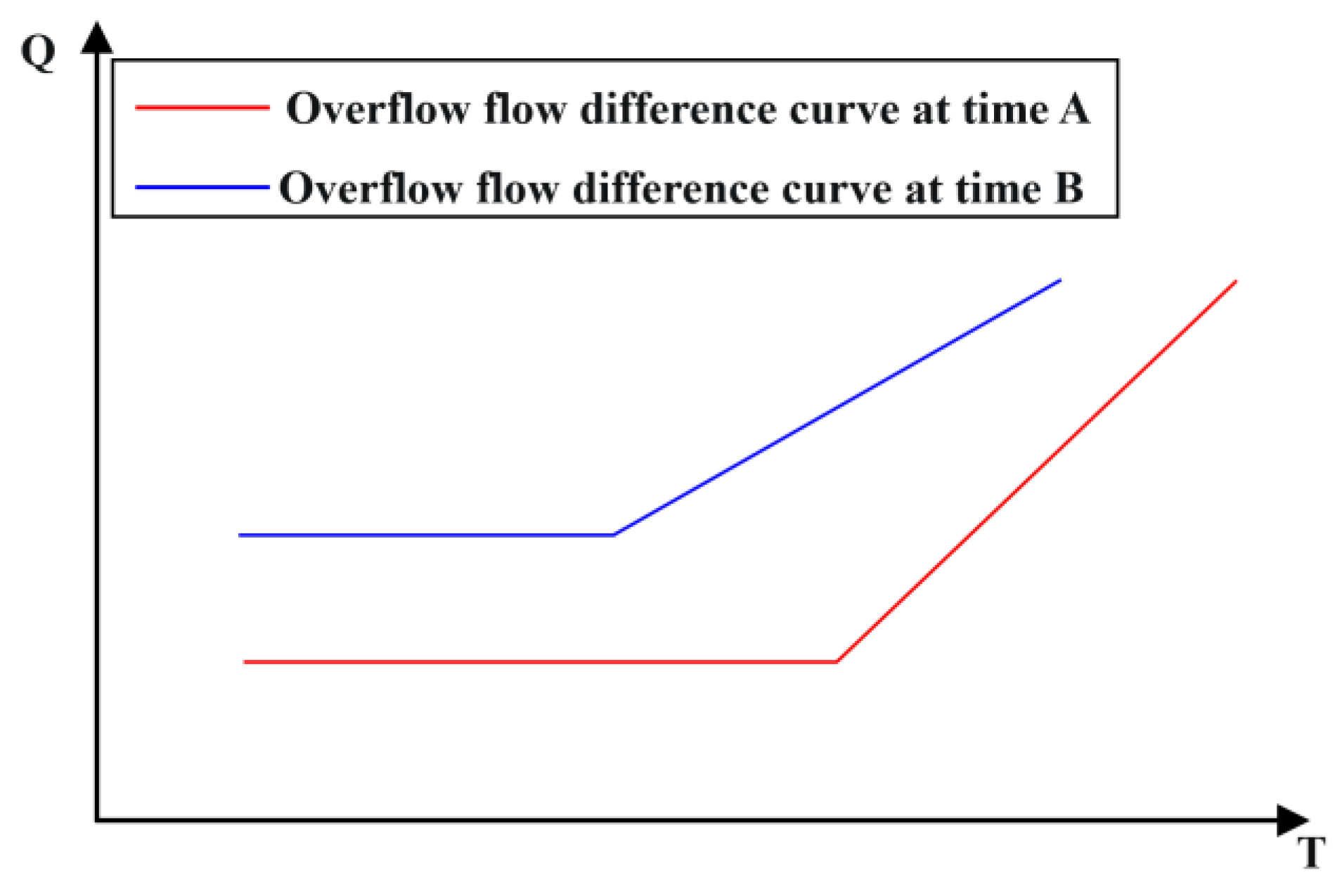

- (1)

- Flow rate differential

- ①

- Steady State: the flow rate differential remains within a relatively stable range, indicating a balanced flow of drilling fluid entering the wellbore and returning to the surface.

- ②

- Kick State: the flow rate differential increases as a larger volume of gas returns to the surface through the wellbore.

- ③

- Pump on State: the flow rate differential increases as a large volume of mud is injected into the wellbore.

- ④

- Loss State: the flow rate differential decreases as some drilling fluids are absorbed or leaked into the formation.

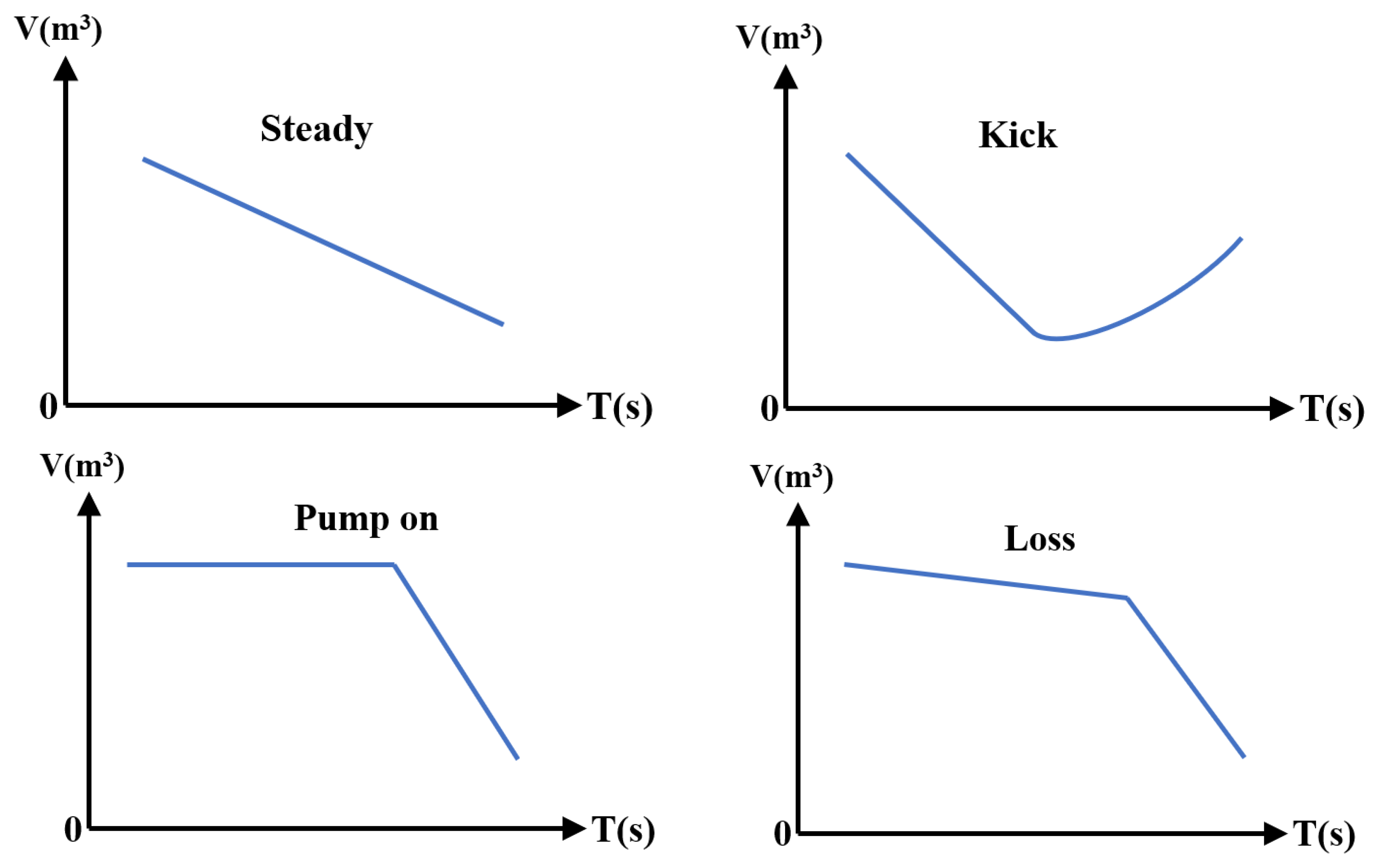

- (2)

- Mud Pit Increment

- ①

- Steady State: The mud pit increment is maintained within an appropriate range to replenish the drilling fluid consumed during the drilling process. Without mud replenishment, the mud pit increment will decrease as drilling fluid is consumed.

- ②

- Kick State: the mud pit increment increases to compensate for the decrease in mud volume due to gas invasion

- ③

- Pump on State: the mud pit increment decreases to accommodate the additional mud volume pumped into the wellbore.

- ④

- Loss State: the mud pit increment decreases to compensate for the lost drilling fluid.

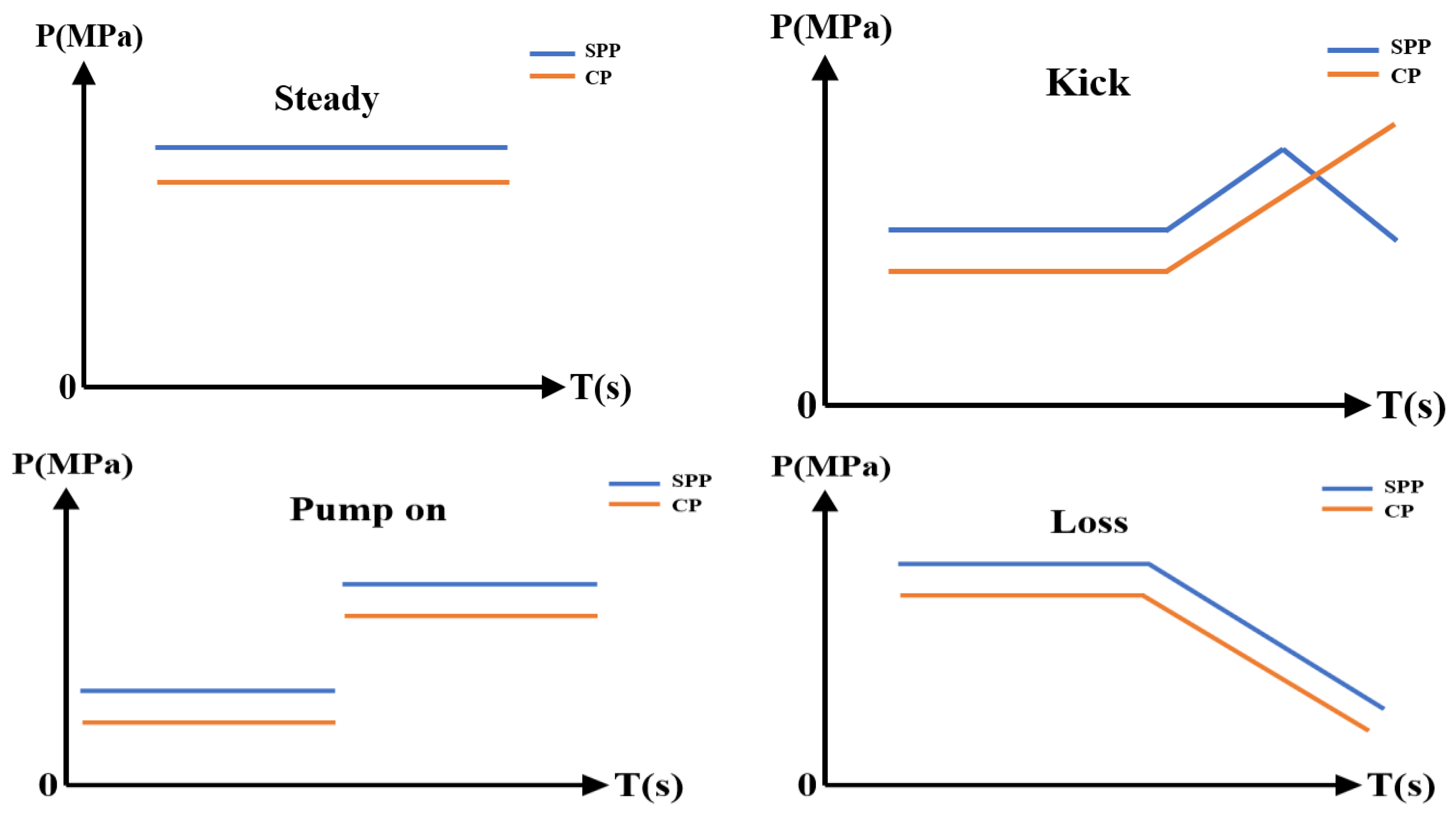

- (3)

- Casing Pressure (CP) and Standpipe Pressure (SPP) Changes

- ①

- Steady State: casing pressure and standpipe pressure changes are minimal, indicating no abnormal influx or pressure variations.

- ②

- Kick State: CP and SPP changes increase due to the added pressure from gas influx. As well control measures are implemented, the SPP is expected to decrease, while the CP is expected to further increase.

- ③

- Pump on State: CP and SPP changes may increase instantaneously as the wellbore pressure rises due to the large volume of mud injection.

- ④

- Loss State: CP and SPP changes decrease due to the pressure loss in the wellbore caused by losses.

- (4)

- Rate of Penetration (ROP) Changes

- ①

- Steady State: the ROP remains relatively stable, ensuring good drilling progress.

- ②

- Kick State: If the density of the drilling fluid is not adjusted promptly when gas kick, it can lead to a decrease in the bottom hole pressure compared to the formation pressure or a reduction in the positive pressure difference between the bottom hole pressure and formation pressure, resulting in an increase in the ROP.

- ③

- Pump on State: When pump on operations begin, the increased flow rate of drilling fluid circulating through the drill string can enhance the hydraulic horsepower at the bit. This can result in an increased bit penetration rate and, therefore, an accelerated ROP.

- ④

- Loss State: When drilling fluid is lost to the formation, it reduces the hydrostatic pressure exerted by the drilling fluid column. As a result, the effective weight on the bit decreases, leading to a decrease in the ROP.

3. The Principle of Data Processing and Filtering

4. Pattern Recognition Representation Methods

4.1. Pattern Classification

4.2. Optimal Matching Algorithm

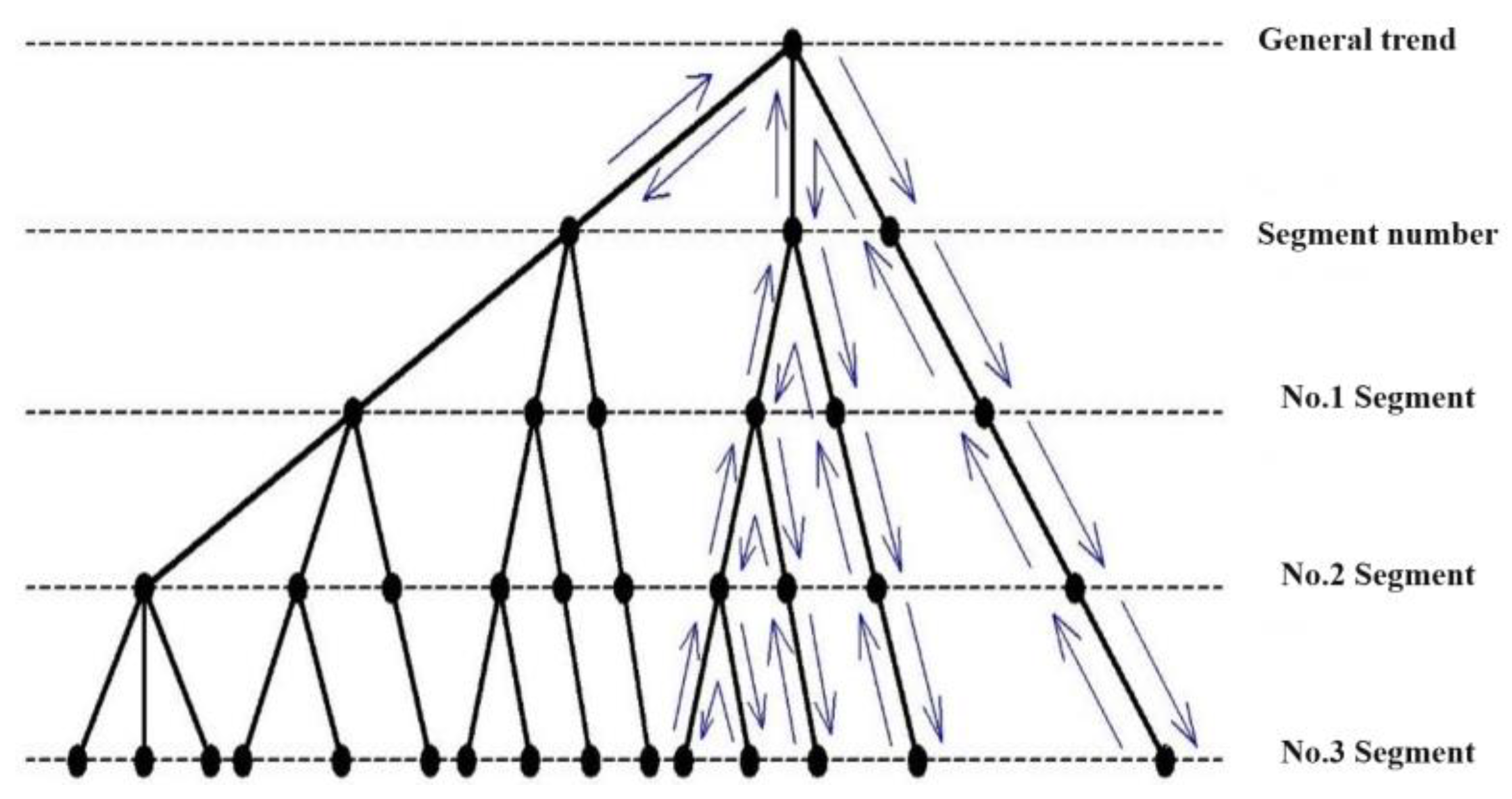

- (1)

- The root node is all features (level 0), one feature is discarded on each node, and each leaf node represents a variety of selection combinations. In the PRKD method, the first-level leaf node is the segment number, the second-level leaf node is the curve information of each segment, and so on, as shown in Figure 8.

- (2)

- Record the maximum criterion function value of the currently searched leaf nodes and set the initial value to 0 in order to avoid the same combination of branches and leaves in the entire tree. In the PRKD method, the matching degree of each combination must be recorded.

- (3)

- P is defined as the value of the real-time matching degree. At each level, the feature that is least likely to be discarded is placed on the leftmost side, and the search starts from the right side. In the PRKD method, from left to right, each leaf node is xi, K, the change in K, and function value.

- (4)

- If the left level of the abandoned feature is not below this node, search for the leaf node, update the value of Pmax, and then go back to the previous branch.

- (5)

- If P < Pmax on the node, then do not search down, but instead retrace upwards. Each retrace will put back the abandoned feature (put it back on the list to be discarded). If the process has retraced to the top (root) and cannot search further down, then the leaf node of P = Pmax is the solution.

4.3. Measures of Pattern Matching Degree

5. Bayesian Framework

- (1)

- Prior information: Kick prior probability is the kick probability derived from the uncertain profile of formation pressure. Prior probabilities for other events, such as state events and pump on events, can be obtained from statistics. If the prior information of each parameter is missing, its influence is neglected.

- (2)

- Likelihood function: the similarity measure between kick characteristic data and the basic model of overflow, which is obtained by multiplying the PRKD model results with the weight vector of overflow characteristic parameters.

- (3)

- Posteriori probability: posteriori probability is proportional to the product of prior probability and the likelihood function, and can be obtained by normalization on this basis.

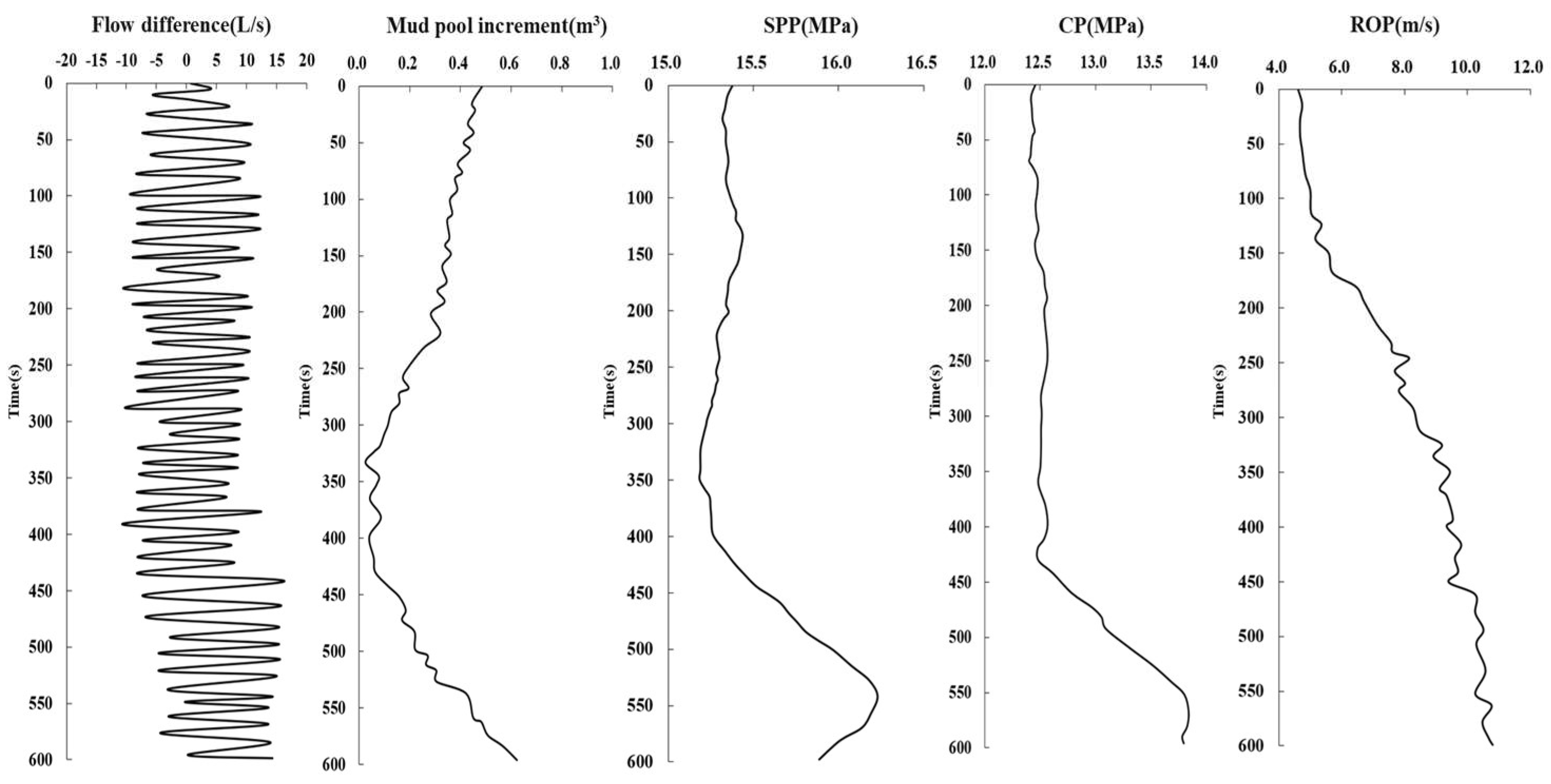

6. Case Analysis

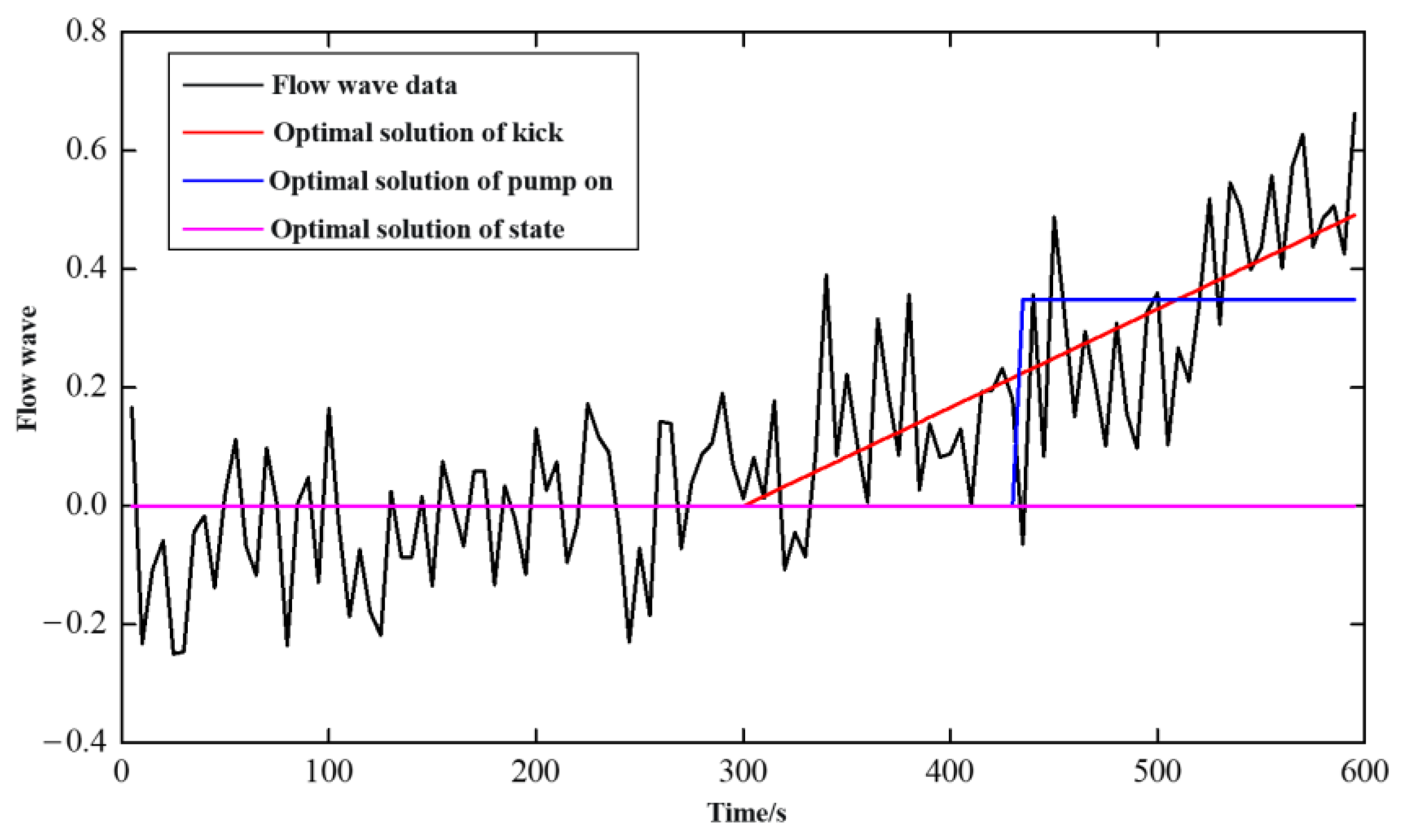

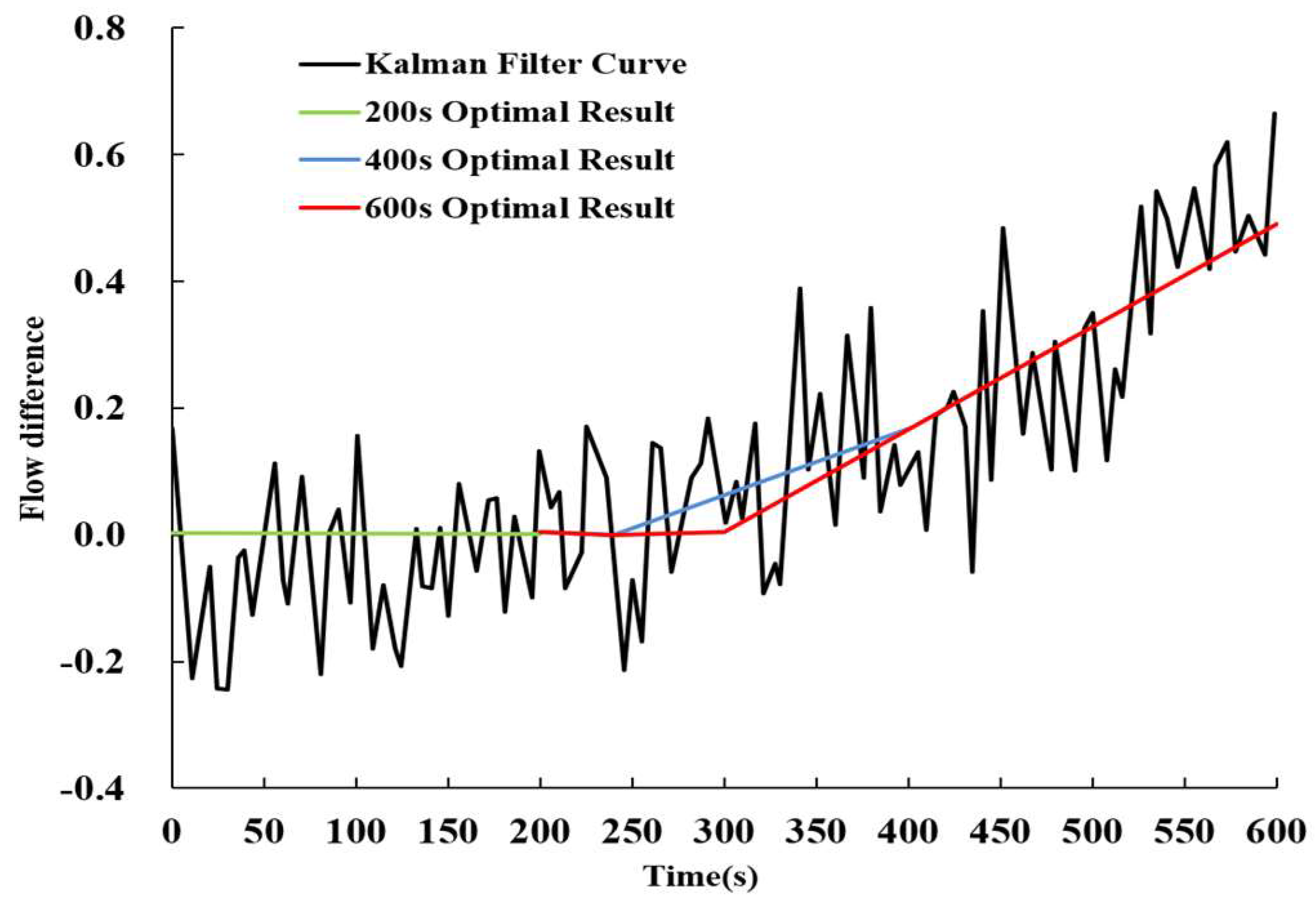

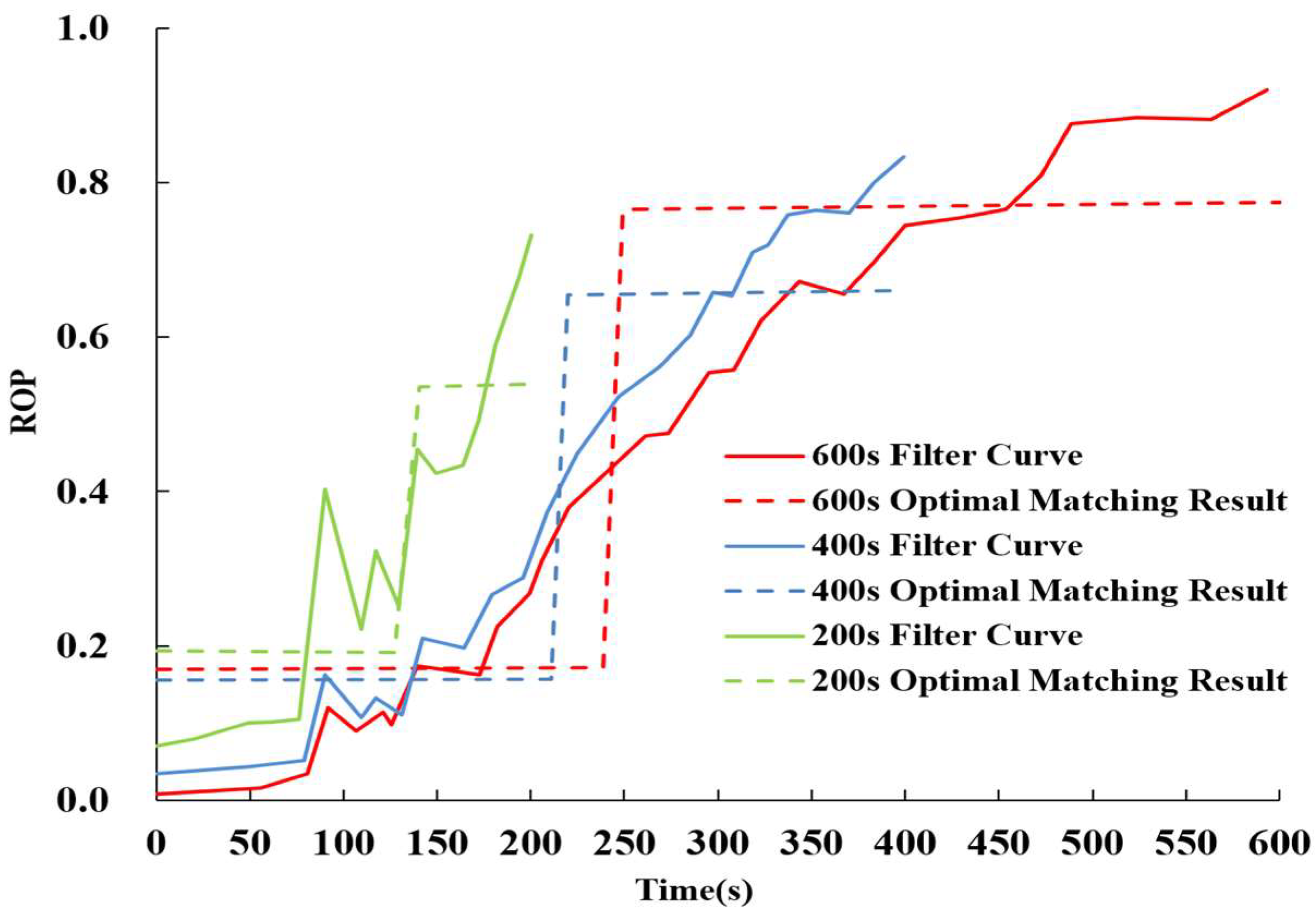

6.1. Basic Pattern Matching Results

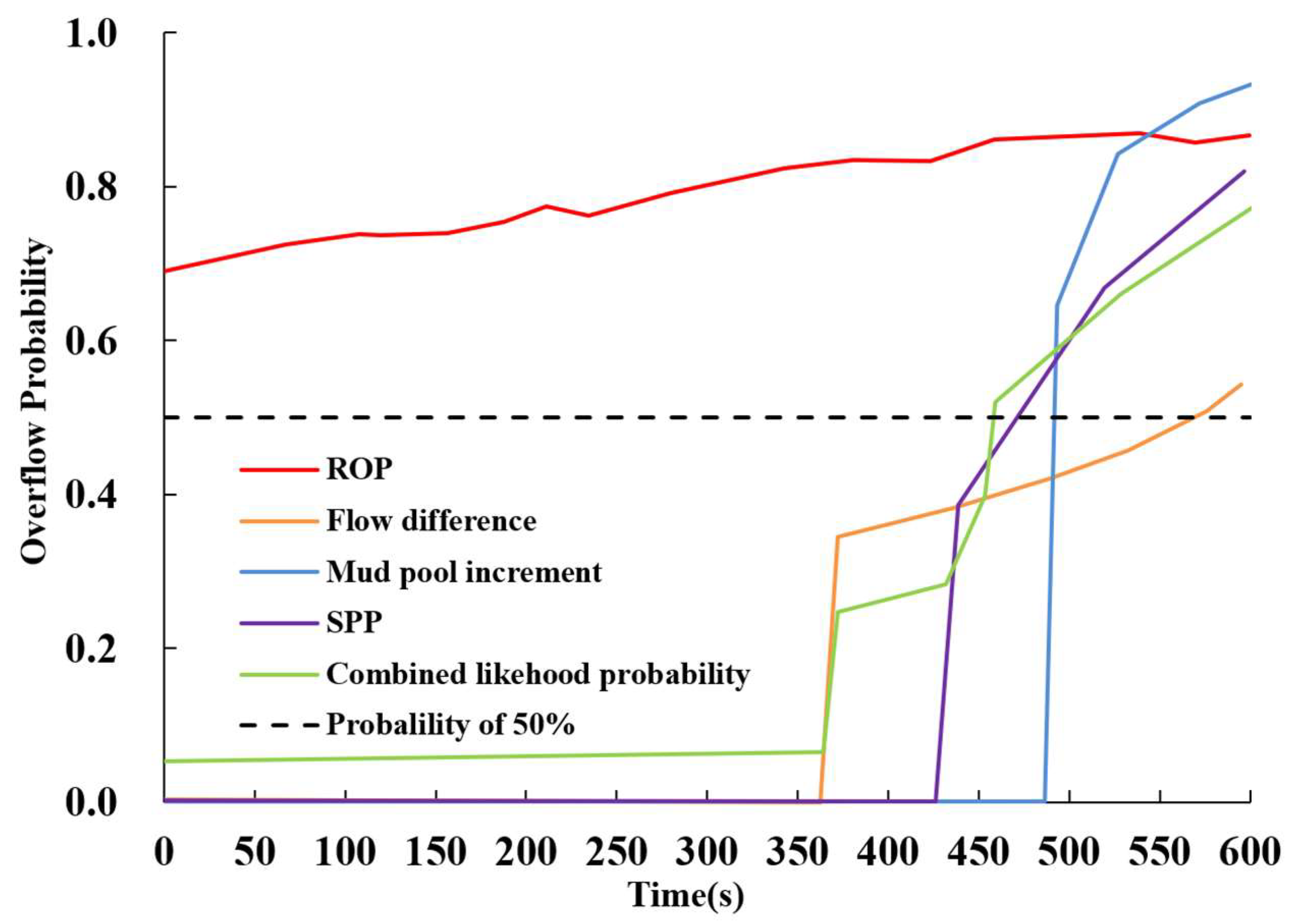

6.2. Overflow Probability Analysis

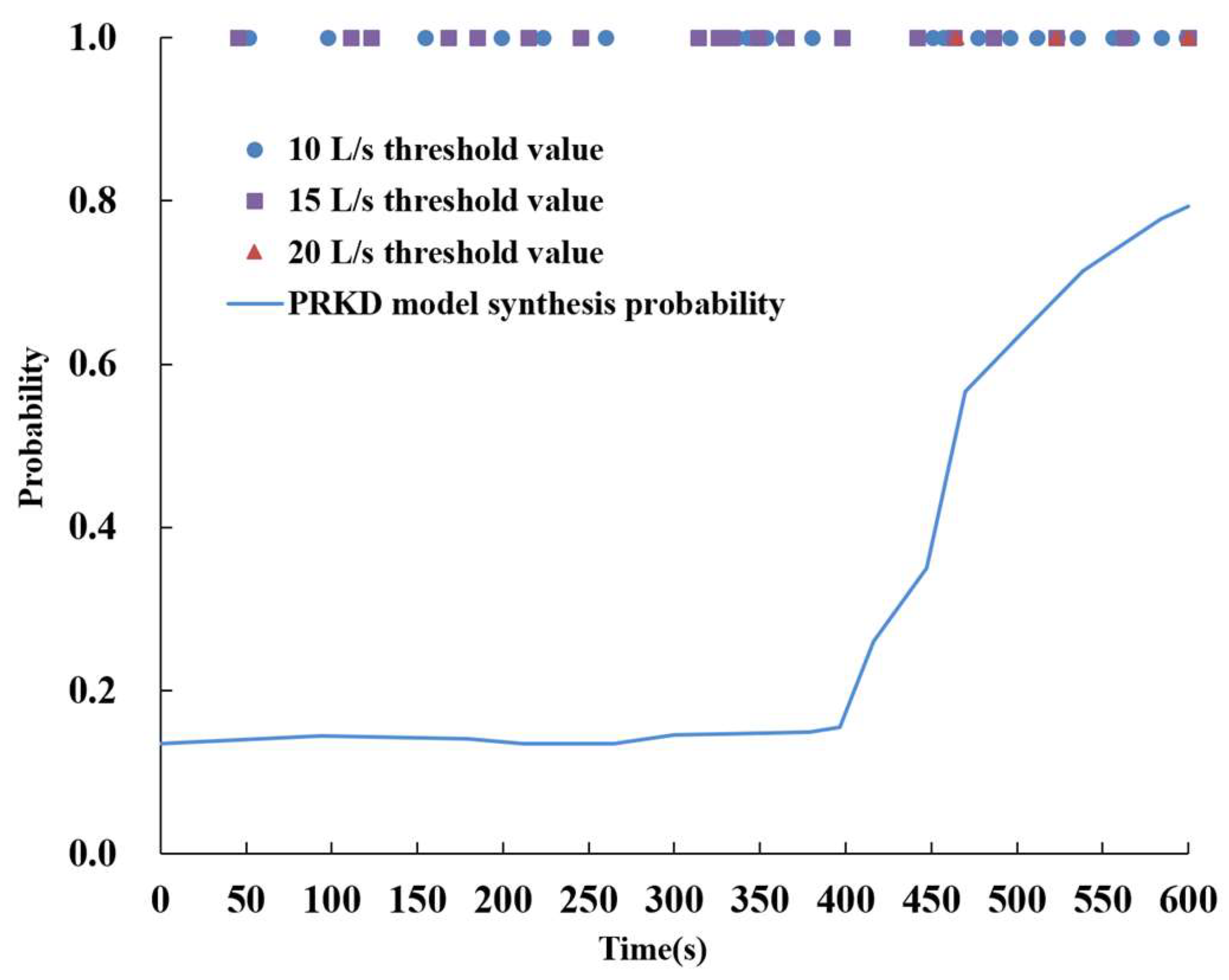

6.3. Comparison with Traditional Methods

- (1)

- Comparison of result accuracy

- (2)

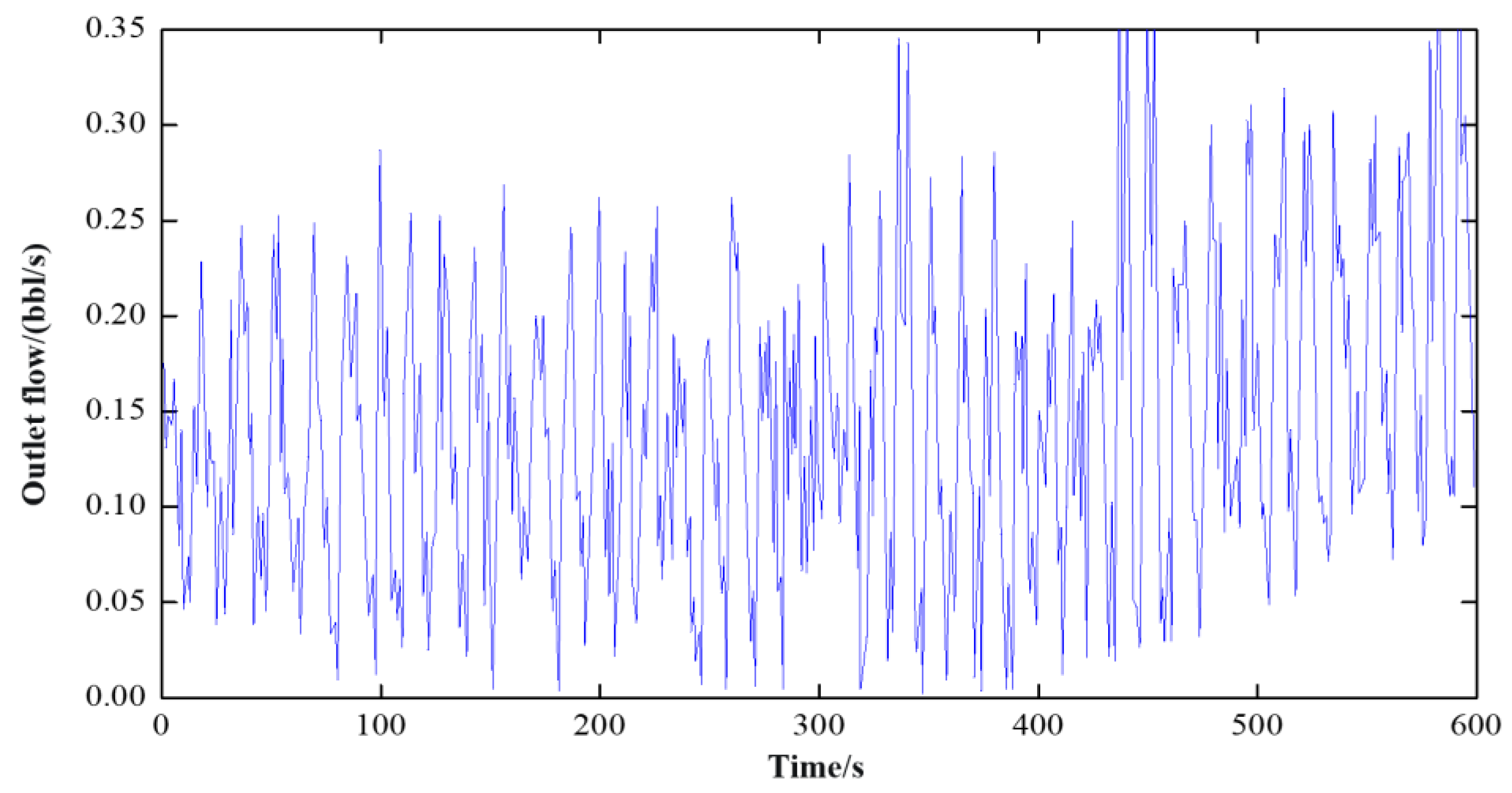

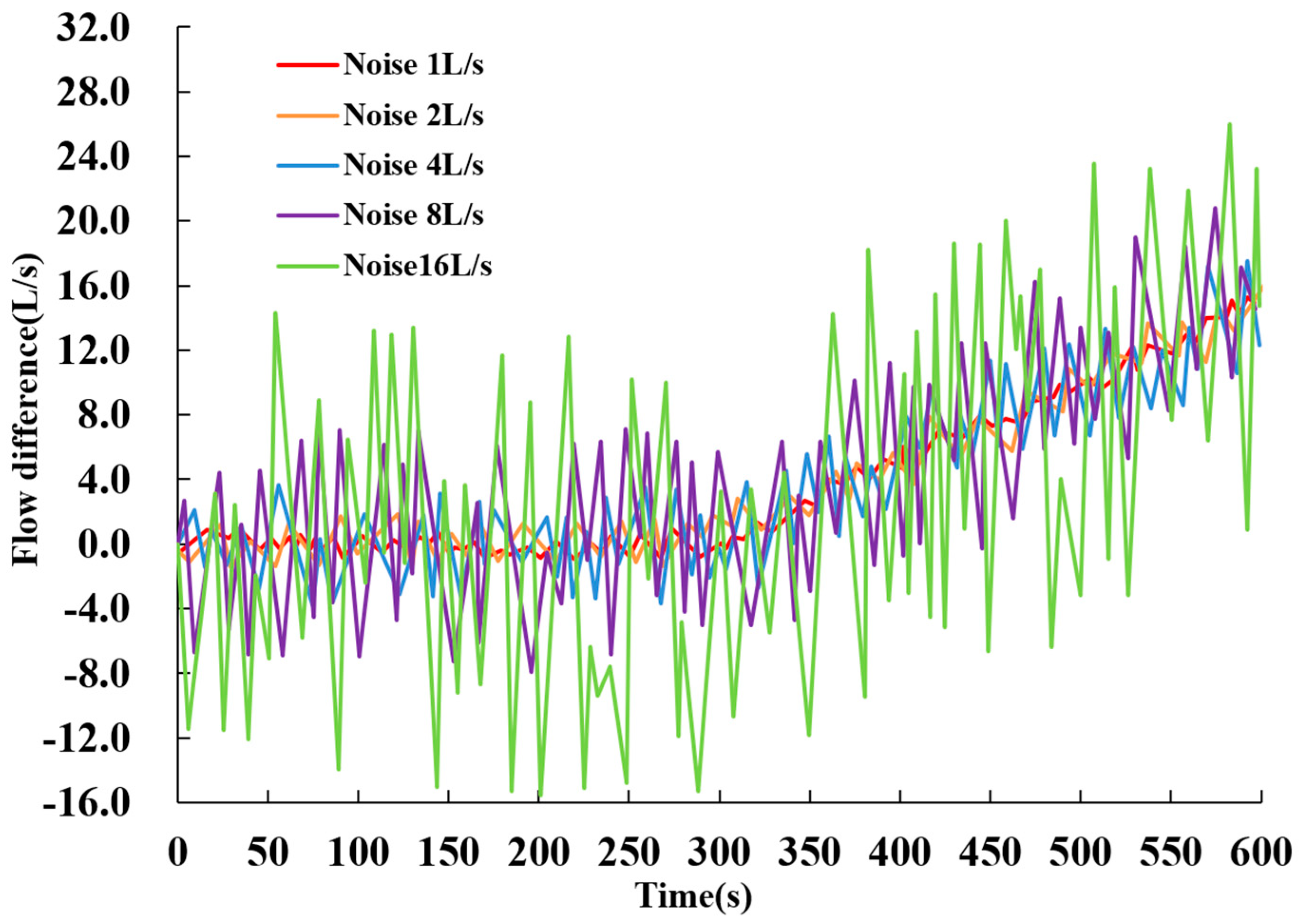

- The influence of data noise

6.4. Bayesian Probability Analysis

- (1)

- Prior probability: basic events can be divided into overflow events and non-overflow events, which can be obtained according to pre-drilling kick probability calculation and prior data:

- (2)

- Likelihood function: the PRKD method is used to obtain the likelihood probability of each overflow characteristic parameter:

- (3)

- Posterior distribution:

7. Conclusions

- (1)

- A single-parameter gas intrusion monitoring method for offshore drilling called PRKD based on pattern recognition is established by combining multiphase flow calculations, data filtering theory, pattern recognition theory, and the Bayesian framework. By integrating sophisticated computational techniques with pattern recognition algorithms, PRKD enhances the reliability and precision of kick detection. This enables the implementation of proactive measures to mitigate potential risks, protecting the environment and human lives while optimizing drilling operations.

- (2)

- Although the PRKD method can minimize the impact of data noise to the maximum extent possible, the probability result obtained from a single type of detection data will still be disturbed by noise. Combining the comprehensive probability of various available types of data and adopting “comprehensive diagnosis probability over 50%” as the overflow judgment standard, can meet the requirements of engineering practice.

- (3)

- The traditional threshold method has low accuracy and a high false positive rate in diagnosing kicks, while the PRKD model shows better diagnostic results in the chosen case study. When the threshold value is set at 10 and 15 L/s, the threshold method has a high false positive rate in the range of 0 to 400 s. When the threshold value is set at 20 L/s, the threshold method lacks continuity and has low accuracy. For example, at 460 s in the graph, it diagnoses an overflow, while at 470 s it diagnoses a non-overflow. Compared to the threshold method, the PRKD model detects the overflow at 465 s and provides the output in the form of probabilities, which can provide engineers with more reference information.

- (4)

- In the case analysis of standard overflow pattern data, the occurrence of overflow is at 300 s. As the intensity of noise increases, the time at which overflow is diagnosed gradually extends. In this case, the PRKD model performs well when the noise amplitude is below 8 L/s. Under severe conditions, with a noise amplitude of 16 L/s, the PRKD model detects continuous overflow approximately 200 s after the actual overflow occurs (at around 500 s), which meets the requirements of engineering practice.

- (5)

- Based on the case analysis, the PRKD method combines the probabilistic information of pre-drilling kicks and various characteristic parameters to predict a 95.8% probability of overflow occurrence at the specified location, which satisfies the requirements in the field. The gas invasion monitoring method proposed in this study delivers accurate diagnostic results with a low false positive rate, thereby providing valuable guidance for gas invasion monitoring in drilling operations.

- (6)

- Through case studies, it has been observed that the proposed kick monitoring method in this paper can accurately and rapidly detect the occurrence of well kicks. Additionally, this method exhibits good noise resistance and outperforms traditional threshold-based methods in terms of lower false positive rates and higher monitoring accuracy. Furthermore, this method is not limited to kick monitoring alone but can also be applied for real-time monitoring of other drilling conditions such as wellbore leakage. However, due to the difficulty in obtaining a large amount of field data, the PRKD kick monitoring model established in this study is still not perfect. Future work will focus on further improving the PRKD kick monitoring model.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liang, H.; Zou, J.; Liang, W. An early intelligent diagnosis model for drilling overflow based on GA–BP algorithm. Clust. Comput. 2019, 22, 10649–10668. [Google Scholar] [CrossRef]

- Yin, Q.; Yang, J.; Tyagi, M.; Zhou, X.; Hou, X.; Wang, N.; Tong, G.; Cao, B. Machine learning for deepwater drilling: Gas-kick-alarm Classification using pi-lot-scale rig data with combined surface-riser-downhole monitoring. SPE J. 2021, 26, 1773–1799. [Google Scholar] [CrossRef]

- Jin, Y.; Chao, F.; Shujie, L.; Weiguo, Z.; Renjun, X.; Yi, W. Key technological innovation and practice of well construction in ultra-deepwater shallow formations. Acta Pet. Sin. 2022, 43, 1500–1508. [Google Scholar]

- Zhang, Z.; Sun, B.; Wang, Z.; Pan, S.; Lou, W.; Sun, D. Intelligent well killing control method driven by coupling multiphase flow simulation and real-time data. J. Pet. Sci. Eng. 2022, 213, 110337. [Google Scholar] [CrossRef]

- Yang, J.; Wu, S.; Tong, G.; Wang, H.; Guo, Y.; Zhang, W.; Zhao, S.; Song, Y.; Yin, Q. Acoustic prediction and risk evaluation of shallow gas in deep-water areas. J. Ocean. Univ. China 2022, 21, 1147–1153. [Google Scholar] [CrossRef]

- Jiang, H.; Liu, G.; Li, J.; Zhang, T.; Wang, C.; Ren, K. Numerical simulation of a new early gas kick detection method using UKF estimation and GLRT. J. Pet. Sci. Eng. 2019, 173, 415–425. [Google Scholar] [CrossRef]

- Yin, Q.; Yang, J.; Borujeni, A.T.; Shi, S.; Sun, T.; Yang, Y.; Geng, Y.; Xia, Q.; Wu, X.; Zhao, X. Intelligent Early Kick Detection in Ultra-Deepwater High-Temperature High-Pressure (HPHT) Wells Based on Big Data Technology. In Proceedings of the 29th International Ocean and Polar Engineering Conference, Honolulu, HI, USA, 16–21 June 2019; OnePetro: Richardson, TX, USA, 2019. [Google Scholar]

- Hu, Z.; Yang, J.; Li, W.; Li, S.; Feng, P.; Xin, Y. Research and development of compressible foam for pressure management in casing annulus of deepwater wells. J. Pet. Sci. Eng. 2018, 166, 546–560. [Google Scholar] [CrossRef]

- Maus, L.D.; Tannich, J.D.; Ilfrey, W.T. Instrumentation requirements for kick detection in deep water. J. Pet. Technol. 1979, 31, 1029–1034. [Google Scholar] [CrossRef]

- Speers, J.M.; Gehrig, G.F. Delta flow: An accurate, reliable system for detecting kicks and loss of circulation during drilling. Spe Drill. Eng. 1987, 2, 359–363. [Google Scholar] [CrossRef]

- Anfinsen, B.T.; Rolv, R.; Rogaland, R. Sensitivity of earlykick detection parameters in fullscale gas kick experiments with oil- and water-based drilling muds. In Proceedings of the IADC/SPE Drilling Conference, New Orleans, LA, USA, 18–21 February 1992. SPE23934. [Google Scholar]

- Fraser, D.; Lindley, R.; Moore, D.; Vander Staak, M. Early kick detection methods and technologies. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014. SPE170756. [Google Scholar]

- Nayeem, A.A.; Venkatesan, R.; Khan, F. Monitoring of down-hole parameters for early kick detection. J. Loss Prev. Process Ind. 2016, 40, 43–54. [Google Scholar] [CrossRef]

- Yin, Q.; Yang, J.; Tyagi, M.; Zhou, X.; Wang, N.; Tong, G.; Xie, R.; Liu, H.; Cao, B. Downhole quantitative evaluation of gas kick during deepwater drilling with deep learning using pi-lot-scale rig data. J. Pet. Sci. Eng. 2022, 208, 109136. [Google Scholar] [CrossRef]

- Yang, H.; Li, J.; Liu, G.; Wang, C.; Jiang, H.; Luo, K.; Wang, B. A new method for early gas kick detection based on the consistencies and differences of bottomhole pressures at two measured points. J. Pet. Sci. Eng. 2019, 176, 1095–1105. [Google Scholar] [CrossRef]

- Hu, Z.; Yang, J.; Wang, L.; Hou, X.; Zhang, Z.; Jiang, M. Intelligent identification and time-efficiency analysis of drilling operation conditions. Oil Drill. Prod. Technol. 2022, 44, 241–246. [Google Scholar]

- Liao, M.Y. Drilling state monitoring and fault diagnosis based on multi-parameter fusion by neural network. J. China Univ. Pet. 2007, 31, 149–152. [Google Scholar]

- Nybo, R.; Bjorkevoll, K.S.; Rommetveit, R. Spotting a false alarm. integrating experience and real-time analysis with artificial intelligence. In Proceedings of the SPE Intelligent Energy International Conference and Exhibition, Amsterdam, The Netherlands, 25–27 February 2008. SPE112212. [Google Scholar]

- David, H.; Stuart, J.; Ben, J. Early kick detection for deepwater drilling: New probabilistic methods applied in the field. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–3 October 2001. SPE71369. [Google Scholar]

- Pournazari, P.; Ashok, P.; van Oort, E.; Unrau, S.; Lai, S. Enhanced kick detection with low-cost rig sensors through automated pattern recognition and real-time sensor calibration. In Proceedings of the SPE Middle East Intelligent Oil and Gas Conference and Exhibition, Abu Dhabi, United Arab Emirates, 15–16 September 2015. SPE176790. [Google Scholar]

- Al-Obaidi, A.R.; Mohammed, A.A. Numerical Investigations of Transient Flow Characteristic in Axial Flow Pump and Pressure Fluctuation Analysis Based on the CFD Technique. J. Eng. Sci. Technol. Rev. 2019, 12, 70–79. [Google Scholar] [CrossRef]

- Muojeke, S.; Venkatesan, R.; Khan, F. Supervised data-driven approach to early kick detection during drilling operation. J. Pet. Sci. Eng. 2020, 192, 107324. [Google Scholar] [CrossRef]

- Hargreaves, D.; Jardine, S.; Jeffryes, B. Early kick detection for deepwater drilling: New probabilistic methods applied in the field. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011; OnePetro: Richardson, TX, USA, 2001. [Google Scholar]

- Reitsma, D. A simplified and highly effective method to identify influx and losses during Managed Pressure Drilling without the use of a Coriolis flow meter. In Proceedings of the SPE/IADC Managed Pressure Drilling and Underbalanced Operations Conference and Exhibition, Kuala Lumpur, Malaysia, 24–25 February 2010; OnePetro: Richardson, TX, USA, 2010. [Google Scholar]

- Geekiyanage, S.C.; Ambrus, A.; Sui, D. Feature selection for kick detection with machine learning using laboratory data. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Glasgow, Scotland, UK, 9–14 June 2019; American Society of Mechanical Engineers: New York, NY, USA, 2019; Volume 58875. [Google Scholar]

- Bang, J.; Mjaaland, S.; Solstad, A.; Hendriks, P.; Jensen, L.K. Acoustic gas kick detection with wellhead sonar. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 25–28 September 1994; OnePetro: Richardson, TX, USA, 1994. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Yang, J.; Hu, Z.; Xu, D.; Li, L.; Fu, C. A Novel Pattern Recognition based Kick Detection Method for Offshore Drilling Gas Kick and Overflow Diagnosis. Processes 2023, 11, 1997. https://doi.org/10.3390/pr11071997

Xu Y, Yang J, Hu Z, Xu D, Li L, Fu C. A Novel Pattern Recognition based Kick Detection Method for Offshore Drilling Gas Kick and Overflow Diagnosis. Processes. 2023; 11(7):1997. https://doi.org/10.3390/pr11071997

Chicago/Turabian StyleXu, Yang, Jin Yang, Zhiqiang Hu, Dongsheng Xu, Lei Li, and Chao Fu. 2023. "A Novel Pattern Recognition based Kick Detection Method for Offshore Drilling Gas Kick and Overflow Diagnosis" Processes 11, no. 7: 1997. https://doi.org/10.3390/pr11071997

APA StyleXu, Y., Yang, J., Hu, Z., Xu, D., Li, L., & Fu, C. (2023). A Novel Pattern Recognition based Kick Detection Method for Offshore Drilling Gas Kick and Overflow Diagnosis. Processes, 11(7), 1997. https://doi.org/10.3390/pr11071997