Active Disturbance Rejection Control of Five-Phase Motor Based on Parameter Setting of Genetic Algorithm

Abstract

:1. Introduction

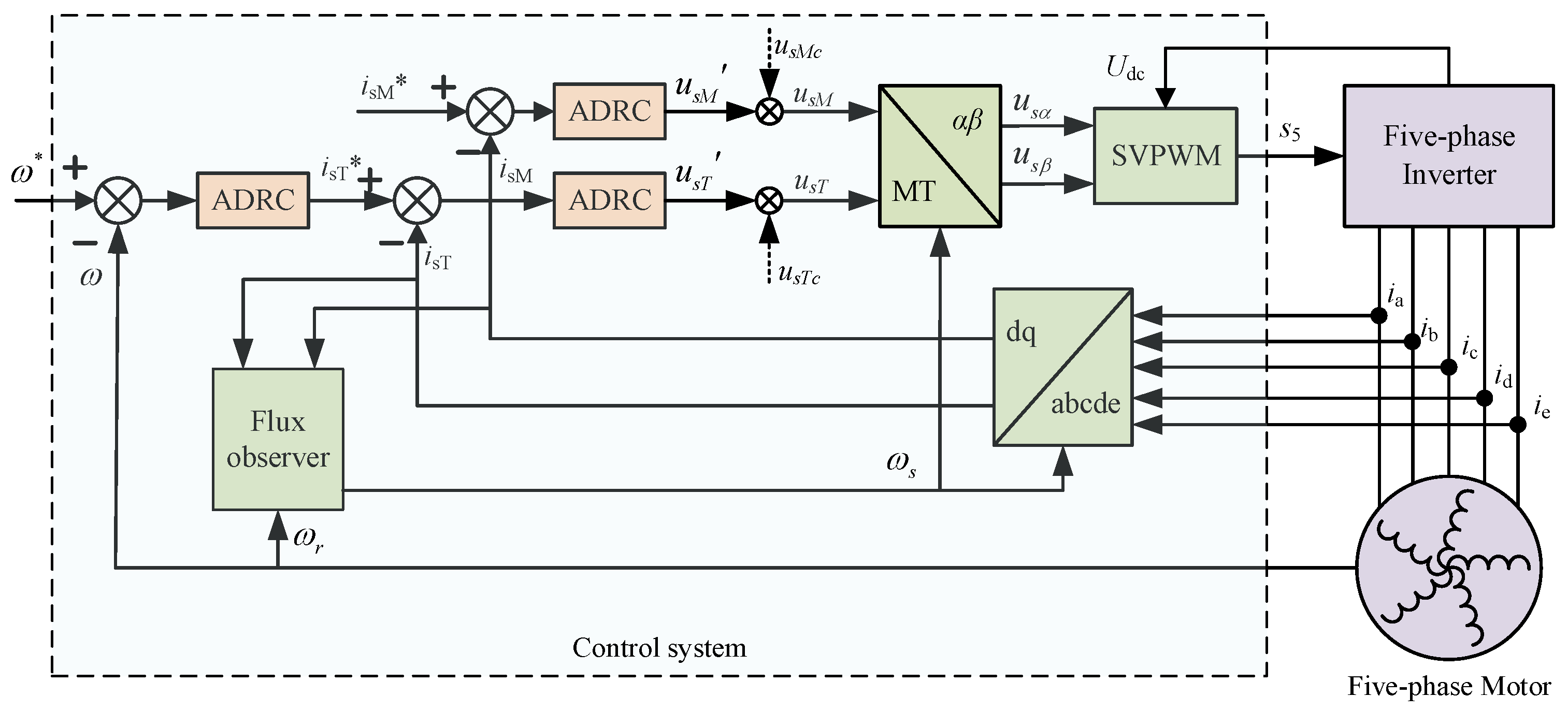

2. Analysis of ADRC for Five-Phase Induction Motor

2.1. Principle of Five-Phase Motor

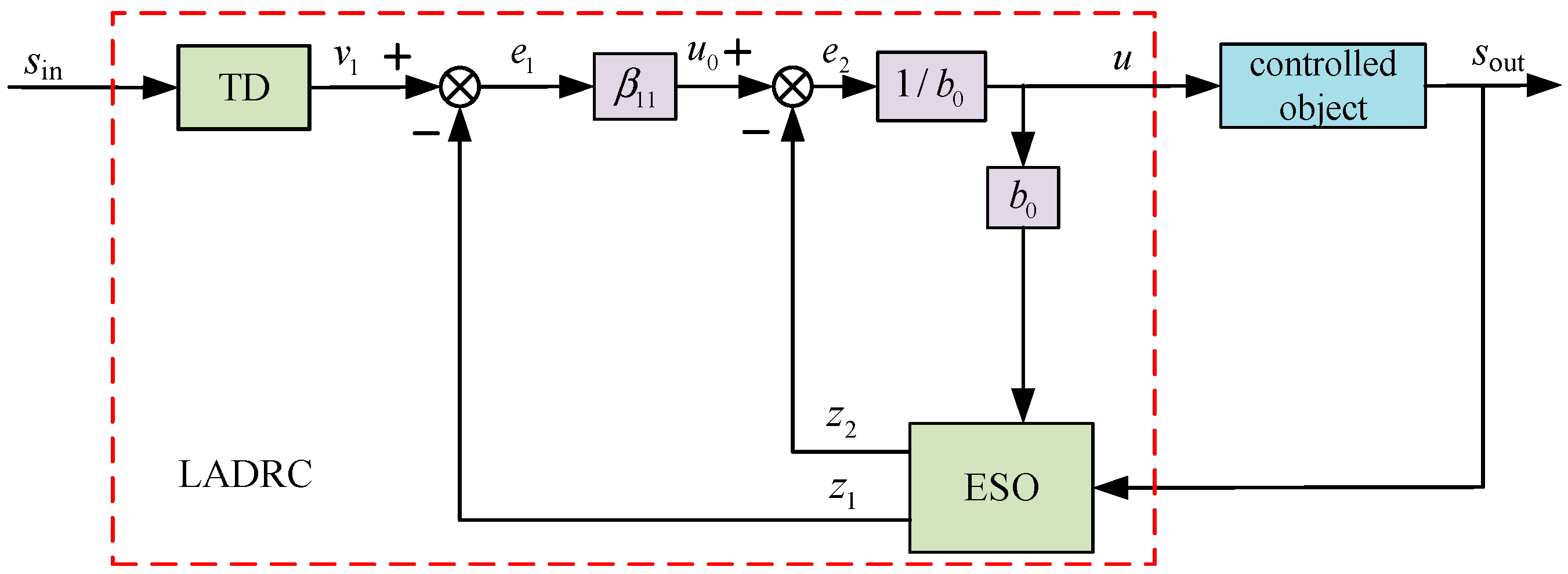

2.2. Principle of Linear ADRC

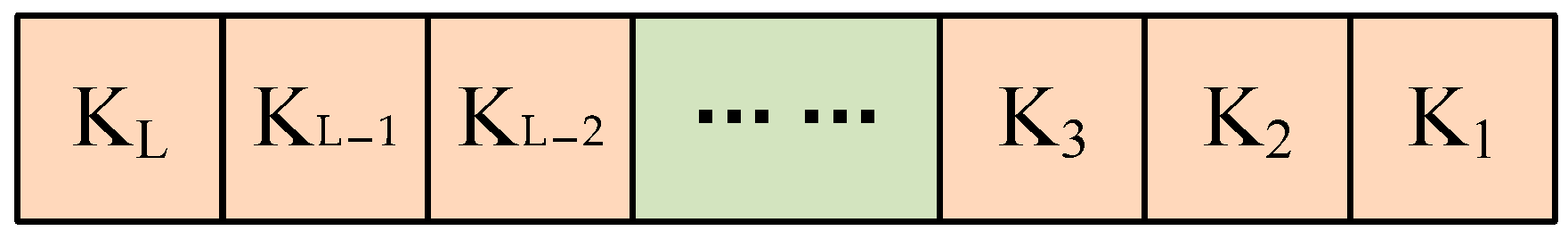

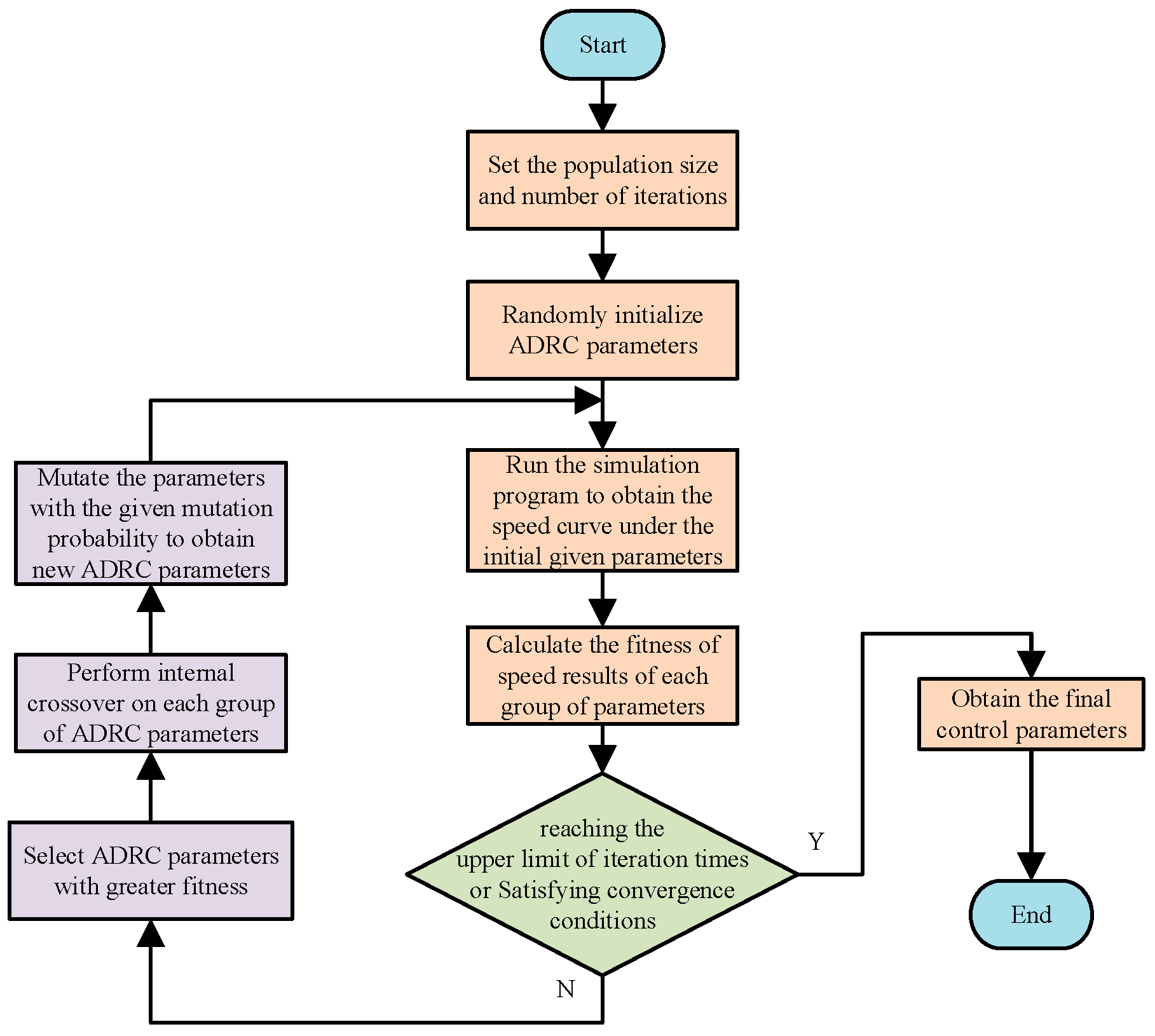

3. ADRC Parameter Optimization Based on GA

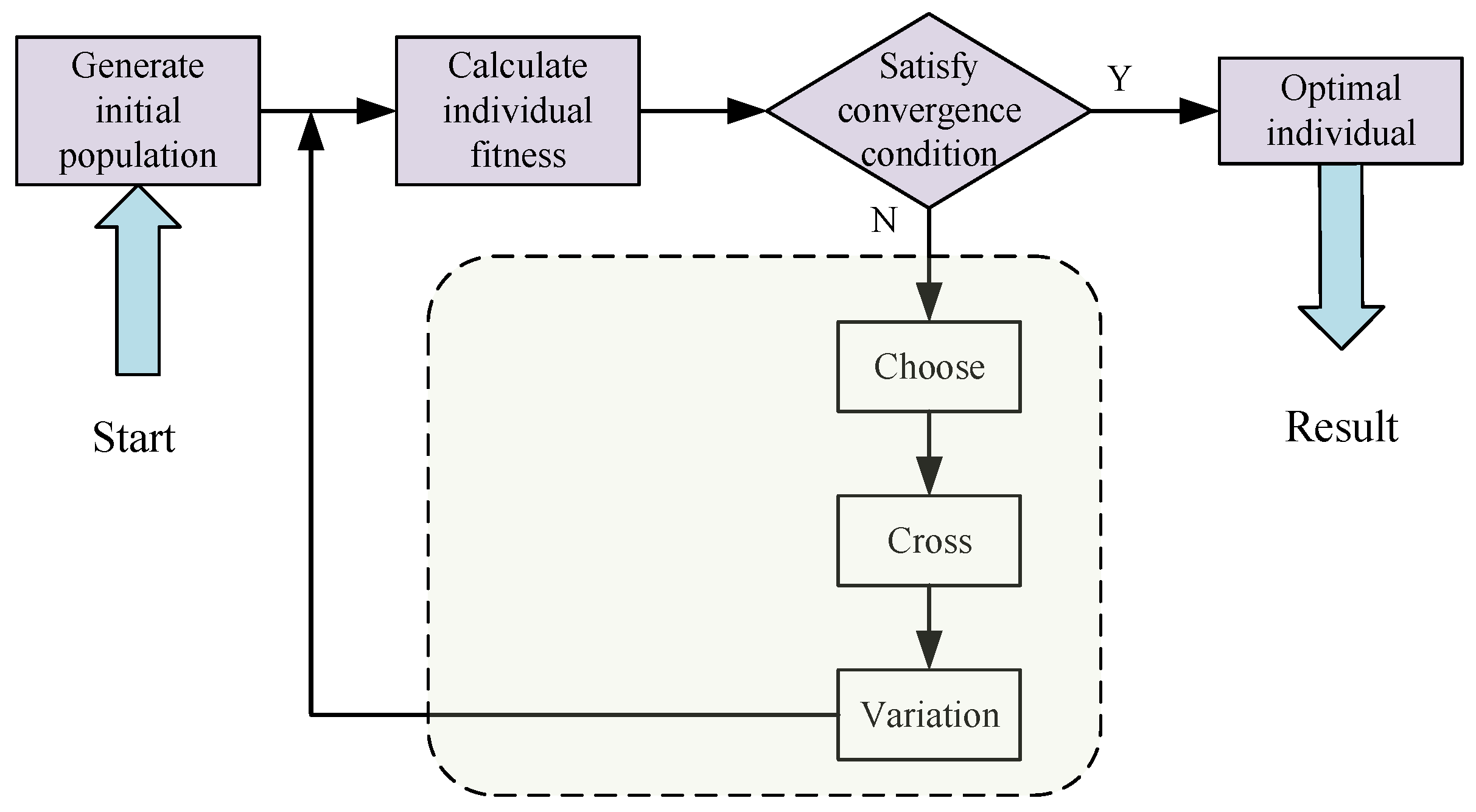

3.1. Basic Principles of Genetic Algorithm

- (1)

- Initialize design parameters

- (2)

- Objective function determination

- (3)

- Selection crossing and mutation

3.2. Parameter Setting Process Based on Genetic Algorithm

- (1)

- The control parameters of the current-loop ADRC and the speed-loop ADRC are roughly adjusted based on the dynamic energy of the speed.

- (2)

- Keep the ADRC parameters of the speed loop obtained in the first step unchanged, take the dynamic tracking performance of the current loop as the optimization objective, and obtain the optimized ADRC parameters of the current loop.

- (3)

- Keep the ADRC parameters of the current loop obtained in step 2 unchanged, and then obtain the optimized ADRC parameters of the speed loop by taking the speed dynamic energy as the optimization objective.

4. Simulation and Experimental Analysis

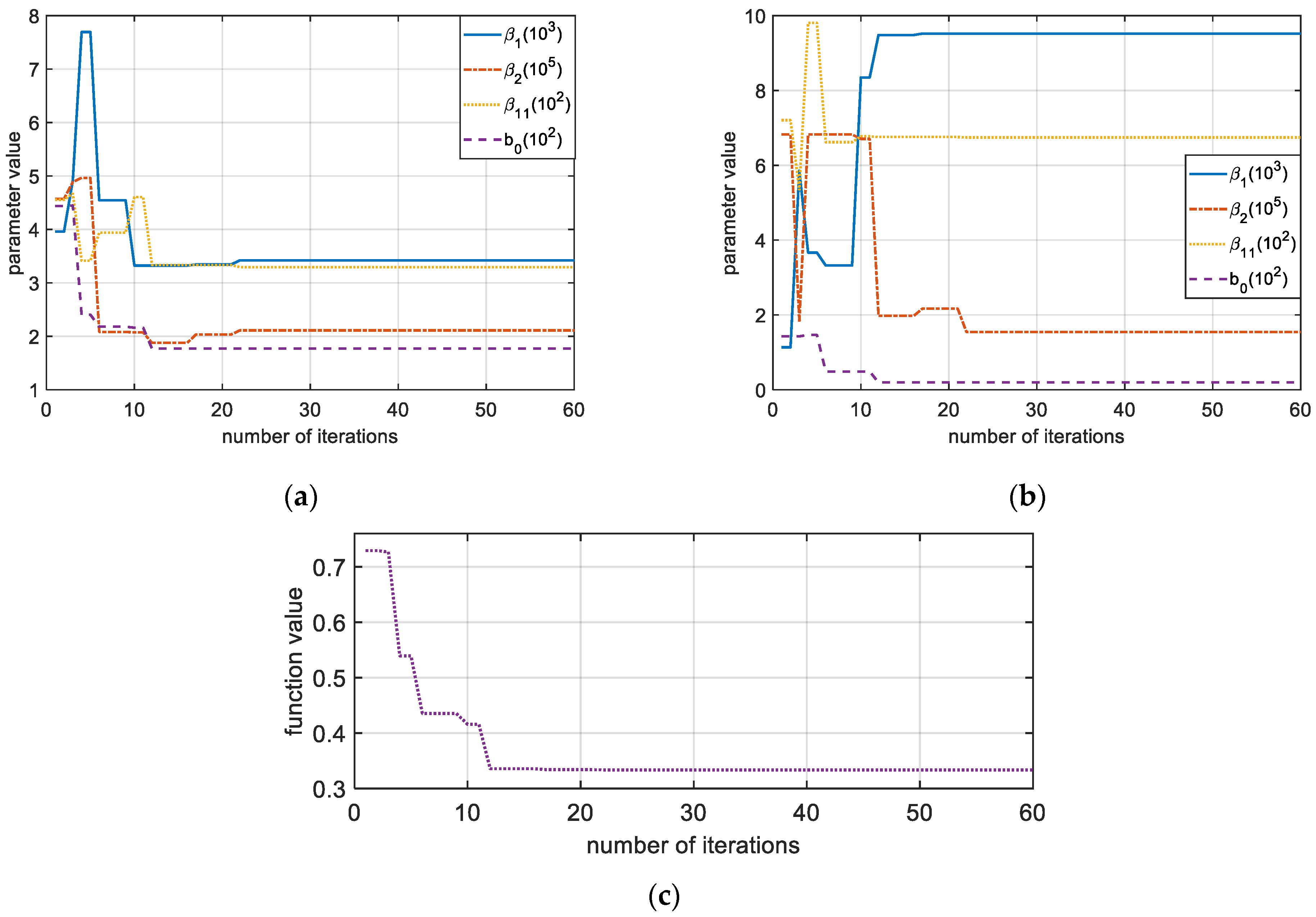

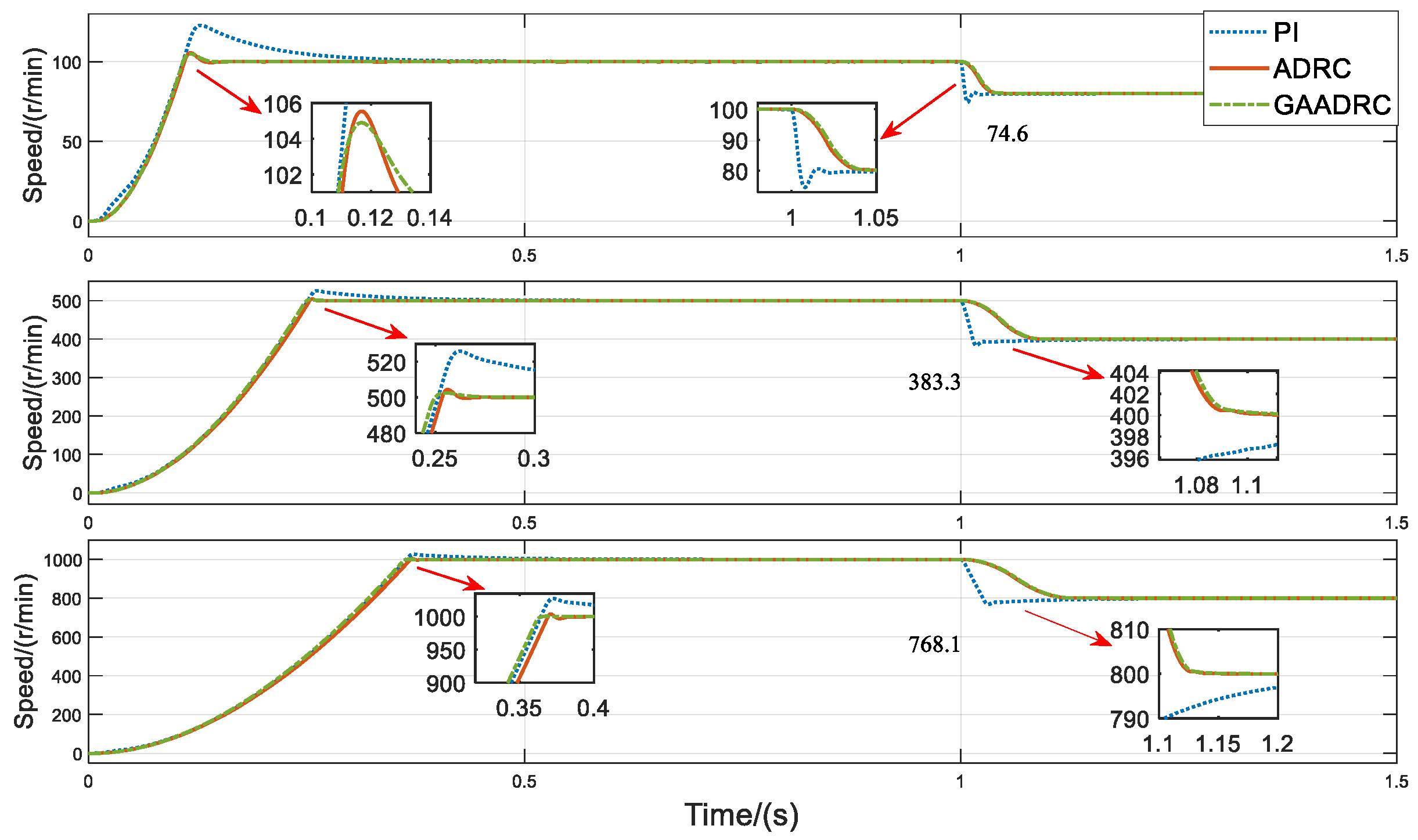

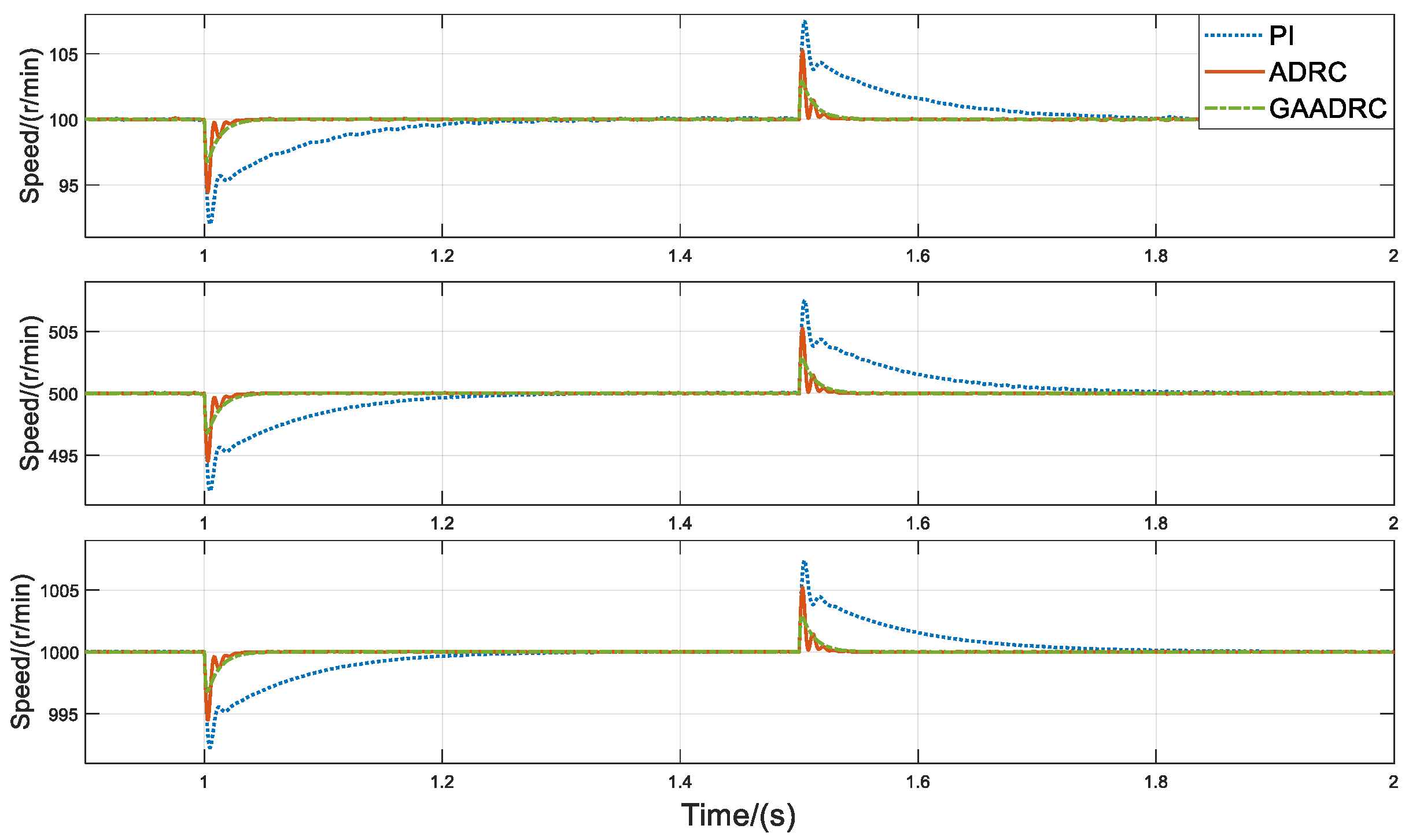

4.1. Analysis of Simulation Results

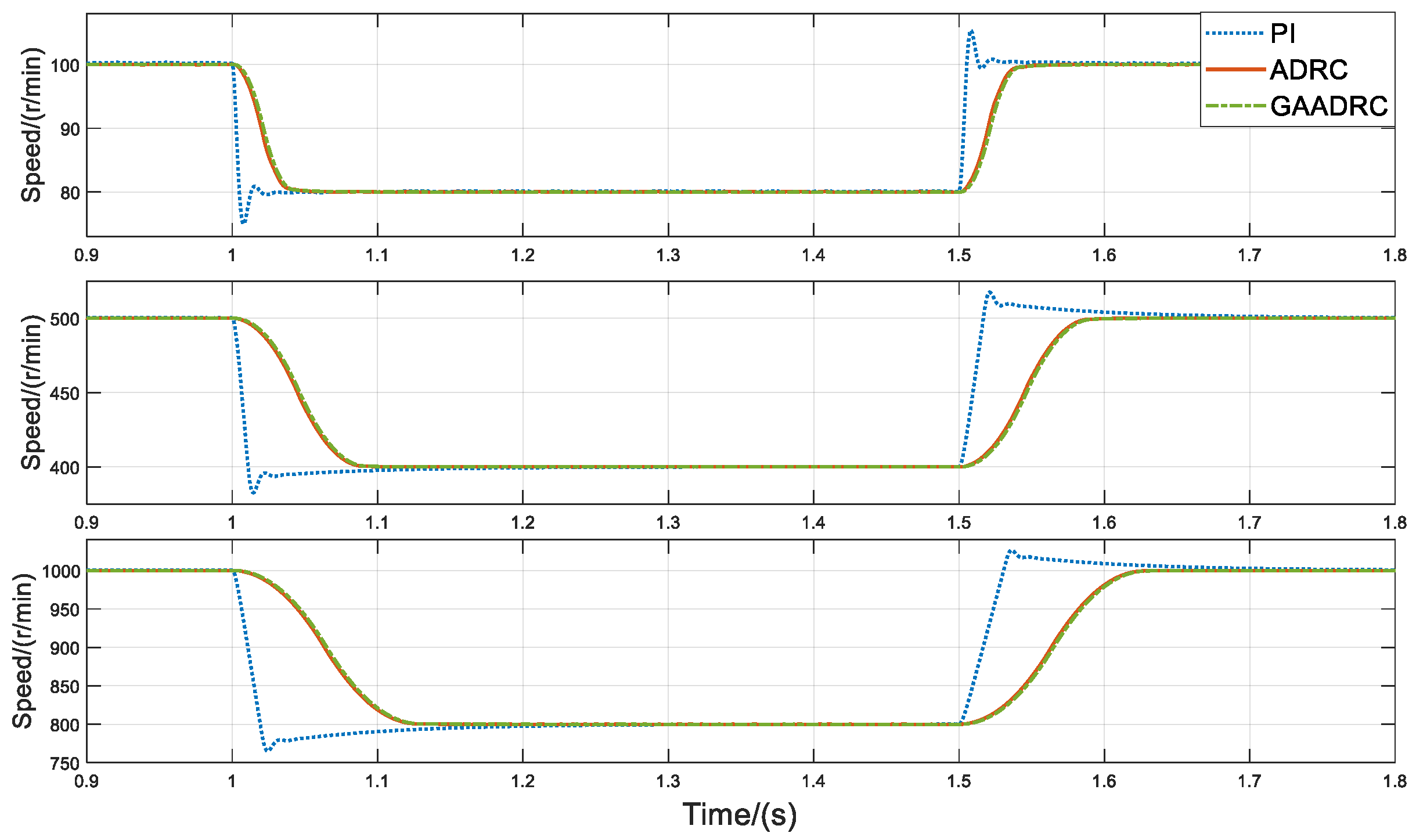

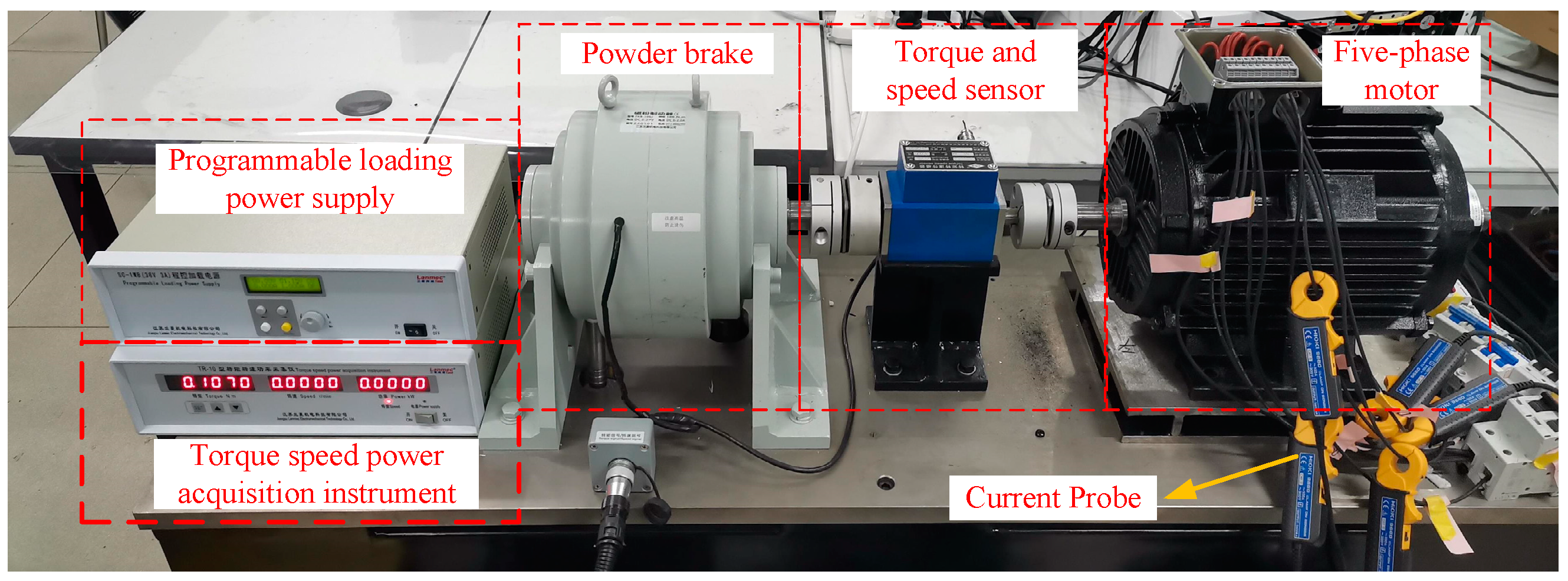

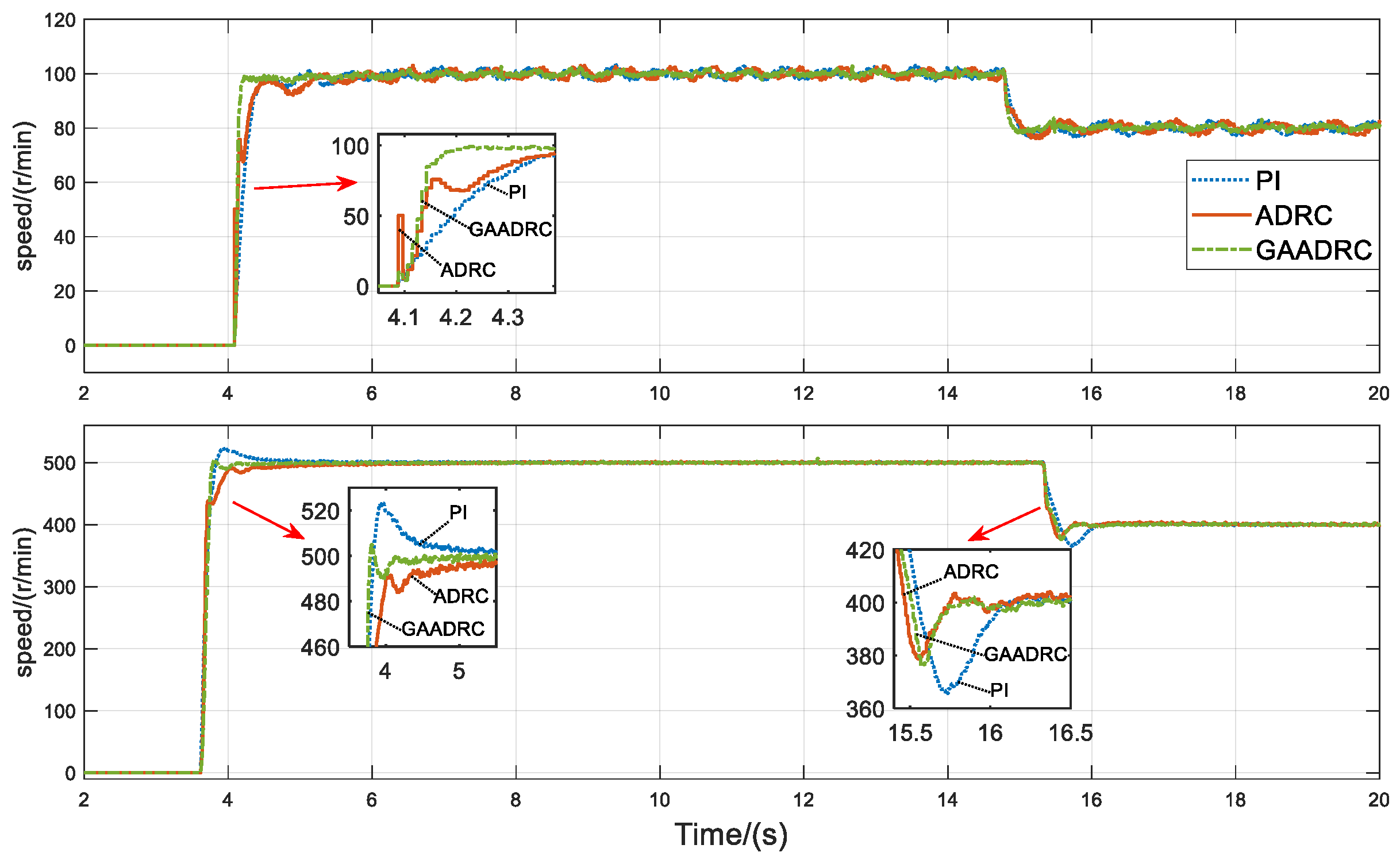

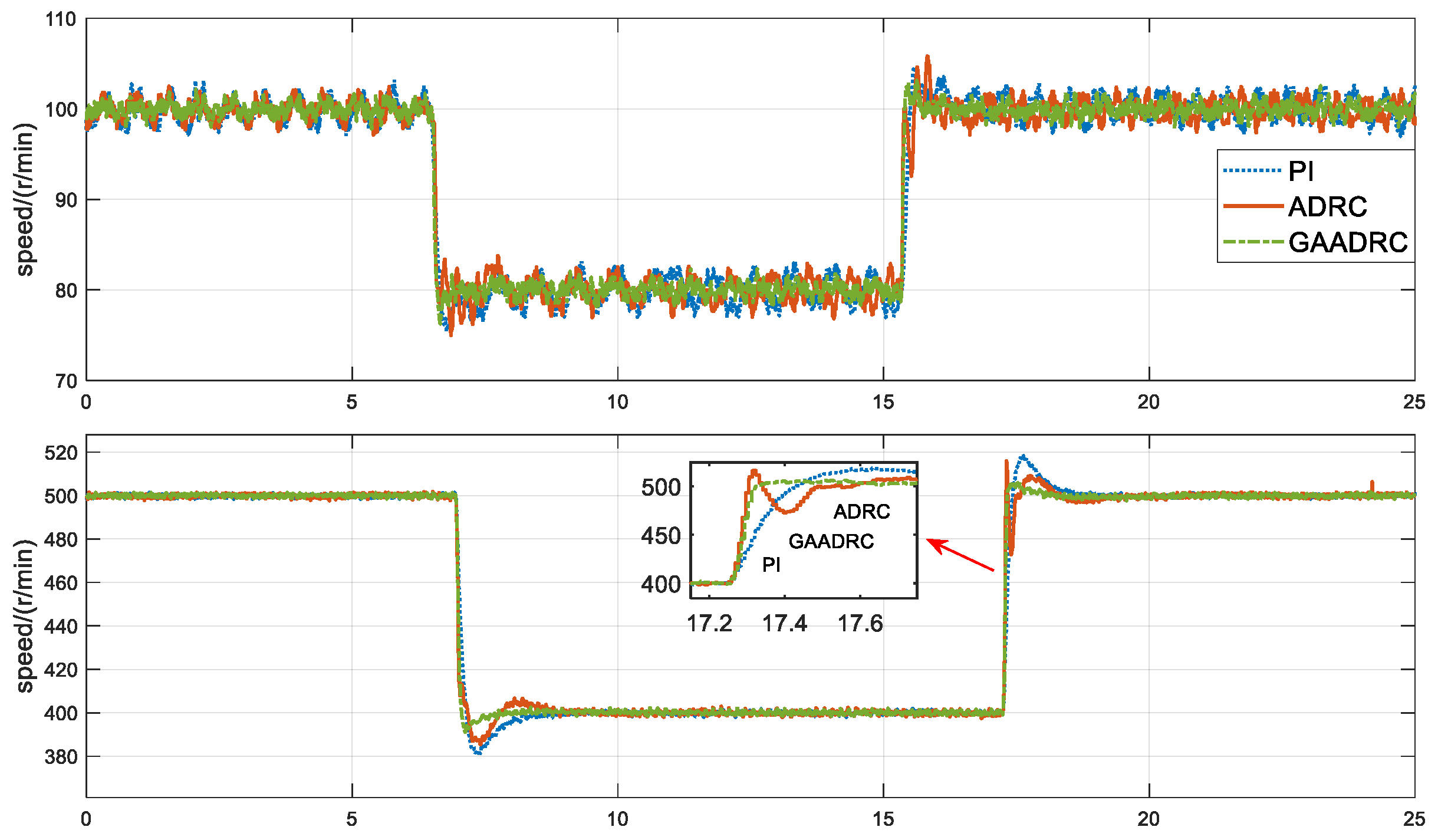

4.2. Analysis of Experimental Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, J. From PID to active disturbance rejection control. IEEE Trans. Ind. Electron. 2009, 56, 900–906. [Google Scholar] [CrossRef]

- Huang, Y.; Han, J. Analysis and design for the second order nonlinear continuous extended states observer. Chin. Sci. Bull. 2000, 45, 1938–1944. [Google Scholar] [CrossRef]

- Zheng, Q.; Gao, Z.; Technology. Active disturbance rejection control: Some recent experimental and industrial case studies. Control Theory Technol. 2018, 16, 301–313. [Google Scholar] [CrossRef]

- Wang, H.; Pan, T.; Gao, Z.; Jin, H. Active Disturbance Rejection Control for Discrete Systems. In Proceedings of the 9th IEEE Data Driven Control and Learning Systems Conference (DDCLS), Liuzhou, China, 22 November 2020; pp. 378–382. [Google Scholar]

- Wu, Z.; Li, D.; Xue, Y.; Sun, L.; He, T.; Zheng, S. Modified active disturbance rejection control for fluidized bed combustor. ISA Trans. 2020, 102, 135–153. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Liu, X.; Huang, Y. Synchronous Generator Excitation System for a Ship Based on Active Disturbance Rejection Control. Math. Probl. Eng. 2021, 2021, 6638370. [Google Scholar] [CrossRef]

- Beltran-Carbajal, F.; Valderrabano-Gonzalez, A.; Favela-Contreras, A.R.; Cesar Rosas-Caro, J. Active Disturbance Rejection Control of a Magnetic Suspension System. Asian J. Control 2015, 17, 842–854. [Google Scholar] [CrossRef]

- Sui, S.; Zhao, T. Active disturbance rejection control for optoelectronic stabilized platform based on adaptive fuzzy sliding mode control. ISA Trans. 2022, 125, 85–98. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Cheng, L.; Xia, Y.; Yuan, Y. Active Disturbance Rejection Attitude Control for a Dual Closed-Loop Quadrotor Under Gust Wind. IEEE Trans. Control Syst. Technol. 2018, 26, 1400–1405. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, J.; Wang, C.; Zhu, X.; Zhou, Z.; Li, W.; Jia, Y.; Li, Z.; Wu, S.; Meng, J. An adaptive linear active disturbance rejection control method for HVDC transmission system. Energy Rep. 2023, 9, 3282–3289. [Google Scholar] [CrossRef]

- Bingül, Ö.; Yıldız, A. Fuzzy logic and proportional integral derivative based multi-objective optimization of active suspension system of a 4× 4 in-wheel motor driven electrical vehicle. J. Vib. Control 2023, 29, 1366–1386. [Google Scholar] [CrossRef]

- Du, C.; Yin, Z.; Zhang, Y.; Liu, J.; Sun, X.; Zhong, Y. Research on Active Disturbance Rejection Control With Parameter Autotune Mechanism for Induction Motors Based on Adaptive Particle Swarm Optimization Algorithm With Dynamic Inertia Weight. IEEE Trans. Power Electron. 2019, 34, 2841–2855. [Google Scholar] [CrossRef]

- Yin, Z.; Du, C.; Liu, J.; Sun, X.; Zhong, Y. Research on Autodisturbance-Rejection Control of Induction Motors Based on an Ant Colony Optimization Algorithm. IEEE Trans. Ind. Electron. 2018, 65, 3077–3094. [Google Scholar] [CrossRef]

- Elmouhi, N.; Essadki, A.; Elaimani, H. Improved control for DFIG based wind power system under voltage dips using ADRC optimized by genetic algorithms. Int. J. Electr. Comput. Eng. Syst. 2022, 13, 357–367. [Google Scholar] [CrossRef]

- Yang, Z.; Lu, C.; Sun, X.; Ji, J.; Ding, Q. Study on Active Disturbance Rejection Control of a Bearingless Induction Motor Based on an Improved Particle Swarm Optimization-Genetic Algorithm. IEEE Trans. Transp. Electrif. 2021, 7, 694–705. [Google Scholar] [CrossRef]

- Ali, S.; Yang, G.; Huang, C. Performance optimization of linear active disturbance rejection control approach by modified bat inspired algorithm for single area load frequency control concerning high wind power penetration. ISA Trans. 2018, 81, 163–176. [Google Scholar] [CrossRef] [PubMed]

- Kang, C.; Wang, S.; Ren, W.; Lu, Y.; Wang, B. Optimization design and application of active disturbance rejection controller based on intelligent algorithm. IEEE Access 2019, 7, 59862–59870. [Google Scholar] [CrossRef]

- Villarreal-López, E.; Coral-Enriquez, H.; Medina-Camacho, S.; Hurtado-Cortés, L. Online parameter adjustment of an active disturbance rejection controller for a robotic manipulator via simulated annealing. In Presented at AETA 2019-Recent Advances in Electrical Engineering and Related Sciences: Theory and Application; Springer: Berlin/Heidelberg, Germany, 2021; pp. 460–469. [Google Scholar]

- Zeng, W.-F.; Yan, L. The parameter setting and application study of adrc based on immune genetic algorithm. In Proceedings of the 2010 IEEE International Conference on Intelligent Computing and Intelligent Systems, Xiamen, China, 29–31 October 2010; IEEE: New York, NY, USA; Volume 2, pp. 183–186. [Google Scholar]

- Gao, L.; Guo, X.; Mei, D.; Qu, Z. Parameter tuning of active disturbance rejection control based on improved differential evolution algorithm. In Proceedings of the 2022 7th International Conference on Intelligent Computing and Signal Processing (ICSP), Xi’an, China, 15–17 April 2022; pp. 342–346. [Google Scholar]

- Yildiz, A. Parametric synthesis of two different trunk lid mechanisms for sedan vehicles using population-based optimisation algorithms. Mech. Mach. Theory 2021, 156, 104130. [Google Scholar] [CrossRef]

- Liu, K.; Ji, H.; Zhang, Y. Extended state observer based adaptive sliding mode tracking control of wheeled mobile robot with input saturation and uncertainties. Proc. Inst. Mech. Eng. 2019, 233, 5460–5476. [Google Scholar] [CrossRef]

- Shin, E.-C.; Park, T.-S.; Oh, W.-H.; Yoo, J.-Y. A design method of PI controller for an induction motor with parameter variation. In Proceedings of the IECON’03. 29th Annual Conference of the IEEE Industrial Electronics Society (IEEE Cat. No. 03CH37468), Roanoke, VA, USA, 2–6 November 2003; pp. 408–413. [Google Scholar]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| 1.60 | 1.35 | ||

| 0.7802 H | 0.7871 H | ||

| 0.7871 H | J | 0.01986 kg·m2 | |

| 1 |

| Parameters | ||||

|---|---|---|---|---|

| Speed loop | 4995.61 | 440,860.8 | 492.72 | 259.12 |

| Current loop | 9921.81 | 999,022.5 | 994.14 | 35.29 |

| Control Mode | 0–100–80 r/min | 0–500–400 r/min | 0–1000–800 r/min | |||

|---|---|---|---|---|---|---|

| Starting | Deceleration | Starting | Deceleration | Starting | Deceleration | |

| PI | 22.82% | 6.75% | 5.16% | 4.17% | 2.75% | 3.99% |

| ADRC | 5.54% | 0.102% | 0.88% | 0.0118% | 0.38% | 0.0029% |

| GAADRC | 4.90% | 0.032% | 0.52% | 0.0035% | 0.06% | 0.0011% |

| Control Mode | Startup Process | Deceleration Process | ||

|---|---|---|---|---|

| Overshoot | Adjust Time | Overshoot | Adjust Time | |

| PI | 4.74% | 0.603 s | 8.65% | 0.67 s |

| ADRC | 0% | 0.695 s | 5.30% | 0.35 s |

| GAADRC | 1% | 0.158 s | 5.95% | 0.35 s |

| Control Mode | Deceleration Process | Startup Process | ||

|---|---|---|---|---|

| Overshoot | Adjust Time | Overshoot | Adjust Time | |

| PI | 4.78% | 0.816 s | 3.72% | 0.671 s |

| ADRC | 3.65% | 0.645 s | 3.20% | 0.210 s |

| GAADRC | 2.25% | 0.192 s | 1.18% | 0.062 s |

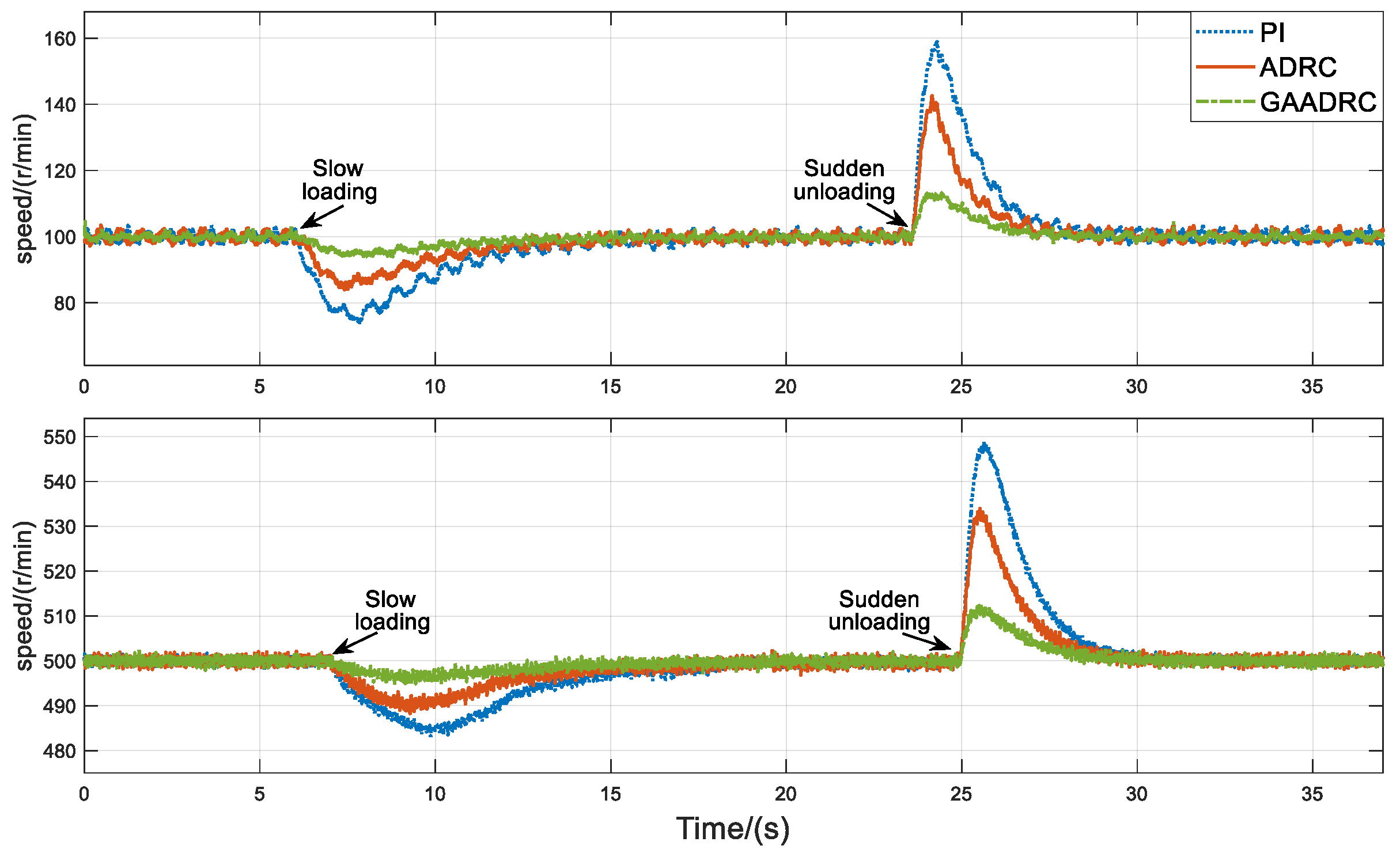

| Steady Speed | Speed Drops When Slow Loading (r/min) | Speed Rises When Sudden Unloading (r/min) | ||||

|---|---|---|---|---|---|---|

| PI | ADRC | GAADRC | PI | ADRC | GAADRC | |

| 100 r/min | 26.5 | 16.1 | 6.3 | 59.0 | 42.5 | 13.3 |

| 500 r/min | 16.9 | 11.7 | 5.2 | 49.0 | 34.0 | 12.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, R.; Zhao, J.; Xiong, Y.; Luo, X. Active Disturbance Rejection Control of Five-Phase Motor Based on Parameter Setting of Genetic Algorithm. Processes 2023, 11, 1712. https://doi.org/10.3390/pr11061712

Zeng R, Zhao J, Xiong Y, Luo X. Active Disturbance Rejection Control of Five-Phase Motor Based on Parameter Setting of Genetic Algorithm. Processes. 2023; 11(6):1712. https://doi.org/10.3390/pr11061712

Chicago/Turabian StyleZeng, Rongtao, Jinghong Zhao, Yiyong Xiong, and Xiangyu Luo. 2023. "Active Disturbance Rejection Control of Five-Phase Motor Based on Parameter Setting of Genetic Algorithm" Processes 11, no. 6: 1712. https://doi.org/10.3390/pr11061712

APA StyleZeng, R., Zhao, J., Xiong, Y., & Luo, X. (2023). Active Disturbance Rejection Control of Five-Phase Motor Based on Parameter Setting of Genetic Algorithm. Processes, 11(6), 1712. https://doi.org/10.3390/pr11061712