Using Nano-Fluids Minimum Quantity Lubrication (NF-MQL) to Improve Tool Wear Characteristics for Efficient Machining of CFRP/Ti6Al4V Aeronautical Structural Composite

Abstract

1. Introduction

2. Experimental Setup

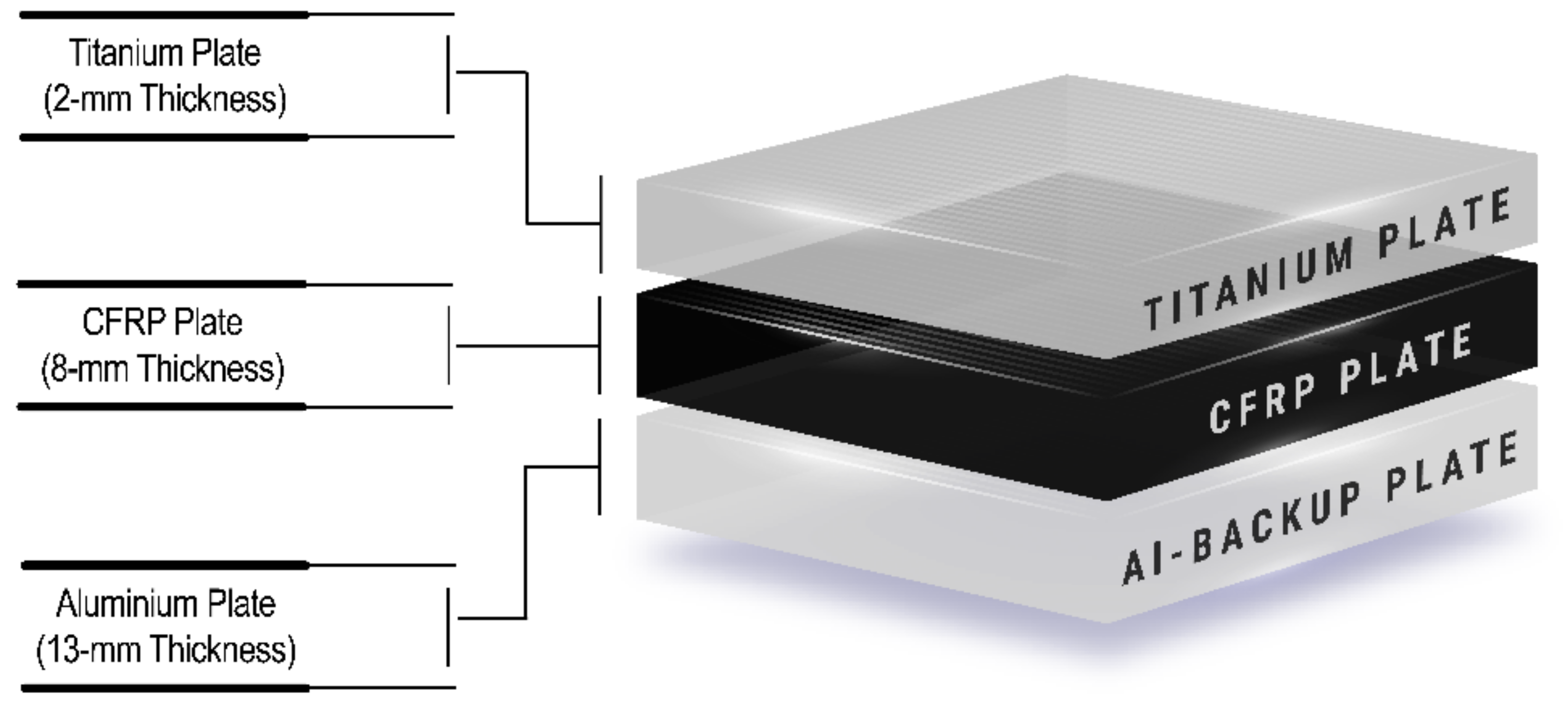

2.1. Machine Tool and Workpiece

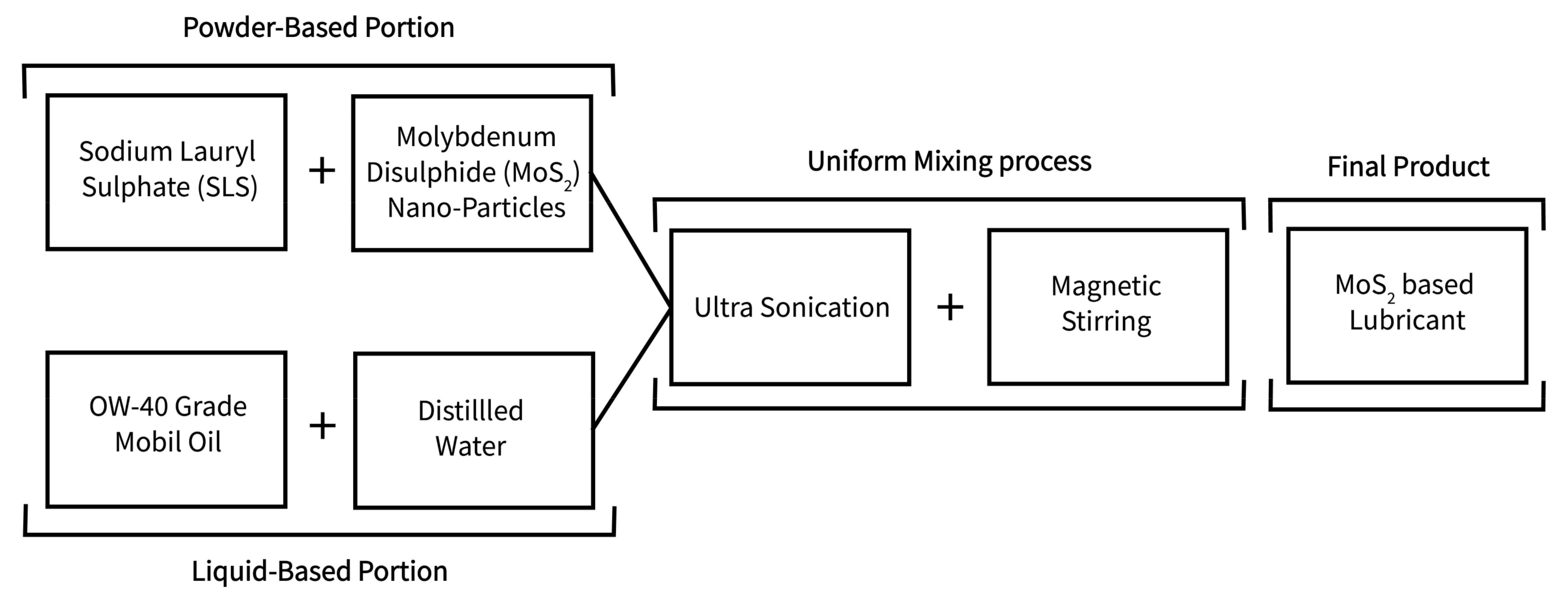

2.2. Experimental Design and Minimum Quality Lubrication Setup

2.3. Tool Wear Measurement

3. Results and Discussion

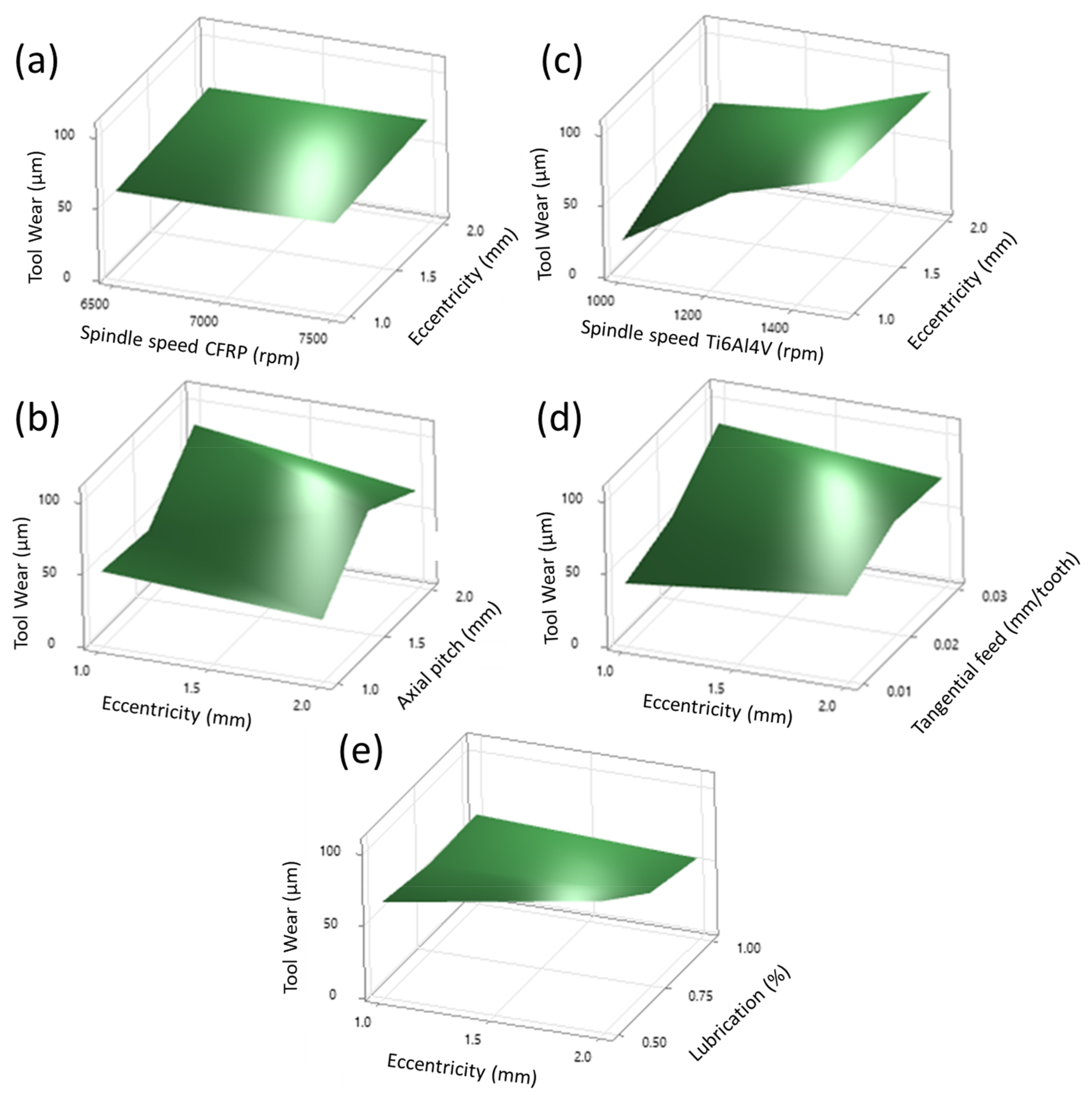

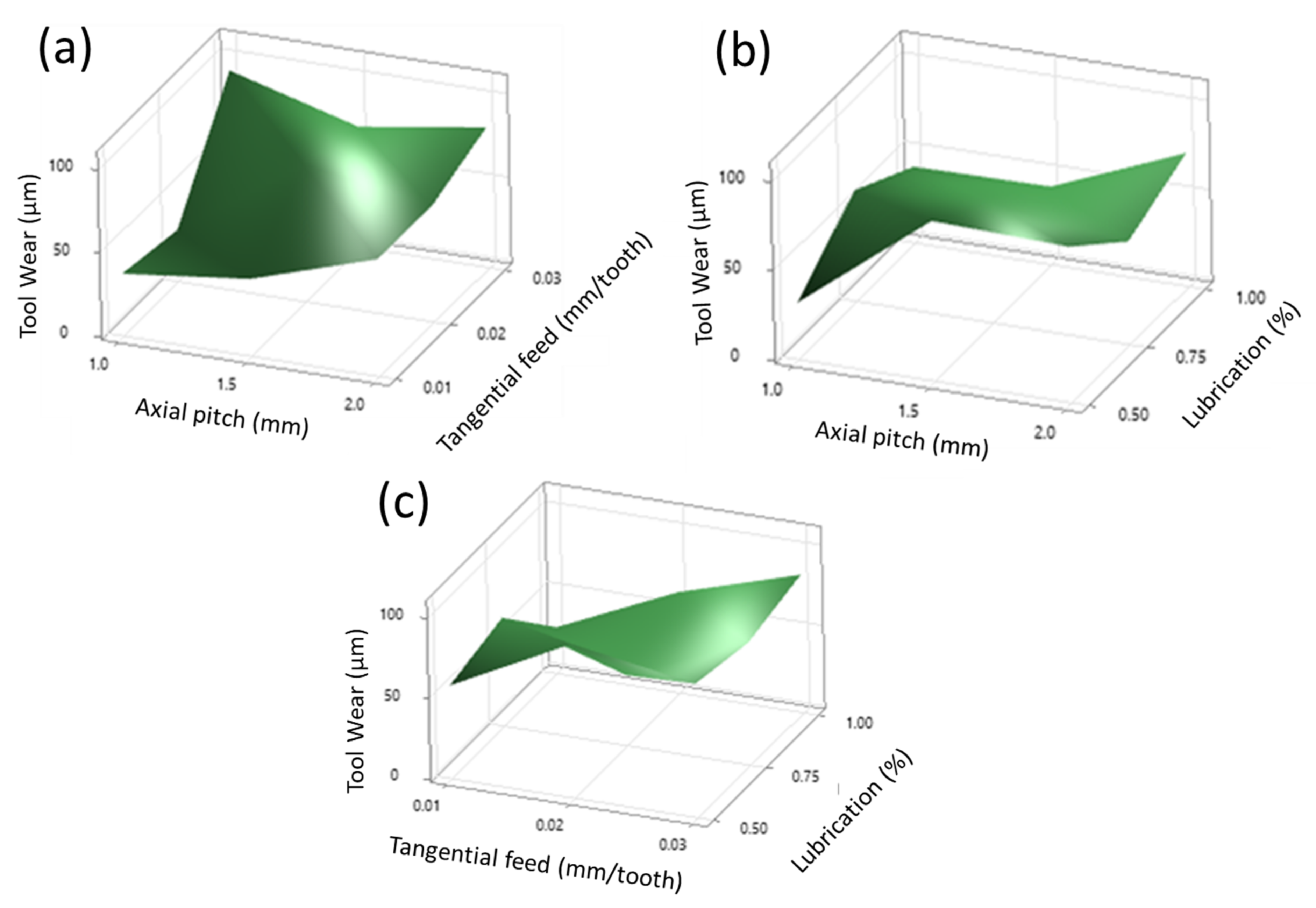

3.1. Parametric Analysis

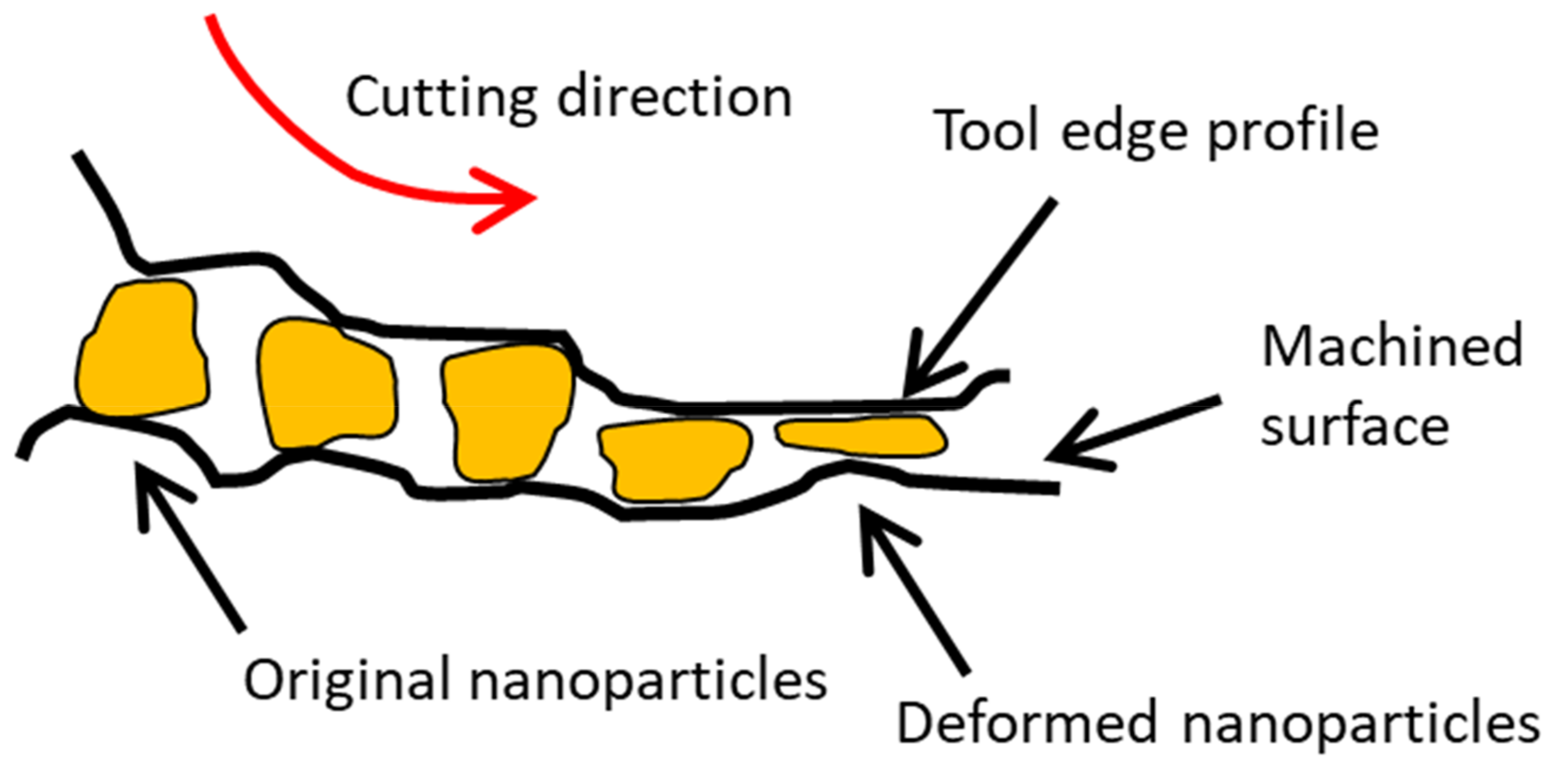

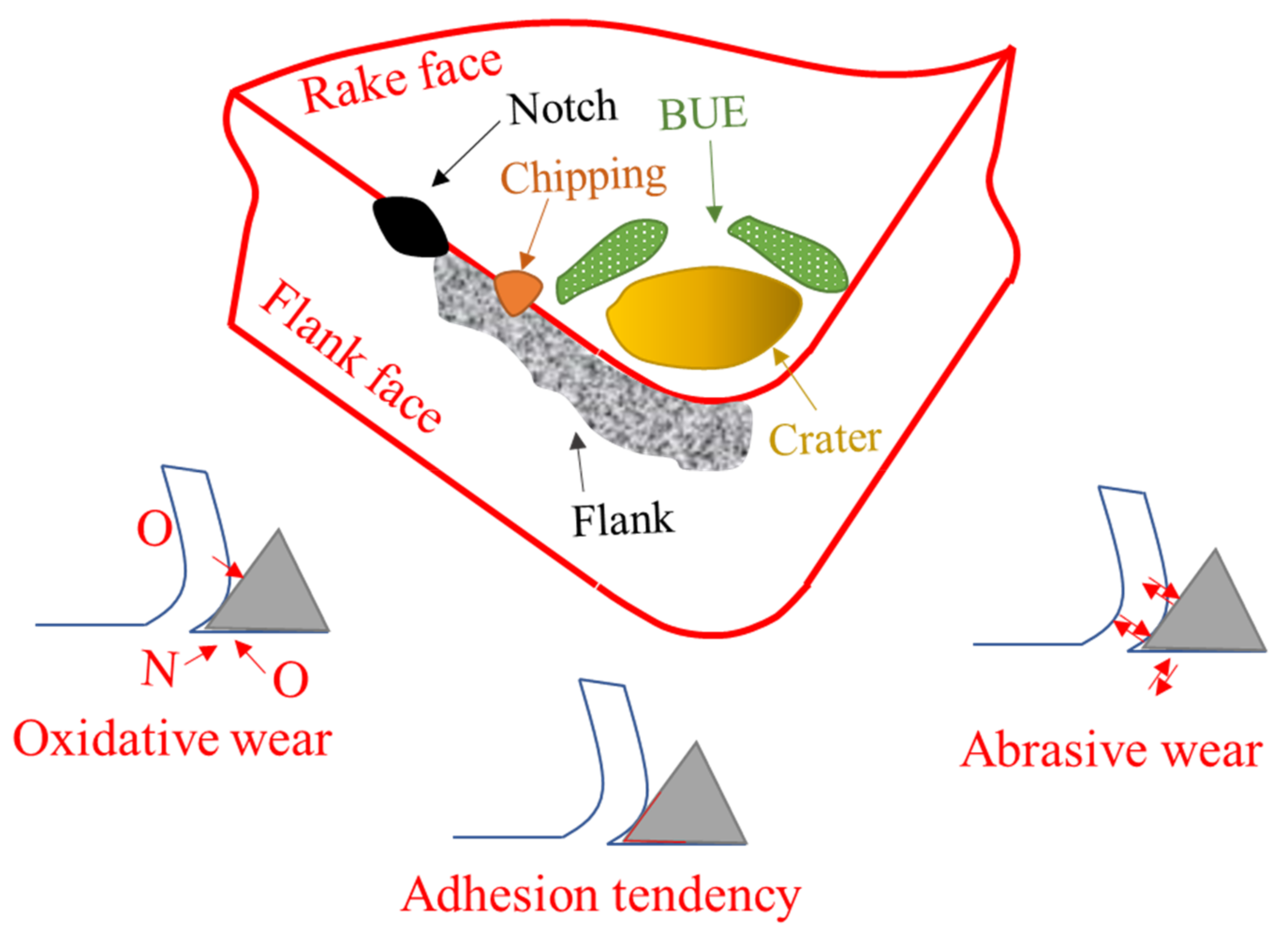

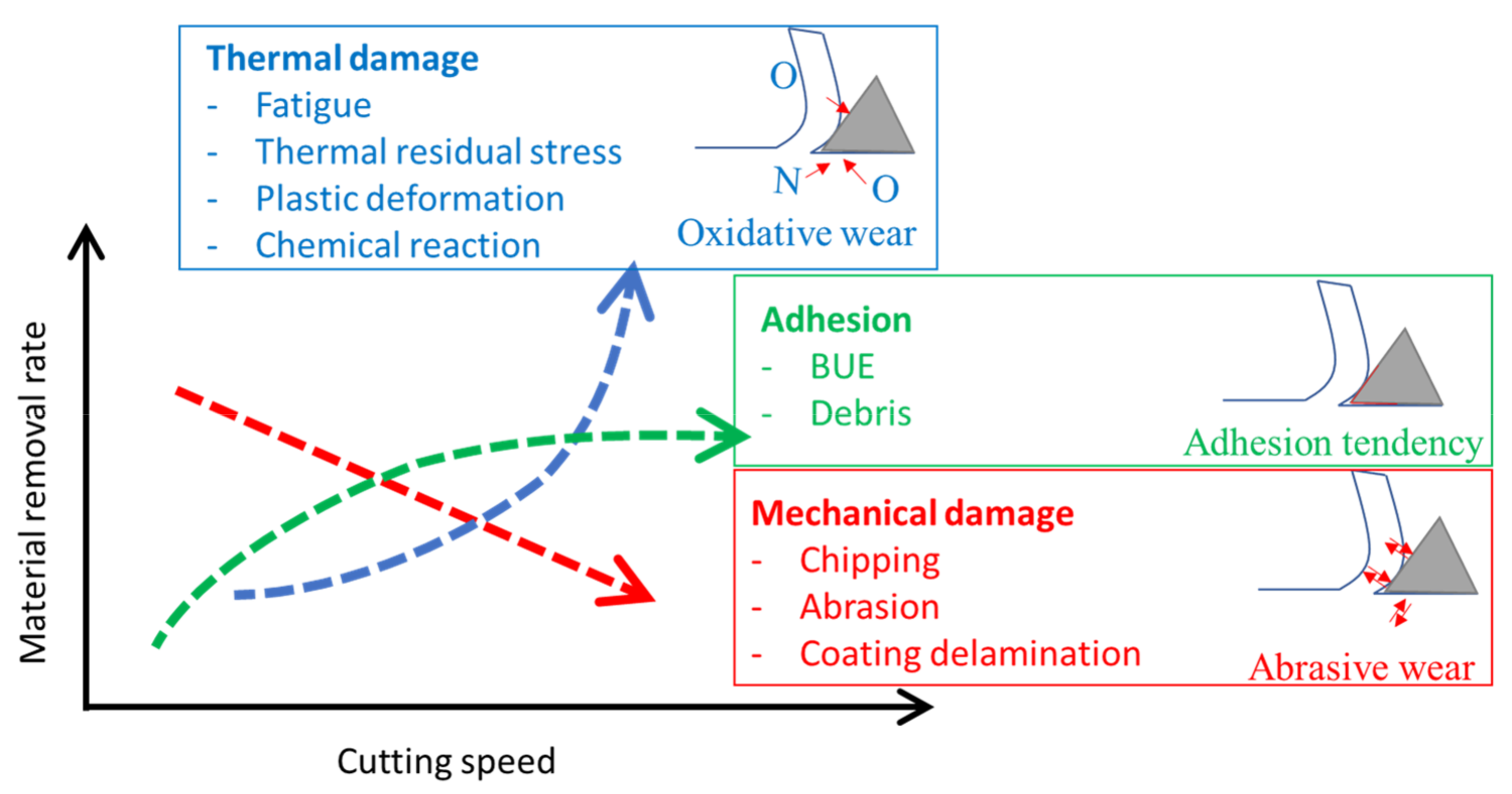

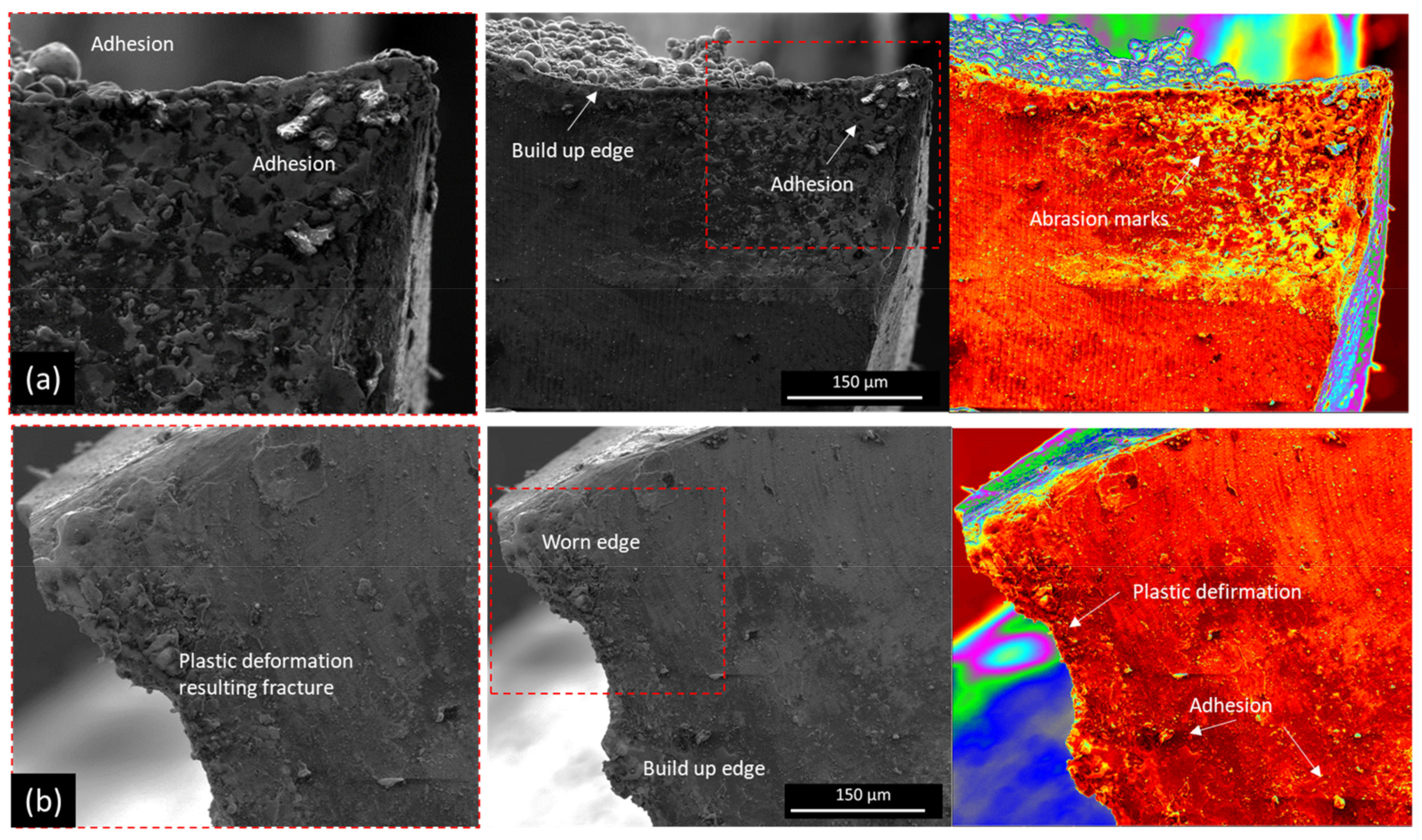

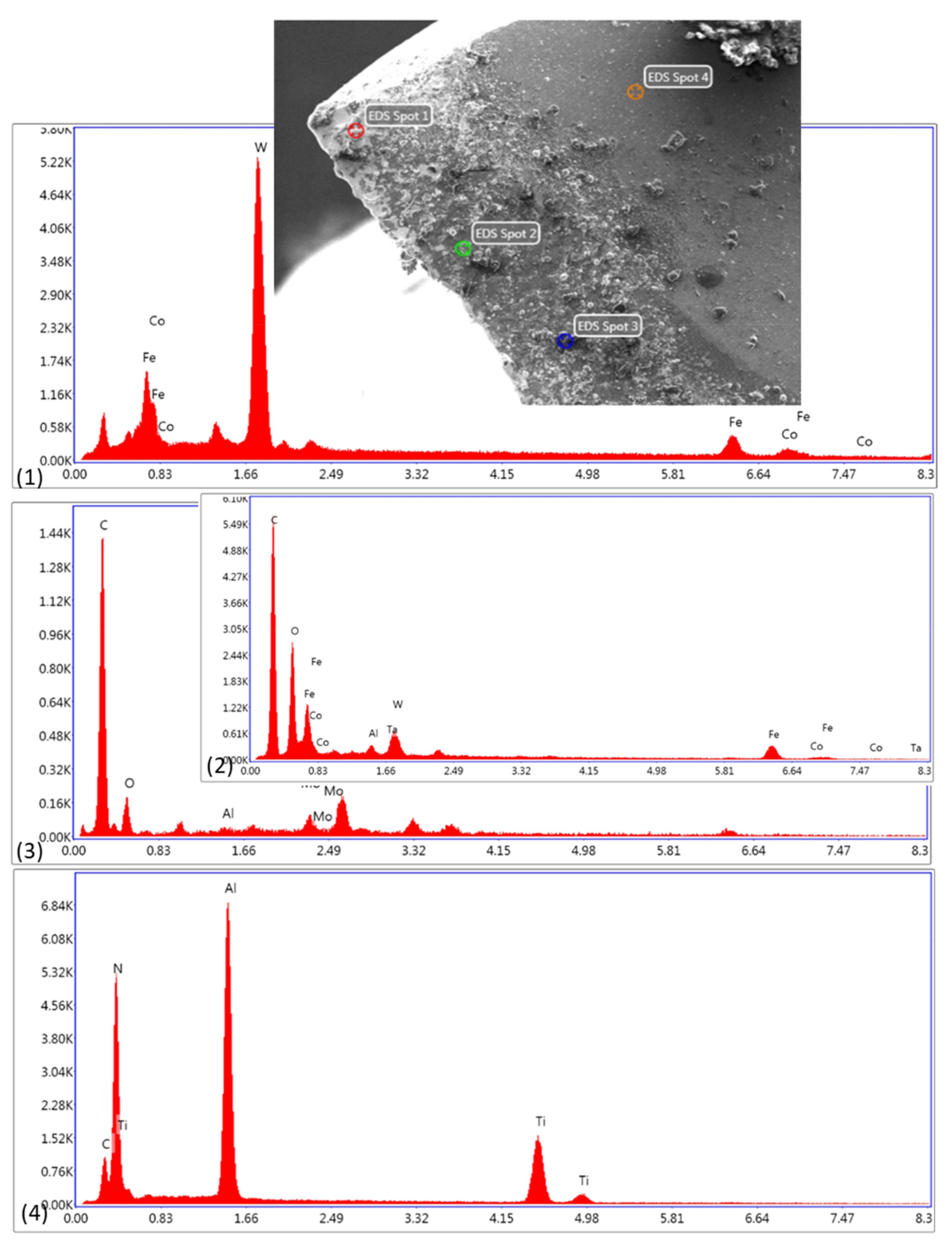

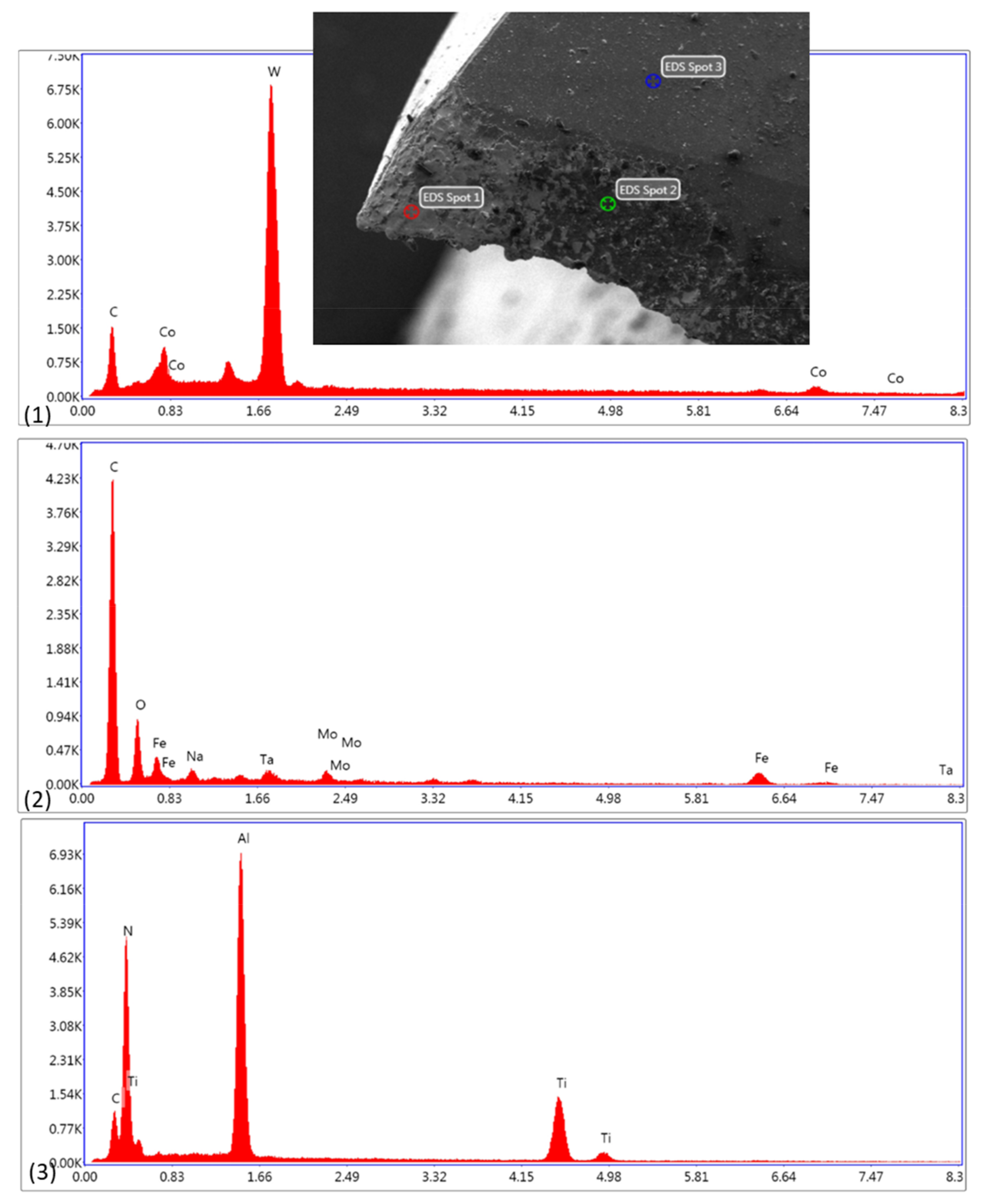

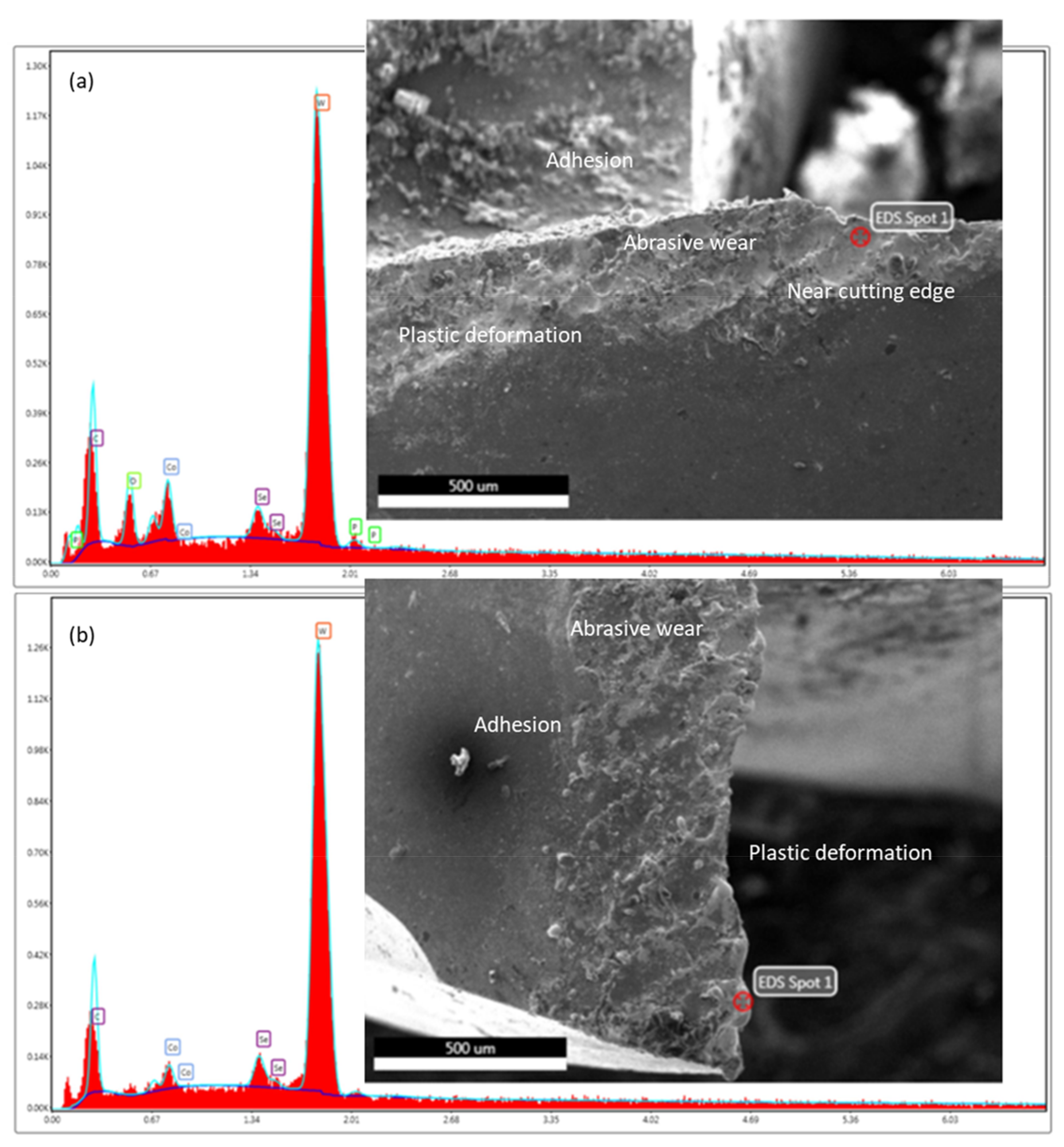

3.2. Tool Wear Mechanisms

3.3. Extended Study

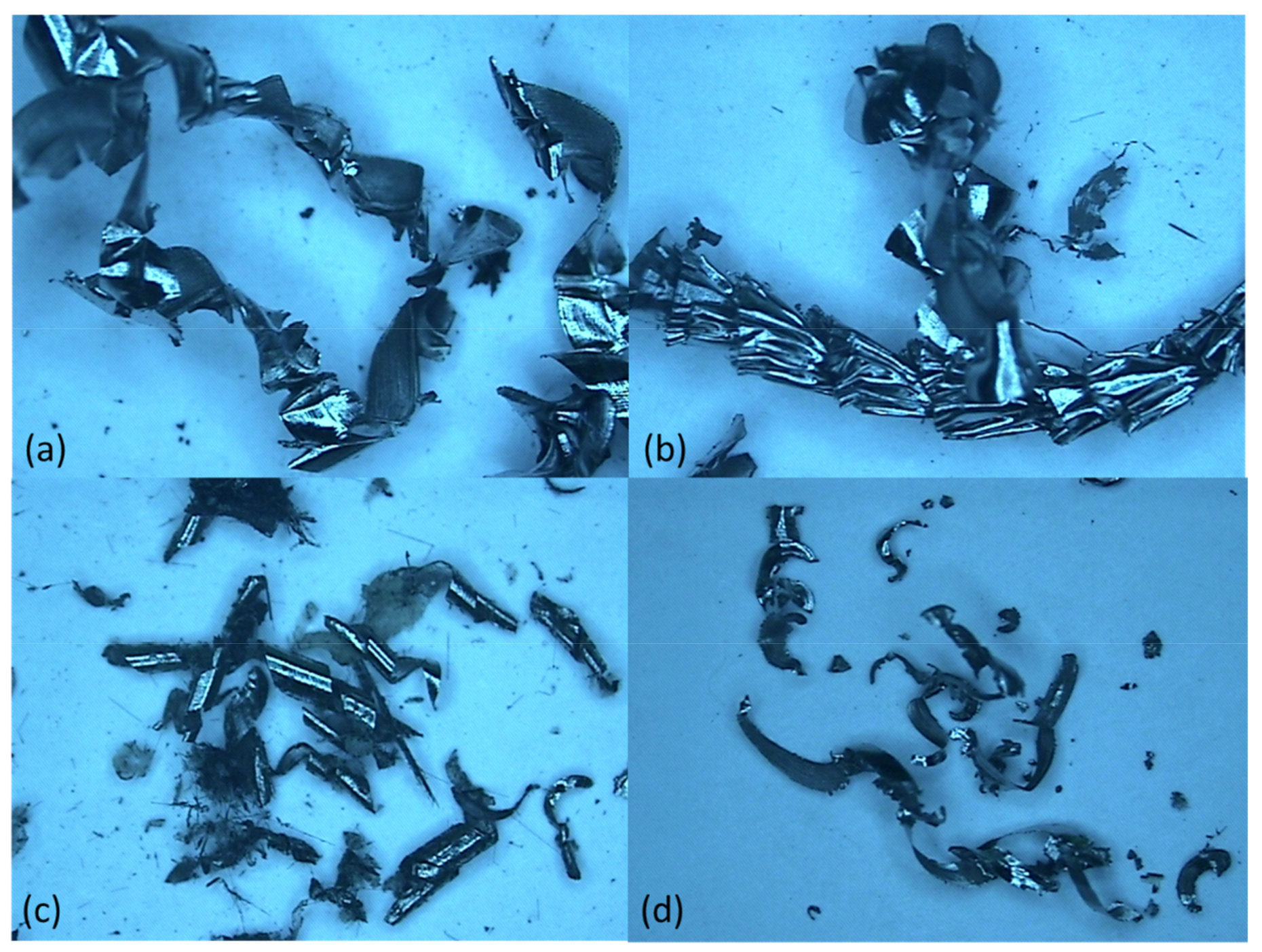

3.4. Chip Morphology

4. Conclusions

- A low level of axial pitch and lubrication resulted in tool wear in the range of ~46 µm, whereas low levels of tangential feed and lubrication resulted in tool wear around ~59 µm. An increase in the amount of MoS2 in the lubricant for the MQL setup resulted in wear reduction at low levels of axial pitch and tangential feed. Therefore, high levels of nanofluids with low levels of other variables are recommended to reduce tool wear conditions.

- The analysis of tool wear showed extreme tool wear (106 µm) at eccentricity level 2, spindle speed for Ti6Al4V of 1500 rpm, spindle speed for CFRP of 6500 rpm, axial pitch of 1.5 mm, tangential feed of 0.02 mm/tooth, and 0.5% MoS2 nanoparticles, whereas low tool wear (13 µm) was observed at eccentricity level 1, spindle speed for Ti6Al4V of 1000 rpm, spindle speed for CFRP of 7500 rpm, tangential feed of 0.01 mm/tooth, the axial pitch of 1.5 mm, and 1% of MoS2 nanoparticles. The high nanoparticles concentration of 1% resulted in discontinuous chip formation.

- Lubrication which carried a percentage of nanoparticles in the fluid had different effects as compared to axial pitch and tangential feed. The increase in the MoS2 concentration from 0.5% to 1% in the lubricant reduced tool wear from ~85 µm to ~75 µm. This improvement was because of the tribological characteristics of the nanoparticles in the cutting zone.

- The elements W and Co were introduced near the tool nose as a result of adhesion tendency and abrasion, whereas the cutting edge showed evidence of C, O, Fe, and Co with a reduced content of Al and Ti. There was also evidence of Mo on the cutting edge, showing the formation of tribo-film of 1% nano particles. However, the experimental conditions with 0.5% nano particles resulted in low Mo transfer on the tool surface.

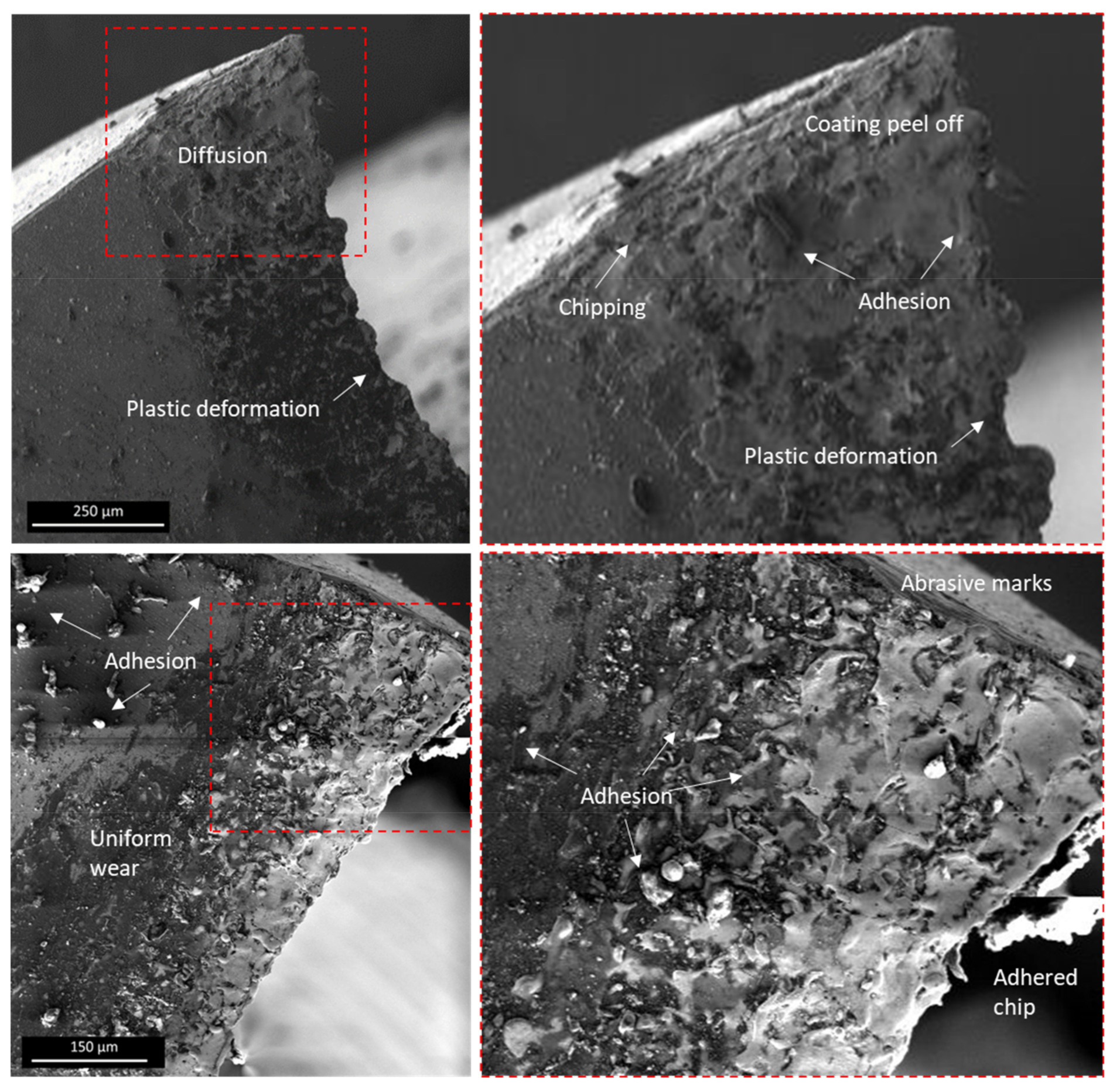

- In the extended study, abrasion was found to have a major effect on the tool wear mechanism, resulting from long tool engagement and leading to tool fracture. The abrasive wear significantly removed the coating at the cutting edge and severe plastic deformation was observed. Chemical analysis shows the diffusion of C at a high rate as compared to metal elements such as W and Co. The diffusion of elements was found to be one of the major reasons for tool fragility.

- The chipping mechanism was observed at the cutting edge and was significantly increased between peripheral and frontal edges. The appearance of fractures in this region was associated with local cutting speed and stress at frontal and peripheral edges, respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hynes, N.R.J.; Vignesh, N.J.; Jappes, J.W.; Velu, P.S.; Barile, C.; Ali, M.A.; Farooq, M.U.; Pruncu, C.I. Effect of Stacking Sequence of Fibre Metal Laminates with Carbon Fibre Reinforced Composites on Mechanical Attributes: Numerical Simulations and Experimental Validation. Compos. Sci. Technol. 2022, 221, 109303. [Google Scholar] [CrossRef]

- Qi, Z.; Ge, E.; Yang, J.; Li, F.; Jin, S. Influence Mechanism of Multi-Factor on the Diameter of the Stepped Hole in the Drilling of CFRP/Ti Stacks. Int. J. Adv. Manuf. Technol. 2021, 113, 923–933. [Google Scholar] [CrossRef]

- Xu, J.; El Mansori, M. Experimental Study on Drilling Mechanisms and Strategies of Hybrid CFRP/Ti Stacks. Compos. Struct. 2016, 157, 461–482. [Google Scholar] [CrossRef]

- Pereszlai, C.; Geier, N. Comparative Analysis of Wobble Milling, Helical Milling and Conventional Drilling of CFRPs. Int. J. Adv. Manuf. Technol. 2020, 106, 3913–3930. [Google Scholar] [CrossRef]

- Mughal, K.; Mughal, M.P.; Farooq, M.U.; Qaiser Saleem, M.; Haber Guerra, R. Helical Milling of CFRP/Ti6Al4V Stacks Using Nano Fluid Based Minimum Quantity Lubrication (NF-MQL): Investigations on Process Performance and Hole Integrity. Materials 2023, 16, 566. [Google Scholar] [CrossRef]

- Shu, L.; Li, S.; Fang, Z.; Kizaki, T.; Kimura, K.; Arai, G.; Arai, K.; Sugita, N. Study on Dedicated Drill Bit Design for Carbon Fiber Reinforced Polymer Drilling with Improved Cutting Mechanism. Compos. Part Appl. Sci. Manuf. 2021, 142, 106259. [Google Scholar] [CrossRef]

- Ge, J.; Chen, G.; Su, Y.; Zou, Y.; Ren, C.; Qin, X.; Wang, G. Effect of Cooling Strategies on Performance and Mechanism of Helical Milling of CFRP/Ti-6Al-4V Stacks. Chin. J. Aeronaut. 2022, 35, 388–403. [Google Scholar] [CrossRef]

- Xu, J.; Ji, M.; Chen, M.; Ren, F. Investigation of Minimum Quantity Lubrication Effects in Drilling CFRP/Ti6Al4V Stacks. Mater. Manuf. Process. 2019, 34, 1401–1410. [Google Scholar] [CrossRef]

- Farooq, M.U.; Anwar, S.; Ullah, R.; Guerra, R.H. Sustainable Machining of Additive Manufactured SS-316L Underpinning Low Carbon Manufacturing Goal. J. Mater. Res. Technol. 2023, 24, 2299–2318. [Google Scholar] [CrossRef]

- Javid, H.; Jahanzaib, M.; Jawad, M.; Ali, M.A.; Farooq, M.U.; Pruncu, C.I.; Hussain, S. Parametric Analysis of Turning HSLA Steel under Minimum Quantity Lubrication (MQL) and Nanofluids-Based Minimum Quantity Lubrication (NF-MQL): A Concept of One-Step Sustainable Machining. Int. J. Adv. Manuf. Technol. 2021, 117, 1915–1934. [Google Scholar] [CrossRef]

- Gao, T.; Li, C.; Wang, Y.; Liu, X.; An, Q.; Li, H.N.; Zhang, Y.; Cao, H.; Liu, B.; Wang, D. Carbon Fiber Reinforced Polymer in Drilling: From Damage Mechanisms to Suppression. Compos. Struct. 2022, 286, 115232. [Google Scholar] [CrossRef]

- Jadam, T.; Rakesh, M.; Datta, S. Machinability of Ti–6al–4v Superalloy: Performance of Dry Cutting and Nanofluid MQL (MWCNT-Added Rice Bran Oil). Arab. J. Sci. Eng. 2020, 45, 5673–5695. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Van Thanh, D. Evaluation of Minimum Quantity Lubrication and Minimum Quantity Cooling Lubrication Performance in Hard Drilling of Hardox 500 Steel Using Al2O3 Nanofluid. Adv. Mech. Eng. 2020, 12, 1687814019888404. [Google Scholar] [CrossRef]

- Sahoo, S.P.; Datta, S.; Roy, T.; Ghosh, S. Machining Performance of Ti6Al4V under Dry Environment, Pressurized Air Supply, and Water-MQL: Analysis of Machining-Induced Vibration Signals and Captured Thermographs. Sādhanā 2021, 46, 208. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, M.; An, Q. Investigation of Friction in End-Milling of Ti-6Al-4V under Different Green Cutting Conditions. Int. J. Adv. Manuf. Technol. 2015, 78, 1181–1192. [Google Scholar] [CrossRef]

- Pereira, O.; Urbikain, G.; Rodríguez, A.; Fernández-Valdivielso, A.; Calleja, A.; Ayesta, I.; de Lacalle, L.L. Internal Cryolubrication Approach for Inconel 718 Milling. Procedia Manuf. 2017, 13, 89–93. [Google Scholar] [CrossRef]

- Mosleh, M.; Shirvani, K.A.; Smith, S.T.; Belk, J.H.; Lipczynski, G. A Study of Minimum Quantity Lubrication (MQL) by Nanofluids in Orbital Drilling and Tribological Testing. J. Manuf. Mater. Process. 2019, 3, 5. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.I.; Barreiro, J.; de Lacalle, L.L. Cryogenic and Minimum Quantity Lubrication for an Eco-Efficiency Turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Hussein, R.; Sadek, A.; Elbestawi, M.A.; Attia, H. The Effect of MQL on Tool Wear Progression in Low-Frequency Vibration-Assisted Drilling of CFRP/Ti6Al4V Stack Material. J. Manuf. Mater. Process. 2021, 5, 50. [Google Scholar] [CrossRef]

- Rodríguez, A.; Calleja, A.; de Lacalle, L.N.L.; Pereira, O.; Rubio-Mateos, A.; Rodríguez, G. Drilling of CFRP-Ti6Al4V Stacks Using CO2-Cryogenic Cooling. J. Manuf. Process. 2021, 64, 58–66. [Google Scholar] [CrossRef]

- Ji, M.; Xu, J.; Chen, M.; Mansori, M.E. Effects of Different Cooling Methods on the Specific Energy Consumption When Drilling CFRP/Ti6Al4V Stacks. Procedia Manuf. 2020, 43, 95–102. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; Chen, M.; El Mansori, M.; Paulo Davim, J. On the Analysis of Temperatures, Surface Morphologies and Tool Wear in Drilling CFRP/Ti6Al4V Stacks under Different Cutting Sequence Strategies. Compos. Struct. 2020, 234, 111708. [Google Scholar] [CrossRef]

- Senthilkumar, M.; Prabukarthi, A.; Krishnaraj, V. Machining of CFRP/Ti6Al4V Stacks under Minimal Quantity Lubricating Condition. J. Mech. Sci. Technol. 2018, 32, 3787–3796. [Google Scholar] [CrossRef]

- Xu, J.; Ji, M.; Davim, J.P.; Chen, M.; El Mansori, M.; Krishnaraj, V. Comparative Study of Minimum Quantity Lubrication and Dry Drilling of CFRP/Titanium Stacks Using TiAlN and Diamond Coated Drills. Compos. Struct. 2020, 234, 111727. [Google Scholar] [CrossRef]

- Zou, Y.; Chen, G.; Ren, C.; Ge, J.; Qin, X. Performance and Mechanism of Hole-Making of CFRP/Ti-6Al-4V Stacks Using Ultrasonic Vibration Helical Milling Process. Int. J. Adv. Manuf. Technol. 2021, 117, 3529–3547. [Google Scholar] [CrossRef]

- Park, K.-H.; Suhaimi, M.A.; Yang, G.-D.; Lee, D.-Y.; Lee, S.-W.; Kwon, P. Milling of Titanium Alloy with Cryogenic Cooling and Minimum Quantity Lubrication (MQL). Int. J. Precis. Eng. Manuf. 2017, 18, 5–14. [Google Scholar] [CrossRef]

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja, A.; Fernández-Valdivielso, A.; López de Lacalle, L.N. Sustainability Analysis of Lubricant Oils for Minimum Quantity Lubrication Based on Their Tribo-Rheological Performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Rosnan, R.; Azmi, A.I.; Murad, M.N.; Ali, M.A.M. Evaluation of Coated Carbide Drills When Drilling Nickel-Titanium (NiTi) Alloys with Minimum Quantity Nano-Lubricants. In Intelligent Manufacturing and Mechatronics: Proceedings of SympoSIMM 2020; Springer: Berlin/Heidelberg, Germany, 2021; pp. 299–308. [Google Scholar]

- Xu, J.; Ji, M.; Chen, M.; El Mansori, M. Experimental Investigation on Drilling Machinability and Hole Quality of CFRP/Ti6Al4V Stacks under Different Cooling Conditions. Int. J. Adv. Manuf. Technol. 2020, 109, 1527–1539. [Google Scholar] [CrossRef]

- AZO Materials. Available online: https://www.amazom.com (accessed on 20 July 2022).

- End Mills/Ø 6.000 Mm/E8/Company Std./Solid Carbide/FIRE. Available online: https://webshop.guehring.de/en/000009199780060000 (accessed on 28 April 2023).

- Fernández-Valdivielso, A.; López de Lacalle, L.; Urbikain, G.; Rodriguez, A. Detecting the Key Geometrical Features and Grades of Carbide Inserts for the Turning of Nickel-Based Alloys Concerning Surface Integrity. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 230, 3725–3742. [Google Scholar] [CrossRef]

- Sha, Z.H.; Wang, Y.; Zhang, S.F. The Influence of Eccentricity on Thrust Force of Helical Milling in Carbon Fiber Composite Holemaking. Appl. Mech. Mater. 2013, 328, 995–999. [Google Scholar] [CrossRef]

- Denkena, B.; Boehnke, D.; Dege, J.H. Helical Milling of CFRP–Titanium Layer Compounds. CIRP J. Manuf. Sci. Technol. 2008, 1, 64–69. [Google Scholar] [CrossRef]

- Charoo, M.S.; Wani, M.F.; Hanief, M.; Rather, M.A. Tribological Properties of MoS2 Particles as Lubricant Additive on EN31 Alloy Steel and AISI 52100 Steel Ball. Mater. Today Proc. 2017, 4, 9967–9971. [Google Scholar] [CrossRef]

- Sekhar, K.C.; Rama Reddy, V.V.; Srikiran, S.; Daniel, M.; Kumar, S. Investigating the Effect of Nano Crystalline MoS2 Particles on the Surface Integrity of Turned Components. Mater. Today Proc. 2017, 4, 7527–7532. [Google Scholar] [CrossRef]

- Rahmati, B.; Sarhan, A.A.D.; Sayuti, M. Morphology of Surface Generated by End Milling AL6061-T6 Using Molybdenum Disulfide (MoS2) Nanolubrication in End Milling Machining. J. Clean. Prod. 2014, 66, 685–691. [Google Scholar] [CrossRef]

- Uysal, A.; Demiren, F.; Altan, E. Applying Minimum Quantity Lubrication (MQL) Method on Milling of Martensitic Stainless Steel by Using Nano Mos2 Reinforced Vegetable Cutting Fluid. Procedia Soc. Behav. Sci. 2015, 195, 2742–2747. [Google Scholar] [CrossRef]

- Puerta-Morales, F.J.; Gomez, J.S.; Fernandez-Vidal, S.R. Study of the Influence of Helical Milling Parameters on the Quality of Holes in the UNS R56400 Alloy. Appl. Sci. 2020, 10, 845. [Google Scholar] [CrossRef]

- ul Haq, M.A.; Hussain, S.; Ali, M.A.; Farooq, M.U.; Mufti, N.A.; Pruncu, C.I.; Wasim, A. Evaluating the Effects of Nano-Fluids Based MQL Milling of IN718 Associated to Sustainable Productions. J. Clean. Prod. 2021, 310, 127463. [Google Scholar] [CrossRef]

- Liew, W.Y.H. Low-Speed Milling of Stainless Steel with TiAlN Single-Layer and TiAlN/AlCrN Nano-Multilayer Coated Carbide Tools under Different Lubrication Conditions. Wear 2010, 269, 617–631. [Google Scholar] [CrossRef]

- Qin, X.; Gui, L.; Li, H.; Rong, B.; Wang, D.; Zhang, H.; Zuo, G. Feasibility Study on the Minimum Quantity Lubrication in High-Speed Helical Milling of Ti-6Al-4V. J. Adv. Mech. Des. Syst. Manuf. 2012, 6, 1222–1233. [Google Scholar] [CrossRef]

- Li, H.; He, G.; Qin, X.; Wang, G.; Lu, C.; Gui, L. Tool Wear and Hole Quality Investigation in Dry Helical Milling of Ti-6Al-4V Alloy. Int. J. Adv. Manuf. Technol. 2014, 71, 1511–1523. [Google Scholar] [CrossRef]

- Wang, H.; Qin, X.; Li, H.; Tan, Y. A Comparative Study on Helical Milling of CFRP/Ti Stacks and Its Individual Layers. Int. J. Adv. Manuf. Technol. 2016, 86, 1973–1983. [Google Scholar] [CrossRef]

- Wang, C.Y.; Xie, Y.X.; Qin, Z.; Lin, H.S.; Yuan, Y.H.; Wang, Q.M. Wear and Breakage of TiAlN-and TiSiN-Coated Carbide Tools during High-Speed Milling of Hardened Steel. Wear 2015, 336, 29–42. [Google Scholar] [CrossRef]

- Gutzeit, K.; Bulun, G.; Stelzer, G.; Kirsch, B.; Seewig, J.; Aurich, J.C. Sub-Zero Milling of Ti-6Al-4V–Impact of the Cutting Parameters on the Resulting Forces, Tool Wear, and Surface Quality. Int. J. Adv. Manuf. Technol. 2023, 126, 3367–3381. [Google Scholar] [CrossRef]

- Li, J.; Shi, W.; Lin, Y.; Li, J.; Liu, S.; Liu, B. Comparative Study on MQL Milling and Hole Making Processes for Laser Beam Powder Bed Fusion (L-PBF) of Ti-6Al-4V Titanium Alloy. J. Manuf. Process. 2023, 94, 20–34. [Google Scholar] [CrossRef]

- Fernández-Vidal, S.R.; Mayuet, P.; Rivero, A.; Salguero, J.; del Sol, I.; Marcos, M. Analysis of the Effects of Tool Wear on Dry Helical Milling of Ti6Al4V Alloy. Procedia Eng. 2015, 132, 593–599. [Google Scholar] [CrossRef]

| Authors, Year and Reference | Cutting Tool and Experimental Conditions | Lubrication Conditions | Findings |

|---|---|---|---|

| Ge et al., 2022 [7] | Four-flute ultrafine-grained cemented carbide (WC-12%Co) tool; spindle speed, tangential feed per tooth, axial feed, target hole diameter, number of machined holes | Dry and MQL (synthetic lubricating oil with anti-wear agent, stabilizer, and anti-rust agent) | In dry conditions, adhesion and chipping were major drivers of tool wear, whereas in MQL slight adhesion was observed. |

| Hussein et al., 2021 [19] | YG-1 tungsten carbide tool; cutting speed, vibration amplitude | MQL (5% MECAGREEN 550) | MQL system assisted extended hole-making campaign without resulting in tool/chip welding phenomenon. |

| Xu et al., 2019 [8] | Uncoated tungsten carbide tool; cutting speed, feed rate | Dry and MQL (vegetable-based oil) | Improvement in surface morphology of machined holes and reduction in tool-wear severity was observed with MQL in comparison to conventional dry cutting. |

| Rodriguez et al., 2021 [20] | CVD diamond-coated carbide tool; number of machined holes | Dry and CO2 | With CO2, cutting temperature significantly decreased. However, wear-promoting mechanisms were still of concern. |

| Ji et al., 2020 [21] | PVD TiAlN-coated tool; cutting speed, feed rate | Dry and MQL | Friction of tool with hole walls was significantly reduced by MQL system which resulted in superior surface quality. |

| Xu et al., 2020 [22] | Uncoated tungsten carbide (WC/Co) and CVD diamond-coated tools; cutting speed, feed rate, composite stack sequence | Dry | The key wear patterns were observed to be flank wear, abrasion, and adhesion. Similarly, coating peeled off and microchipping resulted in abrupt failure of tools. |

| Senthilkumar et al., 2018 [23] | TG1, TG2, TG3 tools; spindle speed, feed rate, flow rate | MQL (LRT30 3226661 cutting fluid with anti-corrosive properties) | Low level of flow rate 25 mL/h for hole-making in CFRP, whereas Ti alloy required 75 mL/h to minimize cutting forces and reduce tool wear. |

| Xu et al., 2020 [24] | CVD diamond-coated tungsten carbide and PVD TiAlN tools; cutting speed, feed rate | Dry and MQL (vegetable-based MICROLUBE 2000 micro-cutting oil) | Abrasion wear because of worn edges and adhesion wear due to tool/Ti chip welding were main drivers of tool failure. Coating peeled off and edge fractures were also observed. |

| CFRP | |

|---|---|

| Details | Value |

| Tensile modulus | 230 GPa |

| Fiber thickness | 0.25 mm |

| Filament count | 3000 |

| Filament diameter | 7 μm |

| Cutting Tool | |

| Details | Value |

| Helix angle | 30° |

| Diameter tolerance | e8 |

| Tool preparation | Without internal cooling |

| Material | Solid carbide |

| Chamfer angle | 45° |

| Back rake angle | 9° |

| |

| Properties | Levels | Rationale |

|---|---|---|

| Eccentricity (mm) | 1, 2 | The eccentricity and tool diameter directly impacts the thrust forces that help us to control the delamination and tool wear rate. The levels are determined based on guidelines by Sha et al. [33]. |

| Spindle speed Ti (rpm) | 1000, 1250, 1500 | The levels for the spindle speed of machining CFRP and Ti were selected after the literature review and the trial runs [5]. |

| Spindle speed CFRP (rpm) | 6500, 7000, 7500 | |

| Axial itch (mm) | 1, 1.5, 2 | An optimized combination of axial feed per tooth and tangential feed per tooth was used to reduce the effect of cutting forces that have an effect on the diametric variations. The levels used were based on guidelines by Denkena et al. [34] who carried out dry helical milling of CFRP/Ti6Al4V. Using very high axial pitch is the novelty in this research. The micro-focus was on reducing the tool wear, improving the tool life, reducing the machining time, and improving the work quality with minimal errors. |

| Tangential feed (mm/tooth) | 0.01, 0.02, 0.03 | |

| Lubrication (MoS2) (%wt) | 0.5, 0.75, 1 | Molybdenum disulfide (MoS2) is a solid lubricant commonly used in tribological applications due to its excellent lubricating properties [35]. This film acts as a physical barrier between the surfaces, preventing direct metal-to-metal contact and reducing friction [5,17]. Sekhar et al. [36] used 0.5–1.5% MoS2 concentration and found 0.5% as optimal. Rahmati et al. [37] used 0–1% MoS2 concentration during end-milling of aluminum alloys. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mughal, K.; Mughal, M.P.; Farooq, M.U.; Anwar, S.; Ammarullah, M.I. Using Nano-Fluids Minimum Quantity Lubrication (NF-MQL) to Improve Tool Wear Characteristics for Efficient Machining of CFRP/Ti6Al4V Aeronautical Structural Composite. Processes 2023, 11, 1540. https://doi.org/10.3390/pr11051540

Mughal K, Mughal MP, Farooq MU, Anwar S, Ammarullah MI. Using Nano-Fluids Minimum Quantity Lubrication (NF-MQL) to Improve Tool Wear Characteristics for Efficient Machining of CFRP/Ti6Al4V Aeronautical Structural Composite. Processes. 2023; 11(5):1540. https://doi.org/10.3390/pr11051540

Chicago/Turabian StyleMughal, Kiran, Mohammad Pervez Mughal, Muhammad Umar Farooq, Saqib Anwar, and Muhammad Imam Ammarullah. 2023. "Using Nano-Fluids Minimum Quantity Lubrication (NF-MQL) to Improve Tool Wear Characteristics for Efficient Machining of CFRP/Ti6Al4V Aeronautical Structural Composite" Processes 11, no. 5: 1540. https://doi.org/10.3390/pr11051540

APA StyleMughal, K., Mughal, M. P., Farooq, M. U., Anwar, S., & Ammarullah, M. I. (2023). Using Nano-Fluids Minimum Quantity Lubrication (NF-MQL) to Improve Tool Wear Characteristics for Efficient Machining of CFRP/Ti6Al4V Aeronautical Structural Composite. Processes, 11(5), 1540. https://doi.org/10.3390/pr11051540