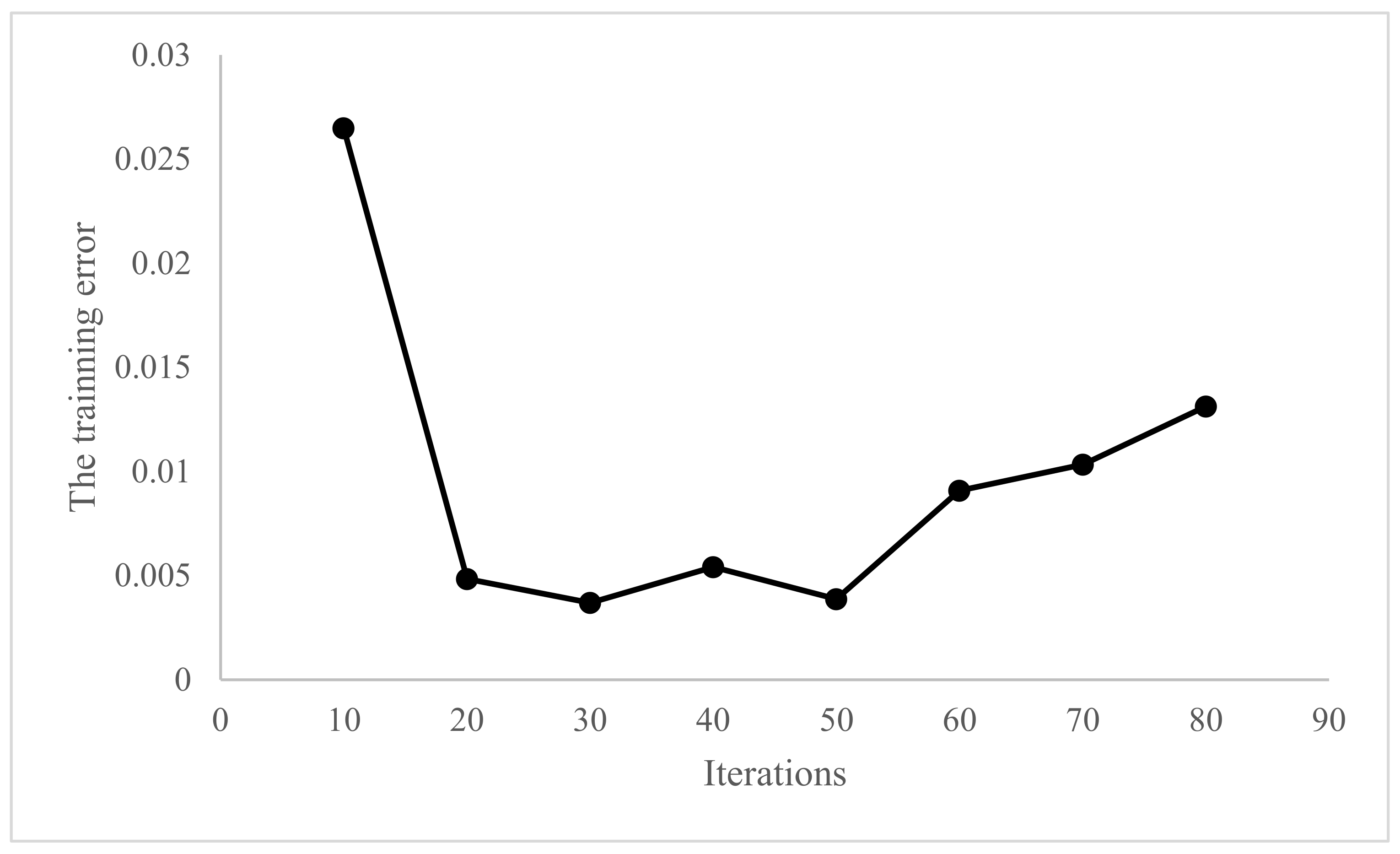

4.1. Model Prediction Results

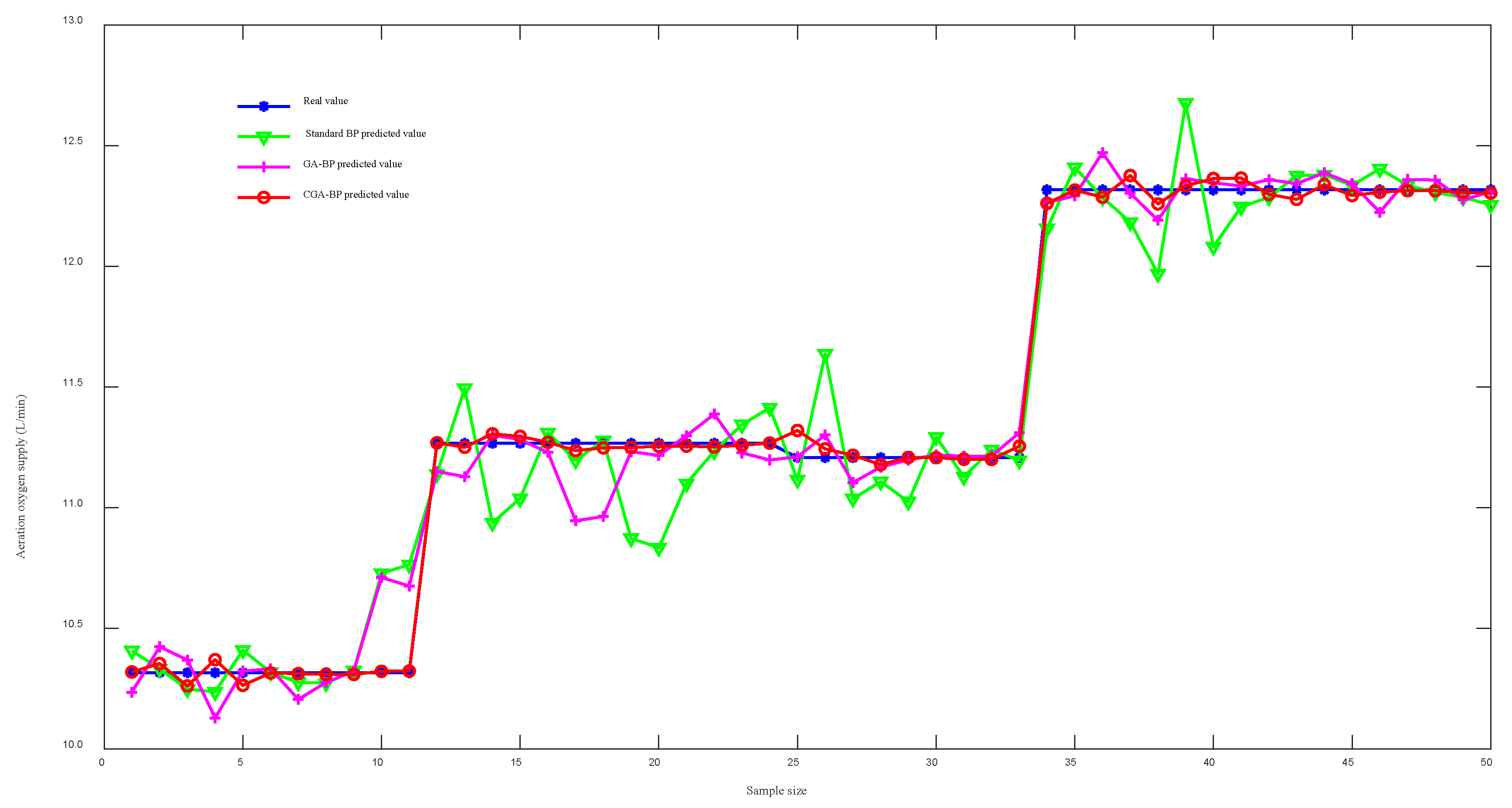

Figure 8 shows the comparison between the predicted and actual values of the standard BP algorithm, GA-BP neural network algorithm and CGA-BP neural network algorithm. It can be seen visually that the trend of variation in the aeration oxygen supply of the CGA-BP neural network algorithm, the GA-BP neural network algorithm and the standard BP algorithm is consistent with the actual changing trend. After the BP neural network was optimized by the GA, the prediction results were more accurate than those of the standard BP neural network, but after the GA-BP neural network was optimized by the clone selection algorithm, the prediction results were closer to the actual value than the GA-BP neural network algorithm, and the CGA-BP prediction value was almost the same as the real value with high accuracy when the real value of aeration is 12.25 min/L.

Figure 9 shows the comparison of the error between the aeration oxygen supply and the actual value of the three algorithms of the standard BP neural network algorithm, the GA-BP neural network and the CGA-BP neural network. From

Figure 9, we can see that the prediction error of the GA-BP neural network is much smaller than the prediction error of the standard BP neural network, and the prediction error of the CGA-BP neural network is almost 0. Therefore, the improved CGA-BP neural network prediction model can accurately predict the next aeration oxygen supply.

The prediction results of aerobic compost aeration oxygen supply based on the CGA-BP neural network show that using six commonly used indicators, such as temperature, humidity, oxygen concentration, room temperature, pH value and EC, to predict the aeration amount further improves the prediction accuracy and improves the aeration efficiency during the compost fermentation process.

In the past, most studies have used aeration control systems to control the aeration rate. Through aeration systems, the oxygen content in sewage tanks can be studied. Through parameter control, the change in oxygen content in the aeration tank does not exceed 0.5 mg/L of soil [

28]. Zhao and others analyzed the operation of the precise aeration control system, indicating that the gas supply volume of the gas supply system has decreased by 30% [

29]. Now, some scholars have introduced modeling methods to control aeration rate and improve aeration efficiency. Jin established an energy consumption prediction model using a BP neural network, and used inflow information to predict dissolved oxygen, providing a reliable basis for the timely scheduling of aeration volume [

30]. Tang established a genetic-algorithm-optimized BP neural network model to predict the aeration rate of the biochemical tank, and the proportion of test sample data prediction errors within 5% reached 98.67% [

31]. The results of this study show that the prediction accuracy is improved to 99.65% by using the clonal selection algorithm to optimize the genetic algorithm and BP neural network.

As can be seen from

Table 7, the genetically optimized BP neural network algorithm has a significant improvement in prediction accuracy over the standard BP neural network algorithm, with an accuracy of 98.94% for the BP neural network algorithm, 99.26% for the genetic-algorithm-optimized standard BP neural network and 99.65% for the clonally optimized genetic algorithm. The MAE, MAPE and MSE of the GA-BP model were 0.083017, 0.0073914 and 0.013188, respectively, and the MAE, MAPE and MSE of the CGA-BP model were 0.038882, 0.003506 and 0.003373, respectively. The MAE, MAPE and MSE of the GA-BP model were improved compared with the standard BP model by 29.4913%, 30.1644% and 53.2490%, and the MAE, MAPE and MSE of the CGA-BP model were improved by 53.1638%, 52.5638% and 74.4260%, respectively, compared with the GA-BP model. This shows that the prediction accuracy of the CGA-BP algorithm is higher than that of the GA-BP algorithm and the BP neural network algorithm, and the error between the predicted and true values of the CGA-BP neural network model is basically zero, which can predict the aeration oxygen supply well and provide data for the next aeration.

4.2. Parameter Changes during Aerobic Composting Fermentation Process

This experiment used the CGA-BP model to predict the aeration oxygen supply for compost fermentation, and used it as the experimental group. The other group is the control group without aeration, which analyzes the changes in moisture content, C/N, pH and EC value during the aerobic composting fermentation process. By comparison, it can be concluded that the CGA-BP aeration oxygen supply prediction model can promote faster and more complete fermentation of compost, and improve the efficiency of compost maturation.

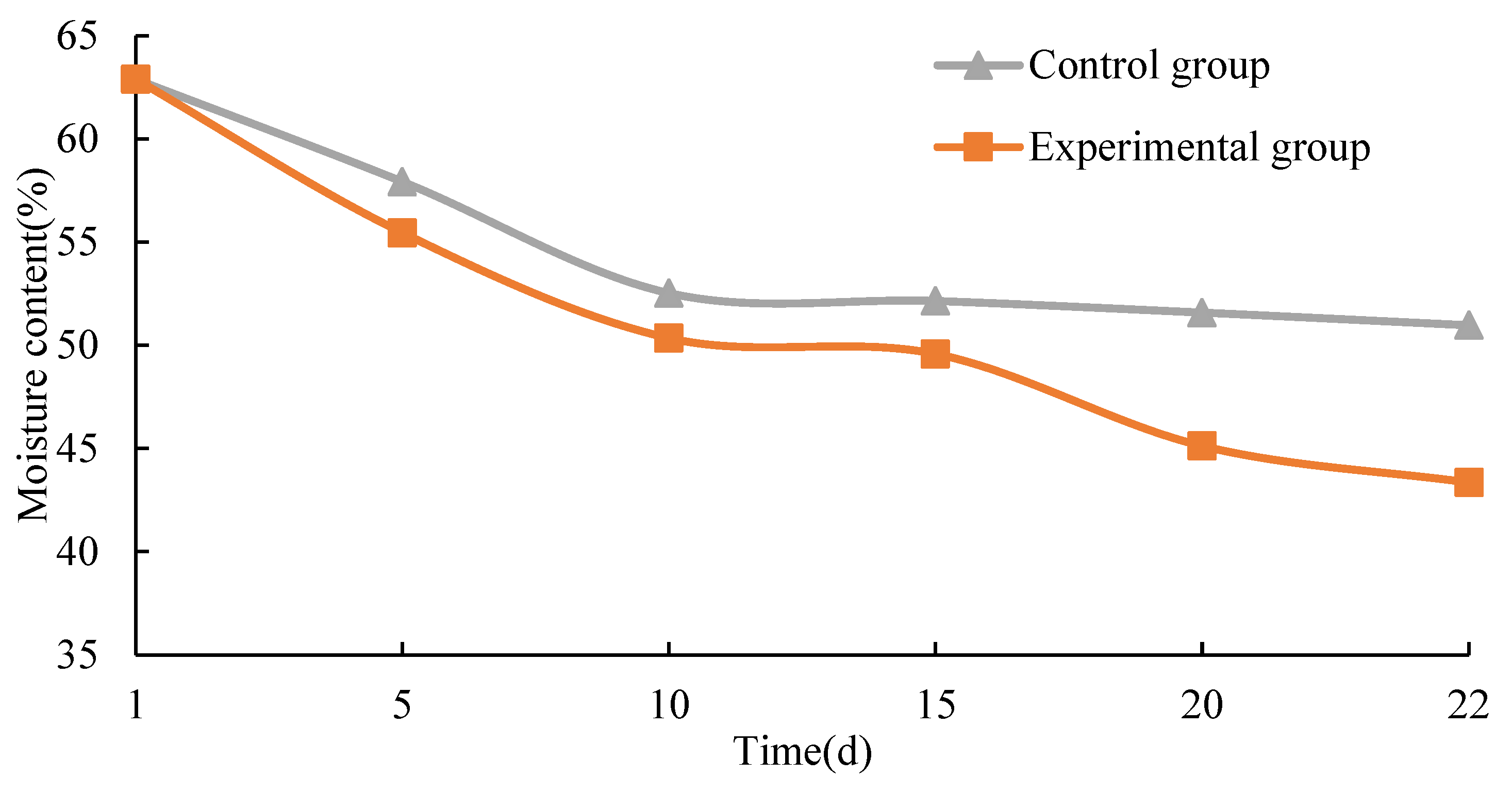

The moisture content of aerobic compost is the main factor affecting the process of aerobic composting and the rate of organic matter decomposition, and its changes are mainly the result of the combined action of organic matter oxidation and decomposition to produce water and ventilation to remove water. The overall moisture content showed a decreasing trend until the end of the composting reaction. The moisture content of the control group and the experimental group decreased by 11.91% and 19.54%, respectively. As shown in

Figure 10, in the early stage of composting, due to the continuous increase in pile temperature, bacterial activity increases and absorbs a large amount of water. After the evaporation of water during the high-temperature period, the rate of decrease in moisture content significantly slows down, and the microbial metabolism rate decreases. The experimental group aerates the compost to fully react, resulting in a more significant decrease in moisture content. At this point, the compost reaches a more mature state.

C/N plays an important role in the growth and metabolism of micro-organisms in compost. Low C/N can lead to high salt content and inhibit microbial growth, while high C/N can lead to substandard nutrient content in compost fertilizers. The C/N change curve is shown in

Figure 11. Comparing the two groups, it was found that the experimental group showed a gradual decrease in C/N during the composting fermentation process, which is more conducive to reducing nitrogen loss and promoting compost maturity.

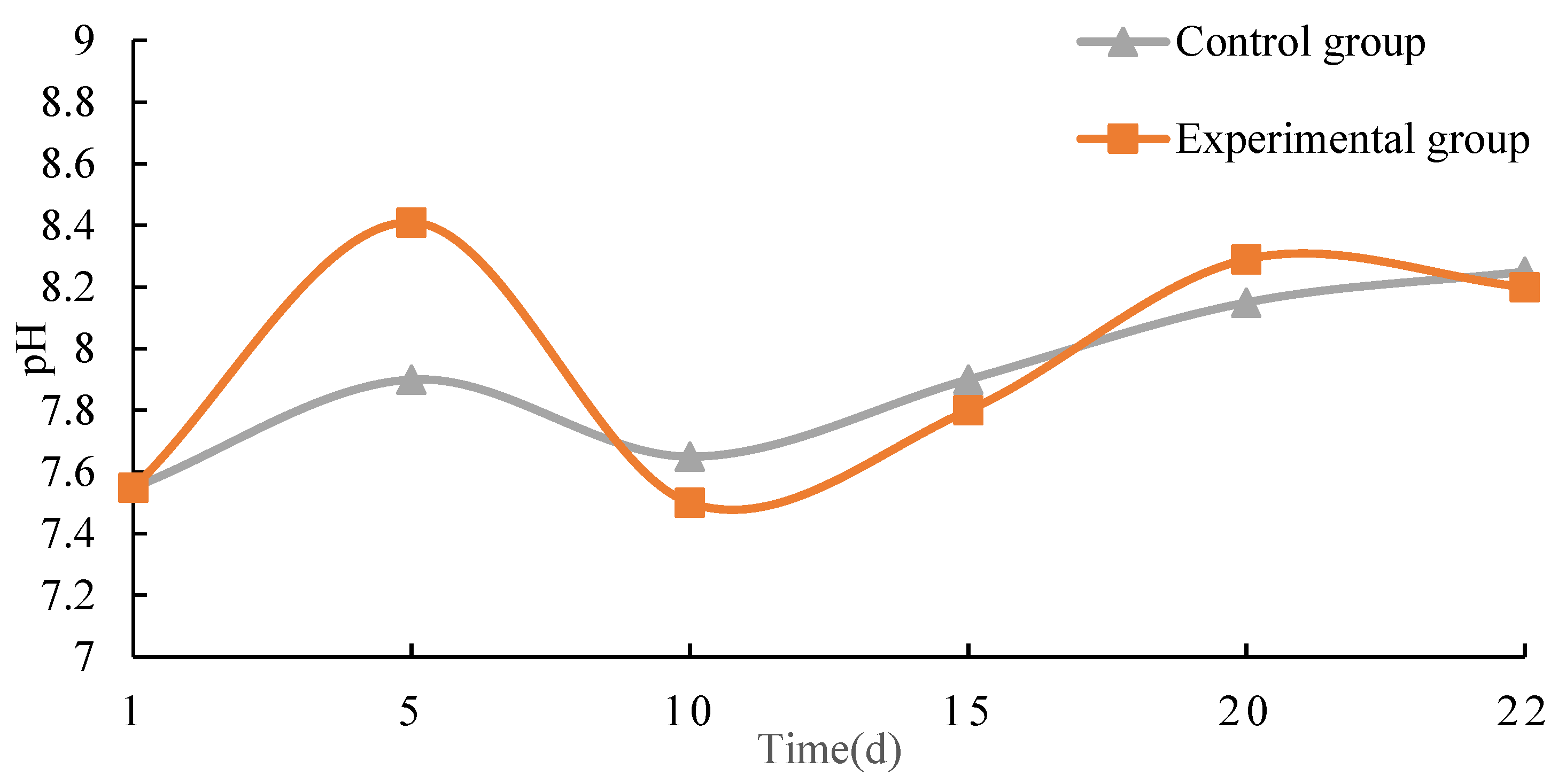

pH is an important parameter that can be used to determine the microbial environment and is also one of the many factors that evaluate the maturity of aerobic compost. Research has shown that composting fermentation can proceed efficiently and smoothly when the pH is between 6 and 9, as shown in

Figure 12, showing the dynamic changes in pH values during various stages of aerobic composting fermentation. The pH value curves of the two groups showed a similar trend of change, showing an overall upward trend, rising first and then decreasing, and then rebounding to a stable range between 7.5 and 8.5. The overall fluctuation range of the pH value of the experimental group is larger than that of the control group, but it tends to stabilize faster than the control group until the compost fermentation is completed. The pH values of the control group and the experimental group are 8.25 and 8.2, respectively, meeting the commonly considered compost maturity standards (pH 8.0–9.0) [

32].

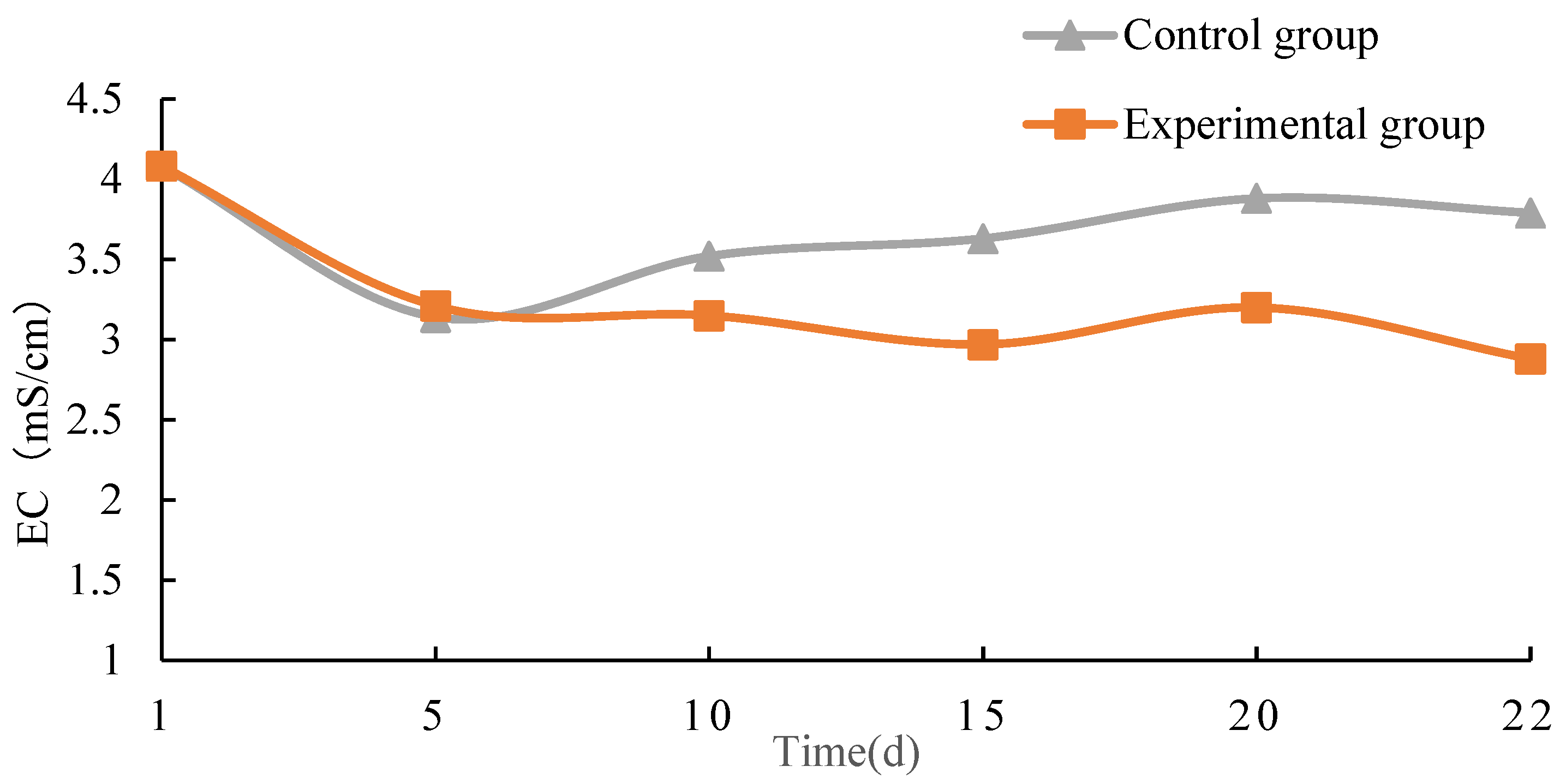

The size of the EC value is directly related to the salt concentration in the aerobic composting fermentation process. Generally speaking, the smaller the EC value, the more harmless it is for plants. The dynamic changes in EC values are shown in

Figure 13. The EC values of the two groups do not change much. During each stage of composting fermentation, the metabolic rate of micro-organisms increases, and the decomposition of organic matter generates a large amount of mineral salts, which increases the EC value. As ammonia volatilizes, the EC value also decreases. The experimental group can fully react in the early stage of composting, and then continue stable fermentation, effectively promoting maturity.