Analytical Model of Hydraulic Fracturing for Low Permeability Hot Dry Rock Reservoirs and DEM Simulation Base on Fluid-Solid Coupling

Abstract

1. Introduction

2. Fluid-Structure Coupling Model

2.1. The Basic Postulates of HDR Resources

2.2. Mathematical Model of Fluid-Structure Coupling

2.2.1. Mathematical Model of Fluid-Structure Coupling in Rock Section

2.2.2. Mathematical Model of Fluid-Structure Coupling in Fracture Section

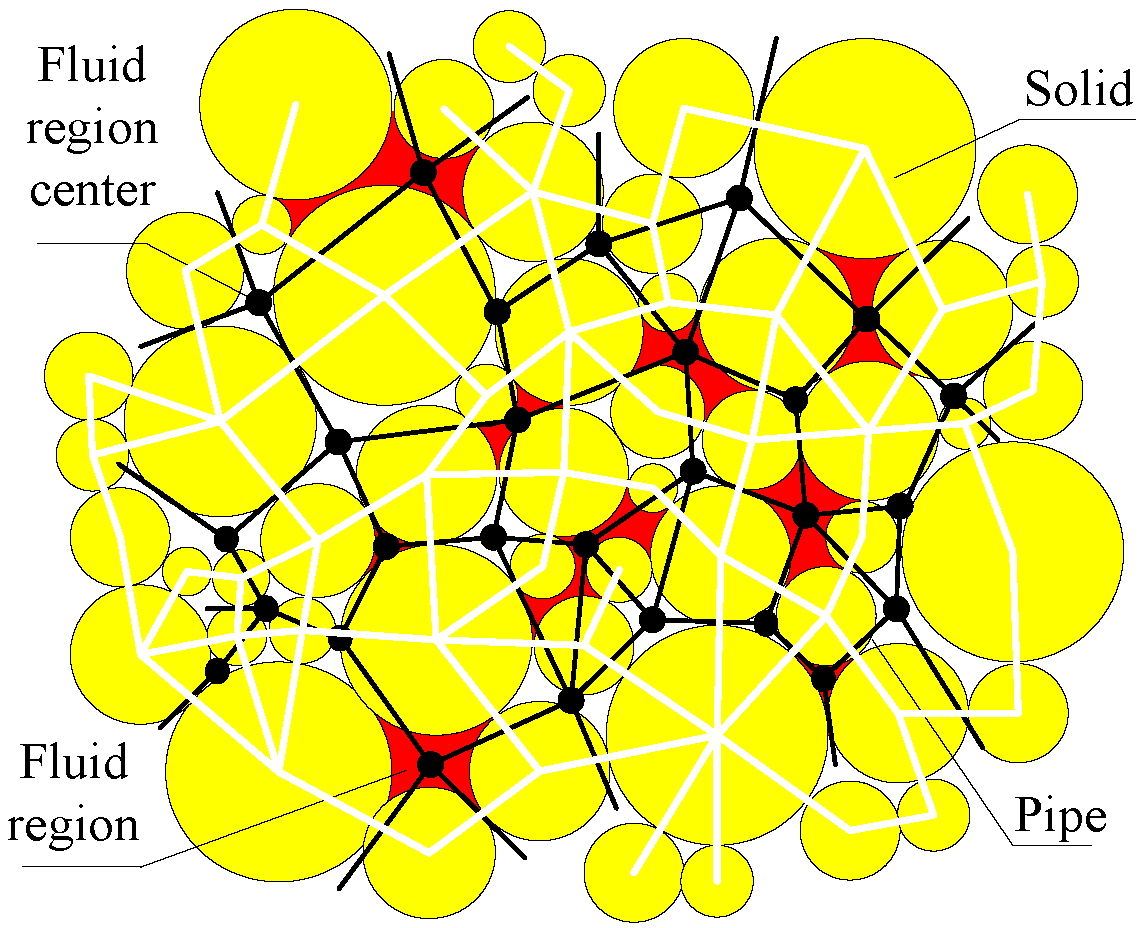

2.3. Hydraulic Fracturing in DEM Simulation Considering Fluid-Structure Coupling

2.3.1. Pressure Calculation in Fluid Region

2.3.2. Analysis of Interaction Force between Fracturing Fluid and Reservoir Particles during Hydraulic Fracturing

2.3.3. Particle Motion Equation Considering the Action of Fracturing Fluid

3. Definition of Hydraulic Fracturing Micro-Fracture Based on Particle Contact Connection Model

4. DEM Simulation of Hydraulic Fracturing in HDR Low Permeability Reservoirs

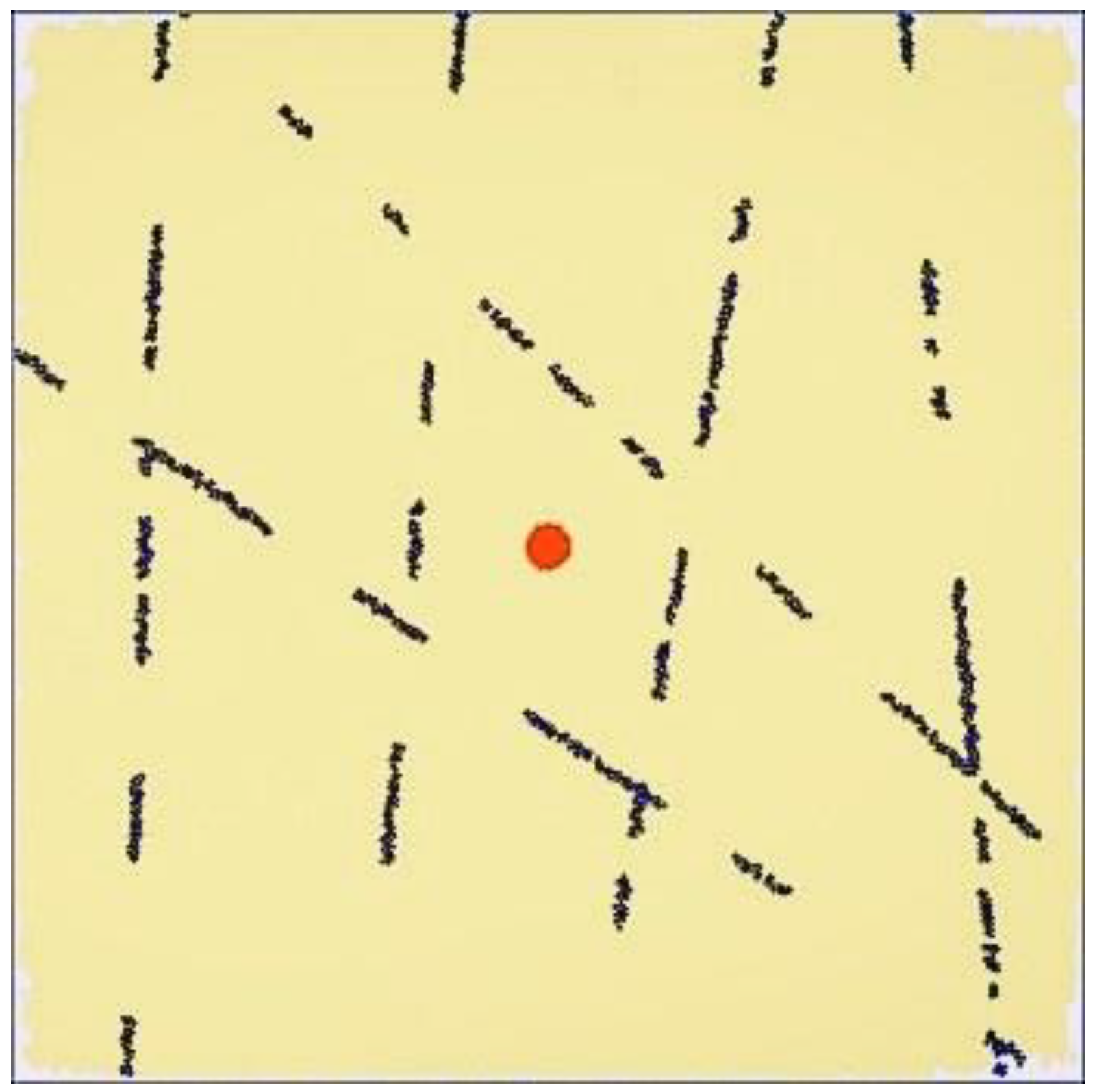

4.1. Reservoir Hydraulic Fracturing DEM Model

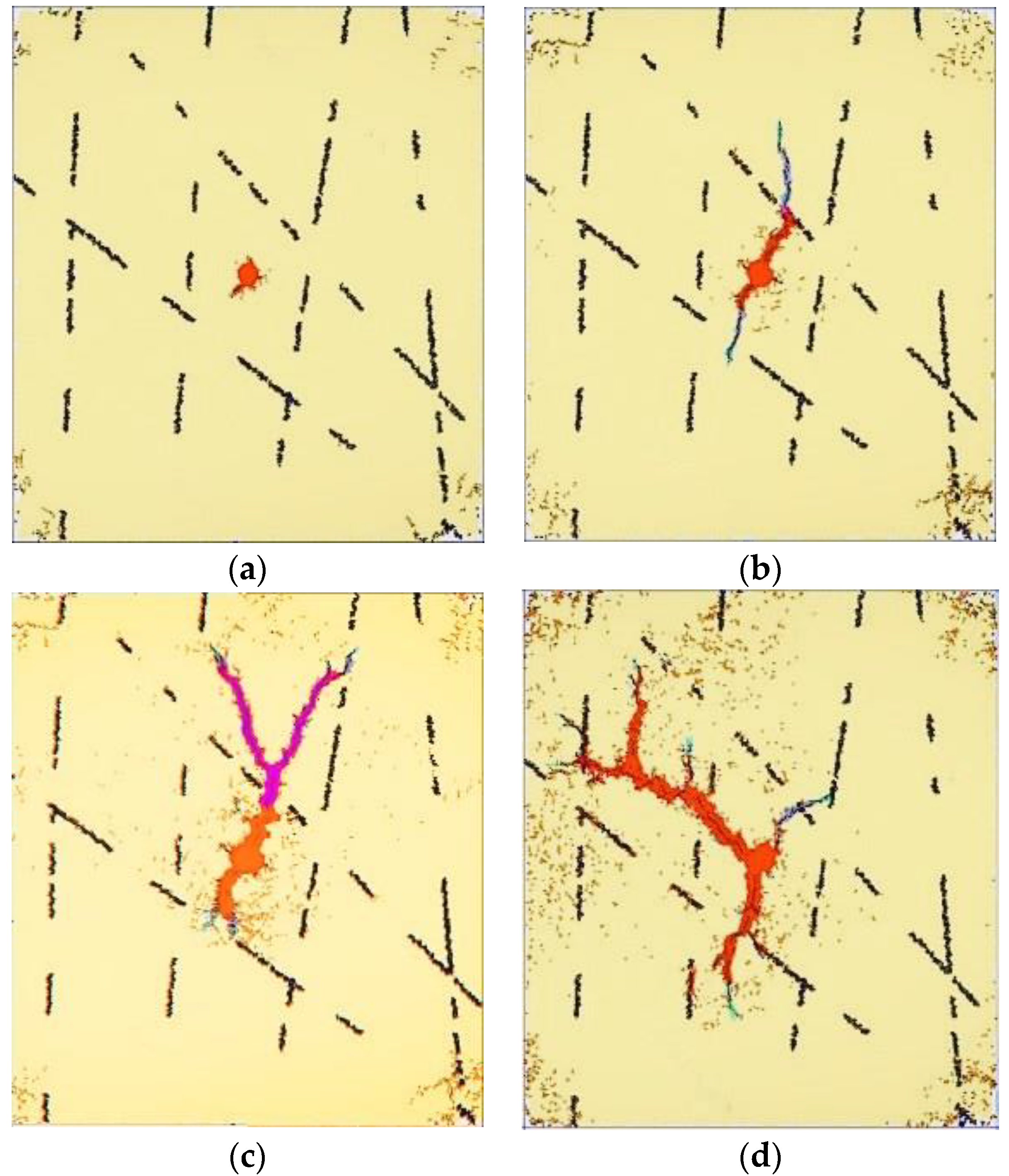

4.2. DEM Simulation Process

4.3. DEM Simulation Result Analysis

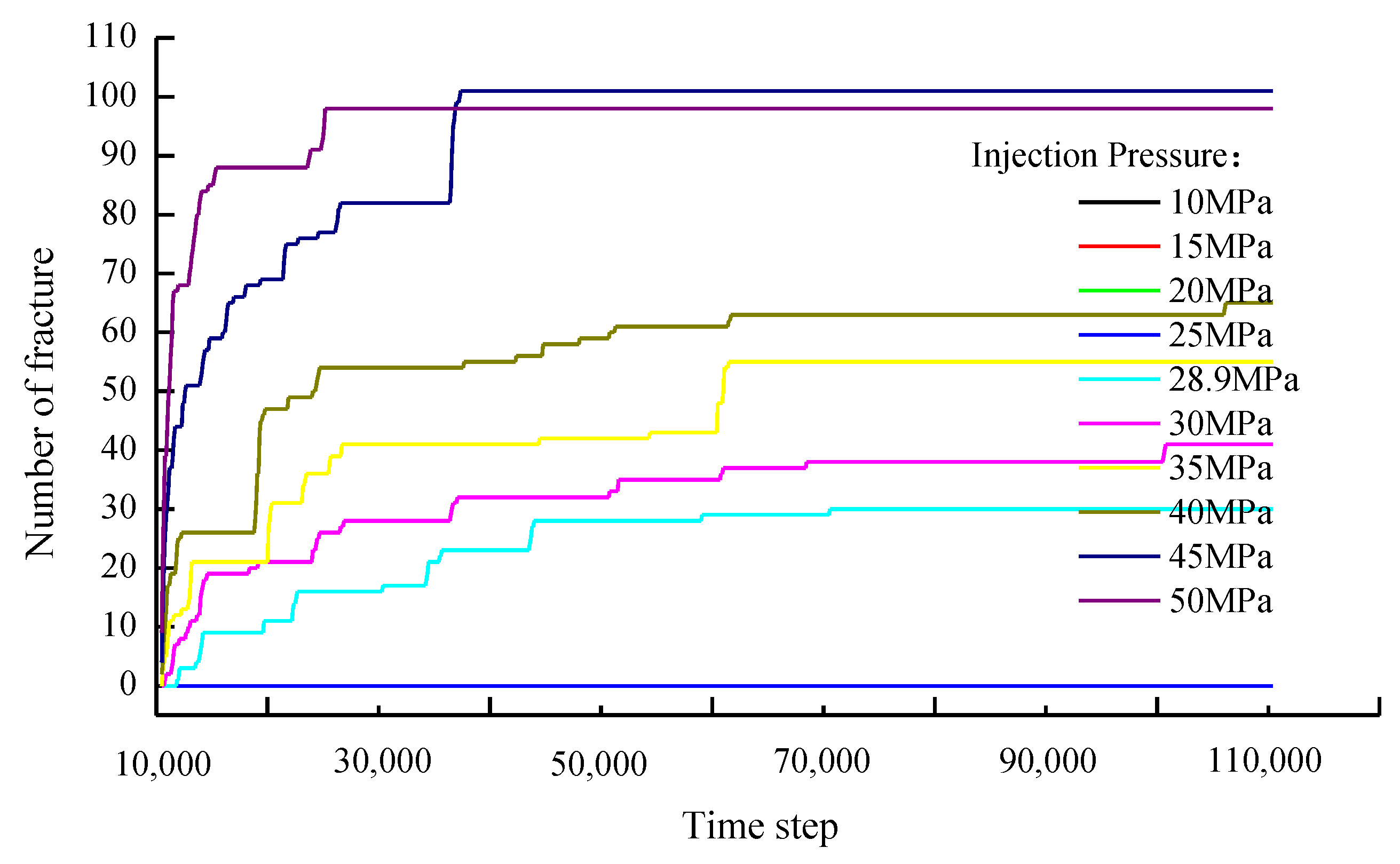

- (1)

- Under the condition that the meso-mechanical parameters of the reservoir particles are certain, we simulated the effects of different injection pressures on the fracturing effect. Wherein, the injection pressure varies from 25 MPa to 65 MPa, and each time increases by 5 MPa;

- (2)

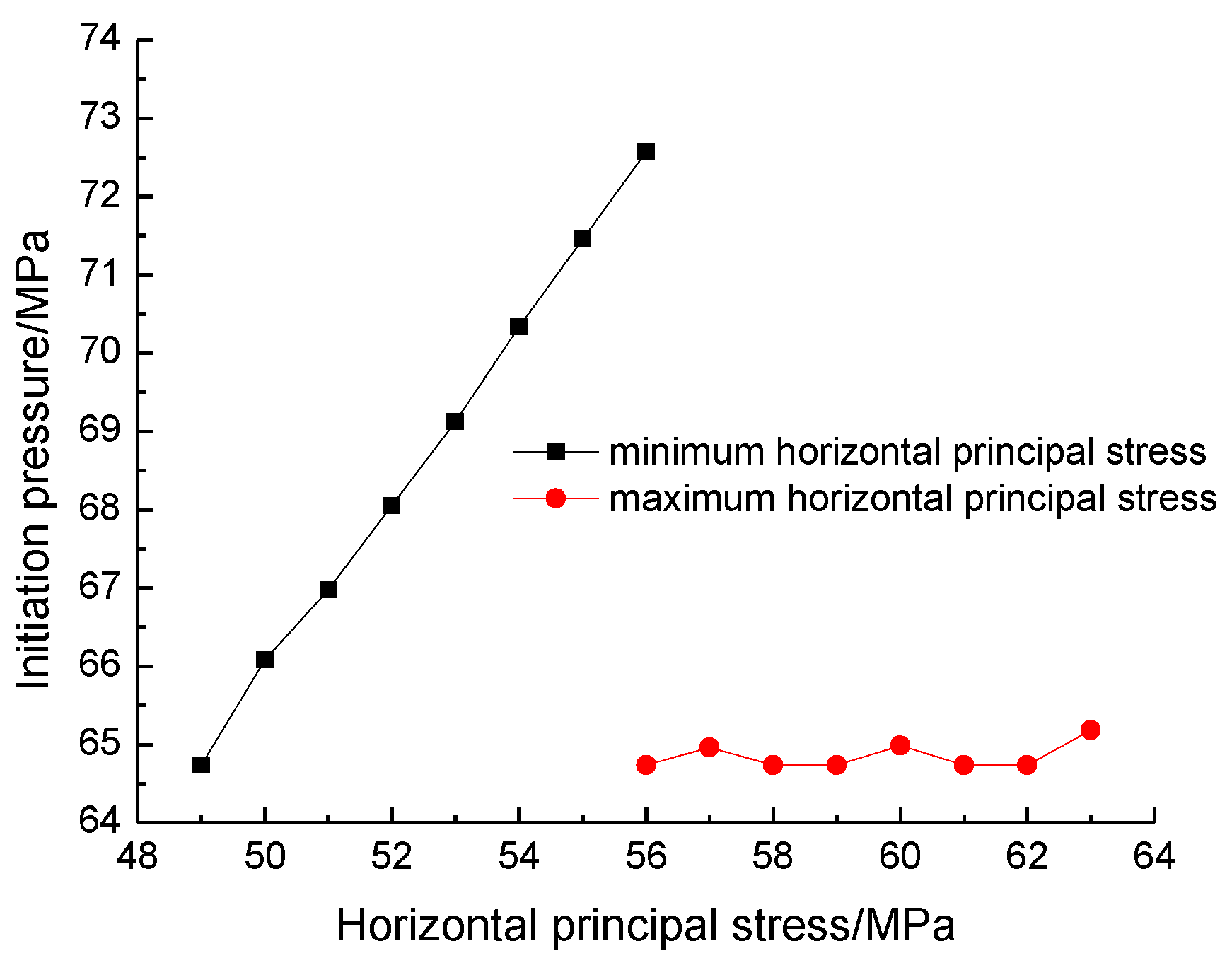

- Under the injection pressure of 65 MPa, we simulated the effect of maximum and minimum horizontal principal stress on the fracturing effect. Wherein, the initial maximum principal stress is 56 MPa, and the minimum principal stress is 49 MPa; each increase is 1 MPa;

- (3)

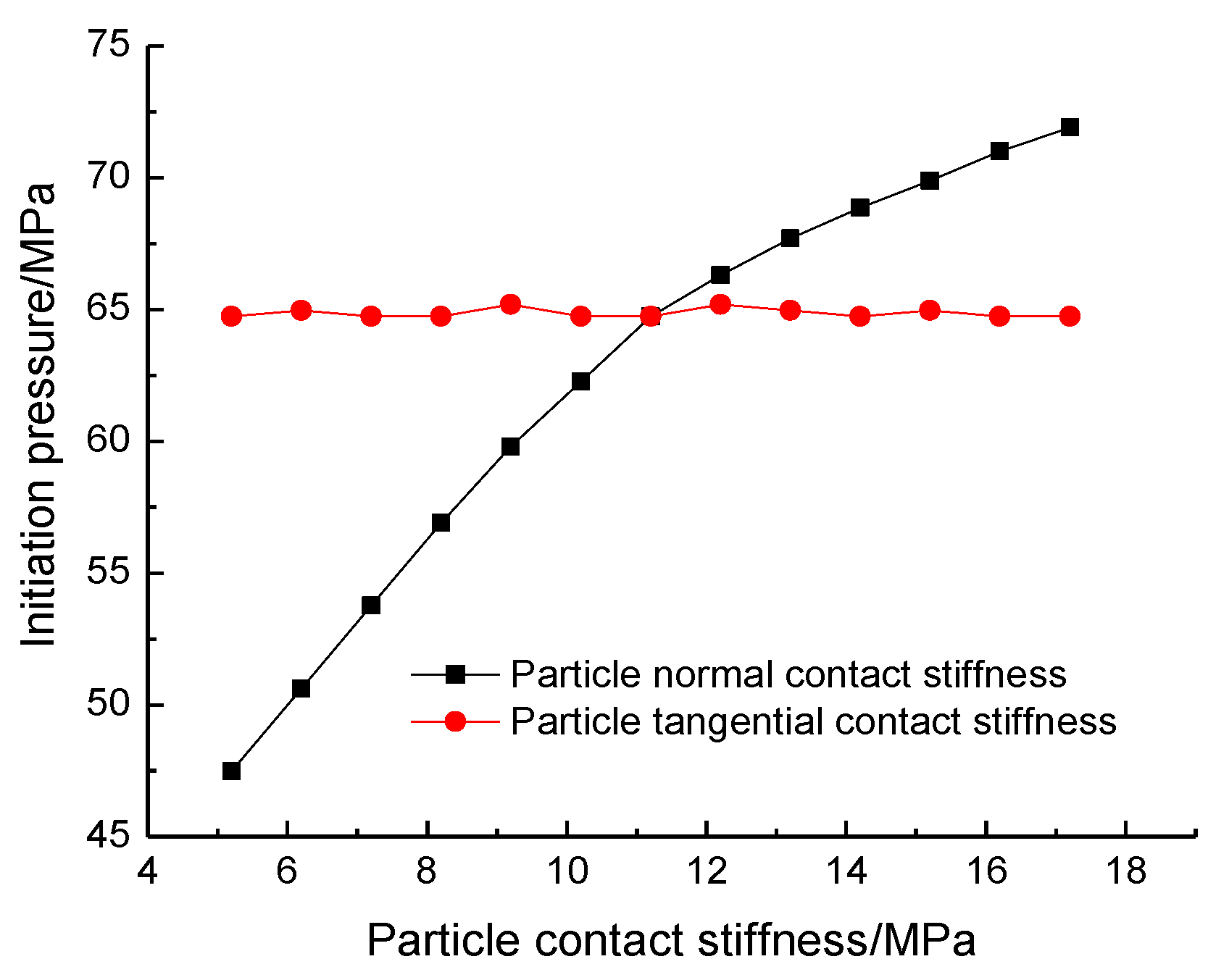

- Under the injection pressure of 65 MPa, we simulated the influence of particle normal contact stiffness (kn) and tangential contact stiffness (ks) on the fracturing effect is 5.2 GPa~17.2 GPa, each time increasing by 1 GPa;

- (4)

- Under the optimal injection pressure, we simulated the influence of the normal connection strength and the tangential joint strength on the fracturing effect is 27.5 MPa~52.5 MPa, each time increasing by 2.5 MPa.

4.3.1. Analysis of Injection Pressure Influence on Reservoir Fracturing

4.3.2. Fluctuation Analysis of Initiation Pressure on Reservoir Fracturing

Fluctuation Analysis of Initiation Pressure Caused by the Horizontal Principal Stress

Fluctuation Analysis of Initiation Pressure Caused by Particle Contact Stiffness

Fluctuation Analysis of Initiation Pressure Caused by Particle Connection Strength

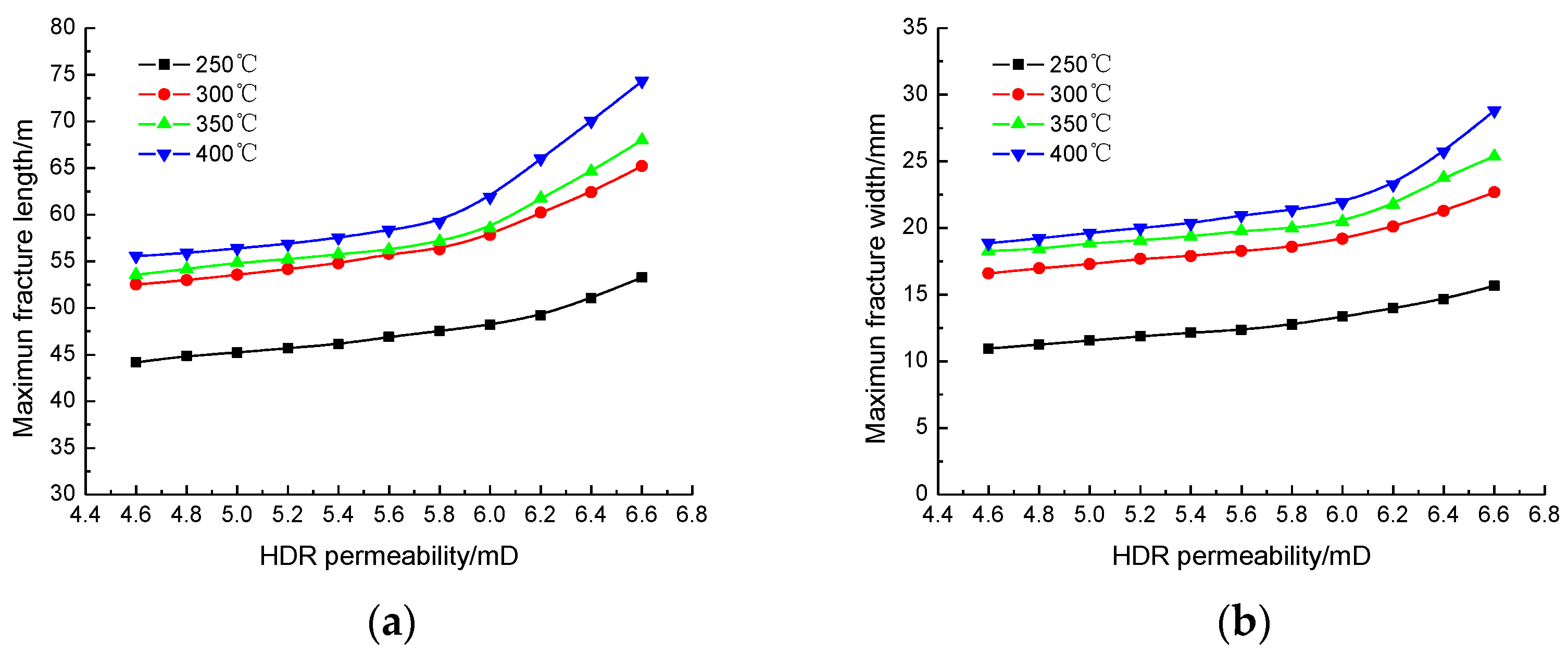

5. Analysis of Fracturing Influence Factors Considering Temperature Effect

5.1. Analysis of HDR Low Reservoir Fracturing Influenced by Injection Pressure

5.2. Analysis of HDR Low Reservoir Fracturing Influenced by Horizontal Minimum Principal Stress

- (1)

- When σh is less than the key minimum principal stress, the maximum fracture length and the fracture width decrease linearly with the increase of the minimum horizontal principal stress;

- (2)

- When σh crosses the key minimum principal stress, the maximum fracture length and the fracture width sharply reduced;

- (3)

- When σh is bigger than the key minimum principal stress, the relationship between the maximum fracture length and the fracture width and the minimum principal stress is approximately linearly inversely proportional, and the slope is smaller than that in the first stage.

5.3. Analysis of HDR Low Reservoir Fracturing Influenced by Reservoir Permeability

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jing, T.; Zhao, W.T.; Gao, S.; Wang, J.; Zhang, J. Practice and Technical Feasibility Study of Hot Dry Rock Geothermal Development. Sino-Glob. Energy 2018, 23, 17–21. [Google Scholar]

- Moya, D.; Aldas, C.; Kaparaju, P. Geothermal energy: Power plant technology and direct heat applications. Renew. Sustain. Renew. Energy 2018, 94, 889–901. [Google Scholar] [CrossRef]

- Xu, T.; Hu, Z.; Li, S.; Jiang, Z.; Hou, Z.; Li, F.; Liang, X.; Feng, B. Enhanced geothermal system: International progresses and research status of China. Acta Geol. Sin. 2018, 92, 1936–1947. [Google Scholar]

- Liu, H.; Li, J.; Pang, H.; Zheng, H.; Liu, D.; Sun, X.; Song, W. Study on ultra-temperature cement slurry technology for hot dry rock well GR1 in Qinghai Gonghe basin. Drill. Fluid Complet. Fluid 2020, 37, 202–208. [Google Scholar]

- Zhou, Z.; Jin, Y.; Lu, Y.; Zhou, B. Present challenge and prospects of drilling and hydraulic fracturing technology for hot dry rock geothermal reservoir. Sci. Sin. Phys. Mech. Astron. 2018, 48, 124621. [Google Scholar] [CrossRef]

- Zhou, Z.; Jin, Y.; Zeng, Y.; Zhang, X.; Zhou, J.; Zhuang, L.; Xin, S. Investigation on fracture creation in hot dry rock geothermal formations of China during hydraulic fracturing. Renew. Energy 2020, 153, 301–313. [Google Scholar] [CrossRef]

- Wu, F.; Li, D.; Fan, X.; Liu, J.; Li, X. Analytical interpretation of hydraulic fracturing initiation pressure and breakdown pressure. J. Nat. Gas Sci. Eng. 2020, 76, 103185. [Google Scholar] [CrossRef]

- Li, G. Research on Reservoir Property and Permeability under Hydraulic Fracturing in Hot Dry Rock. Master′s Thesis, Taiyuan University of Technology, Taiyuan, China, 2018. [Google Scholar]

- Xu, J.; Wu, K.; Yang, S.; Cao, J.; Chen, Z. Nanoscale free gas transport in shale rocks: A hard-sphere based model. In Proceedings of the SPE Unconventional Resources Conference, Calgary, AB, Canada, 16 February 2017. [Google Scholar]

- Xu, J.; Chen, Z.; Wu, K.; Li, R.; Liu, X.; Zhan, J. On the flow regime model for fast estimation of tight sandstone gas apparent permeability in high-pressure reservoirs. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 10, 1–12. [Google Scholar] [CrossRef]

- Hagoort, J.; Weatherill, B.D.; Settari, A. Modeling the Propagation of Waterflood-Induced Hydraulic Fractures. Soc. Pet. Eng. J. 1980, 20, 293–303. [Google Scholar] [CrossRef]

- Settari, A.; Cleary, M.P. Development and testing of a pseudo-three-dimensional model of hydraulic fracture geometry. SPE 1982, 01, 10505. [Google Scholar] [CrossRef]

- Rahim, Z.; Holditch, S.A. Using a three-dimensional concept in a two-dimensional model to predict accurate hydraulic fracture dimensions. J. Pet. Sci. Eng. 1995, 13, 15–27. [Google Scholar] [CrossRef]

- Zillur, R.; Holditch, S.A. The effects of mechanical properties and selection of completion interval upon the created and propped fracture dimension in layered reservoirs. J. Pet. Sci. Eng. 1995, 13, 29–45. [Google Scholar]

- Wei, Y.; Economides, M.J. Transverse hydraulic fractures from a horizontal well. In Proceedings of the SPE Annual Technical conference and Exhibition, Dallas, TX, USA, 9–12 October 2005. [Google Scholar]

- Cheng, Y.; Wang, G.; Wang, R. Rock mechanics problems in horizontal well fracturing. Chin. J. Rock Mech. Eng. 2004, 23, 2463–2466. [Google Scholar]

- Zhang, G.; Chen, M. Non-planar propagation of hydraulic fracture around horizontal well-bole. Eng. Mech. 2006, 23, 160–165. [Google Scholar]

- Zhang, G.; Liu, H.; Zhang, J.; Wu, H.; Wang, X. Three-dimensional finite element numerical simulation of horizontal well hydraulic fracturing. Eng. Mech. 2011, 28, 101–106. [Google Scholar]

- Zhang, G.; Liu, H.; Zhang, J. Simulation of hydraulic fracturing of oil well based on fluid-solid coupling equation and non-linear finite element. Acta Pet. Sin. 2009, 30, 113–116. [Google Scholar]

- Bian, K.; Chen, Y.; Liu, J.; Cui, D.; Li, Y.; Liang, W.; Han, X. The unloading failure characteristics of shale under different water absorption time using the PFC numerical method. Rock Soil Mech. 2019, 41, 1–13. [Google Scholar]

- Cong, Y.; Cong, Y.; Zhang, L.; Jia, L.; Wang, Z. 3D particle flow simulation of loading-unloading failure process of marble. Rock Soil Mech. 2019, 40, 1179–1186. [Google Scholar]

- Tsuji, Y.; Kawaguchi, T.; Tanaka, T. Discrete particle simulation of two-dimension al fluidized bed. Powder Technol. 1993, 77, 79–87. [Google Scholar] [CrossRef]

- Potapov, A.; Hunt, M.; Campbell, C. Liquid solid flows using smoothed particle hydrodynamics and the discrete element method. Powder Technol. 2001, 116, 204–213. [Google Scholar] [CrossRef]

- Jackson, R. Locally averaged equations of motion for a mixture of identical spherical particles and a Newtonian fluid. Chem. Eng. Sci. 1997, 52, 2457–2469. [Google Scholar] [CrossRef]

- Sun, F.; Zhang, D.; Chen, T. Meso-mechanical simulation of fracture grouting in soil. Chin. J. Geotech. Eng. 2010, 32, 474–480. [Google Scholar]

- Yang, F. Stability Analysis of Sandy Soil Tunnel End Based on PFC Fluid Structure Coupling. Master′s Thesis, Changsha University of Technology, Changsha, China, 2018. [Google Scholar]

- Zhang, W.; Sun, J.; Qu, Z.; Guo, T.; Gong, F.; Zhang, H. Thermo-hydro-mechanical coupling model and comprehensive evaluation method of high temperature geothermal extraction. Prog. Geophys. 2019, 34, 668–675. [Google Scholar]

- Guo, L.; Zhang, Y.; Hu, Z.; Xun, T.; Lan, C.; Su, J. The research of hydraulic fracturing and development strategy in enhanced geothermal system. J. Eng. Geol. 2015, 23, 235–241. [Google Scholar]

- Sun, Z.; Xu, Y.; Lu, S.; Xu, Y.; Sun, Q.; Cai, M.; Yao, J. A thermo-hydro-mechanical coupling model for numerical simulation of enhanced geothermal systems. J. China Univ. Pet. 2016, 40, 109–117. [Google Scholar]

- Yang, Y.; Chang, X.; Zhou, W.; Zhou, C. Simulation of Hydraulic Fracturing of Fractured Rock Mass by PFC2D. J. Sichuan Univ. (Eng. Sci. Ed.) 2012, 44, 78–85. [Google Scholar]

- Potyond, D.O.; Cundall, P.A. A bonded particle model for rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 1329–1364. [Google Scholar] [CrossRef]

- Xi, B.; Wu, Y.; Wang, S.; Xiong, G.; Zhao, Y. Experimental study on mechanical properties of granite taken from Gonghe basin, Qinghai province after high temperature thermal damage. Chin. J. Rock Mech. Eng. 2020, 1, 69–83. [Google Scholar]

- Zhu, Z.; Tian, H.; Dong, N.; Dou, B.; Chen, J.; Zhang, Y.; Wang, B. Experimental study of physico-mechanical properties of heat-treated granite by water cooling. Rock Soil Mech. 2018, 39, 169–176. [Google Scholar]

- Sun, Q.; Zhang, Z.; Xue, L.; Zhu, S. Physico-mechanical properties variation of rock with phase transformation under high temperature. Chin. J. Rock Mech. Eng. 2013, 32, 935–942. [Google Scholar]

| Rmax/m | Rmax /Rmin | Interparticle Friction Coefficient | Porosity | Particle Normal Contact Stiffness kn/(N·m−1) | Particle Tangential Contact Stiffness ks/(N·m−1) | Particle Normal Connection Strength/MPa | Shear Strength of Particles/MPa | Density/ Kg·m−3 |

|---|---|---|---|---|---|---|---|---|

| 0.04 | 2.70 | 0.22 | 0.15 | 11.20 × 109 | 11.20 × 109 | 42.5 | 42.5 | 2320 |

| Formation Pressure /MPa | The Apparent Volume of a Domain Vd/mm3 | Permeability /mD | Coefficient of Viscosity /Pa·s | Number of Pipes in a Domain N | Conductivity Coefficient K/(m·s−1) | Volume Modulus of Fluid Kd/kPa | Piping Diameter a/mm |

|---|---|---|---|---|---|---|---|

| 25 | 1 | 5.6 | 0.3 | 2 | 1 × 10−8 | 1.0 × 106 | 1 |

| Temperature/ °C | Interparticle Friction Coefficient | Porosity | Particle Normal Contact Stiffness kn/(N·m−1) | Particle Tangential Contact Stiffness ks/(N·m−1) |

|---|---|---|---|---|

| 250 | 0.22 | 0.15 | 11.20 × 109 | 11.20 × 109 |

| 300 | 0.22 | 0.15 | 8.98 × 109 | 8.98 × 109 |

| 350 | 0.23 | 0.14 | 7.21 × 109 | 7.21 × 109 |

| 400 | 0.23 | 0.14 | 5.78 × 109 | 5.78 × 109 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, H.; Liu, P.; Zhao, Y.; Yang, S.; Zhao, X. Analytical Model of Hydraulic Fracturing for Low Permeability Hot Dry Rock Reservoirs and DEM Simulation Base on Fluid-Solid Coupling. Processes 2023, 11, 976. https://doi.org/10.3390/pr11040976

Fan H, Liu P, Zhao Y, Yang S, Zhao X. Analytical Model of Hydraulic Fracturing for Low Permeability Hot Dry Rock Reservoirs and DEM Simulation Base on Fluid-Solid Coupling. Processes. 2023; 11(4):976. https://doi.org/10.3390/pr11040976

Chicago/Turabian StyleFan, Heng, Peihang Liu, Yating Zhao, Shangyu Yang, and Xinbo Zhao. 2023. "Analytical Model of Hydraulic Fracturing for Low Permeability Hot Dry Rock Reservoirs and DEM Simulation Base on Fluid-Solid Coupling" Processes 11, no. 4: 976. https://doi.org/10.3390/pr11040976

APA StyleFan, H., Liu, P., Zhao, Y., Yang, S., & Zhao, X. (2023). Analytical Model of Hydraulic Fracturing for Low Permeability Hot Dry Rock Reservoirs and DEM Simulation Base on Fluid-Solid Coupling. Processes, 11(4), 976. https://doi.org/10.3390/pr11040976