Process Control of a Compost-Reactor Turning Operation Based on a Composting Kinetics Model

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composting Parameter Collection

2.3. Kinetic model of the Composting Process

2.3.1. Kinetic Model of Organic Matter Degradation

2.3.2. Heat Balance of the Composting Reactor

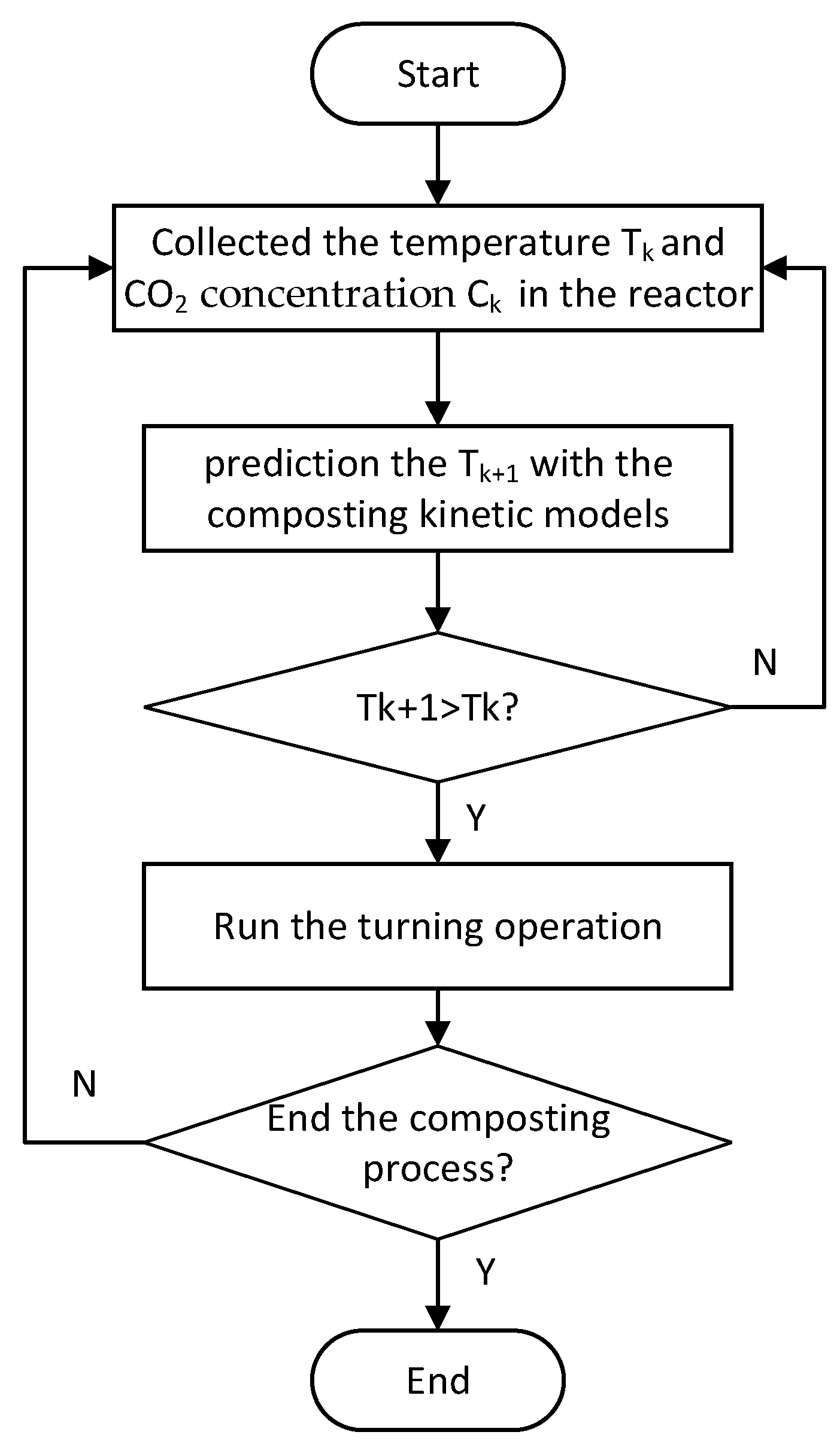

2.4. Turning Decision-Making of the Composting Reactor Based on the Composting Kinetic Model

2.5. Models Fitting and Statistical Analyses

3. Results

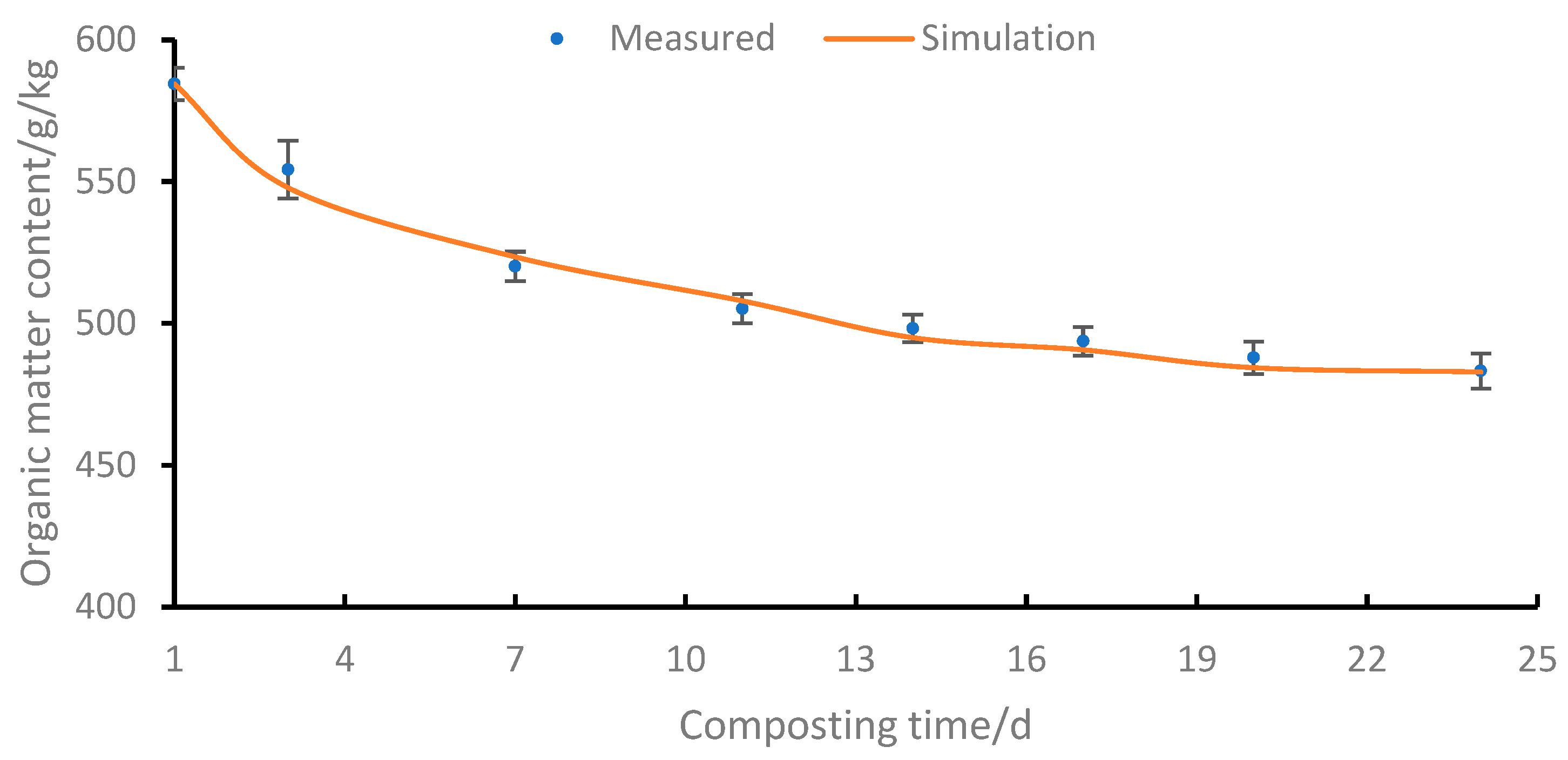

3.1. Simulation of the Composting Kinetic Model

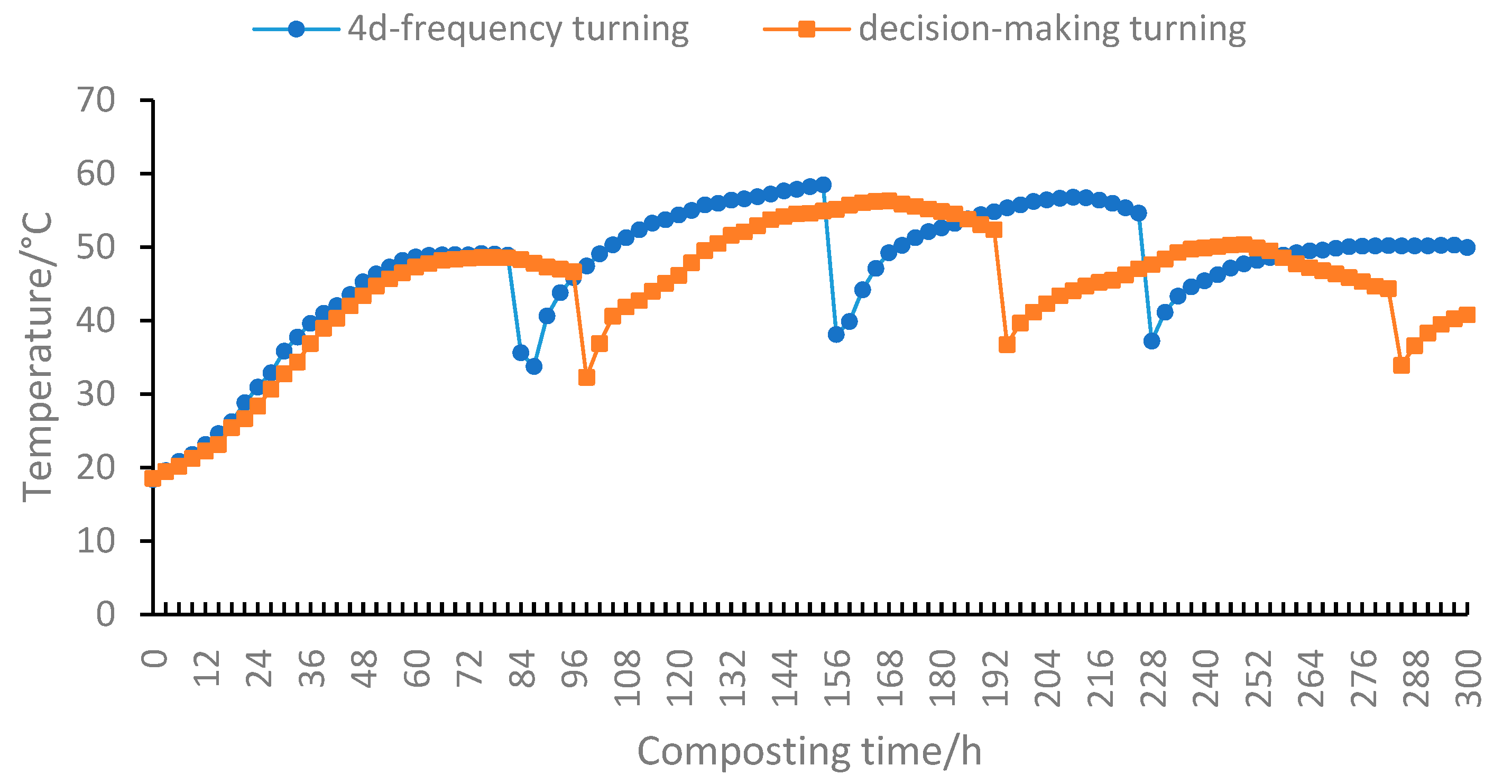

3.2. Results of the Process Control of the Turning Operation Involved in the Decision-Making Process

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Onwosi, C.O.; Igbokwe, V.C.; Odimba, J.N.; Eke, I.E.; Nwankwoala, M.O.; Iroh, I.N.; Ezeogu, L.I. Composting technology in waste stabilization: On the methods, challenges and future prospects. J. Environ. Manag. 2017, 190, 140–157. [Google Scholar] [CrossRef] [PubMed]

- Thomson, A.; Price, G.W.; Arnold, P.; Dixon, M.; Graham, T. Review of the potential for recycling CO2 from organic waste composting into plant production under controlled environment agriculture. J. Clean. Prod. 2022, 333, 130051. [Google Scholar] [CrossRef]

- Yang, Z.; Muhayodin, F.; Larsen, O.C.; Miao, H.; Xue, B.; Rotter, V.S. A Review of Composting Process Models of Organic Solid Waste with a Focus on the Fates of C, N, P, and K. Processes 2021, 9, 473. [Google Scholar] [CrossRef]

- Azim, K.; Soudi, B.; Boukhari, S.; Perissol, C.; Roussos, S.; Thami Alami, I. Composting parameters and compost quality: A literature review. Org. Agric. 2017, 8, 141–158. [Google Scholar] [CrossRef]

- Walling, E.; Trémier, A.; Vaneeckhaute, C. A review of mathematical models for composting. Waste Manag. 2020, 113, 379–394. [Google Scholar] [CrossRef]

- Zhou, Y.; Xiao, R.; Klammsteiner, T.; Kong, X.; Yan, B.; Mihai, F.-C.; Liu, T.; Zhang, Z.; Kumar Awasthi, M. Recent trends and advances in composting and vermicomposting technologies: A review. Bioresour. Technol. 2022, 360, 127591. [Google Scholar] [CrossRef]

- Mason, I.G. Mathematical modelling of the composting process: A review. Waste Manag. 2006, 26, 3–21. [Google Scholar] [CrossRef]

- Ajmal, M.; Aiping, S.; Uddin, S.; Awais, M.; Faheem, M.; Ye, L.; Rehman, K.U.; Ullah, M.S.; Shi, Y. A review on mathematical modeling of in-vessel composting process and energy balance. Biomass Convers. Biorefinery 2022, 12, 4201–4213. [Google Scholar] [CrossRef]

- Fan, S.; Li, A.; ter Heijne, A.; Buisman, C.J.N.; Chen, W.-S. Heat potential, generation, recovery and utilization from composting: A review. Resour. Conserv. Recycl. 2021, 175, 105850. [Google Scholar] [CrossRef]

- Lin, Y.P.; Huang, G.H.; Lu, H.W.; He, L. Modeling of substrate degradation and oxygen consumption in waste composting processes. Waste Manag. 2008, 28, 1375–1385. [Google Scholar] [CrossRef]

- Saldarriagaa, J.F.; Gallegob, J.L.; Lópezc, J. Determination of Kinetics Parameters for Composting Process of the Organic Fraction of Municipal Solid Waste Separated at Source. Chem. Eng. Trans. 2018, 70, 217–222. [Google Scholar] [CrossRef]

- Xiao, D.; Chen, Y.; Xu, W.; Zhan, L. An Aerobic Degradation Model for Landfilled Municipal Solid Waste. Appl. Sci. 2021, 11, 7557. [Google Scholar] [CrossRef]

- Sole-Mauri, F.; Illa, J.; Magrí, A.; Prenafeta-Boldú, F.X.; Flotats, X. An integrated biochemical and physical model for the composting process. Bioresour. Technol. 2007, 98, 3278–3293. [Google Scholar] [CrossRef] [PubMed]

- Kulcu, R.; Yaldiz, O. Determination of aeration rate and kinetics of composting some agricultural wastes. Bioresour. Technol. 2004, 93, 49–57. [Google Scholar] [CrossRef] [PubMed]

- Xi, B.; Li, Y.; Zhang, X.; Huang, G.; Qin, X.; Liu, H. Study on dynamic simulation of composting processes for domestic solid wastes. Tech. Equip. Environ. Pollut. Control 2005, 6, 20–23. [Google Scholar]

- Seng, B.; Kristanti, R.A.; Hadibarata, T.; Hirayama, K.; Katayama-Hirayama, K.; Kaneko, H. Mathematical model of organic substrate degradation in solid waste windrow composting. Bioprocess Biosyst. Eng. 2016, 39, 81–94. [Google Scholar] [CrossRef]

- Ge, J.; Huang, G.; Huang, J.; Zeng, J.; Han, L. Modeling of oxygen uptake rate evolution in pig manure–wheat straw aerobic composting process. Chem. Eng. J. 2015, 276, 29–36. [Google Scholar] [CrossRef]

- Ge, J.; Huang, G.; Huang, J.; Zeng, J.; Han, L. Particle-scale modeling of oxygen uptake rate during pig manure–wheat straw composting: A new approach that considers surface convection. Int. J. Heat Mass Transf. 2016, 97, 735–741. [Google Scholar] [CrossRef]

- Ding, S.; Huang, W.; Xu, W.; Wu, Y.; Zhao, Y.; Fang, P.; Hu, B.; Lou, L. Improving kitchen waste composting maturity by optimizing the processing parameters based on machine learning model. Bioresour. Technol. 2022, 360, 127606. [Google Scholar] [CrossRef]

- Dogan, H.; Aydın Temel, F.; Cagcag Yolcu, O.; Turan, N.G. Modelling and optimization of sewage sludge composting using biomass ash via deep neural network and genetic algorithm. Bioresour. Technol. 2023, 370, 128541. [Google Scholar] [CrossRef]

- Tremier, A.; de Guardia, A.; Massiani, C.; Paul, E.; Martel, J.L. A respirometric method for characterising the organic composition and biodegradation kinetics and the temperature influence on the biodegradation kinetics, for a mixture of sludge and bulking agent to be co-composted. Bioresour. Technol. 2005, 96, 169–180. [Google Scholar] [CrossRef] [PubMed]

- Petric, I.; Avdihodžić, E.; Ibrić, N. Numerical simulation of composting process for mixture of organic fraction of municipal solid waste and poultry manure. Ecol. Eng. 2015, 75, 242–249. [Google Scholar] [CrossRef]

- Ivakhnyuk, G.K.; Skripnik, I.L.; Ksenofontov, Y.G.; Kaverzneva, T.T.; Basharichev, A.V. Investigation of heat flux intensity during composting of organic wastes. IOP Conf. Ser. Earth Environ. Sci. 2020, 548, 022021. [Google Scholar] [CrossRef]

- Golbaz, S.; Zamanzadeh, M.Z.; Pasalari, H.; Farzadkia, M. Assessment of co-composting of sewage sludge, woodchips, and sawdust: Feedstock quality and design and compilation of computational model. Environ. Sci. Pollut. Res. 2020, 28, 12414–12427. [Google Scholar] [CrossRef]

- Tiquia, S.M.; Tam, N.F.Y.; Hodgkiss, I.J. Effects of turning frequency on composting of spent pig-manure sawdust litter. Bioresour. Technol. 1997, 62, 37–42. [Google Scholar] [CrossRef]

- Kalamdhad, A.S.; Kazmi, A.A. Effects of turning frequency on compost stability and some chemical characteristics in a rotary drum composter. Chemosphere 2009, 74, 1327–1334. [Google Scholar] [CrossRef]

- Shangguan, H.; Fu, T.; Shen, C.; Mi, H.; Wei, J.; Tang, J.; Zhou, S. In situ generated oxygen distribution causes maturity differentiation during electrolytic oxygen aerobic composting. Sci. Total Environ. 2022, 850, 157939. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, J.; Chen, X.; Gui, J.; Sun, Y.; Wu, D. Industrial-scale food waste composting: Effects of aeration frequencies on oxygen consumption, enzymatic activities and bacterial community succession. Bioresour. Technol. 2021, 320, 124357. [Google Scholar] [CrossRef]

- Wang, J.; Mao, H.; Wang, X.; Zhou, J. Combinable Multi-storey Adaptive Monitoring System for Composting Fermentation Temperature. Trans. Chin. Soc. Agric. Mach. 2023, 54, 359–367. [Google Scholar]

- Petric, I.; Selimbašić, V. Development and validation of mathematical model for aerobic composting process. Chem. Eng. J. 2008, 139, 304–317. [Google Scholar] [CrossRef]

- Khater, E. Mathematical Model of Compost Pile Temperature Prediction. J. Environ. Anal. Toxicol. 2014, 4, 1000242. [Google Scholar] [CrossRef]

- Jurado, M.M.; Suárez-Estrella, F.; López, M.J.; Vargas-García, M.C.; López-González, J.A.; Moreno, J. Enhanced turnover of organic matter fractions by microbial stimulation during lignocellulosic waste composting. Bioresour. Technol. 2015, 186, 15–24. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, S.; Wen, Q.; Zheng, J. Effect of aeration rate on composting of penicillin mycelial dreg. J. Environ. Sci. 2015, 37, 172–178. [Google Scholar] [CrossRef] [PubMed]

- Gabhane, J.; William, S.P.M.P.; Bidyadhar, R.; Bhilawe, P.; Anand, D.; Vaidya, A.N.; Wate, S.R. Additives aided composting of green waste: Effects on organic matter degradation, compost maturity, and quality of the finished compost. Bioresour. Technol. 2012, 114, 382–388. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Huang, G.; Zhang, A.; Han, L.; Ge, J. Estimating thermal balance during composting of swine manure and wheat straw: A simulation method. Int. J. Heat Mass Transf. 2014, 75, 362–367. [Google Scholar] [CrossRef]

- Bach, P.D.; Nakasaki, K.; Shoda, M.; Kubota, H. Thermal balance in composting operations. J. Ferment. Technol. 1987, 65, 199–209. [Google Scholar] [CrossRef]

- Wang, Y.; Pang, L.; Liu, X.; Wang, Y.; Zhou, K.; Luo, F. Using thermal balance model to determine optimal reactor volume and insulation material needed in a laboratory-scale composting reactor. Bioresour. Technol. 2016, 206, 164–172. [Google Scholar] [CrossRef]

- Hu, Z.; Liu, Y.; Chen, G.; Gui, X.; Chen, T.; Zhan, X. Characterization of organic matter degradation during composting of manure–straw mixtures spiked with tetracyclines. Bioresour. Technol. 2011, 102, 7329–7334. [Google Scholar] [CrossRef]

- Ge, J.; Huang, G.; Huang, J.; Zeng, J.; Han, L. Mechanism and kinetics of organic matter degradation based on particle structure variation during pig manure aerobic composting. J. Hazard. Mater. 2015, 292, 19–26. [Google Scholar] [CrossRef]

- Zhang, Y.; Lashermes, G.; Houot, S.; Doublet, J.; Steyer, J.P.; Zhu, Y.G.; Barriuso, E.; Garnier, P. Modelling of organic matter dynamics during the composting process. Waste Manag. 2012, 32, 19–30. [Google Scholar] [CrossRef]

- Damasceno, F.A.; Day, G.B.; Taraba, J.L.; Barbari, M.; Oliveira, C.E.A.; Frigeri, K.D.M.; Vieira, F.M.C.; Bambi, G. Determination of Thermal, Chemical and Physical Properties of Bedding Materials for Compost Dairy Barns. Animals 2022, 12, 2450. [Google Scholar] [CrossRef] [PubMed]

- Fouda, T.Z. Effect of kinematic parameter on some performance lndces for the self-propelled compost turning machine. AMA-Agric. Mech. Asia Afr. Lat. Am. 2011, 42, 61–65. [Google Scholar]

- Ogunwande, G.A.; Osunade, J.A.; Adekalu, K.O.; Ogunjimi, L.A.O. Nitrogen loss in chicken litter compost as affected by carbon to nitrogen ratio and turning frequency. Bioresour. Technol. 2008, 99, 7495–7503. [Google Scholar] [CrossRef]

- Euzébio, T.A.M.; Ramirez, M.A.P.; Reinecke, S.F.; Hampel, U. Energy Price as an Input to Fuzzy Wastewater Level Control in Pump Storage Operation. IEEE Access 2023, 11, 93701–93712. [Google Scholar] [CrossRef]

- Júnior, M.P.; da Silva, M.T.; Guimarães, F.G.; Euzébio, T.A.M. Energy savings in a rotary dryer due to a fuzzy multivariable control application. Dry. Technol. 2022, 40, 1196–1209. [Google Scholar] [CrossRef]

| Material | pH | C/N Ratio | Organic Matter Content/g/kg |

|---|---|---|---|

| Wool mud | 5.2 | 20 | 476.2 |

| Vinegar lees | 5.7 | 33 | 670.7 |

| Mixed | 6.1 | 25 | 584.5 |

| Organic Matter Content/g/kg | pH | EC | Water Content/% | |

|---|---|---|---|---|

| 4d-frequency turning (CK) | 505.5 ± 5.3 | 7.76 ± 0.13 | 3.92 ± 0.07 | 44.9 ± 1.7 |

| decision-making turning | 489.8 ± 4.6 | 7.13 ± 0.10 | 3.53 ± 0.05 | 41.7 ± 1.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Mao, H.; Zhou, J.; Yao, C.; Wang, Y. Process Control of a Compost-Reactor Turning Operation Based on a Composting Kinetics Model. Processes 2023, 11, 3206. https://doi.org/10.3390/pr11113206

Wang J, Mao H, Zhou J, Yao C, Wang Y. Process Control of a Compost-Reactor Turning Operation Based on a Composting Kinetics Model. Processes. 2023; 11(11):3206. https://doi.org/10.3390/pr11113206

Chicago/Turabian StyleWang, Jizhang, Han Mao, Jing Zhou, Chenzhi Yao, and Yuechen Wang. 2023. "Process Control of a Compost-Reactor Turning Operation Based on a Composting Kinetics Model" Processes 11, no. 11: 3206. https://doi.org/10.3390/pr11113206

APA StyleWang, J., Mao, H., Zhou, J., Yao, C., & Wang, Y. (2023). Process Control of a Compost-Reactor Turning Operation Based on a Composting Kinetics Model. Processes, 11(11), 3206. https://doi.org/10.3390/pr11113206