Abstract

This review presents the nucleate/convective boiling performance for a variety of important low global warming potential (LGWP) alternatives to commonly used high-global warming potential (GWP) refrigerants (such as R-134a, R404A, and R-410A, etc.). Efforts are stressed on the assessment of their evaporation pressure drop and heat transfer coefficient (HTC) characteristics. These alternatives include R-1234ze(Z), R-1234ze(E), R-1233zd (E), R-1234ze(E), R-410A, R-1234yf, and R-513A. The authors investigated the thermo-fluid properties within and outside a tube, mini-channel, micro-fin tube, and plate heat exchanger. The investigation of the numerical, experimental, and simulated results revealed that the evaporation pressure drop and HTC characteristics were dependent on a variety of variables. These factors include the working fluid’s thermodynamics and transport properties, the refrigerant’s mass flux, heat flux, saturation temperature, the vapor quality, the conditions and flow patterns, the orientation of the heating surface, and the geometry (shape, size, and surface area smooth/enhanced) of the heating surface. An expanded LGWP refrigerants, surfaces, and conditions database is needed. Mechanistic models may assist. These models can optimize boiling, anticipate heat transfer, and develop high-performance geometries.

1. Introduction

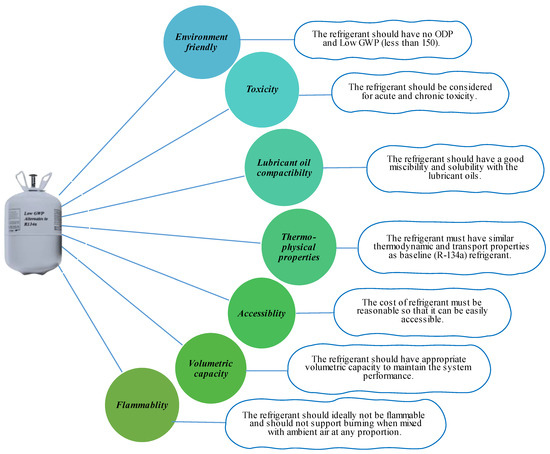

High-global warming potential (GWP) (such as R-134a, R404A, and R-410A, etc.) refrigerants contain a global warming potential as high as 1300 and will be shortly banned. Note that the F-gas regulation (2015), the Montreal Protocol (1985) (IPCC AR6) and its Kigali amendment (2016) suggest that their usage should be decreased by 85% by the year 2047 due to their very high GWP [1]. In a refrigerant with no ODP, LGWP (<150) should be the first priority upon selection. In recent years, efforts to replace R-134a have intensified [2]. As illustrated in Figure 1, various parameters must be considered simultaneously, including GWP, ozone depletion potential (ODP), flammability, toxicity, cost or accessibility factor, thermophysical characteristics, compatibility with lubricant-oil, and the impact of refrigeration. The Alternative Refrigerant Evaluation Program (AREP) and ASHRAE have suggested many R-134a alternatives, including R-1234yf, R-1234zd(E), R-1233ze(E), R-1234ze(Z), R-450A, and R-513A. The subscripts ze, zd, and yf all contain carbon–carbon double bonds, which are essential to the LGWP property. These compounds also have a shorter atmospheric lifespan [1]. Additionally, an isomer with differing physical properties is indicated by the suffixes (E: trans and Z: cis).

Figure 1.

Characteristics of environmentally benign ideal refrigerants.

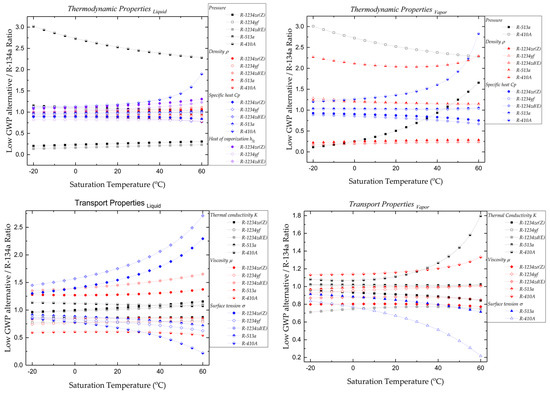

The refrigerant selection is based on their thermophysical properties which is essential in system performance. Hence, relevant saturated properties spanning the range −20 to 60 °C, calculated from REFPROP 10.0 are shown in Figure 2 [3]. In Figure 2 the thermophysical properties for an LGWP refrigerant are termed ratios relative to R-134a. First impressions, except for R-1234ze(Z), R-513a and R-410A, reveal that all refrigerants have similar thermophysical properties at low temperatures.

Figure 2.

Thermophysical properties of LGWP alternatives to R-134a [3].

From this figure, R-1234zd(E) has a lower heat of vaporization and latent heat for R-1234ze (Z) and R-1234yf than that of R-134a. The liquid density of the LGWP substitutes is slightly different (around the order ±20%) when compared to those of R-134a, meaning that the refrigerant mass charge needs adjusting upon drop-in substitution. For a liquid viscosity comparison, R-513A’s viscosity is close to that of R-134a, and R-1234yf has a viscosity that is around 20–30% lower than R-134a, while R-1234ze(Z) and R-1234zd(E) show an appreciably higher viscosity than R-134a. For vapor viscosity, R-1234ze(Z) contains a much lower value than R-134a, thereby can offer less in-tube friction. R-1234yf and R-134a have similar surface tensions; however, R-1234ze(E) has significantly greater surface tension. Hence, the bubble dynamics and departure diameter for R-1234ze(E) must be appreciably different from R-134a. The thermal conductivity of the LGWP alternatives relative to R-134a is comparatively small. Table 1 lists the conventional and alternative refrigerants’ transport and thermodynamic properties at 40 °C. The LGWP refrigerants, R-1234ze(E) and R-1234yf, are slightly flammable (A2L) single-component R-134a replacements. The refrigerant R-513A is an azeotropic blend with 56% R-1234yf and 44% R-134a having a GWP 55.93% lower than R-134a.

Table 1.

At 40 °C, the transport and thermodynamic properties of LGWP refrigerants alternative to R-134a [3].

One of the most significant advantages of the azeotropic (hydrofluorocarbon (HFC) + hydrofluoroolifin (HFO) blend) R-513A is that it is fully non-flammable (A1 class) with comparable properties that may be used to replace R-134a systems with ease. R-450A, which has a very small temperature glide of 0.4 °C, is a zeotropic blend with 58% R-1234ze(E) and 42% R-134a. It is also non-flammable and can also act as a drop-in replacement of R-134a. For low-pressure refrigerants, the R-1233zd(E) refrigerant may be used to replace the R-123/R-245f system.

The performance of heat exchanger imposes direct consequences on HVAC system performance. Hence, boiling and condensation processes play detrimental roles accordingly in the heat transfer equipment. Flow patterns for the boiling and condensation within and outside plain and enhanced surfaces subject to propane were examined by Mauro et al. [4]. A literature review based on the properties of the evaporation and condensation of several LGWP refrigerants on brazed plate heat exchangers (PHEs) were presented by Shon et al. [5]. The HTCs and frictional pressure decrease during vaporization of the LGWP refrigerant on brazed PHEs were the subject of significant study by Longo et al. [6,7,8,9,10].

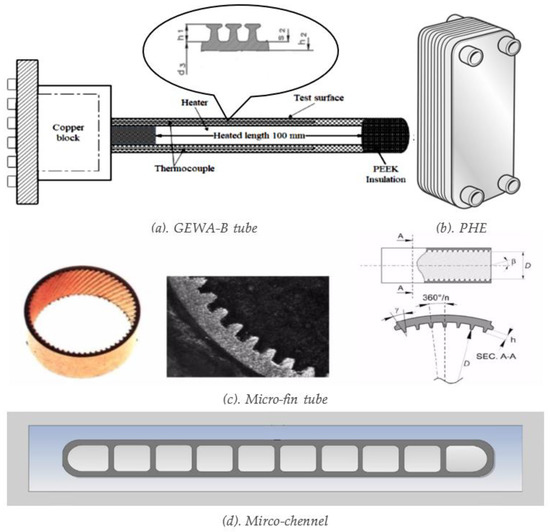

The above literature shows that previous investigations reported specific results under limited conditions, including the working fluid (refrigerants), evaporation within the tubes and micro-channels [11,12,13], evaporation inside and outside of enhanced surfaces [14], and plate heat exchangers [8,9,15,16,17]. Some of the results are not in line with each other. The condensation performance of LGWP refrigerants alternative to R-134a was recently reviewed by Kumar et al. [1]. Hence, the primary objective of the present review stresses the evaporative characteristics of the HTCs and frictional pressure drop of LGWP refrigerants, with particular emphasis and comparison with some high-global warming potential (GWP) (such as R-134a, R-404A, and R-410A, etc.) refrigerant alternatives, in association with in-tube evaporation, nucleate boiling outside the tube for both smooth and enhanced surfaces. Yet, mini-channels, and brazed plate heat exchangers are also reviewed as well. An schematic representation is depicted in Figure 3 [18,19,20]. Additionally, the aspects of the pressure drop and evaporation HTCs are discussed in detail, including the influence of saturation temperature, surface geometry, heat flux, vapor quality, mass flow, and the thermophysical parameters of the refrigerant.

Figure 3.

Evaporator geometries for (a) GEWA-B tube, (b) PHE, (c) micro-fin tube, and (d) micro-channel under discussion in this review [18,19,20].

2. Characteristics of LGWP Refrigerants for Nucleate Pool Boiling Heat Transfer

Outside Enhanced and Smooth Tube Boiling

The present section evaluates the heat-transfer capabilities of R-134a and LGWP alternatives. Boiling outside improved and smooth tubes was tested. The relative evaporation HTCs of LGWP refrigerants compared to R-134a were determined using published studies from the past several decades. Table 2 lists the operating conditions of the experiments and tubings.

Table 2.

Experimental conditions, dimensions and specifications of smooth and enhanced tubes.

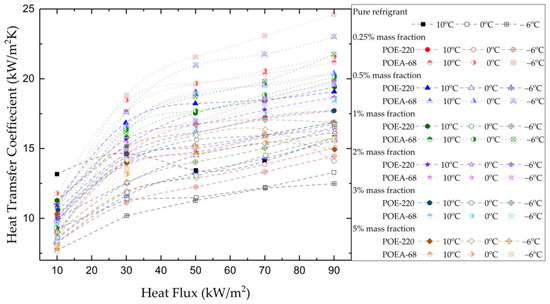

For nucleate boiling subject to a high-viscosity polyol-ester oil (POEA)-220, with a LGWP refrigerant (R-1234ze(E)), Kumar et al. [21] conducted nucleate pool boiling tests on a GEWA-B5H tube at −6, 0, and 10 °C saturation temperatures, with an oil mass fraction ranging from 0.25 to 10% with heat fluxes ranging between 10 and 90 kW/m2. The results were compared to earlier research [19] and the experimental results are shown in Figure 4. It was found that the presence of a lubricant may enhance or degrade the HTC. The phenomenon was strongly related to the saturation temperature. The high-viscosity POEA-220/R-1234ze(E) mix performed better in terms of heat transfer than the low-viscosity oil mixture. These results differ from the results of Jensen and Jackman [22] and Spindler and Hahne [23] (in terms of the influence on HTC enhancement/degradation) and to an extent are similar to the findings of Mohrlok et al. [24]. It is uncertain if high viscosity may easily agglomerate on the boiling surface and eventually impede the heat transfer. The HTC of R-1234ze(E)/POEA-220 is superior to that of the R-1234ze(E)/POEA-68. Note that the refrigerant is volatile, but the oil is nearly non-volatile. In moderate or low liquid pressures, refrigerant evaporation and oil diffusion at the liquid–vapor contact is slow. The boiling process yields a thin oil-rich layer near the heating surface. Heat flux also serves to balance the aforementioned process. Since POEA-220 oil has a better thermal conductivity, heat-transfer efficiency is boosted towards the boiling surface. In this regard, R-1234ze(E)/POEA220 mixtures require lower wall superheats than R-1234ze(E)/POEA-68 mixtures. The boiling mechanism proposed by Kumar and Wang [19] can explain these phenomena. Saturation temperatures and heat flux influences on refrigerant evaporation at the liquid–vapor interface is also discussed. Since a higher liquid pressure and heat flux may promote nucleate boiling appreciably, the oil accumulates more pronouncedly at the heating surface, thereby impeding the HTC substantially. A pure refrigerant combined with lubricating oil changes the bubble dynamics and nucleation sites considerably. The high viscosity of the oil-rich layer limits the formation of larger bubbles, hence increasing the number of nucleation sites and decreasing the bubble departure diameter.

Figure 4.

HTC versus heat flux for pure, R-1234ze(E)/POEA-220 and R-1234ze(E)/POEA-68 oil at 10, 0 and −6 °C [19].

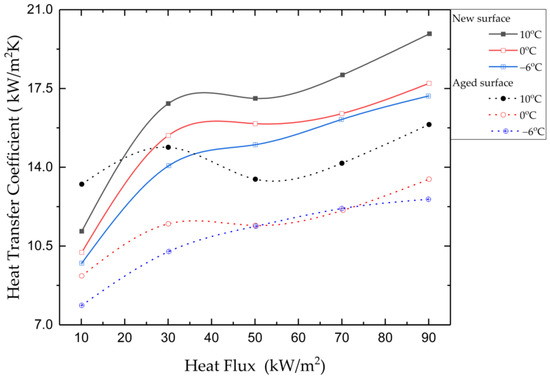

On the other hand, the HTC degrades due to the creation of a micro-sized bubble fog directly above the test surface, which is connected to a higher oil mass fraction at a high heat flux. Furthermore, Kumar et al. [21] also presented HTCs against applied heat fluxes in association with new and aged surfaces at varying saturation temperatures. These experiments were conducted in 4-month gaps. At various saturation temperatures, the HTCs for the new and aged surfaces are displayed in Figure 5. The HTCs were nearly impaired by 10–30% depending on supplied heat flux. Normally the degradation is more significant at higher heat flux regimes. This is because some of the cavities and channels are de-activated after a prolonged operational period when the surface condition change.

Figure 5.

HTCs for new and aged surfaces versus heat flux curves at various saturation temperatures [21].

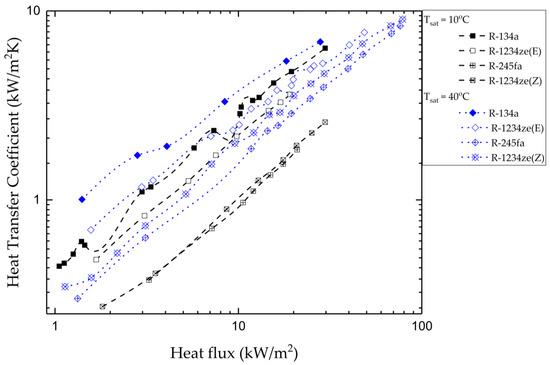

Nagata et al. [25] compared the HTCs at 10 and 40 °C saturation temperatures for the conventional refrigerant R-134a, and its alternatives of R-1234ze(E), R-245fa, and R-1234ze(Z) (Figure 6). Tests were performed on horizontal tubes. The boiling HTCs of R-1234ze(Z) and R-245fa were comparable and much lower than R-1234ze(E) and R-134a. Ribatski and Thome [26] investigated nucleate boiling in a GEWA-B tube submerged in the conventional refrigerant R-134a. The HTCs for a GEWA-B tube is about 2.4 to 5.2 times greater than smooth tubes and the HTCs are unaffected by the saturation temperatures. Despite saturated temperatures, the HTC was approximately 18 kW/m2K at 20 kW. Under the same experimental conditions the HTCs on the GEWA-B5 tube for R-1234ze and R-134a reported by Rooyen and Thome [27] was more than 40 kW/m2K. The HTCs also shared several characteristics with those mentioned in work of Ribatski and Thome [26]. Habert and Thome [28] analyzed the performance of R-236fa and R-134a using four distinct tubes, two for boiling (Turbo-EDE2 and Gewa-B4) and two for condensing (smooth and GEWA-C + LW tube). They reached the conclusion that the GEWA-C + LW tube performs in a manner that is comparable to that of the smooth tube and that there is no improvement for either refrigerant.

Figure 6.

Influence of HTCs and heat flux on R-134a, R-1234ze(Z), R-245fa, and R-1234ze(E) [25].

On the other hand, Spindler and Hahne [23] found that the decrease in the HTC may be attributed to an increase in temperature. HTCs continuously rises with heat flux, which varies from 4 to 80 kW/m2 for pure R-134a refrigerant on a completely submerged GEWA-B tube, running at 28.6 to 20.1 °C. However, the HTC decreases as the saturation temperature decreases. Similar results were reported by Wang et al. [35], who stated that the performance of GEWA-B tubes for nucleate boiling, when subjected to versatile refrigerants at 20 and 0 °C saturation temperatures, was greater than identical tubes tested earlier in the series. This was found to be the case for GEWA-B tubes at 20 and 0 °C saturation temperatures. According to Mohrlok et al. [24], the HTC of GEWA-B tubes becomes higher with the rise in saturation temperatures when using R-507, so long as the heat flow exceeds 4 kW/m2. At −19.6 and −28.6 °C, the HTCs are nearly identical. The HTC is less affected by saturation temperatures between −10.1 and 20.1 °C for heat fluxes between 4 and 20 kW/m2. A rise in saturation temperatures between −19.9 and 0.2 °C and an increase in heat flow both cause an increase in the HTC. However, it is higher at 20 kW/m2 than at 40 kW/m2. However, the work of Mohrlok et al. [24] reported that the effect of heat flux and saturation temperature on the HTC for the GEWA-B tube is conflicting amid several investigations [36,37,38,39,40]. Recent research conducted by multiple researchers utilizing highly wetting liquids and highly improved surfaces (e.g., GEWA and high-flux surfaces) revealed that the HTC always rises with heat flux.

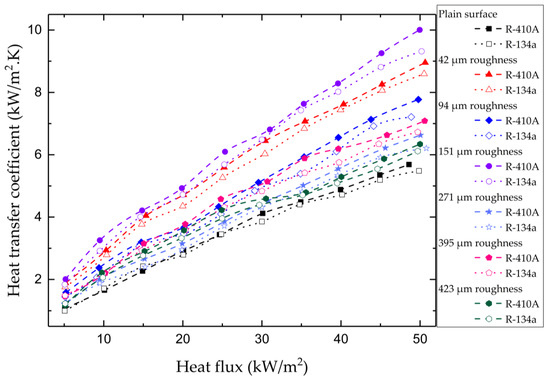

On a horizontal-coated heating surface, Dewangan et al. [40] experimentally examined the nucleate pool boiling HTCs of R-410A and R-134a. The boiling performance on coated surfaces has improved over time due to surface augmentations. By employing a microporous coating, more nucleation prevails and promotes heat transfer accordingly. The effect of coating thickness is depicted in Figure 7 with thickness ranging from 42 to 423 μm subject to the working fluids of R-410A and R-134a. The results indicated that a coating thickness of 151 μm gave the highest HTCs, two times higher than those of a plain surface. Dewangan et al. [41] investigated the heat transfer during the nucleate pool boiling of R-134a and R-410A in plain tubes at 5, 10, 15 and 20 °C saturation temperatures with heat fluxes ranging between 10 and 70 kW/m2. Figure 8 shows that HTCs rise as saturation temperatures rise, confirming the typical pool boiling tendency that as saturation temperature rises, less wall superheat is needed to activate nucleation sites.

Figure 7.

HTCs versus heat flux for seven types of coating [40].

Figure 8.

Influence of the plain and two enhanced surfaces on HTCs [45].

Hung et al. [42] summarized the pool boiling heat-transfer performance and developed a rationally based model to predict nucleate boiling for pure refrigerants with/without lubricant oil. Surface tension and viscosity affect the HTC. During evaporation, an oil-rich layer surrounds the heating surface, and the formed thin lubricant surplus layer and thermal boundary layer affect heat transfer. The oil-rich layer affects surface tension and produces an appreciable surface tension gradient, thereby producing bubbles and stirring the boundary layer with detaching bubbles on the heating surface. According to their model, the presence of a lubricant invariably degrades the HTC during the bubble formation and departure waiting periods but can improve the HTC during the bubble growth phases. These two key parameters compensate each other. Moreover, these factors may further interact with the chemical structure between the interfaces of lubricant and refrigerant.

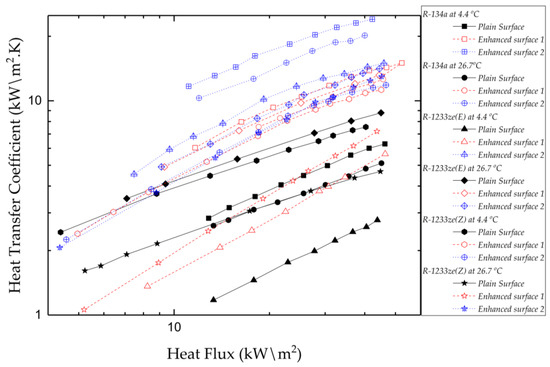

Byun et al. [43] evaluated the pool boiling heat transfer of LGWP refrigerants on plain tubes and enhanced tubes for a turbo-chiller-flooded evaporator. It was discovered that the HTCs of R-1234zd(E) were around 5–11% lower than those of R-134a at 4.4 and 26.7 °C saturation temperatures and 10 to 50 kW/m2 heat fluxes subjected to R-134a, R-1234zd(E), and R-1233zd(E), and the HTCs of R-1233zd(E) were lower than those of R-134a. The heat transfer augmentation ratio of the enhanced tube for R-134a was 2.3, whereas for R-1233zd(E) and R-1234ze(E) the results were observed to be 2.1 and 1.8, respectively. Byun et al. [31] investigated the HTCs of R-1233zd(E) and R-1234ze(E) refrigerants along with a number of other potential alternatives to R-1233zd(E) and R-1234ze(E). Additionally, experiments were conducted on three distinct kinds of tubes, including a plain smooth tube and two enhanced tubes subjected to nucleate boiling with saturated temperatures ranging from 4.4 to 26.7 °C and heat fluxes between 10 and 50 kW/m2. The influence of plain and two enhanced surfaces on HTCs is illustrated in Figure 9. These coefficients were compared to empirical equations. The R-1233zd(E) and R-1234ze(E) plain tube HTCs were 10.8–19.0% and 54.1–62.8% lower than of the HTCs of R-134a, respectively. The findings were further evaluated based on past empirical correlations, which showed sufficient predictions in all cases. R-1233zd(E) and R-1234ze(E) HTCs for the enhancement of the enhanced tube 1 were 9.8–14.0% and 60.0–75.0%, respectively. The HTCs of R-1234ze(E) and R-1233zd(E) for the enhanced tube 2 were 13.3–17.9% and 39.5–43.7% higher than those of the smooth surface, respectively.

Figure 9.

Performance of R-134a at a Tsat = 6 °C for HTCs with different lubrication concentrations [47].

In low-temperature conditions, Shen and Ally [44] conducted an exergy and energy analysis of a two-speed heat pump of R-466A, R-454B, R-452B, and R-32. R-466A, R-454B, R-452B, and R-32 performed significantly better than R-410A. Yet, the refrigerants R-32 and R-454B had the least amount of irreversibility, whereas R-466A had a somewhat higher level of irreversibility than R-410A. Ji et al. [45] investigated the suitability of the Cooper correlation for R-134a at heat fluxes of 10 to 370 kW/m2. They found that at a heat flux less than 250 kW/m2, the R2 of the best-fitting of the HTCs with the Cooper correlation vs. heat flux was only 0.67. For heat flows over 250 kW/m2, a persistent slope decline was observed, meaning the experimental results deviated even more against the Cooper correlation. The appropriate heat flux range using Cooper’s correlation to forecast the R-134a pool boiling heat transfer is suggested to be less than 250 kW/m2.

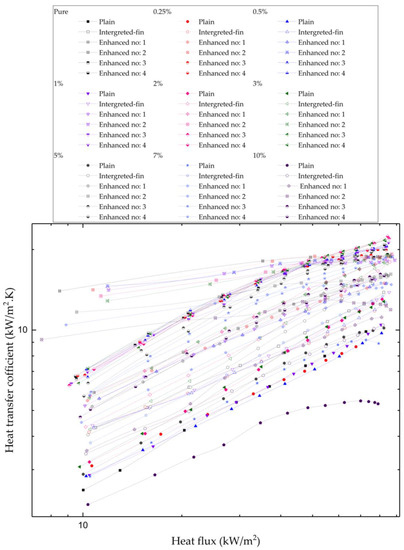

The pool boiling HTCs for the refrigerants R-1234ze(E), R-1233zd(E), and R-134a were studied by Ji et al. [46] for two enhanced tubes containing re-entrant cavity tubes. Both tubes had varied fin densities, but the subsurface tunnel diameter and fin height were the same. Pool boiling HTC was measured at a 6 °C saturation temperature and heat fluxes ranging from 10 to 80 kW/m2. Tube-B1 exhibited a similar boiling HTC for R-134a and R-13234ze(E). When the heat flux was less than 60 kW/m2, the number of nucleation sites for larger fin densities and thinner fin thicknesses was found to be greater than tubes with larger fin thicknesses. At 40 kW/m2, the boiling HTCs of R-134a and R-1234ze(E) for the two enhanced tubes were approximately the same. The boiling heat transfer depends weakly on surface features at increased heat fluxes. For the two tubes under practically cooperating conditions, the boiling HTC of R-1233zd(E) was observed to be reduced by more than 40% when compared to R-134a. Ji et al. [47] assessed the pool boiling HTCs for R-134a combined with a lubricant (PVE). Figure 10 comprises the performance of R-134a at a Tsat = 6 °C. The oil mass fraction ranged from 0.25 to 10%, and the surface heat fluxes from 9 to 90 kW/m2. The performance of tube no. 2 was superior for low heat fluxes, whereas tubes no. 3 and 4 showed better performances when the heat flux was larger than 40 W/m2. The PVE lubricant degraded the pool boiling heat transfer when the oil concentration exceeded 3%.

Figure 10.

Experimental HTCs for R-152a, R-1234yf, and R-134a versus the mass flux [53].

On the other hand, Bobbo et al. [48] found that the results provided by ground source heat pumps working either with R-32 or R-454B were identical. They showed that R-454B had a higher coefficient of performance (COP) and a higher energy efficiency than R-410 and R-32. They discovered that R-454B outperformed R-410 and R-32 in terms of COP and energy efficiency despite it having a lower volumetric heating effect than R-454B.

Jung et al. [49] conducted research with a heat flux ranging from 10 to 80 kW/m2 at a saturation temperature of 7 °C for R-22, R-32, R-125, and R-134a using thermo-excel-E tubes, low-fin tubes, and Turbo-B tubes. According to their results, tubes with a smooth surface and the low-fin tube produced a higher HTC for refrigerants with a higher vapor pressure. R-32 and R-125 are examples of these types of refrigerants. On the other hand, R-125 exhibited a strange behavior and had HTC values much lower when using the Thermo-excel-E and Turbo-B tubes.

3. Evaporation HTCs and Pressure Drop Inside Plain Tubes, Micro-fin Tubes, and Mini-channels

In the direct-expansion evaporator, the refrigerants boil inside the tube, thereby both evaporation and nucleate boiling mechanisms co-exist within the evaporator. Depending on the heat flux, mass flux, and flow pattern, one of these mechanisms may be in control or equilibrium. Different evaporator geometries and configurations using LGWP refrigerants were subsequently reviewed. In the next section, the in-tube evaporation characteristics of LGWP refrigerants in smooth/plain tubes, micro-fin tubes, and mini-channels are studied in more details.

3.1. Boiling Inside the Plain/Smooth Tube

Convective boiling tests were performed on R-448A, R-449A, and R-452B in a micro-fin tube by Kedzierski and Kang [50], who found that R-452B had a 59% greater HTC than R-448A/R-449A. Matsuse et al. [51] conducted an investigation into the flow boiling properties of R-32 inside a horizontal copper circular tube with an inner diameter of 1.0 mm. The range was a Tsat of 283 K, a mass velocity (G) between 0 to 400 kg/m2s, a heat flux (q′′) between 2 and 24 kW/m2, and a vapor quality from 0.05 to 1. Based on the observations and a comparison with previously acquired R-410A data, the pressure drop and boiling heat transfer were made clear. A zeotropic mixture’s two-phase HTCs are always inferior to that of pure R-32 because of a greater mass-transfer resistance. Kondou et al. [52] conducted experiments on the flow boiling of R32/R-1234ze(E) in a horizontal micro-fin tube with an inner diameter of 5.21 mm. The drastic reduction in HTC was brought on by the difference in volatility, which was especially pronounced for the evaporation heat transfer. Table 3 lists the dimensions and specifications of the tube geometry, as well as the experimental conditions that were reported in the relevant research.

Table 3.

Inside the tube, specifications, dimensions, and experimental conditions from the literature.

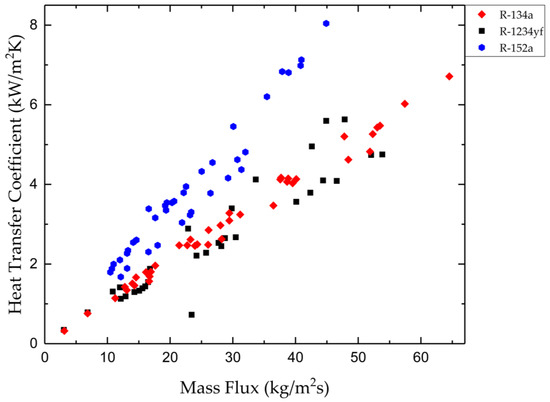

For an oil-free vapor compression refrigeration system with a horizontal tube arrangement, experiments were performed by Li et al. [53] where they studied the evaporation HTCs and pressure drop of R-152a, R-134a, and R-1234yf. According to their findings, R-1234yf was reveals to possess the highest pressure drop, whilst R-152a exhibited the highest HTC, as evidenced in Figure 11. Two existing correlations (the Foust–Christian correlation and the Lockhart–Martinelli correlation) were compared and modified. The improved correlations had a mean absolute percentage error (MAPE) under 16%. The Lockhart–Martinelli correlation was also compared by Saitoh et al. [54] who also developed a correlation for the flow boiling HTC of LGWP R-1234yf inside a smooth horizontal tube 2 mm in diameter. HTCs based on the new correlations agreed well (within ±20%) with the measured values compared to the Lockhart–Martinelli correlation. The Lockhart–Martinelli correlation also fairly forecasts the pressure drop. The significant effects of the mass flux and heat flux on the heat transfer were observed for both low and high vapor quality conditions.

Figure 11.

Evaporation HTCs of the R-404A and alternative refrigerants depicted as a function of mass flux [59].

Yang et al. [55] performed investigations into the flow pressure drop and boiling heat transfer characteristics of the refrigerants R-134a and R-1234yf in a circular tube (tube ID = 4.0 mm). The results of the tests indicated that the pressure drop and flow boiling heat transfer performance were both dependent on the fluid properties, the flow conditions, and the two-phase flow patterns. The two-phase flow pattern at different flow conditions is one of the primary governing factors for pressure drops and HTCs of flow boiling. The flow pattern analysis is capable of explaining the inconsistency in the test results previously published on flow boiling HTCs and pressure drops of the refrigerants R-134a and R-1234yf. Laohalertdecha et al. [56] suggested some correlations for the evaporation HTCs and two-phase friction factor of R-134a in horizontal-corrugated tubes. These developed correlations were in the form of the Nusselt number as a function of the Reynolds number, the Prandtl number, the corrugation pitch and depth, and the internal diameter. They reported that 85–90% of the Nusselt number statistics fell within a 20% margin of error. In a similar fashion, 95% of the results for the two-phase friction factor fell within ±20%.

Longo et al. [57] provided over 100 new HTCs and frictional pressure drop data for R-1234yf flow boiling in a plain copper tube with a diameter of 4 mm subjected to heat fluxes ranging from 15 to 30 kW/m2 and a mass velocity from 300 to 600 kg/m2s. In addition to this, literature correlations were compiled and examined. The performance of R-1234yf in terms of heat transfer was compared to that of R-134a and R-1234ze(E), highlighting the differences between them. Longo et al. [58] also presented a comparison between the evaporation of propane, propylene, and R-404A in the same tube as mentioned in [57]. The experiments were conducted at three distinct saturation temperatures (5, 10 and 20 °C) with a vapor quality of about 0.1 until the dry-out. Because HTCs are less sensitive to vapor quality at lower mass fluxes and at higher heat fluxes regimes, nucleate boiling was the dominant heat transfer mechanism in their experimental conditions. Even though propane’s boiling heat-transfer capability may be offset by the early dry-out, both HTCs proved to be efficient as LGWP alternatives to replace R-404A and R-507A.

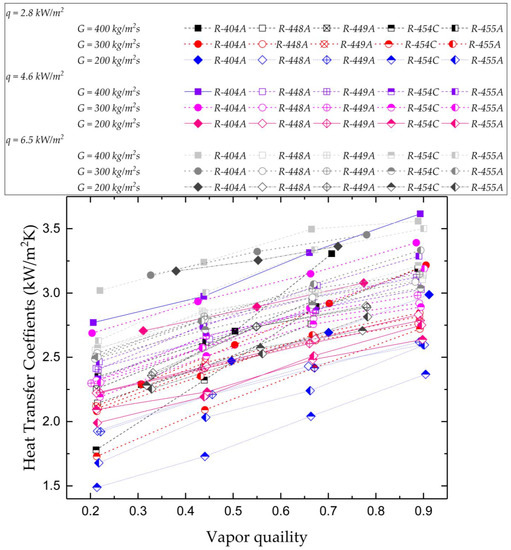

Kim and Kim [59] carried out evaporation experiments for four alternative refrigerants to R-404A in a multiport tube with a hydraulic diameter of 1.61 mm. The heat flux ranged from 2.8 to 6.5 kW/m2, the mass fluxes ranged from 200 to 400 kg/m2s, and the vapor quality changed from 0.2 to 0.8. The saturation temperature was kept constant throughout the testing at 15 °C. According to Figure 12, the HTC generally rises as either the mass flux or the vapor quality rises. However, at a higher heat flux, the mass flux effect on the HTC is negligible. Forced convective boiling involves both convective heat transfer and nucleate pool boiling. Low heat fluxes normally favor convective heat transfer over nucleate pool boiling; as mass flux or vapor quality rise, so does HTC. As heat flux is increased considerably, nucleate boiling becomes more important. The evaporation of R-404A follows a similar trend. However, for R-455A, the mass flux effect on the HTC is still noticeable even at high heat fluxes. This is due to the larger temperature glide, bubble nucleation and mass transfer at the liquid–vapor interface are reduced. The temperature slides of other refrigerants are smaller than R-455A but still bigger than R-404A.

Figure 12.

Effect of mass velocity on flow boiling HTCs at two heat fluxes (i.e., 12 and 60 kW/m2) [73].

3.2. Convective Boiling Inside the Enhanced tube

Kondou et al. [64] found that the superior thermophysical properties of pure R-32 alone can yield better evaporation and condensation HTC than that of R-1234ze(E) in horizontal micro-fin tube geometries. While R-744/R-32/R-1234ze(E) and R-32/R-1234ze(E) mixtures alone approach R-32’s HTC. At mass flux values over 400 kg/m2s, R-744/R-32/R-1234ze(E) exhibited the lowest HTC in a smooth horizontal tube with a 2 mm diameter for Li et al.’s [71] investigation into the HTCs of R-1234yf/R-32 mixes with R-32 mass fractions of 20 and 50%. Evidently, pure R-32 gave the highest HTC. The HTC of the R-1234yf/R-32 mixture exceeded those of pure R-1234yf only at the higher range of R-32 mass percentages (50%). Mashouf et al. [69] compared the flow boiling and condensation patterns of R-600a in a tube with helically dimpled walls to those in a tube without such walls. The helically dimpled tube’s inner surface had shallow and deep protrusions. The smooth tube revealed stratified-wavy, intermittent, and annular flows while no stratified flow pattern was seen in the dimple tube. In the helically dimpled tube, the transition from intermittent to annular occurred at lower vapor quality values. Smith et al. [72] reported a local two-phase flow boiling HTC and pressure drop for the R-410A, R-32 and R-1234yf refrigerants as well as two novel combinations, DR-5 (R-32/R-1234yf (72.5/27.5%)) and DR-5A (R-32/R-1234yf (68.9/31.1%). The tube was a 9.5 mm micro-fin tube and a POE lubricant was also investigated. The results for the mixes were the poorest, although DR-5 exhibited results that were closer to those of R-32 at a vapor quality (x) between 0.3 and 0.6. The authors concluded that R-32’s HTC was up to 40% more than that of R-410A under the same magnitude of mass flux and heat flux (G and q”).

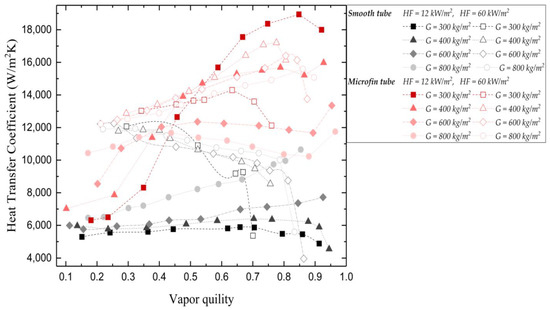

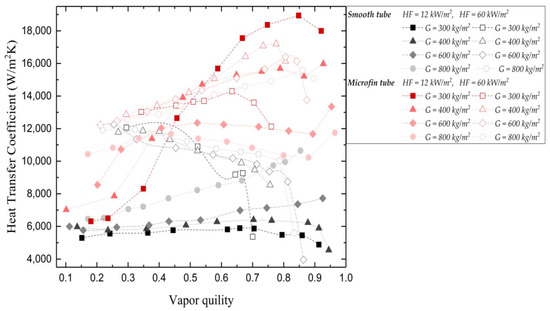

Diani and Rossetto [73] suggested that R-513A can replace R-134a directly. A diverse range of operational circumstances, including mass velocity, heat flux (from 12 to 60 kW/m2) and saturation temperatures (15, 20 and 25 °C), were tested experimentally. A smooth tube with an inner diameter of 2.5 mm and a micro-fin tube with an outer diameter of 2.4 mm were examined. The HTCs of the smooth and micro-fin tubes are shown in Figure 13 with a maximum heat flux of 60 kW/m2 and a saturation temperature of 20 °C. Liquid retention between the fins caused by micro-fins helps to prevent dry-out. HTCs typically decline with vapor quality until dry-out occurs, which could be associated with the localized dried areas on the tube surface as a result of the high heat flux. Since the impact of mass velocity disappears, nucleate boiling appears to be driving force from the phase transition process. It is interesting to note that the flow boiling HTC in smooth tubes and micro-fin tubes was about the same, indicating that nucleate boiling was in control. In contrast with the previous situation when dry-out happened at higher temperatures and lower vapor quality (q = 12 kW/m2), dry-out now occurred at high mean vapor qualities. Figure 14 illustrates the frictional pressure drop in the smooth tube and micro-fin tube with an imposed heat flux of 30 kW/m2. Evidently, the frictional pressure gradient increased considerably with the rise in mass flux. For all measured working conditions, the micro-fin tube exhibited much higher frictional pressure drops.

Figure 13.

Mass velocity influence on two-phase frictional pressure drop at a Tsat = 20 °C and HF = 30 kW/m2 [73].

Figure 14.

HTC in relation to vapor quality against mass velocities at 10 kW/m2 [68].

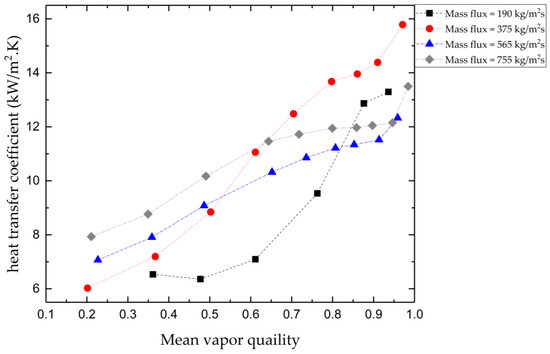

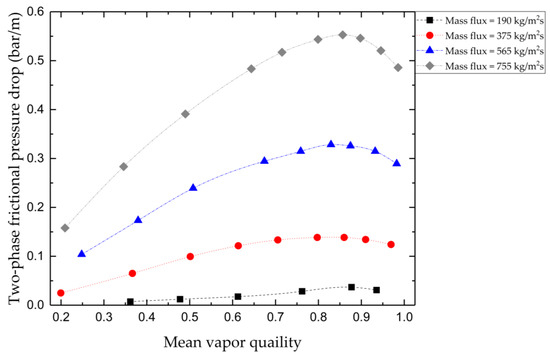

Tests for R-134a flow boiling HTC and pressure drop were conducted by Mancin et al. [68] in a micro-fin tube with an inner diameter of 3.4 mm at a saturation temperature of 30 °C. The mass flux varied from 190 to 755 kg/m2s, the vapor quality changed from 0.2 to 0.99, and the heat fluxes varied from 10 to 50 kW/m2. Figure 15 depicts the two-phase HTCs against vapor quality at various mass velocities at a 10 kW/m2 heat flux. At 190 kg/m2s, HTCs remained unchanged up to 0.5 vapor quality, suggesting nucleate boiling was in control. At a vapor quality >0.65, HTCs at 375 kg/m2s were larger when compared to those at higher mass velocities; this may be attributed to the helical micro-fins. Figure 16 depicts two-phase frictional pressure gradients estimated from the total pressure drop. The two-phase frictional pressure gradient rises with increasing vapor quality, peaks at its highest point, and then begins to fall. When the vapor quality was held constant, frictional pressure drops increased with increasing mass velocity.

Figure 15.

Two-phase HTCs as a function of vapor quality as a function of mass velocities [68].

Figure 16.

Mean HTCs and wall temperatures as a function of vapor quality at a Tsat = 120 °C [84].

3.3. Pressure Drop and Evaporation HTCs Inside Mini/Micro-Channel

Laminated plate and microchannel parallel flow evaporators are frequently employed in mobile air-conditioning systems. Yet, R-134a and R-1234yf are commonly found refrigerants. Table 4 lists the experimental conditions, specifications, and dimensions of the microchannel as reported in the literature.

Table 4.

Experimental conditions, specifications and dimensions of the microchannel as reported in the literature.

The authors of [82] provide a summary of the micro-channels used for experimental and geometric research that have been described in the literature. According to the experimental findings, using R-1234yf reduced the laminated plate evaporator’s cooling capacity by 8.0%. However, the cooling capacity of a micro-channel evaporator was equivalent to or greater than R-134a by up to 6.5%. R-32 and R-134a were measured in a rough round tube of 0.96 mm in diameter by Cavallini et al. [18]. In parallel-port microchannel tubes, Ramirez-Rivera et al. [83] made measurements at two different hydraulic diameters of 0.715 mm and 1.16 mm for two refrigerants. Li et al. [72] measured the boiling HTCs of R-1234yf and R-32 inside a circular tube with an internal diameter of 2 mm. Accordingly, R-32 had a higher HTC than R-1234yf under identical conditions.

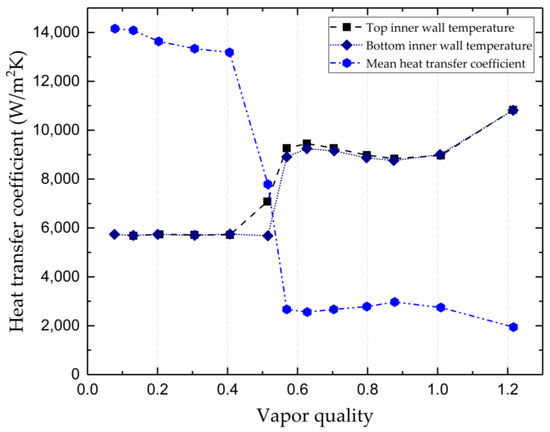

Charnay et al. [84] reported new experimental data on the flow patterns and HTCs observed at higher temperatures during the flow boiling of R-245fa in a mini-channel. The top and bottom internal wall temperatures, as well as the HTCs, are shown in Figure 17. An intermittent and annular flow pattern effectively wet the channel sides, thereby increasing the HTC. At a quality 0.4, a sharp rise in the inner wall temperatures caused a sharp fall in the HTC, signaling the occurrence of dry-out. The top portion of the horizontal tube, at a quality 0.4, revealed the starting point of dry-out. At a quality of 0.57, the tube perimeter dried, and heat transfer ceased further deterioration. This is because once the surface has fully dry-out, the mist flow regime prevails in which sufficient evaporation of the liquid entrainment droplets still prevail to ease the rise in temperature.

Figure 17.

HTCs comparison of R-1234ze(E) and R-32 [77].

Illan-Gomez et al. [85] examined R-134a and R-1234yf in a 1.16 mm hydraulic diameter micro-channel tube. They showed that the R-1234yf HTC increased either when the mass flow increased or when the saturation temperature decreased. R-134a and R-1234yf both have somewhat lower HTCs under identical circumstances. Their investigation indicated that the density ratio, thermal conductivity, and viscosity ratio are crucial for HTC. The pressure drop of R-1234yf was 5–7% lower than that of R-134a. The HTC of for R-1234yf was investigated by Li et al. [86] in a number of upward-arrangement multiport microchannel tubes. They found that the HTC reduced as the quality increased as a result of drying out at lower heat and mass fluxes. Compared to rectangular ports, square ports exhibited a better heat transfer performance.

In order to facilitate effective liquid spreading around the tube perimeter, Chen et al. [79] introduced a unique micro-channel heat sink with a cross-ribbed arrangement. Using a 100 W/cm2 thermal test chip, cross-ribbed, rectangular, and horizontal-ribbed heat sinks were compared. The pressure loss was 22 kPa and the junction temperature was 336.49 K for the cross-ribbed micro-channel. Cross-ribbed micro-channels yield 28.6 and 14.3% more cooling performance than rectangular and horizontal rib heat sinks, respectively. However, the pressure drop penalty was 10.7 and 5.5 times higher. The effects of the microchannel’s aspect ratio at various flow mass fluxes revealed a rather non-linear relation against mass flux.

Zhao et al. [74] used R-1234yf in a simulated model of the mini-channel evaporator. The effectiveness-NTU methodology and the finite element simulation were both utilized for the assessment. Six correlations were compared for the refrigerant’s two-phase heat transfer in the derived model. Under the normal operating circumstances of an automotive AC system, six different samples containing R-1234yf had their predicted and experimental data compared. The constructed model computed R-1234yf’s two-phase HTC utilizing Kandlikar’s correlation. In the evaporator, the two-phase HTC distribution was modeled. R-1234yf had a lower two-phase HTC than R-134a under identical circumstances. The HTCs of both refrigerants decreased with the rise in vapor quality and was especially pronounced in the high-quality regimes.

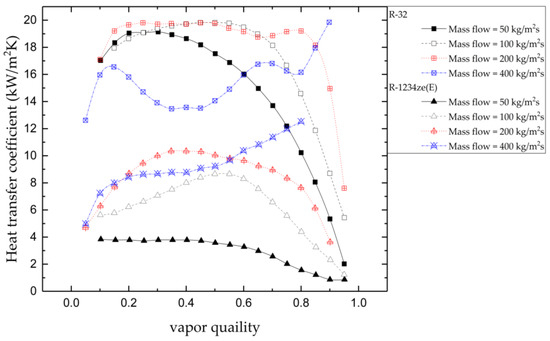

An investigation was conducted on the flow boiling properties of R-32 and R-1234ze(E) by Jige et al. [77] at a saturated temperature of 15 °C. The mass fluxes were between 50 and 400 kg/m2s. In regions with low heat flux, high mass flux, and high vapor quality, forced convective boiling dominated the heat transfer process. A new model of heat transfer considered nucleate boiling, forced convection, and thin-layer evaporation. Figure 18 demonstrates the comparison of HTCs of R-1234ze(E) and R-32. With a standard deviation of less than 15%, it projected the heat transfer characteristics in multiport rectangular mini-channels. At the same mass flow and vapor quality parameters as those used in prior correlations, the frictional pressure loss caused by R-32 was found to be smaller when compared to R-1234ze(E). In a 0.5 mm micro-channel heat exchanger, Nalbandian et al. [80] examined R-1234yf and R-134a flow boiling heat transfer. Depending on the mass velocity and vapor quality, R-134a’s HTCs were from 0 to 22% greater than R-1234yf’s. Kandlikar’s and Balasubramanian’s correlations best predicted their test outcomes. The results were similar to that of larger circular tubes and rectangular micro-channels with similar regulating features for boiling HTCs. They depend heavily on the two-phase flow pattern under different situations.

Figure 18.

Average evaporation HTC comparison of R-1234ze(E) in a PHE at variable operating conditions [15].

4. Characteristics Evaporation HTCs and Pressure Drops Inside Plate Heat Exchangers

Recent research on LGWP refrigerants’ frictional drop characteristics and evaporation HTCs inside plate heat exchangers (PHEs) is discussed in this section. The geometric parameters and experimental conditions of PHEs described in published literatures are outlined in Table 5.

Table 5.

Experimental conditions, specifications and dimensions of a plate heat exchangers in the literature.

The PHEs are widely used in industrial applications such as food processing and chemical operations [97]. Shell-and-plate heat exchangers (SPHE) combine a cylindrical shell with a plate that have been utilized in power plants, ocean thermal energy conversion facilities, and crude oil distillation facilities [98,99,100,101]. The research into these heat exchangers subjected to LGWP refrigerants has not been intensive [16,87,101].

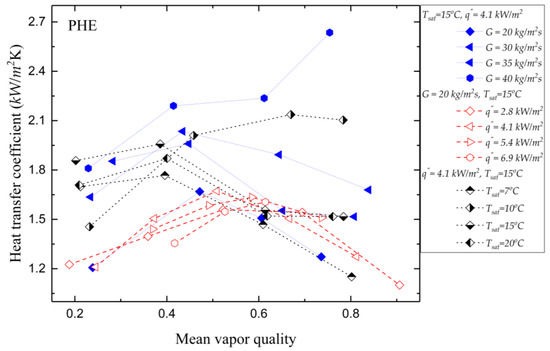

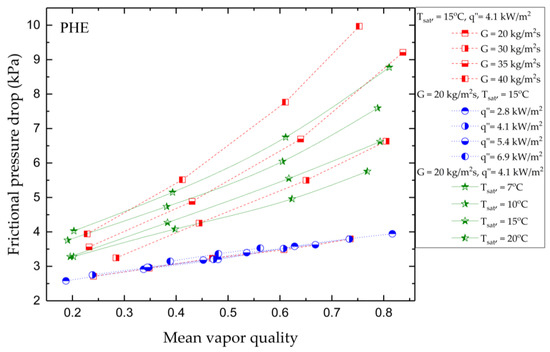

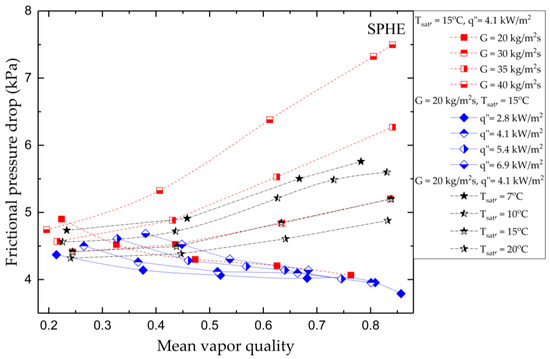

In a PHE, Longo and Gasparella [16] carried out tests to investigate the evaporative HTCs of R-134a, R-410A, R-236fa and R-1234ze(E). After comparing the evaporative HTCs of R-1234ze(E) and R-134a in PHEs, Kim et al. [87] found that both of these refrigerants performed similarly in terms of heat transfer. Nakaoka and Uehara [102] investigated the heat transfer characteristics of R-22 in an SPHE in the context of a thermal energy conversion system for the ocean, whereas Kim et al. [96] inspected the R-410A evaporation HTCs in an oblong SPHE, and a correlation based on the Nusselt number was produced. The evaporation HTC characteristics for R-1234ze (E) were investigated by Jo et al. [15] in a PHE and SPHE at different mass fluxes, vapor qualities, and saturation temperatures. The effects of the heat flow and saturation temperature on the evaporation HTC were moderate. The comparison of average evaporation HTCs of R-1234ze(E) in the PHE and SPHE at variable operating conditions are shown in Figure 19 and Figure 20, respectively. The two-phase frictional pressure drop for R-1234ze(E) in the PHE and SPHE for a given vapor quality increased continuously with increasing mass flux. This happened as a consequence of a considerable pressure drop at the liquid–vapor interface and in association with the complex geometry of the chevron plate. Because of the larger difference in velocity between the vapor and the liquid, the two-phase frictional pressure drop of R-1234ze in both heat exchangers rose as the quality of the vapor increased. The two-phase frictional pressure drop increased in proportion with the increase in Reeq because of an increase in the interfacial friction that occurred in both the types of heat exchangers. As is evident in Figure 21 and Figure 22, when compared to the PHE for a Reeq lower than 2000, the SPHE showed a larger frictional pressure drop. Because of the bigger liquid pool producing the viscous force, compared to the PHE, the SPHE exhibited a greater frictional pressure drop. The influence of heat flux on two-phase frictional pressure drop shows moderate dependence on vapor quality at a fixed saturation temperature and mass flow.

Figure 19.

Average evaporation HTC comparison of R-1234ze(E) at variable operating conditions in the SPHE [15].

Figure 20.

Variations in two-phase frictional pressure drop for R-1234ze(E) as measured in the PHE [15].

Figure 21.

Variation in the R-1234ze(E) HTCs in the OSPHE [96].

Figure 22.

Frictional pressure drop versus quality [103].

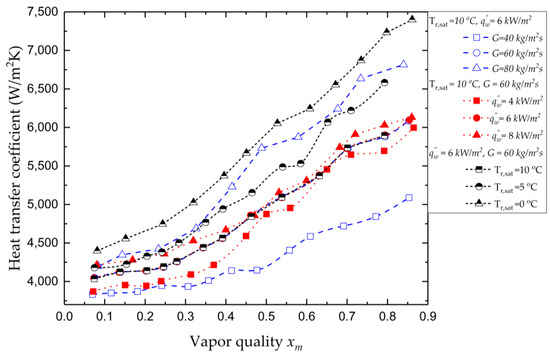

In order to determine the R-410A evaporation HTCs, Kim et al. [96] conducted experiments in an oblong shell-and-plate heat exchanger (OSPHE). The measured mass flow, average imposed saturation temperature, heat flux, and vapor quality of R-410A were examined. This section on testing presents the measured HTCs as average vapor quality variances. Figure 21 depicts the impacts that the mass flux of the refrigerant has on the HTCs of R-410A when the saturation temperature was set at 10 °C and the average heat flux imposed was 6.0 kW/m2. High-speed vapor flow reacting with the complicated chevron structure created a tremendous number of small liquid droplets. Compared to the mass flux effects depicted in Figure 21, the heat flux had a negligible impact on the rate of evaporation throughout the whole vapor-quality zone. The findings show that, except at xm > 0.5, the HTC was higher for a higher heat flux at a given vapor quality. At higher saturation temperatures, R-410A vapor had a lower specific volume, reducing the vapor flow velocity and shear force on the heat transfer surface–liquid interface. A greater R-410A saturation temperature reduced the latent heat of vaporization, and a high-quality vapor may dry the channel wall.

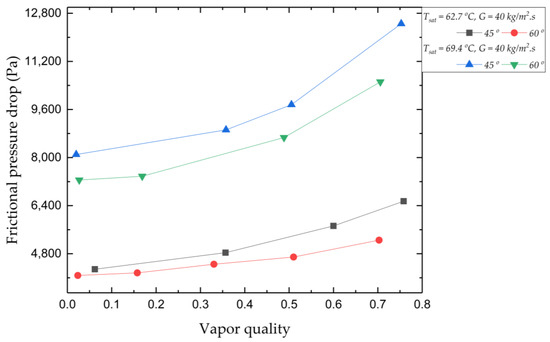

Experimentally based research for the convective boiling of R-245fa in a brazed PHE was given by Imran et al. [103], which compared the chevron angles of 45 and 60°. The HTC was shown to rise with increasing vapor quality until it reached its maximum value at a certain threshold vapor quality, followed by an appreciable decline due to partial dry-out. The HTC was more responsive to the heat flux than to quality, suggesting the favorable nucleate boiling mechanism. At a 60° chevron, the HTC and frictional pressure loss were greater much larger. These outcomes are similar to single-phase plate conditions where the plate geometry provides significant mixing, secondary flow and turbulence [104,105]. Figure 22 demonstrates that when the vapor quality increased, the frictional pressure drop increased at both saturation temperatures of 62.7 and 69.4 °C. When the in-take quality was less than 0.2, the frictional pressure loss behaved linearly. When the vapor quality exceeded this value, the imposed vapor shear produced chaos mixing and revealed a much more significant rise in the pressure drop.

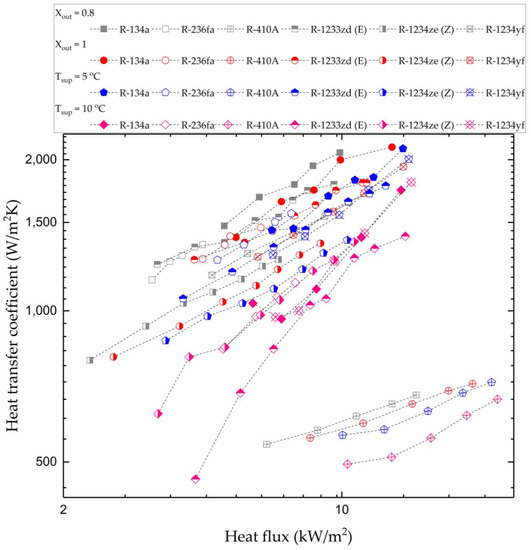

A comprehensive measurement for refrigerant boiling within a commercial brazed PHE was conducted by Longo et al. [6,9,10,16,106,107] in a series of publications. There were several conventional HFC refrigerants tested for comparison, including R-134a, R-410A, R-236fa, R404A, hydrocarbon (HC) refrigerants (R-290, R-600a and R-1270), LGWP HFC refrigerants (R-32 and R-152a), and hydrofluoroolefin (HFO) refrigerants (R-1234yf, R-1234ze(E), and R-1234ze(Z)) in a commercial brazed PHE made up of 10 plates, with each PHE plate containing a 278 mm in flow length and a width of 72 mm. PHEs were a herringbone corrugation type with a 65° chevron angle, a plate height of 2 mm, and an 8 mm wavelength. There were four evaporator outlet conditions (vapor quality 0.8–1, vapor superheat 5–10 °C) for the aforementioned refrigerants, as well as the average HTCs on the refrigerant side versus heat flux for a Tsat = 10 °C. Figure 23 depicts the average HTC on the refrigerant side plotted against heat flux. The primary findings listed in their conclusions are as follows:

Figure 23.

Influence of average HTCs on the refrigerant side and heat flux for a saturation temperature of 10 °C [6,9,10,16,106,107].

- For all of the investigated refrigerants, the HTCs were strongly related to the heat flux, outlet condition, and fluid characteristics and quite independent of saturation temperature.

- The HTC for R-1234ze(E) was 10–20% greater than that for R-134a. Regarding their capacity to transfer boiling heat, the refrigerants R-1234yf and R-1234ze(E) can be considered as appropriate R-134a replacements.

- For the refrigerants R600a, R-290 and R-1270, the boiling HTCs with a vapor quality of about 0.8 were 0–6% higher than those with an outlet vapor quality of around 1, and 5–16% higher and 25–50% higher than the HTCs with a 10 °C of outlet vapor superheat.

- The HTCs of R-410A were 40–50% greater than those of R-134a and 50–60% higher than those of R-236fa when subjected to identical operating conditions.

- When the outlet vapor quality was 0.8, the HTCs were 2–10% higher for R-410A, R-236fa, and R-134a. These saturated boiling HTCs were 5–20% higher than those for R410A, R-236fa, and R-134a when the vapor quality at outlet was around 1. These saturated boiling HTCs were 30–40% higher than those for R410A, R-236fa, and R-134a at a 10 °C vapor super-heating outlet.

- The HTCs for R-1234yf with an outlet vapor quality of 0.8 were 0–2% higher than those with an outlet vapor quality of 1, 1–5% higher than those with a 5 °C outlet vapor superheat, and 15–40% higher than those with a 10 °C outlet vapor superheat.

- The rather small drop in HTCs with increasing vapor quality was most likely caused by dry-out that began in the upper section of the evaporator.

- There was a discernible decline in the two-phase HTCs that occurs with vapor superheat. This was because the single-phase HTCs that impact the superheating section of the heat transfer surface were lower than the two-phase HTCs that affect the boiling component of the heat transfer surface.

- Under the same operating conditions, the observed HTC of R-1234ze(Z) was 17–22% greater than that of R-1233zd(E). This was primarily explained by the different thermophysical and thermodynamic properties between R-1234ze(Z) and R-1233zd, which include better liquid thermal conductivity, lower latent heat of vaporization, and lower pressure (E).

A large database of LGWP refrigerants boiling inside brazed PHEs were collected by Longo et al. [108] who also developed an ANN model to estimate the refrigerant boiling HTCs inside a brazed PHE with a low MAPE. Their research aimed to precisely predict the behavior of other LGWP refrigerants, whose thermophysical and thermodynamic properties have not yet been well characterized. The model exhibited a satisfactory level of congruence with the 1760 data points contained in the database, comprising 16 refrigerants and 15 plate geometries (four natural refrigerants, six LGWP refrigerants). The predictions made by the model had a MAPE of 4.8%. The ANN model predicted boiling within a brazed PHE better than other state-of-the-art analytical computational techniques. The study provided a comprehensive report on the ANN model’s defining parameters. Longo et al. [109] also published and evaluated a database (comprising 2549 data points) on boiling and condensation flow inside a brazed PHE. The gradient boosting machines (GBM) model can predict two-phase diabatic refrigerant flow in a brazed PHE. The model’s MAPE for recreating the entire database is 6.6%. For two-phase pressure drop in a brazed PHE, the GBM model outperforms state-of-the-art analytical computational approaches. Utilizing the h2o package in R or the h2o module in Python in conjunction with the GBM model’s parameters gives a simple approach for applying the model.

5. Conclusions

This study reviewed the nucleate/convective boiling characteristics of LGWP refrigerant alternatives to some major high-GWP refrigerants (such as R-134a, R404A, and R-410A, etc.). Heat transfer and pressure drop characteristics were discussed in detail. The authors reviewed the most prevalent refrigerants, including R-1234yf, R-1234ze(E), R-1234ze(Z), R-513A, and R-450A. Thermo-fluid characteristics were summarized in inside/outside tubes, mini-channels, micro-fin tubes, and plate heat exchangers. Detailed heat transfer coefficient and pressure drop in associated with operating conditions, tube geometry, were also elaborated on in this thorough review. The heat transfer performance included convective boiling inside the tube and nucleate boiling outside the tube.

In order to the improve performance and make up for the inferior qualities of LGWP refrigerants compared to traditional alternatives, it is recommended that researchers concentrate more of their attention on refrigerant-selection techniques that can provide further optimization. In addition to the thermo-fluid characteristics, it is crucial to evaluate all technical, economic, and environmental factors when choosing refrigerants. Researchers are also urged to combine life-cycle analysis and techno-economic analyses. This method offers a tremendously useful perspective on how products perform in terms of the environment over the course of their whole life cycle.

Nonetheless, the existing database requires expansion to include additional LGWP refrigerants, surfaces and conditions. This expansion of the existing database will be essential in order to better understand the performance of various LGWP refrigerants. There are fewer mechanistic-based models for LGWP refrigerants in the literature. These models may assist in the improvement of boiling, forecasting heat transfer performance, and the design of high-performance geometries. To this end, researchers have attempted to incorporate and extend existing mechanistic models for predicting performance. The majority of relationships do not rely on a database of LGWP refrigerants. In future studies, the accurate of these association forecasts for LGWP refrigerants should be determined. To assist in this, there should be greater development of mechanistic-based models for LGWP refrigerants that account for their different physical and chemical properties.

Author Contributions

Conceptualization, Q.N.S. and C.-C.W.; data collection and investigation, Q.N.S.; writing—original draft preparation, Q.N.S.; review, editing, and supervision, C.-C.W. and J.-S.L. administration assistance. All authors have read and agreed to the published version of the manuscript.

Funding

The major funding was from the National Science and Technology Council, Taiwan under contract number 111-2221-E-A49-090-MY3. The project was part supported by the Bureau of Energy, Ministry of Economic Affairs, Taiwan.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| A | Area (m2). | σ | Surface tension (N/m). |

| b | Depth of the corrugation (m). | θ | Contact angle (◦). |

| Bo | Bond number. | Δ | Difference. |

| Cp | Specific heat capacity (J/kg K). | ν | Viscosity (m2/s). |

| D | Diameter (m). | β | Chevron angle. |

| dh | Hydraulic diameter, (m). | α | Helix Angle. |

| g | Gravity (m/s2). | λ | Corrugation Pitch. |

| G | Mass flux (kg/m2). | ε | Corrugation amplitude. |

| h | Heat transfer coefficient (W/m2K). | η | Corrugation Wavelength. |

| H | Height [m]. | Subscript | |

| J | Specific enthalpy (J/kg). | a | Absolute. |

| k | Thermal conductivity (W/m K). | avg | Average. |

| L | Length (m). | ch | Channel. |

| l | Fluid flow plate length (m). | Exp. | Experiment. |

| m | Mass flow rate (kg/s). | fin | Fin. |

| MAPE | Mean absolute percentage error (%). | i | Inside. |

| Nch | Number of channels. | l | Lubricant. |

| Nfin | Number of fins. | m | Mean. |

| N | Number of effective plates. | pl | Plate. |

| P | Pressure (Pa). | o | Outside. |

| P* | Reduced pressure (Pa). | 0 | Pure refrigerant. |

| p | Pitch (m). | r | Refrigerant. |

| Pr | Prandtl number. | sat | Saturation. |

| q” | Heat flux (W/m). | v | Vapor. |

| Q | Heat flow rate (W). | w | Wall. |

| Ra | Arithmetic mean roughness (μm). | Abbreviation | |

| Re | Reynolds number. | ANN | Artificial neural network. |

| Rp | Roughness (μm) | GWP | Global Warming Potential. |

| s | Plate wall thickness (m). | HVAC | Heating, Ventilation, and Air Conditioning. |

| t | Thickness. | HTC | Heat Transfer Coefficient. |

| T | Temperature (K). | HT | Heat Transfer. |

| U | Overall heat transfer coefficient (W/m2K). | HF | Heat Flux. |

| v | Specific volume (m3/kg). | HFC | Hydrofluorocarbon. |

| W | Width (m). | HFO | Hydrofluoroolefin. |

| x | Vapor quality. | LGWP | Low Global Warming Potential. |

| MAPE | Mean absolute percentage error. | ||

| Greek symbols | ODP | Ozone Depletion Potential. | |

| ν | Viscosity (m2/s). | OSPHE | Oblong Shell Plate Heat Exchanger. |

| ω | Mass concentration of oil (%). | PHE | Plate Heat Exchanger. |

| Liquid density (kg/m3). | POEA | Polyolester Oil. | |

| Vapor density (kg/m3). | SPHE | Shell Plate Heat Exchanger. | |

References

- Kumar, A.; Chen, M.R.; Hung, K.S.; Liu, C.C.; Wang, C.C. A comprehensive review regarding condensation of low-GWP refrigerants for some major alternatives of R-134a. Processes 2022, 10, 1882. [Google Scholar] [CrossRef]

- Kumar, A.; Wang, X.Z.; Lakshmi, B.J.; Hung, J.T.; Chen, Y.K.; Wang, C.C. Nucleate boiling heat transfer of R-134a and R-134a/POE lubricant mixtures on smooth tube. Appl. Therm. Eng. 2021, 185, 116359. [Google Scholar] [CrossRef]

- Lemmon, E.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 10.0. 2018; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018. [Google Scholar]

- Mauro, A.W.; Napoli, G.; Pelella, F.; Viscito, L. Flow pattern, condensation and boiling inside and outside smooth and enhanced surfaces of propane (R290). State of the art review. Int. J. Heat Mass Transf. 2021, 174, 121316. [Google Scholar] [CrossRef]

- Shon, B.H.; Jeon, S.W.; Kim, Y.; Kang, Y.T. Condensation and evaporation characteristics of low GWP refrigerants in plate heat exchangers. Int. J. Air-Cond. Refrig. 2016, 24, 1630004. [Google Scholar] [CrossRef]

- Longo, G.; Gasparella, A. Heat transfer and pressure drop during HFC refrigerant vaporisation inside a brazed plate heat exchanger. Int. J. Heat Mass Transf. 2007, 50, 5194–5203. [Google Scholar] [CrossRef]

- Longo, G.; Gasparella, A. Refrigerant R134a vaporisation heat transfer and pressure drop inside a small brazed plate heat exchanger. Int. J. Refrig. 2007, 30, 821–830. [Google Scholar] [CrossRef]

- Longo, G.A. Heat transfer and pressure drop during HFC refrigerant saturated vapour condensation inside a brazed plate heat exchanger. Int. J. Heat Mass Transf. 2010, 53, 1079–1087. [Google Scholar] [CrossRef]

- Longo, G.A. Vaporisation of the low GWP refrigerant HFO1234yf inside a brazed plate heat exchanger. Int. J. Refrig. 2012, 35, 952–961. [Google Scholar] [CrossRef]

- Longo, G.A.; Gasparella, A. HFC-410A vaporisation inside a commercial brazed plate heat exchanger. Exp. Therm. Fluid Sci. 2007, 32, 107–116. [Google Scholar] [CrossRef]

- Min, J.Y.; Jang, S.P.; Kim, S.J. Effect of tip clearance on the cooling performance of a microchannel heat sink. Int. J. Heat Mass Transf. 2004, 47, 1099–1103. [Google Scholar] [CrossRef]

- Mu, Y.T.; Chen, L.; He, Y.L.; Tao, W.Q. Numerical study on temperature uniformity in a novel mini-channel heat sink with different flow field configurations. Int. J. Heat Mass Transf. 2015, 85, 147–157. [Google Scholar] [CrossRef]

- Rozati, A.; Tafti, D.K.; Blackwell, N.E. Effect of pin tip clearance on flow and heat transfer at low Reynolds numbers. J. Heat Transf. 2008, 130, 071704. [Google Scholar] [CrossRef]

- Lin, L.; Kedzierski, M.A. Review of low-GWP refrigerant pool boiling heat transfer on enhanced surfaces. Int. J. Heat Mass Transf. 2019, 131. [Google Scholar] [CrossRef]

- Jo, C.; Lee, D.; Chung, H.J.; Kang, Y.; Kim, Y. Comparative evaluation of the evaporation heat transfer characteristics of a low-GWP refrigerant R-1234ze(E) between shell-and-plate and plate heat exchangers. Int. J. Heat Mass Transf. 2020, 153, 119598. [Google Scholar] [CrossRef]

- Longo, G.A.; Mancin, S.; Righetti, G.; Zilio, C. HFO1234ze (E) vaporisation inside a brazed plate heat exchanger (BPHE): Comparison with HFC134a and HFO1234yf. Int. J. Refrig. 2016, 67, 125–133. [Google Scholar] [CrossRef]

- Longo, G.A.; Zilio, C.; Righetti, G.; Brown, J.S. Condensation of the low GWP refrigerant HFO1234ze(E) inside a Brazed Plate Heat Exchanger. Int. J. Refrig. 2014, 38, 250–259. [Google Scholar] [CrossRef]

- Cavallini, A.; Del Col, D.; Matkovic, M.; Rossetto, L. Pressure drop during two-phase flow of R134a and R32 in a single minichannel. J. Heat Transf. 2009, 131. [Google Scholar] [CrossRef]

- Kumar, A.; Wang, C.-C. Nucleate pool boiling heat transfer of R-1234ze(E) and R-134a on GEWA-B5H and smooth tube with the influence of POE oil. Appl. Therm. Eng. 2022, 201, 117779. [Google Scholar] [CrossRef]

- SWEP. 6.8 BPHE Evaporators. 2022. Available online: https://www.swep.net/refrigerant-handbook/6.-evaporators/asas3/ (accessed on 17 January 2023).

- Kumar, A.; Wang, C.-C. Heat Transfer Performance of R-1234ze(E) with the Effect of High-Viscosity POE Oil on Enhanced GEWA-B5H Tube. Processes 2021, 9, 2285. [Google Scholar] [CrossRef]

- Jensen, M.; Jackman, D. Prediction of nucleate pool boiling heat transfer coefficients of refrigerant-oil mixtures. J. Heat Transfer. 1984, 106, 184–190. [Google Scholar] [CrossRef]

- Spindler, K.; Hahne, E. The influence of oil on nucleate pool boiling heat transfer. Heat Mass Transf. 2009, 45, 979–990. [Google Scholar] [CrossRef]

- Mohrlok, K.; Spindler, K.; Hahne, E. The influence of a low viscosity oil on the pool boiling heat transfer of the refrigerant R507. Int. J. Refrig. 2001, 24, 25–40. [Google Scholar] [CrossRef]

- Nagata, R.; Kondou, C.; Koyama, S. Comparative assessment of condensation and pool boiling heat transfer on horizontal plain single tubes for R1234ze (E), R1234ze (Z), and R1233zd (E). Int. J. Refrig. 2016, 63, 157–170. [Google Scholar] [CrossRef]

- Ribatski, G.; Thome, J.R. Nucleate boiling heat transfer of R134a on enhanced tubes. Appl. Therm. Eng. 2006, 26, 1018–1031. [Google Scholar] [CrossRef]

- Van Rooyen, E.; Thome, J. Pool boiling data and prediction method for enhanced boiling tubes with R-134a, R-236fa and R-1234ze (E). Int. J. Refrig. 2013, 36, 447–455. [Google Scholar] [CrossRef]

- Habert, M.; Thome, J. Falling-film evaporation on tube bundle with plain and enhanced tubes—Part I: Experimental results. Exp. Heat Transf. 2010, 23, 259–280. [Google Scholar] [CrossRef]

- Kumar, A.; Wang, C.-C. Heat transfer characteristics of R-454B and R-454B/POE-oil mixture on smooth and GEWA tube: Alternative to R-410A. Int. J. Heat Mass Transf. 2022, 193, 122972. [Google Scholar] [CrossRef]

- Byun, H.-W.; Kim, D.H.; Yoon, S.H.; Song, C.H.; Lee, K.H.; Kim, O.J. Pool boiling performance of enhanced tubes on low GWP refrigerants. Appl. Therm. Eng. 2017, 123, 791–798. [Google Scholar] [CrossRef]

- Stephan, K.; Mitrovic, J. Heat Transfer in Natural Convective Boiling of Refrigerants and Refrigerant--Oil Mixtures in Bundles of T-shaped Finned Tubes. Am. Soc. Mech. Eng. 1981, 131–146. [Google Scholar]

- Kedzierski, M.A. Enhancement of R123 pool boiling by the addition of hydrocarbons. Int. J. Refrig. 2000, 23, 89–100. [Google Scholar] [CrossRef]

- Kedzierski, M. Enhancement of R123 pool boiling by the addition of N-hexane. J. Enhanc. Heat Transf. 1999, 6, 343–355. [Google Scholar] [CrossRef]

- Kim, N.-H.; Kim, D.-Y. Pool boiling of R-123/oil mixtures on enhanced tubes having different pore sizes. Int. J. Heat Mass Transf. 2010, 53, 2311–2317. [Google Scholar] [CrossRef]

- Wang, C.C.; Chang, Y.J.; Shieh, W.Y.; Yang, C.Y. Nucleate boiling performance of R-22, R-123, R-134A, R-410A, and R-407C on smooth and enhanced tubes. In Proceedings of the American Society of Heating, Refrigerating and Air-Conditioning Engineers, San Francisco, CA, USA, 17–21 January 1998. [Google Scholar]

- Gorgy, E. Nucleate boiling of low GWP refrigerants on highly enhanced tube surface. Int. J. Heat Mass Transf. 2016, 96, 660–666. [Google Scholar] [CrossRef]

- Gorgy, E.; Eckels, S. Average heat transfer coefficient for pool boiling of R-134a and R-123 on smooth and enhanced tubes (RP-1316). HVACR Res. 2010, 16, 657–676. [Google Scholar] [CrossRef]

- Ji, W.-T.; Zhao, C.-Y.; Zhang, D.-C.; Zhao, P.-F.; Li, Z.-Y.; He, Y.-L.; Tao, W.-Q. Pool boiling heat transfer of R134a outside reentrant cavity tubes at higher heat flux. Appl. Therm. Eng. 2017, 127, 1364–1371. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Ma, Z. Experimental study of pool boiling on a novel reentrant cavity tube surface with R134a. Int. J. Heat Mass Transf. 2019, 135, 124–130. [Google Scholar] [CrossRef]

- Dewangan, A.K.; Kumar, A.; Kumar, R. Nucleate Pool Boiling Heat Transfer of Refrigerants Using Coated Surfaces. In Advanced Cooling Technologies and Applications; IntechOpen: London, UK, 2019; p. 85. [Google Scholar]

- Dewangan, A.K.; Sajjan, S.K.; Kumar, A.; Kumar, R. Pool boiling heat transfer on a plain tube in saturated R-134a and R-410A. Heat Mass Transf. 2019, 56, 1179–1188. [Google Scholar] [CrossRef]

- Hung, J.T.; Chen, Y.K.; Chen, T.Y.; Sheng, S.R.; Wang, C. On the Effect of Lubricant on Pool Boiling Heat Transfer Performance. In Proceedings of the 23rd International Compressor Engineering Conference at Purdue, West Lafayette, IN, USA, 11–14 July 2016. [Google Scholar]

- Byun, H.W.; Kim, D.H.; Yoon, S.H.; Song, C.H. Pool boiling Heat Transfer Characteristics of Low GWP Refrigerants on Enhanced tube used in Flooded Evaporator for Turbo-Chiller. In Proceedings of the 12th IEA Heat Pump Conference 2017, Rotterdam, The Netherlands, 15–18 May 2017. [Google Scholar]

- Shen, B.; Ally, M.R. Energy and Exergy Analysis of Low-Global Warming Potential Refrigerants as Replacement for R410A in Two-Speed Heat Pumps for Cold Climates. Energies 2020, 13, 5666. [Google Scholar] [CrossRef]

- Ji, W.-T.; Zhao, C.-Y.; He, Y.-L.; Tao, W.-Q. Experimental validation of Cooper correlation at higher heat flux. Int. J. Heat Mass Transf. 2015, 90, 1241–1243. [Google Scholar] [CrossRef]

- Ji, W.T.; Xiong, S.M.; Chen, L.; Zhao, C.Y.; Tao, W.Q. Effect of subsurface tunnel on the nucleate pool boiling heat transfer of R1234ze (E), R1233zd (E) and R134a. Int. J. Refrig. 2021, 122, 122–133. [Google Scholar] [CrossRef]

- Ji, W.-T.; Zhang, D.-C.; Feng, N.; Guo, J.-F.; Numata, M.; Xi, G.; Tao, W.-Q. Nucleate pool boiling heat transfer of R134a and R134a-PVE lubricant mixtures on smooth and five enhanced tubes. J. Heat Transf. 2010, 132, 233–242. [Google Scholar] [CrossRef]

- Bobbo, S.; Fedele, L.; Curcio, M.; Bet, A.; De Carli, M.; Emmi, G.; Poletto, F.; Tarabotti, A.; Mendrinos, D.; Mezzasalma, G.; et al. Energetic and exergetic analysis of low global warming potential refrigerants as substitutes for R410A in ground source heat pumps. Energies 2019, 12, 3538. [Google Scholar] [CrossRef]

- Jung, D.; An, K.; Park, J. Nucleate boiling heat transfer coefficients of HCFC22, HFC134a, HFC125, and HFC32 on various enhanced tubes. Int. J. Refrig. 2004, 27, 202–206. [Google Scholar] [CrossRef]

- Kedzierski, M.A.; Kang, D. Horizontal convective boiling of R448A, R449A, and R452B within a micro-fin tube. Sci. Technol. Built Environ. 2016, 22, 1090–1103. [Google Scholar] [CrossRef] [PubMed]

- Matsuse, Y.; Enoki, K.; Mori, H.; Kariya, K.; Hamamoto, Y. Boiling heat transfer and pressure drop of a refrigerant R32 flowing in a small horizontal tube. Heat Transf. Eng. 2016, 37, 668–678. [Google Scholar] [CrossRef]

- Kondou, C.; Mishima, F.; Koyama, S. Condensation and evaporation of R32/R1234ze (E) and R744/R32/R1234ze (E) flow in horizontal microfin tubes. Sci. Technol. Built Environ. 2015, 21, 564–577. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, H.; Chen, X.; Liang, K. Evaporation heat transfer and pressure drop of low-gwp refrigerants in a horizontal tube. Int. J. Heat Mass Transf. 2020, 148, 119150. [Google Scholar] [CrossRef]

- Saitoh, S.; Dang, C.; Nakamura, Y.; Hihara, E. Boiling heat transfer of HFO-1234yf flowing in a smooth small-diameter horizontal tube. Int. J. Refrig. 2011, 34, 1846–1853. [Google Scholar] [CrossRef]

- Yang, C.-Y.; Nalbandian, H.; Lin, F.-C. Flow boiling heat transfer and pressure drop of refrigerants HFO-1234yf and HFC-134a in small circular tube. Int. J. Heat Mass Transf. 2018, 121, 726–735. [Google Scholar] [CrossRef]

- Laohalertdecha, S.; Dalkilic, A.S.; Wongwises, S. Correlations for evaporation heat transfer coefficient and two-phase friction factor for R-134a flowing through horizontal corrugated tubes. Int. Commun. Heat Mass Transf. 2011, 38, 1406–1413. [Google Scholar] [CrossRef]

- Longo, G.A.; Mancin, S.; Righetti, G.; Zilio, C. R1234yf and R1234ze (E) as environmentally friendly replacements of R134a: Assessing flow boiling on an experimental basis. Int. J. Refrig. 2019, 108, 336–346. [Google Scholar] [CrossRef]

- Longo, G.A.; Mancin, S.; Righetti, G.; Zilio, C. Hydrocarbon refrigerants HC290 (Propane) and HC1270 (Propylene) low GWP long-term substitutes for HFC404A: A comparative analysis in vaporisation inside a small-diameter horizontal smooth tube. Appl. Therm. Eng. 2017, 124, 707–715. [Google Scholar] [CrossRef]

- Kim, C.-H.; Kim, N.-H. Evaporation heat transfer and pressure drop of low GWP R-404A alternative refrigerants in a multiport tube. Int. J. Heat Mass Transf. 2022, 184, 122386. [Google Scholar] [CrossRef]

- Zürcher, O.; Thome, J.; Favrat, D. Evaporation of ammonia in a smooth horizontal tube: Heat transfer measurements and predictions. J. Heat Transf. 1999, 121, 89–101. [Google Scholar] [CrossRef]

- Mohseni, S.; Akhavan-Behabadi, M. Flow pattern visualization and heat transfer characteristics of R-134a during evaporation inside a smooth tube with different tube inclinations. Int. Commun. Heat Mass Transf. 2014, 59, 39–45. [Google Scholar] [CrossRef]

- Kundu, A.; Kumar, R.; Gupta, A. Evaporative heat transfer of R134a and R407C inside a smooth tube with different inclinations. Int. J. Heat Mass Transf. 2014, 76, 523–533. [Google Scholar] [CrossRef]

- Greco, A. Convective boiling of pure and mixed refrigerants: An experimental study of the major parameters affecting heat transfer. Int. J. Heat Mass Transf. 2008, 51, 896–909. [Google Scholar] [CrossRef]

- Kondou, C.; BaBa, D.; Mishima, F.; Koyama, S. Flow boiling of non-azeotropic mixture R32/R1234ze (E) in horizontal microfin tubes. Int. J. Refrig. 2013, 36, 2366–2378. [Google Scholar] [CrossRef]

- Kim, C.-H.; Kim, N.-H. Evaporation heat transfer of the low GWP alternative refrigerants (R-448A, R-449A, R-455A, R-454C) for R-404A in a microfin tube. Int. J. Refrig. 2021, 128, 118–128. [Google Scholar] [CrossRef]

- Greco, A.; Vanoli, G.P. Evaporation of refrigerants in a smooth horizontal tube: Prediction of R22 and R507 heat transfer coefficients and pressure drop. Appl. Therm. Eng. 2004, 24, 2189–2206. [Google Scholar] [CrossRef]

- Diani, A.; Mancin, S.; Cavallini, A.; Rossetto, L. Experimental investigation of R1234ze (E) flow boiling inside a 2.4 mm ID horizontal microfin tube. Int. J. Refrig. 2016, 69, 272–284. [Google Scholar]

- Mancin, S.; Diani, A.; Rossetto, L. R134a flow boiling heat transfer and pressure drop inside a 3.4 mm ID microfin tube. Energy Procedia 2014, 45, 608–615. [Google Scholar] [CrossRef]

- Mashouf, H.; Shafaee, M.; Sarmadian, A.; Mohseni, S. Visual study of flow patterns during evaporation and condensation of R-600a inside horizontal smooth and helically dimpled tubes. Appl. Therm. Eng. 2017, 124, 1392–1400. [Google Scholar] [CrossRef]

- Longo, G.A.; Mancin, S.; Righetti, G.; Zilio, C. Saturated flow boiling of HFC134a and its low GWP substitute HFO1234ze (E) inside a 4 mm horizontal smooth tube. Int. J. Refrig. 2016, 64, 32–39. [Google Scholar] [CrossRef]

- Li, M.; Dang, C.; Hihara, E. Flow boiling heat transfer of HFO1234yf and R32 refrigerant mixtures in a smooth horizontal tube: Part I. Experimental investigation. Int. J. Heat Mass Transf. 2012, 55, 3437–3446. [Google Scholar] [CrossRef]

- Smith, J.; Deokar, P.; Wong, T. Heat Transfer and Pressure Drop of New LGWP Refrigerants and Lubricant Mixtures in a 9.5 mm (0.374 in) Micro-Finned Tube Evaporator. ASHRAE Trans. 2015, 121, 1Z. [Google Scholar]

- Diani, A.; Rossetto, L. Characteristics of R513A evaporation heat transfer inside small-diameter smooth and microfin tubes. Int. J. Heat Mass Transf. 2020, 162, 120402. [Google Scholar] [CrossRef]

- Zhao, Y.; Liang, Y.; Sun, Y.; Chen, J. Development of a mini-channel evaporator model using R1234yf as working fluid. Int. J. Refrig. 2012, 35, 2166–2178. [Google Scholar] [CrossRef]

- Huai, X.; Koyama, S.; Zhao, T.S.; Shinmura, E.; Hidehiko, K.; Masaki, M. An experimental study of flow boiling characteristics of carbon dioxide in multiport mini channels. Appl. Therm. Eng. 2004, 24, 1443–1463. [Google Scholar] [CrossRef]

- Agostini, B.; Bontemps, A. Vertical flow boiling of refrigerant R134a in small channels. Int. J. Heat Fluid Flow 2005, 26, 296–306. [Google Scholar] [CrossRef]

- Jige, D.; Kikuchi, S.; Eda, H.; Inoue, N. Flow boiling in horizontal multiport tube: Development of new heat transfer model for rectangular minichannels. Int. J. Heat Mass Transf. 2019, 144, 118668. [Google Scholar] [CrossRef]

- Kudo, Y.; Nakaiso, K.; Kariya, K.; Miyara, A. Experimental study on boiling and condensation heat transfer in a horizontal mini channel. In Proceedings of the 16th International Refrigeration and Air Conditioning Conference at Purdue, West Lafayette, IN, USA, 11–14 July 2016. [Google Scholar]

- Chen, H.; Chen, C.; Zhou, Y.; Yang, C.; Song, G.; Hou, F.; Jiao, B.; Liu, R. Evaluation and Optimization of a Cross-Rib Micro-Channel Heat Sink. Micromachines 2022, 13, 132. [Google Scholar] [CrossRef]

- Nalbandian, H.; Yang, C.-Y.; Chen, K.-T. Flow Boiling Heat Transfer of Refrigerants HFO-1234yf and HFC-134a in an Extruded Aluminum Tube with Multi-Port microchannels. Int. J. Refrig. 2022, 142, 37–47. [Google Scholar] [CrossRef]

- Zhang, Y.; Pang, L.; Liu, M.; Xie, Y. Investigation of spray cooling: Effect of different heater surfaces under acceleration. Int. Commun. Heat Mass Transf. 2016, 75, 223–231. [Google Scholar] [CrossRef]

- Qi, Z. Experimental study on evaporator performance in mobile air conditioning system using HFO-1234yf as working fluid. Appl. Therm. Eng. 2013, 53, 124–130. [Google Scholar] [CrossRef]

- Ramírez-Rivera, F.; López-Belchí, A.; Vera-García, F.; García-Cascales, J.; Illán-Gómez, F. Two phase flow pressure drop in multiport mini-channel tubes using R134a and R32 as working fluids. Int. J. Therm. Sci. 2015, 92, 17–33. [Google Scholar] [CrossRef]

- Charnay, R.; Bonjour, J.; Revellin, R. Experimental investigation of R-245fa flow boiling in minichannels at high saturation temperatures: Flow patterns and flow pattern maps. Int. J. Heat Fluid Flow 2014, 46, 1–16. [Google Scholar] [CrossRef]

- Illán-Gómez, F.; López-Belchí, A.; García-Cascales, J.R.; Vera-García, F. Experimental two-phase heat transfer coefficient and frictional pressure drop inside mini-channels during condensation with R1234yf and R134a. Int. J. Refrig. 2015, 51, 12–23. [Google Scholar] [CrossRef]

- Li, J.; Dang, C.; Hihara, E. Up-flow boiling of R1234yf in aluminum multi-port extruded tubes. Int. J. Heat Mass Transf. 2017, 114, 826–836. [Google Scholar] [CrossRef]

- Kim, D.; Lee, D.; Jang, D.S.; Jeon, Y.; Kim, Y. Comparative evaluation of flow boiling heat transfer characteristics of R-1234ze (E) and R-134a in plate heat exchangers with different Chevron angles. Appl. Therm. Eng. 2018, 132, 719–729. [Google Scholar] [CrossRef]

- Solotych, V.; Lee, D.; Kim, J.; Amalfi, R.L.; Thome, J.R. Boiling heat transfer and two-phase pressure drops within compact plate heat exchangers: Experiments and flow visualizations. Int. J. Heat Mass Transf. 2016, 94, 239–253. [Google Scholar] [CrossRef]

- Lee, H.; Li, S.; Hwang, Y.; Radermacher, R.; Chun, H.-H. Experimental investigations on flow boiling heat transfer in plate heat exchanger at low mass flux condition. Appl. Therm. Eng. 2013, 61, 408–415. [Google Scholar] [CrossRef]

- Huang, J.; Sheer, T.J.; Bailey-McEwan, M. Heat transfer and pressure drop in plate heat exchanger refrigerant evaporators. Int. J. Refrig. 2012, 35, 325–335. [Google Scholar] [CrossRef]

- Jokar, A.; Hosni, M.H.; Eckels, S.J. Dimensional analysis on the evaporation and condensation of refrigerant R-134a in minichannel plate heat exchangers. Appl. Therm. Eng. 2006, 26, 2287–2300. [Google Scholar] [CrossRef]

- Djordjevic, E.; Kabelac, S. Flow boiling of R134a and ammonia in a plate heat exchanger. Int. J. Heat Mass Transf. 2008, 51, 6235–6242. [Google Scholar] [CrossRef]

- Hsieh, Y.; Lin, T. Saturated flow boiling heat transfer and pressure drop of refrigerant R-410A in a vertical plate heat exchanger. Int. J. Heat Mass Transf. 2002, 45, 1033–1044. [Google Scholar] [CrossRef]

- Han, D.-H.; Lee, K.-J.; Kim, Y.-H. Experiments on the characteristics of evaporation of R410A in brazed plate heat exchangers with different geometric configurations. Appl. Therm. Eng. 2003, 23, 1209–1225. [Google Scholar] [CrossRef]

- Rossato, M.; Del Col, D.; Muzzolon, A.; Rossetto, L. Flow boiling of R32 inside a brazed plate heat exchanger. Int. J. Refrig. 2016, 69, 165–174. [Google Scholar] [CrossRef]

- Kim, I.K.; Park, J.H.; Kwon, Y.H.; Kim, Y.S. Experimental study on R-410A evaporation heat transfer characteristics in oblong shell and plate heat exchanger. Heat Transf. Eng. 2007, 28, 633–639. [Google Scholar] [CrossRef]

- Abu-Khader, M.M. Plate heat exchangers: Recent advances. Renew. Sustain. Energy Rev. 2012, 16, 1883–1891. [Google Scholar] [CrossRef]

- Arsenyeva, O.P.; Tovazhnyanskyy, L.L.; Kapustenko, P.O.; Khavin, G.L.; Yuzbashyan, A.P.; Arsenyev, P.Y. Two types of welded plate heat exchangers for efficient heat recovery in industry. Appl. Therm. Eng. 2016, 105, 763–773. [Google Scholar] [CrossRef]

- Ayub, Z.H. Plate heat exchanger literature survey and new heat transfer and pressure drop correlations for refrigerant evaporators. Heat Transf. Eng. 2003, 24, 3–16. [Google Scholar] [CrossRef]

- Lim, J.; Song, K.S.; Kim, D.; Lee, D.; Kim, Y. Condensation heat transfer characteristics of R245fa in a shell and plate heat exchanger for high-temperature heat pumps. Int. J. Heat Mass Transf. 2018, 127, 730–739. [Google Scholar] [CrossRef]

- Lee, D.; Kim, D.; Park, S.; Lim, J.; Kim, Y. Evaporation heat transfer coefficient and pressure drop of R-1233zd (E) in a brazed plate heat exchanger. Appl. Therm. Eng. 2018, 130, 1147–1155. [Google Scholar] [CrossRef]

- Nakaoka, T.; Uehara, H. Performance test of a shell-and-plate-type condenser for OTEC. Exp. Therm. Fluid Sci. 1988, 1, 275–281. [Google Scholar] [CrossRef]

- Imran, M.; Usman, M.; Yang, Y.; Park, B.-S. Flow boiling of R245fa in the brazed plate heat exchanger: Thermal and hydraulic performance assessment. Int. J. Heat Mass Transf. 2017, 110, 657–670. [Google Scholar] [CrossRef]

- Sadeghianjahromi, A.; Jafari, A.; Wang, C.-C. Numerical investigation of the effect of chevron angle on thermofluids characteristics of non-mixed and mixed brazed plate heat exchangers with experimental validation. Int. J. Heat Mass Transf. 2022, 184, 122278. [Google Scholar] [CrossRef]

- Jafari, A.; Sadeghianjahromi, A.; Wang, C.-C. Experimental and numerical investigation of brazed plate heat exchangers—A new approach. Appl. Therm. Eng. 2022, 200, 117694. [Google Scholar] [CrossRef]