Effect of Cold-Spray Parameters on Surface Roughness, Thickness and Adhesion of Copper-Based Composite Coating on Aluminum Alloy 6061 T6 Substrate

Abstract

1. Introduction

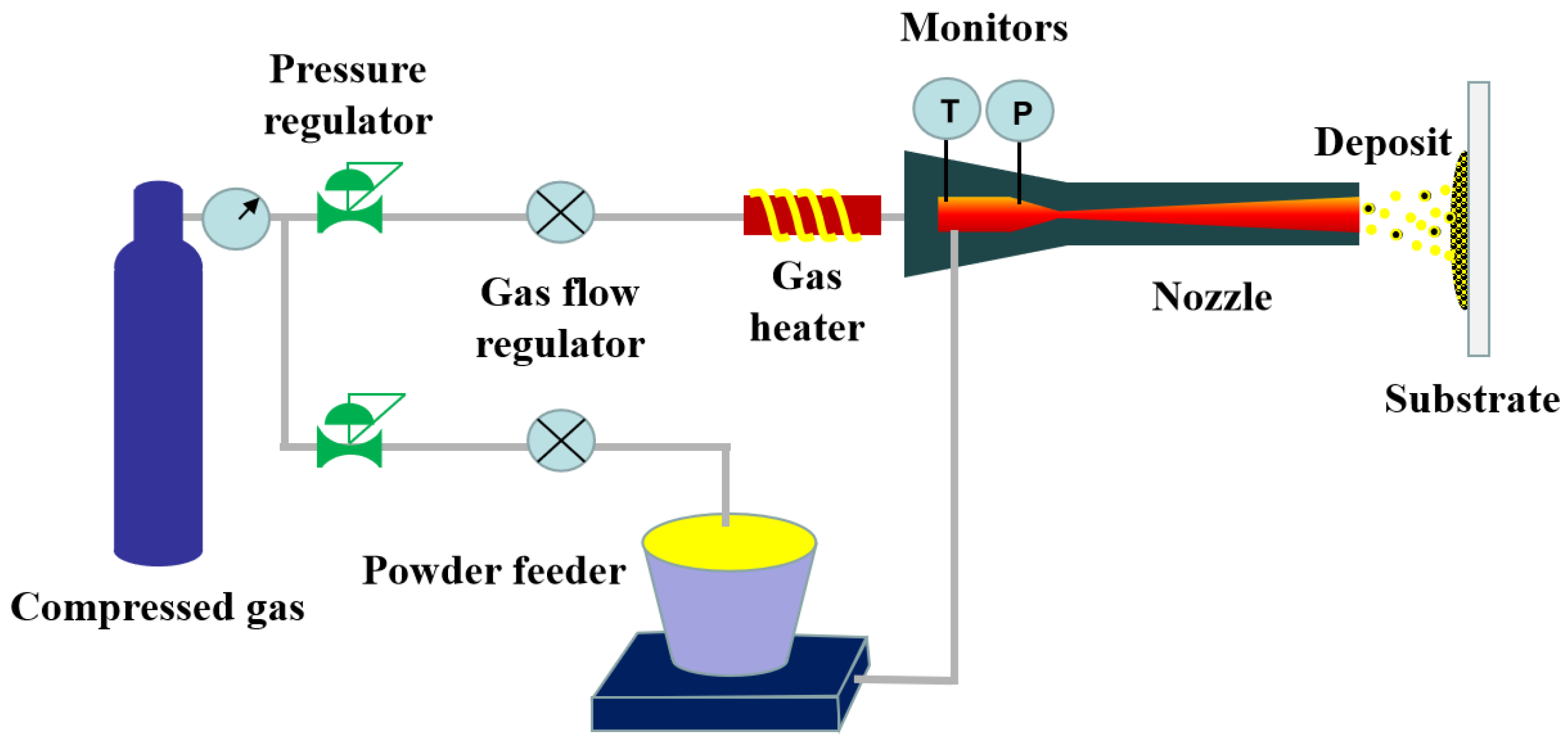

2. Experimental Details

3. Results and Discussion

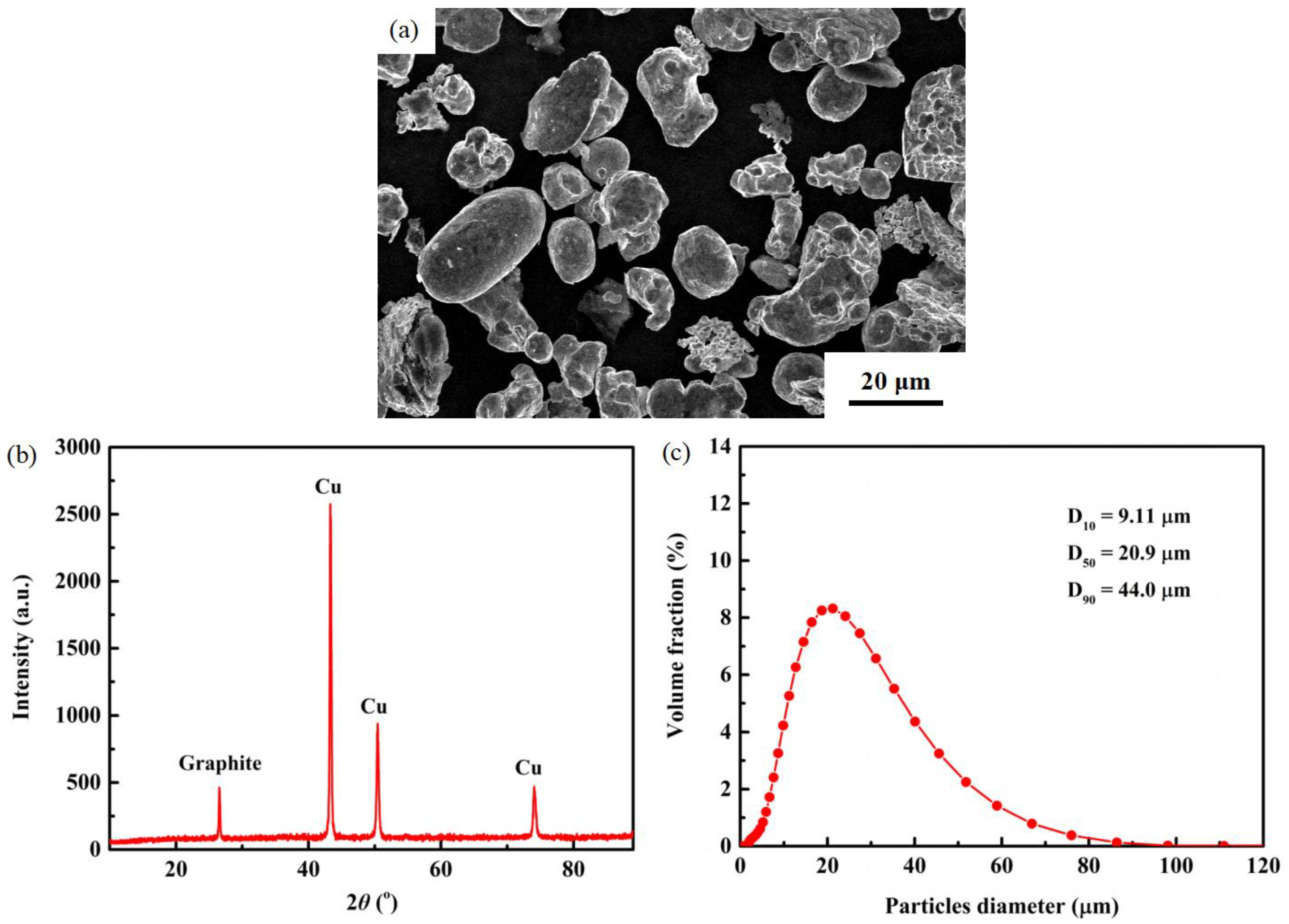

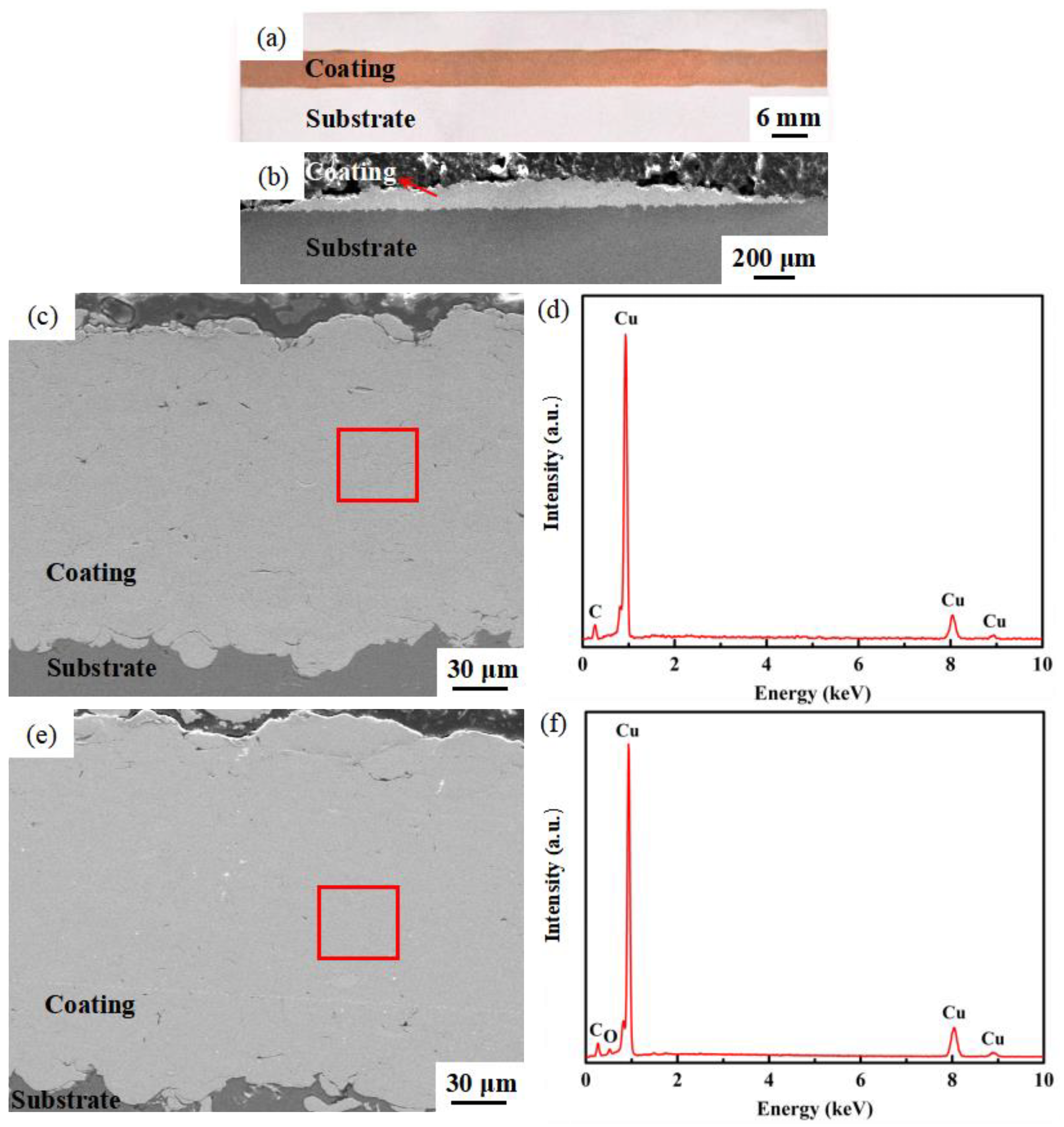

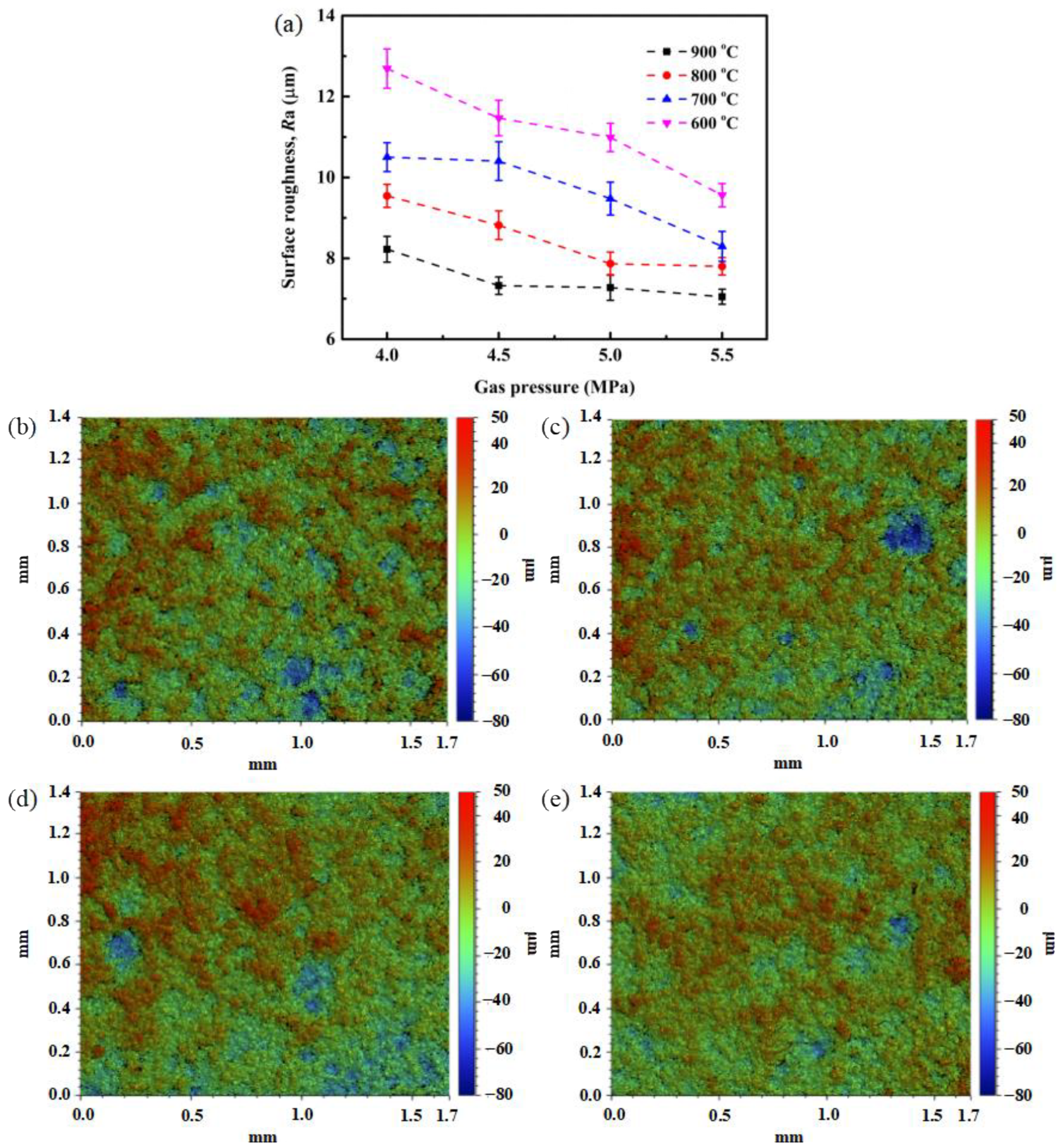

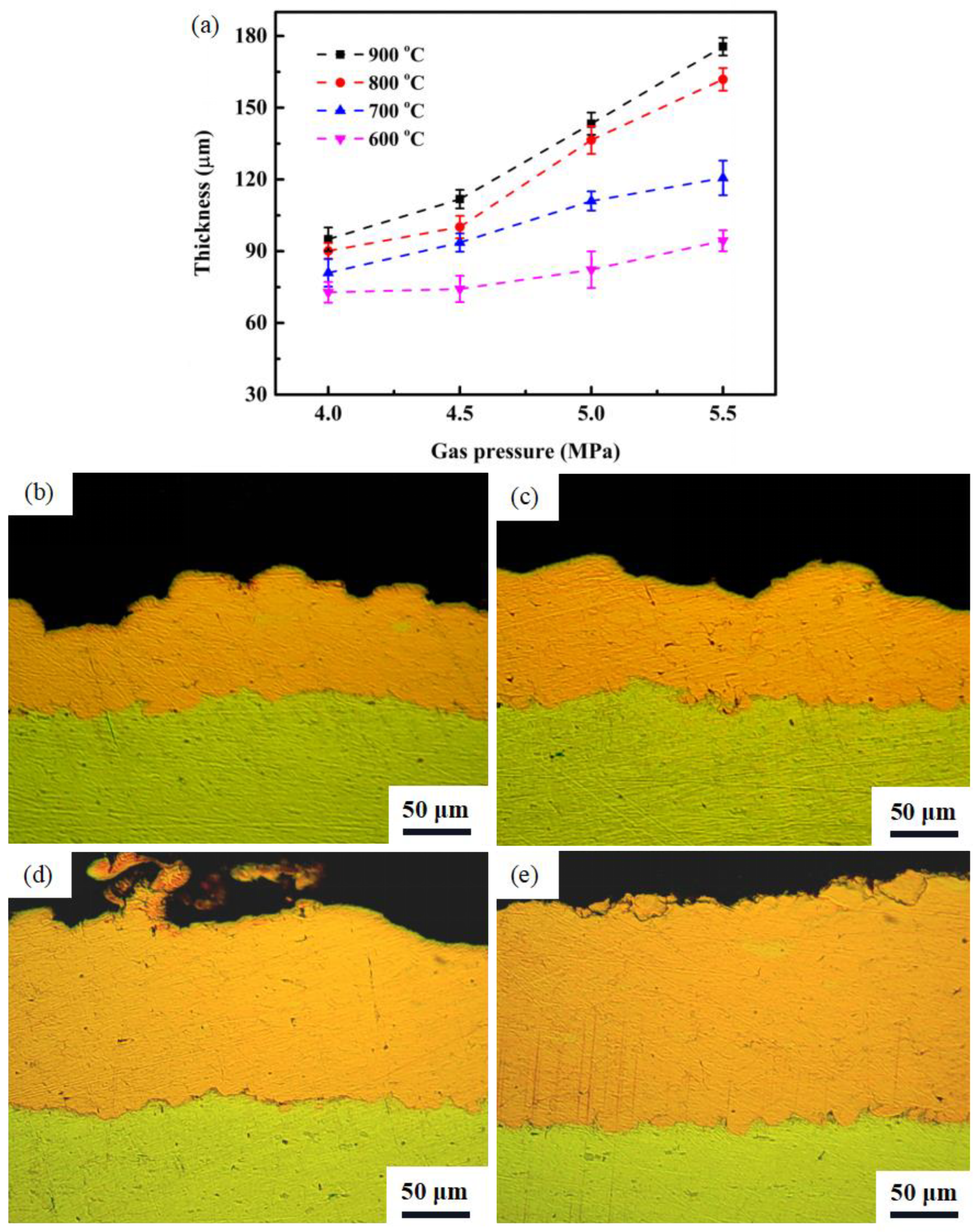

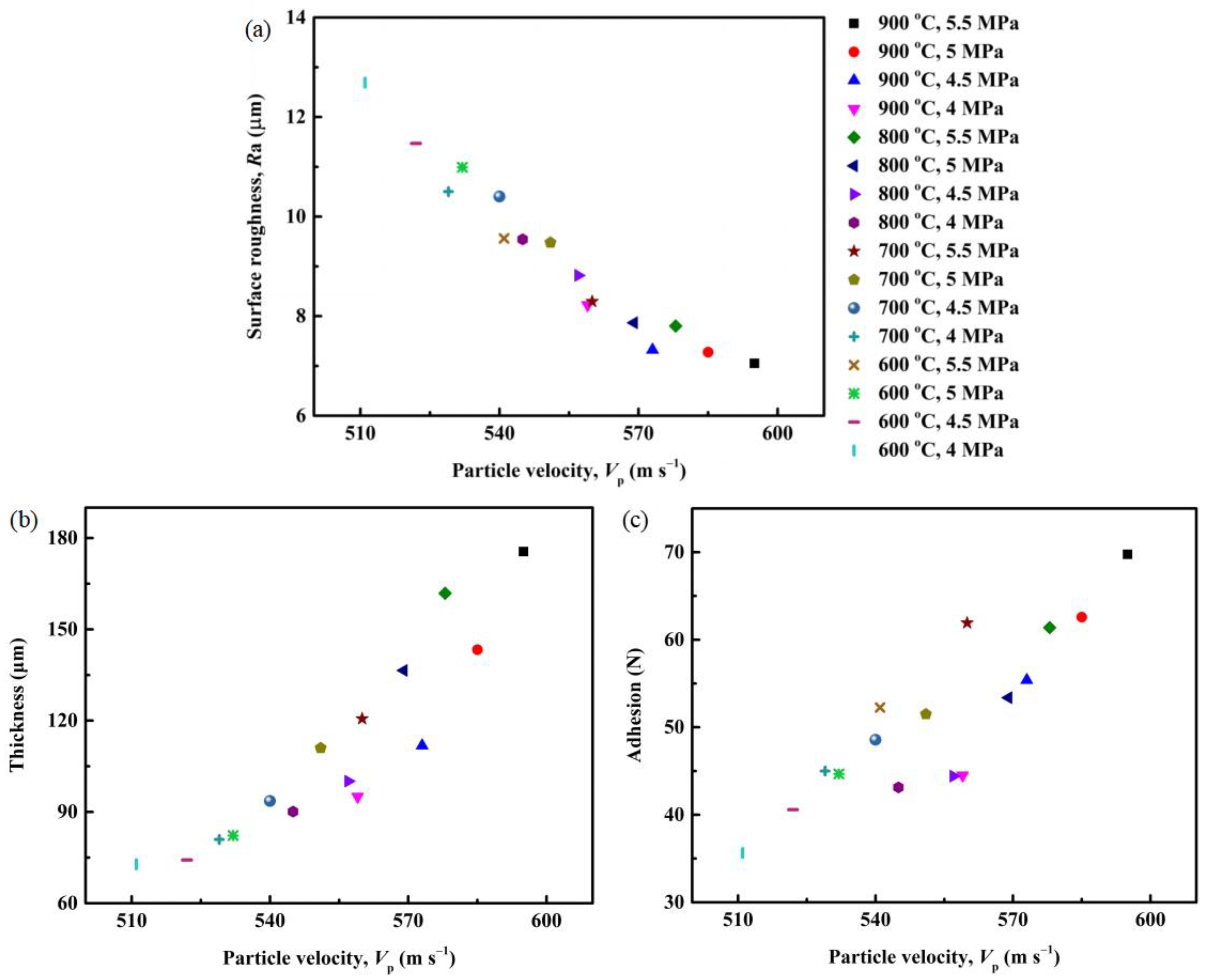

3.1. Characterization

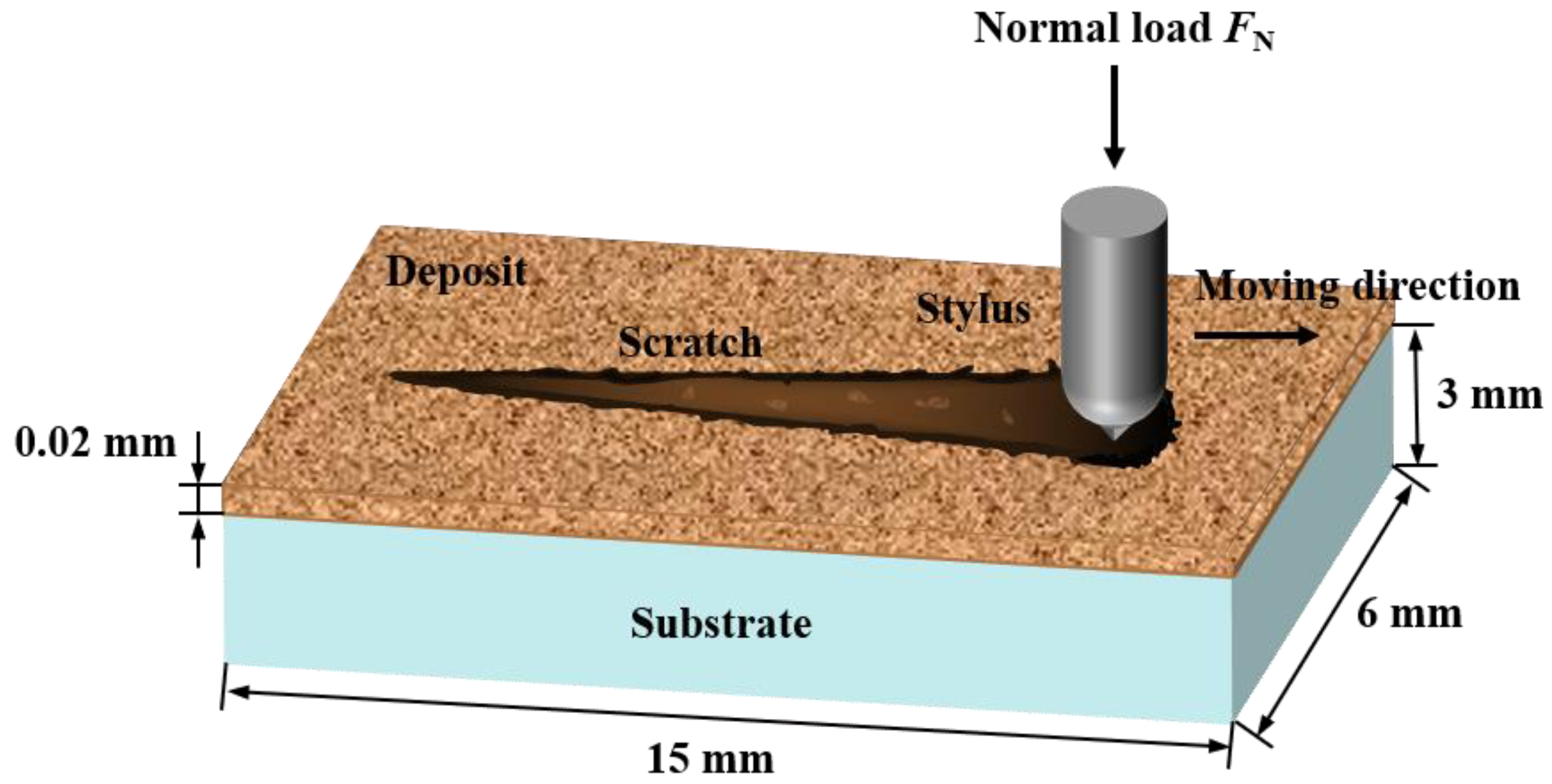

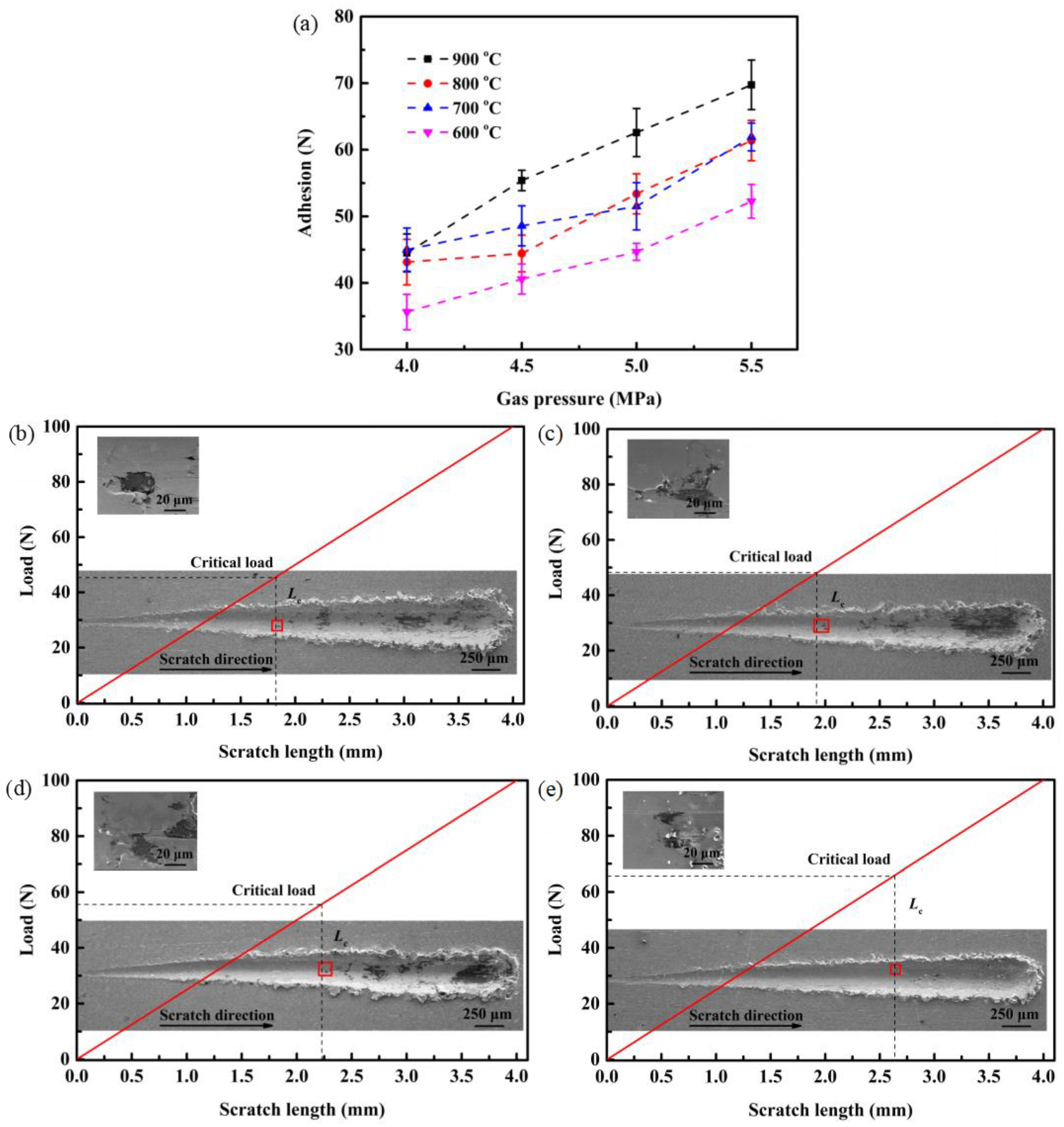

3.2. Adhesion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Parast, M.S.A.; Azadi, M. A short evaluation of simultaneous corrosion fretting fatigue behaviors in piston aluminium-silicon alloys considering effects of nano-particles and heat-treating. Int. J. Fatigue 2023, 168, 107403. [Google Scholar] [CrossRef]

- Franceschini, F.G.; Klegues Montedo, O.R.; Arcaro, S.; Bergmann, C.P. Aluminum borophosphate glaze-coated aluminum alloy substrate: Coating properties and coating/substrate coupling. Ceram. Int. 2021, 47, 2050–2057. [Google Scholar] [CrossRef]

- Huang, Y.; Zhu, Y.; Li, H.; Ma, S. Study on properties of alkaline copper coating by electro-brush plating on aluminium alloys surface. Hot Work. Technol. 2006, 35, 22–24. [Google Scholar]

- Wang, X.; Su, Y.; Ouyang, Q.; Zhu, C.; Cao, H.; Zhang, D. Fabrication, mechanical and thermal properties of copper coated graphite films reinforced copper matrix laminated composites via ultrasonic-assisted electroless plating and vacuum hot-pressing sintering. Mater. Sci. Eng. A 2021, 824, 141768. [Google Scholar] [CrossRef]

- Zhao, R.; Li, W.; Wang, T.; Zhan, K.; Yang, Z.; Yan, Y.; Zhao, B.; Yang, J. Fabrication of Cu/graphite film/Cu sandwich composites with ultrahigh thermal conductivity for thermal management applications. Front. Mater. Sci. 2020, 14, 188–197. [Google Scholar] [CrossRef]

- Jia, S.-K.; Zou, Y.; Xu, J.-Y.; Wang, J.; Yu, L. Effect of TiO2 content on properties of Al2O3 thermal barrier coatings by plasma spraying. Trans. Nonferrous Met. Soc. China 2015, 25, 175–183. [Google Scholar] [CrossRef]

- Sahoo, B.; Das, T.; Paul, J. Thermal spraying and related technologies for the surface modification of Al alloys: Review. Surf. Rev. Lett. 2022, 29, 2230009. [Google Scholar] [CrossRef]

- Ladwig, A.; Babayan, S.; Smith, M.; Hester, M.; Highland, W.; Koch, R.; Hicks, R. Atmospheric plasma deposition of glass coatings on aluminum. Surf. Coat. Technol. 2007, 201, 6460–6464. [Google Scholar] [CrossRef]

- Sahoo, S.P.; Datta, S. Dry machining performance of AA7075-T6 alloy using uncoated carbide and MT-CVD TiCN-Al2O3-coated carbide inserts. Arab. J. Sci. Eng. 2020, 45, 9777–9791. [Google Scholar] [CrossRef]

- Ouyang, J.H.; Nowotny, S.; Richter, A.; Beyer, E. Laser cladding of yttria partially stabilized ZrO2 (YPSZ) ceramic coatings on aluminum alloys. Ceram. Int. 2001, 27, 15–24. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Q.; Chen, F.; Zhang, L.; Li, J.; Zhang, J. Corrosion behavior of laser-cladding NiCrBSi coating in molten aluminum alloy. J. Laser Appl. 2022, 34, 022022. [Google Scholar] [CrossRef]

- Davoodi, F.; Ashrafizadeh, F.; Atapour, M.; Rikhtehgaran, R. A novel approach for evaluation of load bearing capacity of duplex coatings on aluminum alloy using PLS and SVR models. Trans. Nonferrous Met. Soc. China 2022, 32, 1834–1851. [Google Scholar] [CrossRef]

- Liu, N.; Gao, J.; Tong, S.; Xu, L.; Wan, Y.; Sun, H. Improvement in corrosion resistance of micro-arc oxidation coating on PVD. Int. J. Appl. Ceram. Technol. 2022, 19, 2556–2565. [Google Scholar] [CrossRef]

- Lv, G.; Gu, W.; Chen, H.; Feng, W.; Khosa, M.L.; Li, L.; Niu, E.; Zhang, G.; Yang, S.-Z. Characteristic of ceramic coatings on aluminum by plasma electrolytic oxidation in silicate and phosphate electrolyte. Appl. Surf. Sci. 2006, 253, 2947–2952. [Google Scholar] [CrossRef]

- Tong, S.; Xu, L.; Wan, Y.; Wang, Y.; Wang, J. Enhanced corrosion-resistant performance of the PEO coatings on AA7075 alloy by a sol-gel-derived silica layer. Int. J. Appl. Ceram. Tech. 2022, 19, 2613–2622. [Google Scholar] [CrossRef]

- Chanyathunyaroj, K.; Samit, W.; Poonthananiwatkul, C.; Phetchcrai, S. Effect of coatings on the mechanical properties and fatigue life of 6061 aluminum alloys. Trans. Indian Inst. Met. 2021, 74, 2135–2147. [Google Scholar] [CrossRef]

- Winter, L.; Lampke, T. Influence of hydrothermal sealing on the high cycle fatigue behavior of the anodized 6082 aluminum alloy. Coatings 2022, 12, 1070. [Google Scholar] [CrossRef]

- Minto, T.A.; de Oliveira, V.M.C.A.; Voorwald, H.J.C. Plasma immersion ion implantation: Influence on the rotating bending fatigue strength of AA 7050-T7451 aluminum alloy. Int. J. Fatigue 2017, 103, 17–27. [Google Scholar] [CrossRef]

- Zhao, X.; Dong, T.; Fu, B.; Li, G.; Liu, Q.; Li, Y. Microstructure and properties of cold sprayed NiCrAl coating on AZ91D magnesium alloy. Coatings 2021, 11, 193. [Google Scholar] [CrossRef]

- Cavaliere, P.; Perrone, A.; Silvello, A.; Laska, A.; Blasi, G.; Cano, I.G.; Sadeghi, B.; Nagy, S. Cyclic behavior of FeCoCrNiMn high entropy alloy coatings produced through cold spray. J. Alloys Compd. 2023, 931, 167550. [Google Scholar] [CrossRef]

- Wang, Y.; Normand, B.; Mary, N.; Yu, M.; Liao, H. Effects of ceramic particle size on microstructure and the corrosion behavior of cold sprayed SiCp/Al 5056 composite coatings. Surf. Coat. Technol. 2017, 315, 314–325. [Google Scholar] [CrossRef]

- Song, Z.; Li, H. Plasma spraying with wire feeding: A facile route to enhance the coating/substrate interfacial metallurgical bonding. Coatings 2022, 12, 615. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, G.; Pan, J.; Ma, C.; Zhang, G. Non-isocyanate polyurethane coating with high hardness, superior flexibility, and strong substrate adhesion. ACS Appl. Mater. Interfaces 2023, 15, 5998–6004. [Google Scholar] [CrossRef] [PubMed]

- Sedelnikova, M.B.; Ivanov, K.V.; Ugodchikova, A.V.; Kashin, A.D.; Uvarkin, P.V.; Sharkeev, Y.; Tolkacheva, T.V.; Tolmachev, A.I.; Schmidt, J.; Egorkin, V.S.; et al. The effect of pulsed electron irradiation on the structure, phase composition, adhesion and corrosion properties of calcium phosphate coating on Mg0.8Ca alloy. Mater. Chem. Phys. 2023, 294, 126996. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, K.; Lu, X.; Lam, Y.C. A review on the mechanical methods for evaluating coating adhesion. Acta Mech. 2014, 225, 431–452. [Google Scholar] [CrossRef]

- Horgnies, M.; Willieme, P.; Gabet, O. Influence of the surface properties of concrete on the adhesion of coating: Characterization of the interface by peel test and FT-IR spectroscopy. Prog. Org. Coat. 2011, 72, 360–379. [Google Scholar] [CrossRef]

- O’Brien, E.P.; Ward, T.C.; Guo, S.; Dillard, D.A. Strain energy release rates of a pressure sensitive adhesive measured by the shaft-loaded blister test. J. Adhes. 2010, 79, 69–97. [Google Scholar] [CrossRef]

- Sharifi, H.; Aliofkhazraei, M.; Darband, G.B.; Shrestha, S. A review on adhesion strength of peo coatings by scratch test method. Surf. Rev. Lett. 2018, 25, 1830004. [Google Scholar] [CrossRef]

- Nißen, S.; Heeg, J.; Wienecke, M.; Behrend, D.; Warkentin, M. Enhancing adhesion strength of a-C:H:Cu composite coatings on Ti6Al4V by graded copper deposition in a rf-PVD/PECVD hybrid process. Surf. Coat. Technol. 2018, 350, 659–671. [Google Scholar] [CrossRef]

- Cho, M.-Y.; Lee, D.-W.; Ko, P.-J.; Koo, S.-M.; Kim, J.; Choi, Y.-K.; Oh, J.-M. Adhesive Mechanism of Al2O3/Cu Composite Film via Aerosol Deposition Process for Application of Film Resistor. Electron. Mater. Lett. 2019, 15, 227–237. [Google Scholar] [CrossRef]

- De Cerqueira Lima, F.G.; Mescheder, U.; Katona, G.L.; Leiste, H.; Özel, E.; Müller, C.; Reinecke, H. Influence of silicon doping type on the adhesion of seedless electrodeposited copper layers. Surf. Coat. Technol. 2018, 349, 208–216. [Google Scholar] [CrossRef]

- Aniołek, K.; Kupka, M. Mechanical, tribological and adhesive properties of oxide layers obtained on the surface of the Ti–6Al–7Nb alloy in the thermal oxidation process. Wear 2019, 432, 202929. [Google Scholar] [CrossRef]

- Sun, H.; Billard, A.; Luo, H.; Zheng, W.-T.; Zheng, X.-L.; Dai, M.-J.; Lin, S.-S.; Shi, Q.; Sanchette, F. Influence of carbon content on the mechanical properties of TiCN–Cu nanocomposite coatings prepared by multi-arc ion plating. Vacuum 2021, 187, 110139. [Google Scholar] [CrossRef]

- Breuninger, P.; Krull, F.; Huttenlochner, K.; Müller-Reno, C.; Ziegler, C.; Merz, R.; Kopnarski, M.; Antonyuk, S. Microstructuring of steel surfaces via cold spraying with 316L particles for studying the particle-wall collision behavior. Surf. Coat. Technol. 2019, 379, 125054. [Google Scholar] [CrossRef]

- Daroonparvar, M.; Bakhsheshi-Rad, H.R.; Saberi, A.; Razzaghi, M.; Kasar, A.K.; Ramakrishna, S.; Menezes, P.L.; Misra, M.; Ismail, A.F.; Sharif, S.; et al. Surface modification of magnesium alloys using thermal and solid-state cold spray processes: Challenges and latest progresses. J. Magnes. Alloy. 2022, 10, 2025–2061. [Google Scholar] [CrossRef]

- Ralls, A.M.; Daroonparvar, M.; Kasar, A.K.; Misra, M.; Menezes, P.L. Influence of friction stir processing on the friction, wear and corrosion mechanisms of solid-state additively manufactured 316L duplex stainless steel. Tribol. Int. 2023, 178, 108033. [Google Scholar] [CrossRef]

- Wei, F.J.; Chou, B.Y.; Fung, K.Z.; Tsai, S.Y. Thermomechanical properties of cold-sprayed copper coatings from differently fabricated powders. Surf. Coat. Technol. 2022, 434, 128128. [Google Scholar] [CrossRef]

- Wu, J.; Fang, H.; Yoon, S.; Kim, H.; Lee, C. Measurement of particle velocity and characterization of deposition in aluminum alloy kinetic spraying process. Appl. Surf. Sci. 2005, 252, 1368–1377. [Google Scholar] [CrossRef]

- Huang, J.; Ma, W.; Xie, Y.; Fukanum, H.; Zhang, K.; Wang, G.; Huang, R. Influence of cold gas spray processing conditions on the properties of 316L stainless steel coatings. Surf. Eng. 2019, 35, 784–791. [Google Scholar] [CrossRef]

| Elements | Si | Cr | Cu | Fe | Mn | Ti | Zn | Mg | Al |

|---|---|---|---|---|---|---|---|---|---|

| 6061 aluminum alloy plate | 0.4–0.8 | 0.04–0.35 | 0.15–0.4 | ≤0.7 | ≤0.15 | ≤0.15 | ≤0.25 | 0.8–1.2 | Balance |

| Coating | Gas Temperature (°C) | Gas Pressure (MPa) | Gas Flow of Feeding (SLM) | Traverse Velocity (mm s−1) | Distance from the Substrate (mm) | Deposition Layer (layer) |

|---|---|---|---|---|---|---|

| 1 | 900 | 5.5 | 180 | 50 | 20 | 1 |

| 2 | 900 | 5 | 180 | 50 | 20 | 1 |

| 3 | 900 | 4.5 | 180 | 50 | 20 | 1 |

| 4 | 900 | 4 | 180 | 50 | 20 | 1 |

| 5 | 800 | 5.5 | 180 | 50 | 20 | 1 |

| 6 | 800 | 5 | 180 | 50 | 20 | 1 |

| 7 | 800 | 4.5 | 180 | 50 | 20 | 1 |

| 8 | 800 | 4 | 180 | 50 | 20 | 1 |

| 9 | 700 | 5.5 | 180 | 50 | 20 | 1 |

| 10 | 700 | 5 | 180 | 50 | 20 | 1 |

| 11 | 700 | 4.5 | 180 | 50 | 20 | 1 |

| 12 | 700 | 4 | 180 | 50 | 20 | 1 |

| 13 | 600 | 5.5 | 180 | 50 | 20 | 1 |

| 14 | 600 | 5 | 180 | 50 | 20 | 1 |

| 15 | 600 | 4.5 | 180 | 50 | 20 | 1 |

| 16 | 600 | 4 | 180 | 50 | 20 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, L.; Xue, N.; Li, W.; Liu, S.; Tu, Z.; Chen, Y.; Zhang, J.; Dai, S.; Liu, Q.; Shi, X.; et al. Effect of Cold-Spray Parameters on Surface Roughness, Thickness and Adhesion of Copper-Based Composite Coating on Aluminum Alloy 6061 T6 Substrate. Processes 2023, 11, 959. https://doi.org/10.3390/pr11030959

Shao L, Xue N, Li W, Liu S, Tu Z, Chen Y, Zhang J, Dai S, Liu Q, Shi X, et al. Effect of Cold-Spray Parameters on Surface Roughness, Thickness and Adhesion of Copper-Based Composite Coating on Aluminum Alloy 6061 T6 Substrate. Processes. 2023; 11(3):959. https://doi.org/10.3390/pr11030959

Chicago/Turabian StyleShao, Ling, Na Xue, Weiwei Li, Song Liu, Zhibiao Tu, Yingwei Chen, Jitang Zhang, Sheng Dai, Qijie Liu, Xinxing Shi, and et al. 2023. "Effect of Cold-Spray Parameters on Surface Roughness, Thickness and Adhesion of Copper-Based Composite Coating on Aluminum Alloy 6061 T6 Substrate" Processes 11, no. 3: 959. https://doi.org/10.3390/pr11030959

APA StyleShao, L., Xue, N., Li, W., Liu, S., Tu, Z., Chen, Y., Zhang, J., Dai, S., Liu, Q., Shi, X., Wang, T., Chen, M., Huang, Y., Xu, F., & Zhu, L. (2023). Effect of Cold-Spray Parameters on Surface Roughness, Thickness and Adhesion of Copper-Based Composite Coating on Aluminum Alloy 6061 T6 Substrate. Processes, 11(3), 959. https://doi.org/10.3390/pr11030959