A Novel Continuous Roll-Forming Process of Elastomer Molds

Abstract

1. Introduction

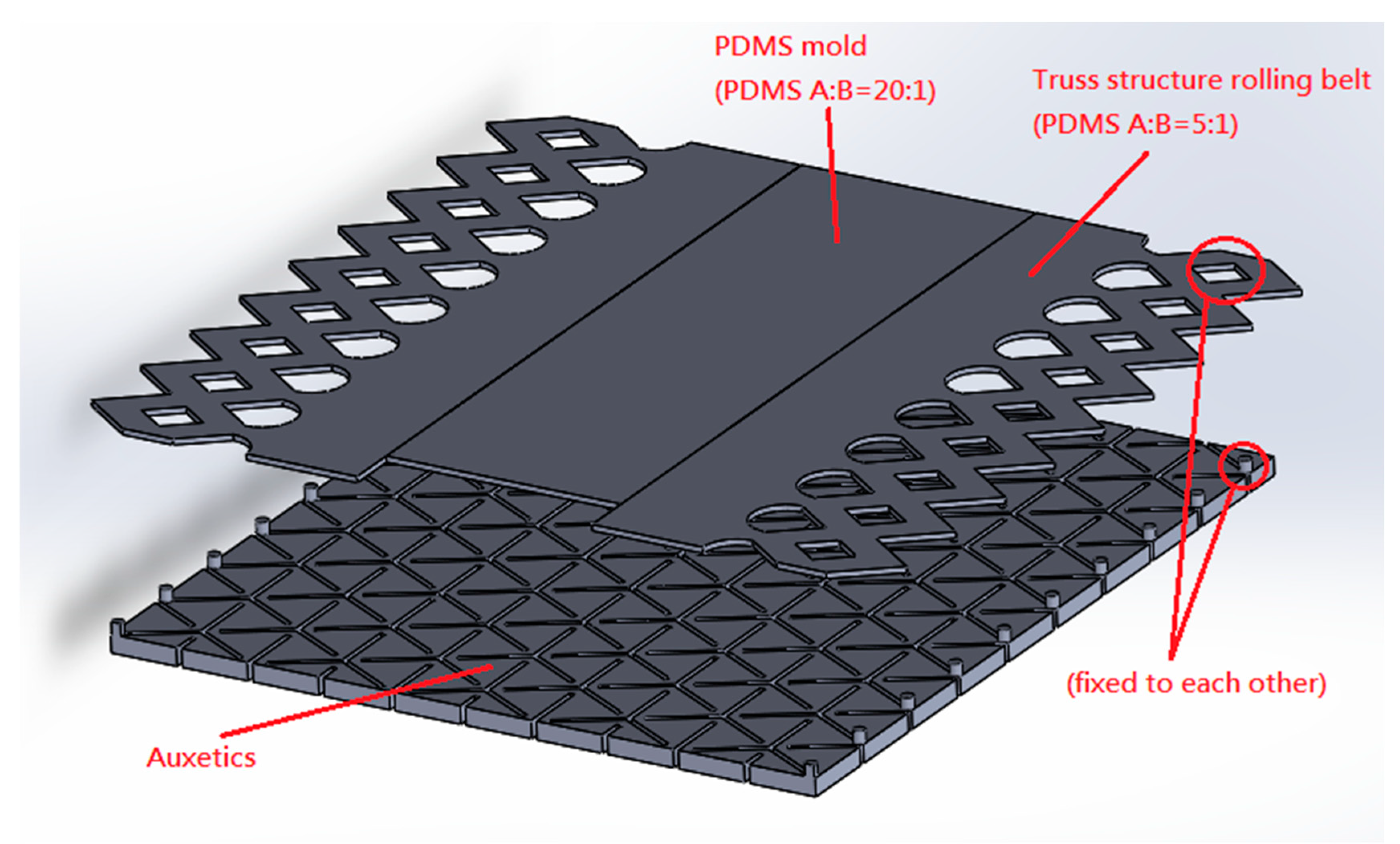

2. Design of Mold Deformation and Simulation Analysis of Auxetic Structure

2.1. Design of Mold Deformation System

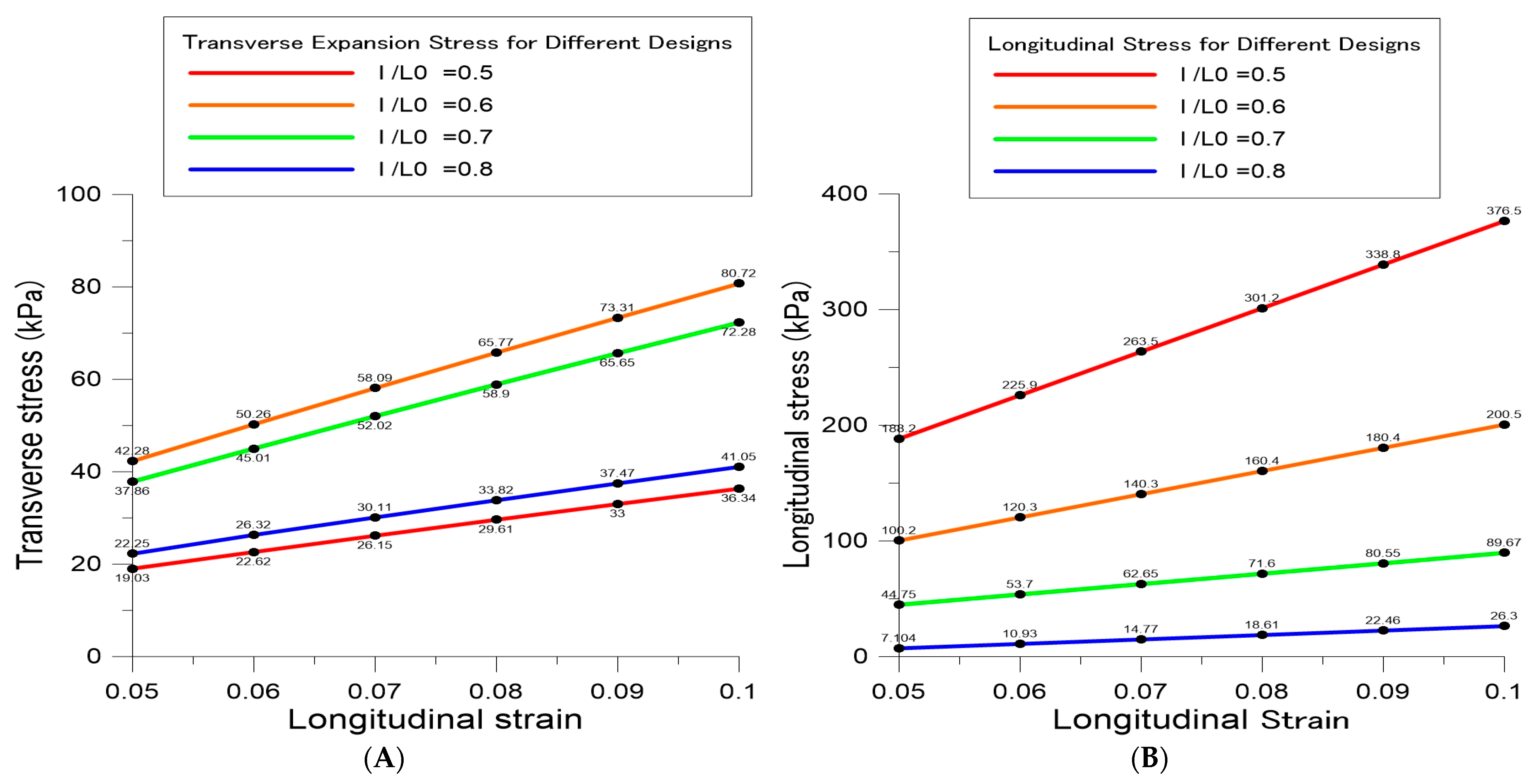

2.2. Selection of Auxetics and Their Structures and Simulation Analysis of Mold Rolling Belt

2.2.1. Selection of Materials and Setting of Parameters of Simulation Materials

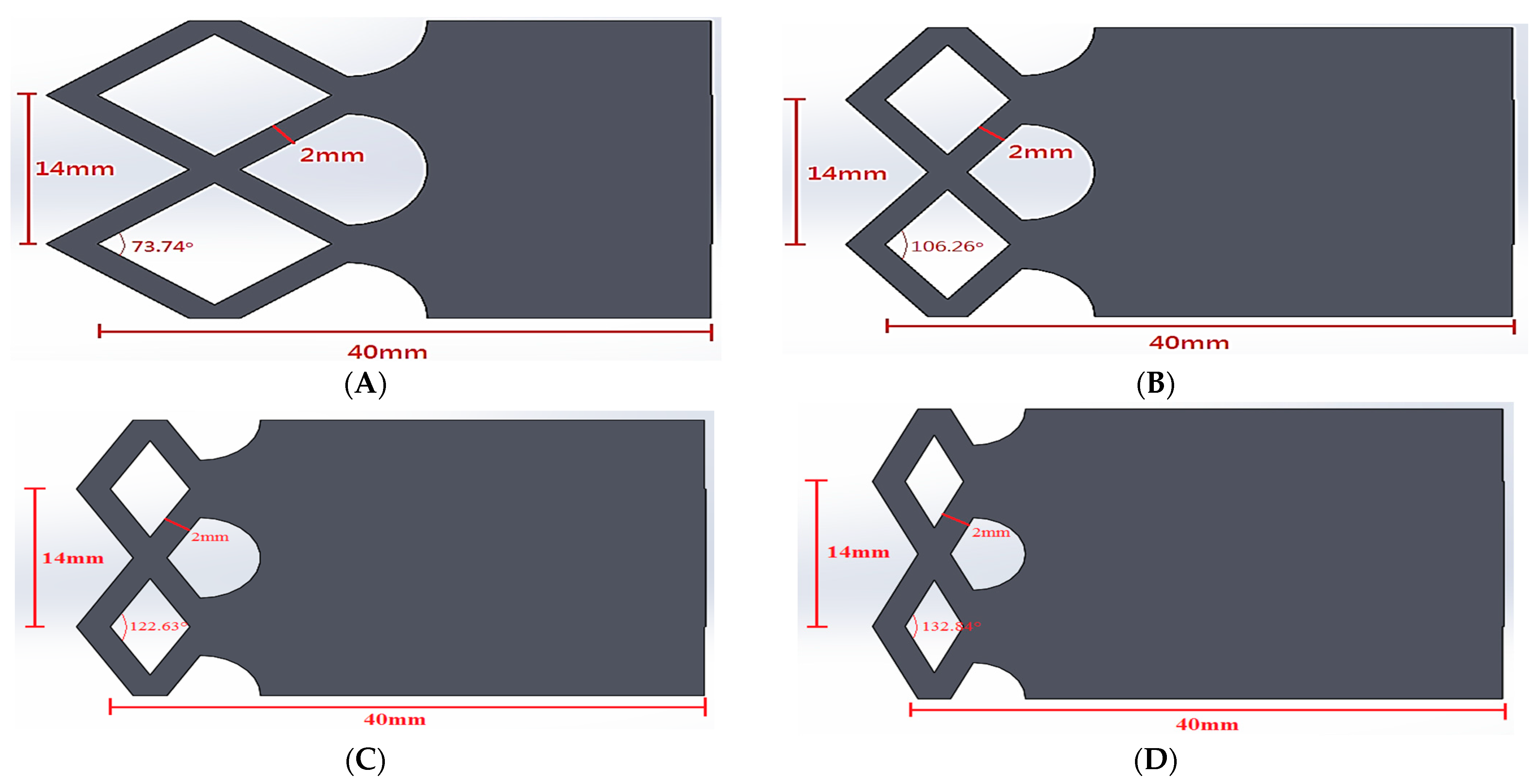

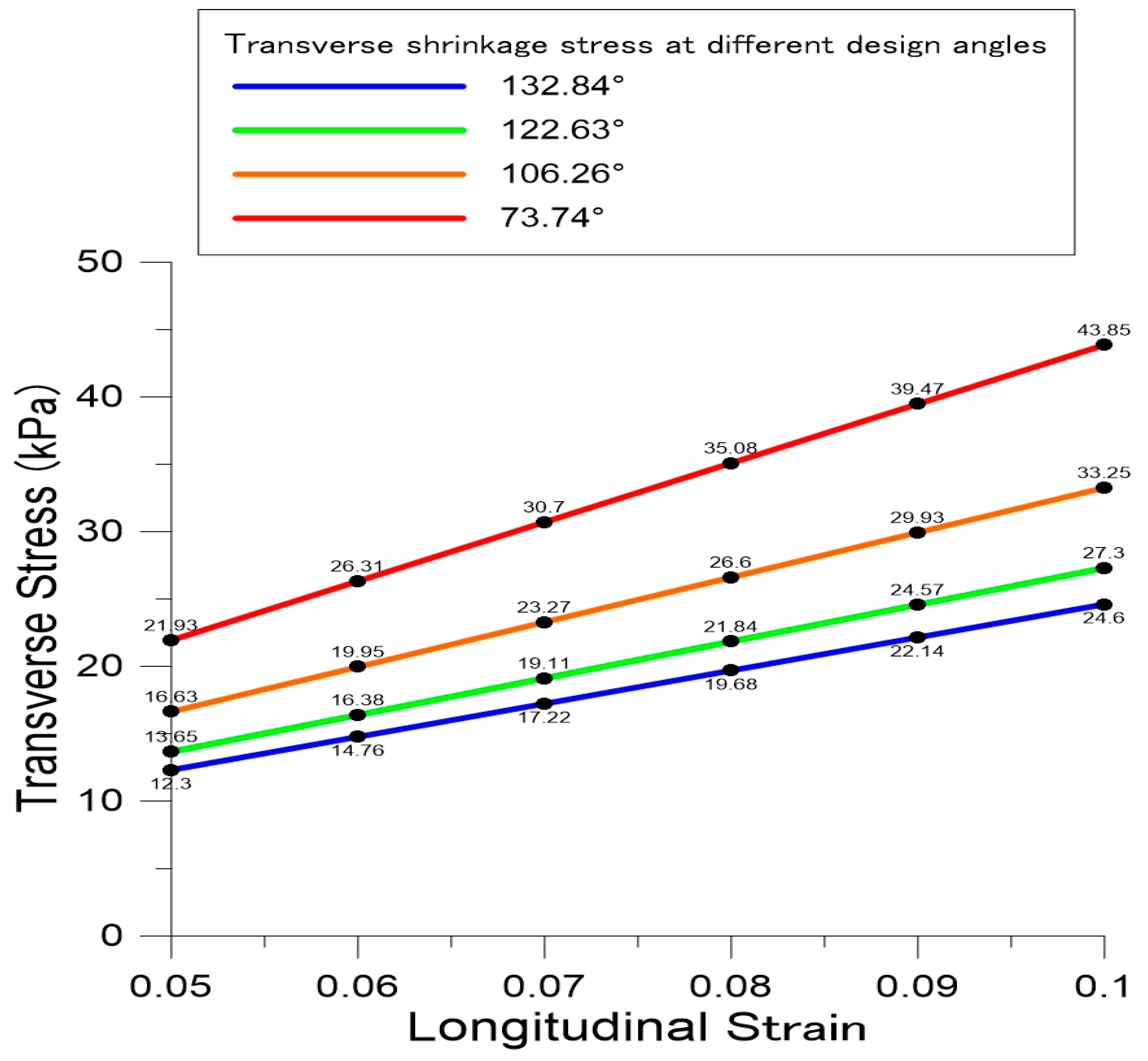

2.2.2. Design and Selection of Auxetic Structure

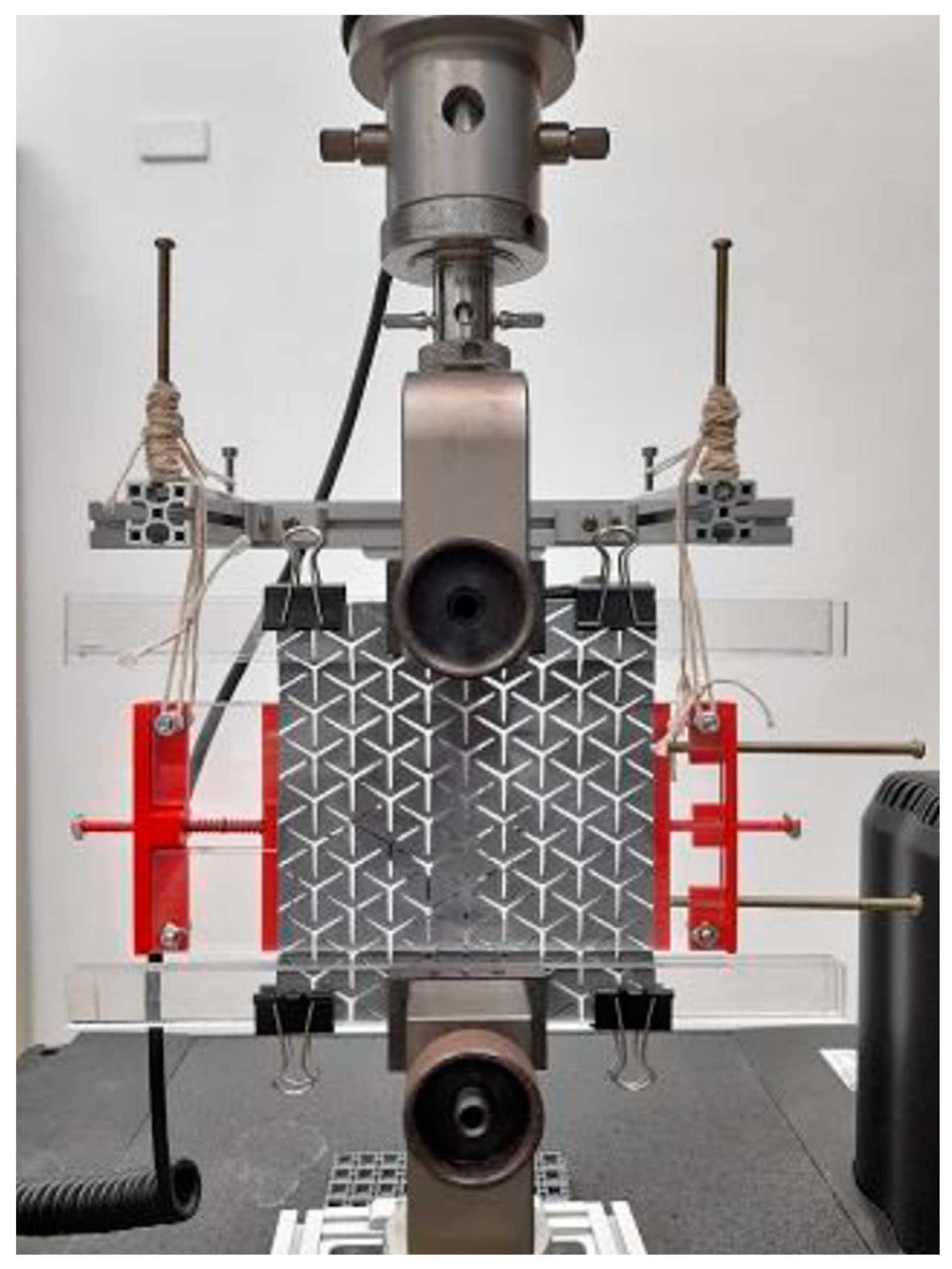

2.2.3. Simulation Analysis of the Auxetic Structure and Mechanical Property Testing

3. Experimental Methods

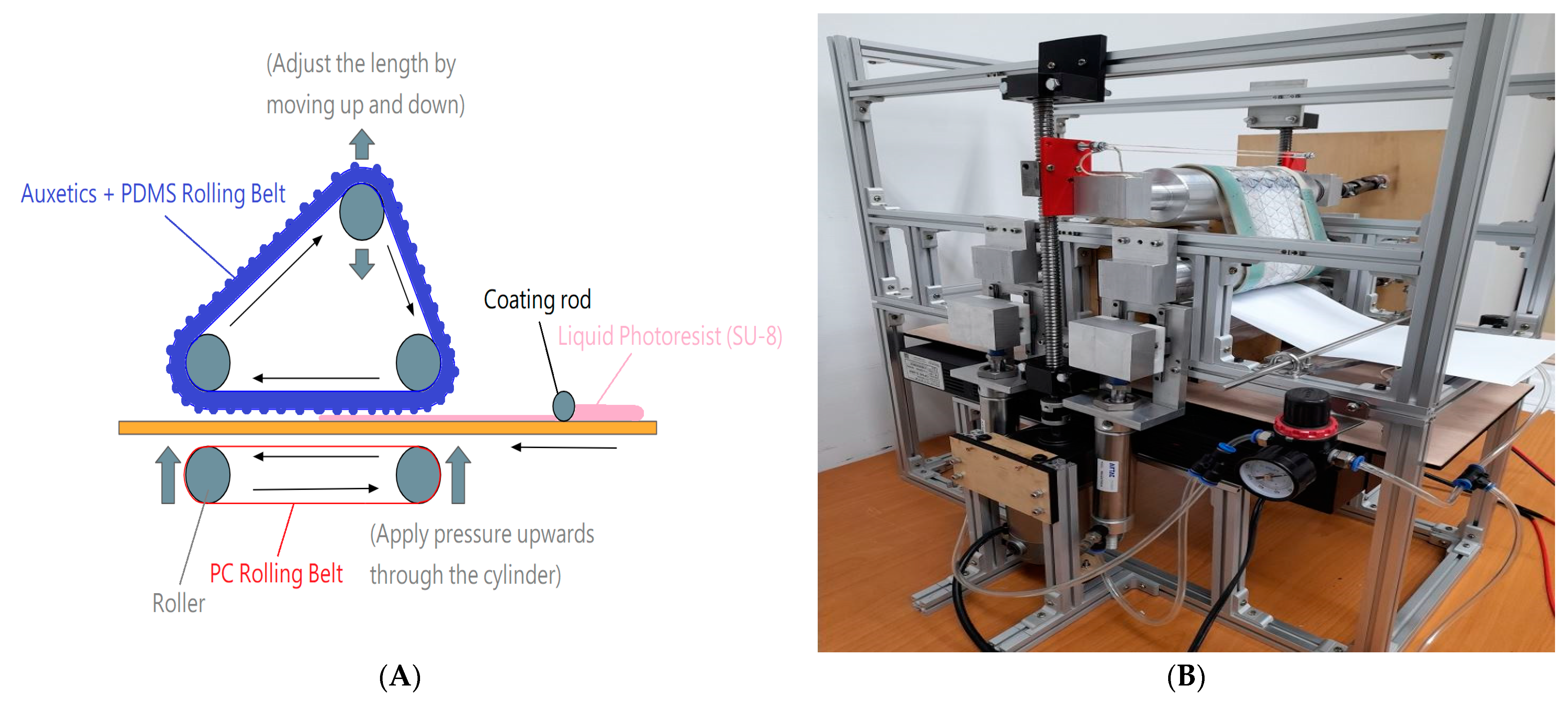

3.1. Design and Development of Imprint System Machine

3.1.1. Design, Simulation, and Selection of Mold Rolling Belt Trusswork

3.1.2. Design, Erection, and Actuating Program of System Machine

3.2. Microstructure Size and Selection of Photoresist

3.3. Imprint Replication Molding Procedure

4. Results and Discussion

4.1. Simulation Analysis and Discussion on Microstructure Replication Molding

4.1.1. Effect of the Thickness of the PDMS Rolling Belt on the Deformation Degree of the Microstructure

4.1.2. Effect of Microstructure Size on the Deformation Degree

4.2. Discussion on the Study of Replication Molding

4.2.1. Y-Shaped Rigid Rotational Auxetic Structure—Effect of Truss Structure Thickness and PDMS Mold Rolling Belt Thickness

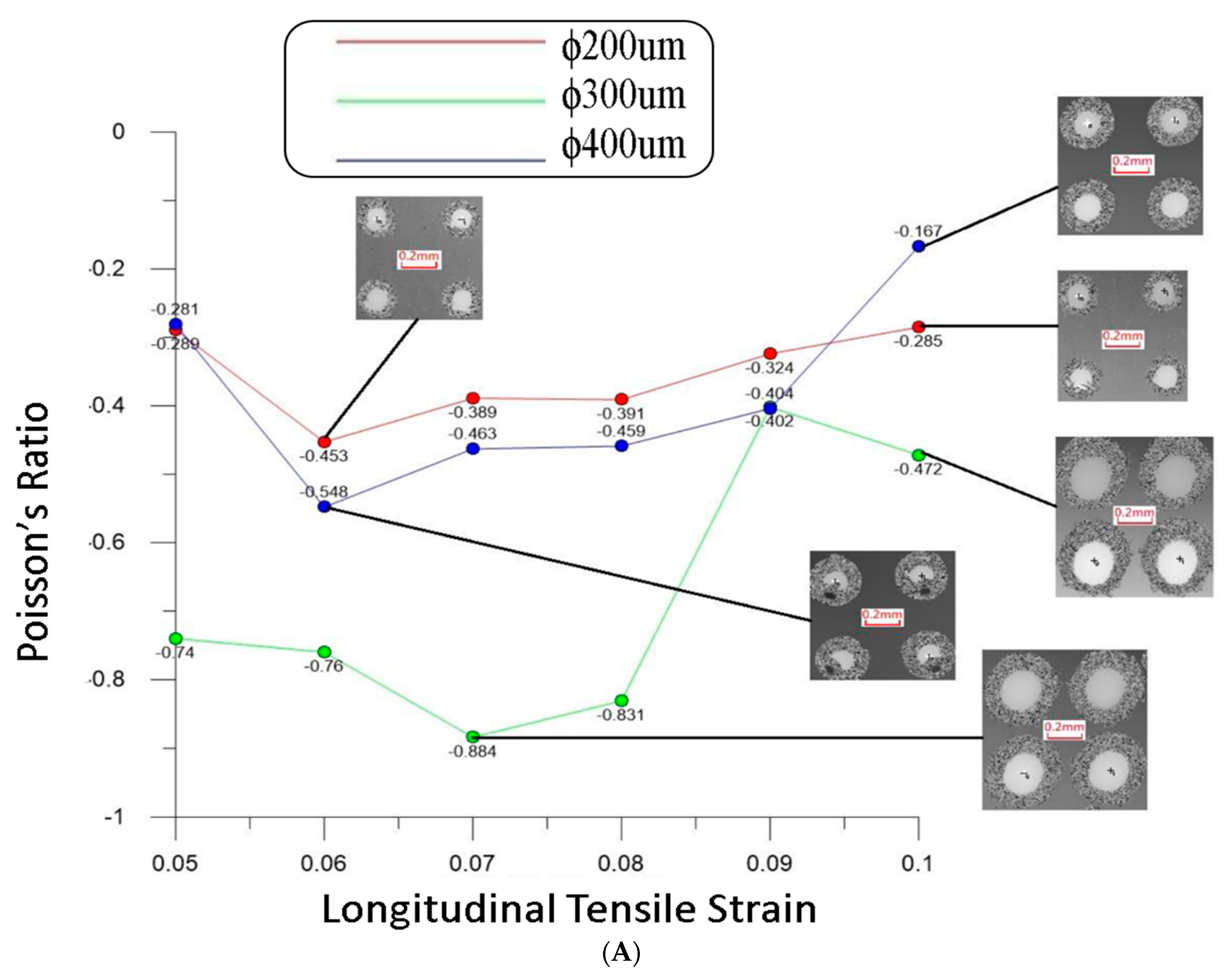

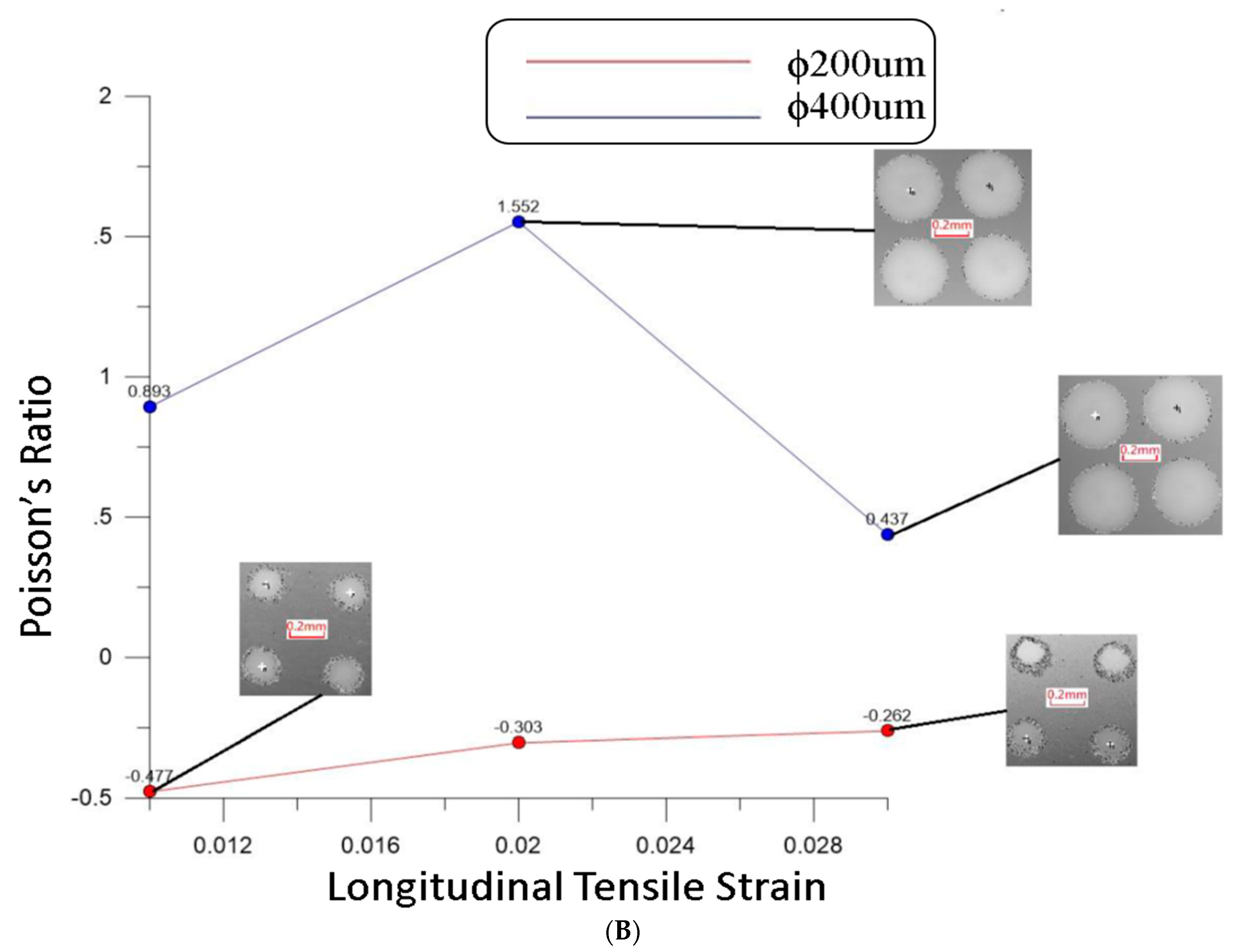

4.2.2. Effect of Poisson’s Ration

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mpupa, A.; Dinc, M.; Mizaikoff, B.; Nomngongo, P. Exploration of a Molecularly Imprinted Polymer (MIPs) as an Adsorbent for the Enrichment of Trenbolone in Water. Processes 2021, 9, 186. [Google Scholar] [CrossRef]

- Zheng, R.; Jia, H.; Abualigah, L.; Liu, Q.; Wang, S. Deep Ensemble of Slime Mold Algorithm and Arithmetic Optimization Algorithm for Global Optimization. Processes 2021, 9, 1774. [Google Scholar] [CrossRef]

- Wolska, J.; Jalilnejad Falizi, N. Membrane Emulsification Process as a Method for Obtaining Molecularly Imprinted Polymers. Polymers 2021, 13, 2830. [Google Scholar] [CrossRef]

- Bender, M.; Otto, M.; Hadam, B.; Vratzov, B.; Spangenberg, B.; Kurz, H. Fabrication of nanostructures using a UV-based imprint technique. Microelectron. Eng. 2000, 53, 233–236. [Google Scholar] [CrossRef]

- Weng, Y.-J. Forming of Dynamic Microstructure of Flexible Polymer. Materials 2019, 12, 3332. [Google Scholar] [CrossRef]

- Lei, Z.; Su, W. Mold Level Predict of Continuous Casting Using Hybrid EMD-SVR-GA Algorithm. Processes 2019, 7, 177. [Google Scholar] [CrossRef]

- Roeder, M.; Guenther, T.; Zimmermann, A. Review on Fabrication Technologies for Optical Mold Inserts. Micromachines 2019, 10, 233. [Google Scholar] [CrossRef]

- Hasanah, A.N.; Safitri, N.; Zulfa, A.; Neli, N.; Rahayu, D. Factors Affecting Preparation of Molecularly Imprinted Polymer and Methods on Finding Template-Monomer Interaction as the Key of Selective Properties of the Materials. Molecules 2021, 26, 5612. [Google Scholar] [CrossRef]

- Meshalkin, V.P.; Belyakov, A.V. Methods Used for the Compaction and Molding of Ceramic Matrix Composites Reinforced with Carbon Nanotubes. Processes 2020, 8, 1004. [Google Scholar] [CrossRef]

- Weng, Y.-J.; Huang, J.-C.; Chen, Y.-Y.; Hsu, S.-T.; Zhang, Z.-R. A Study on the Dynamic Forming Mechanism Development of the Negative Poisson’s Ratio Elastomer Molds—Plate to Plate (P2P) Forming Process. Polymers 2021, 13, 3255. [Google Scholar] [CrossRef]

- Tahir, U.; Kim, J.I.; Javeed, S.; Khaliq, A.; Kim, J.-H.; Kim, D.-I.; Jeong, M.Y. Process Optimization for Manufacturing Functional Nanosurfaces by Roll-to-Roll Nanoimprint Lithography. Nanomaterials 2022, 12, 480. [Google Scholar] [CrossRef] [PubMed]

- Lim, S.H.; Ly, N.H.; Lee, J.A.; Kim, J.E.; La, S.-W.; Huong, V.T.; Tran, T.-G.; Ho, N.T.; Noh, S.M.; Son, S.J.; et al. Nanopatterned Polymer Molds Using Anodized Aluminum Templates for Anti-Reflective Coatings. Polymers 2021, 13, 3333. [Google Scholar] [CrossRef]

- Asgar, M.A.; Kim, J.; Haq, M.R.; Kim, T.; Kim, S.M. A Comprehensive Review of Micro/Nano Precision Glass Molding Molds and Their Fabrication Methods. Micromachines 2021, 12, 812. [Google Scholar] [CrossRef] [PubMed]

- Weng, Y.-J.; Lee, H.-J. Large-area roll printing and replication forming with curvature control of microlens array structures. Microsyst. Technol. 2021, 27, 3437–3445. [Google Scholar] [CrossRef]

- Shi, Y.; Jiang, Z.; Cao, J.; Ehmann, K.F. Texturing of metallic surfaces for superhydrophobicity by water jet guided laser micro-machining. Appl. Surf. Sci. 2020, 500, 144286. [Google Scholar] [CrossRef]

- Lee, Y.-C.; Leeghim, H.; Lee, C.-Y. Micropatterning of Metal-Grid Micro Electro Mechanical Systems (MEMS) Sensor for Crack Detection Using Electrohydrodynamic Printing System. J. Nanosci. Nanotechnol. 2020, 20, 4385–4389. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Hong, M. Parallel Laser Micro/Nano-Processing for Functional Device Fabrication. Laser Photon- Rev. 2020, 14, 1900062. [Google Scholar] [CrossRef]

- Shahapurkar, K.; Venkatesh, C.; Tirth, V.; Manivannan, C.; Alarifi, I.M.; Soudagar, M.E.M.; El-Shafay, A.S. Influence of Graphene Nano Fillers and Carbon Nano Tubes on the Mechanical and Thermal Properties of Hollow Glass Microsphere Epoxy Composites. Processes 2021, 10, 40. [Google Scholar] [CrossRef]

- Hong, J.; Kim, S.K.; Cho, Y.-H. Flow and solidification of semi-crystalline polymer during micro-injection molding. Int. J. Heat Mass Transf. 2020, 153, 119576. [Google Scholar] [CrossRef]

- Wang, W.; Gardi, G.; Malgaretti, P.; Kishore, V.; Koens, L.; Son, D.; Gilbert, H.; Wu, Z.; Harwani, P.; Lauga, E.; et al. Order and information in the patterns of spinning magnetic micro-disks at the air-water interface. Sci. Adv. 2022, 8, eabk0685. [Google Scholar] [CrossRef]

- Colburn, M.; Johnson, S.; Stewart, M.; Damle, S.; Bailey, T.; Choi, B.; Wedlake, M.; Michaelson, T.; Sreenivasan, S.V.; Ekerdt, J.; et al. Step and Flash Imprint Lithography: A New Approach to High-Resolution Patterning. In Proceedings of the Part of the SPIE Conference on Emerging Lithographic Technologies Ill, Santa Clara, CA, USA, 14–19 March 1999. [Google Scholar]

- Ruchhoeft, P.; Colburn, M.; Choi, B.; Nounu, H.; Johnson, S.; Bailey, T.; Damle, S.; Stewart, M.; Ekerdt, J.; Sreenivasan, S.V.; et al. Patterning curved surfaces: Template generation by ion beam proximity lithography and relief transfer by step and flash imprint lithography. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1999, 17, 2965. [Google Scholar] [CrossRef]

- Lee, H.; Hong, S.; Yang, K.; Choi, K. Fabrication of 100nm metal lines on flexible plastic substrate using ultraviolet curing nanoimprint lithography. Appl. Phys. Lett. 2006, 88, 143112. [Google Scholar] [CrossRef]

- Li, Z.; Gu, Y.; Wang, L.; Ge, H.; Wu, W.; Xia, Q.; Yuan, C.; Chen, Y.; Cui, B.; Williams, R.S. Hybrid Nanoimprint-Soft Lithography with Sub-15 nm Resolution. Nano Lett. 2009, 9, 2306–2310. [Google Scholar] [CrossRef] [PubMed]

- Xia, Y.; Whitesides, G.M. Extending Microcontact Printing as a Microlithographic Technique. Langmuir 1997, 13, 2059–2067. [Google Scholar] [CrossRef]

- Pokroy, B.; Epstein, A.K.; Persson-Gulda, M.C.M.; Aizenberg, J. Fabrication of Bioinspired Actuated Nanostructures with Arbitrary Geometry and Stiffness. Adv. Mater. 2009, 21, 463–469. [Google Scholar] [CrossRef]

- Liu, L.; Khan, H.A.; Li, J.; Hillier, A.C.; Lu, M. A strain-tunable nanoimprint lithography for linear variable photonic crystal filters. IOP Publ. Nanotechnol. 2016, 27, 295301. [Google Scholar] [CrossRef] [PubMed]

- Min, H.; Zheng, N.; Fan, Z.; Jiang, Y.; Cheng, X. UV-curable nanoimprint resist with liquid volume-expanding monomers. Microelectron. Eng. 2019, 205, 32–36. [Google Scholar] [CrossRef]

- Delachat, F.; Teyssedre, H.; Pain, L.; Chevalier, X.; Nicolet, C.; Navarro, C. Evaluation of adhesion layers performances for soft UV nanoimprint lithography. In Novel Patterning Technologies for Semiconductors, MEMS/NEMS, and MOEMS; SPIE: Bellingham, WA, USA, 2019; Volume 10958, pp. 138–144. [Google Scholar] [CrossRef]

- Weng, Y.-J. Research and development of the asymmetric grayscale roll-to-plate processing technology. Int. J. Adv. Manuf. Technol. 2018, 98, 1339–1353. [Google Scholar] [CrossRef]

- Deshmukh, S.S.; Goswami, A. Recent developments in hot embossing–a review. Mater. Manuf. Process. 2021, 36, 501–543. [Google Scholar] [CrossRef]

- Weng, Y.-J. The development of a dynamic rubber balloon spring-based asymmetric photocurable imprint system. Optik 2020, 201, 163479. [Google Scholar] [CrossRef]

- Handte, T.; Scheller, N.; Dittrich, L.; Thesen, M.W.; Messerschmidt, M.; Sinzinger, S. Manufacturing of nanostructures with high aspect ratios using soft UV-nanoimprint lithography with bi- and trilayer resist systems. Micro Nano Eng. 2022, 14, 100106. [Google Scholar] [CrossRef]

- Kono, T.; Hatano, M.; Tokue, H.; Kobayashi, K.; Kato, H.; Suzuki, M.; Suzuki, M.; Fukuhara, K.; Kobayashi, K.; Kato, H.; et al. Improvement of nano-imprint lithography performance for device fabrication. In Novel Patterning Technologies; SPIE: Bellingham, WA, USA, 2018; Volume 10584, pp. 160–168. [Google Scholar] [CrossRef]

- Ali, R.A.M.; Espulgar, W.V.; Aoki, W.; Jiang, S.; Saito, M.; Ueda, M.; Tamiya, E. One-step nanoimprinted hybrid micro-/nano-structure for in situ protein detection of isolated cell array via localized surface plasmon resonance. Jpn. J. Appl. Phys. 2018, 57, 03EC03. [Google Scholar] [CrossRef]

| Width (mm) | Horizontal Shrinkage Stress (Vertical Tensile Strain = 0.05) (kPa) | Horizontal Shrinkage Stress (Vertical Tensile Strain = 0.1) (kPa) | Data Trend Line |

|---|---|---|---|

| 1.4 | 10.643 | 21.286 | |

| 1.5 | 11.372 | 22.744 | |

| 1.6 | 11.945 | 23.889 | |

| 1.7 | 12.658 | 25.316 | |

| 1.8 | 13.185 | 26.37 | |

| 1.9 | 13.484 | 26.967 | |

| 2 | 14.195 | 28.39 | |

| 2.1 | 14.649 | 29.298 | |

| 2.2 | 15.106 | 30.212 | |

| 2.3 | 15.537 | 31.074 | |

| 2.4 | 15.755 | 31.51 | |

| 2.5 | 16.21 | 32.42 | |

| 2.6 | 16.254 | 32.507 | |

| 2.7 | 16.723 | 33.446 | |

| 2.8 | 17.288 | 34.576 | |

| 2.9 | 17.739 | 35.477 | |

| 3 | 17.878 | 35.755 |

| Vertical Tensile Strain | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | |

|---|---|---|---|---|---|---|---|

| Poisson’s Ratio | |||||||

| 0 | 12.859 | 15.43 | 18.002 | 20.574 | 23.145 | 25.717 | |

| −0.2 | 18.002 | 21.603 | 25.203 | 28.803 | 32.404 | 36.004 | |

| −0.4 | 23.146 | 27.775 | 32.404 | 37.033 | 41.662 | 46.291 | |

| −0.6 | 28.289 | 33.947 | 39.605 | 45.263 | 50.92 | 56.578 | |

| −0.8 | 33.433 | 40.119 | 46.806 | 53.492 | 60.179 | 66.865 | |

| −1 | 38.576 | 46.291 | 54.007 | 61.722 | 69.437 | 77.152 |

| Thickness | 1 mm | 2 mm | 3 mm |

|---|---|---|---|

| Vertical strain of shape | 0.228 | 0.23 | 0.228 |

| Horizontal strain of shape | 0.0418 | 0.0421 | 0.0423 |

| Depth strain of shape | −0.10598 | −0.1062 | −0.1062 |

| Vertical strain of position spacing | 0.1004 | 0.1006 | 0.1008 |

| Horizontal strain of position spacing | 0 | 0 | 0 |

| Thickness | 1 mm | 2 mm | 3 mm |

|---|---|---|---|

| Vertical strain of shape | 0.272 | 0.276 | 0.273 |

| Horizontal strain of shape | 0.26856 | 0.2687 | 0.27043 |

| Depth strain of shape | −0.174 | −0.1706 | −0.1702 |

| Vertical strain of position spacing | 0.1002 | 0.1006 | 0.1014 |

| Horizontal strain of position spacing | 0.098486 | 0.10053 | 0.1007 |

| Microstructure Diameter | 100 µm | 150 µm | 200 µm | 250 µm | 300 µm | 400 µm |

|---|---|---|---|---|---|---|

| Vertical strain of shape | 0.114 | 0.11067 | 0.109 | 0.1028 | 0.0933 | 0.07125 |

| Horizontal strain of shape | 0.021175 | 0.019645 | 0.020104 | 0.021265 | 0.01594 | 0.0098 |

| Depth strain of shape | −0.053 | −0.05173 | −0.0508 | −0.04456 | −0.0476 | −0.04695 |

| Vertical strain of position spacing | 0.05 | 0.0506 | 0.0506 | 0.0506 | 0.0512 | 0.0546 |

| Horizontal strain of position spacing | 0 | 0 | 0 | 0 | 0 | 0 |

| Microstructure Diameter | 100 µm | 150 µm | 200 µm | 250 µm | 300 µm | 400 µm |

|---|---|---|---|---|---|---|

| Vertical strain of shape | 0.23 | 0.2233 | 0.2175 | 0.2052 | 0.188 | 0.14175 |

| Horizontal strain of shape | 0.042182 | 0.041306 | 0.03507 | 0.036203 | 0.0305 | 0.018192 |

| Depth strain of shape | −0.1062 | −0.105867 | −0.1029 | −0.1 | −0.0977 | −0.09205 |

| Vertical strain of position spacing | 0.1006 | 0.1002 | 0.1014 | 0.1034 | 0.1024 | 0.1088 |

| Horizontal strain of position spacing | 0 | 0 | 0 | 0 | 0 | 0 |

| Microstructure Diameter | 100 µm | 150 µm | 200 µm | 250 µm | 300 µm | 400 µm |

|---|---|---|---|---|---|---|

| Vertical strain of shape | 0.136 | 0.133 | 0.131 | 0.126 | 0.1107 | 0.0825 |

| Horizontal strain of shape | 0.134278 | 0.13015 | 0.12854 | 0.120692 | 0.11016 | 0.078815 |

| Depth strain of shape | −0.08694 | −0.08493 | −0.08262 | −0.082344 | −0.07728 | −0.074935 |

| Vertical strain of position spacing | 0.05 | 0.0508 | 0.05 | 0.0516 | 0.0518 | 0.0556 |

| Horizontal strain of position spacing | 0.0492 | 0.0507 | 0.0512 | 0.0517 | 0.0531 | 0.0566 |

| Microstructure Diameter | 100 µm | 150 µm | 200 µm | 250 µm | 300 µm | 400 µm |

|---|---|---|---|---|---|---|

| Vertical strain of shape | 0.272 | 0.2673 | 0.2615 | 0.2524 | 0.2217 | 0.16475 |

| Horizontal strain of shape | 0.26856 | 0.2603 | 0.2571 | 0.24138 | 0.2203 | 0.15763 |

| Depth strain of shape | −0.174 | −0.17 | −0.1652 | −0.16472 | −0.15457 | −0.14985 |

| Vertical strain of position spacing | 0.1002 | 0.1014 | 0.1002 | 0.1032 | 0.1034 | 0.1112 |

| Horizontal strain of position spacing | 0.0985 | 0.10146 | 0.10252 | 0.1034 | 0.1064 | 0.1133 |

| Longitudinal Tensile Strain | 0.05 | 0.06 | 0.07 | 0.08 | 0.09 | 0.1 | |

|---|---|---|---|---|---|---|---|

| Microstructure | Diameter (µm) | ||||||

| Uni-microstructural longitudinal length (µm) | 200 | 250 | 260 | 255.7 | 270.4 | 264.5 | 276.5 |

| 300 | 308.3 | 311.4 | 313.4 | 320.1 | 331.8 | 349.8 | |

| 400 | 477.5 | 462.8 | 465.4 | 481 | 474.1 | 489.5 | |

| Uni-microstructural lateral length (µm) | 200 | 225.6 | 237.3 | 240.5 | 240.3 | 234.5 | 231.2 |

| 300 | 312.6 | 325.6 | 322.5 | 324.4 | 310.8 | 333 | |

| 400 | 435 | 438.7 | 447 | 437.7 | 421.6 | 422.6 | |

| Uni-microstructural height (µm) | 200 | 23 | 23 | 23 | 23 | 24 | 24 |

| 300 | 39 | 40 | 40 | 39 | 39 | 39 | |

| 400 | 35 | 35 | 35 | 35 | 34 | 35 | |

| Longitudinal period distance of microstructure (µm) | 200 | 511.5 | 516.6 | 528.8 | 529.4 | 532.3 | 547.2 |

| 300 | 510.6 | 515.4 | 514 | 523.7 | 538 | 538 | |

| 400 | 526 | 529.8 | 529.1 | 535.8 | 548 | 563 | |

| Lateral period distance of microstructure (µm) | 200 | 495.5 | 501.5 | 504.5 | 504.8 | 503 | 505.6 |

| 300 | 507.6 | 511.7 | 514 | 520.7 | 510.6 | 514.2 | |

| 400 | 501.5 | 510.7 | 507.8 | 510.7 | 513.6 | 504.6 | |

| Replication rate (%) | 200 | 87 | 89 | 90 | 91 | 96 | 97 |

| 300 | 92 | 96 | 97 | 96 | 97 | 97 | |

| 400 | 93 | 94 | 96 | 97 | 94 | 98 | |

| Longitudinal Tensile Strain | 0.01 | 0.02 | 0.03 | |

|---|---|---|---|---|

| Microstructure | Diameter (µm) | |||

| Uni-microstructural longitudinal length (µm) | 200 | 240.2 | 258.4 | 243.2 |

| 400 | 423.4 | 423.2 | 417.1 | |

| Uni-microstructural lateral length (µm) | 200 | 238.9 | 240.5 | 229.2 |

| 400 | 398.8 | 405.4 | 401.5 | |

| Uni-microstructural height (µm) | 200 | 14 | 14 | 14 |

| 400 | 9 | 9 | 9 | |

| Longitudinal period distance of microstructure (µm) | 200 | 514.2 | 520 | 517.6 |

| 400 | 511.1 | 515.4 | 518.9 | |

| Lateral period distance of microstructure (µm) | 200 | 501 | 498.4 | 496.5 |

| 400 | 483.3 | 468.8 | 485.4 | |

| Replication rate (%) | 200 | 95 | 96 | 97 |

| 400 | 90 | 90 | 92 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.-Y.; Weng, Y.-J. A Novel Continuous Roll-Forming Process of Elastomer Molds. Processes 2023, 11, 931. https://doi.org/10.3390/pr11030931

Chen Y-Y, Weng Y-J. A Novel Continuous Roll-Forming Process of Elastomer Molds. Processes. 2023; 11(3):931. https://doi.org/10.3390/pr11030931

Chicago/Turabian StyleChen, Yuan-Yang, and Yung-Jin Weng. 2023. "A Novel Continuous Roll-Forming Process of Elastomer Molds" Processes 11, no. 3: 931. https://doi.org/10.3390/pr11030931

APA StyleChen, Y.-Y., & Weng, Y.-J. (2023). A Novel Continuous Roll-Forming Process of Elastomer Molds. Processes, 11(3), 931. https://doi.org/10.3390/pr11030931