A Review of the Settling Law of Drill Cuttings in Drilling Fluids

Abstract

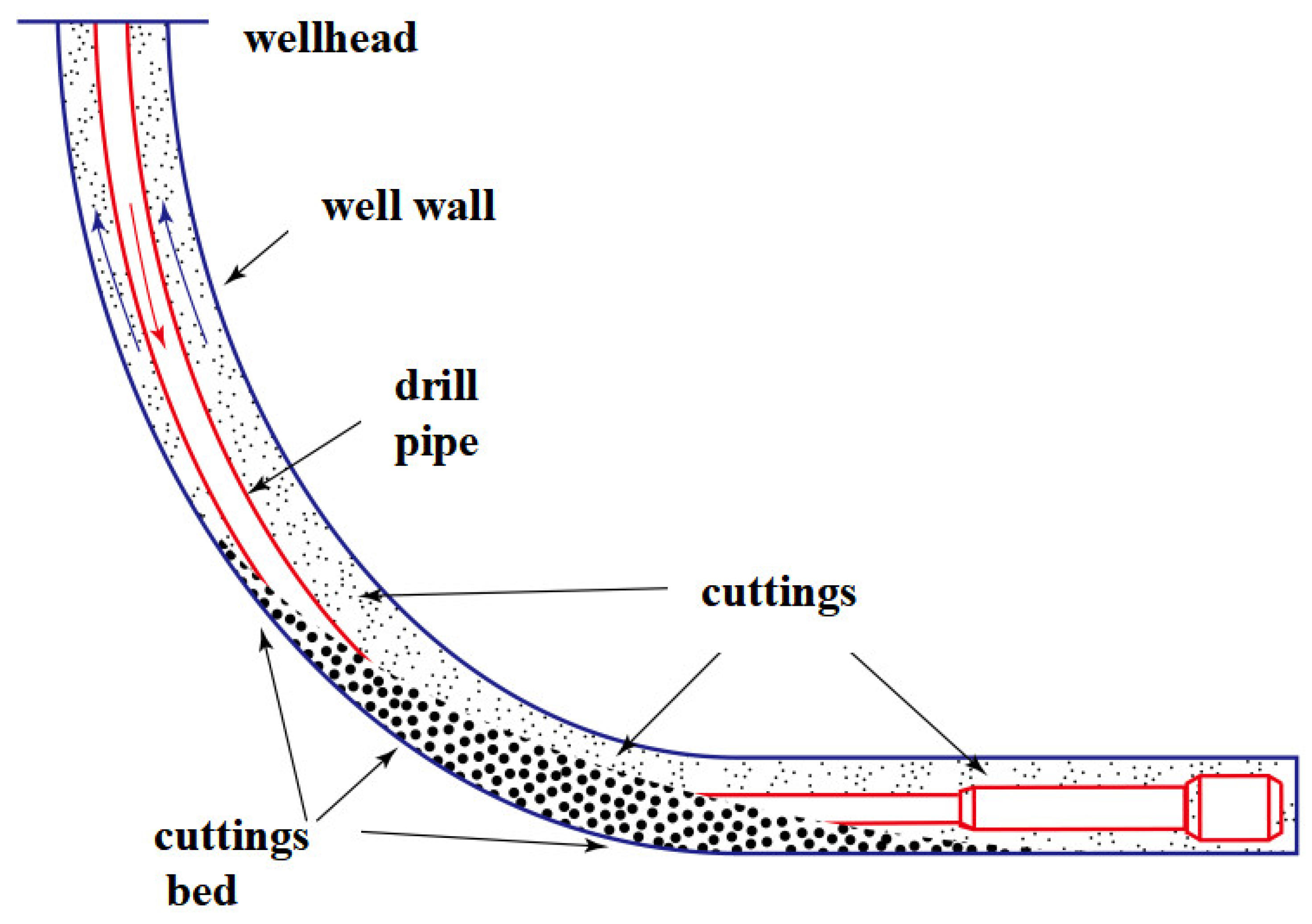

:1. Introduction

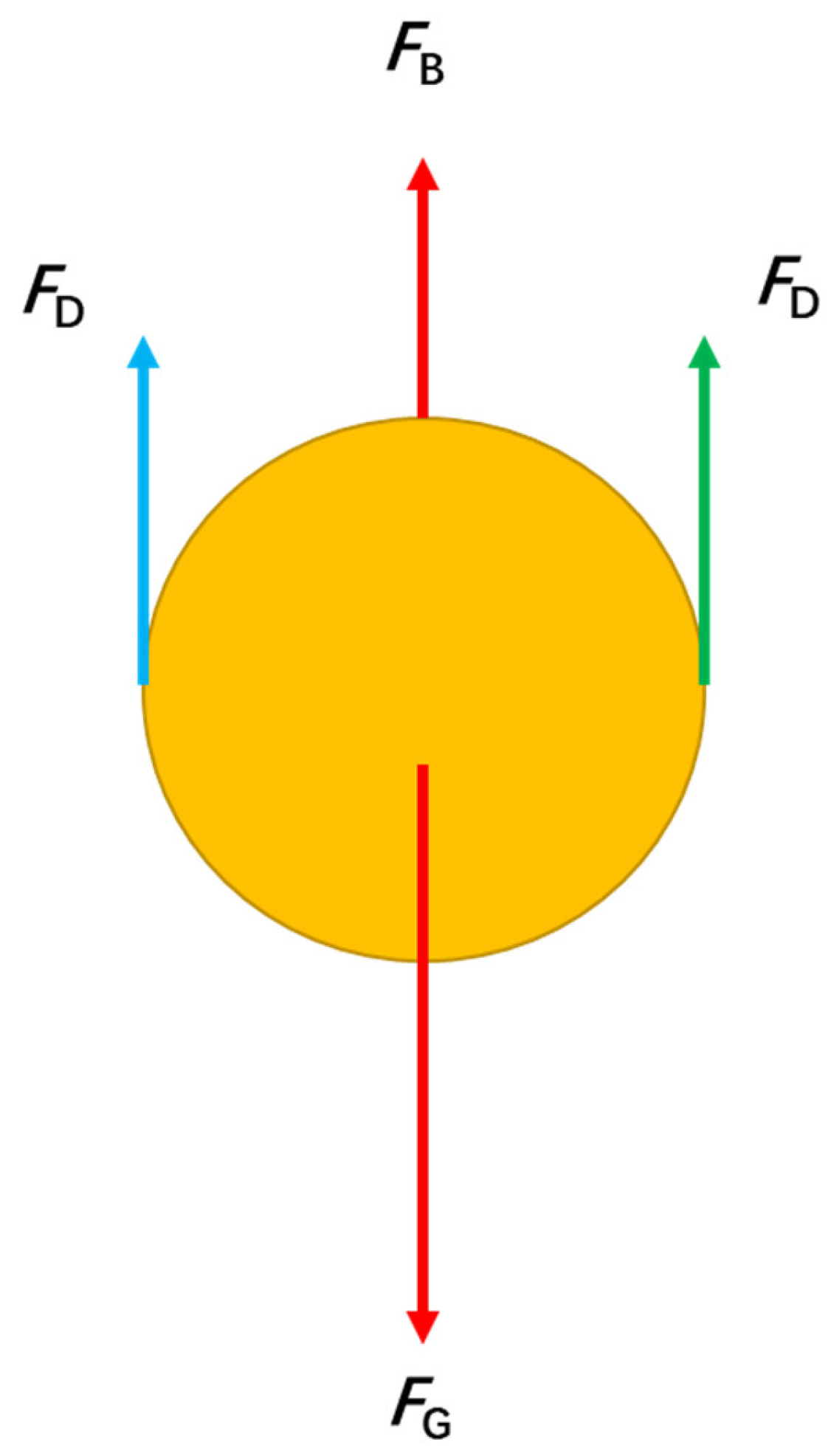

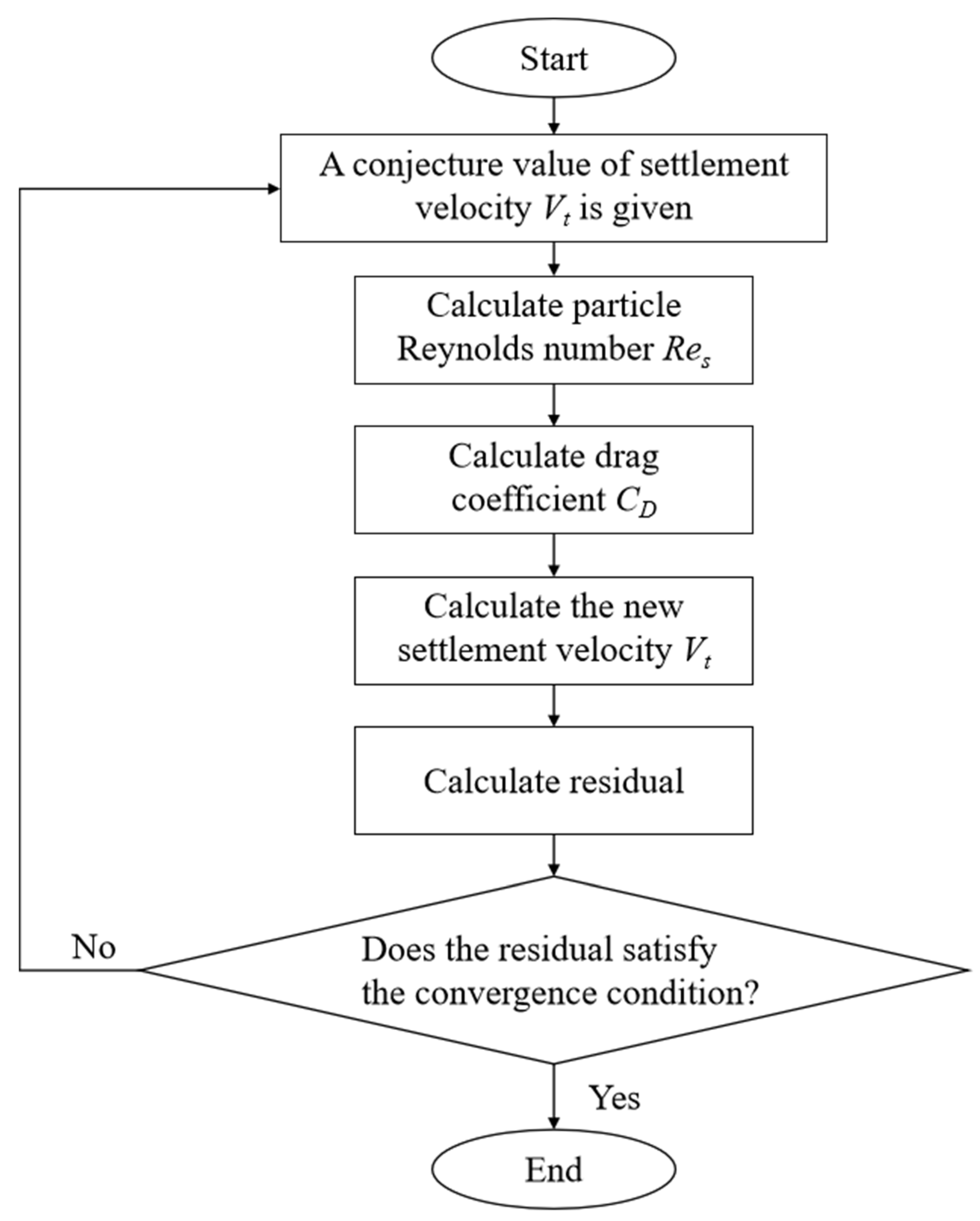

2. Theoretical Analysis

3. Analysis of Influencing Factors

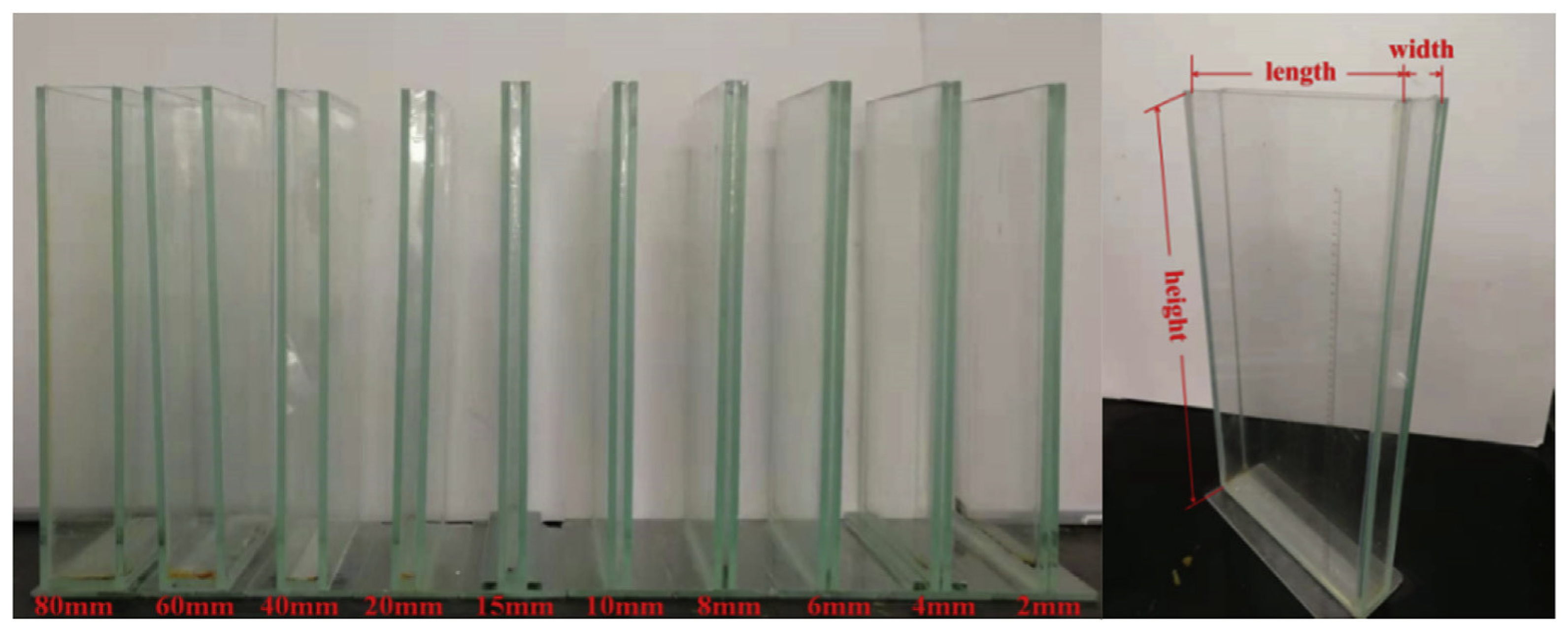

3.1. The Impact of the Wall-Blocking Role on the Particle Sedimentation Law

3.2. The Impact of Fluid Rheology on the Particle Sedimentation Law

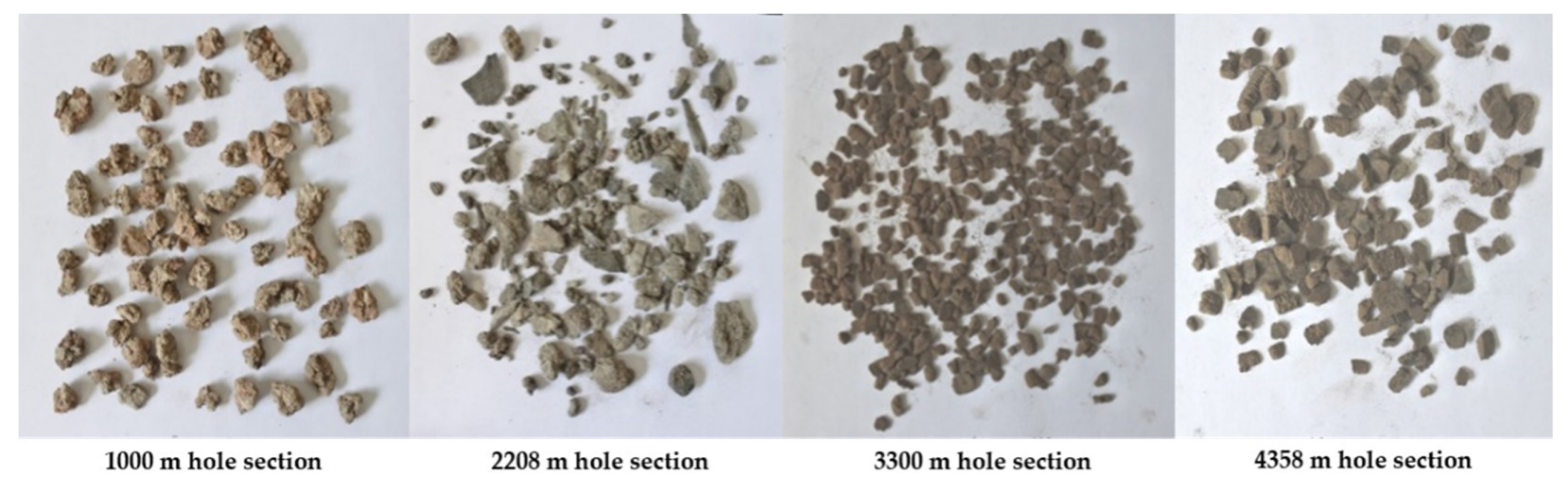

3.3. The Impact of Particle Geometry on the Particle Sedimentation Law

3.4. The Impact of Particle Concentration on the Particle Sedimentation Law

4. Conclusions and Prospects

- (1)

- There are many factors affecting the sedimentation of particles, including the shape of the sedimentation channel, the rheological properties, the shape of the particles, and so forth, which will affect the sedimentation process of a single particle. For a multi-particle sedimentation system, in addition to the above influencing factors, the mutual effect between particles is the major element affecting the sedimentation of particles.

- (2)

- The test method of cuttings sedimentation performance in the laboratory mainly involves the single-particle settling method based on the Stokes theory formula. The time required for single-particle cuttings to settle in drilling fluid to the bottom of the vessel is observed and measured, and the settling rate is calculated. However, the quantity and volume of cuttings produced in the drilling process are very large, and the concentration and collision of cuttings will change the settling rate of the cuttings. Therefore, it is difficult for the single-particle cuttings settling method to truly reflect the settling characteristics of cuttings groups, so it is urgent to develop new devices and new experimental methods to further explore the settling mechanism of cuttings groups.

- (3)

- Compared with Newtonian fluid, the shear dilution of non-Newtonian fluid will increase the settling rate of particles. At this time, the settling rate of particles is affected by the particle diameter, flow index, and consistency index. The different rheological properties of non-Newtonian fluids have different effects on the particle sedimentation law. The existing CD-Res prediction models for non-Newtonian fluids are mostly used for power-law fluids and Herschel–Bulkley fluids. The amount of research on CD-Res prediction models for other non-Newtonian fluids is relatively low, which brings inconvenience to actual field operations. Therefore, this is the main research direction in the future—to study the law of particle sedimentation in other types of non-Newtonian fluids by experimental means and establish the corresponding CD-Res correlation equation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, Y.; Lun, Z.; Pan, Z.; Wang, H.; Zhou, X.; Zhao, C.; Zhang, D. Occurrence space and state of shale oil: A review. J. Pet. Sci. Eng. 2022, 211, 110183. [Google Scholar] [CrossRef]

- Hu, Q.; Li, Y.; Sun, X.; Chen, M.; Bu, Q.; Gong, B. Integrating test device and method for creep failure and ultrasonic response of methane hydrate-bearing sediments. Rev. Sci. Instrum. 2023, 94, 025105. [Google Scholar] [CrossRef] [PubMed]

- Moreira, B.A.; de Oliveira Arouca, F.; Damasceno, J.J.R. Analysis of Suspension Sedimentation in Fluids with Rheological Shear-Thinning Properties and Thixotropic Effects. Powder Technol. 2017, 308, 290–297. [Google Scholar] [CrossRef]

- Li, S.Q.; Chen, Z.; Li, W.; Yan, T. A FE Simulation of the Fracture Characteristics of Blunt Rock Indenter under Static and Harmonic Dynamic Loadings using Cohesive Elements. Rock Mech. Rock Eng. 2023, 56, 2935–2947. [Google Scholar] [CrossRef]

- Massie, G.W.; Castle-Smith, J.; Lee, J.W. Amocos training initiative reduces wellsite drilling problems. Pet. Eng. Int. 1995, 67, 48–55. [Google Scholar]

- Movahedi, H.; Vasheghani, F.M.; Jamshidi, S. Application of hydrated basil seeds (hbs) as the herbal fiber on hole cleaning and filtration control. J. Pet. Sci. Eng. 2017, 152, 212–228. [Google Scholar] [CrossRef]

- Mahmoud, H.; Alhajabdalla, M.; Nasser, M.S. Settling behavior of fine cuttings in fiber-containing polyanionic fluids for drilling and hole cleaning application. J. Pet. Sci. Eng. 2021, 199, 199. [Google Scholar] [CrossRef]

- Agwu, O.E.; Akpabio, J.U.; Alabi, S.B. Settling velocity of drill cuttings in drilling fluids: A review of experimental, numerical simulations and artificial intelligence studies. Powder Technol. 2018, 339, 728–746. [Google Scholar] [CrossRef]

- Anemangely, M.; Ramezanzadeh, A.; Tokhmechi, B. Drilling rate prediction from petrophysical logs and mud logging data using an optimized multilayer perceptron neural network. J. Geophys. Eng. 2018, 15, 1146–1159. [Google Scholar] [CrossRef]

- Yan, T.; Qu, J.; Sun, X. Numerical investigation on horizontal wellbore hole cleaning with a four-lobed drill pipe using CFD-DEM method. Powder Technol. 2020, 375, 249–261. [Google Scholar] [CrossRef]

- Li, Y.; Tang, B.; Jiao, S.; Su, Q. Snake Optimization-Based Variable-Step Multiscale Single Threshold Slope Entropy for Complexity Analysis of Signals. IEEE Trans. Instrum. Meas. 2023, 72, 6505313. [Google Scholar] [CrossRef]

- Yao, L.; Yuan, P.; Tsai, C.Y.; Zhang, T.; Lu, Y.; Ding, S. ESO: An Enhanced Snake Optimizer for Real-world Engineering Problems. Expert Syst. Appl. 2023, 230, 120594. [Google Scholar] [CrossRef]

- Chen, H.; Kuru, E.; Hu, K. A generalized model for field assessment of particle settling velocity in viscoelastic fluids. Powder Technol. 2023, 427, 118697. [Google Scholar] [CrossRef]

- Arnipally, S.K.; Kuru, E. Settling velocity of particles in viscoelastic fluids: A comparison of the shear-viscosity and elasticity effects. SPE J. 2018, 23, 1689–1705. [Google Scholar] [CrossRef]

- Goossens, W.R.A. A new explicit equation for the terminal velocity of a settling sphere. Powder Technol. 2020, 362, 54–56. [Google Scholar] [CrossRef]

- Abbas, A.K.; Alsaba, M.T.; Al Dushaishi, M.F. Comprehensive Experimental Investigation of Hole Cleaning Performance in Horizontal Wells Including the Effects of Drill String Eccentricity, Pipe Rotation, and Cuttings Size. J. Energy Resour. Technol. 2022, 144, 063006. [Google Scholar] [CrossRef]

- Dietrich, W.E. Settling velocity of natural particles. Water Resour. Res. 1982, 18, 1615–1626. [Google Scholar] [CrossRef]

- Sun, X.; Sun, M.; Li, Z. A Novel Prediction Model of the Drag Coefficient of Shale Cuttings in Herschel–Bulkley Fluid. Energies 2022, 15, 4496. [Google Scholar] [CrossRef]

- White, F.M. Fluid mechanics McGraw-Hill series in mechanical engineering. Univ. Rhode Isl 2007, 157, 813. [Google Scholar]

- Stokes, G.G. On the effect of the internal friction of fluids in the motion of pendulums. Trans. Camb. Philos. Soc. 1851, 9, 8–106. [Google Scholar]

- Shiller, L.; Naumann, A.A. Drag coefficient correlation. Z. Des Ver. Dtsch. Ingenieure 1935, 77, 318–320. [Google Scholar]

- Haider, A.; Levenspiel, O. Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Technol. 1989, 58, 63–70. [Google Scholar] [CrossRef]

- Cheng, N.S. Comparison of formulas for drag coefficient and settling velocity of spherical particles. Powder Technol. 2009, 189, 395–398. [Google Scholar] [CrossRef]

- Abraham, F.F. Functional dependence of drag coefficient of a sphere on Reynolds number. Phys. Fluids 1970, 13, 2194–2195. [Google Scholar] [CrossRef]

- Clift, R.; Gauvin, W.H. Motion of entrained particles in gas streams. Can. J. Chem. Eng. 1971, 49, 439–448. [Google Scholar] [CrossRef]

- Brown, P.P.; Lawler, D.F. Sphere drag and settling velocity revisited. J. Environ. Eng. 2003, 129, 222–231. [Google Scholar] [CrossRef]

- Terfous, A.; Hazzab, A.; Ghenaim, A. Predicting the drag coefficient and settling velocity of spherical particles. Powder Technol. 2013, 239, 12–20. [Google Scholar] [CrossRef]

- Roos, F.W.; Willmarth, W.W. Some experimental results on sphere and disk drag. AIAA J. 1971, 9, 285–291. [Google Scholar] [CrossRef]

- Goossens, W.R.A. Review of the empirical correlations for the drag coefficient of rigid spheres. Powder Technol. 2019, 352, 350–359. [Google Scholar] [CrossRef]

- Yao, S.; Chang, C.; Hai, K.; Huang, H.; Li, H. A review of experimental studies on the proppant settling in hydraulic fractures. J. Pet. Sci. Eng. 2022, 208, 109211. [Google Scholar] [CrossRef]

- Munroe, H.S. The English Versus the Continental System of Jigging: Is Close Sizing Advantageous. Trans. AIME J. 1889, 17, 637–651. [Google Scholar]

- Francis, A.W. Wall effect in falling ball method for viscosity. J. Appl. Phys. 1933, 4, 403–406. [Google Scholar] [CrossRef]

- Fidleris, V.; Whitmore, R.L. Experimental determination of the wall effect for spheres falling axially in cylindrical vessels. Br. J. Appl. Phys. 1961, 12, 490. [Google Scholar] [CrossRef]

- Di Felice, R. A relationship for the wall effect on the settling velocity of a sphere at any flow regime. Int. J. Multiph. Flow 1996, 22, 527–533. [Google Scholar] [CrossRef]

- Kehlenbeck, R.; Felice, R.D. Empirical relationships for the terminal settling velocity of spheres in cylindrical columns. Chem. Eng. Technol. 1999, 22, 303–308. [Google Scholar] [CrossRef]

- Haberman, W.L.; Sayre, R.M. Motion of rigid and fluid spheres in stationary and moving liquids inside cylindrical tubes. David Taylor Model Basin Rep. 1958, 106, 23–26. [Google Scholar]

- Chhabra, R.; Agarwal, S.; Chaudhary, K. A note on wall effect on the terminal falling velocity of a sphere in quiescent Newtonian media in cylindrical tubes. Powder Technol. 2003, 129, 53–58. [Google Scholar] [CrossRef]

- Lali, A.; Khare, A.; Joshi, J.; Nigam, K. Behaviour of solid particles in viscous non-Newtonian solutions: Settling velocity, wall effects and bed expansion in solid-liquid fluidized beds. Powder Technol. 1989, 57, 39–50. [Google Scholar] [CrossRef]

- Chhabra, R.; Tiu, C.; Uhlherr, P. A study of wall effects on the motion of a sphere in viscoelastic fluids. Can. J. Chem. Eng. 1981, 59, 771–775. [Google Scholar] [CrossRef]

- Sugeng, F.; Tanner, R. The drag on spheres in viscoelastic fluids with significant wall effects. J. Non-Newton. Fluid Mech. 1986, 20, 281–292. [Google Scholar] [CrossRef]

- Acharya, A.R. Particle transport in viscous and viscoelastic fracturing fluids. SPE Prod. Eng. 1986, 1, 104–110. [Google Scholar] [CrossRef]

- Zhu, Z.; Song, X.; Li, G.; Xu, Z.; Jing, S.; Qin, X.; Duan, S. Predicting wall drag coefficient and settling velocity of particle in parallel plates filled with Newtonian fluids. Particuology 2021, 58, 242–250. [Google Scholar] [CrossRef]

- Ilic, V.; Tullock, D.; Phan-Thien, N.; Graham, A. Translation and rotation of spheres settling in square and circular conduits: Experiments and numerical predictions. Int. J. Multiph. Flow 1992, 18, 1061–1075. [Google Scholar] [CrossRef]

- Faxen, V.H. The resistance against the movement of a rigour sphere in viscous fluids, which is embedded between two parallel layered barriers. Ann. Phys. 1922, 68, 89–119. [Google Scholar]

- Brenner, H. The slow motion of a sphere through a viscous fluid towards a plane surface. Chem. Eng. Sci. 1961, 16, 242–251. [Google Scholar] [CrossRef]

- Lorentz, H. A general theorem concerning the motion of a viscous fluid and a few consequences derived from it. Versl. Konigl. Akad. Wetensch. Amst. 1896, 5, 168–175. [Google Scholar]

- Liu, Y.J.; Mukul, M.S. Effect of fracture width and fluid rheology on proppant settling and retardation: An experimental study. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005. [Google Scholar]

- Machac, I.; Lecjaks, Z. Wall effect for a sphere falling through a non-Newtonian fluid in are ctangular duct. Chem. Eng. Sci. 1995, 50, 143–148. [Google Scholar] [CrossRef]

- Malhotra, S.; Sharma, M.M. Settling of spherical particles in unbounded and confined surfactant-based shear thinning viscoelastic fluids: An experimental study. Chem. Eng. Sci. 2012, 84, 646–655. [Google Scholar] [CrossRef]

- Zhang, G.D.; Li, M.Z.; Xue, J.Q.; Wang, L.; Tian, J.-L. Wall-retardation effects on particles settling through non-Newtonian fluids in parallel plates. Chem. Pap. 2016, 70, 1389–1398. [Google Scholar] [CrossRef]

- Song, X.Z.; Zhu, Z.; Xu, Z.; Li, G.; Faustino, M.A.; Chen, C.; Jiang, T.; Xie, X. Experimental study on the wall factor for spherical particles settling in parallel plates filled with power-law fluids. J. Pet. Sci. Eng. 2019, 179, 941–947. [Google Scholar] [CrossRef]

- Ofei, T.N.; Lund, B.; Saasen, A. Effect of particle number density on rheological properties and barite sag in oil-based drilling fluids. J. Pet. Sci. Eng. 2021, 206, 108908. [Google Scholar] [CrossRef]

- Ofei, T.N. Effect of yield power law fluid rheological properties on cuttings transport in eccentric horizontal narrow annulus. J. Fluids 2016, 2016, 4931426. [Google Scholar] [CrossRef]

- Khan, A.R.; Richardson, J.F. The resistance to motion of a solid sphere in a fluid. Chem. Eng. Commun. 1987, 62, 135–150. [Google Scholar] [CrossRef]

- Chhabra, R.P. Motion of spheres in power law (viscoinelastic) fluids at intermediate Reynolds numbers: A unified approach. Chem. Eng. Process. Process Intensif. 1990, 28, 89–94. [Google Scholar] [CrossRef]

- Peden, J.M.; Luo, Y. Settling Velocity of Variously Shaped Particles in Drilling and Fracturing Fluids. SPE Drill. Eng. 1987, 2, 337–343. [Google Scholar] [CrossRef]

- Reynolds, P.A.; Jones, T.E.R. An Experimental Study of the Settling Velocities of Single Particles in Non-Newtonian Fluids. Int. J. Miner. Process. 1989, 25, 47–77. [Google Scholar] [CrossRef]

- Koziol, K.; Glowacki, P. Determination of the free settling parameters of spherical particles in power law fluids. Chem. Eng. Process. 1988, 24, 183–188. [Google Scholar] [CrossRef]

- Kelessidis, V.C. Terminal velocity of solid spheres falling in Newtonian and non-Newtonian liquids. Tech. Chron. Sci. J. TCG 2003, 5, 43–54. [Google Scholar]

- Rushd, S.; McKibben, M.; Sanders, R.S. A new approach to model friction losses in the water-assisted pipeline transportation of heavy oil and bitumen. Can. J. Chem. Eng. 2019, 97, 2347–2358. [Google Scholar] [CrossRef]

- Shah, S.N.; El Fadili, Y.; Chhabra, R.P. New model for single spherical particle settling velocity in power law (visco-inelastic) fluids. Int. J. Multiph. Flow 2007, 33, 51–66. [Google Scholar] [CrossRef]

- Macha, I.I. Fall of spherical particles through non-Newtonian suspensions. Chem. Eng. Sci. 1995, 50, 3323–3327. [Google Scholar] [CrossRef]

- Okesanya, T.; Kuru, E.; Sun, Y. A new generalized model for predicting the drag coefficient and the settling velocity of rigid spheres in viscoplastic fluids. SPE J. 2020, 25, 3217–3235. [Google Scholar] [CrossRef]

- Lee, Y.; Bobroff, S.; Mccarthy, K.L. Rheological characterization of tomato concentrates and the effect on uniformity of processing. Chem. Eng. Commun. 2002, 189, 339–351. [Google Scholar] [CrossRef]

- Talmon, A.M.; Huisman, M. Fall velocity of particles in shear flow of drilling fluids. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2005, 20, 193–201. [Google Scholar] [CrossRef]

- Merkak, O.; Jossic, L.; Magnin, A. Spheres and interactions between spheres moving at very low velocities in a yield stress fluid. J. Non-Newton. Fluid Mech. 2006, 133, 99–108. [Google Scholar] [CrossRef]

- Putz, A.M.V.; Burghelea, T.I.; Frigaard, I.A.; Martinez, D.M. Settling of an isolated spherical particle in a yield stress shear thinning fluid. Phys. Fluids 2008, 20, 8. [Google Scholar] [CrossRef]

- Pakzad, L.; Ein-Mozaffari, F.; Upreti, S.R.; Lohi, A. Experimental and numerical studies on mixing of yield-pseudoplastic fluids with a coaxial mixer. Chem. Eng. Commun. 2013, 200, 1553–1577. [Google Scholar] [CrossRef]

- Ahonguio, F.; Jossic, L.; Magnin, A. Influence of surface properties on the flow of a yield stress fluid around spheres. J. Non-Newton. Fluid Mech. 2014, 206, 57–70. [Google Scholar] [CrossRef]

- Pettyjohn, E.S.; Christiansen, E.B. Effect of particle shape on free-settling rates of isometric particles. Chem. Eng. Prog. 1948, 44, 157–172. [Google Scholar]

- Komar, P.D. Settling velocities of circular cylinders at low Reynolds numbers. J. Geol. 1980, 88, 327–336. [Google Scholar] [CrossRef]

- Dioguardi, F.; Mele, D. A new shape dependent drag correlation formula for non-spherical rough particles. Experiments and results. Powder Technol. 2015, 277, 222–230. [Google Scholar] [CrossRef]

- Wadell, H. The coefficient of resistance as a function of Reynolds number for solids of various shapes. J. Frankl. Inst. 1934, 217, 459–490. [Google Scholar] [CrossRef]

- Bouwman, A.M.; Bosma, J.C.; Vonk, P.; Wesselingh, J.A.; Frijlink, H.W. Which shape factor(s) best describe granules. Powder Technol. 2004, 146, 66–72. [Google Scholar] [CrossRef]

- Corey, A.T. Influence of the Shape on the Fall Velocity of Sand Grains. Ph.D. Thesis, Colorado State University, Fort Collins, CO, USA, 1949. [Google Scholar]

- Williams, G.P. Particle roundness and surface texture effects on fall velocity. J. Sediment. Petrol. 1997, 36, 255–259. [Google Scholar] [CrossRef]

- Tran-Cong, S.; Gay, M.; Michaelides, E.E. Drag coefficients of irregularly shaped particles. Powder Technol. 2004, 139, 21–32. [Google Scholar] [CrossRef]

- Xu, Z.; Song, X.; Li, G. Settling behavior of non-spherical particles in power-law fluids: Experimental study and model development. Particuology 2019, 46, 30–39. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, L.; Wu, Y. New simple correlation formula for the drag coefficient of calcareous sand particles of highly irregular shape. Powder Technol. 2018, 326, 379–392. [Google Scholar] [CrossRef]

- Shahi, S.; Kuru, E. An experimental investigation of settling velocity of natural sands in water using Particle Image Shadowgraph. Powder Technol. 2015, 281, 184–192. [Google Scholar] [CrossRef]

- Yow, H.N.; Pitt, M.J.; Salman, A.D. Drag correlations for particles of regular shape. Adv. Powder Technol. 2005, 16, 363–372. [Google Scholar] [CrossRef]

- Chien, S.F. Settling velocity of irregularly shaped particles. SPE Drill. Complet. 1994, 9, 281–289. [Google Scholar] [CrossRef]

- Yang, F.; Zeng, Y.H.; Huai, W.X. A new model for settling velocity of non-spherical particles. Environ. Sci. Pollut. Res. 2021, 28, 61636–61646. [Google Scholar] [CrossRef] [PubMed]

- Hölzer, A.; Sommerfeld, M. New simple correlation formula for the drag coefficient of non-spherical particles. Powder Technol. 2008, 184, 361–365. [Google Scholar] [CrossRef]

- Swamee, P.K.; Ojha, C.S.P. Drag coefficient and fall velocity of nonspherical particles. J. Hydraul. Eng. 1991, 117, 660–667. [Google Scholar] [CrossRef]

- Zhu, X.; Zeng, Y.H.; Huai, W.X. Settling velocity of non-spherical hydro-chorous seeds. Adv. Water Resour. 2017, 103, 99–107. [Google Scholar] [CrossRef]

- Thompson, T.L.; Clark, N.N. A holistic approach to particle drag prediction. Powder Technol. 1991, 67, 57–66. [Google Scholar] [CrossRef]

- Ganser, G.H. A rational approach to drag prediction of spherical and nonspherical particles. Powder Technol. 1993, 77, 143–152. [Google Scholar] [CrossRef]

- Novotny, E.J. Proppant transport. In Proceedings of the SPE Annual Fall Technical Conference and Exhibition, Denver, CO, USA, 9–12 October 1977. [Google Scholar]

- Aziz, K.; Govier, G.W. Pressure drop in wells producing oil and gas. J. Can. Pet. Technol. 1972, 11, 720304. [Google Scholar] [CrossRef]

- Nolte, K.G. Fluid flow considerations in hydraulic fracturing. In Proceedings of the SPE Eastern Regional Meeting, Charleston, WV, USA, 1–4 November 1988. [Google Scholar]

- Daneshy, A.A. Numerical Solution of Sand Transport in Hydraulic Fracturing. J. Pet. Technol. 1978, 30, 132–140. [Google Scholar] [CrossRef]

- Richardson, J.F.; Zaki, W.N. Sedimentation and fluidization: Part I. Trans. Inst. Chem. Eng. 1954, 32, 35–53. [Google Scholar]

- Maude, A.D.; Whitmore, R.L. The wall effect and the viscometry of suspensions. Br. J. Appl. Phys. 1956, 7, 98. [Google Scholar] [CrossRef]

- Sharma, M.M. Advanced Fracturing Technology for Tight Gas: An East Texas Field Demonstration; University of Texas: Austin, TX, USA, 2005. [Google Scholar]

- Tomac, I.; Gutierrez, M. Micromechanics of proppant agglomeration during settling in hydraulic fractures. J. Pet. Explor. Prod. Technol. 2015, 5, 417–434. [Google Scholar] [CrossRef]

- Clark, P.E.; Jamal, A.Q. Prop transport in hydraulic fractures: A critical review of particle settling velocity equations. In Proceedings of the SPE/DOE Low Permeability Gas Reservoirs Symposium, Denver, CO, USA, 27–29 May 1981. [Google Scholar]

- Dunand, A.; Soucemarianadin, A. Concentration effects on the settling velocities of proppant slurries. In Proceedings of the SPE Annual Technical Conference and Exhibition, Las Vegas, NV, USA, 22–26 September 1985. [Google Scholar]

- Kirkby, L.L.; Rockefeller, H.A. Proppant settling velocities in nonflowing slurries. In Proceedings of the SPE/DOE Low Permeability Gas Reservoirs Symposium, Denver, CO, USA, 19–22 May 1985. [Google Scholar]

| Author | CD-Res Relationship | Range of Application |

|---|---|---|

| Schiller and Naumann [21] | ||

| Haider and Levenspiel [22] | ||

| Cheng [23] | ||

| Abraham [24] | ||

| Clift [25] | ||

| Brown [26] | ||

| Terfous [27] | ||

| Roos [28] |

| Author | Wall Factor Relationship | Applicable Region |

|---|---|---|

| Munroe [31] | Turbulent flow | |

| Francis [32] | Laminar flow | |

| Fidleris [33] | Graphic method | All ranges |

| Felice [34] | Transition region and turbulence | |

| Kehlenbeck [35] | Transition region | |

| Haberman [36] | Laminar flow |

| Author | CD-Res Relationship | Sphere of Application |

|---|---|---|

| Khan and Richadson [54] | ||

| Kelessidis and Mpandelis [59] | ||

| Renaud [60] | ||

| Shah [61] | ||

| Machac [62] | ||

| Okesanya [63] |

| Particle Shape | Spherical Degree | Particle Shape | Spherical Degree |

|---|---|---|---|

| Sphere | 1.0 | Polygon | 0.8~0.65 |

| Spherical | 1.0~0.8 | Long strip | 0.65~0.5 |

| Flat | <0.5 | Cube | 0.806 |

| Flat | 0.671 | Cylinder (height = diameter) | 0.877 |

| Cylinder (diameter:high = 1:10) | 0.580 | Circular plate (diameter:thickness = 1:10) | 0.472 |

| Author | Wall Factor Relationship |

|---|---|

| Aziz [90] | |

| Nolte [91] | |

| Daneshy [92] | |

| Richardson [93] | |

| Maude [94] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Z.; Yuan, Y.; Chen, Y.; Jiang, E.; Wang, H.; Zhang, X. A Review of the Settling Law of Drill Cuttings in Drilling Fluids. Processes 2023, 11, 3165. https://doi.org/10.3390/pr11113165

Hou Z, Yuan Y, Chen Y, Jiang E, Wang H, Zhang X. A Review of the Settling Law of Drill Cuttings in Drilling Fluids. Processes. 2023; 11(11):3165. https://doi.org/10.3390/pr11113165

Chicago/Turabian StyleHou, Zhaokai, Yuan Yuan, Ye Chen, Enyuan Jiang, Huaishan Wang, and Xu Zhang. 2023. "A Review of the Settling Law of Drill Cuttings in Drilling Fluids" Processes 11, no. 11: 3165. https://doi.org/10.3390/pr11113165

APA StyleHou, Z., Yuan, Y., Chen, Y., Jiang, E., Wang, H., & Zhang, X. (2023). A Review of the Settling Law of Drill Cuttings in Drilling Fluids. Processes, 11(11), 3165. https://doi.org/10.3390/pr11113165